#m20 threaded rod

Explore tagged Tumblr posts

Video

youtube

Say goodbye to loosening troubles! Goodfix & Fixdex GROUP anchor bolts provide you with a long-lasting and reliable fastening solution

if you interested fastener anchor bolt, click here to see more https://www.fixdex.com/products/

#youtube#threaded bar#m10 threaded rod#threaded stud#m20 threaded bar#b7 threaded rod#threaded rod anchor#m20 threaded rod#galvanized threaded rod#concrete wedge anchors#wedge anchor bolts#wedge bolt#expansion anchor#concrete anchor bolts#threaded rod#welding rod#stainless steel threaded rod#12mm threaded rod#fixdex#goodfix

0 notes

Text

Name: Titanium fastener

Specification: M20*80

Brand: TC4 /Gr5

Standards: HG/T3651-99,GB/T12459,GB/T13401

Product process: Vacuum melting a forging a rolling a quenching heat treatment a blowing a rough shape a end face a milling six aspects a pliers deburring a rolling thread a hexagonal turning thread bottom hole a aging heat treatment a hexagonal turning internal thread a hexagonal turning internal thread correction (to remove the residue in the thread hole) a fine turning rod a hexagonal turning internal thread correction - a cleaning a inspection a storage..

Whatsapp + 86 183 9274 3987

0 notes

Text

Because I'm trying to not waste my time with YT comments, I'll tell y'all that doing wheel alignments by calculating how many turns you need to do on the tie rod is absolutely a fabulous idea because it's just straight math.

Using a line to establish the toe measurement of the wheel, then using the two deviation measurements to deduce how far from 0 deg you are is simple. Then the adjustment you need to make can be derived from the thread pitch of your tie rod.

The best part is the bolt doesn't care about anything other than how many degrees of rotation you put on it (ie turns). A 2.5mm pitch means one turn is 2.5mm of linear travel, while a 64 TPI means you need 64 turns to move one inch. Just take how much you're skewed off and then calculate how many turns you need. That should get you within factory tolerance every time.

The only reason measures are in degrees and minutes instead is because it's a standard way to define the specification. Along with the related tools and measuring devices, it also reduces the necessary skill level for the procedure. Just turn the bolt until it reads what you want. It's simple and repeatable with minimal effort. But you can still get the job done if you put in effort and use your head.

Just to get some numbers in here, a deviation of a degree six inches from center is about 3/8ths (~9.5mm) which would be if you had 12in rims. Factory tolerance is often about 10 to 15 minutes which is a sixth to a quarter of a degree. For convenience, a quarter degree then is 3/32nds (~2.38mm). A typical M20 x 2.5mm bolt which is comparable to a tie rod end, as stated above, moves 2.5mm linearly for every turn. That is about 0.675mm (very nearly 4 thousandths of an inch) per quarter turn. the point of the example is that you can very easily get within spec with some string, a cheap caliper, and a little math. Requisite napkin math warning, I didn't calculate the deviations but measured them from a less than ideal set of lines I drew with a compass and ruler. But for illustration it's plenty good.

#long post is long#but I hope the mechanically inclined out there gained something#the reason you'd wanna do the brain work is so you only have to make one maybe two adjustments at most#you could very well just go in quarter turns and check every time but that's incredibly wasteful compared to ten minutes or so of math

0 notes

Text

How to Create an Eye Bolt: Eye Bolt Suppliers in Mumbai

Delta Fitt Inc. is a prominent Eye Bolts Suppliers In Mumbai. Making an eye bolt from scratch is a complex manufacturing process for Eye Bolt Manufacturer in Mumbai that requires specialised equipment and materials. It's not something that can usually be done in a conventional home workshop. I can, however, give you a simplified outline of the stages required in creating an eye bolt; nevertheless, keep in mind that this is a very simplified version of the genuine industrial process.

Materials and Tools:

Steel rod or bar stock

Heat source (e.g., propane forge)

Anvil

Hammer

Tongs

Thread-cutting die and tap

Drill press

Steps:

Material Selection: Choose a suitable steel rod or bar stock. The material should be strong enough to handle the intended load. Common materials include stainless steel, carbon steel, and alloy steel.

Heating: Heat the steel rod in a propane forge or other suitable heating equipment until it reaches a malleable temperature. This is typically in the range of 1,600 to 2,200 degrees Fahrenheit (870 to 1,200 degrees Celsius).

Forging the Eye: Once the steel is heated, place it on the anvil and use a hammer to shape one end into an eye. The eye can be round or oval, depending on your design. Continue shaping and hammering until you achieve the desired eye shape.

