#diesel system cleaner

Explore tagged Tumblr posts

Text

Understanding the Importance of Diesel Injector Cleaner

Discover why maintaining a clean fuel injection system is crucial for optimal engine performance and longevity, and how Bluechem Australia's diesel injector cleaner stands out in this aspect.

Bluechem Australia has high-performance diesel fuel injector cleaners specifically designed to effectively remove deposits from fuel injection systems. We have the best diesel injector cleaners in Australia to inject new life into your engine system.

If you have a diesel car and looking for diesel fuel system cleaners for the efficient performance of your vehicle, we have the right options here. Our products are manufactured, researched and developed by the bluechemGROUP for superior performance. Check out our diesel fuel cleaners today to find the right one for your vehicle.

Contact- Web - https://www.bluechemaustralia.com.au/diesel-injector-cleaner/ Mail - [email protected] Ph - 0498 880 115 Address - UNIT 4, 63 Brunel Rd, Seaford VIC 3198, AU

#diesel system cleaner#diesel injector cleaner#diesel fuel injector cleaner#diesel fuel cleaner#diesel fuel system cleaner#best diesel injector cleaner australia#powermaxx diesel system cleaner

0 notes

Text

WHAT ARE BYPASS FILTERS?

A bypass filter, also known as a pressure relief valve, is a very important part of an oil filter. When oil is too thick or the filter is clogged, the valve opens. If the valve doesn’t open then the filter may eventually burst.

Bypass filters are designed to remove fine organic and inorganic particles. It also increases the total volume of oil used. Thus, if you have contamination issues and want to extend operating equipment life, extend lube oil & service intervals, and consider adding bypass filters. We can say that Bypass filtration can be considered another aspect to save money and downtime.

Most of the existing manufacturers use ‘full-flow’ oil filters which are designed to protect the component from large particles but they cannot remove soot, water, or silt. Full-flow filters alone cannot keep oil clean for a long-term period. The fine particles which account for most of the contamination can be removed by the bypass filters.

It is advised to do the homework before buying a bypass filter. Some important factors to consider are:

1) Capture efficiency - The higher the beta ratio, the better will be the capture efficiency. A good beta ratio selection can control the escape of particles through the element. It is just like a good shepherd keeping the flock of sheep in a controlled and organized manner in the field.

2) Pressure/flow - Suitably designed filter element has calculated flow and velocity of oil through its microvoids. It is as important as keeping the water stream in a controlled way for gardening purposes. Else, it may spoil the sole purpose of watering.

3) Dirt Holding Capacity - It is not only necessary to have high capture efficiency but also a good filter element capacity is a must-have to retain the collected contamination. A well-engineered element has dedicated space to imprison the unwanted contaminants.

4) Heating element (to eliminate solid and liquid contaminants) - An elevated temperature helps to dislodge the solid contaminants and accelerates the rate of removal of volatile impurities.

5) Type of filtration media - Filter media varies with grade and type of oil widely. This may be a fine filter paper to absolute and depth filter media.

For more such interesting Articles and Case Studies: Click Here

6) Compatibility of fluid - Not every filter element can be used with any grade of oil. A small mistake in element selection can destroy the element as well as may cause a collapse of the entire system.

7) Surface area for the filtration – The higher surface area will give a lower pressure drop across the filter and also helps to achieve higher flow rates.

8) Compact in size - Reduction of size in regards to the filter elements and housing gives us multiple benefits like space and cost-saving, aesthetic look, better maintainability, low recurring expenditure, etc.

9) Inexpensive to use and install - At the end of every engineering and calculation, economics comes into the picture. It is always suggested to go with optimized design and correct sizing to overcome financial constraints.

We don’t need any additional setup to establish a Bypass filtration system; it can be done within the existing skilled limits. Please note that a bypass filtration system can be of great benefit if installed and maintained appropriately and it helps to prevent post-filtration fugitive contamination ingress into the system.

We will be happy to help you in the entire journey of the right filter selection. Contact - [email protected] or WhatsApp us at +91 7030901267.

#minimac#minimacsystems#filter#filter skid#filter replacement#contact minimac#Lube Oil Filter#hydraulic oil#oil cleaning machine#Lube oil cleaning#hydraulic oil cleaning#FRF#oil flushing#transformer oil cleaning#oil condition monitoring#Fluid Power Equipment#electrostatics lube cleaner#coalser separator#Diesel purification systems#chemical cleaning#technology#varnish removal#oil contamination

2 notes

·

View notes

Text

#Mechanic in Merrick NY#Diesel Turbo Cleaners in Merrick NY#Fuel System Cleaning Services near me#Diesel Injector Cleaning Services near me

1 note

·

View note

Text

Things Biden and the Democrats did, this week #20

May 24-31 2024

The EPA awards $900 million to school districts across the country to replace diesel fueled school buses with cleaner alternatives. The money will go to 530 school districts across nearly every state, DC, tribal community, and US territory. The funds will help replace 3,400 buses with cleaner alternatives, 92% of the new buses will be 100% green electric. This adds to the $3 billion the Biden administration has already spent to replace 8,500 school buses across 1,000 school districts in the last 2 years.

For the first time the federal government released guidelines for Voluntary Carbon Markets. Voluntary Carbon Markets are a system by which companies off set their carbon emissions by funding project to fight climate change like investing in wind or solar power. Critics have changed that companies are using them just for PR and their funding often goes to projects that would happen any ways thus not offsetting emissions. The new guidelines seek to insure integrity in the Carbon Markets and make sure they make a meaningful impact. It also pushes companies to address emissions first and use offsets only as a last resort.

The IRS announced it'll take its direct file program nationwide in 2025. In 2024 140,000 tax payers in 12 states used the direct file pilot program and the IRS now plans to bring it to all Americans next tax season. Right now the program is only for simple W-2 returns with no side income but the IRS has plans to expand it to more complex filings in the future. This is one of the many projects at the IRS being funded through President Biden's Inflation Reduction Act.

The White House announced steps to boost nuclear energy in America. Nuclear power in the single largest green energy source in the country accounting for 19% of America's total energy. Boosting Nuclear energy is a key part of the Biden administration's strategy to reach a carbon free electricity sector by 2035. The administration has invested in bring the Palisades nuclear plant in Michigan back on-line, and extending the life of Diablo Canyon in California. In addition the Military will be deploying new small modular nuclear reactors and microreactors to power its installations. The Administration is setting up a task force to help combat the delays and cost overruns that have often derailed new nuclear projects and the Administration is supporting two Gen III+ SMR demonstration projects to highlight the safety and efficiency of the next generation of nuclear power.

The Department of Agriculture announced $824 million in new funding to protect livestock health and combat H5N1. The funding will go toward early detection, vaccine research, and supporting farmers impacted. The USDA is also launching a nation wide Dairy Herd Status Pilot Program, hopefully this program will give us a live look at the health of America's dairy herd and help with early detection. The Biden Administration has reacted quickly and proactively to the early cases of H5N1 to make sure it doesn't spread to the human population and become another pandemic situation.

The White House announced a partnership with 21 states to help supercharge America's aging energy grid. Years of little to no investment in America's Infrastructure has left our energy grid lagging behind the 21st century tech. This partnership aims to squeeze all the energy we can out of our current system while we rush to update and modernize. Last month the administration announced a plan to lay 100,000 miles of new transmission lines over the next five years. The 21 states all with Democratic governors are Arizona, California, Colorado, Connecticut, Delaware, Hawaii, Illinois, Kentucky, Maine, Maryland, Massachusetts, Michigan, New Jersey, New Mexico, New York, North Carolina, Oregon, Pennsylvania, Rhode Island, Washington, and Wisconsin.

The Department of Transportation announced $343 million to update 8 of America's oldest and busiest transportation stations for disability accessibility. These include the MBTA's the Green Line's light-rail B and C branches in Boston, Cleveland's Blue Line, New Orleans' St. Charles Streetcar route, and projects in San Francisco and New York City and other locations

The Department of interior announced two projects for water in Western states. $179 million for drought resilience projects in California and Utah and $242 million for expanding water access in California, Colorado and Washington. The projects should help support drinking water for 6.4 million people every year.

