#hydraulic oil filter

Explore tagged Tumblr posts

Text

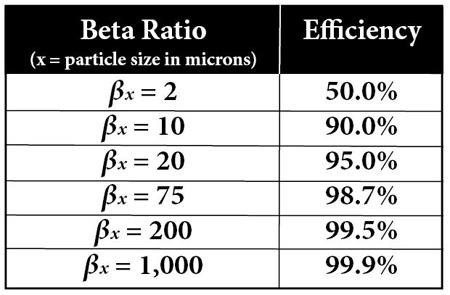

Understanding of the BETA factor

What is the Beta Ratio?

The beta ratio refers to the efficiency in which a given filter element removes the particle of a given size. The Beta Ratio is calculated using the ISO multi-pass test standard 16889:1999.

How is it measured?

Get your filter check today, Call +91 7030901266

So, to purchase a filter with a beta ratio of 2-10 is considered poor, it is advised to use filters with at least a Beta factor of 75 and 98.7% effectiveness. High quality, efficient filter assemblies can achieve 200 to 2000 Beta Ratio for given particle size and should be ideal to achieve a low level of contamination.

Also read: https://www.linkedin.com/pulse/you-buying-right-oil-filter-anshuman-agrawal-mlt-1-/

We at Minimac Systems Pvt Ltd. provide services of Total Lubrication Management and Lubrication Consulting that helps you optimize your Lubrication needs. Minimac stands for MINImum MAChinery Maintenance.

#frf#oil flushing#minimac systems#power#minimac#oil & gas#hydraulic oil#lube oil filter#hydraulic oil filter#contamination#oil purification system#oil purification machine#oil contamination#oil purification#oil testing#oil filter machine#oil filter systems#oil filters#oil industry#oil and gas#turbine oilanalysis maintenance lubrication reliability contaminationcontrol oil powerplants oilfiltration rotatingequipment mechanical bre#turbinemaintenance#wind turbines#gas turbine#steam turbine#steel#metal#mining#oil dehydration systems

2 notes

·

View notes

Text

Smart Filtration: How IoT-Enabled Hydraulic Filters Are Revolutionizing Predictive Maintenance

Imagine getting a text message from your hydraulic system saying, "Hey, I need a filter change next week!" Sounds futuristic? Well, it's happening now. Every year, companies lose millions due to unexpected equipment breakdowns. But what if your hydraulic oil filter could tell you exactly when it needs attention? That's where IoT-enabled smart filtration comes in. It's not just about preventing problems – it's about saving money, time, and resources.

Real-Time Monitoring

Smart sensors attached to hydraulic oil filters constantly check filter condition. Prevents sudden failures and unnecessary maintenance.

Install pressure sensors and connect them to your monitoring system.

A manufacturing plant in Gujarat reduced downtime by 45% after implementing real-time monitoring.

Predictive Alerts

The system warns you before problems happen. Helps plan maintenance during off-peak hours.

Set up alert thresholds in your monitoring software.

Construction company saved ₹5 lakhs yearly by avoiding emergency repairs.

Data-Driven Decisions

Collect and analyze filter performance data. Helps understand patterns and optimize maintenance schedules.

Use dashboard software to track trends.

Mining company extended filter life by 30% using data insights.

Remote Monitoring

Check filter status from anywhere using your phone. Reduces need for physical inspections.

Install mobile app connected to sensors.

Oil refinery manages 50 filters with just two technicians instead of five.

Cost Optimization

Smart systems help use filters for their full life. Reduces waste and saves money.

Follow system recommendations for changes.

Average 25% reduction in filter replacement costs.

Integration Capabilities

Smart filters work with existing maintenance systems. Creates a complete maintenance picture.

Use standard protocols to connect systems.

Factory reduced overall maintenance time by 35%.

Environmental Impact

Better filter management means less waste. Helps meet environmental goals.

Track and report on waste reduction.

Smart systems reduce oil waste by up to 40%.

Conclusion:

Smart filtration isn't just a trend – it's the future of maintenance. By implementing IoT-enabled hydraulic oil filters, you're not just buying equipment; you're investing in reliability and efficiency. The technology is ready, and the benefits are clear.

What Next?

Assess your current filtration system

Calculate potential savings

Start with a pilot project

Ready to make your hydraulic systems smarter? Contact India Filters today for a free consultation. Our experts will help you choose the right smart filtration solution for your needs.

#hydraulic filter#hydraulic oil filter#Hydraulic oil Filters Manufacturers in India#IoT-Enabled Hydraulic Filters

0 notes

Text

🏭 Best Turbine Oil Cleaning System & Oil Filtration Machines in India ⚙️

Looking for high-performance oil filtration solutions? 🌍 OilFilterMachineIndia.com is a trusted manufacturer and supplier of advanced oil filtration systems designed for industrial applications. From Turbine Oil Cleaning Systems to Transformer Oil Filtration Plants, we provide top-notch filtration solutions to enhance machinery efficiency and oil purity.