Cutting: After forging the eye, use a hacksaw or other cutting tool to cut the rod to the desired length for the eye bolt.

Threading the Shank: To create threads on the shank of the eye bolt, you'll need a threading die and tap. Secure the shank in a vise and carefully thread it using the die and tap. Ensure that the threading is straight and accurate.

Heat Treatment: Heat the eye bolt to a specific temperature (annealing or tempering) and then cool it slowly to improve its mechanical properties and toughness. The exact temperatures and cooling process depend on the type of steel you're using.

Surface Finish: You can choose to finish the eye bolt to enhance its resistance to corrosion. Common surface finishes include galvanization, painting, or simply cleaning and oiling the surface to prevent rust.

Quality Inspection: Thoroughly inspect the eye bolt to ensure it meets the required specifications and quality standards. Check the dimensions, threading, and overall quality.

Packaging: Once the eye bolt passes inspection, package it for storage or transportation. Packaging can include placing it in containers or bags to protect it.

We Also a best Manufacturer and Suppliers in such Cities

Eye Bolts Manufacturer in Rajkot

Eye Bolts Manufacturer in Ludhiana

Eye Bolts Manufacturer in Pune

Eye Bolts Manufacturer in Ahmedabad

Eye Bolt Manufacturers in Delhi

Eye Bolts Supplier in Mumbai - Delta Fitt Inc

Delta Fitt Inc. is an Eye Bolt Manufacturers in Mumbai it specialises as a Eye Bolts Manufacturers In Mumbai for high-quality eye bolts and associated hardware goods.We take great pride in offering an assortment of eye bolts designed to satisfy various industrial requirements. We supply some of the greatest bolts to a range of companies throughout the globe.

They may be customized to the customer's specifications and available in a variety of sizes, shapes, and dimensions. As a leading Ring Bolts or Eye Bolts Manufacturer, our products are widely used in various industries.

Delta Fitt Inc understands the significance of versatility, which is why we stock an expansive variety of shoulder eye bolts, M16 eye bolts, 1/2 eye bolts and stainless eye bolts - plus oval eye bolts and galvanised eye bolts.

At Delta Fitt Inc, our commitment to customer satisfaction extends far beyond just our selection of M20 eye bolts - these range from eye foundation bolts, forged eye bolts and stainless steel eye bolts - we even stock small 5/16 eye bolts, gate eye bolts and long eye bolts to fulfil any customer need.

Also see our Washer Weight Chart in Kg

Website: deltafitt.com

Product: Eye Bolts Manufacturer in Mumbai

Other Sources: Carriage Bolt Manufacturer in India, Stud Bolt Manufacturers in India.

0 notes

Text

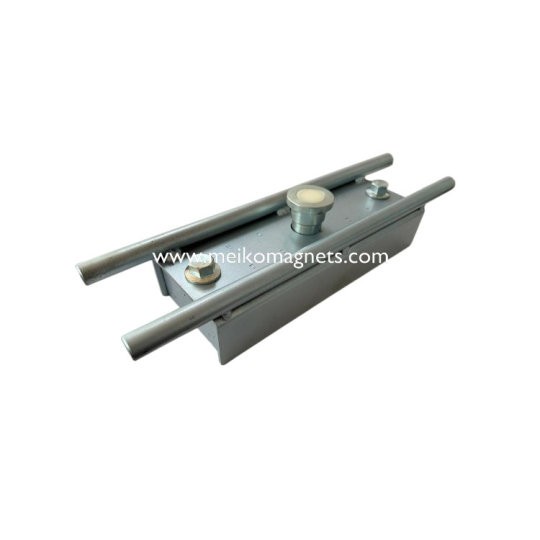

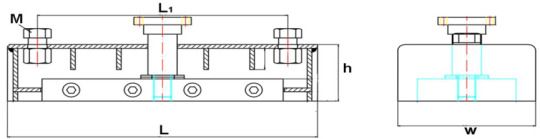

Precast Concrete Push Pull Button Magnets with Sided Rods, Galvanized

Precast Concrete Push/Pull Button Magnet is the standard magnetic fixing solution for holding precast framework on the steel table. It's widely used for steel, wooden/plywood frames with or without extra adaptors. This type button magnets with two sided rods could be put into the steel frame directly, no extra adaptors required. It's produced with steel casing with welded steel rods, and switchable spring button integrated magnetic system. Profiting by the emerged super neodymium magnet block, it could afford powerful and incessancy retaining force against the framework from silding and moving issues. Owing to maximize the performance of magnetic force, the critical point is to clean out any small crushed concrete or ferrous nails and stuffs under magnet before installation. In front of pushing down the spring button, put the magnets into the right position and make the sided rods hanging on the framework grooves, no more extra welding or bolting needed. The follow-up operation is only to depress the button and it works now. After demoulding, better to use a special lever tool to release the button.