HUD announced $150 million for affordable housing for tribal communities. This adds to the over $1 billion dollars for tribal housing announced earlier in the month. Neil Whitegull of the Ho-Chunk Nation said at the announcement "I know a lot of times as Native Americans we've been here and we've seen people that have said, ‘Oh yeah, we'd like to help Indians.’ And they take a picture and they go away. We never see it, But there's been a commitment here, with the increase in funding, grants, and this administration that is bringing their folks out. And there's a real commitment, I think, to Native American tribes that we've never seen before."

Secretary of State Antony Blinken pledged $135 million to help Moldavia. Since the outbreak of Russia's war against neighboring Ukraine the US has given $774 million in aid to tiny Moldavia. Moldavia has long been dependent on Russian energy but thanks to US investment in the countries energy security Moldavia is breaking away from Russia and moving forward with EU membership.

The US and Guatemala launched the "Youth With Purpose” initiative. The initiative will be run through the Central America Service Corps, launched in 2022 by Vice President Harris the CASC is part of the Biden Administration's efforts to improve life in Central America. The Youth With Purpose program will train 25,000 young Guatemalans and connect with with service projects throughout the country.

Bonus: Today, May 31st 2024, is the last day of the Affordable Connectivity Program. The program helped 23 million Americans connect to the internet while saving them $30 to $75 dollars every month. Despite repeated calls from President Biden Republicans in Congress have refused to act to renew the program. The White House has worked with private companies to get them to agree to extend the savings to the end of 2024. The Biden Administration has invested $90 Billion high-speed internet investments. Such as $42.45 billion for Broadband Equity, Access, and Deployment, $1 billion for the The Middle Mile program laying 12,000 miles of regional fiber networks, and distributed nearly 30,000 connected devices to students and communities, including more than 3,600 through the Tribal Broadband Connectivity Program

#Thanks Biden#joe biden#us politics#politics#American politics#climate change#climate action#nuclear power#h5n1#accessibility#tribal communities#Moldavia#Guatemala#water#internet

1K notes

·

View notes

Text

They re-laid the ballast and sleepers on Sunday, and by mid-day Monday, the last of the temporary rails were bolted together. It was, to quote a workman, a “hack job”, but it could be replaced after the busy winter hols.

Douglas pulled an inspection train across the newly repaired section shortly after supper, and it was with great jubilation that the Fat Controller deemed the line “fit to re-open.”

That night, Duck was the first to come back, running the last (and only) train of the day. He was ecstatic to be back in his own shed, and there was much merriment and joy as he shunted Alice and Mirabel into the empty carriage sheds. He whistled gaily to the engines on the small railway, who yelled at him to keep the noise down, didn’t he have any idea how late it was.

Then he turned to the yard, and his gaiety died down significantly. “Wha-what?” He stuttered, staring in confusion and slight horror. “What have you done?”

Bear rolled his eyes, having endured quite enough of Duck’s personality in the last ten minutes. “I needed trucks for the track work.”

“Yes I see that. Did you fetch them with your eyes shut?”

Bear growled. The yard was only a mess if you had been indoctrinated into the Great Western Shunting System - which, in fairness, he had been - but he’d been told that the first train would arrive in the morning, not tonight. “No, the work just finished early, is all. I’m fine, by the way.”

“That’s no excuse!” Duck ploughed on, getting into a proper strop. “You should’ve been cleaning as you went! Single Workings 3:7 clearly states-”

“I know what it says, and I don’t care.” Bear snapped. “If we’re going to get into this, what about Emergencies 12:5, hmmm? Shouting chapter and verse at me isn’t going to make the yard cleaner.”

Duck tripped over his own tongue while Bear smiled spitefully. “Now, I was going to offer to help you clean the yard while my driver is still on shift, but instead I think I’ll let you fix things to your exacting specifications.”

Bear’s driver, who had been performing an inspection on his engine, looked at Bear in surprise, Duck in shock, and decided to reverse Bear into the shed to end the confrontation. In a few minutes, snoring could be heard through the closed doors.

“Well..!” Duck said, thoroughly surprised. “What got into him?”

“The fact that you haven’t figured it out is, quite frankly, appalling.” boomed a voice from across the goods yard. Duck glared, but the glare quickly turned to surprised suspicion when the trucks didn’t start laughing. They always laughed after someone got a one-liner in.

Instead, a sea of surly faces stared back at him. “What are you looking at?” he asked, suddenly off-kilter.

“That wasn’t very nice.” A flatbed scowled, backed up by a wave of agreeing murmurs.

Duck didn’t know whether to scowl or be frightened at the show of unity, and shunted the worryingly quiet trucks until the end of his driver’s shift.

When he was backed in next to Bear, he thought about saying something, to see if the diesel was still awake, but in the end he went uneasily to sleep.

-

The next morning, Bear woke up much later than he usually would. Duck was gone, the yard was organized, Oliver was receding into the distance, and there was a long line of trucks sitting by the goods shed.

His driver came over, train orders in his hand. “Right-o, first we’ve got these to take, then we’ve got passenger trains with Truro for the rest of the day. Excited?” He wasn’t one of Bear’s usual drivers, and he completely missed the smile that hid a scowl.

The trucks didn’t miss it. As he rolled past the train, the brake van - the SR Queen Mary, finally on his way back to whence he came - eyed him with sympathy. “Keep your guard up, once you’re with him.”

“Back to reality…” the low loader rumbled.

The Fish Van didn’t say anything, but gave him a look of sombre understanding.

A long line of hoppers, full of tunnel debris, were somewhat more cheerful. “You’ve got us, remember.” their leader whispered.

Bear felt somewhat uplifted by this, but, as he waited for his driver to perform a brake test, his spirit began to wane. There was a crowd of passengers on the platform, already waiting for the next train. A large group of them were wearing shirts with the Great Western Railway logo stitched into them. They had cameras, of course, and were taking pictures every which way, except his.

One pointed a lens his way, and was promptly shoved by several friends. “Don’t waste your film,” they said, “on that box on wheels.”

By the time the signal dropped, Bear felt deeply morose. He set off, leaving the station behind, each turn of his wheels bringing him closer to the big station, and City of Truro.

-

The train halted at Haultraugh station. The inbound train was Duck’s, and as more passengers flowed in and out of the train, someone made a comment, loud enough to be heard over the hustle and bustle, that “this was straight out of the sixties.”

As the last passengers boarded, someone else replied, “yeah, the 18-60s.”

Bear stared at the GWR branding covering the station. There’s no place for me here.

Next to them, Duck was off in his own world. One of the porters had asked him how Truro was doing, and this had led to a lengthy and animated description of how bored and disrespected Truro felt in the yard at the big station. Gordon was the apparent ringleader, finding great fun in pushing Truro’s buttons. Bear’s engine note took on a notably staccato beat, and the trucks began grumbling to each other. The porter paid this no mind, but Duck began looking quizzically across the platform, trying to figure out what, if anything, was the matter.

Meanwhile, Bear’s driver was looking up and down the platform. “What’s the holdup? Where’s the signal?” He scoffed, climbing out of the cab and knocking on the door of the signal box.

Inside he found the signalman, looking quite aggrieved and holding a pair of flags. “Signal lever’s jammed. Points are good. Go out and I’ll wave you through.” He kicked the lever for good measure, a resounding clang emanating from the lever frame. “Piece of junk…”

Bear’s driver exited the box, noting for the first time that anything seemed to be amiss with his engine. “You alright?”

“Are we going?” Bear’s short, clipped tones could be mistaken for anticipation if you weren’t that bright.

“Yeah! Yeah, hold your horses.” The driver jumped back into the cab, and set off the instant the annoyed looking signalman waved the green flag.

Bear set off sluggishly. He didn’t care if he got there, or how long it took.

