#flanges suppliers

Explore tagged Tumblr posts

Text

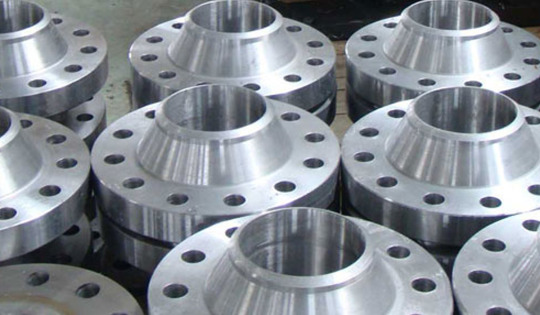

Forged Stainless Steel 304 Flanges: Key Features and Applications

1. Material Composition:

Produced using forging processes from Stainless Steel 304.

Contains 18% chromium and 8% nickel.

2. Corrosion Resistance:

Superior corrosion resistance in both chemical and marine environments.

3. Temperature Resistance:

Exceptional performance under high temperatures and pressure conditions.

4. Types of Flanges Available:

Weld Neck Flanges

Slip-On Flanges

Blind Flanges

Socket Weld Flanges

Threaded Flanges

5. Applications:

Widely used in oil and gas, power plants, and food processing.

Ideal for piping connections where high strength and temperature tolerance are necessary.

6. Durability:

Forged flanges ensure long-lasting durability, high strength, and enhanced mechanical properties.

3 notes

·

View notes

Text

Understanding Different Types of Flanges

When it comes to piping systems, flanges play a vital role in ensuring secure connections and facilitating maintenance. In this article, we will explore various types of flanges, including GI flanges, MS flanges, SS 304 flanges, SS 316 flanges, and their blind counterparts. Understanding these flanges will help you make informed decisions when selecting the right products for your industrial needs.

GI Flange

GI (Galvanized Iron) flanges are widely used in plumbing and industrial applications due to their corrosion resistance and durability. They provide a reliable connection in piping systems and are available in various sizes to suit different needs. You can find high-quality GI Flanges at Udhhyog, ensuring the best performance in your applications.

MS Flange

Mild Steel (MS) flanges are known for their strength and affordability. They are commonly used in construction and manufacturing processes. MS flanges are versatile and can be easily welded to pipes. For the lowest prices on MS Flanges, Udhhyog offers a variety of options tailored to your project requirements.

SS 304 Flange

Stainless Steel 304 (SS 304) flanges are popular for their excellent corrosion resistance and durability. They are commonly used in food processing, chemical industries, and marine applications. SS 304 flanges maintain their strength in high-temperature environments. Check out Udhhyog for competitive pricing on SS 304 Flanges.

SS 316 Flange

SS 316 flanges are even more resistant to corrosion than SS 304 flanges, making them ideal for harsh environments, including marine and chemical applications. Their ability to withstand high temperatures and corrosive substances makes them a preferred choice in many industries. You can find quality SS 316 Flanges at Udhhyog.

GI Blind Flange

GI Blind flanges are used to seal the end of a piping system, preventing the flow of fluids. They are essential for maintenance and inspection purposes. With their corrosion-resistant properties, GI Blind flanges ensure longevity and reliability. Explore Udhhyog's offerings for GI Blind Flanges.

MS Blind Flange

Similar to GI Blind flanges, MS Blind flanges serve to close off piping systems. They are cost-effective and provide strong sealing capabilities. For a reliable supply of MS Blind Flanges, look no further than Udhhyog.

SS 304 Blind Flange

SS 304 Blind flanges offer the same corrosion resistance and durability as their regular SS 304 counterparts. They are crucial in ensuring the integrity of your piping system while providing easy access for maintenance. Check out Udhhyog's selection of SS 304 Blind Flanges.

SS 316 Blind Flange

SS 316 Blind flanges are the ideal choice for demanding applications, especially in chemical processing and marine environments. Their robust construction guarantees durability and performance. For premium quality SS 316 Blind Flanges, Udhhyog is your go-to supplier.