As a professional shuttering magnets manufacturer in China, Meiko Magnetics are serving and participating in hundreds of precasting projects by outputting our professional knowledge and qualified products on magnetic system concerning on precast filed. Here you can find all required magnets for your easier and more efficient fixing solutions in the modular construction.

Standard Dimensions ITEM NO. L W h L1 M Adhesive Force Net Weight mm mm mm mm kg kg SM-450 170 60 40 136 M12 450 1.8 SM-600 170 60 40 136 M12 600 2.0 SM-900 280 60 40 246 M12 900 3.0 SM-1350 320 90 60 268 M16 1350 6.5 SM-1500 320 90 60 268 M16 1500 6.8 SM-1800 320 120 60 270 M16 1800 7.5 SM-2100 320 120 60 270 M16 2100 7.8 SM-2500 320 120 60 270 M20 2500 8.2 Advantages -High Forces from 450KG to 2500KG in small body, save the space of your mold extremely -Integrated automatic mechanism with steel springs for easier operation -Welded threads M12/M16/M20 to adapt required form-work fixture -Multi-functions magnets for different purpose -Various type of adapters are equipped to match your side rail profile, no matter wooden, plywood, steel, aluminum mold.

Read the full article

#PrecastBoxMagnets#PrecastButtonMagnets#PrecastConcreteMagnets#PrecastMoldMagnet#PrecastPushPullButtonMagnets#PrecastPushPullMagnets#PrecastSwitchableButtonMagnet#PrecastSwitchablePull/PushMagnet#ShutteringMagnets#ShutteringMagnetswithAdaptor#SideRodsPrecastMagnets

0 notes

Text

Nickel Aluminium Bronze NES 833 Part 2 - Ananka Fasteners

Ananka Group is a leading Aluminium Bronze Fasteners Manufacturer in India, producing a wide range of Aluminium Bronze Fasteners in various sizes, grades, and scales. Our Aluminium Bronze Fasteners are manufactured by national & international standards. C614 Aluminum Bronze Studs are alloyed with zinc and have higher corrosion resistance to high-velocity seawater. Ananka Group is a manufacturer of all kinds of metal products. We are in the industry for several years.

Our Aluminum Bronze Threaded Rod can be used in high wear and tear applications. We offer various sizes of studs, screws, rods, and fasteners in the aluminum bronze range. We produce the most popular grade C63000 Aluminium Bronze Bolts And Nuts which are used in seawater applications and marine applications for high shock resistance and abrasion resistance.

Specifications of Aluminum Bronze Fasteners

Aluminum Bronze Alloy Fasteners Material Specification:- C63000 Nickel Aluminum Bronze Plow Bolts, UNS C62300 Bolts

Aluminum Bronze Fasteners / Bolts Standard:- DIN, UNI, ISO, JIS, GB, IS, BS, ASME, ANSI, ASTM and all International Standards

C61400 Aluminum Bronze Fasteners/ Bolts Size:- M2, M2.5, M3, M4, M5, M6, M8, M10, M12, M14, M16, M20, M24, M30, M36 to M160

Length of C955 Aluminum Bronze Hex Cap Screw:- 3 mm to 200 mm

C614 Aluminum Bronze Bolts, Studs Threads:- METRIC, BSW, BSF, UNC, UNF or as required

C630 Nickel Aluminum Bronze Allen Cap Screw Standard:- ANSI – American National Standards Institute - ANSI B 18.2.4 2M, ANSI B 28.2.4 1M, Aluminum Bronze Alloy Stud Bolt length are defined in ASME B16.5 standard, Aluminum Bronze Hex nuts are defined in ASME B18.2.2, ASME B18.5 DIN: 931, 933, 934, 970 UTS – Unified Thread Standard: UNC, UNF, UNEF, UNS, NPT, NPTF ISO – International Organization for Standardization: ISO 4032, ISO 4033, JIS standards

Source of Raw Materials to Manufacture Cual10ni5fe4 Aluminum Bronze Socket Cap Screw:- Tata Steel, JSPL, RINL, Usha Martin, Dhamm Steel, Mukund Steel, etc.

