#fully threaded rod end bolts

Explore tagged Tumblr posts

Text

Warnings: oral (f receiving), fem!Reader, shibari

Synopsis: Douma initiates you into the world of shibari

Author: @dumadono

A/N: Welcome to another day of Kinktober '23 Collaboration Today's prompt: shibari

Masterlist

Douma's heart is captivated by artistry, and what greater embodiment of artistic expression is there than the ancient Japanese art of bondage, known as shibari or, in its traditional form, kinbaku?

_________________

That day, he embarks on a journey from mere admiration to active engagement and beyond. This is why the two of you find yourselves strolling along this quiet, desolate dirt path, burdened with an array of tools and paraphernalia, ready to delve into the world of bound passion and creative intimacy.

"Have you ever ventured into the art of shibari?" you inquire, your voice hesitant like a gentle breeze.

"A few times, yet I never fully mastered it, lotus," he responds, his words flowing like a tranquil stream.

"How so, Douma-sama?" you question, curiosity dancing in your eyes.

"Shibari, my little lotus, is an art of intricate knots and delicate ties," he answers, his voice a seductive whisper. "It requires patience, precision, and a deep connection between the one tying and the one being bound. I believe we share such a connection."

You blush at his words.

You now find yourself at a single-room wooden dwelling. Douma has frequented this place, studying its secrets, delivering various items, and readying the weathered edifice you now encounter for its current purpose. For several months, no soul has ventured here, and this aligns perfectly with Douma's intentions. Silence reigns, a tranquility he diligently maintains.

Now that you are both inside, and you undress completely.

In complete silence, Douma's actions speak volumes. His kisses and tender caresses trace your body with affection, focusing on your breasts and ass. As you sit on a small stool, he carefully unravels coils of rope. One end is guided through the first of the eye bolts, draping down to your shoulders. The length is matched with the other end, and a secure knot is tied at the eye bolt. With your arms extended, Douma has you hold a sturdy bamboo rod behind your head, spanning from one hand to the other.

Methodically, deliberately, and with deep affection, Douma begins to weave the ropes around you, starting at your underarms and winding them around until they reach your hands. Ornamental knots adorn each hand, and then the ropes are guided back up, securing them to the same eye bolt. Your upper body is now firmly bound, your arms suspended about three feet above the floor. Despite only four points of suspension, the bamboo and the rope's intricate threading ensure your weight is evenly distributed.

Next, another rope passes through the far eye bolt, and it's employed to secure your ankles to another bamboo rod intended to maintain your legs apart. A third rope descends, slipping beneath the small of your back, alleviating most of the weight from your ankle restraints. Two additional ropes loop under your back, the first just below your breasts, and the second halfway between the first and the rope near your hips. All of this consumes a substantial amount of time due to the meticulous knot work being executed.

At this juncture, you are suspended from the eye bolts with only your head left unsupported. Douma brushes your hair, "You're such a good lotus, so obedient to me."

You're now completely bound.

“How are you feeling, my precious lotus?” Douma asks, his tone lacing with sweetness.

“I’m good, master,” you reply, offering him a smile. “Keep going.”

Removing the stool, Douma stands back to assess his handiwork. To a casual observer, it might appear as if you are being tortured, but the reality is quite the opposite. In truth, you are utterly comfortable and at peace. You feel more liberated than you have ever felt before. You have surrendered yourself completely to Douma and have no decisions to worry about.

The height at which you are suspended is carefully selected to grant Douma ideal access to your pussy while he occupies the stool. His eyes remain closed as he skillfully employs his mouth and tongue, bringing you to orgasm after orgasm while you hover weightlessly in the air. He possesses an innate sense of timing, allowing just enough respite before resuming his attention. Overwhelmed by ecstasy and a profound sensation of boundless pleasure, your passionate cries fill the space. This experience is unlike any you've ever encountered, an unprecedented expression of love and desire.

Douma's skilled tongue dances slowly on your clitoris, occasionally gliding down the slit to your sweet entrance, which emits juices he adores so much. He places tender licks here and there, occasionally applying a gentle suction to your lips, all while humming with delight.

You inquire about him, expressing your desire to please him in return.

Douma responds, breaking his silence for the first time since your arrival, stating that this experience is for your satisfaction, and you need not worry about his release at this moment. It's also unlikely that you'd be in a condition to attend to his needs after this intense scene.

After a few hours, you are lowered from your suspended position. You're tired. Exhaustion has taken its toll, and Douma gently carries you along the deserted dirt road back to his shrine while weariness overcomes you, and you eventually fall asleep in his comforting embrace.

"I love you so much, little lotus," Douma whispers, placing a tiny kiss on your temple.

#kinktobercollab‘23#kinktober 2023#kinktober2023#divider by cafekitsune#douma#douma smut#douma x reader#douma x you#douma x y/n#douma x reader smut#kny smut#kny x reader#kimetsu no yaiba#demon slayer#demon slayer smut#douma kny#kny douma#upper moon two#kny x you#kinktober 23

223 notes

·

View notes

Text

Inconel Fasteners: A Comprehensive Guide

Introduction to Inconel

Inconel is a family of nickel-chromium-based superalloys known for their exceptional strength, corrosion resistance, and ability to withstand extreme temperatures. Developed by Special Metals Corporation, Inconel alloys are widely used in aerospace, marine, chemical processing, and power generation industries.

The primary advantage of Inconel is its ability to retain mechanical strength even in high-temperature and corrosive environments. It resists oxidation, carburization, and chloride-induced stress corrosion cracking, making it an ideal material for fasteners used in critical applications.

What Are Inconel Fasteners?

Inconel fasteners are bolts, nuts, washers, screws, and studs made from Inconel alloys. These fasteners are designed to perform in extreme conditions where ordinary steel or stainless steel fasteners would fail. The combination of nickel, chromium, and iron (along with other elements in varying amounts) provides outstanding durability, even in the harshest environments.

Characteristics of Inconel Fasteners

High-Temperature Resistance: Can withstand temperatures exceeding 1000°C.

Corrosion Resistance: Excellent resistance to oxidation, pitting, and crevice corrosion.

Superior Strength: High tensile and yield strength.

Resistance to Creep and Fatigue: Maintains integrity under prolonged exposure to stress and heat.

Non-Magnetic: Some Inconel alloys exhibit non-magnetic properties, making them suitable for specific applications.

Different Types of Inconel Fasteners

1. Inconel Bolts

Hex bolts

Anchor bolts

U-bolts

J-bolts

Stud bolts

2. Inconel Nuts

Hex nuts

Lock nuts

Wing nuts

Flange nuts

Dome nuts

3. Inconel Washers

Flat washers

Spring washers

Belleville washers

Fender washers

4. Inconel Screws

Machine screws

Socket head cap screws

Set screws

Self-tapping screws

5. Inconel Studs

Fully threaded studs

Double-end studs

Tap-end studs

Each type of fastener is available in different grades of Inconel, such as Inconel 600, Inconel 625, Inconel 718, and Inconel 925, depending on the application and environment.

Uses of Inconel Fasteners

1. Aerospace Industry

Used in jet engines, gas turbines, and exhaust systems due to high heat resistance.

2. Marine Industry

Ideal for shipbuilding, offshore drilling platforms, and seawater applications due to exceptional corrosion resistance.

3. Chemical Processing Industry

Used in reactors, heat exchangers, and pressure vessels to withstand harsh chemicals and extreme temperatures.

4. Power Generation

Essential in nuclear reactors, steam turbines, and other high-temperature power generation equipment.

5. Oil and Gas Industry

Used in pipelines, valves, and drilling equipment exposed to high pressure and corrosive fluids.

6. Medical Industry

Applied in medical implants and surgical instruments due to its non-reactive properties.

7. Automotive Industry

Used in high-performance and racing vehicles for exhaust systems and turbocharger components.

Specifications of Inconel Fasteners

Common Standards for Inconel Fasteners

ASTM B166 (Rod and bar)

ASTM B167 (Pipe and tubing)

ASTM B168 (Plate, sheet, and strip)

ASTM F2281 (Bolting materials)

UNS N06600 (Inconel 600)

UNS N06625 (Inconel 625)

UNS N07718 (Inconel 718)

Mechanical Properties of Inconel 625 Fasteners (Example)

Tensile Strength: 930 MPa (135 ksi)

Yield Strength (0.2% Offset): 517 MPa (75 ksi)

Elongation: 50%

Hardness: Rockwell B88

Chemical Composition of Inconel 625

Conclusion

Inconel fasteners are an essential component in industries requiring high-performance fastening solutions. Their ability to resist extreme temperatures, corrosion, and mechanical stress makes them a preferred choice in aerospace, marine, oil and gas, and many other industries.

