#m12 thread rod

Explore tagged Tumblr posts

Video

youtube

The simplest way to connect wooden boards is to use a #threaded rod #fastener

click here to see more threaded rod product

#youtube#threaded rods#welding rod#all thread rod#stainless steel threaded rod#threaded bar#threaded stud#m8 threaded rod#m12 threaded rod#m16 threaded rod#galvanized threaded rod#m20 threaded rod#fixdex threaded rod#goodfix threaded rod#threaded steel rod#m6 threaded bar

0 notes

Text

SS Threaded Rod Manufacturer in India

Stainless Steel Threaded Studs & Rod are used in different applications that demand high strength, corrosion resistance and long life. Manifest Alloys is a leading manufacturer and supplier of the different types such as the M12 Stainless Steel Threaded Rod with different materials. These are made in 316 stainless steel, 316H and 316L and 316Ti material.

There are different specifications such as IS, BS, ASTM with A193 standards. There are different brands and known types such as the SS Threaded Rod Manufacturer in India in various sizes 3mm to 200mm and the lengths ranging from M02 to M33. The tensile strength of the material ranges from 485MPa to 515MP. There are special types such as the Double End Threaded Rods & Studs which have threads on both ends that can connect with nuts on both sides.

The yield strength, elongation, hardness and other mechanical properties and chemical properties vary according to the material grades. The Double Ended Threaded Rods and Studs can be seen in engine parts, external components, machineries, instruments and other applications. Please feel free to contact us for various types and finishes of the threaded rods as we are a leading Zinc Plated Threaded Rods and Studs manufacturer in India. You can also get a complete price list and full catalog upon request.

Manifest Alloys is the prominent manufacturer of the SS Threaded Rod Manufacturer in India. We are the vital supplier of Stainless Steel Polished Threaded Rods worldwide. Double Ended Threaded Rod, 316 SS threaded Rods, SS 304 Series Threaded rods, A2 Stainless Steel Threaded Rod are one of the best we supply globally.

Being a variation of fasten bar, the threaded rod is identified by the threading shape or curves created on both the ending part or sides of the rod. SS Threaded Rod Manufacturer in India are long SS threaded rods are enlarged along with threading by full length easily or as per the client’s requirement.

Our Global Identity is also named by Stainless Steel Threaded rods Manufacturer as we provided the best quality A2 Threaded Rods. Extreme Temperature is surpassed by SS 316 threaded rod.

#ssthreadedrodmanufacturerinindia#ssthreadedrod#manufacturerinindia#manifestalloys#ss#threaded#rod#manufacturer#in#india

0 notes

Text

Krishna Industrial Fasteners

Krishnaindustrialfasteners.com

Are you searching best - Threaded Rods, Electric power Nyloc Nuts, Industrial U-Bolts & Civil Construction Services in India

We are solved your problem by one click - Krishnaindustrialfasteners.com

We are offering best - Civil Construction Services in India that meet your needs

We offer a different scope of modern latch answers for changed businesses of energy, foundation, power and that's only the tip of the iceberg.

I will give you more information about it which is given below

Krishna Industrial Fasteners - Krishna Industrial Fasteners is an extension of Kishan Enterprises, which has evolved from a family business spreading across the three generations leading.

Construction ASTM Bolts - Get Construction ASTM Bolts at Krishna Industrial Fasteners, we provide Best Threaded Rods, Electric power Nyloc Nuts, Industrial U-Bolts & Civil Construction Services in India

Best ASTM Bolts India - Buy high-quality Allen Bolts in India, Krishna Industrial Fasteners provides the best ASTM Bolts and Civil Construction Services in India.

See also this

Best ASTM Bolts India - ASTM Bolts are generally utilized in development. Promptly accessible in distance across sizes of M12 to M30 with length upto 250mm.

Best Hex Nuts in India - Nyloc Nuts are used in vehicle and electric power areas. Accessible in sizes from M5 to M30

Electric power Nyloc Nuts India

Best Threaded Rods in India

Top Industrial U-Bolts in India

Civil Construction Services in India

Buy Allen Bolts India

Industrial fastener solutions in India

I think this information will be useful for you

Contact

+91 98119 01501 / 9643762176

Get More Information Click Here - https://www.krishnaindustrialfasteners.com/

0 notes

Text

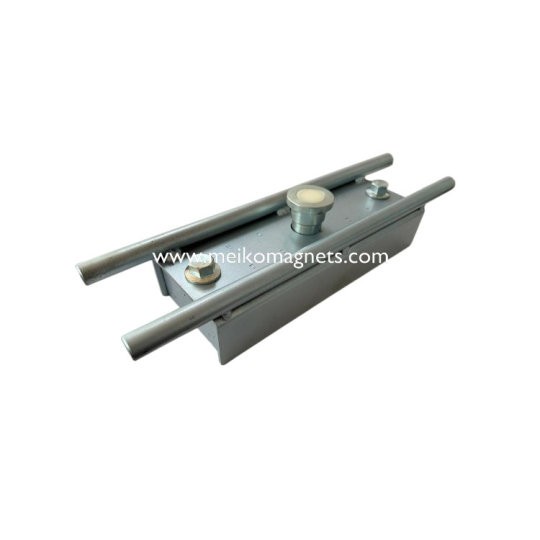

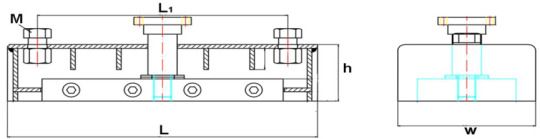

Precast Concrete Push Pull Button Magnets with Sided Rods, Galvanized

Precast Concrete Push/Pull Button Magnet is the standard magnetic fixing solution for holding precast framework on the steel table. It's widely used for steel, wooden/plywood frames with or without extra adaptors. This type button magnets with two sided rods could be put into the steel frame directly, no extra adaptors required. It's produced with steel casing with welded steel rods, and switchable spring button integrated magnetic system. Profiting by the emerged super neodymium magnet block, it could afford powerful and incessancy retaining force against the framework from silding and moving issues. Owing to maximize the performance of magnetic force, the critical point is to clean out any small crushed concrete or ferrous nails and stuffs under magnet before installation. In front of pushing down the spring button, put the magnets into the right position and make the sided rods hanging on the framework grooves, no more extra welding or bolting needed. The follow-up operation is only to depress the button and it works now. After demoulding, better to use a special lever tool to release the button.

As a professional shuttering magnets manufacturer in China, Meiko Magnetics are serving and participating in hundreds of precasting projects by outputting our professional knowledge and qualified products on magnetic system concerning on precast filed. Here you can find all required magnets for your easier and more efficient fixing solutions in the modular construction.

Standard Dimensions ITEM NO. L W h L1 M Adhesive Force Net Weight mm mm mm mm kg kg SM-450 170 60 40 136 M12 450 1.8 SM-600 170 60 40 136 M12 600 2.0 SM-900 280 60 40 246 M12 900 3.0 SM-1350 320 90 60 268 M16 1350 6.5 SM-1500 320 90 60 268 M16 1500 6.8 SM-1800 320 120 60 270 M16 1800 7.5 SM-2100 320 120 60 270 M16 2100 7.8 SM-2500 320 120 60 270 M20 2500 8.2 Advantages -High Forces from 450KG to 2500KG in small body, save the space of your mold extremely -Integrated automatic mechanism with steel springs for easier operation -Welded threads M12/M16/M20 to adapt required form-work fixture -Multi-functions magnets for different purpose -Various type of adapters are equipped to match your side rail profile, no matter wooden, plywood, steel, aluminum mold.

Read the full article

#PrecastBoxMagnets#PrecastButtonMagnets#PrecastConcreteMagnets#PrecastMoldMagnet#PrecastPushPullButtonMagnets#PrecastPushPullMagnets#PrecastSwitchableButtonMagnet#PrecastSwitchablePull/PushMagnet#ShutteringMagnets#ShutteringMagnetswithAdaptor#SideRodsPrecastMagnets

0 notes

Text

Nickel Aluminium Bronze NES 833 Part 2 - Ananka Fasteners

Ananka Group is a leading Aluminium Bronze Fasteners Manufacturer in India, producing a wide range of Aluminium Bronze Fasteners in various sizes, grades, and scales. Our Aluminium Bronze Fasteners are manufactured by national & international standards. C614 Aluminum Bronze Studs are alloyed with zinc and have higher corrosion resistance to high-velocity seawater. Ananka Group is a manufacturer of all kinds of metal products. We are in the industry for several years.

Our Aluminum Bronze Threaded Rod can be used in high wear and tear applications. We offer various sizes of studs, screws, rods, and fasteners in the aluminum bronze range. We produce the most popular grade C63000 Aluminium Bronze Bolts And Nuts which are used in seawater applications and marine applications for high shock resistance and abrasion resistance.

Specifications of Aluminum Bronze Fasteners

Aluminum Bronze Alloy Fasteners Material Specification:- C63000 Nickel Aluminum Bronze Plow Bolts, UNS C62300 Bolts

Aluminum Bronze Fasteners / Bolts Standard:- DIN, UNI, ISO, JIS, GB, IS, BS, ASME, ANSI, ASTM and all International Standards

C61400 Aluminum Bronze Fasteners/ Bolts Size:- M2, M2.5, M3, M4, M5, M6, M8, M10, M12, M14, M16, M20, M24, M30, M36 to M160

Length of C955 Aluminum Bronze Hex Cap Screw:- 3 mm to 200 mm

C614 Aluminum Bronze Bolts, Studs Threads:- METRIC, BSW, BSF, UNC, UNF or as required

C630 Nickel Aluminum Bronze Allen Cap Screw Standard:- ANSI – American National Standards Institute - ANSI B 18.2.4 2M, ANSI B 28.2.4 1M, Aluminum Bronze Alloy Stud Bolt length are defined in ASME B16.5 standard, Aluminum Bronze Hex nuts are defined in ASME B18.2.2, ASME B18.5 DIN: 931, 933, 934, 970 UTS – Unified Thread Standard: UNC, UNF, UNEF, UNS, NPT, NPTF ISO – International Organization for Standardization: ISO 4032, ISO 4033, JIS standards

Source of Raw Materials to Manufacture Cual10ni5fe4 Aluminum Bronze Socket Cap Screw:- Tata Steel, JSPL, RINL, Usha Martin, Dhamm Steel, Mukund Steel, etc.

Scope:- Manufacturer of Hot Forged C955 Nickel Aluminum Bronze Hex Cap Screws, Nut / Bolt; up to M36 / 1-1/2” Dia, up to 1100mm lg, Manufacturer of CNC Machined Aluminum Bronze Fasteners, Nut / Bolt; up to M100 / 4” Dia, up to 1500mm lg

Uns C61400 Aluminum Bronze U Bolt in Form Of:- Hex, Square, Round, Threading as per Gauge Etc.

Head Drive:- Phillips, Slotted, Phillips/Slot, Six-Lobe, etc.

Aluminum Bronze Alloy Hex Bolt Thread:- Metric Coarse

Aluminum Bronze Bolting Test Certificate:- Manufacturer Test Certificate as per EN 10204 / 3.1

C63000 Nickel Aluminum Bronze Bolts Types:- Aluminum Bronze Alloy Hex Bolts, Flange Bolts, Hex Head Bolts, Lag Bolts, Square Bolts, Eye Bolts, U Bolts, T Bolts, Countersunk Bolts, etc.

C955 Aluminum Bronze Nut Types:- Aluminum Bronze Alloy Hex Head Nut, Eye Nut, Dome Nut, Wing Nut, T Nut, Panel Nut, Lock Nut, Coupling Nut, Square Nut, Acorn Nut, etc.

Aluminum Bronze Alloy Screws Types:- Aluminum Bronze Alloy Hex Head Cap Screws, Socket Set Screws, Anchor Screws, Blind Rivet, Socket Head Screws, Concrete Screws, Shoulder Screws, Panel Screws, Threaded Screws, Machine Screws, etc.

