#gate valve repair

Explore tagged Tumblr posts

Text

Storing and Maintaining Your Gate Repair Safety Gear

In the field of gate repair, ensuring the integrity and readiness of safety equipment is crucial. Properly storing helmets, gloves, and goggles can extend their usability, ensuring personal safety while also being cost-effective. Helmets should be kept out of direct sunlight and in well-ventilated spaces to prevent material degradation. Gloves need a dry environment to avoid moisture buildup that can lead to deterioration. For goggles, it’s important to store them in areas free from dust accumulation. Exploring these storage methods may uncover additional strategies to enhance the longevity and performance of your safety gear.

Cleaning Your Safety Equipment

Regular maintenance is essential for the effectiveness and longevity of safety gear. Keeping your equipment clean plays a vital role in the upkeep of gate repair safety gear. Dirt, grease, and debris buildup can impair the functionality and safety of helmets, gloves, and harnesses. To maintain high safety and operational standards, it's important to follow recommended cleaning practices tailored to each type of gear.

For helmets, use mild soap and warm water to gently scrub the outer shell and padding, ensuring you air dry them afterwards.

Gloves should be checked for punctures and cleaned with suitable fabric cleaners based on their material—leather gloves require different care than synthetic ones.

Harnesses need careful attention; soak them in a mild detergent solution and hand wash, making sure to remove oil or grime from the straps without damaging the fibers.

Effective Storage Techniques

Proper storage is essential for maintaining the condition and readiness of safety gear. When it comes to gate repair safety equipment like helmets, gloves, and goggles, the methods of storage matter as much as the locations. Each item should be kept in a clean, dry space to prevent deterioration from moisture or pollutants.

For example, helmets should be hung on designated racks instead of tossed into tool bins, which can compromise their structural integrity. Gloves should be stored flat to avoid permanent creases that could weaken the material over time, and a dedicated shelf or drawer can help maintain their shape and function.

Goggles, which can easily get scratched and impair visibility, should be kept in protective cases or on padded shelves. Temperature control is also important, as extreme conditions can damage the materials of safety gear, making them brittle or overly elastic. Therefore, choose a storage area that remains relatively cool and out of direct sunlight.

By implementing these storage techniques, you can ensure that your gate repair safety gear meets the highest safety standards, while also fostering a sense of professionalism and shared responsibility within your team.

#auto gate repair near me#automatic gate opener repair near me#Automatic Gate Repair#automatic gate repair companies near me#automatic gate repair near me#commercial gate repair#driveway gate repair#driveway gate repair near me#electric driveway gate repair#electric gate repair#electric gate repair near me#fence and gate repair#fence gate repair#fence gate repair near me#gate opener repair#gate opener repair near me#gate operator repair#gate operator repair near me#gate operators repair#gate repair companies near me#gate repair company#gate repair company near me#gate repair near me#gate repair service#gate repair services#gate valve repair#iron gate repair#iron gate repair near me#lift gate repair#lift gate repair near me

0 notes

Text

The importance of regular servicing for your Sewage Pumping Station cannot be overstated. Depending on the system's application, scheduling annual or more frequent maintenance is essential for optimal performance and longevity. A comprehensive service visit by Packaged Pumping Stations Limited includes cleaning and inspection of the pump, non-return and gate valves, pipework, guide rails, electrical and level control systems, as well as ensuring the overall safety and security of the installation. To safeguard your investment and maintain the efficiency of your Pumping Station, reach out to the expert team at Packaged Pumping Stations Limited at 01332 854868.

#sewage pumping station#annual servicing#pumped systems#maintenance frequency#service visit#pump cleaning#bearing inspection#impeller check#non-return valve#gate valve#pipework#guide rails#electrical check#pump repair#pump replacement#Packaged Pumping Stations

0 notes

Note

Rodimus has fallen in love and is about to bond with Getaway. When Ratchet and Drift sit him down and show him evidence of Getaway cheating and he's devastated.

Personally I can never see Rodimus ever liking Getaway in any capacity but I can see them using each other as a quick frag when they first meet.

Its one of the worst experiences Rodimus has in his life and he doesn’t even overload. Getaway asked and he made a face before standing up and just walking out of Getaway’s hab completely unsatisfied and going to meet up with one of his aft call bots that he knows will get him off.

That night he heads to join, Cyclonus, Tailgate and Whirl for a frag session because he needs three very well experienced and nasty mechs to get the horrible feeling and thought of Getaway out of his memory files and off his frame.

He’s feeling a lot more satisfied hours later when he leaves the trios hab with a nice limp in his gate and a tiredness only a good fragging can give a bot.

He doesn’t think of Getaway or their horrible time until he and his crew stop on a planet and he meets the con twins Skyquake and Dreadwing. He’s smiling so wide with his spoiler bouncing and valve twitching just itching for a fun time as he locks optics with the two.

Before he knows it he’s bent wide over with two huge spikes stuffing his port like the spike slut he is as they both thrust inside of him with a servo choking his neck cables just the way he likes it and another slapping his sensitive valve raw.

Its when they finish and carry him back to his ship for Magnus to take does he see Getaway glaring at him and he’s so confused as to why until he remembers the horrible time they had together and immediately pushes the thought aside with a shiver of disgust.

Really, there was no way the mech actually thought lasting less than five minutes was gonna sate him. He knows he’s a slut but even sluts need more than five minutes.

He purposely tries to never think on the encounter again only to have the same issue when he’s on the bridge.

Magnus and Megatron are standing on either side of him, servos gently caressing both his sides making his tanks flutter and his aft wiggle as he smiles giddy and leans into them.

He’s thinking of all the fun they’ll have together as they usher him towards the door where it opens to reveal Getsway glaring angrily at him making him confused all over again.

Its Magnus stepping forward asking what Getaway needs with a clipped tone that makes the other look away and walk off.

He feels himself shiver in pure disgust as he remembers once again, how terrible their time was and how pitiful his stroke game felt. He tells the two as much after Megatron stares down where Getaway was last seen. He doesn’t want the mech to get hurt but he does wish he’d stay away from him.

He gives Magnus a nice, long surprise under the desk gift after making sure Getaway had a completely different schedule than him. He helped the mech organize two book shelves after, he didn’t care at all for stuff like that, but it made Magnus smile and happy so he did it.

He was having his fun as usual with the conjunx pair and the conjunx trio along with a spike swirl for Rewind and Chromedome as a job well done on helping repair a part of the ship. Along with letting Nautica use her servo to spank him when her frustrations became too much. He allowed Skids to watch and couldn’t help giggling at how the mech got so nervous when he moaned looking his way.

Rodimus was, to put it frankly, a slut.

He was decepticon share ware when he was Hot rod and changing to Rodimus, even when he was Rodimus prime, did nothing to curb his need for spike. Sure it lowered his libido but that put it on the healthy high scale instead of beyond the high scale. His doc First aid was grateful while he worked it so he could enjoy the more deeply kinky intimate parts of fragging instead of going so rough he would break.