🔥 Our Premium Oil Filtration Solutions

We specialize in manufacturing, supplying, and exporting a wide range of oil cleaning machines and filtration systems to meet industrial needs.

🔹 Turbine Oil Cleaning System ⚙️ 🔹 Oil Cleaning Machines 🏗️ 🔹 Turbine Oil Cleaning Systems 🔥 🔹 Oil Filtration Plant 🛢️ 🔹 Gear Oil Filtration Systems ⚙️ 🔹 Industrial Oil Filter Machine 🛠️

🔹 Oil Filtration Systems 🏭 🔹 Double Stage Oil Transformer Machine 🚀 🔹 Oil Filtration Elements 🔩 🔹 Oil Filtration Machine 🔥 🔹 Oil Filtration & Cleaning Systems 🛢️ 🔹 Thermic Oil Filtration Systems 🌡️ 🔹 On-Site Oil Testing 🧪 🔹 Online Oil Cleaning Systems 🔍 🔹 Hydraulic Oil Online Filters 🔧 🔹 Mobile Oil Filtration Plant 🚚 🔹 Portable Oil Filtration Plant 🏭 🔹 Portable Oil Filtration System ⚙️ 🔹 Turbine Oil Filtration Plant 🏗️ 🔹 Turbine Oil Filtration Machine 🌍 🔹 Transformer Oil Filtration System 🔥 🔹 Transformer Oil Cleaning Systems 🏭 🔹 Evacuation System for Transformers 🛢️ 🔹 Transformer Oil Filtration Plant 🚀 🔹 Two-Stage Transformer Oil Filtration Plant 🔩 🔹 Transformer Evacuation System ⚡ 🔹 Transformer Oil Filtration Machine ⚙️ 🔹 Transformer Oil Filter Machine 🏗️ 🔹 Turbine Oil Flushing System 🔥 🔹 Centrifugal Oil Cleaner 🏭 🔹 Oil Testing Equipment 🧪 🔹 Visgage Oil Test Kits 🔍 🔹 Karl Fischer Moisture Measurement Equipment 🌡️ 🔹 Online Inline Particle Counters 🔧 🔹 Online Oil Contamination Sensors 🏭 🔹 Laser Particle Counters 🚀 🔹 Industrial Filters 🏗️ 🔹 Transformer Oil Reclamation Units ⚙️ 🔹 Industrial Oil Filters 🛢️

✅ Why Choose Us?

✔ High-Efficiency Oil Cleaning & Filtration Solutions ✔ Advanced Technology for Oil Purity & Equipment Protection ✔ Customized Oil Filtration Plants for Industrial Applications ✔ Reliable Exporters & Suppliers Across India

🔗 Explore Our Full Range of Oil Filtration Machines Here 👉 OilFilterMachineIndia.com

📞 Get in Touch Today! ✉��� #OilFiltration #IndustrialFiltration #TransformerOilCleaning #TurbineOilCleaning #OilPurification #HydraulicOilFilters #IndustrialOilFilterMachine 🚀

#Turbine Oil Cleaning System#Oil Cleaning Machines#Turbine Oil Cleaning Systems#Oil Filtration Plant#Gear Oil Filtration Systems#Industrial Oil Filter Machine#Oil Filtration Systems#Double Stage Oil Transformer Machine#Oil Filtration Elements#Oil Filtration Machine#Oil Filtration & Cleaning Systems#Thermic Oil Filtration Systems#On Site Oil Testing#Online Oil Cleaning Systems#Hydraulic Oil Online Filters#Mobile Oil Filtration Plant#Portable Oil Filtration Plant#Portable Oil Filtration System#Turbine Oil Filtration Plant#Turbine Oil Filtration Machine#Transformer Oil Filtration System#Transformer Oil Cleaning Systems#Evacuation System for Transformers#Transformer Oil Filtration Plant#Two Stage Transformer Oil Filtration Plant#Transformer Evacuation System#Transformer Oil Filtration Machine#Transformer Oil Filter Machine#Turbine Oil Flushing System#Centrifugal Oil Cleaner

0 notes

Text

Top 10 Quality Hydraulic Oil Filter Machine Manufacturers

Rayon India's Hydraulic Oil Filter Machine ensures seamless filtration, keeping your machinery running smoothly. With user-friendly design, it efficiently removes contaminants, extending equipment lifespan. Simplify maintenance with our reliable solution. Trust Rayon India for hassle-free filtration, optimizing performance and reducing downtime.