Behind him, the brake van could sense the disappointment and despair radiating down the brake line, all the way at the end of the train. Slowly, steadily, and stealthily enough to not alert the guard, he began slipping on his own brakes.

The other trucks in the train felt this, and realized what was happening. Slowly but surely, the train began to get heavier and heavier as Bear kept going.

-

The train made it halfway up the tunnel before grinding to a halt on the grade. There was no radio reception in the tunnel, and with Bear’s engine belching out more diesel exhaust every second, the driver made a quick determination to back down to Bulgy’s Bridge and try again.

Slowly, with the brakes mostly released, the train rolled back into the clear air, slowly click-clacking over the new jointed rails as it rolled back towards Bulgy’s Bridge. The tunnel mouth was now a jagged hole in the side of the rock, scarred and pitted in spots where the decorative portal had been chiselled away.

“So,” Bear addressed the train, taking care to not be heard by his driver. “Does anyone want to explain why we stalled out in the tunnel? Something that hasn’t happened with stone trains that are twice as heavy?”

There was a moment of guilty silence on the brake line, then:

“We can’t let you go without a fight.”

“You shouldn’t go back to that.”

“We like you too much to subject you to the snake.”

Bear was struck absolutely dumb by that, and felt a warm and fuzzy sensation in his fuel tanks. As his driver brought the train to a halt by the bridge, he couldn’t help but feel incredibly… honored? Was that the correct word? Liked? He pondered on this for some time, and was finally brought back to reality by his driver banging on the control desk in the cab. “Wakey wakey! Time to do some work!”

Bear chose not to dignify that with a response and instead allowed his engine to rev up to full power, to get the train moving up the hill and through the tunnel at a sufficient speed.

Then, nothing happened.

Or rather, nothing seemed to happen. Bear was pulling against the train with quite a lot of force, but it just didn’t move. His engine revved, his wheels slipped, and the train went nowhere.

It did not take a brain surgeon to figure out what was wrong: the trucks were quite serious about not letting Bear go back to Truro, and were doing everything in their power to stop him.

“We’re not joking…” came a low voice up the brake line.

Bear didn’t think they were, and was quite willing to sit out here for some time. It was a nice day compared to most of last week - the sun was out, and it was a few degrees above freezing - and if the railway had to send another engine to help him up the hill, then so be it.

“Ah, for the love of pete!” Unfortunately, Bear’s driver was a dedicated sort, someone who had a lot of interest in doing his job to the best of his ability, and someone who had no interest in being labelled as “the one who stalled in the tunnel”. He was going to get this train to Tidmouth come hell or high water, and so he didn’t let off the throttle, much to Bear’s annoyance.

“We’re not going anywhere like this. Call for a banker.”

“Absolutely not!” was the retort. What happened instead was that the train was put into reverse, and backed up even more to let the slack in. Bear knew what he was doing, and also knew that it wasn’t going to work. The trucks did too, and there was a bit of light laughter from most of the train. They even let him move the train a bit, rolling well beyond Bulgy’s Bridge without a fight.

The exception was the lead truck, who was looking at the coupling chain with worry. “That’s starting to stretch a little…”

Then, as has happened many times before, there was trouble.

Bear’s driver released the brakes, set the reverser to “forward”, and then jammed the throttle as far forward as it would go.

Bear set off with a great cloud of smoke and clag, his engine roaring like a wounded animal. The first five trucks on the train, realizing that something very bad could happen to them if they kept the brakes on, had let up. The slack went out of the train with a quintuple bang! as those trucks were yanked into motion. Then, the coupling to the rest of the train, who were not going to move under any circumstances, was pulled on.

They did not move, and the train screeched to a halt, Bear’s wheels spun furiously, sparking on the rails.

Then the coupling chain snapped.

Bear shot forward, suddenly free of the rest of the train. Fortunately, the vacuum brake hose also separating meant that his brakes came on automatically, and he came to a shuddering and screeching stop less than a hundred feet away, atop Bulgy’s Bridge.

“Now look at what’s happened!” He barked at his driver. “I told you to stop hammering on the throttle like a neanderthal!”

Then, things got worse.

When the rails had been re-laid after the derailment, the workers had done everything properly… except on Bulgy’s Bridge. The bridge, which still bore its scars from when Bulgy had gotten stuck underneath it almost twenty years ago, was known to be a fragile structure, and couldn’t withstand heavy or sustained vibrations.

“Heavy or sustained vibrations” is exactly what would happen when a ballast tamper machine was brought over the line. It “tamped” ballast by extending vibrating rods into the gravel and shaking them until the ballast had become smooth and level. This wasn’t possible on Bulgy’s Bridge, and so the workers had smoothed everything down as well as they could by hand before re-opening the line to traffic. And, for the trains that had gone over it so far, it had been fine - mostly because it had been light engines like Duck and Oliver, who moved over it quickly.

Bear, on the other hand, weighed as much as Duck and Oliver combined, and had just come to an abrupt stop directly on top of the mostly un-leveled ballast.

As Bear began to berate his driver for the problems that he had most certainly caused, the gravel underneath the sleepers began to shudder and shake.

Suddenly, and with distressingly little noise, the gravel on the right side of the line subsided, the sleepers and rails sagged as one, and Bear found himself tilted at an extremely worrying angle on top of Bulgy’s Bridge.

His driver closed his eyes in horror, and didn’t open them again until everything in the cab had stopped moving.

Bear, meanwhile, was so utterly overwhelmed with what was happening that he couldn’t even muster up a bit of shock. “Driver, this is your fault.”

-

Having already dealt with a calamitous derailment on the Little Western once this week, the railway was extremely quick in responding to the accident, and both a crane and the Fat Controller were there before lunch.

“Bear,” he said seriously. “I mean this in as non-insulting a manner as possible, but the fact that this was not your fault astounds me.”

“Don’t worry sir, the others will find a way to blame me for it anyways.”

“I-” The Fat Controller didn’t know how to respond to that, and had to choose his next words carefully. “I see.” He paused again. “I would actually like to mention something, now that you’ve brought that up.”

“Sir?”

“Yes.” Again, he had to choose his words carefully. “Due to… recent circumstances, British Rail has agreed to let us trial City of Truro on his own merits.”

“Sir? Does that mean that I don’t have to run trains with him anymore?” Bear’s tone was suddenly ecstatic, which the Fat Controller unfortunately didn’t understand the full connotations of.

“Indeed.” he said, eyes twinkling slightly. “Apparently his ability to be “more reliable than a diesel” was quite a point in his favor.” A pause. “Not that it is a mark against you in any way.”

“Of course sir, thank you sir!” Bear looked like Christmas came early, which did not mesh well with the fact that he was perilously close to falling off of a bridge.

“I’m glad you understand.” Charles Hatt smiled warmly. “And one more thing - I have been informed by the foreman that… removing you from this situation will involve damaging your paintwork in some way. Obviously, that cannot stand, and so I will have you sent to the works tomorrow or the day after for a temporary touch up. Once the holidays are over, you will receive a new coat of paint in any color you like. You’ve earned it.”

Bear’s smile was the biggest it had been in almost a month, and it stayed there throughout the cleanup process, even as the lifting chains gouged long silvery stripes all over his paintwork.

-

It took until well past dinnertime for the tracks to be put right again, and once Bear was checked over by works staff (again), he was immediately put to work with the permanent way gang, who worked throughout the night. Finally, at one in the morning, the work was declared “done!”, to much celebration, and the workers went home to bed.

Bear still had a job to do, though, and it wasn’t until two-thirty that he arrived at Tidmouth station with his now very contrite goods train, who didn’t say a word as he shunted them into the goods yard.

The diesel shed was empty, and Bear was asleep before his driver could fully set the brakes.

-

The next morning was cold but sunny, with still, crisp air soaking up the sun’s weak rays.