#Flanges#GIFLange#MSFlange#SS304Flange#SS316Flange#BlindFlange#IndustrialSupplies#PipingSolutions#CorrosionResistance#Manufacturing#QualityProducts#Udhhyog#ConstructionMaterials#SteelIndustry#Supplier#PipeFittings#Engineering#IndustrialEquipment#Durability#Procurement

5 notes

·

View notes

Text

ASME B16.5 Flanges Manufacturers in UAE. We are making ANSI B16.5 Flanges, ASME B16.5 Wn Flanges, ASME B16.5 Weld Neck Flanges and ANSI B16.5 Flanges Material plausibly considering sensible expert hours in UAE and uncommon well spring of astonishing ASME B16.5 Class 150 Flanges, most very smart arrangement, cost open in Dubai, India.

Meraki Star Metals Oil & Gas Equipment Trading L.L.C. is all around acclaimed provider of ASME B16.5 Ring Joint Flanges got a handle on by Saudi Aramco. We keep up wide store of ANSI B16.5 Free Flanges, ANSI B16.5 Carbon Steel Flanges, ANSI B16.5 Diminishing Flanges, ASME B16.5 Decreasing Flanges, ASME B16.5 Slip On Flanges, ASME B16.5 Flanges Material and ASME B16.5 Blind Flanges. Meraki Star Metals Oil & Gas Equipment Trading L.L.C. stock total degree of ASME B16 5 Opening Flanges, ANSI B16.5 Expander Flanges in Stock in different sizes.

#ASME B16.5 Flanges Manufacturers in UAE#ASME B16.5 Flanges Suppliers in UAE#ASME B16.5 Flanges Stockists in UAE#ASME B16.5 Flanges Exporters in UAE

12 notes

·

View notes

Text

Future-proofing Your Infrastructure: The Importance of IBR Fitting and Flanges

In today's rapidly evolving industrial landscape, ensuring the longevity and efficiency of your infrastructure is crucial. One often overlooked yet essential component in this regard is IBR (Indian Boiler Regulations) fitting and flanges. Whether you are involved in manufacturing, construction, or any industry requiring reliable piping systems, understanding the significance of partnering with a reputable IBR fitting and flanges distributor in Vadodara or supplier in Gujarat can significantly impact your operational success.

Understanding IBR Fitting and Flanges

IBR regulations are designed to ensure the safety and efficiency of boilers and piping systems in India. IBR fittings and flanges play a pivotal role in maintaining compliance with these stringent standards. These components are manufactured to withstand high pressures and temperatures, making them ideal for critical applications where safety and reliability are paramount.

The Role of a Trusted Distributor

Choosing the right IBR fitting and flanges dealer in Gujarat is not just about acquiring products; it is about forging a partnership that guarantees quality, reliability, and compliance. A reputable distributor not only offers a wide range of IBR-certified products but also provides expert guidance on selecting the right fittings and flanges for your specific needs. They understand local regulations and can ensure that your installations meet all necessary compliance requirements.

Benefits of IBR Fitting and Flanges

Safety and Reliability: IBR-certified fittings and flanges undergo rigorous testing to ensure they can withstand extreme conditions without compromising safety.

Compliance Assurance: By partnering with a distributor who understands IBR regulations, you mitigate the risk of non-compliance issues that could lead to costly fines or operational disruptions.

Long-term Cost Efficiency: Investing in high-quality IBR fittings and flanges reduces the likelihood of premature failures and the need for frequent replacements, thus lowering maintenance costs over time.

Why Choose a Local Supplier?

Opting for an IBR fitting and flanges supplier in Gujarat offers several strategic advantages:

Proximity and Accessibility: Local suppliers provide faster delivery times and easier access to technical support and after-sales services.

Understanding of Local Needs: They are familiar with local industrial requirements and can recommend solutions tailored to your specific operational challenges.

Support for Growth: Building a long-term relationship with a local supplier fosters collaboration and allows for scalable solutions as your business expands.

Selecting the Right Partner

When selecting an IBR fitting and flanges distributor in Vadodara or supplier in Gujarat, consider the following factors:

Reputation and Experience: Look for distributors with a proven track record of reliability and customer satisfaction.