Address : KHASRA NO. 1318,Morta Industrial Area,Near Hotel Vivaan Meerut Road, Morta ,GHAZIABAD - 201003 U.P

0 notes

Text

5 Maintenance Tips for Extending the Lifespan of Your Hydraulic Oil Filter Machine

We at Sumesh Petroleum recognise how crucial it is to maintain the efficiency of your hydraulic systems. A well-maintained hydraulic oil filter machine is essential to accomplishing this. You may assure optimal performance for years to come and prolong the lifespan of your machine by adhering to these easy suggestions.

1. Adopt a Prevention Mentality: Regular Maintenance Is Essential

Your Hydraulic Oil Filter Machine depends on regular maintenance, just like your car does. Make a timetable for cleanings, filter changes, and inspections by consulting the instructions that came with your machine. By taking a proactive stance, you can spot small problems early on and take action before they become bigger ones.

2. Filter Frenzy: Choosing the Correct Filter and Changing It When Needed

Not every filter is made equally! Make sure the filter type you're using is the right one that the maker of your machine recommends. This ensures maximum filtering effectiveness and shields your system from impurities. It's important to follow the suggested filter change schedule. A clogged filter strains your system and decreases flow.

3. Oil Analysis: An Insight into the Health of Your System

Think about putting in place a routine programme for oil analysis. It is possible to obtain important information about the condition of your hydraulic system by submitting oil samples to a laboratory. Oil analysis enables you to take corrective action before significant harm happens by early detection of degradation, contamination, and other equipment problems. 4. Maintaining Cleanliness: The Enemy Is Contamination

Hydraulic systems can become contaminated by moisture, dirt, and debris. The longevity of your equipment may be considerably shortened by this contamination. To reduce the danger of contamination, keep the area around your hydraulic oil filter machine clean and make sure that the oil and filters are stored properly.

5. Pay Attention! Pay Attention to Odd Sounds

Your Hydraulic Oil Filter Machine uses audio to communicate. Observe the sounds it makes when it operates normally. Any strange noises, such as excessive clanging, grinding, or whining, may be signs of an impending issue. Please do not hesitate to contact a competent technician for an inspection if you hear something unusual.

You can increase the longevity of your hydraulic oil filter machine, maximise performance, and guarantee the smooth running of your hydraulic systems by according to these easy maintenance guidelines. Get in touch with Sumesh Petroleum right now for more details on hydraulic oil filter machines or preventative maintenance schedules!

0 notes

Text

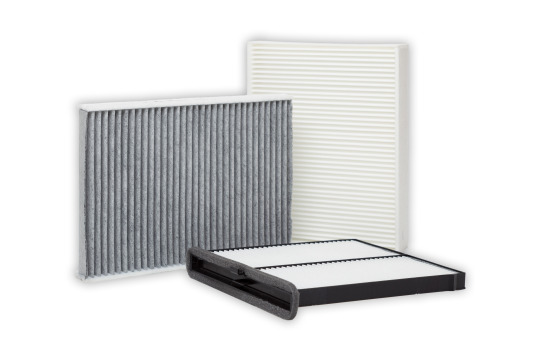

Cabin Filters and Fuel Filters Breathe Fresh, Drive Smooth with Action Group

Action Group's Cabin and Fuel Filters are made for maximum performance and best possible vehicle health. They will enhance your driving experience. Our Cabin Filters guarantee that your car's inside is clean and comfortable while capturing dust, pollen, and other pollutants to provide you a breath of fresh air. Our selection of fuel filters protects your engine by keeping contaminants from getting to vital parts, guaranteeing a smooth and effective fuel delivery system. You can rely on Action Group to provide high-quality filters that prolong the life of your car and improve driving comfort. Take a look at our selection now and benefit from improved engine performance and cleaner air. Drive with assurance and the Action Group at your side.

Company Name: ACTION GROUP

Phone No: +60362585868

#Cabin Filters#fuel filtes#Coolant filters#MANN+HUMMEL#Industrial Filters#OE Filters#car filters#Cabin filters#Car AirCon Filter#Car Replacement Filters#Fuel Filter#Heavy Duty Filters#Filtration Solutions#Aftermarket Filters#High Efficiency Filters#Auto filters#Hydraulic Filters#Air Oil Separator#Oil Filters#MANN FILTER#Car Air Filters#Performance Filters

0 notes

Text

How to clean a hydraulic oil filter ?

Cleaning a hydraulic oil filter typically involves removing the filter from the hydraulic system and then using appropriate methods to remove the accumulated dirt and debris. Here’s a general guide on how to clean a hydraulic oil filter:

Ensure safety: Before starting any maintenance on hydraulic systems, make sure the system is depressurized and the equipment is turned off.