Ananka Fasteners is a leading manufacturer, supplier, and exporter of Inconel fasteners, offering high-quality products that meet international standards. If you are looking for reliable and durable Inconel fasteners, get in touch with us today!

Frequently Asked Questions (FAQs)

Q1: What makes Inconel fasteners different from stainless steel fasteners?

Inconel fasteners offer superior high-temperature and corrosion resistance compared to stainless steel, making them suitable for extreme environments.

Q2: What is the most commonly used Inconel grade for fasteners?

Inconel 625 and Inconel 718 are the most widely used grades due to their excellent mechanical and chemical properties.

Q3: Are Inconel fasteners expensive?

Yes, Inconel fasteners are more expensive than stainless steel fasteners due to their superior properties and complex manufacturing process.

Q4: Can Inconel fasteners be used in seawater applications?

Yes, Inconel fasteners, especially Inconel 625, are highly resistant to seawater corrosion and are used in marine applications.

Q5: Where can I buy high-quality Inconel fasteners?

You can purchase premium-quality Inconel fasteners from Ananka Fasteners, a trusted manufacturer and supplier in the industry.

#ananka#anankafastenrs#fasteners#fastenersmanufacturer#linkedin#articles#inconel#inconelfasteners#blog#anankafasteners#manufacturer#supplier#mumbai#hex#bolt#usa

0 notes

Text

Discover Alternate Names for a Stud Bolt | Stud Bolt Terminology

If you work in construction, engineering, or any field that involves fastening materials together, you’ve likely encountered stud bolts. But did you know that these essential fasteners go by various names? In this article, I’ll explore alternate names for stud bolts and provide insights into their applications and terminology. Understanding these terms can enhance your communication and help you make more informed decisions in your projects.

Table of Contents

What is a Stud Bolt?

Alternate Names for Stud Bolts

Related Terminology You Should Know

Applications of Stud Bolts

Conclusion

What is a Stud Bolt?

A stud bolt is a type of fastener consisting of a long rod with threads on both ends. It is typically used in conjunction with nuts to secure two or more components together. Unlike standard bolts that have a head on one end, a stud bolt is designed to be installed in a blind hole, which makes it particularly useful in high-strength applications.

Key Characteristics of Stud Bolts:

Threaded Ends: Both ends are fully threaded, allowing for easy fastening with nuts.

Versatile Use: Commonly used in industrial, mechanical, and construction applications.

High Strength: Designed to withstand significant loads and stress.

Alternate Names for Stud Bolts

Understanding the different types for stud bolts can help you navigate conversations with colleagues or when sourcing materials. Here are some common alternate names:

Double-Ended Bolt

This term emphasizes the fact that the bolt has threads on both ends. It's often used interchangeably with "stud bolt" in various industries.

Threaded Rod

A threaded rod is a general term that refers to a long rod with continuous threads along its length. While it can serve similar functions, it may not always be classified strictly as a stud bolt.

Stud

In some contexts, the term "stud" is used to describe a stud bolt, particularly when discussing its installation or structural applications.

Anchor Bolt

While not identical, anchor bolts are often discussed alongside stud bolts in construction. They are specifically designed to attach structures to concrete.

Tie Rod

In structural engineering, tie rods are used to hold structures together, similar to stud bolts, but they may not always be fully threaded.

Related Terminology You Should Know

In addition to the alternate names for stud bolts, there are other important terms related to their use and installation:

Nut

A nut is a hexagonal or square block with a hole in the center, designed to fit onto the threads of a stud bolt, securing it in place.

Washers

Washers are flat discs that are used alongside nuts to distribute the load and reduce friction, preventing damage to surfaces.

Torque

Torque refers to the rotational force applied to tighten a stud bolt. Proper torque is crucial for ensuring that the bolt is securely fastened without over-tightening.

Load Capacity

The load capacity of a stud bolt refers to the maximum weight or force it can withstand without failing. Knowing the load capacity is vital for safety and performance.

Applications of Stud Bolts

Stud bolts have a wide range of applications across various industries. Here are some common uses:

Construction

In construction, stud bolts are often used to secure beams, columns, and other structural components.

Manufacturing

In manufacturing settings, they play a critical role in assembling machinery and equipment.

Automotive

The automotive industry uses stud bolts for securing engine components and other critical parts.

Marine

In marine applications, stud bolts are used to secure various equipment and fixtures due to their high strength and corrosion resistance.

Oil and Gas

In the oil and gas sector, stud bolts are crucial for securing pipelines and tanks, often in high-pressure environments.

Conclusion

In conclusion, understanding the terminology surrounding stud bolts and their alternate names can help you navigate your projects more effectively. Whether you refer to them as double-ended bolts, threaded rods, or simply studs, knowing these terms enhances your communication with colleagues and suppliers.

0 notes

Text

What Are The Types Of Threaded Rods?

Threaded rods are an important component in numerous production and mechanical applications. Also called all-thread rods, stud bolts, or completely threaded bars, these versatile fasteners are designed for assembling one-of-a-kind systems, machines, and materials. They are broadly utilized in industries such as production, automotive, manufacturing, and greater. However, no longer all threaded rods are the identical, as they range in terms of materials, sizes, and threading styles. Understanding the different sorts let you pick out the right one on your venture.

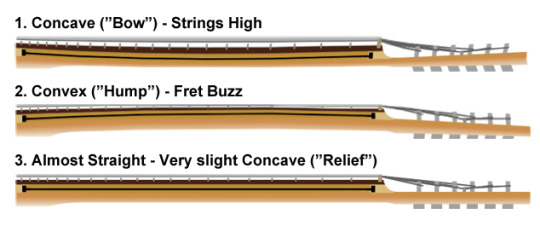

1. Fully Threaded Rods

Fully Threaded Rods are threaded along their whole duration. They are one of the maximum commonplace kinds, offering uniform strength and grip throughout the entire rod. Due to their design, they may be perfect for applications requiring anxiety and compression. Fully threaded rods are often used in production for securing structural additives, striking pipes, or developing strong connections in frameworks. They are available a number of substances, together with metal, stainless-steel, and brass, permitting them to perform properly in exclusive environments, from fashionable to corrosive settings.

2. Partially Threaded Rods

As the name indicates, partially Threaded Rods have threads handiest on a component in their duration, leaving the relaxation of the rod easy. This kind of rod is frequently preferred in programs in which motion or adjustment is needed, as the unthreaded phase can serve as a pivot or bearing floor. Partially threaded rods are usually used in machinery, automotive parts, and different situations where a mixture of energy and versatility is vital. While no longer as universally applicable as absolutely threaded rods, they are vital in situations where pressure distribution must be controlled efficiently.

3. Acme Threaded Rods

Acme Threaded Rods are prominent with the useful resource of their trapezoidal thread design, which affords better electricity and sturdiness as compared to standard threaded rods. The threads are wider and flatter, making them especially desirable for heavy loads and high-pressure applications. Acme threads are regularly utilized in lead screws, jacks, and industrial machines in which precision movement or lifting is wanted. Due to their robust nature, Acme threaded rods are frequently determined in environments that require wear resistance and lengthy-lasting overall performance.

4. Double-Ended Threaded Rods

Double-ended Threaded Rods have threads on each end, leaving the centre phase unthreaded. These rods are regularly used for connecting additives in which each forestall want to be constant securely. One not unusual software is in car repair, wherein double-ended rods are used as connecting rods or tie rods. They are also discovered in plumbing and electric applications wherein securing multiple quantities of machine is required. These rods offer flexibility in installation, bearing in mind short and easy assembly of numerous structures.

5. Metric Threaded Rods

Metric threaded rods are outstanding thru their use of the metric machine for measuring thread period and pitch. They are generally used in countries that comply with the metric machine, ensuring compatibility with different metric-based totally additives. Metric threaded rods are available in each truly and in part threaded variations, and they arrive in several substances, consisting of carbon metallic, stainless steel, and aluminium. These rods are often utilized in international obligations or industries with strict adherence to metric requirements, making them vital for worldwide manufacturers.

6. Fine Threaded Rods

Fine threaded rods have threads which are spaced carefully collectively, which provides greater preserving energy and better resistance to loosening due to vibration. These rods are particularly beneficial in excessive-precision applications, such as in aerospace, car, or engineering tasks, in which tolerances are tight and every element need to be securely fastened. Fine threads provide better tension manipulate, making them appropriate for sensitive or high-overall performance assemblies.