Product Range and Quality: Ensure they offer a diverse range of IBR-certified products from reputable manufacturers.

Technical Expertise: Verify their technical expertise and their ability to provide comprehensive support throughout the procurement and installation process.

Conclusion

In conclusion, the importance of IBR fitting and flanges in future-proofing your infrastructure cannot be overstated. By partnering with a trusted distributor in Vadodara or Gujarat, you not only ensure compliance with regulatory standards but also enhance the safety, reliability, and efficiency of your piping systems. Make the right choice today to safeguard your investments and propel your business towards sustainable growth and success.

For more information on IBR fitting and flanges solutions tailored to your needs, contact Tube Trading, your premier partner in Gujarat for reliable and compliant industrial solutions.

This blog emphasizes the critical role of IBR fitting and flanges in industrial infrastructure, focusing on their significance, benefits, and the importance of choosing a reputable distributor in Gujarat.

#IBR fitting and flanges distributor in Vadodara#IBR fitting and flanges dealer in Gujarat#IBR fitting and flanges supplier in Gujarat#Civil industry#Agriculture sector#steel industries

4 notes

·

View notes

Text

Super Duplex S32760 Flanges Manufacturers in India

The manufacturer and supplier of Very Duplex Steel Flanges made their products in a variety of sizes and forms for the customer in response to interest. The manufacturer, stockist, and supplier of the entire stainless steel item, including this, is Sankalp Alloys Overseas. They provide everything and deliver the product while maintaining excellent quality and price as well.

Super Duplex Steel Flanges are regarded as the best in the series of steel Flanges based on their characteristics and strong points. The austenitic toughened steel is offered in Very Choice with a few components like copper, zinc, and chromium. The majority of businesses use a lot of Duplex steel products since they provide high strength when they come into touch.

There are many kinds of Flanges accessible, for example, Welding Neck Wall It is by and large utilized in low-temperature and high-pressure applications since they required the unhindered liquid stream conveyed by the line framework. Long welding Neck-They is equivalent to a weld neck just contrast in a lengthy welding neck the tightened center point (neck) is expanded and performs like an exhausting expansion. Slip-on Spine It is appended to the fittings or the line by two filet welds, one external the hole and the other one executed inside the rib. They are handily perceived by their minimal and thin shape.

Strung Rib This is attached by screwing the line into the spine rather than using a crease weld. They are typically used in small, low-temperature, low-stress applications like utility and water management. They are legally required in dangerous areas like petrol stations and industries. Since welding associations could be dangerous in this type of environment. Spine Attachment Weld To connect this type of rib to the lines, a single fillet weld is performed on the exterior of the rib. Joint-joint ribs This spine frequently uses an alloy with a stub end and a component with a level spacing. Dark Spine Due to the necessary catapulting forces and the structure pressure, these Flanges reduce outstanding mechanical forces.

A few other exceptional sorts of rib are Nipo rib, Weldo rib, Turn Rib, Elbo Rib, Lactro Rib, Growing spine, and Lessening Rib.

Specification of Super Duplex Stainless Steel S32750/S32760 Flanges

Super Duplex Stainless Steel Flanges Specification: ASTM A182 / ASME SA182 Dimension Standard : ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. Standard: ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. Size: 1/2" (15 NB) to 48" (1200NB) Class / Pressure : 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. Flange Face Type: Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) DIN Flanges : DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673. JIS Flanges : JIS B2220 5K, JIS B2220 10K, JIS B2220 16K, JIS B2220 20K BS Flanges: BS4504 PN 6, BS 4504 PN 10, BS4504 PN 16, BS4504 PN 25, BS4504 PN 40, BS 4504 PN 64, BS 4504 PN 100, BS 4504 PN 160, BS 4504 PN 250, BS 10, BS Table D, BS Table E, BS Table F, BS Table H.

12 notes

·

View notes

Text

DUPLEX STEEL & ENGINEERING -

Duplex steel and engg. Co. Pvt. Ltd is one of the leading manufacturer of Duplex Steel 2205, Super duplex 2507, pipe, Tube, sheet, plates, flanges, fasteners in India.