Scope:- Manufacturer of Hot Forged C955 Nickel Aluminum Bronze Hex Cap Screws, Nut / Bolt; up to M36 / 1-1/2” Dia, up to 1100mm lg, Manufacturer of CNC Machined Aluminum Bronze Fasteners, Nut / Bolt; up to M100 / 4” Dia, up to 1500mm lg

Uns C61400 Aluminum Bronze U Bolt in Form Of:- Hex, Square, Round, Threading as per Gauge Etc.

Head Drive:- Phillips, Slotted, Phillips/Slot, Six-Lobe, etc.

Aluminum Bronze Alloy Hex Bolt Thread:- Metric Coarse

Aluminum Bronze Bolting Test Certificate:- Manufacturer Test Certificate as per EN 10204 / 3.1

C63000 Nickel Aluminum Bronze Bolts Types:- Aluminum Bronze Alloy Hex Bolts, Flange Bolts, Hex Head Bolts, Lag Bolts, Square Bolts, Eye Bolts, U Bolts, T Bolts, Countersunk Bolts, etc.

C955 Aluminum Bronze Nut Types:- Aluminum Bronze Alloy Hex Head Nut, Eye Nut, Dome Nut, Wing Nut, T Nut, Panel Nut, Lock Nut, Coupling Nut, Square Nut, Acorn Nut, etc.

Aluminum Bronze Alloy Screws Types:- Aluminum Bronze Alloy Hex Head Cap Screws, Socket Set Screws, Anchor Screws, Blind Rivet, Socket Head Screws, Concrete Screws, Shoulder Screws, Panel Screws, Threaded Screws, Machine Screws, etc.

Aluminum Bronze Washer Types:- Aluminum Bronze Alloy Machine Washers, Flat Washer, Star Washers, Sealing Washer, Lock Washer, Split Washer in India

Nickel Aluminum Bronze Alloy Fasteners Packing:- IN BULK: canton, pallet, Small Box’s / carton/pallet, or customer request

Ready Stock Available Metric Aluminum Bronze Fasteners Aluminum Bronze Alloy Bolts M16 x 65mm DIN933 Aluminum Bronze Bolts M16 x 45mm DIN933 C61400 Aluminum Bronze Hex Nut M16 C63000 Aluminum Bronze Washer M16 C614 Aluminum Bronze Bolts M16 X 60mm C959 Aluminum Bronze Bolts M16 X 55mm C62300 Aluminum Bronze Bolts M16 X 35mm C63000 Nickel Aluminum Bronze Bolts M12 X 90mm C955 Aluminum Bronze Bolts M12 X 70mm C630 Nickel Aluminum Bronze Bolts M20 x 70mm Cual10ni5fe4 Aluminum Bronze Bolts M20 x 75mm

Source:- https://anankafasteners.com/aluminium-bronze-fasteners-manufacturer-india/ Call & WhatsApp:- +91 83690 74984 Mail:- [email protected] Website:- https://anankafasteners.com/

#nickel#bronze#aluminum#hex#screw#hdg#manufacturer#supplier#fasteners#ananka#anankafasteners#screwhead#uk#usa#uae#mumbai#gujarat#chennai#delhi#russia#italy#france

2 notes

·

View notes

Text

How to measure bolt standards?

Bolt introduction:

Bolts: mechanical parts, cylindrical threaded fasteners with nuts, a type of fasteners composed of two parts, the head and the screw (cylinder with external threads), which need to be matched with the nut for tightening Two parts with through holes are firmly connected.

This connection form is called bolt connection. If the nut is unscrewed from the bolt, the two parts can be separated, so the bolt connection is a for detachable connection.

1. Measuring bolt

Knowing how to find the diameter and length of the fastener is an important first step in obtaining the correct fastener.

2. Measuring bolt diameter

To measure the diameter of screws and bolts, measure the distance from the external thread on one side to the external thread on the other side. This is called the large diameter and is usually the appropriate size for the bolt. You can also measure from one side to the other side of the threaded bottom cavity to find the smaller diameter.

Simple method (not precise enough)

Use vernier calipers and bolts to measure the thread of the outer dao, and the nut to measure the bottom of the thread of the screw. According to the measured value, use the closest standard size.

Easier way

Find a set of fixed-value bolts and nuts (the principle is the same as the plug gauge), and then use these standard items and the matching you want to measure (for example, use m20 bolts to measure suspected m20 nuts, if they can be screwed together, then Explain that the nut is m20), it is very convenient to know.

Measurement of hexagon bolts:

To measure hexagonal bolts, you must use a caliper. The measuring method is generally to measure the thread diameter and thread length. If it is half-threaded, in addition to measuring the thread length, the diameter of the light rod and the total length of the polished rod and the thread are also measured.