Conclusion

Threaded Rods come in an extensive type of types, each tailor-made to specific packages and environments. Whether you are operating on a massive-scale production venture or a precision engineering mission, selecting the proper type of threaded rod is essential for ensuring stability, strength, and sturdiness. By information the variations between completely threaded rods, partially threaded rods, Acme rods, and other versions, you can make informed selections so as to beautify the effectiveness of your mission.

0 notes

Text

Benefits of using Full-threaded Stud bolts | Roll Fast

Full-threaded stud bolts are non-headed bolts, these are in the form of a rod and have threads from end to end. A threaded rod, also known as a stud, is a relatively long rod that is threaded on both ends. The fully threaded studs have no head, are threaded along their entire length, and have a higher tensile strength. We offer full-threaded stud bolts in different grades like 8.8, 10.9, 12.9, B7, B8, L7, B16, and more for petrochemical industries. The most common application of these studs is in industries like manufacturing, plumbing, construction, petrochemical, and automobile manufacturing. Fully Threaded Studs are ideal for making custom assemblies using thread-locking adhesive and along with that, they can also be used for custom applications based on individual requirements. The fully threaded studs have no head, are threaded along their entire length, and have a higher tensile strength. The thread may extend along the complete length of the rod.

visit source URL : https://www.roll-fast.com/industries-served/petrochemical-industries/full-threaded-stud-bolts.html

0 notes

Text

Threaded Rods Manufacturers in India: Elevating Industrial Standards

Threaded rods are essential components in various industries, ensuring structural stability and support in diverse applications.

Types of Threaded Rods

Fully Threaded Studs

Fully threaded studs are versatile fasteners used in construction and engineering projects, offering reliable structural connections in different sizes and grades.

Double Ended Threaded Studs

Double-ended threaded studs find applications where precise fastening is crucial, providing secure bolt-like connections on both ends for manufacturing and machinery industries.

Zinc Plated Threaded Rods

Zinc plated threaded rods offer enhanced corrosion resistance, making them suitable for outdoor applications in construction and marine industries.

Body Studs

Body studs, also known as body bolts, are specialized threaded rods used in automotive and machinery assembly for secure component attachment.

About Threaded Rods Fasteners

Threaded Rods, commonly referred to as studs, are elongated rods with threads on both ends, designed for tension applications. They come in various types, including fully threaded studs, double-ended threaded studs, zinc plated threaded rods, and body studs, catering to diverse industrial needs.

Industrial Applications of Threaded Rods

Threaded rods serve critical roles across multiple industries:

Oil & Gas Industries

In oil and gas sectors, threaded rods secure crucial equipment and infrastructure, ensuring operational safety and reliability.

Nuclear Energy Sector

Threaded rods provide structural support in nuclear power plants, contributing to the safety and efficiency of energy production.

Petroleum Industries

Threaded rods are integral to pipeline construction, refinery equipment assembly, and offshore drilling platforms in petroleum industries.

Defence Industry

In defense applications, threaded rods are vital for manufacturing military vehicles, equipment, and infrastructure, ensuring robustness and durability.

Aerospace Industry

In aerospace applications, threaded rods support aircraft, spacecraft, and satellite systems, offering structural reliability in extreme conditions.

Quality Assurance and Global Reach

Sachiya Steel International upholds stringent quality standards, holding ISO certification to ensure that its threaded rods meet global quality benchmarks. With exports to over 85 countries, the company establishes itself as a leading threaded rods exporter from India.

Sustainable Practices and Innovation

Sachiya Steel International prioritizes sustainable manufacturing practices, minimizing environmental impact while investing in research and development for continuous innovation in threaded rod production.

Challenges Faced by the Industry

Despite the industry's growth, threaded rod manufacturers encounter challenges such as market competition and rapid technological advancements. However, companies like Sachiya Steel International address these challenges through expertise, advanced technologies, and product innovation.

Client Testimonials and Success Stories

Sachiya Steel International boasts a track record of satisfied clients and successful projects across various industries, demonstrating its commitment to delivering high-quality threaded rods that exceed customer expectations.

Future Outlook and Industry Trends

The future of threaded rods manufacturing in India looks promising, with projected market growth driven by industrialization, infrastructure development, and technological innovations. Advancements in materials and manufacturing processes will shape the industry's trajectory, offering new avenues for growth and expansion.

Conclusion

Threaded rods manufacturers like Sachiya Steel International play a pivotal role in India's industrial landscape, offering high-quality products that elevate industrial standards across diverse sectors. With a commitment to quality, sustainability, and innovation, these manufacturers contribute significantly to India's industrial growth and global presence.

For More Info Visit our Website: https://sachiyasteel.com/threaded-rods-manufacturers-in-india.php

Email Us: [email protected]

Contact Us: 097690 56007

0 notes

Text

What is a Stud Bolt? Types, Grades, and Standards

Delta Fitt Inc., your dependable Stud Bolts Manufacturers in India, Welcome to the realm of precise fasteners. We are well-known for our attention to quality and perfection, and we specialise in creating stud bolts, which serve as the foundation of solid connections in a range of sectors. Consider Delta Fitt Inc, where each bolt is a testament to great engineering.

What is a Stud Bolt?

Stud bolts are specialist fasteners used to provide secure and long-lasting connections in a variety of applications. These threaded rods include bolts at both ends and a unique design that includes an unthreaded centre part. Stud bolts are key structural components in the construction, oil & gas, petrochemical, and power generation industries, due to their high tensile strength and ease of installation.

Their threaded design enables for simple installation, making them useful in situations needing frequent disassembly. Stud bolts are dependable components in the fastener landscape, helping to maintain structural and mechanical stability.

Types of Stud Bolts

Fully Threaded Stud Bolts:

Ideal for applications requiring maximum thread engagement. Commonly used in scenarios where both ends need to be screwed into different components.

Double-End Stud Bolts:

Threaded on both ends, allowing for versatile applications.Used when components need to be tightened from both ends simultaneously.

Tap-End Stud Bolts:

Features threads on one end and a chamfered point on the other. Useful in situations where quick alignment and engagement are necessary.

Continuous Thread Stud Bolts:

Uninterrupted threading for the entire length.Suitable for heavy-duty applications where strength is paramount.

Top 3 ASTM Standard Stud Bolt Grades

ASTM A193 Grade B7 Stud Bolts:

B7 stud bolts, known for their high tensile strength and durability, are integral in critical applications. As reputable B7 Stud Bolts Manufacturers in India,We assure precision engineering and provide sturdy solutions for sectors where secure fastening is critical. Deltafitt Inc can supply B7 stud bolts that fulfill high quality requirements, assuring reliability in a variety of industrial environments.

ASTM A193 Grade B8 Stud Bolts:

B8 stud bolts, synonymous with corrosion resistance and exceptional performance, play a crucial role in demanding environments. As leading B8 Stud Bolts Manufacturers in India, Delta Fitt specializes in producing these bolts with precise engineering, providing dependable solutions for industries that require corrosion-resistant fastening. Count on us to supply high-quality B8 stud bolts that satisfy demanding quality requirements, assuring longevity and consistent performance in a wide range of industrial applications.

ASTM A193 Grade B8M Stud Bolts:

B8M stud bolts are known for their corrosion resistance, making them perfect for use in harsh situations. We excel in producing these bolts with precision engineering as a trusted B8M stud bolts manufacturer in India. Our B8M stud bolts are reliable solutions for industries that require corrosion protection, offering endurance and consistent performance across a wide range of industrial applications. Count on us for high-quality B8M stud bolts that exceed stringent quality requirements while delivering long-lasting fastening solutions.

Visit Delta Fitt for Choosing the Best Stud Bolts

Finally, Stud bolts are hidden fastener shining examples, securing structures and components across a wide range of industries. From construction to oil and gas, the kinds, selection criteria, and adherence to standards are critical for their successful usage. Understanding the subtleties of stud bolts enables industries to assure project safety, dependability, and lifespan.

Delta fitt, obtained the best stud bolts by top Stud Bolt Manufacturer in India, takes centre stage. Learn about their competitive advantages, manufacturing strategies, and market position. Examine the benefits, emphasise key aspects, and learn about industry challenges. Consider the future danger of stud bolt expansion. Choose best quality stud bolts like B7 & B8 Stud Bolts reliability for secure projects. Make the right choice for lasting reliability. Choosing these stud bolts from trusted B8 and B7 Stud Bolts suppliers in India creates a construction cooperation.

As a Stud Bolt Suppliers in India, Elevate your projects with the robust reliability of Stud Bolts. Secure success now!