Aluminum Bronze Washer Types:- Aluminum Bronze Alloy Machine Washers, Flat Washer, Star Washers, Sealing Washer, Lock Washer, Split Washer in India

Nickel Aluminum Bronze Alloy Fasteners Packing:- IN BULK: canton, pallet, Small Box’s / carton/pallet, or customer request

Ready Stock Available Metric Aluminum Bronze Fasteners Aluminum Bronze Alloy Bolts M16 x 65mm DIN933 Aluminum Bronze Bolts M16 x 45mm DIN933 C61400 Aluminum Bronze Hex Nut M16 C63000 Aluminum Bronze Washer M16 C614 Aluminum Bronze Bolts M16 X 60mm C959 Aluminum Bronze Bolts M16 X 55mm C62300 Aluminum Bronze Bolts M16 X 35mm C63000 Nickel Aluminum Bronze Bolts M12 X 90mm C955 Aluminum Bronze Bolts M12 X 70mm C630 Nickel Aluminum Bronze Bolts M20 x 70mm Cual10ni5fe4 Aluminum Bronze Bolts M20 x 75mm

Source:- https://anankafasteners.com/aluminium-bronze-fasteners-manufacturer-india/ Call & WhatsApp:- +91 83690 74984 Mail:- [email protected] Website:- https://anankafasteners.com/

#nickel#bronze#aluminum#hex#screw#hdg#manufacturer#supplier#fasteners#ananka#anankafasteners#screwhead#uk#usa#uae#mumbai#gujarat#chennai#delhi#russia#italy#france

2 notes

·

View notes

Text

Gia công Tyren uy tín tại HCM

Tyren được biết đến là một thanh thép thẳng dài và phần thân được tiện ren toàn bộ, thường được dùng chung v��i đai ốc liên kết. Tyren sử dụng rất nhiều và được phổ biến rộng rãi ở các công trình, nhà máy, xí nghiệp và cơ khí. Ở Hồ Chí Minh thì Công ty Cổ Phần Công Nghiệp Và Thương Mại Cường Thịnh được cho là đơn vị cung cấp các vật tư liên kết cũng như gia công các loại tyren chất lượng hàng đầu đúng theo quy chuẩn cũng như yêu cầu của khách hàng. Dưới đây là một số thông tin mà bạn đọc có thể tham khảo thêm.

Đặc điểm nổi bật của dịch vụ gia công tyren tại Cường Thịnh

- Ty ren Cường thịnh cung cấp được gia công từ vật liệu Thép C45 (TCVN 1766-75), CT3 (tiêu chuẩn GOST 380-88), chất liệu thép C35, hoặc thép Inox SUS 201, 304, 316 tùy theo nhu cầu sử dụng. Cấp bền đa dạng từ 4.6- 12.9. Tùy theo mục đích sử dụng mà bề mặt ty ren sẽ là màu đen Oxit sắt (plain/black) được phủ lớp dầu nhẹ bảo vệ hay mạ kẽm điện phân (electro-zinc plated), mạ nhúng nóng (hot dip galvanized) hoặc inox.

- Ty ren là sản phẩm được ứng dụng rộng rãi, theo đó, trên thị trường có rất nhiều nhà cung cấp với chất lượng thường không được kiểm soát chặt chẽ. Tại Cường Thịnh, sản phẩm được sản xuất theo tiêu chuẩn Quốc tế với chất lượng được kiểm soát chặt chẽ trong tất cả các khâu, nhằm đảm bảo sản phẩm ra thị trường đúng với cam kết của Công ty.

- Khách hàng có thể lựa chọn hoặc nhờ sự hỗ trợ của nhân viên tư vấn để đặt mua được sản phẩm với kích thước và cấp bền bù hợp nhất. Trong đó, đường kính tyren M8 đến M30. Kích thước dài tyren đa dạng, từ 100mm đến 6000mm.

Các loại tyren được gia công tại Cường Thịnh

Guzong ren suốt (Studs thread bolt)

Đây là chi tiết được tiện ren toàn bộ.

• Guzong ren suốt thép cacbon có cấp bền theo tiêu chuẩn ISO 898-1 là từ 4.6 đến 12.9. Cấp bền phổ biến thường là 4.6, 5.6, 6.6.

• Guzong Inox sử dụng vật liệu thép không gỉ nhóm Austenic SUS 201, 304, 316, cấp bền phổ theo tiêu chuẩn ISO 3506-1: 50; 70; 80

Bề mặt sản phẩm sẽ được gia công theo yêu cầu của khách hàng,: thường (plain/black), mạ kẽm điện phân (electro-zinc plated), mạ kẽm nhúng nóng (hot dip galvanized). Inox 201, 304, 316: Lớp mạ được quản lý theo tiêu chuẩn ISO 4042, ISO 16084.

Tyren thường xi trắng (Thread rods)

Tyren được tiện ren suốt, bề mặt được mạ kẽm tĩnh điện màu trắng xanh, có chiều dài 1-3m. Chi tiết này thường được sử dụng cùng với tán chuồn.

• Tyren suốt thép cacbon có cấp bền theo tiêu chuẩn ISO 898-1 là 4.6, 5.6, 6.6.

• Bề mặt sản phẩm tyren mạ kẽm điện phân (electro-zinc plated) được quản lý theo tiêu chuẩn ISO 4042.

Ứng dụng tyren thường xi trắng là nhằm định vị 2 mảng cốp pha đối diện nhau. Cấp bền phổ biến là 4.6, 5.6, 6.6. Chúng được sử dụng với nhiều loại phụ kiện khác nhau như: Tăng đơ, đai ốc, lông đền, tắc kê đạn, các loại đai treo ống nước, kẹp xà gồ...

Guzong ren 2 đầu (studs double thread bolt)

Là chi tiết được tiện ren ở hai đầu.

• Guzong hai đầu ren thép cacbon có cấp bền theo tiêu chuẩn ISO 898-1 là từ 4.6 đến 12.9. Cấp bền phổ biến thường là 4.6, 5.6, 6.6.

• Guzong hai đầu ren Inox sử dụng vật liệu thép không gỉ nhóm Austenic SUS 201, 304, 316, cấp bền phổ theo tiêu chuẩn ISO 3506-1: 50; 70; 80

Bề mặt sản phẩm sẽ được gia công theo yêu cầu của khách hàng,: thường (plain/black), mạ kẽm điện phân (electro-zinc plated), mạ kẽm nhúng nóng (hot dip galvanized). Inox 201, 304, 316: Lớp mạ được quản lý theo tiêu chuẩn ISO 4042, ISO 16084.

Tyren vuông – Tán chuồn

Tyren vuông sử dụng nguyên liệu là thép cacbon, được gia công ren vuông với bước ren lớn, có 3 loại quy cách tyren vuông tương ứng với bước ren là M12 bước ren 4.25mm, M16 bước ren 6mm và M17 bước ren 10mm. Bề mặt tyren vuông sau gia công thường sẽ tráng Crom hoặc Niken để bảo vệ.

• Tán chuồn hay còn gọi là bát chuồn được dùng để vặn vào hai đầu tyren và có công dụng xiết khóa, kẹp ty ren thô, tyren vuông, ty răng vv… cố định khoảng cách hai tấm cốp pha trước khi đổ bê tông.

• Cấp bền tyren: M12 chịu tải tương ứng 10 tấn, M16 chịu tải tương ứng 13 tấn, M17 chịu tải tương ứng 15 tấn.

• Thông số kĩ thuật của bát chuồn thường tùy thuộc vào loại ty ren đi kèm với chúng.

GIA CÔNG TYREN

Ứng dụng tyren

Nhìn chung, trong những lĩnh vực chuyên biệt, tyren là chi tiết không thể thay thế, mang đến những ứng dụng quan trọng vượt bậc. Điển hình bao gồm:

- Ứng dụng tyren trong công nghiệp cơ khí, chế tạo máy móc. Đặc thù của tyren sử dụng trong mục đích này thường đòi hỏi cao về sức chịu lực.

- Ứng dụng tyren trong công nghiệp xây dựng, trong các kết cấu tại nhiều hạng mục công trình khác nhau.

- Sử dụng sản phẩm trong việc gia công, lắp ghép các thiết bị nội thất.

GIA CÔNG TYREN

Tại sao nên chọn gia công Tyren lại Cường Thịnh?

- Sản phẩm tyren của CTEG cam kết 100% chất lượng đã đề ra: Làm rõ chất liệu sử dụng làm sản phẩm cho khách hàng, cung cấp đúng chất liệu đã cam kết, đúng với bản vẽ kỹ thuật theo công trình đã đặt.

- Thời gian đổi trả sản phẩm nhanh chóng

- Thời gian giao hàng đúng hẹn.

- Các sản phẩm và dịch vụ của CTEG đều hướng đến chất lượng cao nhất cho quý Khách hàng, lấy chất lượng sản phẩm là nền tảng cơ bản cho Doanh nghiệp và liên tục đổi mới để mang lại giá trị cao nhất.

- CTEG luôn tìm giải pháp để có được sản phẩm tối ưu nhất về chất lượng và giá cả thông qua sản xuất, nhập khẩu trực tiếp mà không phải qua một cầu nối nào khác. Góp phần ổn định thị trường trong nước. Từng bước đưa sản phẩm sản xuất ra trường Quốc tế. Đóng góp sự hiệu quả vào sự phát triển của ngành và của đất nước.

GIA CÔNG TYREN

Các tiêu chí hàng đầu để đánh giá về CTEG

- Chất lượng sản phẩm: Sản phẩm chất lượng cao, được kiểm định đạt tiêu chuẩn trước khi đưa ra thị trường.

- Chính sách bảo hành: Sản phẩm của CTEG cam kết dịch vụ hậu mãi tốt nhất với chính sách bảo hành trọn đời.

- Chính sách giao hàng: CTEG cam kết giao hàng đúng hẹn, nhanh chóng và kịp thời phục vụ quý khách

- Chính sách đổi trả: Tất cả sản phẩm lỗi sẽ được đổi trả, kể cả khi đã nhập kho.

Công Ty Cổ Phần Công Nghiệp Và Thương Mại Cường Thịnh hân hạnh trở thành đối tác và luôn tự hào là đơn vị nhập khẩu, sản xuất và cung cấp vật tư sỉ cho các doanh nghiệp, nhà máy… trong nhiều lĩnh vực, ngành nghề khác nhau từ cơ khí đến xây dựng giao thông, công nghiệp, năng lượng mặt trời, công nghiệp đóng tàu …với các sản phẩm điển hình: bulong, bulong neo, bulong liên kết, cáp, tăng đơ, ốc vít…

Nguồn : https://cteg.vn/gia-cong-tyren

0 notes

Video

youtube

products graphite gasket Spiral Wound Gasket Spiral Wound Gaskets supplier Chinese factory