Bear, who had been woken up at seven in the morning after less than five hours of sleep, quite frankly could not bring himself to care about that, and grumbled all the way to the fuel depot, the station, the goods yard, and then most of the way to Haultraugh. He only stopped grumbling once he was awake enough to remember, as he burst into the sunlight at the end of the tunnel, that he was finally free of this wretched branch line and could go to the works soon!

This massively improved his mood, and he almost forgot how tired he was, as he rolled across the temporary speed restriction at Bulgy’s bridge, and through Haultraugh station. As he rolled into Arlesburgh, he was almost smiling.

“Well well well,” A stern voice immediately quelled any chances of enjoying the morning. “Look who shows his face around here!” Duck, a distinctly upset expression on his face, puffed into view. “You break my branch line, leave me stranded here all day - let’s not even get into what the passengers had to endure - and then just waltz off to the big station without so much as a by-your-leave? What sort of Western work ethic is that?”

He was really getting into full flow now. “And this is after you leave my yard a complete and utter disaster for more than a week! Whatever do you have to say for yourself?”

Bear was a patient engine, he really was. He could understand Duck’s position, he really could. He was even willing to hear him out, and talk with him like an adult. After all, they were both what people would call “grown-ups”. For goodness’ sake, he was twenty years old - far older and more mature than most of the diesels on the mainland!

But then… he looked behind Duck.

There, in the shed, was City of fucking Truro’s smug fucking face. He looked thrilled at what was happening.

And something in Bear went snap.

“Duck.” He said firmly, cutting the steam engine off mid-word. “You can take your Great Western work ethic and you can shove it down your boiler tubes. I do not care any more.”

Duck’s face moved like he was trying to say something, but he seemed unable to process what was happening.

“Furthermore,” Bear continued. “I didn’t break anything.” He glared daggers at Truro, who blinked in surprise. “The great green disaster over there is responsible for all of that. Unless you think that I shattered my gearbox out of a sense of whimsy.”

“I… I… I…” Duck couldn’t seem to put syllables together.

“In a similar fashion, I didn’t derail the Siphon wagons - if we’re really going to hand out blame like Christmas presents, it was Donald’s fault for not checking anything before he set off down the line with a bunch of plain-bearing equipped vans like it was the 1930s. Although, to go even further back, it was that one’s fault for moving the Siphons across the yard for no clear reason other than that he felt like it!”

Truro could hear everything, and blinked like he was offended. Good.

Duck looked like someone had smacked him across the face.

“Of course, let’s just blame it on me, why don’t we?” Bear could feel the indignation coursing through his systems, and let it flow. “As I can do nothing right, and only bring about confusion and delay! Yes, of course I wanted to almost fall off of Bulgy’s Bridge yesterday; it was part of my larger plan to learn to drive on the roads like an automobile, leaving the rails to wither and die on the vine like Doctor Beeching!”

“Bear, I-”

“Oh no! Don’t you “Bear” me! For all you know, that’s true! You’ve not taken your eyes off of Truro for a month now! “Truro” this and “Truro” that! If you like him so much, why don’t you give him the branch line and spend the rest of your life licking his buffers like the obsequious toady you seem intent on becoming! I thought you were my friend, but you can’t even notice something going on right in front of you!”

Truro was now glaring. The signalman had left his box, the trucks were silent, and Duck was so confused he was almost in tears. On the platform, the passengers started looking in their direction.

“Bear-”

“No, no.” He snapped, fire blooming in his eyes. “Use my goddamned number. You don’t have the right to use my name!”

Duck looked horrified. Good.

Bear pressed on, a month’s worth of frustration and aggravation spilling out uncontrollably. “So you know what, Montague? I’ve had it. That’s what this is. If you and Truro and Oliver want to play pretend in some fantasy recreation of a time that died a long time ago, be my guest! But I will have no part in it.”

The stationmaster appeared out of the station building and began making a beeline across the tracks.

“You can take your Great Western Railway, and all its idiotic traditions, and you can shove it someplace unpleasant!” He roared, engine growling menacingly. “But I’m done!” “And before I go…” The stationmaster was getting closer, and Bear could tell that he was going to be silenced one way or the other. He tried to think if there was anything else he wanted to say, but all he could see was Truro, looking so unjustly offended on Duck’s behalf. “Oi, you! Domeless wonder! I wish that they’d kept Great Bear, and scrapped you!”

22 notes

·

View notes

Text

Green Power Ltd. – Your Trusted Partner for Solar Energy Projects in Bangladesh

Green Power Ltd. – Your Trusted Partner for Solar Energy Projects in Bangladesh As Bangladesh accelerates its transition to renewable energy, Green Power Ltd. is here to support business leaders, energy investors, and enterprises in navigating and capitalizing on the solar energy sector. We specialize in delivering turnkey solar solutions, from bid preparation to EPC execution, ensuring seamless project development that aligns with BPDB requirements. How We Add Value to Independent Power Producer with solar Power Plants: ✅ Bid Preparation – Structuring compliant, competitive proposals to increase your chances of winning. ✅ Land Arrangements – Securing strategically located lands near BPDB-designated substations. ✅ Tariff Development – Designing sustainable, cost-effective tariffs for a business case. ✅ Turnkey EPC Services – Offering full-scale Engineering, Procurement & Construction with advanced IoT-enabled solutions. ✅ Feasibility Studies – Ensuring project viability with in-depth pre and post-bid analyses. ✅ Rooftop Solar + BESS – Cutting energy costs significantly by integrating Battery Energy Storage Systems, reducing diesel reliance from BDT 30/kWh to BDT 4/kWh. Why Work With Us? 🔹 Expertise in Large-Scale Solar Projects 🔹 Strong Network with Land & Policy Experts 🔹 Proven Track Record in Renewable Energy 🔹 Commitment to Sustainability & Business Growth Let’s build a cleaner, cost-efficient, and energy-secure future for Bangladesh—together. 📩 Contact us today to explore collaboration opportunities. Telephone: +88-02-222274-959 Cell: +88 01711 537474 Email: [email protected]

GreenPowerLtd #SolarEnergy #BPDB #RenewableEnergy #Bangladesh #CorporateSustainability #SolarInvestment #IndependentPowerProducer #IPP #SolarPowerPlant #Solar #Solarfarm

2 notes

·

View notes

Text

Fuel-Efficient Cars: Revolutionizing the Road to Smarter Driving

youtube

In an age where environmental awareness and financial prudence go hand in hand, fuel-efficient cars have become a vital choice for modern drivers. At Efficient Car, we’re committed to guiding you through this exciting transition to smarter, more sustainable driving. Let’s dive into what makes fuel-efficient vehicles the cornerstone of today’s automotive landscape, their benefits, and how to pick the perfect model for your lifestyle.

Understanding Fuel-Efficient Cars Fuel-efficient cars are engineered to deliver maximum performance with minimal fuel consumption. By leveraging advanced technologies, lightweight materials, and innovative designs, these vehicles reduce fuel usage and emissions. Whether powered by gasoline, diesel, hybrid systems, or electricity, fuel-efficient cars are tailored for both eco-conscious and budget-savvy drivers.

Why Choose Fuel-Efficient Cars?

Significant Cost Savings Fuel-efficient cars offer excellent mileage, cutting down your fuel expenses dramatically. While the upfront cost of some models might be higher, the long-term savings often outweigh the initial investment—particularly for frequent travelers or those with long commutes.

Reduced Environmental Impact Opting for a fuel-efficient car is a direct way to reduce greenhouse gas emissions and contribute to cleaner air. These vehicles use less fuel, making them a practical solution for combating climate change and supporting global sustainability goals.

Cutting-Edge Technology Modern fuel-efficient cars are packed with state-of-the-art features, such as regenerative braking, energy recovery systems, and intelligent driving modes. These innovations not only enhance fuel efficiency but also elevate the overall driving experience.

Higher Resale Value With sustainability becoming a top priority for buyers, fuel-efficient vehicles are highly sought after in the resale market. Their durability, lower running costs, and alignment with eco-friendly values make them a smart investment.