#stud bolt manufacturers in india#B7 Stud Bolts Manufacturer in India#B8 Stud Bolts Manufacturers in India#stud bolt manufacturers

0 notes

Text

youtube

Video of the day: Unstable Aircraft Design?! The Incredible Story of China Eastern flight 583 (or, a cautionary tale on why you should fasten your seatbelt whenever you're sitting down on a plane)

Chances are that anything you're flying in today is more pitch stable than the MD-11, but it's definitely better safe than sorry.

Video thumbnail description: An MD-11 passenger airliner with China Eastern Airlines livery, obviously photoshopped with a 'wiggly' distortion effect. Text reads ROLLERCOASTER AT 33,000 FEET!

Sponsored segment timecodes: 6:35 - 8:00 (it's BetterHelp so skip it)

Under the read more:

Video 'spoilers'

Content warnings

Accessibility notes

Comment highlights

Content warnings: The plane doesn't crash, but many passengers are injured and several killed during a rollercoaster-style cycle of flying to recover from an issue. The video is simulated and doesn't show passengers or injuries.

Accessibility: Video is well-narrated with accurate captions. Some animated diagrams are used to illustrate plane design and engineering, but are described in narration. A few definitions of terminology are shown visually, but are also summarised verbally.

Highlights from the comments:

From user @.djmech3871: I remember this very well. I was a World Airways 31:51 mechanic on the MD-11 and after this incident we had to install a mechanical lock on the flap/slat handle. RIP to the two people who died.

From user @.randallhunt9170: It was this and other peculiarities that eventually relegated the MD-11 to cargo work only.

From user @.jackdbur: MD tried many "New" things to make sales many of their ideas were badly engineered and executed, much of this is due to how the company was organised, Management > bean counters > engineering. Thin push rods to lock baggage doors what could go wrong, those big bolts holding the engines on we can go a size down and save some money, & this one let's make this airliner unstable as to see what happens.

From user @.Wolfeson28

Exactly. My first thought when I heard that was: why on earth would you want the slats to always default to the retracted or the extended position? What you want in the event of the system failing is for the flaps and slats to stay in whichever position they're already in! This is so befuddling in that it's almost the same problem that contributed to the crash of American 191 in Chicago - the plane didn't have a mechanical system to lock the slats in place, so when the hydraulics on the left wing were compromised, those slats retracted under the air load and the wing ended up stalling. In the same vein, the unusually high speeds and reduced stability mentioned earlier directly contributed to the crashes of FedEx flights 14 (Newark) and 80 (Narita). The more I learn about the DC/MD-10/11 series of planes, the more I can't help feeling they're almost as bad as their reputations make them seem.

From user @.kenoliver8913:

And compounded by some poor ergonomic design. Keyboards and important levers/switches should be spaced far enough apart you can never hit one while operating the other. Think about if you were trying to punch numbers into that keyboard as you hit a little real turbulence …

From user @.grantcivyt

This thread is why there appears so little innovation in commercial aviation. Safety is important but so is experimentation.

From user @.sparkyy0007 All fail safe systems must be designed to fail to a predictable default position, either extended or retracted. In the case of a flap system failure, a flap remaining in some undefined position could cause complete loss of roll control by becoming an unintentional aileron. Flaps fully extended fail-safe position allows a reasonable landing speed and the ability to synchronize the working flaps to the fail-safe to maintain roll stability.

From user @.akchuck100: My wife was in management at the Hospital in Anchorage when this happened. It was called a 'CODE External" over the hospital wide speakers. That meant that there were a large number of casualties coming into the hospital from outside the hospital (as opposed to a code internal, casualties from an 'In Hospital' emergency'). The emergency plan was designed for emergencies like a plane crash at the airport in town. The expectation was that employees would rush to the hospital to give help within 20 minutes or so. However, even though Providence Alaska Medical Center was the closest Hospital and because of the distance from the incident over the Aleutian Islands, it was still another 6 hours before the first casualties were expected to arrive at the hospital. There were 150, non-English speaking Chinese nationals who needed medical help. Great praise should go to not only the hospital personnel who rushed into work and then waited for the emergency to arrive, but to the passengers and crew who dealt with the victims for A LONG F-ING TIME before they could get real medical help. Also, great appreciation should go to all the employees of every Chinese restaurant in town (especially 'Charlies Bakery') who supplied VOLUNTEER translators to the hospital at a moments notice.

#posts#video of the day#aviation#aviation accidents#video#plane crash cw#I'm hoping the accessibility notes make it easy to tell if it's worth your while clicking through#rather than finding out after you start the video

1 note

·

View note

Photo

Threaded Rod Bolt and Nuts

Click here to see more of this product

#Threaded Rod Bolt#Threaded Rod Nuts#threaded stud bolt#m7 threaded rod#threaded rod anchor bolts#astm a307 threaded rod#threaded rod screw#din 976 threaded rod standard#b7 all thread rod#bend threaded rod#m10 double end threaded stud#fully threaded rod end bolts#threaded anchor rods#fully threaded stud bolt#m12 thread rod#screw threaded rod

0 notes

Text

How do you select hydraulic cylinder seals?

Hydraulic cylinders do the work of harnessing fluid pressure and flow to generate linear motion and force. They are used in industrial machines like presses and plastic molding machines. Also, in mobile equipment like excavators and mining trucks!

Selection of Proper Hydraulic cylinder seals:

The main objective of designing hydraulic seals is to manage high-pressure dynamic applications, mostly hydraulic cylinders.

An Unsuitable hydraulic seal can cause cylinder oil leakage and easy deformation and failure of the seal.

The parts of the cylinder that need to be sealed are usually included rod, ram, gland, or Hydraulic cylinder piston seals, which may also require wipers or bearing strips. After knowing the place to seal, one will understand if it is a single acting or double acting seal method.

They are selected by the guidelines given below:

a. reciprocating speed

b. fluid pressure range

c. temperature ranged. fluid media

e. application

a) One should choose the right cylinder type:

There are two basic hydraulic cylinder designs. They are for industrial applications like tie-rod and welded cylinders. The Hydraulic seal manufacturers help in the selection of seals by issuing many guidelines.

The tie-rod cylinders are designed in such a way, where they can use the high-strength threaded steel tie rods. It is always on the outside of the cylinder housing. It gives additional strength and strong stable functioning. NEPA is the standard measurement tool. The tie-rod cylinders are manufactured as per the standards set and thus, manage the dimensions and pressure ratings accordingly.

Hydraulic cylinder piston seals are selected by many norms. There is heavy-duty housing with a barrel welded in mill-type cylinders or welded cylinders. They are bolted directly to the end caps.

b) Selection of proper mountings:

In a cylinder’s performance, it should be noted that mounting methods play a very decisive role. The Hydraulic piston seals suppliers globally advise users on cylinder mounting methods. In stationery cylinders, the fixed mounts on the centerline of the cylinder are advised. They are ideal for straight-line force transfer which causes less wear and tear. One has to take care as to mount the cylinder even if it is the cylinder body is stationed or pivots.

The tie-rod cylinders possess high-strength threaded steel tie rods on the outskirt of the cylinder housing. This gives more strength and stability. There are guidelines for all the cylinders. They are the bore diameter, stroke, rod diameter, pressure ratings, etc. The installations of cylinders are very easy. They can be mounted either sideways or foot – mounted. Thus, it is relatively easy to generate offset loads.

Piston-rod diameter is critical in Hydraulic cylinder piston seals. Piston-rod diameters can range from 0.5 to more than 20 inches. The sizing of the loads is very important. The Hydraulic seal manufacturers always take into consideration while designing a cylinder to generate a required force, sizing the rod is always the first consideration. Need to determine bore size for the available pressure!

c) Rod bending needs to be prevented:

There are instances of a fully extended rod, which will bend under its weight, mostly in cylinders with long strokes.

Excessive bending leads to wear and damage to Hydraulic cylinder piston seals. It could also cock the piston inside the bore, which can score and damage the inner surface of the cylinder. The Hydraulic seal manufacturers always take care during production to see that the rod deflection should never exceed 1 to 2 mm.

It could even cock the piston inside the bore, which damages the inner surface of the cylinder.

d) Sizing is very important:

Most of the companies use smaller cylinders for being cost-effective. They operate at higher pressures. Also, the smaller cylinders require less flow. Mainly the smaller pumps, lines, valves, etc. Many installations see an overall cost reduction by moving to higher pressures according to many Hydraulic piston seals suppliers.

To choose a cylinder with a weight of 20% more is required than the load. The Hydraulic cylinder piston seals will suffer efficiency losses, actual pressure below the rated system pressure, slip-stick on a cylinder, and bearings!

1 note

·

View note

Text

1.