DUPLEX STEEL 2205 / UNS S31803PLATES / SHEETS / COIL Request the latest Duplex Steel 2205 Plates / Sheets / Coil Price List. Please Call +91 98691 88888 or Send an Email to [email protected] for Duplex Steel UNS S31803, 1.4462 Pipe Plates / Sheets / Coil Ready stock information and updated price list.

https://www.unisteelsengg.com

#Duplex Steel 2205 Sheet#Super duplex 2507 Plate#Stainless Steel Pipe#SS Tubes#duplex 2205 pipe#duplex 2205 tube#316 Stainless steel Sheet#Inconel 200 Flanges#Monel 400 Tube Fittings#Nickel Alloy 20 Sheet#Titanium Grade 2 Round Bar#Hastelloy C22 Angle Bar Supplier#Alloy 20 Butt weld Fittings Dealer#Inconel 600 Flanges Exporter in India

2 notes

·

View notes

Text

Nascent Group is Producers and Providers of Slip on Flanges We painstakingly gripped to ANSI/ASME B16.9 making models. These Flanges are basically furnished with a raised face. These Flanges contain a ring which is made arrangements to a line end. This line end communicates with the Flanges face inside some pack; such a system awards applying weld address the insider portion over.

#Slip On Flanges Manufacturers In India#Slip On Flanges Exporters In India#Slip On Flanges Suppliers

2 notes

·

View notes

Text

ASTM F436 Type 1: A Comprehensive Guide

Introduction to ASTM F436 Type 1

ASTM F436 Type 1 is a standard specification that covers hardened steel washers designed for use with high-strength structural bolts, nuts, and other fasteners. These washers are critical in construction and engineering applications where high-load bearing capacity and durability are required. The specification ensures that the washers maintain performance under various stress conditions.

Understanding ASTM F436 Type 1 Washers

ASTM F436 Type 1 washers are manufactured from hardened steel and are used to distribute the load of a threaded fastener, reducing stress concentrations and preventing damage to the bolted components. These washers come in various forms, including flat, beveled, and clipped types, each serving specific purposes in structural applications.

Features of ASTM F436 Type 1 Washers

High Strength: Manufactured from hardened steel, these washers provide excellent strength and durability.

Corrosion Resistance: Coatings such as zinc plating and galvanizing enhance resistance to corrosion.

Standard Dimensions: These washers adhere to strict dimensional requirements for consistent performance.

Load Distribution: They help in evenly distributing loads, reducing stress on fasteners and structural elements.

Chemical Composition of ASTM F436 Type 1

ASTM F436 Type 1 washers are made from carbon steel and alloy steel. The chemical composition typically includes:

Carbon (C): 0.17% - 0.25%

Manganese (Mn): 0.50% - 0.90%

Phosphorus (P): ≤ 0.035%

Sulfur (S): ≤ 0.040%

Silicon (Si): 0.15% - 0.35%

These elements contribute to the washer's strength, hardness, and wear resistance.

Mechanical Properties of ASTM F436 Type 1

The mechanical properties of ASTM F436 Type 1 washers are designed to ensure structural integrity in high-load applications. These include:

Hardness: 38-45 HRC

Tensile Strength: Typically above 150,000 psi

Yield Strength: Ensures high resistance to deformation under load

Impact Resistance: Designed to withstand heavy structural stress without cracking

Types of ASTM F436 Washers

Flat Washers: Used for general load distribution.

Beveled Washers: Designed for use with I-beams and other structural applications.

Clipped Washers: Used in tight spaces where a full circular washer may not fit.

Applications of ASTM F436 Type 1 Washers

These washers are widely used in:

Structural Steel Construction: Connecting beams, girders, and heavy-duty steel frameworks.

Bridges: Providing additional support in bolted joints for high-load bearing capacity.

Heavy Machinery: Used in bolted assemblies that undergo high vibration and stress.

Power Plants and Industrial Equipment: Ensuring secure fastening in high-temperature and high-pressure environments.

Advantages of ASTM F436 Type 1 Washers

Enhanced Fastener Performance: Distributes load evenly, reducing the risk of bolt failure.