He’s been on berth leave multiple times for having his insides shifted and his valve sprained.

“Hey Roddy,” he felt his spoiler bounce and his tank soften, his optics felt softer at the sight of Drift coming towards him. But that changed when he noticed the mech looking unhappy.

“What’d I do?”

He never fragged Drift or Ratchet.

They never invited him to berth so he never flirted or did anything inappropriate.

He was a slut.

Not a creep or perv who couldn’t respect boundaries.

“Nothing Roddy, you haven’t done anything,” Drift reassured. The mech put an arm around his waist like he always did and led him back to his hab where Ratchet was sitting down waiting for them.

He sat between the two on the couch and felt an awkward tension resting heavily in the room.

He felt better having Ratchet shift him onto his lap but he still felt nervous.

“Okay, whats up guys? What’d I do?”

“Roddy,” Drift sighed his designation and he was quick to apologize, “Stop that. You didn’t do anything kid. We just wanted to talk.”

His optic ridges touched but he nodded.

“Its about you and Getaway,” Ratchet said after a moment silence, “the mechs been….”

“He’s been stalking you, even with your two different schedules,” Drift finished, his fangs poked out and his servos were tight.

“Stalking me? But..why? We aren’t a thing…I’ve never…”

“Aw damnit.”

“Kid?”

“The first few days in…I..um..well its cause of that. Don’t worry about it. I’ll take care of it,” Rodimus sighed rubbing his face plate and going to stand when Ratchet and Drift held him in place on the medics lap.

“He harrassin ya cause he wants ya in berth again?”

The way both of them of them lock onto him, protective fields shrouding him making it hard to vent but so easy to melt against.

“No..I..I don’t know what he wants..I..well..I like to..explore my options..sometimes,” he blushed in a dazed.

“Kid ya like spike. We know. The crew knows. A lot of cybertron knows. It’s fine kid. I’m called the party ambulance for a reason.”

“We know your reputation Roddy. We don’t care.”

“Speak for yourself kid. I’m happy you’ve slowed down and haven’t caught any viruses. First aid used to have a mental breakdown when he had to out your valve back into place.”

“Ratchet!”

“What Kid? Its fine. I’ve popped mine back into place a few times myself,” Ratchet shrugged at Rodimus who looked…beyond shell shocked even if he shouldn’t. His reputation was very well known.

“I..how long have you two know?”

“Since we’ve known you,” Drift said easily, he was still angry but the digit he used to brush along Rodimus’s cheek was anything but. It was hard not to lean into it.

“Wait..if you knew I was share ware,” Drift’s servo gripping his face plate giving him a sharp look made him back track.

“I mean, used to be shareware,” he rushes. It still doesn’t loosen Drifts hold so he continues.

“Why are you always inviting me over and having me spend the night if you know I’m a spike slut?”

Maybe he should’ve put more thought into all the times they had him sit on their laps or would cuddle with him in berth and make sure he couldn’t leave. Or when he’d cook dinner and lunch every day and one of them always digit fed him with a now noticeably lame excuse of “we want to make sure you eat enough.”

“Told ya we’d have to spell it out,” Ratchet grouched, wrapping his arms around the speedster who felt weary but unafraid.

“We like you Roddy. More than what you think,” Drift interrupted his musings, thumb rubbing his cheek.

“We’ve been in love with you for a very long time now and we’re pretty sure you feel the same. Even if you don’t want to admit it,” Drift finished.

“Kid you run faster than Blurr from affection thats not a one night sexual conquest. So we figured it best to ease you into the idea of being with us. We don’t have any intent to change who you are. We know you love spike and we’re fine with it. We just want you to come home to us at the end of it.”

He felt his optics watering and he wanted to hide.

They were right of course.

He was afraid of romantic feelings, relationships, love.

But when it came to the two mechs holding him he couldn’t help but fall in love.

Subconsciously he lessened the amount of mechs he’d sleep with on a drastic scale the more time he spent with them intimately.

He didn’t want to give up his frag sessions with Megatron and Minimus or the wild rides with Cyclonus, Tailgate and Whirl, but he hadn’t really ventured out much aside from basic non penetration with Nautica, Chromedome and Rewind and letting Skids watch. Of course he had fun with Skyquake and Dreadwing, but he didn’t leave his comm number like he usually did for a second round.

“I don’t..please don’t..”

“Relax kid, we know. We know,” Ratchet let him curl up and hide.

It was embarrassing as it was needed.

“I’m not..you picked wrong. You shouldn’t want me.”

The engine rev from Ratchet was the first real warning and he kept silent.

“We know exactly who we picked Rodimus and we aren’t picking anyone else but the three of us.”

That was the second warning, hearing his designation from Drift was always serious and while his insecurities were tugging at him, he let Ratchets warm servo rubbing his thigh quiet the storm.

They stayed like that for a while.

Sitting on the couch until Rodimus felt Ratchet’s signs of stiffness.

He fell into rhythm without thinking much as he shifted and stood helping the mech up and using his outlier to warm the space between them.

Eventually they retired to berth where Ratchet and Drift locked Rodimus in a tangle of limbs.

He didn’t mind. It was grounding.

Helped him feel without panicking.

He looked down and let his digits curl loosely between theirs and day dreamed.

They didn’t say anything. Didn’t push or rush him.

They just enjoyed their time together and that made things feel..as easy as onlining.

Rodimus didn’t see or hear about Getaway after that but he did notice Drift cleaning energon off his sword and Ratchet wiping energon from his med kit.

He figured it best not to ask.

#rodimus#drift#ratchet#dratchrod#dratchet#transformers#rodimus prime#getaway#megatron#magnus#chromedome#rewind#nautica#skids#skyquake#dreadwing#cyclonus#tailgate#whirl#megatron x ultra magnus#cywhirlgate#cygate#cdrw#drift transformers#transformers x reader

67 notes

·

View notes

Text

Day 7-Tired

Day 7 -Sleepy

Other Stories

Other Days

Duke struggled on, every puff of his pistons more difficult than the last, but he would not fail, not his passengers, not his railway, and certainly not Staurt and Falcon. The coaches rolled quietly behind him, as if they could sense just how hard it was to keep moving.

‘Just make it to the platform. Just make it to the platform. Just make it to the platform,’ he chanted in his mind.

“Grandpuff?”

He would not fail, he couldn't.

“Grandpuff!”

He barely heard Falcon call out to him.

‘Come on,’ he chided himself, ‘push on, push on.’

His wheels slipped, and he despaired as the train slowed.

Clunk

He felt an engine take the weight of the train from behind, allowing his wheels to get their grip once more.

‘Push on! You’ve never let his grace down, don't start now!’ His exhaust barked as he pushed forward, steam pouring both from his funnel and the cracked valve. The engine behind kept up every wheel turn, their whistle sounding through the valley.