Tempting Tincas

The tiny red tip of the float sat motionless in the gentle sway of the still water, anchored to the bottom with two BB shots. The float may not be the correct colour to grant the best visibility. There may be slightly too little or too much of it showing from your added shot, but you can see it, and that’s all that matters. All you want as you sit there, transfixed with anticipation, is for that pimple of colour to disappear, which it surely will. The yearning and the craving for a take and a squirming fight is like a drug. You could easily describe most fisherman as addicts, or dreamers in need of their next fix. It is an extremely strong addiction made up of potential new records be it British, world or personal, or just the knowledge that you are doing everything right and the hard work and preparation has paid off. The pride in catching a beautiful trout on a fly that you created yourself. Or just the peace a solitude of not having to worry about the daily grind, your only concern when on the bank is whether it’s going to rain or not. I confess I am an addict and there is no amount of cold turkey that can cure me, and to be honest, I don’t want to be cured.

The sun was beating down and my polarised glasses cut through the water to show a few dark shadows lurking below, sifting through my grounbait for more substantial offerings. Today’s location is Mythe, a private club water controlled by The Birmingham Anglers Association (BAA). At around 600 meters long and as wide as the River Severn which runs along its one side it is one of my favourite venues. The hot sun of the warmer months causes a large amount of weed to grow here which means only half of the pegs are fishable at certain times on the year. The riverside bank is a jungle, imagine an untrodden terrain with thick overgrown bushes, steep slopes, ditches and barbed wire making their upmost effort to bar your progress. If you do venture this way though, you will probably end up with a few leaves and twigs in your hair and down your collar and maybe a rip in your favourite fishing t- shirt however you will find some of the most beautiful swims from which you can temp a few bites. A fellow angler and good friend of mine Rich has spent countless hours secateurs in hand carving pathways to the waters edge. Rich is a font of knowledge when it comes to Mythe and he often regales me with tales of his trips 30 years earlier when all the pegs where fishable, he is an in-depth encyclopaedia of every peg on the pool and has a story to tell for practically all of them.

Clear spots can be found in amongst the thick weed and most the pegs have a patch of lilies or a deep hole in which to place your bait. Bream are in abundance here with weights of over 100lb regularly being caught on the method or open-ended feeder. Large bags of fish are also caught on the pole or waggler however, this being my chosen method for the day. Carp are a rarity as they are not targeted very often, but the few photographs I have seen of these old warriors show beautiful dark oak coloured mirrors with apple slice scales and striking bronze commons. Rich also tells me of an orange bellied common which has evaded capture for a long time, he has sent me many videos of fish close to 30lb taking floating dog biscuits from one of his many walks around the pool fish spotting. I have also heard rumours of an elusive Catfish hiding somewhere amongst the gloomy depths but who knows, this pool seems to be a bit of a mystery and I don’t think anyone knows for certain what zoo creatures it could hold. Catching one of these legends is on my bucket list, however today I am here targeting Tench, one of my favourite species.

I have selected a peg with a thick blanket of weed framing a deep weed less hole with lilies at my feet and to my left. The water is crystal clear gradually gaining a green hue the further out you look out towards the centre of the lake. After laying a few balls of gound-bait and a scattering of sweetcorn next to the lilies I lowered my lobworm and tightened my line pulling my float to where red meets black. I am fishing the lift method; my float is held in place by two rubber stops and is set at between 5 and 10 inches over depth with shot on the bottom. I pinch my shots onto a small piece of braid threaded onto my line using a rig ring. This is also held in place with rubber stops. Doing this means there is no weaknesses in your set up, some split shots have sharp edges and squeezed directly onto your line can cut into it and cause breakages under pressure. When the Tench takes my bait and lifts the shot off the lake bed the float will rise up and lay flat, however it is suggested to strike before it reaches that point.

Though still water specimen hunting is predominantly based around bolt rigs and buzzers there is a period generally from mid-May where this more traditional method for catching Tench is particularly effective. The warmer temperatures and longer days cause the Tincas to move in to the margins in search of damsel fly nymphs and other immerging insects and fishing at such close quarters the bolt rig loses its impact and a float fished correctly will produce a lot more fish.

I hadn’t arrived early for today’s session. A few beers the night before in the local pub had cause me to oversleep slightly but I didn’t mind as it was summer with plenty of daylight ahead of me. I had got to the lake at around 9am and had chosen my peg and set up for half past. My first bight came 10 minutes later. It was slow and tentative. The float lifted a centimetre and settled again, half a second later it did the same and started creeping slowly to the left. I strike into a small greedy Perch half the length of my lobworm. Returned, rebaited and repositioned I waited once more.

The sun had decided to hide for a while behind a thick white cloud. Thankfully not the thick black kind as I hadn’t even considered bringing my umbrella, not in mid-June. I always travel quite light when I am not targeting Carp. A decent sized bream was my next piece of the action, around the 4lb mark. A slow short fight then like a wet flannel it floated to the surface and was dragged motionless towards the bank. A few of these in the keepnet wouldn’t be a bad result for the day but sadly it was not the prize I was after. Unlike some anglers I appreciate caching bream. A large shoal of bin lids in your swim can make for a great day, especially in match fishing where large weights can be obtained quickly once you have got them feeding, which doesn’t seem to take long, these fish are eating machines and will make short work of a large bed of bait.

By mid-day the temperature cooled a little; it was still warm but not the blistering heat of the past couple of days. A scattering of clouds and a slight breeze made it very comfortable with intermittent blasts of sunshine and shade. I think if the weather had been the same as earlier in the week the fishing would have been very hard. This was proved a few days later when a session with my dad was cut short due to only two bites between us in 5 hours of fishing in relentless heat, we were rewarded with 2 small Roach and two rather sunburnt faces.

Instead the bites were steady and with five perch in the keepnet and a few more bream I decided to mix it up a little and try a cocktail. A lobworm tail with two grains of corn on a size twelve hook. I sat watching the float twitch, bob, dip and sway for a about twenty minutes, there were a lot of small fish in the swim and I think my large bait was being picked up and dropped every couple of seconds by optimistic roach with mouths too small to take bait fully.

Finally, it lifted, this happened so quickly it was almost flat before I had chance to strike. Strike into weightless, air, weightless, nothing. “Bugger it”. It seems that I drifted into a daydream for a while easy to do when sat in the sunshine. I rebaited my hook and recast to the same spot and tightened up, determined not to lose concentration this time. I didn’t have to wait very long for another take and this time I didn’t miss it, my rod bent double and my 4lb line groaned and creaked painfully and my clutch hissed like and angry cat as the fish pushed itself into the weed in front of me. I managed to bully it back into open water and after a taxing battle I finally saw the olive-green shape and red eye break the surface. A few small final breaks for freedom and she gave in and slid into the web of my landing net. What a flawless specimen. A plump almond shaped body, black fins and a wide paintbrush like tale. Tipping the scales to 4lb 8oz I was pleased with my first Mythe Tench and what a beauty.

The next half an hour or so produced a few more Perch and Bream followed by another characteristic Tinca bite, my float raised out if the water and I lifted into another powerful creature. A lot of head shaking and dives to the weed almost confirmed to me this was another Tench. After a couple of minutes, the shaking stopped and I was left with a solid weight and no movement. The fish had hidden itself deep within the weed bed opposite. Doubtful, I lowered my rod pleading that it will release itself on its own with the line being slack. To my surprise and relief, I saw the line start to move. I tightened up to feel the relentless pulling once more. It seems the fishing gods are on my side today. The fish broke the surface and displayed itself for the first time. It was certainly a Tench but this one was unlike any I have caught previously. It had the typical bright red eyes and dark paddle like fins but its body was as black as coal. Securely in the net I admired its beauty and prepared the fish for its Photo shoot. What a beauty, and a lucky capture I think, that fish could have easily been lost. Returned safely it was time to pack up. I emptied my keepnet of 7 Bream and laid it out on the bank to dry, content with a successful day.

#fishing#carpfishing#fisherman#outdoors#nature#lovelife#passion#catchandrelease#uk fishing#line breakers carp#shimano

1 note

·

View note

Text

The Sketch

Chapter 3, segment 3

Previous - Next

full chapter on ao3 here

In the hallway, Johan struggled to fight against the two men pulling him back. He tried to hit them off, tried to run, he tried to scream, but a gag was stuffed into his mouth, and the butt of a revolver smacked against the back of his head,

once, dazing him,

twice, stunning him,

thrice, and it all went black.

Joey fought against the haze in his mind, hearing voices, voices he could not process.

However, we are not Johan, and therefore, these voices can be understood.

“Good thing the hospital isn't too far,” Fleishcher huffed, dragging Joey backwards. The lanky man groaned in his confusion. Disney nodded with a scowl; “It’s also a good thing we planned this, just in case.”