The diameter of the polished rod and the diameter of the thread can be compared to determine whether this screw needs to be reduced.

After the thread is measured, the pitch can be measured, And then measure the head. If it is a hexagonal head, you need to measure the opposite side of the hexagon. The diagonal can be measured but not because the opposite side can be calculated. Then measure the thickness of the hexagon again.

If it is an internal hexagon, not only the opposite side of the hexagon, but also the depth of the hexagon, then the diameter and thickness of the head.

0 notes

Text

4110000460 absorber SDLG

4110000460 absorber SDLG TD-B02223 TA700.55A.7 FT300.55B.029 FT700.55D.029 JBT982-8 FT700.55D.129 FT300.55B.165 FT300.55B.166 GBT91-3.2X16-A0P TD800.55B-02 GBT93-12-A0P FT700.55D.147 JBT982-8 TD800.55B.4 FT800.55.120a GBT5783-M12X40-A3L FT800.55.119b GBT91-4X36-A0P GBT6181-M20-A9L GBT6181-M20-A9L GBT5781-M8X30-A2L GBT93-16-A0P GBT6170-M16-A2L TD800.55D.1 GBT899-GM16-M16X50-8.8-A3L RISER KIT PLUG,THREADED OIL PIPE PLUG ASSEMBLY HANDLE WHEEL ASSEMBLY I COMBINED GASKET COVER PLATE TENSION RUBBER SLEEVE ADJUSTING NUT PIN BOLT SPRING WASHER HOLLOW BOLT COMBINED GASKET BREATH CONNECT STEEL PIPE ASSEMBLY CONNECTING BOLT BOLT UPPER PULL ROD SUPPORT SEAT PIN NUT NUT BOLT SPRING WASHER NUT LIFTER ASSEMBLY 8.8-A3L STUD TA700.55.4 2011.10.15 TD800.55B.2 GBT93-8-A0P Q67516 TD800.55B.3-01 GBT5783-M8X16-A2L GBT97.1-8-A0P TD800.55B.3 FT700.55D.136 FT700.55D.136 GBT893.1-26 FT650.40.167 FT700.55D.109 TD800.55B.3.1 GBT3452.1-34.5X2.65G DIPSTICK Email:[email protected] Wechat/whatsapp:0086-1301 3515 908 Read the full article

0 notes

Video

youtube

Stainless Steel Threaded Rod Manufacturer In Mumbai

Micro Metals is PED Manufacturer of Stainless Steel Threaded Rod manufacturers in India. We produce A2-70 Threaded Rod, 18-8 Stainless Steel Threaded Rod, 304 Stainless Steel Threaded Rod, Stainless Steel Threaded Weld Studs ISO 13918, and Stainless Steel Double End Studs DIN 939 in Mumbai. We are specialist in A2 Stainless Steel Threaded Rod, in various sizes including M2, M2.5, M3, M4, M5, M6, M8, M10, M12, M14, M16, M20, M24, M30, M36 to M160. We are BHEL and ONGC approved supplier of Duplex 2205 Threaded Rod. We are one of the largest exporter of 410 Stainless Steel Threaded Rod. View our type of 18-8 Stainless Steel Threaded Rod price list. We also Manufacture SS 304 Hex Threaded Bar. We also Stock A2 Threaded Rod. Call us for free sample of 304 SS Threaded Rod. for more sizes in ready stock and Price List

click on below link. http://bit.ly/2MFZusL

Follow Us On Twitter : http://bit.ly/2R58cz7

Instagram : http://bit.ly/2Zk1wAg

Pinterest : http://bit.ly/2IwyVRi

0 notes

Video

youtube

The simplest way to connect wooden boards is to use a #threaded rod #fastener

click here to see more threaded rod product

#youtube#threaded rods#welding rod#all thread rod#stainless steel threaded rod#threaded bar#threaded stud#m8 threaded rod#m12 threaded rod#m16 threaded rod#galvanized threaded rod#m20 threaded rod#fixdex threaded rod#goodfix threaded rod#threaded steel rod#m6 threaded bar

0 notes

Text

Name: Titanium fastener

Specification: M20*80

Brand: TC4 /Gr5

Standards: HG/T3651-99,GB/T12459,GB/T13401

Product process: Vacuum melting a forging a rolling a quenching heat treatment a blowing a rough shape a end face a milling six aspects a pliers deburring a rolling thread a hexagonal turning thread bottom hole a aging heat treatment a hexagonal turning internal thread a hexagonal turning internal thread correction (to remove the residue in the thread hole) a fine turning rod a hexagonal turning internal thread correction - a cleaning a inspection a storage..