‘Ah, Skarloey.’ Duke thought, ‘Her railway must have sent her to help out.’

Duke frowned, that didn't make sense last he heard was Skarloey was barely running herself, she certainly was not capable of pushing with such vigor unless she’d been overha…oh.

He eased his throttle back and his vision cleared slightly; the engine running alongside him on the yard sidings was no longer painted blue or named Falcon, but was red and named Sir Handel. He wasn't on the Mid-Sodor any more, that railway hadn't existed for twenty long years, but on the Skarloey Railway. He let his crew finally close his throttle and regulator, letting Skarloey take the weight of the train the last several yards to the station. His crew were quickly out and examining him, asking why he’d pushed himself and risked increasing the damage. Duke stayed quiet, not knowing how to answer. How to tell them he'd forgotten not just where but when he was.

Skarloey pulled alongside with a wheesh to silence the crew.

“I forget we're not back then sometimes too,” She said quietly

She met Duke's eyes, and Duke saw terrible understanding there.

She looked down to the rails, the crews and Falcon silent, “One minute I’m almost asleep in the sheds, next I'm back broken. One bump away from my boiler bursting beyond repair, waiting for the day the railway's forced to scrap me to make ends meet. In the dark I can't see the changes to the shed, and I’m left thinking I dreamed the last few years until the sky is light enough for me to see again.

“That's why you can't sleep,” Fal…Sir Handel said heavily.

“I don't like sleeping in the shed either,” Duke admitted horsley. “I keep thinking I'm back in the shed, waiting to be found again.”

Skarloey’s driver’s expression hardened, and she bent down to look her engine in the eye, “we’ll fix it,” she looked over to Duke, ‘for both of you.”

“You can't save us from the past.” Skarloey reminded gently. “It has already happened,” She said.

“Watch me,” her driver said firmly and strode off towards the Thin Controllers office.

***

Duke returned from Crovan’s Gate works the next night. He felt better, if embarrassed by his lapse. The other engines didn't mention it, but the shed arrangement had changed. He was shunted into the shed facing the back of the shed rather than out, which confused him until he was realized he was being placed in front of Skarloey, with Rheneas to the side of his sister. An electric fixture had been fitted between them, although he had no idea what it was called, and it emitted a soft warm light between the two engines.

No one said a word, but Duke found himself incredibly grateful he had not just found a new railway, but a new home.

A/N:Hello Loves! Skarloey is refered to as 'she' in multiple places in the Reverand's notes, so generfluid Skarloey. Love Y'all!

#ttte fanfic#rws fanfic#fanfic#Traintober#Traintober24#Traintober2024#ttte skarloey#ttte falcon#ttte sir handel#ttte duke#Prompt-Sleepy#Genderfluid Characters#Fem Skarloey

18 notes

·

View notes

Text

Thomas the Tank Engine [NWR AU]

(Brief) History

Thomas is an LB&SCR E2 built in 1915. He was hired out to the newly-formed NWR, where he was subsequently (and quite suspiciously) sold after being written off as "lost in action". After the end of WWI, Thomas was allocated to Vicarstown to act as station pilot. During his tenure here, he was dragged along behind the Wild Nor' Wester as far as Crovan's Gate, after which he required new bearings on his coupling rods and valve gear.

In 1925, Thomas ran away down Gordon's Hill with a goods train. This act of negligence caused The Fat Director to re-allocate him to Wellsworth to learn how to handle wagons properly. His tenure here was short, however, as the then newly-purchased James also ran away down Gordon's Hill with a goods train later that month. After the alarm was raised, Thomas sprung into action with the breakdown train, his actions earned him re-assignment to the Ffarquhar Branchline. He worked here rather uneventfully for some thirty years until 1955 when a cleaner meddled with his controls and he ran into the stationmaster's house, badly damaging his front end. Repairs took longer than previously thought due to some issues securing the works drawings from Brighton, and when he finally returned to traffic in 1957, he had been completely rebuilt and reclassified. His running plate had been brought flush with his bufferbeams, his boiler, cab, bunker and tanks had been lowered and his classification was changed from LB&SCR E2 to NWR A1.

Returning to traffic, he had quite the few run-ins with Daisy, whom had done his work in his absence, as well as with the freshly-bought FQC No. 2 Mavis. From here, Thomas' life calmed down significantly, and except from a few mainline railtours, he has mostly remained on his little branchline in peace.

Personality

Thomas is, as expected, a cheeky little bugger with a loud mouth. He's immature, fussy, impatient and a joker. Since getting his branchline however, Thomas has matured somewhat, though he is still the witty little blighter he was in 1915.

This is my first stab at an existing character, it may not be the most fleshed-out, but I tried.

See you in the next one.

Cheerio!

#ttte#steam locomotive#railway#alt history#steam engine#locomotive#ttte au#rws au#ttte headcanon#ttte thomas

12 notes

·

View notes

Text

Unlocking Workplace Safety: Essential LOTO Kits for Every Industry

Workplace safety is a top priority for industries that deal with hazardous energy sources. Lockout Tagout procedures are designed to protect employees from unexpected machinery start-ups and energy releases during maintenance or servicing. Without proper LOTO measures, workers are at risk of serious injuries, which can lead to operational disruptions and legal consequences for businesses.

LOTO kits provide a comprehensive solution for energy isolation, ensuring that workers can perform maintenance tasks safely. These kits contain essential lockout devices, padlocks, tags, and other tools necessary for implementing an effective lockout program. This article explores the importance of LOTO kits, their components, and the best options for different industries.

The Importance of LOTO Kits in Workplace Safety

LOTO kits are not just a regulatory requirement; they are a crucial investment in workplace safety. Here’s why they are essential:

Prevents Accidents & Injuries - Proper lockout procedures help eliminate risks associated with the release of hazardous energy.

Ensures Compliance - LOTO kits help industries comply with safety regulations such as OSHA (Occupational Safety and Health Administration) and ANSI (American National Standards Institute).

Enhances Productivity - A well-organized LOTO system minimizes downtime by providing quick and easy access to necessary tools.

Improves Accountability - Lockout kits ensure that only authorized personnel can restore energy, preventing unauthorized machine startups.

LOTO Kits for Different Industries

Each industry has unique safety requirements, and LOTO kits are designed to cater to these specific needs. Here’s a look at essential LOTO kits for various industries:

1. Manufacturing Industry

Comprehensive LOTO kits with circuit breaker lockouts, valve lockouts, and padlocks.

Ensures safe maintenance of heavy machinery and conveyor systems.

2. Oil & Gas Industry

Specialized valve lockout devices for handling hazardous liquids and gases.

Weather-resistant lockout padlocks and durable lockout tags.

3. Electrical & Power Plants

Electrical lockout kits with plug lockouts, breaker lockouts, and insulated padlocks.

Protects workers from electrical hazards during repairs.

4. Food & Beverage Industry

Corrosion-resistant LOTO devices to comply with food safety standards.

Ensures safe handling of processing machinery.