Improved Corrosion Resistance: Optional coatings improve longevity in harsh environments.

High Durability: Designed for use in high-stress and high-load applications.

Compliance with Standards: Meets ASTM specifications for quality and performance.

ASTM F436 Type 1 Washer Coatings

To improve their resistance to corrosion and wear, ASTM F436 Type 1 washers are often coated with:

Zinc Plating: Provides a barrier against rust and corrosion.

Hot-Dip Galvanization: Adds a thick, durable coating for extreme environments.

Phosphate Coating: Enhances lubricity and corrosion resistance.

How to Choose the Right ASTM F436 Type 1 Washer

When selecting ASTM F436 Type 1 washers, consider the following:

Application Requirements: Identify load-bearing and environmental conditions.

Coating Needs: Determine if corrosion protection is necessary.

Size and Thickness: Ensure compliance with structural requirements.

Manufacturer Quality: Select washers from certified manufacturers for guaranteed performance.

Conclusion

ASTM F436 Type 1 washers play a crucial role in structural and industrial fastening applications. Their high-strength properties, corrosion resistance, and compliance with ASTM standards make them indispensable in construction, heavy machinery, and infrastructure projects. Understanding their specifications, properties, and applications ensures the proper selection and use of these washers in high-performance environments.

Frequently Asked Questions (FAQs)

Q1: What is the difference between ASTM F436 Type 1 and Type 3 washers?

A: Type 1 washers are made from carbon or alloy steel, while Type 3 washers are made from weathering steel with enhanced corrosion resistance.

Q2: Can ASTM F436 Type 1 washers be used with stainless steel bolts?

A: While they can be used together, it's advisable to consider potential galvanic corrosion when combining different metals.

Q3: What are the hardness requirements for ASTM F436 Type 1 washers?

A: The washers must have a hardness of 38-45 HRC to meet ASTM specifications.

Q4: Where can I buy ASTM F436 Type 1 washers?

A: These washers can be purchased from industrial fastener suppliers, manufacturers, and online marketplaces specializing in structural fasteners.

Q5: Do ASTM F436 Type 1 washers come in different sizes?

A: Yes, they are available in various standard sizes to accommodate different bolt diameters and structural requirements.

For high-quality ASTM F436 Type 1 washers, always choose a reputable manufacturer to ensure compliance with industry standards and optimal performance.

#ananka#anankafasteners#linkedin#blog#f436#flange#articles#blogs#flangewasher#washer#manufacturer#fasteners#usa#supplier#mumbai

0 notes

Text

Stainless Steel Threaded Flange Online

The development of industrial and commercial infrastructure depends on high-quality pipe fittings to secure durability while achieving efficiency and safety standards. Between plumbing projects and construction work as well as industrial installations selecting the appropriate pipe cross-fitting stands is an essential choice. With the convenience of digital technology, sourcing top-notch products like Pipe Cross online has never been easier, especially when you’re looking for trusted options in India.

#best pipe elbow manufacturee in india#pipe cross online#best steel pipe end cap#flanges suppliers online in india#forged steel reducer online#pipe end cap online#flanges manufacturers online in india

0 notes

Text

Finding the Best Pipe Fittings Suppliers in Mumbai: A Complete Guide

Pipe fittings are essential components in any piping system, ensuring secure connections, smooth fluid flow, and structural integrity. Whether for plumbing, industrial pipelines, or high-pressure applications, choosing the right pipe fittings supplier is crucial for ensuring durability and efficiency.

Mumbai, being a leading industrial and commercial hub, hosts a vast network of manufacturers and suppliers offering high-quality pipe fittings in various materials and specifications. This article explores why Mumbai is the ideal place for sourcing pipe fittings, the types available, and how to choose the right supplier.

Why Source Pipe Fittings from Mumbai?

1. Industrial & Manufacturing Hub

Mumbai is home to some of India's largest industries, including oil & gas, chemicals, construction, and pharmaceuticals. This ensures easy access to high-quality pipe fittings that meet industry-specific requirements.