Locate the filter: Identify the location of the hydraulic oil filter in your system. It is usually found in the hydraulic reservoir or in-line with the hydraulic lines.

Remove the filter: Depending on the type of filter, you may need to use a wrench or other tools to loosen and remove the filter from its housing. Be cautious to avoid spillage of hydraulic oil during this process. It’s a good idea to have a drain pan or absorbent materials ready to catch any oil that may leak.

Inspect the filter: Examine the filter for signs of damage or excessive contamination. If the filter is damaged or clogged beyond cleaning, it may need to be replaced instead of cleaned.

Pre-clean the filter: Before performing a thorough cleaning, you can use compressed air or a soft brush to remove loose debris and dirt from the filter. Be careful not to damage the filter media during this step.

Clean the filter: There are different methods to clean a hydraulic oil filter, depending on the type and level of contamination. Some common cleaning methods include:

Soaking: Submerge the filter in a cleaning solution recommended by the filter manufacturer or use a suitable solvent to dissolve the contaminants. Gently agitate the filter to help loosen the debris. Follow the manufacturer’s instructions for the appropriate soaking time.

Backflushing: If the filter is designed for backflushing, use a low-pressure source of clean hydraulic fluid to flush the filter in the opposite direction of the normal flow. This helps dislodge and remove contaminants from the filter media.

Ultrasonic cleaning: In some cases, ultrasonic cleaning machines can be used to clean the filter. These machines use sound waves to create high-frequency vibrations that help dislodge contaminants from the filter media.

Rinse and dry: After cleaning, thoroughly rinse the filter with clean water or a suitable cleaning solution to remove any remaining cleaning agents. Allow the filter to air dry completely before reinstalling it.

Reinstall the filter: Once the filter is dry, carefully reinstall it into its housing or mounting location. Make sure it is properly seated and securely fastened according to the manufacturer’s instructions.

Dispose of waste properly: Properly dispose of the used cleaning solution, contaminated filters, and any other waste materials according to local regulations and guidelines.

It’s important to note that not all hydraulic oil filters are designed to be cleaned and reused. Some filters are intended for one-time use and should be replaced when they become clogged or damaged. Always refer to the manufacturer’s recommendations and guidelines for proper maintenance and cleaning procedures specific to your hydraulic oil filter.

1 note

·

View note

Text

They say, ‘prevention is better than cure’, but when it comes to hydraulic rams, you need both." When dealing with hydraulic rams, you need a reliable source for the Best Hydraulic Ram Repairs. Look no further than Hyspec Fluid Power. Our experienced technicians use state-of-the-art equipment to diagnose and repair all types of hydraulic rams. We offer timely and cost-effective repairs, ensuring that your equipment is back up and running in no time. Contact us today to learn more about our hydraulic ram repair services and keep your operations running smoothly.

#hydraulic#hydraulic power units#industrial#business#hydraulic filters#hydraulic-oil#hydraulic cylinders#hydraulic power packs

0 notes

Text

Late night hcs i managed to retrieve from my brain

I hc their face/lips to be akin to alkali metals. I wrote this loosely in my Optimus fic, but never elaborated on it.

Alkali metals are very unstable and reactive, they react to air and water, therefore need to be kept under oil or sealed at all times. But surely there's a Cybertronian compound that is more advanced and can withstand the earth's atmosphere.

There are even more malleable metals on earth, ones that change from solid to liquid in matter of moments with a slight temperature change. Think mercury. (Cesium in picture)

Human teeth are very strong. They are the hardest substance in all of us. I forgot how much psi they can take but long story short:

Leaves us to definitely be able to chew on bots to some degree. (assuming you don't break your jaw first, also brush your teeth if you want any chance of fighting cons with your teeth!)

On the topic of inner workings, we often just call it mesh, but that leaves a lot up to our imagination. I see their "mesh" as very similar to:

Finely woven to allow for liquid/energon/or whatever else they have to pass through.

Material could be anything honestly. I personally see plastics, probably a cybertronian version of some sort of nylon.

But if we want to stick with metal, I can see very thin sheets of foil braided in. Perhaps something close to duct tape. (Actual duct tape, for ducts)

Further topics I want to investigate in:

An earth equivalent of energon. Perhaps a crystal or compound that behaves close to it. Just so we have a mental image of it, in writing or reading.

I hc processing energon to be similar to distillation. Regardless of what crystal I assign it, it should be able to have a boiling point where it then can be condensed into a liquid. (along with filtering out impurities)

I also wanted to explore transformium from the movies, but mercy its so cgi-ed. I don't know where to start.

Amorphous metals. Also known as Metallic glass. It really doesn't look too different even though it's make up is different.

why is the first thing google suggests when I look up Amorphous metal??