5. Construction Industry

Portable lockout kits with durable hasps and padlocks for on-site work.

Helps ensure the safety of electrical and mechanical equipment in temporary work locations.

Key Components of a LOTO Kit

A complete LOTO kit contains various lockout tagout devices that cater to different energy sources. Some of the essential components include:

1. Lockout Padlocks

Used to secure lockout devices in place, ensuring they cannot be removed accidentally.

Available in different materials like steel, aluminum, and non-conductive plastic for electrical applications.

2. Lockout Hasps

Allow multiple workers to apply their own padlocks to a single lockout point.

Ensures group lockout procedures are followed during multi-person maintenance work.

3. Electrical Lockout Devices

Circuit Breaker Lockouts: Prevent accidental re-energization of circuit breakers.

Plug Lockouts: Secure electrical plugs to stop unauthorized access.

Switch Lockouts: Lock out toggle switches, buttons, or control panels.

4. Valve Lockout Devices

Used to lock out various types of valves, including ball valves, gate valves, and butterfly valves.

Prevents hazardous liquids or gases from being released during maintenance.

5. Lockout Tags

Clearly indicate why equipment is locked out and who is responsible for the lockout.

Help communicate safety measures to all workers.

6. Lockout Stations & Storage Boxes

Organized storage solutions for LOTO devices.

Help keep all necessary equipment in one place for easy access.

How to Choose the Right LOTO Kit for Your Workplace

When selecting a LOTO kit, consider the following factors:

Industry-Specific Requirements: Choose a kit designed for the hazards present in your industry.

Durability: Select high-quality materials that can withstand harsh working conditions.

Compliance: Ensure the LOTO kit meets OSHA and other safety regulations.

Storage & Organization: Opt for kits with lockout stations or carrying cases for easy access and organization.

Conclusion

LOTO kits are an essential part of workplace safety, protecting workers from hazardous energy while ensuring compliance with safety regulations. By investing in the right Lockout Tagout kit for your industry, you can create a safer work environment, reduce risks, and improve overall efficiency. Prioritizing workplace safety is not just a legal requirement - it’s a responsibility that safeguards lives and enhances productivity.

Would you like to learn more about choosing the best LOTO kit for your industry? Start exploring your options today and take a proactive step toward safety!

0 notes

Text

Unlocking Workplace Safety: Essential LOTO Kits for Every Industry

Workplace safety is a top priority for industries that deal with hazardous energy sources. Lockout Tagout procedures are designed to protect employees from unexpected machinery start-ups and energy releases during maintenance or servicing. Without proper LOTO measures, workers are at risk of serious injuries, which can lead to operational disruptions and legal consequences for businesses.

LOTO kits provide a comprehensive solution for energy isolation, ensuring that workers can perform maintenance tasks safely. These kits contain essential lockout devices, padlocks, tags, and other tools necessary for implementing an effective lockout program. This article explores the importance of LOTO kits, their components, and the best options for different industries.

The Importance of LOTO Kits in Workplace Safety

LOTO kits are not just a regulatory requirement; they are a crucial investment in workplace safety. Here’s why they are essential:

Prevents Accidents & Injuries - Proper lockout procedures help eliminate risks associated with the release of hazardous energy.

Ensures Compliance - LOTO kits help industries comply with safety regulations such as OSHA (Occupational Safety and Health Administration) and ANSI (American National Standards Institute).

Enhances Productivity - A well-organized LOTO system minimizes downtime by providing quick and easy access to necessary tools.

Improves Accountability - Lockout kits ensure that only authorized personnel can restore energy, preventing unauthorized machine startups.

LOTO Kits for Different Industries

Each industry has unique safety requirements, and LOTO kits are designed to cater to these specific needs. Here’s a look at essential LOTO kits for various industries:

1. Manufacturing Industry

Comprehensive LOTO kits with circuit breaker lockouts, valve lockouts, and padlocks.

Ensures safe maintenance of heavy machinery and conveyor systems.

2. Oil & Gas Industry

Specialized valve lockout devices for handling hazardous liquids and gases.

Weather-resistant lockout padlocks and durable lockout tags.

3. Electrical & Power Plants

Electrical lockout kits with plug lockouts, breaker lockouts, and insulated padlocks.

Protects workers from electrical hazards during repairs.

4. Food & Beverage Industry

Corrosion-resistant LOTO devices to comply with food safety standards.

Ensures safe handling of processing machinery.

5. Construction Industry

Portable lockout kits with durable hasps and padlocks for on-site work.

Helps ensure the safety of electrical and mechanical equipment in temporary work locations.

Key Components of a LOTO Kit

A complete LOTO kit contains various lockout tagout devices that cater to different energy sources. Some of the essential components include:

1. Lockout Padlocks

Used to secure lockout devices in place, ensuring they cannot be removed accidentally.

Available in different materials like steel, aluminum, and non-conductive plastic for electrical applications.

2. Lockout Hasps

Allow multiple workers to apply their own padlocks to a single lockout point.

Ensures group lockout procedures are followed during multi-person maintenance work.

3. Electrical Lockout Devices

Circuit Breaker Lockouts: Prevent accidental re-energization of circuit breakers.

Plug Lockouts: Secure electrical plugs to stop unauthorized access.

Switch Lockouts: Lock out toggle switches, buttons, or control panels.

4. Valve Lockout Devices

Used to lock out various types of valves, including ball valves, gate valves, and butterfly valves.

Prevents hazardous liquids or gases from being released during maintenance.

5. Lockout Tags

Clearly indicate why equipment is locked out and who is responsible for the lockout.

Help communicate safety measures to all workers.

6. Lockout Stations & Storage Boxes

Organized storage solutions for LOTO devices.

Help keep all necessary equipment in one place for easy access.

How to Choose the Right LOTO Kit for Your Workplace

When selecting a LOTO kit, consider the following factors:

Industry-Specific Requirements: Choose a kit designed for the hazards present in your industry.

Durability: Select high-quality materials that can withstand harsh working conditions.

Compliance: Ensure the LOTO kit meets OSHA and other safety regulations.

Storage & Organization: Opt for kits with lockout stations or carrying cases for easy access and organization.

Conclusion

LOTO kits are an essential part of workplace safety, protecting workers from hazardous energy while ensuring compliance with safety regulations. By investing in the right Lockout Tagout kit for your industry, you can create a safer work environment, reduce risks, and improve overall efficiency. Prioritizing workplace safety is not just a legal requirement - it’s a responsibility that safeguards lives and enhances productivity.

Would you like to learn more about choosing the best LOTO kit for your industry? Start exploring your options today and take a proactive step toward safety!

0 notes

Text

Heavy-Duty Valves for High-Performance Industries

Introduction

Selecting the right valve is crucial for efficient fluid control in industrial applications. Both ball valves and gate valves serve important roles, but their functions, benefits, and best-use cases differ significantly.

Understanding Ball Valves & Gate Valves

What is a Ball Valve?