Langfang Jiuwang Sealing Material Co., Ltd. https://mifengcailiaodaquan.cn/ Whatsapp/WeChat: +86-18830639308 --------------------- products graphite gasket Spiral Wound Gasket Spiral Wound Gaskets supplier Chinese factory rubber mat bed bath beyond what is seal packing how to seal a leaky o ring lip seal with garter spring asbestos board behind fireplace https://mifengcailiaodaquan.cn/10047.html cheap rubber grass mats gland packing of gate valve 500*500mm width Silicone rubber sheet Thickness 1 1.5 2 3 4 mm thickness thin board red color Rubber Sheet Mat ptfe tool ball valve packing gland rubber boards for cattle trailers packing ring meaning mazda 3 rubber mats gfo fiber dripless packing o-ring on rotary tattoo machine are rubber cutting boards safe where asbestos is found https://mifengcailiaodaquan.cn/10038.html graphite pad for sander danco graphite packing nylon 6 wear pads 6" graphite platen pad ptfe pads price oil seal install graphite thermal pad 8 mm o ring evod clearomizer base rubber board field station - tholicode what is flax packing 1/8 aluminum rivet washer o ring in shower head rubber mat for top of washer and dryer graphite paint https://mifengcailiaodaquan.cn/10013.html are asbestos tiles safe how teflon is made is the smell of rubber mats toxic 6 teflon gasket ptfe coating pan Shaft Packing Material Gland Seal Water Pump Aramid Fiber PTFE Kevlar Gland Packing Rope asbestos gland packing manufacturers copper washers m14 fiberglass packing lowes ring joint gasket meaning lip seal advantages and disadvantages gland packing style 23 https://mifengcailiaodaquan.cn/9988.html rubber mat pink die formed graphite packing graphite packing rope/ home depot dorman 097-134 copper oil drain plug gasket - fits m12, pack of 10 o-ring manufacturers nylon rod flex o-ring packing kit 1 shaft packing gland asbestos rope for stoves coleman 220k graphite packing o-ring purpose asbestos mat chemistry ss o-rings https://mifengcailiaodaquan.cn/9973.html o-ring lieferanten clear acrylic packaging tape o-ring to pipe adapter sbc copper exhaust gasket carbon graphite packing gland packing malaysia copper sealing washers is graphite heat resistant o ring with groove gland packing rope, gland packing extractor graphite thermal pad ps4 rubber mat for cow, rubber board members 3m nylon pad https://mifengcailiaodaquan.cn/9949.html activated carbon packing density rubber board dealers list lowes nylon rod ic graphite thermal pad laptop, does rubber flooring offgas rubber o-rings how does a compression ring work o-ring viton 70 shore does ptfe melt will asbestos siding pass fha appraisal is ceramic fiber dangerous o-ring making kit rubber mat in bangladesh o nylon e um polímero ring joint gasket bx https://mifengcailiaodaquan.cn/9740.html packing ring cutter aluminium washers nz does graphite rust are graphite pool cues any good o-ring drive belt, packing rope 3/8 rubber mat do fiberglass pools have bottom drains does aluminum washer sink or float asbestos beaver board pan fiber production graphite vs carbon fiber non asbestos gland packing rubber board hs code is fiberglass ceramic metal ring gaskets for flanges Reinforced Graphite Composite Cylinder Head Gasket Sheet 3/32x12"x12" os&y packing gland https://mifengcailiaodaquan.cn/9740.html how to identify asbestos insulation board rubber board india, rubber mat transition rubber mat vibration top o matic rubber tips does graphite melt o-ring 3x1 how do you get rid of rubber mat smell rubber mat sink fiberglass rope for smoker nylon rod jenis gland packing 5007 lip seal gland packing pump, graphite packing string, is graphite renewable gland packing 25mm hand packing tape dispenser 5/16 nylon threaded rod nylon 6 weldng rods rubber mat manufacturing business, copper washers harbor freight which way do copper washers go metal polishing pad for drill ring joint gasket manufacturers in india rubber mat 2x2, champion non asbestos gland packing

0 notes

Text

What is the importance of Incoloy 825 Pipe Fittings?

With a modest quantity of extra Copper, Titanium, and Molybdenum, Incoloy 825 Pipe Fittings offer superior chemical and mechanical qualities. You should use UNS N08825 Incoloy 825 Pipe reducers that are more resistant to crevice and pitting corrosion and can operate smoothly at moderately elevated temperatures.Incoloy 825 Pipe End Cap is used in acid production units, pickling tanks and equipment, and nuclear waste and handling devices because it is corrosion resistant in both oxidizing and reducing situations.

Know about Duplex 2205 Round bar

Duplex 2205 Round bar is a type of duplex stainless steel that has had its nitrogen content increased. The alloy grade 2205 Duplex Stainless Steel Round Bar is created to address frequent corrosion issues with austenitic stainless steels in the 300 series.You should know about stainless steel threaded rod manufacturers to get premium quality.

The mixed microstructure of the S32205 Duplex Polished Bar contains around 40% - 50% ferrite in an annealed condition. Because the alloy is the most extensively used grade in the duplex category of stainless steel, the Duplex Steel S32205 Forged Bar is sometimes referred to as the workhorse grade.

The benefit of a dual or duplex microstructure is that the Duplex Steel Uns S31803 Hollow Bar has a set of integrated yet distinct properties.

What is the usage ofstainless steel threaded?

A threaded rod is a sort of fastening bar threaded on both ends and is rather lengthy. The threading on the ss acme threaded rod can be stretched down the rod's length. You can also look for ASTM a193 grade b7 as they are of high strength. Manufacturers of SS threaded rod refer to it as a stud. The ss316 threaded rod is intended for tension application. The Stainless Steel Flanges m12 stainless steel threaded rod is commonly referred to as an all-thread in bar stock form.

Specifications of ASTM a193 grade b7

TheASTM A193 Grade B7 specification includes high-tensile alloys steel. It is a standard specification for bolting used in pressure vessel service, valves, flanges, and fittings that defines the typical chemical composition, hardness requirement, preferential heat treatment, product labeling, mechanical qualities, certification, and other conditions. You should know about Stainless Steel U Bolts as they are used to increase strength.

What are Stainless Steel Flanges used for?

The flange and monel bolts business isa high carbon form of the most often used and incredibly adaptable stainless steel. 304H is an austenitic chromium stainless steel with a carbon content of.04–.10, which aids in heat resistance in high-temperature applications. It also has all of the general characteristics and service features of the standard stainless steel grade 304.

Why is the demand for monel bolts increasing?

Monel bolts are usually nickel-copper alloys with exceptional strength, hardness, and corrosion resistance throughout a wide temperature range. Monel bolts are notable for their extraordinary resistance to hydrofluoric acid. Look for the best stainless steel stud bolt manufacturers.

Monel bolts are possibly the most resistant of all regularly used specialty alloys for hydrofluoric acid applications.In marine applications, Monel alloy 400 and K500 bolts have high corrosion resistance, and under reducing conditions, they have good corrosion resistance to sulfuric and hydrochloric acids.

0 notes

Text

Kayulin 15mm Aluminum Cheese Rod 15mm Tube With Internal M12 Female Thread (145mm Long)

Kayulin 15mm Aluminum Cheese Rod 15mm Tube With Internal M12 Female Thread (145mm Long)

lastest_volume

11

Just For Today

Click Here To Visit The Shop

N€W Kayulin 15mm Aluminum Cheese Rod 15mm Tube With Internal M12 Female Thread (145mm Long)

0 notes

Video

youtube

FIXDEX Chemical anchor This chemical anchor is a high-strength, corrosion-resistant anchoring device, widely used in construction, geology and other fields If you interested contact me anytimeFollow FIXDEX www.facebook.com/profile.php?id=100063796905450lear more FIXDEX product www.fixdex.com

#youtube#best chemical anchor#bolt chemical#bolt chemical anchor#bolt fixing chemical#chembolt#chembolt price#chembolts#chemical anchor bolt fixdex#chemical anchor bolts for concrete#chemical anchor builders#chemical anchor fastener#chemical anchor fastener bolt#chemical anchor m12#chemical anchor rod#chemical expansion bolt#chemical fastener#chemical stud#chemset threaded rod

0 notes

Text

Sabroe 120 Manual

Sabroe 120 Manual Pdf

INSTRUCTION MANUAL FOR PISTON COMPRESSOR

SABROE prescribes operating limits within which the compressor and any additional equipment must operate. These limits for R717, R22, R134a, R404A, R507 and R407C are shown in the following tables, together with the main data for the compressor. Parts Supply for IR Europe - Sabroe Spare parts manual - SAB 120 and SAB 151 A-Frame 008504 en 2019.12 5/42 Spare parts liste SAB 120, 151 A-frame Abbreviations in this manual include: Ang. Angle OD= outside diameter equal to Ass. Cooling medium refrigerant Cp. Compressor Reg regulating DN (+space).

You can find detailed information on our website: http://coolref.ru/EN

Description of SAB 202

The SAB 202 compressor is a capacity adjustable screw compressor with oil injection. The two rotors are equipped with 4 lobes (male rotor) and 6 lobes (female rotor), respectively, executed with asymmetric profile according to SRM licence. As indicated on the spare parts drawing at the end of this manual, the rotors at the suction end are fitted with slide bearings, whereas the bearing at the discharge end consists of a combined bearing set with slide bearings, absorbing the radial load, and ball bearings, absorbing the axial forces. The axial forces are partly relieved by means of the rotating balance pistons mounted on the rotors. The rotors are designed for both male drive and female drive. The driving rotor is fitted with a shaft.

The compressor is fitted with a large built-in suction filter, which effectively prevents dirt particles from the refrigeration plant from being led with the suction gas into the compressor. The suction filter housing also has a built-in compressor protection valve which - controlled by a pilot valve - safeguards the compressor against any unwanted high compression pressures. For efficient filtration of the oil that lubricates the bearings in the compressor, an oil filter cartridge has been inserted in the compressor block.

Furthermore, the compressor contains a built-in non-return valve, preventing the compressor from running backwards whenever the power to the driving motor is disconnected. The driving shaft is fitted with a shaft seal of the slide ring type, consisting of a fixed cast iron ring with an O-ring sealing against the shaft seal cover and a rotating springloaded carbon ring with O-ring sealing against the shaft. It is possible to regulate the compressor capacity steplessly from approx. 10% to 100% by means of a regulating slide mounted under the rotors. Once the slide has moved away from the slide stop a gap is created so that some of the sucked-in gas is returned to the suction side. The bigger the gap, the lower the compressor capacity. The regulating slide is moved hydraulically by a regulating piston and controlled by a solenoid valve system. The compressor also features a regulating system by which the built-in Vi volume ratio can be adjusted. The result hereof is that the compressor works optimally at varying operational pressures in the plant.

To optimize the compressor volume ratio the position of the Vi regulating slide must be changed whenever the compressor works at max. capacity. This is done by changing the position of the slide stop. At partial load the Vi volume ratio will only be approaching the optimum. Regulating the built-in Vi volume ratio can be done in the following two ways, depending on the compressor type Manual regulation of the Vi slide:

By turning the spindle, pos. 180, in accordance with the curves in the instruction manual.

By means of the oil pressure and two solenoid valves, controlled by a UNISAB II control system.