Food for thought when writing/reading~

References: Lot's of NileRed, a clip from Wheeler Scientific, and a clip from Hydraulic Press Channel. Oh and ofc wiki.

#transformers#transformers headcanons#rambles#maccadam#is this even transformers x anyone? it probably isn't#but i did mention a small chunk on teeth#transformers x human#Scientifically incorrect content#someone whos actually in science come help

98 notes

·

View notes

Text

Letters from Watson: The Engineer's Thumb

Part 1: The Fun Bits

Hatherly is "exceedingly pale" and Watson mentions agitation as a cause even though he's already noted the possibility for excessive blood loss, and that railway cases are "seldom trivial." Hooray for Victorian medicine.

Fun fact: if you're fainting from blood loss you already need a transfusion. As of '89 we are two decades before safe (relatively) blood transfusions, when the ABO clotting factors were discovered. However, given the pain and stress, the cause of Hatherly's fainting doesn't have to be hypovolemic shock. Hatherly did just lose a thumb.

A carbolised bandage would have been a bandage treated with phenol (carbolic acid) as a disinfectant. I would not recommend raiding Watson's stash for it, as carbolic acid can cause chemical burns.

I cannot decide if Holmes' habit of smoking all the leftovers of his previous day's pipes is gross or endearing.

In two years, Hatherly has earned 27 pounds and 10 shillings. (Using the trusty Bank of England inflation calculator, which does not DO fractions of a pound, this is just over 2,870 modern pounds, or $3590) He is not having a great start.

Reminder that a guinea is 1 pound, one shilling. 50 guineas is almost double the amount Hatherly has ever made in his entire practice. And yet the thing that actually makes him suspicious is that the consultation is scheduled for late at night, after the trains have stopped running.

Fuller's earth is a white, highly absorbent clay, used as a chemical filter and absorber. Actual mineral composition may vary, but the use it was named for was when wool processors (Fullers) would use it to clean oils and dirt from wool. This step would have been prior to spinning or felting the fiber.

A hydraulic press would be extremely unnecessary for shaping any kind of clay, since it's... clay. The first time I read this I confused Fuller's Earth with Diatomaceous earth, which is powdery in structure and therefore might need some kind of squishing to be formed into a brick.

I was unable to find any town or city named Eyford, so I'm assuming it's another slightly fictionalized location.

The horse trick here has always struck me as a clever insight on Holmes' part: of course, he is already aware that this is a scam of some kind, and that the secrecy measures would include a lot of misdirection

14 notes

·

View notes

Text

Preserving 35 kL of Prime 46 Oil from Solid and Moisture Impurities

Minimac Rescues Bihar Power Station : Customized Solution for Solid Contamination and Moisture Wins.

Synopsis

In Begusarai, Bihar, a 720 MW coal-fired power station owned by a major PSU recently faced high Solid Contamination and Moisture Levels in two tanks each with 115 MW power potential. To avert disruption, Minimac provided a customized solution, deploying a specialized machine to lower NAS levels and address moisture and solid contamination saving the plant from a potential failure.

Initial Findings

The power plant's poor operational condition had resulted in the oil degrading to its maximum limit, physical inspection revealed highly contaminated oil with various unwanted contaminants such as sludge, metal parts, insects, dirt, etc.

Problems

Two primary lubrication oil tanks, each with a substantial 115 MW power potential, experienced significant contamination from solids and moisture. Utilizing the contaminated oil to initiate the turbine posed a critical risk of tripping the overall system, leading to potential catastrophic failures.

Client’s Requirement

To Purify 15 kL & 20 kL of Prime 46 Oil from the respective tanks.

To remove Moisture and Solid Contaminants.

To Achieve NAS ≤ Class 8.

To Achieve Moisture ≤ 500 PPM.

Customized Solution.

Solutions

Deploying Minimac’s customized machine at the site along with trained and skilled engineers.

Oil filtration system(150 LPM & 200 LPM) to bring the NAS level of oil to the desired range.

Low Vacuum Dehydrator (100 LPM) to maintain consistent moisture levels in the oil using the vacuum dehydration ensuring smooth turbine operation in its active state.

Our Service Engineer installed the equipment and provided training on its operation and effective handling to the client's team.

Job executed within a limited time-span on the running unit without hindering the client’s operations and oil tanks.

Value TypeOil Tank under UNIT 7 (15kL)Oil Tank under UNIT 8 (20kL)BeforeAfterBeforeAfterNASClass 12Class 8Class 12Class 8Moisture Level13000 PPM64 PPM700 PPM42 PPM

Cost Saving

This plant managed to save:

Cost of Oil Replacement: ₹75 Lakhs. Approx

Cost of Downtime: ₹1 Cr. Approx

CO2 e Saving

4,20,000 kg of CO2 e / 0.42 gigagrams of CO2 e

Benefits

Prevented the environment from harm by averting the emission of 4,20,000 kg of CO2e.