Fleishcher flagged a cab, even as the commotion within the courthouse grew exponentially.

“Please, he’s hurt, get us to the hospital straight away,” Disney spoke in a masked voice, pulling Joey and Fleishcher into the car with him. Henry ran out of the courthouse, his lab coat flapping behind him, and he cursed as they zoomed away. Disney smirked, and muttered to Fleishcher. “No problems from here on out - once he can’t do what they expect him to, this one will be at a loss, for good. We’re in the clear. By the way, after this, I don’t expect to work with you again.”

“Agreed,” Fleishcher nodded. Joey tried to raise his head, unable to see anything but the blackness in his darkened eyes. “Our sleeping beauty is trying to wake, aw.”

“He doesn’t look anything like I expected,” Disney opined, putting a hand onto Joey’s face to turn and inspect it better. “I’m surprised that one of… his type was able to get up so high. No wonder he wore a mask. And what is he, Mexican?”

“I’m pretty sure that was stated in court,” Fleishcher interjected. Disney hummed, and neither spoke, until Fleishcher recontinued in a low tone. “Do you think that Stein fellow is after us?”

“Undoubtedly,” Disney leaned back with a grin. “But it’s not like he’s gonna catch us or figure out where we’re going.”

Henry scanned the area, cursing, wishing the police would do a better job of looking for the cab, and remembered the jacket that Bertrum had been torn off of Disney. There must be a clue in it! There has to be! There absolutely has to be… there must be!

He ran as fast as he could, feeling the cold breath of a demon on his neck, dodging other dashing wandering souls, ducking and jumping around them, and snatched the forgotten coat from off the ground. He searched the pockets hastily, and found, crumpled in the breast pocket, a small brochure. It was from the very hospital he worked at, and his eyes narrowed as he glanced over it. His eyes widened, and the paper drifted to the ground, the man already running as fast as he could to get a cab or

“Bertrum!” Henry gasped, bumping into the panicking greek. “I know where he is, I need to get to the hospital!”

“The hospital?” Bertrum’s eyebrows shot up, Lacie stepping back in surprise as well, and she asked, “Why would they take him there?!”

“Walter Jackson Freeman,” Henry wheezed in explanation. The name had no meaning to Lacie, but to Bertrum, he understood immediately. He grabbed Henry by his arm and ran him to his car, and he called to the befuddled mechanic, “I’ll see you at home, Lacie!”

Bertrum speed through the streets, and even so, Henry had a sneaking suspicion that they got to the hospital sooner than they should have, not that he was ungrateful for it. Time was of the utmost importance, and the clock seemed to tick faster and faster. Both of them ran out of the car, and dashed into the hospital.

“Where is he?” Bertrum panted as Henry dashed before him. “Slow down, for Zeus’ sake! Actually, don’t slow down! Speed up, I’ll catch up to you! Go!”

And so Henry did, running as fast as he could, praying he would not be too

“We’re late,” Disney hissed to Fleishcher. Joey was in a wheelchair, fisherman’s thread digging into his wrists to restrain him, his head sunk against his chest, pounding with the blows he had received. A small groan of exhaustion escaped him. “But no matter. Mr. Drew here has a specially made appointment.”

“What does this thing do again? A leucotomy?” Fleishcher asked, briskly walking alongside his fiendish partner. “What good will that do for us, exactly?”

“If the head doesn’t function fully, the body will collapse,” Disney explained. “And that applies to a business as well. Without Drew able to function, well, the whole studio will fall apart. And then free sailing from here on out.”

“L-Leucotomy…?” Johan mumbled, blinking in the bright hospital light. “A… a l-lobotomy?”

“Someone’s finally putting the pieces together, hm?” Disney chuckled, grinning at the still dazed chicano. Joey squinted in the harsh lighting. “Oh, don’t worry about it. When it’s over, you won’t be able to have an opinion on it, anyways.”

“What!?” Johan shrieked, the situation becoming clear to him. “No! No! Help! Help! Hel-MMPH!”

Joey hyperventilated against Fleishcher’s hand pressing to his mouth. He tried to scream around it, but found the gag shoved into his mouth and tied in place, again. Tears started to trickle from his eyes.

“Shh, shh, it’ll all be over soon…” they entered a presentation hall. The glint of the two ice pick rods burned into Joey’s eyes, as did all the electrical equipment. Despair flooded his system, drowning every hope away. “It’ll all be over soon….”

Henry’s polished shoes left skid marks as he ran down, down, down, jumping over the stair rail to skip some steps and shave some seconds, just a few. He ran as fast as he could, faster than when he ran from the ink, feeling the cold air of the demon on the nape of his neck, and yet, he never ran so fast, never ran so fast in his life, in any of his lives, desperate to save the one person that understood him, that knew him inside and out, whose smile he never wanted to lose, who would go through

“A lobotomy is a very delicate procedure,” Mr. Freeman spoke in a showman’s voice to the amassed crowd. “It calms the mind. It relaxes the body. It frees those that go through it into a sense of tranquility, assuring them that all is right in the world - and so it is.”

Johan’s head was held back, yet there was no need: he was paralyzed by the sight of the “ice picks” that would be used to bore into a skull, his skull. The way the so called doctor waved them around without any care as to the result, flashing in the far too bright light. He was chained once more, tightly bound to the board. Johan scanned the crowd with his eyes, praying to see someone that might help him, but found that they were all mesmerized by Freeman’s performance. Joey felt his hair being brushed back, and it felt soothing, and he tried to relax into it. The gag would come out, it had to, it must, and he would be able to cry for help. But what if it was deflected as insanity? What if no one cared? Tears trickled from the corners of his eyes.

“We shall now anesthetize the patient with electrotherapy,” Freeman continued, peering over Joey. “As you can see, this young man has been brought on account of his sexual preference - the lobotomy procedure is very powerful, and many have used it to correct this.”

Johan wanted to slap him. How dare he? He was slim, he was tall, he was gay, and he was proud of it!

“Please, shock the patient,” the psychologist instructed his assistant, who nodded, and pressed the two electrodes to the sides of Joey’s head, and god! The pain! It laced through his body, and he screamed against the gag stuffed in his mouth. His head, had it not been held back ever so gently, would have thrashed from side to side to avoid the pain. His whole body convulsed. His hair was brushed back again, and it tingled and stung like hundreds of swarming mosquitoes. “And now, my assistant will cut the patient’s hair until-”

“Stop!”

The doors slammed into the walls, breaking indents into them, bits of ceiling falling. Henry’s shoes clacked against the floors as he ran towards the stage.

“There’s been a confounding mistake!” he shouted, and Freeman made his assistant put down the razor he held. He jumped down the stage to greet Henry. “Well, I’ll say! Whatever is the matter, doctor?”

“That man is not a patient, he’s Joey Drew!” Henry panted, hands on his knees, looking up at the other doctor. His eyes widened. “He’s been kidnapped from the courthouse by….”

Henry whipped around and pointed at the two men attempting to escape from the theater room.

“Disney and Fleishcher!”

The two businessmen looked at each other and then attempted to bolt, but immediately bumped into Bertrum, who grabbed them both by their ears.

Henry ran to Joey as the police came in to sort everything out, Freeman at his heels. Henry held Johan’s unconscious head in his hands, tears burning in his eyes.

“Did you…?” he asked Freeman when the man caught up. Freeman put a hand on Henry’s shoulder and shook his head. “W-why is he….?”

“Seems like the shock was too much for him,” Freeman scratched his head. “That’s odd, normally those that go through a transorbital lobotomy are able to respond even as the treatment is occuring.”

“Good thing we’re already in a hospital,” Henry muttered, taking the abandoned razor and cutting at the wire tying Joey down to the wheelchair. He and Freeman exchanged a few words, and he ended up chatting with the man as he wheeled Joey to a room he knew was always available, writing in his vitals and reason for being in the hospital (Shock, both emotional and physical). Henry and Freeman shared a cup of tea as they spoke together. Then, Freeman shook his watch out of his sleeve, bid Henry a goodbye, and left. Henry’s hands ran through Joey’s hair, and he was so grateful that it was still there for him to do so. Joey’s eyes fluttered open at the warm touch. Henry’s smile felt like it would tear his cheeks, and small tears filmed over his eyes. “Hello, honeybee.”

“Hen… ry?” Joey croaked, his throat raw. He managed to see Henry clearly after blinking a few times, and then smiled back at him. “H-hello, doctor.”

“How are you feeling?” Henry asked, squeezing his hand. “Need anything?”