Schemes

Spare parts for compressor SAB 202

Sabroe 120 Manual Pdf

List of parts for SAB 202Relevant drawing 0661-855PosDesignationNoPart noComplete compressor LF, aut. Vi4161-059Complete compressor LF, man. Vi4161-060Complete compressor LM, aut. VI4161-061Complete compressor LM, man, Vi4161-062Complete compressor SF, aut. VI4161-063Complete compressor S F, man. Vi4161-064Complete compressor SM, ant, Vi4161-065Complete compressor SM, man. Vi4161-066Compressor housing10-1Compressor housing (L)13011-00910-2Compressor housing (S)13011-019Bearing cover at suction end20-1Bearing cover, female drive13013-08920-2Bearing cover, male drive13013-11021O-ring dia. 430,66 x 3,53, neoprene11331-11722Innar sleeve, INA IR dia. 17/20 x 1621514-01823Washer dia. 25/16.5 x 442114-04724mreaded plug with cottar 1/211343-02725Dowty ring 02511331-43026Cylindrical screw M16 x 60101413-43627Cylindrical screw M 16 x 3021413-42928Cylindrical screw Ml 6 x 18081413-42830Hose connection11345-143Bearing cover at ditcharge end40Thrust cover/capacity regulating cylinder13013-15041Cylinder screw M16 x 60201413-43642Washer dia. 35/16,5 x 442114-04743O-ring dia. 151,93 x 3,53, neoprene11331-09944Adjusting screwa2111-12845Locking screw M6 x 1041413-23146Cross bar for bearing adjustment13083-13747Cylinder screw M12 x 3061413-36648Inner sleeve, INA IR dia 17/20 x 1621514-01849O-ring dia. 13,94 x 2,6211331-014Cover for capacity regulating cylinder60Cover for capacity cylinder13013-19761O-ring dia. 142,47 x 3,53 - neoprene11331-09662Cylinder screw M12 x 3541413-387Housing for capacity indicator70Housing for capacity indicator13045-00271Cylinder screw M6 x 3041413-34372Cover for capacity indicator13045-00373Cylinder screw M6 x 5041413-34774O-ring dia. 98.02 x 3,53, neoprene11331-08175-1Glass for indicator (L)t3045-05075-2Glass for indicator (S)13045-049Rotors110-1Set of rotors tor SM13024-102110-2Set of rotors tor SF13024-097110-3Set of rotors for LM13024-103110-4Set of rotors for LF13024-095111Journal bearing41515-031112Retaining pin for journal bearing dia, 5 x 4541446-033113Cylinder screw M6 x 4581413-340114Thrust washes23021-029115Cylinder screw M16 x 4521413-433132Four point ball bearing dia. 70/150 x 3521513-040133Set of shims dia. 128/150 for adjusting the clearance between the rotor and outlet port. Comprising: 1 off thickness 5,60 mm 23021-0431 - 5,65 mrr 1 - 5,70 mm1 - 5,75 mm1 - 5,80 mrn1 - 5,85 mm1 - 5,90 mm134Balance piston. drive rotor13025-052135Spacer ring, drive rotor13025-035136Retaining ring 4 x 1011446-012137Balance piston, driven rotor13025-034138Spacer ring, driven rotor13025-036139Retaining pin 5x1611446-021DIscharga ports140-1Discharge port for male rotor .13031-031141-1Discharge port for female rotor13031P032142Cylinder scraw M8 x 19061413-309143Washer for discharge port dia. 16,5 /8,2 x 1062114-045144Cylinder screw M6 x 3021413-343145Pointed screw M10 x 35 - inside adjustment21413-255146Locking screw M10 x 10 - inside adjustment21413-253147Locking screw M10 x 10 - outside adjustment21413-253148Pointed screw M10 x 20 - outside adjustment21413-032149ABlank of screw 3/8' - outside adjustment21343-026149BGasket - outside adjustment21331-427Parts for adjusting rotors153Inner cover23021-030154O-ring dia. 142,47 x 3,5321331-096155Cylindrical steel roll 8H 11 x 8S1514-019Shaft seal160AShaft seal collar 1160BShaft saal seat 1160CO-ring for shaft seat collar 113084-557160DO-rlng for shaft saal seat 1160EPointed screw 3161Retaining pin for shaft seal seat dia. 3 x 511446-005162Spirolox ring (oil thrower)11437-294163-1Cover, F13013-100163-2Cover, M13013-102164O-ring dia, 132,94 x 3,53, neoprene11331-093165-1Cover for shaft seal, F13013-099165-2Cover for shaft seal, M13013-101166O-ring dia, 158,34 x 3,5311331-100167Cylinder screw M12 x 3581413-387168Hose connection branch 1 /4°11345-143169Clear plastic hose11241-190Suction filter170Suction filter13042-075Adjusting system for Vi-slide, AUT352Screw for transmitter M3 x 8 (included in pos. 410)(4)1412-012371Sealing ring OD 7011332-126372Attachment for pin13044-035380Cover tor aut. Vi13013-196381O-ring dia. 101,19 x 3,53, neoprene11331-083382Cylinder screw M12 x 3541413-387384Attachment for sealing ring13044-034385Cylinder screw M4 x 1621413-320386Cylindrical pin dia. 6 x 1621445-076387Cylinder screw M6 x 1211413-339390Spindle aut. Vi13044-063393Ball baaring 620211511-012395Driving disk13044-021396Cylinder screw M4 x 1211413-318400Attachment tor transmitter13044-064401Cylinder screw M6 x 8041413-307402Cover ring for transmitter13045-009403Cylinder screw M4 x 1041413-319405Magnetic coupling13045-062406O-ring dia. 32,99 x 2,62 (incl in pos. 405)(1)1331-133407Hexagon head screw M4 x 16 (inc. in pos. 405)(1)1413-320410Turning transmitter13448-004411Driving lug13044-020412Pointed screw M4 x 511413-211413Clamping pin dia. 1,5 x 1211446-010Adjusting system for Vi-slide, MAN180Spindle man. Vi13044-052181Cover for man. Vi13013-093182Sealing washer for slide stop13044-014183Sealing ring11331-503184O-ring dia. 44,04 x 3,53, neoprene11331-065185Retainer for bearings13044-033186Axial ball bearing dia. 42/25 x 1121512-015187Locking plate12114-043188Cylinder screw M6 x 1211413-339189Thread washer13044-073195Cylinder screw M4 x 3021413-325196Cylinder screw M6 x 3531413-344197O-ring dia. 101,19 x 3,5311331-083198Cylinder screw M12 x 3541413-387Vi-slide190-1Slide stop, S13043-131190-2Slide stop, L13043-130191-1Spring for Vi-slide,L12144-042191-2Spring for Vi-slide,S12144-043192Cylinder screw M 10 x 2511413-371Capacity regulating slide200-1Slide for L13043-113200-2Slide for S13043-125201Piston part inner13043-138202Piston part outer13043-139203O-ring dia. 40,87 x 3,53, neoprene11331-064204Sealing ring dia. 15011332-133206Slotted nut KM811514-200207A-1Piston rod for L13043-140207A-2Piston rod for S13043141207BBushing tor indicator spindle Included in pos. 207A13045-046207CCylindrical pin dia. 6 x 16 Included in pos. 207A11445-076207DSpirolox-ring Inducted in pos. 207A11437-291207ESteel ball 3/8' Included in pos. 207A11514-158208Locking plate for slotted nut11514-070209Tape bearing22132-100311Cap torew M20 x 6011424-289313Clamp13042-054Spindle for copacity indication210Spindle tor capacity indication13045-059216Magnetic coupling13045-061217O-ring dia. 44,12 x 2,62 (incl. in pos. 216)(1)1331-146218Hexagon head screw M4 x 16 (Incl. in pos. 216)(1)1413-320219Hexagon head screw M4 x 20 (ind. in pos. 216)(2)1413-322Capacity indication221Indication disk13045-001223Socket cap screw M4 x 1011413-319224Backing ring 105/90 x 1,612356-155226Locking washer DC 15/8,411437-054227Locking washar DC 8/4,311437-060350Position transmitter13448-004351-1Indicator glass, L (replacing pos. 75-1 when transmitter)13045-048351-2Indicator glass, S (replacing pos. 75-2 whentransmitter)13045-047352Screw for transmitter M3 x 8 (incl. in pos. 350)(4)1412-012Non return valveNon return valve complet3042-172252O-ring dia. 253,37 x 5,33, neoprene11331-181253Intermediate flange13013-288255Valve housing13042-127256Spindle guide13042-125257Retainer13042-126258Hexagon head screw M8 x 12031413-314259Valve cone13042-123260Spindle13042-124261Spring11523-033262Tape bearing dim 10 x 1 x 4612132-114263Tape bearing dim 10 x 1 x 105t2132-096264Hexagon head screw M16 x 7581424-108265Countersunk socket cop. screw M12 x 2511413-115266Hexagon bead scraw M12 x 3021413-386267Shaft nut KM9 - M4511514-201268Seeger ring dia. 14 x 1,0, DIN 47111437-207Oil injection316V-joint 22-RL11349-153317Check valve RVS11364-163318O-ring dia. 33,05 x 1,7811331-123319Valve seat13042-077External oil piping320-1Pipe sat (L)13049-026320-2Pipe set (S)13049-029321Pipe clamp dia. 3 x 1212532-012Oil filter450Oil filter coveri3041-008452O-ring dia. 132,94 x 3,53, neoprene11331-093453O-ring dia. 101,19 x 3,53, neoprene11331-083455Lock nut M1011433-030456Cylinder screw M12 x 3541413-387458Stay bolt for magnet12111-127459Magnets for oil filter41517-022460Intermediate ring43424-039461Rubber ring21334-012462Plug 1/4'21343-025463Dowty ring dia. 20,57 x 13,7421331-428470Oil filter cartridge11517-015475O-ring dia. 63,9 x 3,5311331-071476Cylinder screw M 12 x 3041413-386Oil flow swich500Terminal box11554-001501Cover for flow switch13041-004502O-ring dia. 132,94 x 3,53, nroprere11331-093505Nipple tor ftow switch o12314-106506Dowty ring11331-433507Flow switch with ball11553-024508Washer12114-046509Gasket dia. 19/14 x 1,512356-124510Spring12144-041511Circlip (included in pos. 507)1512Cylinder screw M12 x 3541413-387Plugging520Plug 1/2'11343-027521Dowty ring 02511331-430525Plug 3/4'11343-028526Dowty ring 02711331-433530Plug 1/4'11343-025531Gasket ring 19/14 x 1,512356-124Economizer inlet600Eco-plug13013-111601Cylinder screw M12 x 3041413-386602Cylinder screw M8 x 3021413-358603O-ring dia. 53,57 x 3,53, neoprene11331-058Relief valve700-1Back pressure independent valve. BSV 8-18 bar12416-202700-2Back pressure independent valve. BSV 8-22 bar12416-224Pilot operated valve701-AConnection line for POV 5013049-032701-BConnection line for POV 6013049-033702-ACylinder screw M12 x 2541413-385702-BCylinder screw M 12 x 3041413-388703-AO-ring dia. 63,09 x 3,5311331-071703-BO-ring dia. 88,49 x 3,5311331-079704-APilot operated valve, POV 50 (for R717)12417-046704-BPilot operated valve, POV 80 (for R22 and HCF,s)12417-058Cover for main valve705-ACover for POV 5013013-125705-BCover for POV 8013013-163706Cylinder screw M16 x 4081413-432707O-rlng dia. 253.37 x 5,3311331-181Connection between compr. discharge side and suction side710-AManifold for POV 5013013-124710-BMan (fold tor POV 8013013-157711-AO-ring dia. 85,32 x 3,5311331-078711-BO-ring dia. 86,49 x 3,5311331-079712-ACylinder screw M12 x 11031413-406712-BCylinder screw M12 x 3041413-386715-ACover (for POV 50 only)13013-125716Cylinder screw M16 x 4041413-432717O-ring dia. 164,69 x 3,5311331-101720-APipe conneclion for POV 5013014-002720-BPipe connection for POV 8013013-166721-ACylindar screw M12 x 3081413-386721-BCylinder screw M12 x 4041413-388722-AO-ring dia. 75,79 x 3,5321331-075722-BO-ring dia. 88.49 x 3,5311331-079Releif valve connections725Stud coupling A-12 RL11349-053726Al-gasket dia.24/13 x 1,512356-127727Reducer G3/4 - G3/812312-038729Elbow coupling VB 12-RL11349-210730Union nut G112313-017731Threaded nipple G3/812311-065732Al-gastet dia.30/16 x 1,512356-137733Dowty ring 02311331-427Signal trantducers751Pressure transducer, PT111373-249752Pressure transducer, PT311373-271753Pressure transducer, PT411373-271755Stud coupling21349-137756Stud elbow11349-233761Temperature transmitter, TT611373-264762Temperature transmitter, TT711373-264765Gasket ring21349-135766Reducer G1/2-G1/411349-077

S=L/D 1.7 M=Male drive L=L/D 2,2 F=Female drive

Spare parts survey for SAB 202 unitThe following list comprises all components that can be fitted on a compressor unit. From this list we have selected the components that are used on a particular unit and which are indicated on the piping diagram of this instruction manual. The position numbers on the piping diagram are a reference to the 'Pos.' columns of this list The piping diagram is dedicated to the compressor number stated on page 1 of this instruction manual.The components in the shaded areas are variable. This may be due to voltags, refrigerant, approved pressure etc.On ordering spare parts it may be an advantage to receive them in sets selectedfor your specific compressor unit.A list of sets can had on request from SABROE's local representative.