Tax Incentives and Perks Governments worldwide incentivize the purchase of fuel-efficient cars through tax credits, subsidies, and reduced registration fees—especially for hybrid and electric models. These financial benefits further sweeten the deal for prospective buyers.

Popular Types of Fuel-Efficient Cars

Hybrid Cars: These combine a traditional internal combustion engine with an electric motor, offering impressive fuel economy and lower emissions. Notable models include the Toyota Prius and Honda Insight.

Electric Vehicles (EVs): EVs like the Tesla Model 3 and Nissan Leaf rely entirely on rechargeable batteries, emitting zero greenhouse gases while boasting remarkable energy efficiency.

Diesel Cars: Known for their superior highway mileage, diesel vehicles like the Volkswagen Passat remain popular in certain markets despite tightening emissions regulations.

Advanced Gasoline Cars: Compact models such as the Honda Civic and Toyota Corolla demonstrate how traditional gasoline-powered cars can achieve remarkable efficiency through innovations like turbocharging and direct fuel injection.

How to Choose the Right Fuel-Efficient Vehicle

Assess Your Driving Habits Your daily commute and lifestyle will dictate the type of fuel-efficient car that suits you best. Urban drivers may prefer compact hybrids, while long-distance travelers might benefit from diesel or extended-range hybrid options.

Check MPG Ratings High miles-per-gallon (MPG) ratings are a hallmark of efficiency. Tools like the EPA’s fuel economy guide can help you compare different models and make an informed decision.

Factor in Maintenance Costs Though fuel-efficient cars save on fuel, some—like hybrids and EVs—may come with unique maintenance needs. Research service costs to ensure the vehicle fits your budget long-term.

Think Beyond Today Investing in a fuel-efficient car isn’t just about immediate savings. Consider its lifespan, reliability, and resale value to ensure it remains a wise choice for years to come.

Fuel Efficiency Meets the Future The automotive industry is advancing rapidly, with innovations like solid-state batteries, hydrogen fuel cells, and improved aerodynamics setting new benchmarks for efficiency. Governments are also pushing for stricter emissions standards, driving the widespread adoption of hybrids and EVs.

By 2030, it’s estimated that fuel-efficient cars will dominate new vehicle sales, making now the perfect time to join the movement toward smarter, greener transportation.

Why Choose Efficient Car? At Efficient Car, we pride ourselves on connecting drivers with the most advanced and fuel-efficient models available. Our team offers:

Expert advice tailored to your needs.

A curated selection of high-performance, eco-friendly vehicles.

A seamless car-buying experience that prioritizes your values and lifestyle.

Whether you’re upgrading your current vehicle or taking your first step into sustainable driving, we’re here to guide you every step of the way.

Conclusion Fuel-efficient cars are not just the future—they’re the present. Offering unmatched savings, reduced environmental impact, and cutting-edge technology, they represent the smarter choice for today’s drivers. Partner with Efficient Car and embark on a journey toward a more sustainable and cost-effective driving experience. Explore our lineup and make the switch to smarter driving today!

2 notes

·

View notes

Text

Facing Challenges: Car Transport Companies and the Switch to Clean Fuels

As the world shifts towards greener energy solutions, car transport companies are facing new challenges and opportunities. Staying competitive and meeting customer demands is important for car shipping services. Explore how these companies are adapting to alternative fuel innovations, and how integrating electric and hybrid vehicles into their fleets and adjusting their services to accommodate this change.

From operational adjustments to training staff on new technologies, discover the practical steps car transport companies are taking to embrace a cleaner future.

Alternative Fuel Innovations

The automotive industry has been making significant strides in developing alternative fuel technologies to reduce reliance on traditional fossil fuels and decrease environmental impact. These innovations have an influence on nationwide car transport services, as they adapt to accommodate vehicles with diverse fuel systems.

Hydrogen Fuel Cells

Hydrogen fuel cell technology has emerged as a promising alternative to conventional internal combustion engines. These systems generate electricity through a chemical reaction between hydrogen and oxygen, producing only water vapor as a byproduct. This clean energy solution has an impact on reducing carbon emissions in the transportation sector.

For nationwide vehicle driveaway services, the adoption of hydrogen fuel cell vehicles presents new challenges and opportunities. Transport companies are adapting their processes to handle these vehicles safely, ensuring proper fueling and maintenance during long-distance shipping. The increasing popularity of hydrogen-powered cars has an influence on the infrastructure development along major transport routes, with more hydrogen refueling stations being established to support these vehicles.

Solar-Powered Accessories

Solar power has found its way into various automotive applications, particularly in the form of solar-powered accessories. These innovative additions harness the sun's energy to power auxiliary systems in vehicles, reducing the load on the main power source and improving overall efficiency.

In the context of auto transport services in California and across the nation, solar-powered accessories have an impact on vehicle preservation during transit. For instance, solar-powered ventilation systems can help maintain optimal temperatures inside vehicles during long journeys, protecting interiors and sensitive electronics from extreme heat. This technology has an influence on the quality of service provided by car shipping companies, ensuring vehicles arrive at their destinations in prime condition.

Biodiesel Compatibility

Biodiesel, a renewable fuel produced from vegetable oils or animal fats, has gained traction as an alternative to petroleum-based diesel. Many modern diesel engines are now designed to be compatible with biodiesel blends, offering a more environmentally friendly option for drivers and transport companies alike.

For San Jose auto shipping services and other transport providers, the increased compatibility with biodiesel has an impact on fuel options and environmental considerations. Transport companies are increasingly incorporating biodiesel-compatible vehicles into their fleets, reducing their carbon footprint while maintaining performance standards. This shift has an influence on the overall sustainability of nationwide car transport operations, aligning with growing environmental concerns and regulations.

The integration of these alternative fuel innovations in the automotive industry has a significant impact on nationwide car transport services. As vehicles become more diverse in their fuel requirements, transport companies are adapting their practices to accommodate these changes.

For those interested in learning more about how these alternative fuel technologies affect car shipping and the broader automotive landscape, it is recommended to read the full details on luckystarautotransport.com, where comprehensive information about these advancements is available. For those interested in learning more about how these innovations affect, nationwide car transport and the broader automotive industry, it is recommended to read this contact form on luckystarautotransport.com interested in the transport industry and its improvement toward sustainability.

For those interested in learning more about how these innovations affect, nationwide car transport and the broader automotive industry, it is recommended to navigate this website and discover the untapped market potential of eco-conscious consumers in the transport industry and its improvement toward sustainability.

Clean fuels aren’t just a trend—they’re the future of car transport. Will you adapt or get left behind?

youtube

3 notes

·

View notes

Text

Exploring the Benefits of the Vauxhall Vivaro Electric for Urban Driving

The demand for electric commercial vehicles is rising rapidly as businesses seek sustainable and cost-effective transport solutions. One of the most practical choices for professionals in Ayrshire is the new Vauxhall Vivaro Electric vans in Ayrshire. These modern vans offer a blend of efficiency, practicality, and environmental consciousness, making them an ideal choice for urban driving.

Why Choose an Electric Van?

Electric vans are quickly becoming the preferred option for businesses looking to reduce their carbon footprint while maintaining efficiency in daily operations. With advancements in battery technology, electric vans now offer significant range, fast charging capabilities, and lower running costs compared to traditional diesel or petrol vehicles.

For businesses operating in Ayrshire, transitioning to an electric van can bring long-term benefits, particularly with local incentives and infrastructure improvements supporting sustainable transport.

Key Benefits of the New Vauxhall Vivaro Electric Vans in Ayrshire

1. Zero Emissions for Cleaner Urban Transport

One of the standout features of the new Vauxhall Vivaro Electric vans in Ayrshire is their zero-emission capability. This means they do not produce harmful pollutants, making them ideal for city centres, low-emission zones, and environmentally conscious businesses. With many urban areas prioritising air quality, using an electric van ensures compliance with regulations while contributing to a healthier environment.