2. Wide Range of Materials & Customization

Suppliers in Mumbai provide pipe fittings in stainless steel, carbon steel, brass, copper, PVC, and alloy steel—offering solutions for diverse applications. Many suppliers also offer customized fittings tailored to unique specifications.

3. Cost-Effective & Competitive Pricing

Due to the competitive market, suppliers in Mumbai offer affordable pricing without compromising on quality, making it an ideal destination for bulk sourcing of pipe fittings.

4. Proximity to Major Ports & Transport Networks

Mumbai’s strategic location with access to major ports, railways, and roadways ensures faster and more efficient delivery of pipe fittings across India and internationally.

Types of Pipe Fittings Available in Mumbai

1. Elbows

90° and 45° elbows for directional changes in piping systems.

Available in seamless and welded variants for different pressure conditions.

2. Tees (Equal & Reducing)

Used to split or combine fluid flow in pipelines.

Essential for industries like plumbing, petrochemicals, and HVAC systems.

3. Couplings (Full & Half Couplings)

Joins two pipes together, ensuring leak-proof connections.

Commonly used in oil & gas pipelines and water distribution systems.

4. Reducers (Concentric & Eccentric)

Helps connect pipes of different diameters while maintaining flow efficiency.

Widely used in power plants and refineries.

5. Unions

Designed for easy disconnection and maintenance of pipelines.

Ideal for temporary installations in water and gas supply systems.

6. Flanges

Available in weld neck, slip-on, blind, and threaded types.

Used for secure connections between pipes, valves, and pumps.

7. Valves

Controls the flow of liquids and gases within pipelines.

Types include ball valves, gate valves, and check valves.

8. Cross Fittings

Used in fire protection systems and industrial setups requiring four-way connections.

How to Choose the Right Pipe Fittings Supplier in Mumbai

1. Industry Reputation & Experience

Look for suppliers with a strong track record and experience in catering to industries such as oil & gas, power plants, and construction.

2. Quality Standards & Certifications

Ensure the supplier provides ISO-certified products and adheres to international standards like ASTM, ASME, and API for quality assurance.

3. Product Variety & Customization

A good supplier should offer a wide range of pipe fittings in different materials, sizes, and finishes. Customization options are a plus for industry-specific needs.

4. Competitive Pricing & Bulk Availability

Compare pricing among multiple suppliers to get the best value without compromising on quality. Bulk availability is crucial for large-scale projects.

5. On-Time Delivery & Logistics Support

Timely supply is essential to prevent project delays. Choose a supplier with a proven track record of prompt deliveries and reliable logistics.

6. Technical Support & After-Sales Service

A reliable supplier should offer technical assistance, helping customers choose the right fittings and providing after-sales support for installation and maintenance.

Industries That Rely on Pipe Fittings Suppliers in Mumbai

Mumbai-based suppliers cater to a wide range of industries, including:

✅ Oil & Gas Pipelines✅ Petrochemical & Chemical Processing✅ Power Plants & Energy Sector✅ Construction & Infrastructure Development✅ Pharmaceutical & Food Processing✅ Water Treatment & Plumbing Systems✅ Marine & Shipbuilding Industry

Final Thoughts

Choosing the right pipe fittings supplier in Mumbai is key to ensuring durable, high-performance piping systems. Mumbai’s well-established industrial ecosystem, combined with its competitive pricing and superior logistics, makes it the perfect destination for sourcing high-quality pipe fittings.

For businesses looking to upgrade their piping infrastructure, explore Mumbai’s top suppliers today and find the best solutions tailored to your needs. 🚀

#flange manufacturers in mumbai#flanges suppliers in mumbai#flanges in mumbai#flanges supplier in mumbai#flange manufacturer in mumbai#flange dealers in mumbai#flange supplier in mumbai#flange manufacturer in navi mumbai

1 note

·

View note

Text

#stainlesssteel#stainless steel coil#yihocalvin#yiho#stainless steel sheet#stainless steel pipe supplier#stainless steel water bottle#stainless steel flanges#stainless steel cookware

1 note

·

View note

Text

Things You Should Know About Hastelloy Flanges By Manilaxmi Industrial

Manilaxmi Industrial: When it comes to choosing materials for industrial applications, Hastelloy flanges stand out as a top option due to their remarkable properties and performance। Understanding Hastelloy flanges' characteristics and benefits can help you make informed choices about your projects, whether you're working in chemical processing, oil and gas production, or power generation। What you need to know about Hastelloy flanges is here।

What are Hastelloy Flanges?