Whatsapp + 86 183 9274 3987

0 notes

Text

Rope Bridge project at Middle East's biggest resort

Salwa Resort, Abu Samra, Qatar

The Dahab Mountain Water and Adventure Park - Salwa Beach Resort, Doha is set to become the Middle East’s premier destination beach resort, located on three million square meters of prime coastline in the southwest corner of Qatar less than 100 kilometres from Doha. With sweeping views of the Arabian Gulf, this ambitious 362-key property will feature a wide range of remarkable facilities, including three kilometres of private beach, a luxury marina and yacht club, a themed water park, a dive centre, cinemas, a shopping mall, an Arabian village, a 2,800 square meter spa and health club, and much more. The complex is expected to open in 2019. The Hilton Salwa Beach Resort & Villas, Qatar is expected to be the largest of its kind in the Middle East and a first for Qatar.

The Salwa Resort is designed to become one of the largest resorts and residential projects in Qatar. Constructed on 257 acres of land in the Salwa area, the beach resort and villas is a massive project that includes a water park, marina, dive centre, cinemas, pools, a health club, spa and a considerable retail space. In addition to the rooms and suites in the main hotel building, the resort will also include two small ‘villages’ of family villas.

Project requirements:

Adventure Play Area

3 Rope Bridges [each around 7m length] to be suspended at a height of around 7m between concrete and steel structures.

A 10m length Net Tunnel to be suspended 5.7m high between steel structures.

A Scramble Net ‘U’ shaped bridge at 5.6m length, at around 7m height between concrete and steel structures.

A 13.6m length safety netted walkway as part of a themed ‘Rock-Art’ concrete ‘dead-tree’.

All products to be ‘wrapped’ in safety netting.

Supply, shipping and installation.

Design solutions:

3 x Rope Bridges (timber walkways), 6.2m, 6.95m and 7.56m lengths

Load points to carry Rope Bridges - M20 Swivel Load Rings [10 tonnes break-load certificated] - 6 at each end

Connection points between Load Points and Rope Bridges structural ropes - Rope 'soft-shackles' [15 T break-load certificated + preloaded labels]

Structural ropes for Rope Bridges - 12mm Manilla Superbraid Rope [9.2 T certificated break-load]

Wooden walkway - Timber Slats [Celcure treated + prepared] [45 x 220mm]

Child friendly - Anti-slip strips - 1000 x 90mm

Rope work - 12mm polyhemp rope - balustrade + frapping

Safety - Safety netting [45mm mesh fall arrest certificated netting], both sides [to height of 1.8m + top], all in hemp colour

1 x Net Tunnel

8170mm x 1000mm log Net Tunnel, the tunnel will have 3 x 1000mm in diameter x 38 mm OD galvanised steel pipes with 4 lugs welded on equally apart. There will be 45mm x 5mm walk-on safety net attached to each steel ring [all black], the whole will further be dressed in a 45mm x 5mm walk-on safety net in hemp colour

Load points to carry Net Tunnel - G100 M20 Swivel Load Rings [10 T break-load certificated] - 4 at each end

Connection points between Load Points and Net Tunnel structural ropes - Rope 'soft-shackles' [15 T break-load certificated + preloaded labels]

Structural ropes for Net Tunnel - 12mm Manilla Superbraid Rope [9.2 T certificated break-load]

Rope work - 12mm polyhemp rope frapping

1 x Scramble Net

5600mm x 1000mm wide x 1800mm high 'U' Bridge, floor of bridge will be made from 16mm PP rope woven together with a meh size of 100mm, the sides and the roof will be made from 45mm x 5mm walk-on safety net [all black], the whole will further be dressed in a 45mm x 5mm walk-on safety net in hemp colour

Load points to carry Scramble Net - G100 M20 Swivel Load Rings [10 T break-load certificated] - 6 at each end

Connection points between Load Points and Scramble Net structural ropes - Rope 'soft-shackles' [15 T break-load certificated + preloaded labels]

Structural ropes for Scramble Net - 12mm Manilla Superbraid Rope [9.2 T certificated break-load]

Rope work - 12mm polyhemp rope frapping

1 x ‘Dead Tree’ Balustrades, 13.5m length

Load points to carry balustrades - M20 Swivel Load Rings [10 tonnes break-load certificated] - 6 at each end

Connection points between Load Points and balustrade structural ropes - Rope 'soft-shackles' [15 T break-load certificated + preloaded labels]

Structural ropes for balustrade - 12mm Manilla Superbraid Rope [9.2 T certificated break-load]

Safety - Safety netting [45mm mesh fall arrest certificated netting], both sides [to height of 1.8m + top], all in hemp colour

Installation plan:

✔️We supplied a two-man expert-installation team to work the following schedule - 14 work days, 2 travel days, 4 rest days plus 2 contingency days, plus two local staff provided by our client. Everything was prepared at our Surrey Hills workshop in the UK and shipped by 5-pallets air-freight because of the project timeline, but with a longer lead time could easily have been shipping container.