2. Cost Savings on Fuel and Maintenance

Switching to an electric van eliminates fuel costs, which can be a major expense for businesses. Electricity is significantly cheaper than diesel or petrol, allowing drivers to save on operational expenses. Additionally, electric vehicles have fewer moving parts, resulting in lower maintenance costs. With reduced servicing requirements, businesses in Ayrshire can keep their fleets running efficiently without frequent costly repairs.

3. Impressive Driving Range and Charging Convenience

Modern electric vans are designed to meet the demands of daily operations. The new Vauxhall Vivaro Electric vans in Ayrshire come with a competitive range, making them suitable for both city driving and longer routes. Charging is also convenient, with multiple public charging points available across Ayrshire. Home and workplace charging options further enhance usability, ensuring businesses have minimal downtime.

4. Quiet and Comfortable Driving Experience

Electric vans operate much quietly than their combustion engine counterparts, reducing noise pollution and providing a smoother driving experience. This is especially beneficial for urban driving where stop-and-go traffic can be frequent. Drivers will appreciate the enhanced comfort, making long working hours behind the wheel more manageable.

5. Government Incentives and Grants

To encourage the adoption of electric vehicles, the UK government offers various grants and incentives. Businesses in Ayrshire can take advantage of these schemes to reduce the upfront cost of purchasing electric vans. Lower road tax and exemption from congestion charges also make electric vans a financially sound choice.

6. Enhanced Cargo Space and Practicality

The new Vauxhall Vivaro Electric vans in Ayrshire are designed with practicality in mind. With spacious cargo areas and flexible configurations, they can accommodate different business needs, from courier services to tradespeople requiring storage for tools and equipment. The payload capacity remains competitive, ensuring businesses do not compromise on carrying capabilities when switching to electric.

7. Advanced Technology and Safety Features

Modern electric vans are equipped with cutting-edge technology to improve safety and convenience. Features such as regenerative braking, advanced driver-assistance systems, and infotainment options enhance the overall driving experience. With intuitive controls and smart connectivity, businesses can optimise their logistics and efficiency.

Making the Switch to Electric in Ayrshire

Ayrshire is witnessing a shift towards greener transport solutions, with expanding infrastructure supporting electric vehicle users. The availability of charging stations, combined with local initiatives to promote sustainable transport, makes it the perfect time for businesses to transition to electric vans.

Adopting the new Vauxhall Vivaro Electric vans in Ayrshire is not just about keeping up with trends; it’s about future-proofing your business. With increasing fuel costs and stricter environmental regulations, investing in an electric van ensures you stay ahead while contributing to a cleaner and more sustainable community.

Final Thoughts

The new Vauxhall Vivaro Electric vans in Ayrshire offer a compelling solution for businesses and individuals looking for an efficient, eco-friendly, and cost-effective transport option. With their impressive range, lower operational costs, and advanced features, they provide a seamless transition into the world of electric mobility.

Whether you are a delivery service, a contractor, or a small business owner, making the switch to an electric van can bring substantial long-term benefits. With growing support for electric vehicles in Ayrshire, now is the perfect time to consider upgrading to a sustainable driving solution.

#New Vauxhall Vivaro Electric vans Ayrshire#Official Vauxhall Dealer in Ayrshire#Official Vauxhall Dealer in Cumnock#Vauxhall Business Vans in Ayrshire#Vauxhall Business Vans in Cumnock#Vauxhall Commercial Vans Ayrshire#Vauxhall Commercial Vans in Cumnock#New Vauxhall Car Deals in Ayrshire#New Vauxhall Car Deals in Cumnock#New Vauxhall Vans in Ayrshire#New Vauxhall Vans in Cumnock#New Vauxhall Vivaro Electric vans in Cumnock

0 notes

Text

Exploring Bluechem Australia's Diesel Exhaust System Cleaner Options

Not all diesel exhaust system cleaners are created equal. At Bluechem Australia, we offer a range of options to suit your specific needs:

Fuel Additive Cleaners: These cleaners are added directly to your diesel fuel and work continuously to prevent build-up within the exhaust system. They are ideal for preventative maintenance and maintaining optimal performance.

Direct Application Cleaners: These cleaners are applied directly to the DPF or into the fuel intake system for a more concentrated and targeted cleaning. They are ideal for addressing existing clogs and restoring efficiency.

Contact- Web - https://www.bluechemaustralia.com.au/diesel-exhaust-system-cleaner/ Mail - [email protected] Ph - 0498 880 115 Address - UNIT 4, 63 Brunel Rd, Seaford VIC 3198, AU

0 notes

Text

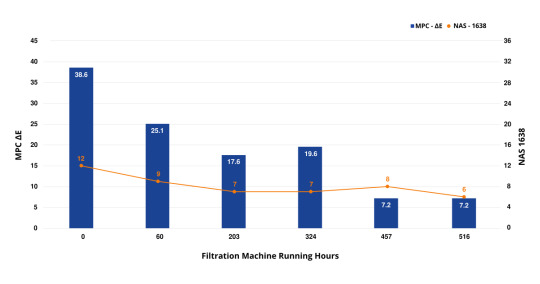

Efficiently Eliminating Varnish from 23,500 Liters of Oil in Just 516 Hours

Mitigating a Potential Power Crisis in Western India through Varnish and Solid Contamination Removal

Synopsis

A Power Plant supplying a major 1967 MW of power to the Western India, based in Dabhol, Maharashtra,and owned by one of the largest PSU’s, faced troubles with recurring turbine trip downs in two of its main turbines due to a sticky oil residue.Varnish and Solid Contaminants were identified with initial MPC values ΔE=38.6 and NAS 1638=Class 12, which needed reduction to ΔE≤15 and NAS 1638≤Class 6.Minimac's FS 500 machine, with a 3-stage system, achieved this in 516 hours, preventing frequent tripping, valve failures, erratic operations, extensive overhauls, and potential losses of ₹50 lakhs.

Initial Findings

Minimac's team conducted a site visit, analyzing the situation and taking an initial oil sample. Third-party lab testing revealed significant findings, with initial oil MPC values at ΔE=38.6 and NAS 1638 classification of Class 12.

Problems

The client encountered frequent turbine shutdowns in two of its primary turbines due to sticky oil residue within the Gas Turbines' (GTs) bearings and valves. A subsequent oil analysis confirmed the existence of varnish in the oil. As a result, Minimac was entrusted with the responsibility of removing the varnish from the main lube oil.

Client’s Requirements

To Purify 23,500 liters of Prime 32 oil.

To remove the varnish and solid contaminants.

To Achieve ΔE≤15 from its initial reading of 38.6.

To achieve NAS 1638≤Class 6 from its initial reading of Class 12.

Smooth & Timely Execution without any downtime.

Customized Solution.

No spillage.

Solutions

Deploying our customized machine at the site along with our trained and skilled engineers

FS 500: A miraculous 500-liter-per-minute machine featuring a 3-stage flushing and filtration system

It encapsulates varnish removal capacity and mechanical filters to effectively give the desired results.

It was connected to the main oil tank (MOT) of unit 3A, which contained 23,500 liters of Prime 32 oil.

Along with the equipment’s installation, our Service Engineer trained the client’s team on the functioning of the machine and the effective handling of the same.

Job executed 24/7, with continuous oil testing. Remarkably, set KPIs achieved in just 516 hours, showing significant improvement, reaching ΔE=7.2 and NAS 1638: Class 6.

Benefits

Prevented the environment from harm by averting the emission of 2,82,000 kilograms of CO2e.

Extended Oil Life.

Elimination of Oil Replacement Costs.

An enormous quantity of oil was cleaned in a limited amount of time.

Increased Machine Reliability.

Cost Saving

This Plant managed to save:

Cost of Oil Replacement: ₹50 Lakhs Approx.

Cost of Downtime : ₹1 Cr. Approx.