“I feel… fine…” Johan admitted, though he seemed worried. “I need to know if th-they… you know… went through with i-it?”

“No, I got there just in time,” Henry told him. “You know, I heard that he was going to lobotomize you under the word that you’re gay.”

“Oh, I am!” Joey proudly stated, grinning. “Very much so!”

“Well, I am as well,” Henry chuckled, eyes crinkling. “Perhaps more than you!”

“Excuse me my good sir!” he cried out. “You were the one married to a young Eleanor, and then to a Diane, weren’t you?”

“That may be so,” Henry hummed, tapping his chin, “But now….”

His hand came to rest on Johan’s. His blue eyes looked right into red ones, glistening and gleaming with love and genteelity.

“But now what?” the dark man smiled dazzlingly, stealing Henry’s breath away with his sheer beauty. A princeling, that is what Joey was. One of the forgotten fair folk. His eyelashes batted in a playful manner. “Doesn’t change the fact you are certainly less gay than I!”

“Doesn’t it, now?” Henry grinned, climbing onto the white hospital bed, nuzzling against the side of Johan’s chin, making the lanky man laugh and wriggle under his weight. Henry pressed little kisses to the other’s collarbone, making him burst out into a fit of giggles. Henry hugged him tightly, slipping under the blanket to garner the warmth from his beloved. He smiled at Joey, who smiled back sadly, hand coming to rest on Henry’s cheek, wiping away Henry’s stray tears as he said to him in his sonorous and musical voice, “Don’t cry, mi amor! It’s all ok, it’s fine.”

“I know,” Henry smiled, pulling Joey all the closer to himself, their opposite bodies like puzzle pieces, clicking together perfectly, “and that’s why I’m crying.”

#control art#control writes#the sketch#lobotomy#joey drew#johan ramirez#the big picture#henry stein#henry x joey#bertrum piedmont#disney#fleisher#walter jackson freeman#historical figures#lacie benton#perspective play#action#tw homophobia#but its ok#queue pasa?#creatorship

9 notes

·

View notes

Text

ASTM A193 Grade B8LN Bolts, Nuts, and Fasteners - Manufacturer, Supplier & Exporter

Introduction to ASTM A193 Grade B8LN Fasteners

ASTM A193 Grade B8LN fasteners are high-performance stainless steel fasteners designed for high-temperature and high-pressure applications. These fasteners are manufactured from austenitic stainless steel, specifically Type 304 with nitrogen addition, providing enhanced mechanical properties, corrosion resistance, and excellent performance in demanding environments.

B8LN fasteners undergo a carbide solution treatment, which enhances their strength and durability. The addition of nitrogen improves their resistance to pitting and crevice corrosion, making them ideal for applications in the chemical, marine, and food processing industries.

Characteristics of B8LN Fasteners

Material: Austenitic Stainless Steel (Type 304 with nitrogen addition)

Heat Treatment: Carbide solution treated

Corrosion Resistance: Excellent resistance to oxidation, pitting, and crevice corrosion

Strength: Higher tensile and yield strength due to nitrogen content

Magnetic Properties: Non-magnetic in the annealed condition

Weldability: Good weldability with standard welding techniques

Chemical Composition of ASTM A193 B8LN Fasteners

The chemical composition of Grade B8LN fasteners ensures their superior corrosion resistance and strength:

Mechanical Properties of B8LN Fasteners

The mechanical properties of ASTM A193 Grade B8LN fasteners are crucial for their high-performance applications:

Types of ASTM A193 B8LN Fasteners

B8LN fasteners are available in various forms, including:

Bolts: Hex bolts, flange bolts, U-bolts, carriage bolts, eye bolts, and anchor bolts

Nuts: Hex nuts, lock nuts, flange nuts, coupling nuts, and wing nuts

Washers: Flat washers, spring washers, and lock washers

Stud Bolts: Fully threaded and double-ended stud bolts

Threaded Rods: Available in various lengths and diameters

Applications of B8LN Fasteners

Due to their superior corrosion resistance and mechanical properties, ASTM A193 B8LN fasteners are widely used in:

Petrochemical and Chemical Processing: For equipment and piping exposed to corrosive chemicals

Marine Industry: Due to their excellent resistance to saltwater corrosion

Food Processing Equipment: Where hygiene and resistance to corrosive cleaning agents are essential

Pharmaceutical Industry: In environments requiring high purity and corrosion resistance

Power Generation: In nuclear and conventional power plants where high-strength and corrosion resistance are needed

Advantages of Using B8LN Fasteners

High Corrosion Resistance: Suitable for harsh and corrosive environments

Enhanced Strength: Due to nitrogen addition and carbide solution treatment

Durability: Long-lasting performance with minimal maintenance

Versatility: Available in various types and sizes for different industrial applications

Good Weldability: Can be easily welded using standard techniques

B8LN Fasteners Manufacturer & Supplier

Ananka Fasteners is a leading manufacturer, supplier, and exporter of ASTM A193 Grade B8LN fasteners. We provide high-quality fasteners that meet international standards and specifications. Our B8LN fasteners are manufactured with precision and undergo rigorous quality testing to ensure superior performance.

Why Choose Ananka Fasteners?

High-Quality Materials: Manufactured using premium-grade stainless steel

Certified Products: All fasteners comply with ASTM and international standards

Customization: Available in different sizes, coatings, and specifications as per client requirements

Global Supply: We export B8LN fasteners to various countries worldwide

Competitive Pricing: Affordable pricing with bulk order discounts

Conclusion

ASTM A193 Grade B8LN fasteners are high-performance stainless steel fasteners known for their superior strength, corrosion resistance, and durability. They are widely used in industries requiring high-quality, reliable fasteners for critical applications. As a trusted manufacturer and supplier, Ananka Fasteners ensures top-notch quality and adherence to global standards.

Frequently Asked Questions (FAQs)

Q1: What makes B8LN fasteners different from other stainless steel fasteners?A1: B8LN fasteners are made from Type 304 stainless steel with nitrogen addition, providing enhanced strength and corrosion resistance compared to standard B8 fasteners.

Q2: Are B8LN fasteners suitable for high-temperature applications?A2: Yes, B8LN fasteners are designed for high-temperature and high-pressure applications, making them ideal for industries like petrochemical and power generation.

Q3: Can B8LN fasteners be welded?A3: Yes, B8LN fasteners have good weldability and can be welded using standard stainless steel welding techniques.

Q4: Where can I buy high-quality B8LN fasteners?A4: You can purchase high-quality ASTM A193 B8LN fasteners from Ananka Fasteners, a trusted manufacturer, supplier, and exporter.

For more details, reach out to Ananka Fasteners and get the best fastener solutions for your requirements!

#ananka#anankafasteners#gradeb8ln#gardeb8#article#blog#gardematerial#material#manufacturer#fasteners#usa#mumbai#supplier#tumblr#blog tumblr#hex#bolts

0 notes

Text

Threaded Rods & Bars, Hex Bolts, Hex Nuts Fasteners manufactures exporters India threadedrodsmanufacturers.com +91-9876270000

Kapson India are manufactures & exporters of various types of products like- Threaded Rods / Bars, All Threaded Rods & Bar, Fully Threaded Rods & Bars, Zinc Plated Fully Threaded Rods, Low Carbon Threaded Rods, Carbon Steel Threaded Rods, Mild Steel Threaded Rods, Hotdip Galvanized Threaded Bars, Electro Galvanized Threaded Bar, HDG Threaded Bar, EN8 Threaded Bar, DIN 975 Threaded Rods, DIN 976 Threaded Rods, Grade 4.8, 6.8, 8.8 Threaded Rods, Thread Rods 6mm,8mm,10mm,12mm, Unified Threaded Rods, UNC Threaded Rods, UNF Threaded Rods, Metric Threaded Rods, Acme Threaded Rods, Trapezoidal Threaded Rods, Threaded Rods, Threaded Bars, Industrial Threaded Rods & Bar, Construction Threaded Rods, Continuous Threaded Rods, Double End Threaded Rods, Thread Rods & Thread Bars, Threaded Rods for HVAC System, Threaded Rods for Plumbing, Threaded Rods for Cable Tray Support, Threaded Rods for Ducting / Ducts, Threaded Rods - Strut Support System, SAG Rods, Coil Rods and Tie Rods, Threaded Studs, Hex Nuts, Hex Bolts, Hexagonal Nuts, Hexagonal Bolts, High Tensile Fasteners, Precision Fasteners, Plain Washers, Spring Washers, Spring Channel Nut, Strut Channel, Channel Accessories, Channel Brackets, Channel Fitting Accessories, Variety of Pipe Clamps , Hanger Clamps , Cantilever Arms, Base Plates etc. We exports our products to various countries like- Australia, Canada, USA , United Kingdom, Africa, UAE, Bangladesh, Sri Lanka and Nepal etc. from India, Punjab, Ludhiana. http://www.threadedrodsmanufacturers.com - Mobile No- 9876270000

We are also reputed manufacturers of High Tensile Fasteners Products in India like Hex Nuts, Hex Bolts, Steel Plain Washers, U-Bolts, Anchor Foundation Bolts, Long Nut, Connector Nut / Coupling Nut etc. Kapson India is also serving construction industry with the supply of Scaffoldings & Couplers products which includes pressed couplers, drop forged couplers & scaffolding and formwork accessories etc. Since our inception, we have gained our reputation by manufacturing of high quality fasteners products with highly competitive offered prices and timely delivery to National and International Market.