✔️We worked the math calculations for loads so that we could design and specify materials specific to the project.

Load Calculations for Salwa Resort, Abu Samra, Qatar Rope Bridge Project

✔️We designed a complete structural system based upon a load attachment swivel load ring that rotates through 360º and pivots 90º - each bridge system could work load-ring to load-ring and 6 at each end/12 in total, in the knowledge that we have a certificated and load tested unit proof tested to 2.5 times the weight load limit. We also designed and fabricated a steel bracket attachment for the load-rings that would be either welded to structural steel beams or fixed to concrete using a Hiliti® threaded rod and compound adhesive system. Hilti® were also engaged on-site to undertake ‘pull-out’ load tests on installed systems so that we had complete provenance of certification through accredited services.

✔️We researched rope systems and worked closely with Southern Ropes to design an ‘all-rope’ design with break-loads in excess of all calculations plus a safety ratio. From swivel load ring to structural rope we employed rope ‘Soft Shackles’ load-tested and certificated to 15 tonnes and Super Ropes braided in manilla colour fabric load-tested and certified to 8.4 tonnes.

Rope Bridge Soft Shackle Load Certificate

Rope Bridge SuperBraid Structural Ropes in Manilla - Certificate 1

Rope Bridge SuperBraid Structural Ropes in Manilla - Certificate 2

✔️We pre-produced deck board ‘slats’ using 1200x220x45mm, C24 and Celcure treated timbers, with rounded edges on all faces and pre-routed rope channels on the reverse. We also screw-fixed anti-slip surfaces to all deck boards.

Rope Bridge Decking Slats - Celcure Timber Treatment

Rope Bridge Decking Slats - Celcure Timber Treatment Safety Data Sheet

✔️We introduced a hemp coloured polypropylene and high tenacity safety netting with a mesh break-load at 3.2kN to the sides and above through each of the Rope Bridges and around the Scramble Net Bridge, Net Tunnel and ‘Dead Tree’ balustrades.

Rope Bridge Safety Netting Data Sheet

✔️We used 12mm polyhemp for frapping and dressing, particularly on the Rope Bridges for friction-weave and hand-weaved balustrade rope work, with a linear strength of around 1.4 tonnes and an average of 24 friction knots every 1m of Rope Bridge.

0 notes

Text

How To Make An Eye Bolt: Eye Bolt Suppliers in Mumbai

Delta Fitt Inc. is a prominent Eye Bolts Suppliers In Mumbai. Making an eye bolt from scratch is a complex manufacturing process for Eye Bolt Manufacturer in Mumbai that requires specialised equipment and materials. It's not typically something that can be done in a typical home workshop. However, I can provide you with a simplified overview of the steps involved in making an eye bolt, but keep in mind that this is a highly simplified version of the actual industrial process

Materials and Tools:

Steel rod or bar stock

Heat source (e.g., propane forge)

Anvil

Hammer

Tongs

Thread-cutting die and tap

Drill press

Steps:

Material Selection: Choose a suitable steel rod or bar stock. The material should be strong enough to handle the intended load. Common materials include stainless steel, carbon steel, and alloy steel.

Heating: Heat the steel rod in a propane forge or other suitable heating equipment until it reaches a malleable temperature. This is typically in the range of 1,600 to 2,200 degrees Fahrenheit (870 to 1,200 degrees Celsius).

Forging the Eye: Once the steel is heated, place it on the anvil and use a hammer to shape one end into an eye. The eye can be round or oval, depending on your design. Continue shaping and hammering until you achieve the desired eye shape.

Cutting: After forging the eye, use a hacksaw or other cutting tool to cut the rod to the desired length for the eye bolt.

Threading the Shank: To create threads on the shank of the eye bolt, you'll need a threading die and tap. Secure the shank in a vise and carefully thread it using the die and tap. Ensure that the threading is straight and accurate.