Saved 35 kL of Oil from being incinerated.

Extended Oil Life.

Reduced NAS & Moisture Levels.

Elimination of Oil Replacement Costs.

Task Successfully performed without any shut downs and in a limited amount of time.

No Accidents/ Spillage.

HSE Norms Fulfilled Diligently.

Abbreviations Used

kL : kilolitre

kg : kilogram

MW : Megawatt

NAS : National Aerospace Standard

LPM : Litres Per Minute

PPM : Parts Per Million

HSE : Health, Safety & Environment

Oil Visuals : Before & After

Filter Visuals : Before

Strainer Conditions Before Filtration Filter Visuals : After

Subscribe to our WhatsApp Community and be a part of our Journey - Click Here

#frf#oil flushing#minimac systems#power#minimac#oil & gas#hydraulic oil#lube oil filter#contamination#hydraulic oil filter#chemical cleaning flushing#chemical flushing#chemical cleaning#lube oil flushing systems#lube oil flushing#lubeoil#transformer oil filtration#oil filtration#oil filtration systems#oil filtration machine#oil dehyration#oil dehydration systems#lvdh full form#lvdh#mlc lvdh#frf condition systems#frf machine#condition monitioring#oil condition monitoring#oil cleaning machine

0 notes

Text

Common Myths and Misconceptions About Hydraulic Oil Filters

When it comes to maintaining hydraulic systems, the hydraulic oil filter is a key component often overlooked or misunderstood. But what if everything you thought you knew about these filters was actually holding your equipment back? Let’s clear up some of the most common myths and misconceptions surrounding hydraulic oil filters to ensure your machinery runs smoothly and efficiently.

Myth 1: All Hydraulic Oil Filters Are the Same

Not true! Hydraulic oil filters come in various types, each designed for different purposes and machinery. Using the wrong filter can lead to poor performance or even damage to your system.

Myth 2: Filters Don’t Need Regular Replacement

Hydraulic oil filters need regular replacement to function effectively. Over time, they get clogged with dirt and debris, reducing their ability to protect your system.

Myth 3: A Bigger Filter is Always Better

Bigger isn’t always better. The right filter size depends on your system’s specifications. Using a larger filter than needed can cause issues like pressure drops and reduced efficiency.

Myth 4: Filters Only Protect Against Large Particles

While hydraulic oil filters do trap large particles, they are also crucial for catching microscopic contaminants that can cause significant wear and tear on your system.

Myth 5: You Can Skip Filter Maintenance

Skipping maintenance might seem like a time-saver, but it’s a shortcut to expensive repairs. Regular checks and timely replacements of hydraulic oil filters are essential for keeping your system in top shape.

Myth 6: A Clean Filter Means It’s Working Well

A clean-looking filter isn’t necessarily effective. Some contaminants are too small to see but can still clog the filter or pass through it, causing damage. Regular testing and replacement are necessary, even if the filter looks clean.

Conclusion

Understanding the truth behind these myths is crucial for the longevity and efficiency of your hydraulic system. Regular maintenance and using the right hydraulic oil filter, especially from a trusted filters manufacturer in India, are simple steps that can prevent costly downtime and repairs.

Ready to ensure your machinery stays in peak condition? Start by reviewing your hydraulic oil filter maintenance schedule. If you need help choosing the right filter from a reputable filters manufacturer in India or setting up a maintenance plan, don’t hesitate to contact us today!

#hydraulic oil filter#hydraulic filter manufacturers#hydraulic filter manufacturers in India#hydraulic oil filters suppliers

1 note

·

View note

Text

🏭 Turbine Oil Cleaning System in India – AR Engineering ⚙️

Looking for the best Turbine Oil Cleaning System in India? 🌍 AR Engineering is an ISO-certified company and India’s most trusted brand in Turbine Oil Cleaning Systems, Industrial Oil Purification Systems, and Oil Filtration Machines. Our advanced oil purification solutions help industries improve machinery performance and extend oil life.

🔗 Explore our top-notch oil filtration solutions 👉 Turbine Oil Cleaning System

🔥 Our High-Performance Oil Filtration & Cleaning Solutions

We specialize in manufacturing, supplying, and exporting oil filtration and cleaning systems for industrial applications.