Hastelloy flanges are components made from Hastelloy, a high-performance alloy primarily composed of nickel, chromium, and molybdenum. This superalloy is renowned for its excellent corrosion resistance, high-temperature strength, and durability in harsh environments. Flanges are used to connect pipes, valves, pumps, and other equipment, ensuring a secure and leak-proof system.

Key Properties of Hastelloy Flanges?

1. Corrosion Resistance: Hastelloy flanges are highly resistant to various forms of corrosion, including pitting, crevice corrosion, and stress corrosion cracking. This makes them ideal for use in aggressive environments where other materials might fail.

2. Temperature Resistance: These flanges can withstand extreme temperatures, both high and low, without losing their structural integrity. This property is crucial for industries that operate under severe thermal conditions.

3. Mechanical Strength: Hastelloy flanges offer exceptional mechanical strength, ensuring durability and reliability even under high stress and pressure.

4. Versatility: Due to their unique properties, Hastelloy flanges are versatile and suitable for a wide range of applications across various industries

Types of Hastelloy Flanges?

Hastelloy flanges come in different types, each designed for specific applications and connection methods. Common types include:

• Weld Neck Flanges: These flanges are designed to be welded to the pipe, providing a strong and leak-proof connection ideal for high-pressure applications.

• Slip-On Flanges: Easier to install than weld neck flanges, these are slipped over the pipe and then welded. They are suitable for low-pressure environments.

• Blind Flanges: Used to close the end of a pipe or valve, blind flanges are essential for testing and maintenance purposes.

• Socket Weld Flanges: These flanges are similar to slip-on flanges but have a socket for welding, providing a smoother flow inside the pipe.

• Lap Joint Flanges: These are used with a stub end and are ideal for systems that require frequent disassembly.

Applications of Hastelloy Flanges?

Given their superior properties, Hastelloy flanges are used in a variety of demanding applications, such as:

• Chemical Processing: The exceptional corrosion resistance of Hastelloy makes it perfect for handling corrosive chemicals and acids.

• Oil and Gas: In the oil and gas industry, Hastelloy flanges are used in pipelines and equipment exposed to harsh environments and high pressures.

• Power Generation: These flanges are used in power plants, particularly in high-temperature and high-pressure sections.

• Marine Engineering: Hastelloy’s resistance to seawater corrosion makes it ideal for offshore and marine applications.

Advantages of Using Hastelloy Flanges?

1. Longevity: The durability and resistance to wear and tear extend the lifespan of the equipment, reducing the need for frequent replacements.

2. Safety: Enhanced mechanical strength and corrosion resistance ensure safer operations in critical applications.

3. Cost-Effective: Despite the higher initial cost, the longevity and reliability of Hastelloy flanges can lead to cost savings over time by minimizing downtime and maintenance.

#Hastelloy Flanges#Hastelloy Flange Manufacturer#Hastelloy Flanges Supplier#Buy Hastelloy Flanges Online#Hastelloy Flange Types#Hastelloy C276 Flanges#Hastelloy C22 Flanges#Hastelloy Flanges Price#Industrial Hastelloy Flanges#Hastelloy Flanges Exporter#Custom Hastelloy Flanges#High-Quality Hastelloy Flanges#Corrosion-Resistant Hastelloy Flanges#Hastelloy Flanges for Chemical Industry#Hastelloy Flanges for Oil & Gas#Hastelloy Flanges Specifications#Hastelloy Flanges Distributor#Hastelloy Flanges Stockist#Hastelloy Flanges Applications#Best Hastelloy Flanges

2 notes

·

View notes

Text

3 notes

·

View notes

Text

Sinopec-approved flanges in UAE

Meraki Star Metals Oil & Gas Equipment Trading L.L.C offers a wide quality extent of Incoloy 800/800H/800HT Flanges, which has presumably the best components like high versatility, outrageous arrangement, strength and that is only the start. Incoloy 800 Slip on Flanges (UNS N08800) is used for process piping, heat exchangers, warming part sheathing, carburizing gear, and nuclear steam-generator tubing. Incoloy 800 Flanges (UNS N08810) has added carbon and reinforcing treatment that considers higher jerk and break properties at 1100 Degree F (800 Degree C).