CO2e Savings

Total Savings = 2,82,000 kg of CO2e/0.282 gigagrams of CO2e

Graph

Subscribe to our WhatsApp Community and be a part of our Journey - Click Here

#frf#oil flushing#minimac systems#power#minimac#oil & gas#hydraulic oil#lube oil filter#contamination#hydraulic oil filter#oil filtration machine#oil filtration#oil contamination#fire resistance flauid#oil oil filtration systems#oil dehydration systems#elc#electrostatics lube cleaner#transformer oil#transformer oil cleaning#transformer oil filtration#transformers#diesel oil purification#coalescer separator#lube oil flushing systems#lube oil flushing#lube oil#hydraulic oil machine#hydraulic oil filter#hydraulic oil cleaning

0 notes

Text

What is the Efficiency of a Bio CNG Plant?

Introduction

Bio CNG (Compressed Natural Gas) is emerging as a sustainable alternative to conventional fuels, offering an eco-friendly solution for energy needs. The efficiency of bio CNG plants plays a crucial role in determining their viability, cost-effectiveness, and environmental benefits. Understanding the factors that influence efficiency can help industries and governments optimize operations for maximum output.

Understanding Efficiency in Bio CNG Production

Efficiency in a bio CNG plant is measured by the ratio of energy output to input, methane yield, and overall resource utilization. A well-optimized plant can achieve an energy output-to-input ratio of approximately 25:1, meaning it produces significantly more energy than it consumes. This high efficiency makes bio CNG a competitive option compared to fossil fuels.

Key Factors Influencing Bio CNG Plant Efficiency

Several factors impact the efficiency of bio CNG plants, including:

1. Feedstock Quality and Composition

Organic waste, agricultural residues, and animal manure serve as raw materials.

High-methane-yield feedstocks, such as Napier grass or food waste, enhance gas production.

Proper pre-treatment removes impurities and maximizes methane potential.

2. Digestion Process and Retention Time

Anaerobic digestion is the core process in bio CNG production.

Longer retention times (typically 20–40 days) allow for complete breakdown of organic matter.

Maintaining an optimal temperature (35–55°C) improves bacterial activity and gas yield.

3. Advanced Purification Technologies

Water scrubbing, pressure swing adsorption (PSA), membrane separation, and cryogenic separation enhance methane purity.

High-quality purification systems ensure methane levels reach 90% or higher, improving fuel quality and efficiency.

4. Energy Consumption in the Process

Efficient pumps, mixers, and blowers reduce overall energy consumption.

Using biogas-generated electricity within the plant enhances sustainability.

Comparing Bio CNG Efficiency with Other Renewable Energy Sources

Bio CNG vs. Biogas: Bio CNG is a more refined version of biogas, with higher methane content and better combustion efficiency.

Bio CNG vs. Solar and Wind: Unlike intermittent solar and wind energy, bio CNG offers continuous energy production, making it a reliable fuel source.

Bio CNG vs. Fossil Fuels: Producing bio CNG reduces greenhouse gas emissions by up to 90% compared to diesel and petrol.

Challenges in Maximizing Bio CNG Efficiency

Despite its advantages, certain challenges must be addressed:

High initial investment costs for setting up purification and compression units.

Logistics and transportation hurdles for collecting and processing raw materials.

Variability in feedstock supply, affecting consistency in methane yield.

Future Innovations to Enhance Bio CNG Plant Efficiency

To further improve efficiency, ongoing research focuses on:

Hybrid purification techniques that combine multiple separation technologies.

AI-driven process optimization for real-time monitoring and control.

Carbon capture and utilization (CCU) for reusing CO₂ separated during purification.

Conclusion

The efficiency of bio CNG plants depends on factors such as feedstock quality, digestion process, purification methods, and energy management. With an energy output-to-input ratio of 25:1, bio CNG is proving to be a highly efficient renewable fuel. Investing in advanced technologies and innovative processes will further enhance its sustainability and commercial viability, making it a key player in the transition to cleaner energy.

0 notes

Text

Natural Gas Vehicles Market Supply Chain Challenges and Future Strategies to 2033

The global automotive industry is undergoing a significant transformation, driven by the urgent need for sustainable and environmentally friendly transportation solutions. Among the various alternatives to conventional gasoline and diesel vehicles, Natural Gas Vehicles (NGVs) have emerged as a compelling option. Utilizing compressed natural gas (CNG) or liquefied natural gas (LNG) as fuel, NGVs offer a cleaner and often more economical alternative to traditional fossil fuels. This article delves into the current trends, growth drivers, challenges, and future projections of the NGV market leading up to 2032.

Market Overview

The global NGV market has witnessed steady growth over the past decade, with increasing adoption across both developed and developing regions. In 2023, the market was valued at approximately USD XX billion. Projections indicate that by 2032, the market could reach USD XX billion, representing a compound annual growth rate (CAGR) of XX% during the forecast period.

𝗗𝗼𝘄𝗻𝗹𝗼𝗮𝗱 𝗮 𝗙𝗿𝗲𝗲 𝗦𝗮𝗺𝗽𝗹𝗲 𝗥𝗲𝗽𝗼𝗿𝘁👉https://tinyurl.com/3j3fsrtx

Growth Drivers

Several factors are propelling the growth of the NGV market:

Environmental Concerns and Emission Regulations: Governments worldwide are implementing stringent emission norms to combat air pollution and reduce greenhouse gas emissions. NGVs emit significantly lower levels of harmful pollutants compared to their gasoline and diesel counterparts, making them an attractive option for meeting these regulations.

Cost-Effectiveness: Natural gas often costs less than conventional fuels, leading to lower operating expenses for vehicle owners. This economic advantage is particularly appealing for commercial fleets and public transportation systems.

Abundant Natural Gas Reserves: The global availability of natural gas reserves ensures a stable and reliable supply, reducing dependence on imported oil and enhancing energy security for many countries.

Technological Advancements: Continuous improvements in NGV technology, including enhanced fuel storage systems and more efficient engines, have increased the performance and appeal of these vehicles.

Regional Insights

Asia-Pacific: This region dominates the NGV market, with countries like China and India leading the adoption. In India, for instance, the government plans to convert a third of its heavy-duty long-haul trucking fleet to operate on LNG over the next five to seven years, aiming to reduce pollution and decrease diesel consumption.

Europe: European countries are investing in NGV infrastructure to diversify their energy mix and reduce transportation emissions. The focus is on integrating NGVs into public transportation and freight services.

North America: The United States and Canada are witnessing gradual adoption of NGVs, driven by both environmental policies and the economic benefits of domestic natural gas production.

Latin America: Countries like Brazil and Argentina have a long history of NGV usage, supported by favorable government policies and abundant natural gas resources.

Challenges

Despite the positive outlook, the NGV market faces several challenges:

Infrastructure Development: The expansion of refueling infrastructure is crucial for widespread NGV adoption. Inadequate refueling stations can deter potential users due to range anxiety and inconvenience.

High Initial Conversion Costs: Converting existing vehicles to run on natural gas or purchasing new NGVs involves higher upfront costs, which can be a barrier for individual consumers and small businesses.

Competition from Electric Vehicles (EVs): The rapid advancement and adoption of EVs pose a competitive threat to NGVs. As battery technology improves and charging infrastructure expands, EVs are becoming increasingly viable for a broader range of consumers.

Public Awareness and Perception: Limited awareness and misconceptions about the safety and benefits of NGVs can hinder market growth. Educational initiatives are necessary to inform the public and promote acceptance.

Future Outlook

Looking ahead to 2032, the NGV market is expected to experience sustained growth, driven by:

Policy Support and Incentives: Governments are likely to continue offering incentives for NGV adoption, including tax breaks, subsidies, and grants for infrastructure development.

Advancements in Fuel Storage and Engine Technology: Innovations aimed at increasing fuel efficiency, reducing vehicle weight, and enhancing safety will make NGVs more competitive.

Integration with Renewable Natural Gas (RNG): The use of RNG, derived from organic waste, can further reduce the carbon footprint of NGVs, aligning with global sustainability goals.

Expansion in Emerging Markets: As developing countries urbanize and seek sustainable transportation solutions, the demand for NGVs is expected to rise, presenting significant market opportunities.