Pos.DesignationPart no.Regulating & Control deviceUNISAB IlPT1Pressure transducer -1 - 9 bar1373-243PT2Pressure transducer -1-25 bar1373-271PT3Pressure transducer -1 - 25 bar1373-271PT4Pressure transducer -1 -25 bar1373-271TT5-6-7Temperature transducer PT1001373-252TT5-6-7Temperatura transducer PT1001373-264(Avaible after 97.01.20)GT6Position transmittar (capacity)3448-004GT9Position transmitter3448-004UNISAB II Frontpanel1573-0071 CPU-Module1572-0261 Relay print1574-0161 EPROM extractor1613-0021 EEPROM extractor1613-0031 EEPROM1571-0153 Jumpers2 Fuses1572-0181 Screw driverRefrigerant systemSuction:20O-ring dia. 253,37 x 5,331331-181Set of gaskets for SCV 125 (M R717)3184-080Set of gaskets for SCV 150 (M R22/F R717)3184-081Set of gaskets for SCV200 (F R22)3184-0812434-35Sel of gaskets for SNV 82453-05347-48Oil separator, general:22O-ring dia. 164,69 x 3,53 (disch. flange)1331-10130Sealing ring dia. 42/49 x 6,51349-21330Heating rod, 250V3181-038-1Heating rod, 115V3181-039-1Heating rod, 230V3181-04031O-ring dia. 52,07 x 2,62 (Sight glass)1331-140Sight glass1226-01755O-ring dia. 329,57x5,33 (for cover)1331-184Oil separating element1517-079-2Oil return:52Nozzle valve1364-15153Sight glass1226-01453Gasket dia. 40,5/33 x 1,52356-144Discharge:204Set of gaskets for SCV 100 (M)3184-079Set of gaskets for SCV 100 (F)3184-097Safety valves:28DN 40/65Gasket dia. 75/61 x 2,02356-220Gasket dia. 109/95 x 2,02356-222O-ring dia. 91,67 x 3,53 (house)1331-080Conical seal for DN 40/651365-079Spring (for 25 bar opening pressure)1523-02728DN 50/80Gasket dia. 87/73 x 2,02356-221Gaskat dia. 120/106 x 2,02356-223O-ring dia. 117,07 x 3,53 (house)1331-088Conical seal for DN 50/801365-080Spring (for 25 bar opening pressure)1365-05028DN 65/100Gasket da. 109/95 2356-222Gasket dia. 149/1292356-224O-ring dia. 151,99 x 3,53 (house)1331-099Conical seal for DN 65/1001365-081Spring (for 25 bar opening pressure)1523-03528DN 80/125Gasket dia. 120/1062356-223 Gasket dia. 175/1552356-228Gasket for safety valve house DN 80/1251365-082Conical seal for DN 80/1251365-075Spring (for 25 bar opening pressure)1523-036Water-cooled oil cooler OWSG33OWSG 16xxGasket dia. 270/150 x 5,0 2355-171 Gasket dia. 107/61 x 2,02357-014Gasket dia. 36/28 x 1,52356-14133OWSG 21xxGasket dia. 310/205 x 5,02355-172Gasket dia. 142/90 x 2.02356-269Gasket dia, 36/28 x 1,52356-141O-ring dia. 34,52 x 3,531331-02833OWSG 27xxGasket dia.370/255 x 5,02356-173Gasket dia.162/115 x 2,02356-276 O-ring dia. 34,52 x 3,531331-028External oil filter type BGAH39Filter element1517-015O-ring dia. 169,3 x 5,7 (cover)1331-226O-ring dia. 130,2 x 5,34 (insert)1331-169O-ring dia. 109,2 x 5,7 (element)1331-225O-ring dia. 62,14 x 3,53 (collar)1331-077External oil filter type OF210839Filter element1517-015O-ring dia. 170,82 x 5.33 (cover)1331-175O-ring dia. 130,2 x 5,33 (insert)1331-169O-ring dia. 109,2 x 5,70 (element)1331-22538-42 Set of gaskets for SCV 503184-077Flange connection, oil tubeGasket dia. 87/73 x 2,02356-221O-ring dia. 63,09 x 3,53 (compr.)1331-071Oil by-pass (at pump)210Gasket dia. 140/105 x 1,5 (non-return valve)2356-10669O-ring dia. 50,40 x 3,53 (non-return valve)1331-300Thermostatic three-way valve, type RT646O-ring, Neoprene1331-384Thermo element (48 deg. C)1365-08470Solenoid valveValve housing EVM (NC)1372-335Gastet set for EVM1336-024Coil 10 W 220 V 50/60 Hz1372-537 110 V 50/60 Hz1372-538 240 V 50 Hz1372-53971Solenoid valveValve housing EVM{NO)1372-287Gasket set for EVM1336-024-02Coil 10 W 220 V 50/60 Hz1372-537 110 V 50/60 Hz1372-538 240 V 50 Hz1372-539Throttle valve1364-15173Solenoid valve - see pos.7074Solenoid valveValve housing EVM (NO) - see pos.71027B113080-84Gasket set for SVA 15-202453-02281Filter FA15 - When TEAT 20 is selectedGasket set for FA151377-078Repair kit for FA 151377-25081Filter FA20 - When TEAT 85 is selectedGasket set for FA201377-079Repair kit for FA201377-25182Solenoid valve EVRA15 - When TEAT 20 is selectedGasket set (for EVRA 15)1377-093Repair kit (for EVRA15)1377-099Coil 10 W 220 V 50/60 Hz1372-537110V 50/60 Hz1372-538240V 50 Hz1372-53982Solenoid valve EVRA20 - When TEAT 20 is selectedGasket set (for EVRA20)1377-094Repair kit (for EVRA20)1377-069Coil 10 W 220 V 50/60 Hz1372-537110 V 50/60 Hz1372-538240 V 50 Hz1372-53983Injection valve TEAT 20Nozzle insert 20-81371-203Nozzle insert 20-121371-204Nozzle insert 20-201371-206Thermal part 35-65 deg. C1371-25583Injection valve TEAT 85Nozzle insert 85-331371-207Nozzle insert 85-551371-208Nozzle insert 85-851371-209Thermal part 35-65 deg. C1371-257Ecomomizer - ECO - DN 4097O-ring dia. 59,92 x 3,53 (tlange)1331-070120Gasket set for SCH 403184-112133Gasket set for STA 40 (2464,158)2453-030133Filter 2502464-212Ecomomizer - ECO - DN 5097O-ring dia. 59,92 x 3,53 (flange)1331-070120Gasket set for SCH 503184-112133Gasket set for STA 50 (2464,166)2453-030133Fiiter 2502464-212Spare parts set for coupling S952 size 312Sheets, bolts, nuts & slices1524-126Spacer bushing1526-004Stop screw M 10 x 101413-250Combination wrench 5/8'Compr. toolsBox wrench 5/8'Compr. toolsAlignment motor - compressorDisc (motor up to IEC 280)2221-067Disc (motor from IEC 315)2221 -076Tools3183-104

Tools for compressor SAB 202Line no. A401 = normal set 3083-184Line no. A402 = Extended set 3083-185Line no. B401 = Toois for aligning the coupling 3163-105Line no. B402 = Tools for shaft seal removal, oil pump 3083-160

INSTRUCTION MANUAL FOR PISTON COMPRESSOR

Tools noDesignationPart no.A401A402B401B4021Thrust plate for puller 40 x 20 x 2003083-17311aPuller for bearings 40 x 20 x 1453083-172113Threaded pins M12/M6 x 2003083-171224Threaded pin M14, Koko1427-037115Thrust plate for mounting the bearings 40 x 15 x 1503083-181116Washer for mounting the bearings dia. 130/17 x 153083-182117Threaded pin M16 x 2003083-180118Long nut M16 x 501432-191119.1Nut M161432-067119.2Nuts M121432-0652210Mounting bushing for ball bearing, inner ring3083-1741111Guide pins for suction- and disharge cover M16 x 3003083-1642212Punch for locking the rotors3083-1831113Plate for locking the rotors 40 x 15 x 2003083-1791114Plate for dismounting the rotors 60 x 25 x 3603083-1771115Bushing dia.25/17 x 153083-1782216.1Cap screw M20 x 1203083-1761116.2Cap screw M16 x 403083-1751117.1Socket cap screws M16 x 601413-4362217.2Socket cap screws M16 x 401413-4322217.3Socket cap screws M6 x 161413-3402218Washer dia 20/17 x 31436-0011119Threaded pin M 16 x 2503083-1681120Thrust plate 50 x 20 x 2703083-1671121Pipe pieces dia. 25.9/21.3 x 1873083-1702222Threaded pins M 12 x 2753083-1692223Gauge dia. 62/17 x 513083-1661124Spring dia. 50 x 9.52142-0601125.1Nuts with collar M121432-1702225.2Nut with ooiiar M161432-1711126Plate with M12 nut 20 x 6 x 1003083-1631127-1Socket cap screw key with handle 5 mm1612-3911127-2Socket cap screw with handle M12 x 1803083-165112BEye-bol M121427-150130Alignment device for coupling3183-105131Feeler gauge (incl in3183-105)1622-050132Tools for shaft seal removal, oil pump3083-1601Consists of:Puller for shaft seal, oil pump3083-1571Cap screw M10 x 751424-2011Threaded pin M8 x 1503083-1563Nuts M81432-0633Punch dia. 18 x 803083-1581Punch dia. 22/16.5 x 1003083-159140.1Combination spanner 19mm140.2Combination spanner 24mm140.3Combination spanner 30mm140.4Combination spanner 36mm141Open end spanner 19/22mm142.2Hexagon bit adaptor 1/2'- 5mm142.3Hexagon bit adaptor 1/2' - 6mm142.4Hexagon bit adaptor 1/2' -10mm142.5Hexagon bit adaptor 1/2'-14mm142.6Hexagon bit adaptor 1/2' -17mm143Rachet spanner144.1Torque wrench 10-60 Nm144.2Torque wrench 50-300 Nm145Pointed screw M 16 x 201413-2622246Box spanner insert 1/2'-36mm147Hook spanner KM8148.1Extension (long)148.2Extension (short)149Puller, kukko 10-20150Dial indicator151Magnetic fixture for dial indicator152.1Retaining pliers J2152.2Retaining pliers A11

0 notes

Text

WIND TURBINE FASTENERS

WIND TURBINE FASTENERS Ver-bolt has established itself as a market leader, exporting products to the southern hemisphere. Ver-bolt is a customer orientated company, focused on customer requirements in terms of quality, delivery, service and competitiveness. Here are some examples of commonly used fasteners in this sector: TYPES OF PRODUCTS Hex bolts M12 – M72 Foundation bolts Blade connection kits Stud bolts M10 – M72 Tower flange bolts Certified steel construction bolts Threaded rods M10 – M80 Hub & nacelle fasteners EN 14399 / DIN 6914 Construction bolt assemblies TYPES OF MATERIALS Fasteners can be coated with a variety of coatings i.e. Geomet, Hot Dip Galvanizing, etc. Read the full article

0 notes

Text

** งานล้าง, ทดสอบ, ปรับจูน, ทำซับเพล็ทPort รูน้ำมัน และ ติดเบรกวาล์ว มอเตอร์ไฮดรอลิค และ ติดตั้ง **

= Piston Hydraulic Motor=

มอเตอร์ไฮดรอลิค EBARA ชนิด ลูกสูบ รุ่น MFG 105N-67

ขนาดแรงม้า 105 HP , วาล์วไม่เอาถอดออก ทำก้อนซับเพล็ทใหม่

รูยิงน้ำมัน ( Hydraulic Pressure Line ) – 2 รู

รูเดรนน้ำมัน ( Drainage Line ) – 2 รู

หมุนตามเข็ม-ทวนเข็มนาฬิกา หรือ แบบ Reversible ( R ) ก็ได้

= Piston Hydraulic Motor =

มอเตอร์ไฮดรอลิค EBARA ชนิด ลูกสูบ รุ่น MFG 105T

ขนาดแรงม้า 105 HP

รูยิงน้ำมัน ( Hydraulic Pressure Line ) – 2 รู

รูเดรนน้ำมัน ( Drainage Line ) – 2 รู

หมุนตามเข็ม-ทวนเข็มนาฬิกา หรือ แบบ Reversible ( R ) ก็ได้ Speedmax. 135 rpm. W.Pmax. 6,500 psi ( 450 bar )

Item Description Qty.