🔹 Turbine Oil Cleaning System 🏗️ 🔹 Oil Cleaning Machines 🔩

🔹 Turbine Oil Cleaning Systems ⚙️ 🔹 Oil Filtration Plant 🚀 🔹 Gear Oil Filtration Systems 🏭 🔹 Industrial Oil Filter Machine 🛢️ 🔹 Oil Filtration Systems 🔧 🔹 Double Stage Oil Transformer Machine 🔥 🔹 Oil Filtration Elements 🔍 🔹 Oil Filtration Machine 🏗️ 🔹 Oil Filtration & Cleaning Systems 🌡️ 🔹 Thermic Oil Filtration Systems 🔩 🔹 On-Site Oil Testing 🧪 🔹 Online Oil Cleaning Systems 🏭 🔹 Hydraulic Oil Online Filters 🛢️ 🔹 Mobile Oil Filtration Plant 🚚 🔹 Portable Oil Filtration Plant 🏗️ 🔹 Portable Oil Filtration System ⚡ 🔹 Turbine Oil Filtration Plant 🔥 🔹 Turbine Oil Filtration Machine 🏭 🔹 Transformer Oil Filtration System 🌍 🔹 Transformer Oil Cleaning Systems 🛢️ 🔹 Evacuation System for Transformers ⚙️ 🔹 Transformer Oil Filtration Plant 🚀 🔹 Two-Stage Transformer Oil Filtration Plant 🔧 🔹 Transformer Evacuation System 🏭 🔹 Transformer Oil Filtration Machine 🛢️ 🔹 Transformer Oil Filter Machine 🔥 🔹 Turbine Oil Flushing System 🏗️ 🔹 Centrifugal Oil Cleaner ⚙️ 🔹 Oil Testing Equipment 🧪 🔹 Visgage Oil Test Kits 🔍 🔹 Karl Fischer Moisture Measurement Equipment 🌡️ 🔹 Online Inline Particle Counters 🛢️ 🔹 Online Oil Contamination Sensors 🔧 🔹 Laser Particle Counters 🚀 🔹 Industrial Filters ⚙️ 🔹 Transformer Oil Reclamation Units 🏭 🔹 Industrial Oil Filters 🔩

✅ Why Choose AR Engineering?

✔ ISO Certified & Industry Leader in Oil Filtration ✔ High-Efficiency Oil Cleaning & Purification Solutions ✔ Advanced Technology for Industrial Applications ✔ Trusted Manufacturer & Supplier in India

🔗 Get the Best Turbine Oil Cleaning Solutions Now 👉 Turbine Oil Cleaning System

📞 Contact Us Today! ✉️ #TurbineOilCleaning #OilFiltration #IndustrialOilFilters #TransformerOilFiltration #HydraulicOilFilters #OilPurification 🚀

#Turbine Oil Cleaning System#Oil Cleaning Machines#Turbine Oil Cleaning Systems#Oil Filtration Plant#Gear Oil Filtration Systems#Industrial Oil Filter Machine#Oil Filtration Systems#Double Stage Oil Transformer Machine#Oil Filtration Elements#Oil Filtration Machine#Oil Filtration & Cleaning Systems#Thermic Oil Filtration Systems#On Site Oil Testing#Online Oil Cleaning Systems#Hydraulic Oil Online Filters#Mobile Oil Filtration Plant#Portable Oil Filtration Plant#Portable Oil Filtration System#Turbine Oil Filtration Plant#Turbine Oil Filtration Machine#Transformer Oil Filtration System#Transformer Oil Cleaning Systems#Evacuation System for Transformers#Transformer Oil Filtration Plant#Two Stage Transformer Oil Filtration Plant#Transformer Evacuation System#Transformer Oil Filtration Machine#Transformer Oil Filter Machine#Turbine Oil Flushing System#Centrifugal Oil Cleaner

0 notes

Text

Top 10 Quality Hydraulic Oil Filter Machine Manufacturers

Rayon India's Hydraulic Oil Filter Machine ensures seamless filtration, keeping your machinery running smoothly. With user-friendly design, it efficiently removes contaminants, extending equipment lifespan. Simplify maintenance with our reliable solution. Trust Rayon India for hassle-free filtration, optimizing performance and reducing downtime.

Address : KHASRA NO. 1318,Morta Industrial Area,Near Hotel Vivaan Meerut Road, Morta ,GHAZIABAD - 201003 U.P

0 notes

Text

Malfunction

A little treat! I wrote this for an assignment in my creative writing class and it got kinda whumpy :3

They've got names but they're not established characters or anything! So there's no missed context haha we're just in media res.