Design: Features a rotating ball with a hole that controls flow

Operation: Quarter-turn mechanism for quick open/close

Best For: High-pressure, fast-acting shutoff applications

Industries: Oil & Gas, Water Treatment, Chemical Processing

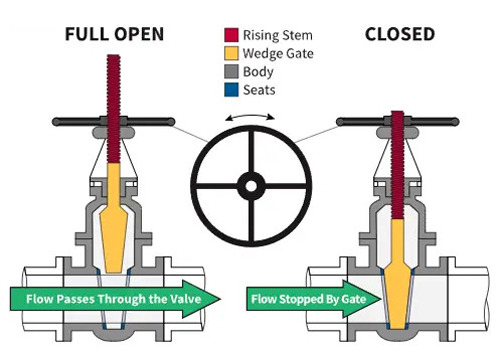

What is a Gate Valve?

Design: Uses a sliding gate to regulate flow

Operation: Multi-turn mechanism for gradual open/close

Best For: Applications requiring full flow or complete shutoff

Industries: Power Plants, Water Distribution, Industrial Manufacturing

Key Differences: Ball Valves vs. Gate Valves

Feature Ball Valve Gate Valve Operation Quarter-turn (fast)Multi-turn (slow)Flow Control On/Off, some throttling Full open/close Durability High, less prone to wear More wear due to gate movement Leak Prevention Excellent sealing (tight shutoff)Moderate (prone to leaks over time)Size & Cost Compact, slightly higher cost Larger, cost-effective Maintenance Low, easy to repair Requires more maintenance

When to Use Each Valve?

Choose a Ball Valve If:

✅ You need quick shutoff and tight sealing ✅ Operating under high-pressure or high-temperature conditions ✅ Looking for low maintenance and long service life

Choose a Gate Valve If:

✅ You require full, unrestricted flow with minimal pressure drop ✅ Applications need gradual flow control ✅ Working with large pipe diameters and cost-sensitive projects

Applications of Ball & Gate Valves in Udyog (Industries)

Oil & Gas: Ball valves for high-pressure control, gate valves for large pipelines

Water Treatment: Gate valves for water distribution, ball valves for chemical dosing

Chemical Processing: Ball valves for fast shutoff in corrosive environments

Power Plants: Gate valves for steam applications, ball valves for auxiliary systems

Manufacturing: Both valves used depending on the specific process needs

Maintenance Tips for Longer Valve Life

Inspect regularly for wear and leakage

Lubricate moving parts to prevent corrosion

Ensure proper installation to avoid misalignment issues

Use quality materials suited for the application environment

FAQ

Which is better: a ball valve or a gate valve?

It depends on the application. Ball valves are better for quick shutoff and durability, while gate valves provide full flow with minimal pressure drop.

Do ball valves last longer than gate valves?

Yes, ball valves typically have a longer lifespan due to their design, which experiences less wear and tear compared to gate valves.

Can gate valves be used for throttling?

No, gate valves are not designed for throttling, as partial opening can cause vibration and damage over time. Globe valves are better suited for throttling.

Are ball valves suitable for high-pressure applications?

Yes, ball valves perform exceptionally well in high-pressure systems, ensuring reliable sealing and minimal leakage.

Conclusion

Choosing between a ball valve and a gate valve depends on your industry’s specific needs. Understanding their differences, applications, and maintenance requirements ensures optimal performance and longevity in industrial operations. Investing in the right valve solutions enhances efficiency, reduces downtime, and supports business growth in various Udhhyog sectors.

0 notes

Text

What is a Backwater Valve? | Backwater Valve Explained

A backwater valve is a specialized plumbing device designed to prevent sewage from backing up into your home during heavy rainfall or sewer system overloads. It is a crucial component for homeowners in flood-prone areas like Toronto, where excessive water can overwhelm municipal sewer systems.

How Does a Backwater Valve Work?

A backwater valve is installed on the main sewer line, usually in the basement. It has a one-way flap that allows wastewater to flow out but automatically closes if sewage tries to flow back in. This prevents contaminated water from entering your home.

Key Components of a Backwater Valve:

Flap or Gate – Opens during normal drainage and closes during backflow.

Seals – Ensures an airtight closure when backflow is detected.

Inspection and Maintenance Access – Allows easy maintenance to ensure the valve functions properly.

Benefits of Installing a Backwater Valve

Prevents Basement Flooding – Stops sewage from backing up into your home.

Protects Your Property – Reduces the risk of water damage and costly repairs.

Complies with City Regulations – Many municipalities require backwater valves in flood-prone areas.

Where Should a Backwater Valve Be Installed?

A backwater valve is typically installed:

Inside the basement floor – The most common location where the main sewer line exits the home.

Outside near the foundation – In some cases, outdoor installation may be preferred.

How to Maintain a Backwater Valve

Regular maintenance is essential to keep the backwater valve functioning properly:

Inspect it regularly – Open the valve cover and check for debris.

Clean it periodically – Remove any blockages to ensure smooth operation.

Test the flap movement – Ensure it moves freely and closes tightly.

Professional Backwater Valve Installation

For expert installation, maintenance, and inspection of backwater valves in Toronto, trust Royal Work Basement Waterproofing. Our licensed plumbers ensure your home is protected from sewage backups and flooding.

Final Thoughts

A backwater valve is a simple yet essential device that protects your home from sewer backups and flooding. If you're considering installation, contact Royal Work for professional service and peace of mind.

0 notes

Text

What is A Shut Off Valve: A Guide to Safeguarding Plumbing

A shut off valve is a critical component in piping systems designed to control the flow of liquids or gases. By opening, closing, or partially obstructing pathways, these valves ensure safety, regulate pressure, and prevent leaks. Whether in residential plumbing, industrial processes, or oil and gas pipelines, shut off valves are indispensable for system efficiency and emergency management.

Types of Shut Off Valves

Shut off valves come in various designs, each suited for specific applications. Here are the most common types:

Ball Valve

A ball valve uses a rotating ball with a bore to control flow. It offers quick shut-off, durability, and minimal pressure drop. Ideal for water, gas, and oil systems.

Gate Valve

Gate valves feature a wedge-shaped gate that lifts to allow flow. They’re best for on/off control in low-frequency applications, such as water supply lines.

Globe Valve

Known for precise flow regulation, globe valves use a disc and seat mechanism. Common in HVAC systems and fuel pipelines.

Butterfly Valve

A compact, lightweight valve with a rotating disc. Butterfly valves excel in large-scale water treatment and fire protection systems.

Check Valve

Allows flow in one direction only, preventing backflow. Used in sewage systems and pump discharge lines.

Diaphragm Valve

Utilizes a flexible diaphragm to isolate flow. Ideal for corrosive or slurry fluids in chemical processing.

Needle Valve

Designed for precise flow control with a tapered needle-like plunger. Common in instrumentation and hydraulic systems.