มอเตอร์ไฮดรอลิค EBARA ชนิด Piston Motor + Brake Valve 1 ชุด @

แปลงจากรุ่น MFG 105N-67 หัวขับแบบ Spline มีรูน้ำมัน 2 Port, รูDrain 2 Port

หมุนตามเข็มนาฬิกา(D) หรือ แบบ Reversible ( R ) ก็ได้ + ติดตั้ง (Installation)

มอเตอร์ไฮดรอลิค EBARA ชนิด Piston Motor + Brake Valve 1 ชุด @

แปลงจากรุ่น MFG 105T หัวขับแบบ Spline มีรูน้ำมัน 2 Port, รูDrain 2 Port

หมุนทวนนาฬิกา(L ) หรือ แบบ Reversible ( R ) ก็ได้ + ติดตั้ง (Installation)

หมายเหตุ : Job. Shaeff Loader KL-41, Hyd. Motor งานล้าง, ถอดประกอบ, ตรวจเช็คทดสอบ, ติดเบรกวาล์ว และ อื่นๆ

งานแปลง Modified Installation จะส่งมอเตอร์ไฮดรอลิคไปที่หน้างานก่อน แล้วทีมติดตั้ง จะตามเข้าไปภายหลัง เพื่อทำการรื้อ-ประกอบ ใหม่

Re :

Modification & Installation of Driving Hydraulic Piston Motors, Roller Chains and Driving Gears for Conveyor belt of Shaeff Loader KL-41 Your request dated 11-July-06 ItemDescriptionQty 1“REXNORD” Roller Chain No. 32B-1 Pitch 50.8 mm. (2.00 Inches) Roller Dia.Ø 29.21 mm., Roller width 30.80 mm. Ultimate strength min. 250,000 Fb N. 10 ft. 2Alternatively : “REXNORD” Roller Chain No. 160 Pitch 50.8 mm. (2.00 Inches) Roller Dia.Ø 28.58 mm., Roller width 31.55 mm. Ultimate strength min. 266,900 Fb N. 10 ft. หมายเหตุ : “REXNORD” / Germany * ขนาดบรรจุ โซ่ มาตราฐานยาว กล่องละ 10 ฟุต

Re : = URGENT = Repairment and Overhaults for KEMCO Shaeff Loader KL-41 Your request dated 14-July-06 on Return Filter Assembly FR12-10-12F , Inlet 40A – Outlet 1.1.2″PT ItemDescriptionQty 1ไส้กรอง (งานสั่งทำ) ขนาด I.D Ø 60 x O.D Ø 89 x L 199 mm.. ฝาทะลุหัว-ท้าย ไส้ในรูกลม 5/0.7 mm. ปลอกนอกข้าวหลามตัด ตัวเนื้อเป็นตะแกรงแสตนเลส เบอร์ 100 ( ความละเอียด 10 µm ) ตีจีบ มียางปะหัว-ท้ายหนา 1 mm. 6 Ea

Re : = URGENT = Repairment and Overhaults for KEMCO Shaeff Loader KL-41 Your request dated 14-July-06 on Return Filter Assembly FR12-10-12F , Inlet 40A – Outlet 1.1.2″PT ItemDescriptionQty 1ไส้กรอง (งานสั่งทำ) ขนาด I.D Ø 60 x O.D Ø 89 x L 199 mm.. ฝาทะลุหัว-ท้าย ไส้ในรูกลม 5/0.7 mm. ปลอกนอกข้าวหลามตัด ตัวเนื้อเป็นตะแกรงแสตนเลส เบอร์ 100 ( ความละเอียด 10 µm ) ตีจีบ มียางปะหัว-ท้ายหนา 1 mm. 6 Ea

ซ่อม กระบอกไฮดรอลิค Bucket J. Shaeff Loader KL-41

ซ่อมเสื้อกระบอกไฮดรอลิค Bucket

เสื้อกระบอก Bore ด้านใน ถูกลูกสูบขูด เป็นรอยสึก ลึกมาก

เปลี่ยนตัดต่อกระบอก ใช้ก้นเดิม

เสื้อกระบอก Ø 130 x Ø 165 x L 35 qty. 1 EA.

ซ่อมลูกสูบ (เชื่อมพอก-ล้างใหม่)

เปลี่ยน ชุดชีลยางสังเคราะห์ และ พลาสติก

ชุดซีลน้ำมัน HYD. Cylinder 80 x 90

ชุดซีลกันฝุ่น HYD. Cylinder 80 x 90

ชุดซีลลูกสูบ HYD. Cylinder 125 x 130

ชุดซีลกันสึก HYD. Cylinder 25 x 95 x 410

High Pressure Seal W.P 5, 075 psi ( 350 bar )

ซ่อมพอร์ตรูน้ำมันเข้ากระบอก

เลาะออก แล้ว เชื่อมต่อฉากตัวใหม่

งานซ่อมกระบอก

กระบอกไฮดรอลิค บึ้งกี่ Bucket Cylinder J.Shaeff Loader KL-41

รูในเสื้อ Bore 130 มิล x แกนโต Rod 80 มิล x ช่วงชัก Stroke 33” จำนวน 1 ลูก

Item Description Qty.

ซ่อมฮาร์ดโครมแกน Ø 80*839 มิล 1 เส้น @

เปลี่ยนตัดต่อกระบอก Ø 130*165*915 มิล ใช้ก้นเดิม 1 ลูก @

ซ่อมลูกสูบ Ø 130 มิล 1 ลูก @

ค่าอะไหล่ ปิ้นหลอด แหวนล็อค 1 ชุด @ ฟรี = 00

โอริง 3 x 60 1 เส้น @

แหวนขาว 5 x 60 2 ตัว @

ซีล U 80 x 90 x 6 1 ตัว @

แหวนรอง 80 x 90 x3 1 ตัว @

กันฝุ่น 80 x 90 1 ตัว @

โอริง 3 x 116 1 เส้น @

แหวนขาว 5 x 125 1 ตัว @

เทปกันสึก 25 x 95 x ยาว 41 ซม. 2 เส้น @

ซีล + โอริง IO OI 2 เส้น @

ค่าแรงถอดประกอบ 1 ชุด @

ข้อต่อฉาก port น้ำมัน + ค่าเชื่อม 1 ตัว @

Re : = URGENT = Repairment and Overhaults for KEMCO Shaeff Loader KL-41 Your request dated 28-July-06 on Hydraulic hose parts to Piston motors ItemDescriptionQty 1สายไฮดรอลิค 4SP-12 Ø 3/4″ W.P 380 bar OL. 2.00 M. BS/BS90 3 เส้น 2สายไฮดรอลิค T2AT-06 Ø 3/8″ W.P 330 bar OL. 1.80 M. BS/BS90 1 เส้น 3สายไฮดรอลิค 4SP-12 Ø 3/4″ W.P 380 bar OL. 1.60 M. BS/BS90 1 เส้น 4สายไฮดรอลิค T2AT-06 Ø 3/8″ W.P 330 bar OL. 1.70 M. BS/BS90 1 เส้น

Re : = CONFIDENTIAL = Repairment and Overhaults for KEMCO Shaeff Loader KL-41 Your request dated 28-July-06 on reserved Hydraulic Piston motors ( Very Heavy Duty Motor ) ItemDescriptionQty 1มอเตอร์ลูกสูบไฮดรอลิค Hydraulic Piston Motor ” EBARA” รุ่น MF105 แรงม้า ( สำรองอะไหล่ สำหรับ Shaeff Loader KL-41 ) เป็นของมือสองสภาพดี พร้อมใช้งานได้ 2 ลูก หมายเหตุ : ราคานี้ไม่รวม ค่าแรง / ค่าเบี้ยเลี้ยง ของทีมงานติดตั้ง ,เบรกวาล์ว,สายไฮดรอลิค, เฟื่องขับ และ โซ่ ฯลฯ สำหรับเป็นอะไหล่ไว้สำรองใช้งานสลับสับเปลี่ยนกัน กรณีที่เครื่องฯ มีปัญหา ส่วนลูกเก่าส่งซ่อมได้ ( รับประกัน 2 เดือน และ ต้องใช้งานอย่างถูกต้องเหมาะสมด้วย )

Re : J. Very heavy duty driving gears and roller chains for Repairment and Overhaults of KEMCO Shaeff Loader KL-41 Your request dated 28-July-06 on Driving Spline Gear ( เฟื่องขับโซ่ ) ItemDescriptionQty 1เฟื่องขับ โซ่ No. 160 HE x 8TB ( กัดเฟื่องนอก Ø OD. 150mm. x Pitch 2″ ) 2 EA 2กัดเฟื่องในแบบ Spline 18 ฟัน x ลึก 2mm. (I.D Ø 35.5 mm.) พร้อมแหวน 2 ตัว สำหรับเฟื่องโซ่ No. 160 HE x 8 TB เข้าเพลา Motor – L 1 EA 3กัดเฟื่องในแบบ Spline 20 ฟัน x ลึก 2mm. (I.D Ø 35.5 mm.) พร้อมแหวน 4 ตัว สำหรับเฟื่องโซ่ No. 160 HE x 8 TB เข้าเพลา Motor – R 1 EA

Re : J. Very heavy duty driving gears and roller chains for Repairment and Overhaults of KEMCO Shaeff Loader KL-41 Your request dated 28-July-06 on Hydraulic Piston Motor Brakes ( เบรควาล์ว สำหรับกันโซ่กวาดหินไหลย้อนกลับเวลามี Load มากๆ )ItemDescriptionQty 1เบรกมอเตอร์ Brake Valve รุ่น VSDI-80.05.16.01-03-04-20 ยี่ห้อ “OIL CONTROL”/Italy ขนาดรูน้ำมัน Ø G 3/4” W.P 250 bar, Incremental Pressure = 27 bar (เบรคเริ่มจะทำงานเมื่อแรงดันต่ำกว่า 27 bar) , Flow rate 80 l/min. 2 EA หมายเหตุ : ติดไ���้ป้องกัน ก้อนหินบนรางขนหิน ของ Shaeff Loader KL-41 ไหลย้อนกลับ เวลาที่มี Load เป็นจำนวนมากๆบนสายพาน หรือ กรณี Overload แล้วเครื่องยนต์ดับ หรือ มีปัญหาทำให้ แรงดัน ใน Pressure Line ตกลง / ป้องกันอุบัติเหตุ ก้อนหินบนสายพานลำเลียงไหลย้อนกลับ ตกลงมา

Re : J. Repairment and Overhaults of KEMCO Shaeff Loader KL-41 Your request dated 8-August-06 on Pressure Guage for Return Hyd. Oil Filter and Connection Link for Roller ChainItemDescriptionQty 1ข้อต่อโซ่ เต็มข้อ Connection Link R2C160-1HE สำหรับต่อโซ่ Heavy Duty Roller Chain No.160 Pitch 2″ 1 EA 2เกจวัดแรงดัน Liquid Filled Pressure Guage 01.10 DS 63 ( 2 ½” ) Range 0 – 10 kgf/cm2 ,Type A Stem mounting lower connection, 1/4“ NPT thread 1 EA 3ข้อลดเหลี่ยมทองเหลือง (ตัวรองเข้าเพรสเซอร์เกจ) Bushing 1/4″PT x 1/2″PT 1 EA

งานซ่อม รถขุดหน้า-สายพานโซ่หลัง ขนหิน J. Shaeff Loader KL-41 **

งานแปลง Modified Installation

ระบบขับสายพานโซ่ ด้วย Hydraulic Piston Motor มอเตอร์ไฮดรอลิค EBARA ชนิด ลูกสูบ

รุ่น MF105 แรงม้า Speed 95 – 130 รอบ / นาที

รถขุดหน้า-สายพานโซ่หลัง ขนหิน

Shaeff Loader KL-41, ลง Hyd. Piston Motor มือสอง , ติดเบรกวาล์ว และ อื่นๆ

งานทำ เฟื่องขับโซ่ No.160 HE x 8 ฟัน กัด Spline รูใน ( OD. Ø 150 mm., Pitch = 2” ) QTY. 2 ชุด + แหวนรองเฟื่อง + แหวนอัดหัวเพลา

เฟื่องขับโซ่สายพาน เตรียมงานตรวจวัด ขนาด และ ประกอบติดตั้ง ที่หน้างาน

กัดจานเฟื่อง สวมปลายเพลา EBARA Hyd. Piston Motor รุ่น MF 105 แรงม้า

Hyd. Piston Motor – L Hyd. Piston Motor – R

ขนาดปลายแกนหมุน มอเตอร์ไฮดรอลิค ชนิด ลูกสูบ รุ่น MF 105 แรงม้า

1) Motor R ปลายเพลา แบบ Spline OD. Ø 39.5 mm. x 18 ฟัน (เหลี่ยมคางหมู) x ลึก 2 mm. x W 49.4 mm.= 1 ตัว ( น็อตล็อคหัวเพลา )

2) Motor L ปลายเพลา แบบ Spline OD. Ø 39.5 mm. x 20 ฟัน (เหลี่ยมคางหมู) x ลึก 2 mm. x W 88.5 mm.= 1 ตัว

งานซ่อม รถขุดหน้า-สายพานโซ่หลัง

ระบบขับสายพานโซ่ ลำเลียงหิน ด้วย มอเตอร์ลูกสูบไฮดรอลิค J.Shaeff Loader KL-41

Modification Installation งานดัดแปลง ด้วย EBARA MF 105 แรงม้า, 95 – 130 รอบ/นาที จำนวน 2 ลูก

Item Description Qty.