Incoloy 800 Weld Neck Flanges (UNS N08811) is a nickel-iron-chromium blend, which has a significant part of the comparable characteristics of various people from the 800 composite social occasion. Meanwhile, these Incoloy 800 Outwardly weakened flanges are furthermore being introduced in different sizes and shapes to our clients. We moreover offer these Incoloy 800H Connection Weld Flanges at market driving expenses. Also, similarly as with standard austenitic treated prepares, Incoloy 800 Lap Joint Flanges may be welded using methodologies like MIG, TIG, and shield metal round portion welding. Incoloy 800 Ring Joint Sort Flanges is impenetrable to chloride molecule stress utilization breaking.

The nickel content makes Incoloy 800 Presentation Blind Flanges astoundingly impenetrable to both chloride stress-utilization breaking and to embrittlement from precipitation of sigma stage. Incoloy 800 Spacer Flanges is ordinarily used in electric arrive at warming-part sheathing; steam methane further developing radiators and removed tubing for ethylene; smelling salts refluent coolers, etc. Incoloy 800HT Long Weld Neck Flanges is in like manner used in Compound and Petrochemical dealing.

#Incoloy 800/800HT Flanges Manufacturers in UAE#Incoloy 800/800HT Flanges Suppliers in UAE#Incoloy 800/800HT Flanges Stockists in UAE

2 notes

·

View notes

Text

Premier ERW Pipe Distributor, Supplier, and Provider in Gujarat | tubetrading

Welcome to Tube Trading Co., your go-to destination for top-quality ERW pipes in Gujarat. As the leading distributor, supplier, and provider of ERW pipes, we pride ourselves on offering seamless solutions for all your industrial needs. Whether you're looking for durable pipes for construction projects or reliable solutions for oil and gas applications, we have you covered.

With an extensive inventory and a commitment to exceptional customer service, we ensure timely delivery and competitive prices. Trust Tube Trading Co. as your trusted partner for all your ERW pipe requirements in Gujarat.

#ERW Pipe distributor in Gujarat#ERW Pipe supplier in Gujarat#ERW pipe provider in Gujarat#MSERW Pipe Distributor in Gujarat#MSERW Pipe dealer in Gujarat#MSERW Pipe Supplier in Gujarat#MSERW Pipe Provider in Gujarat#IBR Fitting and Flanges dealer in Gujarat#IBR pipe dealer in Gujarat#IBR pipe distributor in Gujarat#business#distributor#Jindal pipes#steel industry#steel companies#industrial#seamless pipes#piping material#plumbing industry#construction structure#construction sites#manufacturer#tubetrading

7 notes

·

View notes

Text

Incoloy 825 Flanges

Sankalp Alloys Overseas are Manufacturers, Provider, and Exporters of Incoloy 825 Flanges that is Produced using Phenomenal Unrefined parts. Incoloy 825 Flanges are Accessible in various grades and sizes, shapes. we offer these things at additional reasonable costs and these Flanges have a stunning income in the neighborhood as well as the overall market.

INCOLOY 825 ANSI B16.5 / B16.47 FLANGES SPECIFICATION :

Standard: ASTM, ASME, ANSI, JIS, DIN, BSNA 11, EN Ni 99.2, JIS NW 2200, GOST-НП-2

Dimensions: ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Designation: ASTM / ASME B 564 / SB 564

Class: Class 150, Class 300, Class 400, Class 600, Class 900, Class 1500 & Class 2500

Size: 1/2″NB TO 60″NB

Grades: Incoloy 825 (UNS N08825) Flanges, 2.4858

Pressure: DIN PN6, PN10, PN16, PN25, PN40, PN64, PN100, PN160

7 notes

·

View notes