Conclusion

The Natural Gas Vehicles market stands at a pivotal juncture, offering a viable pathway toward cleaner and more sustainable transportation. While challenges remain, the collective efforts of governments, industry stakeholders, and consumers can drive the continued growth and adoption of NGVs. By addressing infrastructure needs, reducing costs, and enhancing public awareness, the NGV market can play a crucial role in the global transition to environmentally friendly transportation solutions.

Read Full Report:-https://www.uniprismmarketresearch.com/verticals/energy-power/natural-gas-vehicles.html

0 notes

Text

Hybrid Energy Systems for Sustainable Power Solutions – PowerLink Energy Australia

Hybrid energy systems are revolutionizing the way power is generated and utilized. PowerLink Energy Australia, a leader in innovative energy solutions, offers cutting-edge hybrid energy systems that seamlessly combine multiple energy sources for maximum efficiency and sustainability. These systems are ideal for industries and communities striving to reduce carbon emissions while ensuring reliable energy supply.

What Are Hybrid Energy Systems?

Hybrid energy systems integrate two or more energy sources—typically renewable energy like solar or wind with conventional energy such as diesel or gas generators. The result is a versatile, efficient, and environmentally friendly power solution that balances energy availability and demand.

Key Features of PowerLink Hybrid Energy Systems

1. Energy Efficiency

By integrating renewable sources, PowerLink hybrid systems optimize energy production and reduce reliance on fossil fuels. This efficiency translates to lower operational costs and a smaller carbon footprint.

2. Seamless Integration

PowerLink systems are designed to combine energy sources smoothly, switching between them as needed. Advanced control systems ensure consistent power supply without interruptions.

3. Scalability

PowerLink hybrid systems can be scaled to meet the energy demands of small businesses, large industries, or off-grid communities, offering flexible and tailored solutions.

4. Durability and Reliability

Built with high-quality materials, these systems are durable and reliable, even in harsh Australian conditions. They provide a stable energy supply, crucial for remote locations or critical operations.

Benefits of Hybrid Energy Systems

Environmental Impact Reduction

By incorporating renewable energy, hybrid systems significantly reduce greenhouse gas emissions, contributing to a cleaner, greener future.

Cost Savings

Combining renewable sources with conventional energy reduces fuel consumption, lowering operational and maintenance costs over time.

Energy Security

Hybrid systems ensure a continuous power supply by leveraging multiple energy sources. They are ideal for areas prone to power outages or limited grid access.

Versatile Applications

From powering remote mining sites to supporting sustainable residential developments, hybrid energy systems are versatile and adaptable to diverse requirements.

Industries Benefiting from PowerLink Hybrid Energy Systems

Mining: Reliable and cost-effective power solutions for remote operations.

Construction: Sustainable energy supply for temporary or long-term project sites.

Agriculture: Power for irrigation systems, storage facilities, and off-grid farming.

Residential: Off-grid and sustainable energy solutions for eco-conscious homeowners.

Why Choose PowerLink Energy Australia?

PowerLink Energy Australia combines innovative technology with a commitment to sustainability. Their hybrid energy systems are designed to meet Australian standards, offering robust, efficient, and eco-friendly solutions. With exceptional customer service and tailored options, PowerLink ensures every client’s energy needs are met.

Conclusion

Hybrid energy systems by PowerLink Energy Australia represent the future of sustainable energy. Combining efficiency, reliability, and environmental consciousness, these systems provide the perfect balance of performance and sustainability. Choose PowerLink for your hybrid energy needs and contribute to a greener tomorrow.

0 notes

Text

What Are the Environmental Considerations for Construction Site Power Generation?

Construction sites are significant energy consumers, and their power generation methods have substantial environmental implications. Understanding the environmental considerations of construction site power generation is crucial for sustainable development and reducing carbon footprints.

1. Traditional Power Generation Challenges

Diesel generators have long been the standard for construction site power generation. However, these traditional power sources come with significant environmental drawbacks:

• High carbon emissions • Significant air pollution • Noise contamination • Non-renewable fuel dependency

These challenges have pushed the construction industry to explore more sustainable power generation alternatives that minimize environmental impact while maintaining operational efficiency.

2. Renewable Energy Alternatives

Modern construction sites are increasingly adopting renewable energy solutions:

Solar Power Options: • Portable solar panels • Solar generator systems • Hybrid solar-battery configurations

Wind Energy Solutions: • Compact wind turbines • Portable wind generation units • Integrated renewable energy systems

These alternatives significantly reduce carbon emissions and provide cleaner energy sources for construction operations.

3. Environmental Regulatory Compliance

Construction companies must navigate complex environmental regulations:

Key Regulatory Considerations: • Emissions standards • Carbon footprint reporting • Energy efficiency requirements • Sustainable development guidelines

Compliance involves: • Regular equipment emissions testing • Implementing low-carbon power generation • Documenting environmental impact • Investing in green technologies

4. Technology and Innovation

Emerging technologies are revolutionizing construction site power generation:

Innovative Solutions: • Hybrid power systems • Smart grid integration • Advanced battery storage • AI-powered energy management • Predictive maintenance technologies

These innovations enable more efficient and environmentally responsible power generation strategies.

Conclusion

Construction site power generation is evolving rapidly. Environmental considerations are no longer optional but essential for responsible project management. By embracing renewable technologies, complying with regulations, and investing in innovative solutions, construction companies can significantly reduce their environmental impact.

Ready to transform your construction site's power generation? Explore sustainable power solutions with JC Davis Power and lead the way in environmental responsibility!

Sustainable power generation isn't just about meeting regulations—it's about creating a better future for our planet and industry.

0 notes

Text

Electrifying Light Commercial Transport: How Electric Trucks Are Redefining Efficiency and Sustainability

The evolution of transportation is in full swing, driven by the global shift towards cleaner and more efficient energy sources. One of the most transformative innovations in the logistics and transport sector is the advent of the electric truck. As traditional diesel-powered vehicles face increasing scrutiny due to environmental concerns and rising fuel costs, electric trucks are emerging as a promising solution for light commercial transport.

Electric trucks are revolutionizing the way goods are moved across cities and regions. Their advanced electric powertrains offer significant advantages over conventional engines, including higher energy efficiency, lower maintenance requirements, and zero tailpipe emissions. These benefits make electric trucks ideal for urban deliveries and short-haul operations, where environmental regulations and fuel efficiency are paramount.

One of the key benefits of an electric truck is its reduced operating cost. With fewer moving parts compared to an internal combustion engine, electric trucks require less frequent maintenance, translating to lower downtime and long-term savings. Additionally, the energy required to power an electric truck is typically less expensive than diesel fuel, helping fleet operators reduce their overall operational expenses.

Sustainability is another driving force behind the adoption of electric trucks. By eliminating harmful emissions, electric trucks contribute significantly to improving air quality in urban areas. This aligns with global initiatives to combat climate change and promote sustainable practices in transportation. The quiet operation of electric trucks also reduces noise pollution, making them an attractive option for city environments where community well-being is a priority.

Furthermore, advancements in battery technology are rapidly extending the range and reliability of electric trucks. Modern batteries offer improved energy density and faster charging capabilities, which means electric trucks can now cover greater distances and spend less time in the charging station. This enhanced performance is critical for businesses that rely on light commercial transport for timely deliveries.

Innovation in electric trucks is also driving the development of integrated fleet management systems. These systems leverage data analytics and real-time monitoring to optimize routes, manage charging cycles, and predict maintenance needs. As a result, operators can achieve higher levels of efficiency, ensuring that every mile driven is both cost-effective and environmentally responsible.

In conclusion, the electric truck is at the forefront of a major transformation in light commercial transport. By offering unmatched efficiency, reduced operational costs, and significant environmental benefits, electric trucks are setting a new standard for sustainability in the transportation sector. For more detailed insights into the future of electric truck technology and its impact on commercial transport, visit Atomix Energy.

1 note

·

View note