ESDV (Emergency Shutdown Valve)

A specialized valve for rapid closure during emergencies, often automated. Critical in oil refineries and gas pipelines.

Uses of Shut Off Valves

Shut off valves serve diverse roles across industries:

- Residential: Isolate water supply during repairs (e.g., ball valves under sinks). - Industrial: Regulate steam, chemicals, or fuels (globe valves, diaphragm valves). - Oil & Gas: Ensure safety with ESDVs during leaks or pressure surges. - Fire Protection: Butterfly valves enable rapid water flow control in sprinkler systems. - Pharmaceuticals: Needle valves maintain precision in fluid handling.

How Do Shut Off Valves Work

The operating mechanism varies by type but follows a general principle:

1. Actuation: Valves are operated manually (handwheel, lever) or automatically (electric/pneumatic actuators).

2. Flow Control:

– Ball/Butterfly Valves: Rotate 90° to open/close. – Gate/Globe Valves: Linear motion raises/lowers the gate or disc. – Check Valves: Rely on flow pressure to open/close.

3. Sealing: Tight seals (rubber, PTFE) prevent leaks when closed.

Choosing the Right Valve

Selecting a shut off valve depends on factors like:

- Fluid Type: Corrosive fluids demand diaphragm valves; gases suit ball valves. - Pressure/Temperature: High-pressure systems require robust ESDVs or gate valves. - Frequency of Use: Ball valves last longer in high-cycle applications.

Conclusion

From ESDVs in hazardous environments to simple ball valves in homes, shut off valves are the backbone of fluid control systems. Understanding their types, uses, and mechanics ensures optimal performance and safety. Regular maintenance and correct valve selection further enhance system longevity.

#ball valve manufacturers in india#ball valve suppliers#china ball valve#china valve manufacturer#valve manufacturer#valve factory#valve price#shut off valve#gate valve#butterfly valve#esdv

1 note

·

View note

Text

Gate Valve Manufacturers & Exporters from India Trusted Source

Gate valves play a crucial role in various industries, ensuring smooth flow control in pipelines. These valves are widely used in oil and gas, water treatment, chemical processing, and other industrial applications.

When it comes to sourcing high-quality gate valves, businesses look for reliable Gate Valve Manufacturers & Exporters from India that offer precision-engineered products with durability and efficiency.

Understanding Gate Valves and Their Importance

Gate valves are designed to control the flow of liquids and gases by using a gate mechanism that moves up and down. They are highly preferred in applications requiring minimal pressure drop and full flow capability. Unlike other valves, gate valves provide a tight seal, preventing leakage and ensuring optimal performance in high-pressure environments.

Key Features of High-Quality Gate Valves

Durability: Made from robust materials like stainless steel, cast iron, and brass, ensuring long-lasting performance.

Leak-proof Design: Gate valves provide a tight seal, reducing the risk of leaks and contamination.

Corrosion Resistance: High-quality coatings and materials enhance resistance to corrosion and harsh environments.

Smooth Operation: Designed for easy opening and closing, ensuring minimal effort during operation.

Wide Application Range: Suitable for industries such as oil & gas, petrochemical, water supply, and power plants.

Why Choose Indian Gate Valve Manufacturers & Exporters?

India has emerged as a global hub for industrial valve manufacturing, known for its advanced engineering, cost-effective solutions, and strict quality standards. Indian manufacturers follow international norms such as API, ANSI, and ISO certifications, ensuring products meet global quality standards.

Advantages of Buying from Gate Valve Manufacturers & Exporters from India

High-Quality Manufacturing: Indian manufacturers use state-of-the-art technology to produce reliable and precision-engineered gate valves.

Competitive Pricing: Due to efficient production processes, Indian gate valves are more affordable without compromising on quality.

Custom Solutions: Manufacturers provide customization options based on specific industrial requirements.

Global Export Network: Indian exporters have a strong presence in international markets, supplying to various industries worldwide.

After-Sales Support: Reliable manufacturers offer maintenance, repair, and support services to ensure long-term product performance.

Applications of Gate Valves in Various Industries

Gate valves are versatile components used in numerous industries, offering efficiency and durability. Some common applications include:

Oil & Gas Industry: Essential for pipeline control, crude oil transportation, and refinery operations.

Water Treatment Plants: Used for water distribution and sewage systems to regulate flow.

Power Plants: Ideal for steam and cooling water applications.

Chemical Industry: Ensures safe handling of aggressive chemicals and hazardous fluids.

Construction & Infrastructure: Used in large-scale projects for water supply and drainage systems.

How to Choose the Right Gate Valve Manufacturer in India?

Selecting the right manufacturer is crucial to ensuring the best quality and performance for your industrial requirements. Here are key factors to consider:

Industry Experience: Choose a manufacturer with years of expertise in valve production.

Certifications & Standards: Ensure they comply with industry standards like API 600, BS 1414, and ISO 9001.

Product Range & Customization: Look for a supplier offering various gate valve designs with custom options.

Material Quality: High-grade materials ensure better durability and corrosion resistance.

Customer Support: Reliable after-sales service and technical assistance add value to your investment.

Conclusion

When looking for Gate Valve Manufacturers & Exporters from India, it is essential to choose a trusted and reputed supplier to ensure product reliability, efficiency, and long-term performance.

With a strong manufacturing base, advanced technology, and adherence to global standards, Indian manufacturers are well-equipped to meet the demands of various industries.

If you are looking for a trusted supplier in Ahmedabad, Mayur Valves System Private Limited offers high-quality gate valves designed to meet industrial needs with precision and reliability.

#Gate Valve Manufacturers & Exporters#Gate Valve Manufacturers & Exporters from Ahmedabad#Gate Valve Manufacturers & Exporters from Gujarat#Gate Valve Manufacturers & Exporters from India

0 notes

Text

Guide to choosing the right ball valve for your project

Parth Valves and Hoses LLP, a trusted provider of high-quality hygienic valves, FDA hoses, and dampers, understands the critical role fluid control plays in various industries. Selecting the right valve is essential for ensuring efficient, safe, and reliable operations. This comprehensive guide focuses on ball valves, providing in-depth insights into their functionality, types, applications, and key considerations for choosing the perfect valve for your specific project.

What is a Ball Valve?

A ball valve is a quarter-turn rotational valve that utilizes a hollow, spherical ball to control the flow of liquids or gases. The ball has a bore (a hole through its center) that allows or blocks flow depending on its position. When the bore is aligned with the flow direction, the valve is open, allowing unimpeded flow. A simple 90-degree rotation of the ball, typically using a lever or handle, positions the solid part of the ball to block the flow path, effectively closing the valve and creating a tight seal.

Ball Valves

Advantages of Ball Valves:

Ball valves offer several advantages that make them a popular choice in various industrial applications:

Quick and Easy Operation: The quarter-turn operation enables rapid opening and closing, making them ideal for emergency shut-off situations and processes requiring frequent on/off control.