THREADED RODS / THREADED BARS / STUDS / COIL RODS / TIE RODS / SAG RODS Threaded Rods & Thread Bars manufacturers exporters in India http://www.threadedrodsmanufacturers.com +91-9876270000 Coil Rods & Tie Rods manufacturers exporters in India http://www.threadedrodsmanufacturers.com +91-9876270000 Threaded Studs manufacturers exporters in India http://www.threadedrodsmanufacturers.com +91-9876270000 Sag Rods Sag Bars manufacturers exporters in India http://www.threadedrodsmanufacturers.com +91-9876270000 Fully Threaded Rods & Bars manufacturers exporters in India http://www.threadedrodsmanufacturers.com +91-9876270000 All Threaded Rods & Bar manufacturers exporters in India http://www.threadedrodsmanufacturers.com +91-9876270000 Sag Rods Sag Bars manufacturers exporters in India http://www.threadedrodsmanufacturers.com +91-9876270000 Zinc Plated Fully Threaded Rods manufacturers exporters in India http://www.threadedrodsmanufacturers.com +91-9876270000 MS Threaded Rods & Bars manufacturers exporters in India http://www.threadedrodsmanufacturers.com +91-9876270000 Low Carbon Threaded Rods manufacturers exporters in India http://www.threadedrodsmanufacturers.com +91-9876270000 Carbon Steel Threaded Rods manufacturers exporters in India http://www.threadedrodsmanufacturers.com +91-9876270000 Mild Steel Threaded Rods manufacturers exporters in India http://www.threadedrodsmanufacturers.com +91-9876270000 Hotdip Galvanized Threaded Bars manufacturers exporters in India http://www.threadedrodsmanufacturers.com +91-9876270000 Electro Galvanized Threaded Bar manufacturers exporters in India http://www.threadedrodsmanufacturers.com +91-9876270000 EN8 Threaded Bar manufacturers exporters in India http://www.threadedrodsmanufacturers.com +91-9876270000 DIN 975 Threaded Rods manufacturers exporters in India http://www.threadedrodsmanufacturers.com +91-9876270000 DIN 976 Threaded Rods manufacturers exporters in India http://www.threadedrodsmanufacturers.com +91-9876270000 Grade 4.8, 6.8, 8.8 Threaded Rods manufacturers exporters in India http://www.threadedrodsmanufacturers.com +91-9876270000 Unified Threaded Rods manufacturers exporters in India http://www.threadedrodsmanufacturers.com +91-9876270000 UNC Threaded Rods manufacturers exporters in India http://www.threadedrodsmanufacturers.com +91-9876270000 UNF Threaded Rods manufacturers exporters in India http://www.threadedrodsmanufacturers.com +91-9876270000 Metric Threaded Rods manufacturers exporters in India http://www.threadedrodsmanufacturers.com +91-9876270000 Acme Threaded Rods manufacturers exporters in India http://www.threadedrodsmanufacturers.com +91-9876270000 Construction Threaded Rods manufacturers exporters in India http://www.threadedrodsmanufacturers.com +91-9876270000 Threaded Rods for HVAC System manufacturers exporters in India http://www.threadedrodsmanufacturers.com +91-9876270000 Threaded Rods for Plumbing manufacturers exporters in India http://www.threadedrodsmanufacturers.com +91-9876270000 Threaded Rods for Cable Tray Support manufacturers exporters in India http://www.threadedrodsmanufacturers.com +91-9876270000 Threaded Rods for Ducting / Ducts manufacturers exporters in India http://www.threadedrodsmanufacturers.com +91-9876270000 Threaded Rods - Strut Support System manufacturers exporters in India http://www.threadedrodsmanufacturers.com +91-9876270000

HIGH TENSILE PRECISION FASTENERS High Tensile Fasteners manufacturers exporters in India http://www.threadedrodsmanufacturers.com +91-9876270000 Hex Bolt Fasteners manufacturers exporters in India http://www.threadedrodsmanufacturers.com +91-9876270000 Hex Nuts Fasteners manufacturers exporters in India http://www.threadedrodsmanufacturers.com +91-9876270000 Hexagonal Bolt Fasteners manufacturers exporters in India http://www.threadedrodsmanufacturers.com +91-9876270000 Hexagonal Nuts Fasteners manufacturers exporters in India http://www.threadedrodsmanufacturers.com +91-9876270000 Plain Washers & Flat Washers manufacturers exporters in India http://www.threadedrodsmanufacturers.com +91-9876270000 Spring Washers manufacturers exporters in India http://www.threadedrodsmanufacturers.com +91-9876270000

SCAFFOLDINGS / COUPLERS & FORMWORK ACCESSORIES Scaffoldings Couplers manufacturers exporters in India http://www.threadedrodsmanufacturers.com +91-9876270000 Formwork Accessories manufacturers exporters in India http://www.threadedrodsmanufacturers.com +91-9876270000

STRUT SUPPORT SYSTEMS & CHANNEL FITTINGS Strut Support Systems manufacturers exporters in India http://www.threadedrodsmanufacturers.com +91-9876270000 Strut Channels manufacturers exporters in India http://www.threadedrodsmanufacturers.com +91-9876270000 Spring Channel Nuts manufacturers exporters in India http://www.threadedrodsmanufacturers.com +91-9876270000 Channels Brackets / Bracketry manufacturers exporters in India http://www.threadedrodsmanufacturers.com +91-9876270000 Channel Accessories & Fittings manufacturers exporters in India http://www.threadedrodsmanufacturers.com +91-9876270000 Pipe Clamps manufacturers exporters in India http://www.threadedrodsmanufacturers.com +91-9876270000 Beam Clamps manufacturers exporters in India http://www.threadedrodsmanufacturers.com +91-9876270000 Hanger clamps manufacturers exporters in India http://www.threadedrodsmanufacturers.com +91-9876270000 Base Plataes manufacturers exporters in India http://www.threadedrodsmanufacturers.com +91-9876270000 Cantilever Arms manufacturers exporters in India http://www.threadedrodsmanufacturers.com +91-9876270000

WhatsApp Numbers +91-9876270000

Calling Numbers +91-9876270000 +91-7696288000 +91-7696388000 +91-8427000124

Contact Person: Mr. Sanjay Kapoor

Email [email protected]

Website http://www.threadedrodsmanufacturers.com

Works & Office KAPSON INDIA Plot no. 1250/D-27, Jaspal Bangar Road, Industrial Area-C, Ludhiana -141122 Punjab (INDIA)

https://youtu.be/aLdz_mHkqgs https://youtu.be/vdcvOjEKn_Y https://youtu.be/9sMAbDfaog8 https://youtu.be/5A9rf7HbZh8 https://youtu.be/BqAeWFjwJEU https://youtu.be/94m2n_Pup9w https://youtu.be/0nZYWFzASyM https://youtu.be/o5WgKT4c6YI

National Market: Our Products range includes Threaded Rods, Threaded Bars, Sag Rods, Coil Rods, Tie Rods, Hex Nuts, Hex Bolts Fasteners, Strut Support Systems, Steel Scaffoldings manufacturers in India Andaman and Nicobar Islands, Andhra Pradesh, Arunachal Pradesh, Assam, Bihar, Chandigarh, Chhattisgarh, Dadra and Nagar Haveli, Daman and Diu, National Capital Territory of Delhi, Goa, Gujarat, Haryana, Himachal Pradesh, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Lakshadweep, Madhya Pradesh, Maharashtra, Manipur, Meghalaya, Mizoram, Nagaland, Odisha, Puducherry, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, Uttarakhand, West Bengal.

International Market: We are exporters of Threaded Rods, Threaded Bars, Sag Rods, Coil Rods, Tie Rods, Hex Nuts, Hex Bolts Fasteners, Strut Support Systems, Steel Scaffoldings from India to following International countries like