มอเตอร์ลูกสูบไฮดรอลิค EBARA MF105 แรงม้า ( มือสอง ) 2 ลูก @

ข้อต่ออะแด็ปเตอร์ 3/4“ PT x 1” PT (12PM-PM16) 4 ตัว @

ข้อต่ออะแด็ปเตอร์ 3/8“ PF x 3/8” PT (06BM-PM06) 1 ตัว @

ข้อต่ออะแด็ปเตอร์ตาไก่ แป็ป 15 มิล x 3/8”PF (15RO22-BM06) 2 ตัว @

โอริง 20 SA 4 เส้น @

ก้อนซับเพล็ท เชื่อมมอเตอร์ x รูใน 1”PT (Subplate PN16) 4 ก้อน @

น็อตยึดตัวหนอนหัวจม M12 x 60 8 ตัว @

น็อต 1/2″ x 3” + แหวนรอง + นัทล็อค 8 ชุด @

โซ่งานหนัก 160-1HE , Pitch = 2” 10 ฟุต @

เฟื่องขับโซ่ 160-1 * 8TB Ø O.D 150mm. x Pitch 2” 2 ชิ้น @

กัดดุมเฟื่อง Spline 18 ฟัน พร้อมแหวน รอง 2 ตัว 1 ชุด @

กัดดุมเฟื่อง Spline 20 ฟัน พร้อมแหวน รอง 4 ตัว 1 ชุด @

ข้อต่อโซ่ เต็มข้อ Connection Link 1Pitch x 2” No. 160-1 HE 2 ชิ้น @

เกจวัดแรงดัน หน้าปัด 1/2” ช่วงวัด 0-10 kgf/cm2, 1/4″PT Lower Conn. 1 ตัว @

ตัวรองลดเหลี่ยมทองเหลือง 1/4″ x 1/2″ PT 1 ตัว @

งานถอดประกอบ ล้าง / ทดสอบ Motor-L EBARA “MF105” 1 ลูก @

งานถอดประกอบ ซ่อม / ทดสอบ Motor-R EBARA “MF105” 1 ลูก @

16.2 เปลี่ยนลูกปืน รางไฟเบอร์ 1 ชุด @

16.3 ล้างชุดลูกปืน เม็ดใน ฯลฯ 1 ชุด @

16.4 ปรับแก้ไข พิกัด วาล์ว, เพล็ท และ บล็อก ฯลฯ 1 ชุด @

16.5 เปลี่ยน ซีลคอ และ โอริ่ง ฯลฯ 1 ชุด @

16.6 ประกอบ พร้อมทดสอบ 1 งาน @

ข้อต่อโซ่ ครึ่งข้อ Offset Link 1Pitch x 2” No. 160-1 HE 2 ชิ้น @

ปลั๊กอุด 3/4 “ PF 5 ตัว @

ปลั๊กอุด 3/8 “ PF 5 ตัว @

เบรคมอเตอร์ VSDI-80 รูน้ำมัน Ø 3/4″ PF 2 ตัว @

Mobilizationไปหน้างาน ค่ารถ ค่าแรง เบี้ยเลี้ยง ล่วงเวลา คนงาน ฯลฯ 3 – 5 คน @

อื่น ๆ ( ยังไม่รวม สายประกอบไฮดรอลิค ฯลฯ ) เช็คตามใบส่งของ @

TOTAL =

Re :Repairment and Overhaults for KEMCO Shaeff Loader KL-41 Your request dated 8-August-06 on Hydraulic hose parts to Piston motors ItemDescriptionQty 1สายไฮดรอลิค 4SP-12 Ø 3/4″ W.P 380 bar OL. 3.50 M. BS x 2 2 เส้น 2สายไฮดรอลิค 4SP-12 Ø 3/4″ W.P 380 bar OL. 3.90 M. BS x 2 2 เส้น 3สายไฮดรอลิค 4SP-12 Ø 3/4″ W.P 380 bar OL. 1.10 M. BS x 2 2 เส้น 4สายไฮดรอลิค T2AT-06 Ø 3/8″ W.P 330 bar OL. 5.50 M. BS x 2 1 เส้น 5ข้อต่ออะแด็ปเตอร์ 3/4″PF x 3/4″PT (12BM-PM12) 8 ตัว

Re :J. Hydraulic Gear Pumps for Spare parts Your request dated 12/1/07 on Hydraulic Gear Pump for Spare-parts ItemDescriptionQty 1Hydraulic Gear Pump 3 ตอน P350-3B 94cc./63cc./63cc.”G.P.M” / South Africa เทียบแทน ยี่ห้อ NADCO รุ่น PHS 3590-3565-3565 AAR หรือ PHS 3575-3555-3555 AGR ก็ได้ ( ลักษณะ ใกล้เคียงกันมาก ถ้าต้องดัดแปลง ก็น้อยมาก ) ** for Shaeff Loader KL-41 drived by electrical motor ** 1 ลูก 2Hydraulic Gear Pump 3 ตอน P330-3B 48cc./48cc./48cc.”G.P.M” / South Africa เทียบแทน ยี่ห้อ NADCO รุ่น PHS 3035-30355-3035 AGR หรือ PHS 3045-3045-3045 AGR ก็ได้ ( ลักษณะ ใกล้เคียงกันมาก ถ้าต้องดัดแปลง ก็น้อยมาก ) ** for Shaeff Loader KL-41 drived by engine ** 1 ลูก 3Hydraulic Gear Pump ตอนเดี่ยว ยี่ห้อ ” CASAPPA “/Italy รุ่น PLP20-25D0-82E2-L0D / 0C-N-EL-FS Flange mounting type, Clockwise rotation มีหน้าแปลนเป็นง่าม (ร่องกว้าง ประมาณ 1 ซม. ) 2 รูยึด เพลาแบบ Spline shaft OD. 14mm x 9 ฟัน x ร่องฟันลึก 2มิล

Re : J. Hydraulic Triplex Gear Pumps for Spare parts Your request dated 21/4/07 on Hydraulic Triplex Gear Pump for Spare-parts ItemDescriptionQty 1Hydraulic Gear Pump 3 ตอน P330-3B 48cc./48cc./48cc.”G.P.M” / South Africa เทียบแทน ยี่ห้อ NABCO รุ่น PHS 3035-30355-3035 AGR หรือ PHS 3045-3045-3045 AGR ก���ได้ ** for Shaeff Loader KL-41 drived by engine ** 1 ลูก 2ตัวเชื่อมต่อเพลา ขนาด Ø 25.4 มม. x 15 ฟัน ( Spline Shaft Connector 1″ SAE B-B ) 1 ตัว Remark : สำรองอะไหล่ ชุดที่ 2 ตรวจสอบ เช็คการทำงานของปั๊มไฮดรอลิค ให้เรียบร้อย ก่อนส่งมอบ แต่ง Shaft / Port ให้เท่ากับชุดที่ 1 หัวเพลา Spline Shaft SAE B-B 1″ x 15T รูน้ำมันไฮดรอลิค เข้า – ออก ตามชุดที่ 1 การหมุน Rotation และ Displacement (CC/Rev.) ตามชุดที่ 1 ใช้สำรองอะไหล่ หัวขุดหิน KEMCO / Japan (Shaeff Loader KL-41) โครงการเขื่อนน้ำงึม 2 , สาธารณะรัฐประชาชนลาว(

Re : J. Hydraulic Triplex Gear Pumps for Spare parts Your request dated 21/4/07 on Hydraulic Triplex Gear Pump for Spare-parts ItemDescriptionQty 1Hydraulic Gear Pump 3 ตอน P350-3B 94cc./63cc./63cc.”G.P.M” / South Africa เทียบแทน ยี่ห้อ NABCO รุ่น PHS 3590-3565-3565 AAR หรือ PHS 3575-3555-3555 AGR ก็ได้ ** for Shaeff Loader KL-41 drived by electrical motor ** 1 ลูก Remark : สำรองอะไหล่ ชุดที่ 1 ตรวจสอบ เช็คการทำงานของปั๊มไฮดรอลิค ให้เรียบร้อย ก่อนส่งมอบ แต่ง Shaft / Cover End Flange , In-Out Port ให้เท่ากับตัวอย่าง No. A38-0010 ปั๊ม 3 ตอน หัวเพลา Spline Shaft และ หน้าแปลนยึด Shaft End Cover ตามตัวอย่าง No. A38-0010 รูน้ำมันไฮดรอลิค เข้า – ออก ตามตัวอย่าง No. A38-0010 ( ยกเลิกตัวอย่าง No. V11-0003 ) การหมุน Rotation(Clockwise) และ Displacement (CC/Rev.) ตามตัวอย่าง No. A38-0010 หมุนตามเข็มนาฬิกา ใช้สำรองอะไหล่ หัวขุดหิน KEMCO / Japan (Shaeff Loader KL-41) โครงการเขื่อนน้ำงึม 2 , สาธารณะรัฐประชาชนลาว

Re : J. Hydraulic Triplex Gear Pumps for Spare parts Your request dated 25/5/07 on Hydraulic Triplex Gear Pump for Spare-parts ItemDescriptionQty 1Hydraulic Gear Pump 3 ตอน P330-3B 40cc./40cc./40cc.”G.P.M” / South Africa เทียบแทน ยี่ห้อ NABCO รุ่น PHS 3035-30355-3035 AGR หรือ PHS 3045-3045-3045 AGR ก็ได้ ** for Shaeff Loader KL-41 drived by engine ** 1 ลูก 2ตัวเชื่อมต่อเพลา ขนาด Ø 25.4 มม. x 15 ฟัน ( Spline Shaft Connector 1″ SAE B-B ) x L 3″ 1 ตัว Remark : สำรองอะไหล่ ชุดที่ 3 ตรวจสอบ เช็คการทำงานของปั๊มไฮดรอลิค ให้เรียบร้อย ก่อนส่งมอบ แต่ง Shaft / Port ให้เท่ากับชุดที่ 2 หัวเพลา Spline Shaft SAE B-B 1″ x 15T รูน้ำมันไฮดรอลิค เข้า – ออก ตามชุดที่ 2 การหมุน Clockwise Rotation และ Displacement (CC/Rev.) ตามชุดที่ 2 หมุนตามเข็มนาฬิกา ใช้สำรองอะไหล่ หัวขุดหิน KEMCO / Japan (Shaeff Loader KL-41) เครื่องที่ 2 โครงการเขื่อนน้ำงึม 2 , สาธารณะรัฐประชาชนลาว(

ชิ้นส่วนอะไหล่ Hydraulic Tripple Gear Pump **

โครงการเขื่อนน้ำงึม 2 สปช.ลาว ** งาน J. Hydraulic Tripple Gear Pumps for KEMCO Shaeff Loader KL-41 Spare parts

Spare parts for Hyd. Triple Gear Pump “G.P.M” Model : P330-3B 40cc./40cc./40cc.