Heat Treatment: Heat the eye bolt to a specific temperature (annealing or tempering) and then cool it slowly to improve its mechanical properties and toughness. The exact temperatures and cooling process depend on the type of steel you're using.

Surface Finish: You can choose to finish the eye bolt to enhance its resistance to corrosion. Common surface finishes include galvanization, painting, or simply cleaning and oiling the surface to prevent rust.

Quality Inspection: Thoroughly inspect the eye bolt to ensure it meets the required specifications and quality standards. Check the dimensions, threading, and overall quality.

Packaging: Once the eye bolt passes inspection, package it for storage or transportation. Packaging can include placing it in containers or bags to protect it.

Eye Bolts Supplier in Mumbai - Delta Fitt Inc

Delta Fitt Inc. (An Extended Unit of WMI Group) is an Eye Bolt Manufacturers in Mumbai it specialises as a Eye Bolts Manufacturers In Mumbai for high-quality eye bolts and associated hardware goods. We are proud to provide a variety of eye bolts that are intended to meet a variety of industrial needs. We provide some of the best bolts available to a variety of businesses worldwide.

They may be customised to meet the needs of the customer and come in an assortment of sizes, shapes, and dimensions. As a leading Ring Bolts or Eye Bolts Manufacturer, our products are widely used in various industries.

Delta Fitt Inc understands the significance of versatility, which is why we stock an expansive variety of shoulder eye bolts, M16 eye bolts, 1/2 eye bolts and stainless eye bolts - plus oval eye bolts and galvanised eye bolts.

At Delta Fitt Inc, our commitment to customer satisfaction extends far beyond just our selection of M20 eye bolts - these range from eye foundation bolts, forged eye bolts and stainless steel eye bolts - we even stock small 5/16 eye bolts, gate eye bolts and long eye bolts to fulfil any customer need.

Website: deltafitt.com

Product: Eye Bolts Manufacturer in Mumbai

Other Sources: Carriage Bolt Manufacturer in India, Stud Bolt Manufacturers in India.

0 notes

Video

youtube

🏗🌏Make Fixing Dexterity👉FIXDEX threaded rods & B7 & din975

#youtube#HDG threaded rods#galvanized threaded rod#galvanised rod#galv threaded rod#hot dipped galvanized threaded rod#threaded rod galvanised#m20 galvanised threaded bar#Threaded Rod Galvanized#A193 B7#b7 threaded rod#astm a193#b7 bolts#b7 studs#a193 b7 bolts#b7 stud bolts#stud bolt a193 b7#astm a 193 gr b7#b7 bolt material#a193 b7 threaded rod#a193 b7 round bar#A193 Grade B7 Bolts#Grade B7 Bolts#Stainless Steel ASTM A193 B7 Bolts Manufacturer

0 notes

Video

youtube

FIXDEX cordially invites you 14th Fastener Expo Shanghai🎉

#youtube#Fastener Expo Shanghai#14th Fastener Expo Shanghai 2024#International Fastener show China#上海紧固件展#Stud bolt and nut#Wedge Anchor#Wedge Anchor Bolts#Wedge Anchors For Brick#Concrete Wedge Anchors#Wedge Bolt#Concrete Wedge#XYLAN Coated Stud Bolt#XYLAN Coated threaded rod#TEFLON COATED Threaded Rods#Galvanized Threaded Rod#Double End Threaded Rod#Chemical Anchor Price#M20 Chemical Anchor#Epoxy Anchors#Resin Anchors#Drywall Fixings#Screwing Into Drywall#Drop In Anchor Fastener#Steel Drop In Anchor#U Hook Bolt#High Tensile U Bolts#J Bolts For Roofing Sheets#Fastenal Flat Washers#Din125a Flat Washer

0 notes

Photo

threaded rod sizes Carbon Steel Din975

click here to see more of this product

#threaded rod sizes#m25 threaded rod#m18 threaded rod#threaded rod screwfix#threaded rods#threaded rod m24#m20 threaded rod#threaded rod sizes chart#threaded rod sizes chart in mm#threaded rod sizes australia#threaded rod sizes in mm#threaded rod sizes south africa#threaded rod sizes philippines#threaded rod sizes metric#threaded rod sizes nz#threaded rod sizes uk#acme threaded rod sizes#metric threaded rod sizes#full threaded rod sizes#metric threaded rod sizes chart#standard threaded rod sizes#stainless steel threaded rod sizes#fully threaded rod sizes chart#all threaded rod sizes chart#standard threaded rod sizes metric#imperial threaded rod sizes#threaded steel rod sizes#threaded lamp rod sizes

1 note

·

View note