Excellent Shut-Off Capability: When closed, ball valves provide a reliable and leak-tight seal, preventing leakage and ensuring efficient flow isolation.

Durability and Reliability: With relatively few moving parts, ball valves are known for their robust construction, minimal maintenance requirements, and long service life.

Versatility: Ball valves can handle a wide range of fluids and gases, including corrosive chemicals, making them suitable for diverse industrial applications.

Compact Design: Their compact design makes them suitable for installations with limited space.

Cost-Effectiveness: Compared to some other valve types like gate or globe valves, ball valves often offer a more cost-effective solution for many applications.

Types of Ball Valves:

Different types of ball valves are available to suit various applications:

One-Piece Ball Valves: These are the most economical type, typically used for low-pressure applications.

Two-Piece Ball Valves: Offer greater versatility and can be easily disassembled for cleaning or maintenance.

Three-Piece Ball Valves: Provide easy access to internal components for maintenance and repair, making them suitable for demanding applications.

Multi-Port Ball Valves: These valves have three or more ports, allowing for complex flow control and diversion.

Key Considerations When Choosing a Ball Valve:

Selecting the appropriate ball valve is crucial for optimal performance, safety, and longevity. Consider the following factors:

Material Compatibility: The valve body, ball, and seals must be chemically compatible with the media being handled. Common materials include:

Stainless Steel: Offers excellent corrosion resistance and is suitable for food processing, chemical, and pharmaceutical applications.

Brass: Cost-effective for water and other non-corrosive media.

PVC: Suitable for corrosive applications at lower temperatures and pressures.

Pressure and Temperature Ratings: The ball valve must be rated to handle the maximum operating pressure and temperature of the system.

Port Configuration: Choose the appropriate port configuration (2-way, 3-way, etc.) based on the specific flow control requirements of your system.

Valve Size: Proper sizing is crucial to ensure optimal flow rates and minimize pressure drop.

End Connections: Select end connections (threaded, flanged, welded) compatible with the piping system.

Actuation: Consider the actuation method based on control needs: manual, electric, or pneumatic.

Seat and Seal Materials: The seat and seal materials (e.g., PTFE, Viton) must be compatible with the media and operating temperature.

Parth Valves and Hoses LLP: Expertise in Fluid Control

While Parth Valves and Hoses LLP specializes in hygienic valves, FDA hoses, and dampers, our deep understanding of fluid control principles allows us to provide expert guidance on selecting the right ball valve for various applications. We can assist you in determining the appropriate material, size, and configuration for your specific needs.

Why Choose Parth Valves and Hoses LLP for Your Fluid Control Needs?

Expert Knowledge: Our team possesses extensive knowledge of fluid control systems and components.

Commitment to Quality: Our 12-month product guarantee on our hygienic products reflects our dedication to quality and reliability.

Customer-Centric Approach: We prioritize customer satisfaction and provide excellent support.

Conclusion:

Selecting the correct ball valve is a critical decision that impacts the efficiency and safety of your operations. By carefully considering the factors outlined in this guide and consulting with fluid control experts like those at Parth Valves and Hoses LLP, you can ensure you choose the ideal valve for your project. Contact us today to discuss your specific requirements and discover how we can contribute to your success.

0 notes

Text

Why Backflow Prevention Devices Are Crucial for Ventura Businesses

20% of waterborne disease outbreaks in commercial settings backtrack from contamination caused by backflow. For businesses in Ventura, protecting the water supply is critical—not just for compliance but for safeguarding the health of employees, customers, and the wider community.

Backflow prevention devices are essential for ensuring your business’s water supply remains clean and safe. These devices stop contaminated water from reversing into the potable water system, which can occur due to pressure changes in the plumbing. Without proper prevention measures, the risks include severe health hazards, business interruptions, and fines.

What Is Backflow and Why Is It Dangerous?

Backflow occurs when the direction of water flow reverses, allowing non-potable (unsafe) water to mix with the clean supply. This can happen due to back siphonage (caused by negative pressure) or backpressure (caused by higher downstream pressure).

Why is backflow dangerous?

Health Risks: Contaminated water may carry harmful bacteria, viruses, or chemicals, causing illnesses such as food poisoning or severe gastrointestinal infections.

Operational Impact: Addressing contamination can lead to costly repairs and forced closures.

Reputation Damage: Customers quickly lose trust in businesses tied to water contamination incidents.

What Types of Businesses Need Backflow Prevention?

Many Ventura businesses require backflow prevention devices to maintain water safety. Here’s a list of industries where these systems are especially crucial:

Restaurants: Kitchens are prone to cross-connections, such as those between dishwashers and sinks.

Hotels: Proximity to sewage systems and high water usage increase the risk of backflow.

Healthcare Facilities: Contaminated water can endanger patient health.

Car Washes: Detergents and chemicals pose a significant contamination threat.

Landscaping Companies: Irrigation systems are common sources of backflow.

It’s not just industrial facilities—any business connected to Ventura’s public water supply needs to comply with local regulations. Failure to do so can result in penalties, operational disruptions, or water service termination.

Why Is Backflow Prevention Critical for Ventura Businesses?

Restaurants face unique challenges due to their water usage and plumbing setups. Grease traps, dishwashing systems, and sewage lines increase the risk of contamination. Even a minor malfunction in a restaurant's plumbing can lead to backflow prevention failure, potentially contaminating the water used for food preparation or cleaning.

Regular inspections and maintenance are vital for ensuring your backflow prevention devices remain effective. At Hansen’s Plumbing, we offer tailored solutions to help Ventura restaurants safeguard their water systems.

How Do Backflow Prevention Devices Work?

Backflow prevention devices are designed to act as barriers, ensuring water flows in one direction. Here are the two most common types:

Reduced Pressure Zone (RPZ) Devices: These use a pressure differential to keep contaminated water from flowing backward. They are highly effective for high-risk applications.

Double Check Valve Assemblies: With two internal valves, these devices create a double layer of protection for medium-risk situations.

Think of these devices as gates that automatically close when water tries to flow in the wrong direction. Regular testing by professionals, like the team at Hansen’s Plumbing, ensures these devices work correctly and comply with Ventura’s regulations.

The Risks of Skipping Backflow Prevention

Neglecting backflow prevention can result in serious consequences:

Hefty Fines: Ventura imposes penalties for non-compliance with water safety regulations.

Water Disconnection: Businesses without backflow prevention systems risk losing access to water services.

Legal Liability: Contamination incidents can lead to lawsuits and damage claims.

Reputation Loss: A single contamination event can tarnish your business's reputation, leading to lost customers and long-term revenue decline.

Taking a proactive approach to backflow prevention not only protects your business but also supports Ventura’s commitment to community safety.

Conclusion: Why Choose Hansen’s Plumbing for Backflow Prevention

Backflow prevention isn’t just a regulatory requirement—it’s an investment in the health and trust of your employees, customers, and community. By prioritizing water safety, Ventura businesses can avoid fines, maintain operations, and safeguard their reputations.