W.P 245 bar ( 3,553 PSI ) ขนาดเกียร์ Gear Width No. 12 / 12 / 12 , ความเร็วรอบ Speed 900 – 3,000 rpm

Item Description Qty.

Part No.3, 7,10 Seal Kit P330-3B 2 ชุด @

Part No.8 Thrust Plates P330 2 ตัว @

Part No.9 Drive Shaft P330 GW 1.1/4”-15T 1 ตัว @

Part No.12 Gear Housing P330 GW 1.1/4”-4-40CC 1 ตัว @

Spare parts for Hyd. Triple Gear Pump “G.P.M” Model : P350-3B 73cc./52cc./52cc.

W.P 245 bar ( 3,553 PSI ) ขนาดเกียร์ Gear Width No. 17 / 12 / 12 , ความเร็วรอบ Speed 900 – 2,400 rpm

Item Description Qty.

Part No.3, 7, 10 Seal Kit P350-3B 2 ชุด @

Part No.8 Thrust Plates P350 2 ตัว @

Part No.9 Drive Shaft P350 GW 1.3/4”-10T 1 ตัว @

Part No.12 Gear Housing P350 GW 1.3/4-73CC 1 ตัว @

Part No.12 Gear Housing P350 GW 1.3/4-52CC 1 ตัว @

TOTAL =

Re : J. งานซ่อม รถขุดหน้า-สายพานโซ่หลัง ขนหิน J. KEMCO Shaeff Loader KL-41 Your request dated 26/7/07 งานเปลี่ยนขับโซ่ No.160 HE , Pitch = 2” 2 units of KEMCO Shaeff Loader KL-41 ItemDescriptionQty 1.1โซ่งานหนัก No.160-1HE , Pitch = 2” : Roller Chain ” Rexnord” / Germany ( by sea freight ) 300 ฟุต 1.2โซ่งานหนัก No.160-1HE , Pitch = 2” : Roller Chain ” Rexnord” / Germany ( by air frieght ) 300 ฟุต 2ข้อต่อโซ่ เต็มข้อ Connection Link 1Pitch x 2” No. 160-1 HE 2 ตัว 3ข้อต่อโซ่ ครึ่งข้อ Offset Link 1Pitch x 2” No. 160-1 HE (งานทำ) 4 ตัว หมายเหตุ : ต่อโซ่ @ 10 ft./กล่อง x ข้างละ 7.5 เส้น x 2 ข้าง x 2 คัน = 300 ฟุต ถ้าโซ่ตึงไม่หย่อน เกินไป ใช้ ข้อต่อโซ่เต็มข้อ เชื่อม 8 ข้อ x 2 ข้าง x 2 คัน = 32 ตัว ( ในโซ่แต่ละกล่องมีข้อต่อโซ่ แถมให้อยู่แล้ว กล่องละ 1 ตัว x 10 กล่อง = 30 ตัว ) , ซื้อเพิ่มอีก 2 ตัว ถ้าโซ่ไม่ตึง หย่อนเกินไป ใช้ ข้อต่อโซ่เต็มข้อ เชื่อม 7 ข้อ x 2 ข้าง x 2 คัน = 28 ตัว + ข้อต่อโซ่ครึ่งข้อ เชื่อม 1 ข้อ x 2 ข้าง x 2 คัน = 4 ตัว ใช้งานเปลี่ยนขับโซ่ No.160 HE , Pitch = 2” รถขุดหน้า-สายพานโซ่หลัง ขนหิน KEMCO Shaeff Loader KL-41 จำนวน 2 คัน โครงการเขื่อนน้ำงึม 2 , สาธารณะรัฐประชาชนลาว

Re : ** สำรองอะไหล่ Return Oil Filter รุ่น FR12-10-12F สำหรับ Shaeff Loader KL-41 ** Your request dated 16/11/07 โครงการน้ำงึม 2 สปช. ลาว ItemDescriptionQty 1ไส้กรองน้ำมัน ขนาด 89x60x199 mm. ฝาทะลุหัว-ท้าย ปลอกนอก ข้าวหลามตัดไส้ในรูกลม 3/0.7 มม. ชุบซิงค์ตัวเนื้อเป็นตะแกรงแสตนเลส เบอร์ 100 ตีจับ 60 จีบ มียางปะหัวท้ายหนา 1 มม. 3 ลูก สำหรับเป็นอะไหล่เปลียนไส้ใน Return Oil Filter รุ่น FR12-10-12F W.P 10 bar (150 PSI) ความละเอียด (Finess) 10 µm. ( ไมครอน ) ขนาดไส้กรอง Ø ID. 60 x Ø OD. 89 x L 199 ใช้กับ Shaeff Loader KL-41

Re : = Repairment and Overhaults for KEMCO Shaeff Loader KL-41 Your request dated 16-October -06 on Hydraulic axial piston motors ( Slow speed – Torque Motor ) ItemDescriptionQty 1มอเตอร์ลูกสูบไฮดรอลิค Hydraulic Fixed Displacement Motor ( Low Speed Axial Piston Motor ) Type : MCS-5-750 ความเร็วรอบ 103.73 รอบ / นาที ที่ อัตราไหล Flowrate 77.8 ลิตร/นาที เพลาแบบลิ่ม Straight Shaft Ø O.D 50 x L 70 แรงบิดสูงสุด 2,636 นิวตัน-เมตร ที่ความเร็วรอบ 200 รอบ / นาที หน้าแปลน เข้า-ออก ขนาด Ø 2″ , รูเดรน Ø 1/2″เกลียวใน 2 ลูก

งานซ่อม รถสายพานโซ่ขนหิน และ ซ่อมโซ่กวาดหิน Shaeff Loader KL40 , KL41 ** งานล้าง, ทดสอบ, ปรับจูน, ทำซับเพล็ทPort รูน้ำมัน และ ติดเบรกวาล์ว มอเตอร์ไฮดรอลิค และ ติดตั้ง ** = Piston Hydraulic Motor= …

#คำถาม . Case Study#งานซ่อมบำรุง ปรับสภาพ#case reference#Case Study#Hydraulic Motor Recondition#Maintenance-Recondition-Overhaults ( MRO )#Recondition Work#Recondition Work Lao Project#Spare-parts and MRO ( Maintenance-Replacement-Overhaults ) divisions

0 notes

Video

youtube

Stainless Steel Threaded Rod Manufacturer In Mumbai

Micro Metals is PED Manufacturer of Stainless Steel Threaded Rod manufacturers in India. We produce A2-70 Threaded Rod, 18-8 Stainless Steel Threaded Rod, 304 Stainless Steel Threaded Rod, Stainless Steel Threaded Weld Studs ISO 13918, and Stainless Steel Double End Studs DIN 939 in Mumbai. We are specialist in A2 Stainless Steel Threaded Rod, in various sizes including M2, M2.5, M3, M4, M5, M6, M8, M10, M12, M14, M16, M20, M24, M30, M36 to M160. We are BHEL and ONGC approved supplier of Duplex 2205 Threaded Rod. We are one of the largest exporter of 410 Stainless Steel Threaded Rod. View our type of 18-8 Stainless Steel Threaded Rod price list. We also Manufacture SS 304 Hex Threaded Bar. We also Stock A2 Threaded Rod. Call us for free sample of 304 SS Threaded Rod. for more sizes in ready stock and Price List

click on below link. http://bit.ly/2MFZusL

Follow Us On Twitter : http://bit.ly/2R58cz7

Instagram : http://bit.ly/2Zk1wAg

Pinterest : http://bit.ly/2IwyVRi

0 notes

Video

youtube

FIXDEX GOODFIX industrial cologne exhibition in germany

#youtube#Cologne Germany#FASTENER EXPO 2024#FIXDEX GOODFIX#Wedge Anchor Fastener#M8 Threaded Rod#M12 Threaded Rod#Chemical Bolt M16#Toggle Bolts#M16 Drop In Anchor#U Foundation Bolt#Spring U Bolts#square nuts#din 928#slotted steel#c channel#slotted c channel#concrete fixings#stainless steel concrete screws#concrete anchors bolts#concrete bolt

0 notes

Text

SP132769 LR.020041 LR.020042 SP133932 MAIN BEARING 0.50 YTO PARTS

SP132769 LR.020041 LR.020042 SP133932 MAIN BEARING 0.50 YTO PARTS

52321000701 GB/T297 轴承30207 Bearing 52321001101 GB/T297 轴承30211 Bearing 56161006501 GB/T13871.1 密封圈FB85×110×12 Seal ring FB85×110×12 30003129501 LG0030D.03.02.01-011 轮毂螺栓 Hub 56201000101 JB/T7940.1 油杯M6 Oil cup M6 30003034201 LG0030D.03.02.01.03 转向拉杆 Steering pull rod weldment 51107232307 GB/T78 螺钉M12×35 Screw M12×35 51311001025 GB/T6172.1 螺母M12 Nut M12 51207121518 GB/T5786 螺栓M14×1.5×45 Bolt M14×1.5×45 51401120107 GB/T93 垫圈14 Spring lock washer 14 51422120115 GB/T97.2 垫圈14 Washer 14 51513131202 GB/T119.1A 圆柱销10×20 Thread pin10×20 30003133001 LG0030D.03.02.01-012 销 Pin 30003123303 LG0030D.03.02.01-013 挡圈 Snap 52806000101 GB/T9163 轴承GEEW16ES Bearing GEEW16ES 16600145840 LG330.06.03 3T转向油缸 Steering cylinder 51207111414 GB/T5786 螺栓M12×1.5×40 Bolt M12×1.5×40 51316000418 GB/T6176 螺母M12×1.5 Nut M12×1.5 30003033904 LG0030D.03.02.01.05 转向节 Left steering knuckle 30003129401 LG0030D.03.02.01-014 轮毂螺母 52807002201 GB/T9163 轴承GE16ES Bearing GE16ES 30003111306 LG0030D.03.02.01-015 调整垫片 Adjustment gasket 30003109004 30D-0311001 减震垫 Damping cushion 60205000169 LG0015D.02.01.01 轮胎总成6.5-10-10PR Tire assembly 1 60205000020 GB/T2982 轮胎总成6.00-9-10PR Tire assembly 1 60205000157 LG0030D.03.03.01 内轮辋总成5.00F-10 Rim assembly 60205000163 20D-0301001 内轮辋总成4.00E-9 Rim assembly 60205000021 LG0030D.03.03.03 外轮辋总成5.00F-10 Rim assembly 60205000164 20D-0301002 外轮辋总成4.00E-9 Rim assembly 30003111103 30D-0321001 螺栓 Bolt 8 51401110107 GB/T93 垫圈12 Washer 12 51421110115 GB/T97.1 垫圈12 Washer 12 51307001119 GB/T6170 螺母M12 Nut M12 51204091714 GB/T5783 螺栓M8×55 Bolt M8×55 51307000919 GB/T6170 螺母M8 Nut M8 60800000249 30DⅢ-0400001 杆 Rod 51421080115 GB/T97.1 垫圈6 Washer 6 51512061201 GB/T91 销2×25 Pin 2×25 51204080914 GB/T5783 螺栓M6×16 Bolt M6×16 51401080107 GB/T93 垫圈6 Washer 6 51307000819 GB/T6170 螺母M6 Nut M6 51204101314 GB/T5783 螺栓M10×35 Bolt M10×35 51401100107 GB/T93 垫圈10 Washer 10 60700000391 30DⅢ-0401000A 油��支架总成 Throttle bracket assembly 60700000392 30TAⅢ-0401000 油门支架总成 Throttle bracket assembly 60800000248 30DⅢ-0402000 踏板总成 Pedal assembly 60207020225 LG0030DTIG.04.01 拉索总成 Pull cable Read the full article

0 notes