At Hansen’s Plumbing, we specialize in providing professional backflow prevention services, from installation to routine maintenance. Our expert team ensures your systems comply with local regulations and function efficiently to protect your business. Don’t wait until it’s too late—contact us today to learn how we can help you stay compliant and safe!

0 notes

Text

Globe Valve Manufacturer in Germany

Valvesonly Europe is a Globe Valve manufacturer in Germany Globe valves are valves that move in a straight line to control media flow. They are usually used for throttling and regulating flow through the valve, but they can also be employed in on/off systems to entirely allow or restrict media.

How Globe Valve works

A globe valve is a type of valve that works by moving a disc as the closing component, providing for control over media flow in a pipeline. These valves create a globular-shaped hollow surrounding the port area, hence their name.

The operation of a globe valve requires an understanding of its moveable disc and stationary seat, which are positioned parallel to the pipe and perpendicular to the disc in a spherical body, with the seat immobile.

The valve disc moves up and down in response to the activation of the top wheel, which can be manipulated manually or using an actuator.

The globe valve is fitted for low-temperature settings, where pressure falls below the disc, and for high-temperature applications, such as steam-operated boilers, where pressure is above the disc.

How is a globe valve made?

Globe valves are generally produced through casting methods due to their intricate design; however, for certain applications, they may also be fabricated from wrought materials. The disc and seat rings are commonly constructed from bronze, but in the case of steel globe valves intended for temperatures above 350°C, stainless steel trim is employed to prevent complications such as seizing and galling. The heat treatment of the valve's mating surfaces is crucial for achieving differential hardness values. Furthermore, alternative trim materials, including cobalt-based alloys, are also utilized. It is necessary to grind the seating surface to ensure complete bearing surface contact during the closure of the valve. In lower pressure classifications, an expanded disk locknut is used to maintain the alignment of the valve, whereas for higher pressure applications, disc guides are incorporated into the valve body.

Types of Globe Valve

Pressure Seal Globe Valve

Bellow Seal Globe Valve

Y Type Globe Valve

Angle Type Globe Valve

Forged Steel Globe Valve

Pressure Globe Valve

Industries Globe Valve

Oil and Gas

Chemical

Mining

Textile

Petroleum

Petrochemical

Pulp and Paper

Marine

Power Generation.

Features of Globe Valve

A globe valve is a device with a globe-shaped body and an interior baffle separating intake and outflow ports. The baffle, also known as the disk or plug, is connected to a stem and a hand wheel. When the wheel is turned or the actuator is activated, the stem raises or lowers the disc.

Advantages of Globe Valve

Globe valves are a reliable and efficient tool for accurately regulating flow in various fluids like water, oil, steam, and chemicals. They are also durable and dependable, with a simple design that simplifies installation, maintenance, and repair.

Applications

Globe valves are crucial in various industries like oil and gas, power generation, chemical processing, and wastewater treatment, regulating fluid flow, pipelines, power plant feedwater, chemical process flow, and water flow in water treatment facilities.

Globe Valve vs. Gate Valve:

Globe Valve

Gate Valve

The construction of a globe valve involves major internal components located within the body cavity.

The gate valve's structure is simpler, with most components positioned on top of the valve body.

High pressure drop

Low pressure drop

Unidirectional

Multidirectional valve

Used for flow control

Used only for isolation

Disk moves in parallel with the medium being pumped.

Moves perpendicular to the fluid flow

Offers more resistance to fluid flow

Offers little resistance to fluid flow

The Globe valve, with the same size and rating, has a higher weight compared to the gate valve.

Weight is comparatively lesser

Costlier due to the complex design

comparatively cheaper

Globe valves are typically not suitable for sizes larger than 12 inches.

can be used for larger sizes as well.

Globe Valve vs. Ball Valve:

Globe Valve

Ball Valve

Provides high-pressure drop

Ball valves have a relatively low pressure drop.

Utilizes a disk that operates against the flow.

use a ball that shuts across the flow.

Linear motion valve

Rotary motion valve

Provides better control than a ball valve

Provides shut-off properties than the globe valve

Is cheaper than ball valves

more complex in design than the globe valve and hence costlier

Slow operation

Quick shut off, possibility of water harmer

What to consider before buying Valvesonly Europe customized Globe Valve manufacturer in Germany

Globe valves are chosen based on their compatibility to specific conditions such as temperature, pressure, and fluid type, which necessitates consideration of valve size, material type, pressure rating, standard, and design to ensure the most appropriate valve.

Design

The standard pattern valve, which has the greatest obstacle to flow, causes a higher fluid pressure loss, but the angle pattern valve is suitable for slug flow and oblique pattern valves are resistant to erosion.

The globe valve disc design includes three discs: composition, plug, and balll. Composition discs are best suited for water system operations, plug discs provide optimal flow regulation, and ball discs are appropriate for low temperature and pressure situations.

Valve sizes

Valve sizing is critical for throttling valves since it controls fluid flow. Globe valve size selection necessitates research and understanding of needs. Manufacturers often size valves for purchasers, with varied sizes for different applications.

As a throttle valve, the globe valve size is critical for estimating pressure loss at precise places within the valve.

Description

Body material- Cast Iron, Cast steel [A216 WCB, WCC, LCB, LCC, WC6, WC9), Ductile Iron, Stainless Steel [SS316, SS304, SS316L, SS904L, CF8, CF8M, F304, F316, F31L, F51, F3, F55, F91]

Class- 150 – 2500; PN10 – PN 450

Size- DN 10 – DN 1200

Ends- Butt weld, Flanged, threaded, socket weld

Operations- Handwheel operated, Pneumatic actuated, Electric actuated, Gear operated

Visit us: https://www.valvesonlyeurope.com/product-category/globe-valve/

1 note

·

View note

Text

Importance of Valves in Plumbing Systems

Introduction

Valves control water flow, pressure, and direction in plumbing systems, ensuring safety and efficiency.

Why Valves Are Essential

Flow Control: Regulate water flow precisely.

Pressure Management: Maintain consistent water pressure.

Leak Prevention: Shut off water supply during repairs.

System Protection: Prevent backflow and contamination.

Types of Valves in Plumbing

Gate Valve: Full flow control with minimal pressure drop.

Ball Valve: Quick shut-off with a simple quarter-turn.

Check Valve: Prevents backflow.

Globe Valve: Throttles flow efficiently.

Butterfly Valve: Compact and easy to operate.

Applications of Plumbing Valves

Residential water supply systems

Commercial buildings

Industrial plumbing networks

Irrigation systems

Benefits of Using Valves

Enhanced safety

Efficient water management

Easy maintenance and repairs

FAQ

Q: What is the most common valve in plumbing? A: Ball valves are most common due to their easy operation and reliability.

Q: How do valves prevent water damage? A: By allowing quick shut-off, valves prevent leaks from causing extensive damage.

0 notes