Content warnings: cyborg whump, medical whump mention, bad caretaking, heart disease mention

Word count: 685

~~~

The entire point of a synthetic heart was to eliminate these sorts of risks.

Chk-chk-chk-shhhh. Gears stuttered around the hydraulic line that kept it beating, and a spark drilled through his t-shirt.

“Jamie?”

“I’m fine,” he huffed. “The usual catch.”

“Like hell! You’re smoking!”

He peeked down. Dirty tendrils curled out of his chest cavity, filtering out through the newly established chimney. The curdling stench of melted rubber trailed with it.

“And why should that matter, Cal? My heart’s already wading in tar.” But Jamie grabbed them by the wrist and stormed into the bathroom.

Chk-chk-shhhhhh. Bag and jacket slammed down onto cracked tiles. His shirt caught on mechanical components.

“Your lungs are still flesh,” Cal said. The bastard leaned their happy ass against the door, content to watch him flail: a feral beast mauling what may have once been associated with a sheep.

“Lungs can’t have arrhythmia.” His voice fluxed and pitched into a squeaky approximation of his doctor’s from within his fabric prison.

“Whitten’s a moron.”

“The only moron who’s agreed to fix me,” Jamie grunted, the shredded remains of his shirt finally fluttering to the ground. “Would it have killed you to help?”

“It would kill you if he hears this and decides to weigh in on his patient’s dysfunctional state. We don’t need you relying on his shoddy craftsmanship to rip away any more of your humanity.”

“Shut the fuck up, Cal.”

To their credit, they did, content to rest in the dim glow of old halogen bulbs. Jamie would have appreciated the sterile hum of fluorescents back in the hospital corridor, but his companion wasn’t entirely devoid of logical thought. Arriving broken to an appointment wouldn’t do him any favors with the doctor.

He turned to the mirror where the faux heart smiled back, nestled comfortably between two steel panels where his pectorals had once wasted the precious space. Wan skin stretched in an endless expanse around it.

Chk-chk-chk-chk-chk-

Jamie’s fist nearly dented the left panel.

-shhhh.

“What did I say? Faulty machinery.”

Jamie’s fist nearly dented Cal’s left cheek. The wood grain bowed around purpled knuckles.

“Make yourself useful and open my back panel.”

“Careful.” They snatched the screwdriver before he got creative. “Whitten will saw that one off next.”

“Good. Maybe I won’t miss next time.”

The screws whined as Cal shimmied them out, already stripped from the last ten times. Oil and grease slithered out when they reached inside for the same loose gear.

“Before I tighten you up…”

“Save it, Calvin,” Jamie spat.

“No. No, listen to me, dammit!” They squeezed the hydraulic line and simulated beating came to a shuddering halt. “That tick-tick-tick in the upper chamber feels familiar, doesn’t it? You didn’t care to notice, but I studied your heart readings before you let that maniac replace it, and this thing is mimicking your atrial fibrillation. Whitten didn’t fix anything!” Jamie’s fist found its mark.

“Get your filthy hands out of my chest! This fucking thing keeps me alive, and you think you can use it as leverage to preach your naturalist bullshit?! How about I squeeze the breath from your throat, huh? How high and mighty will you be then?” An open palm pushed Cal back up against the door.

“This isn’t about an agenda, it’s about him!”

“Human hearts can’t be tightened and adjusted.” Each finger clamped down one by one, compressing supple skin. “One little mistake and it’s all over.”

“Is that a threat?” Cal wheezed.

“Stand down, or it will be.”

Chk-chk-chk-chk-shhh. Smoke billowed up between them.

“Let me be clear,” Jamie continued. “I’d let Whitten pick apart every bone in my body before I let you lay another finger on me.” Cal was flung to the ground, clutching their crushed trachea and retching softly against moldy grout and piss-stained stones. The salt and rot crawled up their tongue.

“Don’t come crawling back when he ruins you too, Jamie.”

He slung his bag over a bare shoulder and dropped the jacket into Cal’s arms. A moment of hesitation, then a wad of saliva splattered across their forehead.

“Keep your sympathy.”

#whump#whump writing#my writing#generic#generic characters#male whumpee#nonbinary caretaker#cal is so done with jamie's bullshit and honestly valid i don't think whittaker has the greatest of intentions#emotional whump#cyborg whump#cyborg#robot whump#robot whumpee#not really robot but the vibes are happening so i figured the tag fits!#writing#medical whump#bad caretaker#bad caretaking#caretaking#this was fun and different!#i'm not usually a bad caretaking fan because it happens often with whumpees who don't have the power to get out of it#but i love giving the whumpee a choice. especially if it's a choice to get worse!#like haha you silly go get hella whumped

11 notes

·

View notes

Text

Maximize Your Vehicle’s Fuel Efficiency with High-Performance Car Air Filters

High-performance air filters are a vital component of a car's engine system, and their role in enhancing fuel efficiency is often underestimated. These filters are engineered to provide a superior level of air filtration compared to standard air filters. In this article, we will explore the critical role of high-performance air filters in improving fuel efficiency and how they contribute to a more environmentally friendly and cost-effective driving experience.

The combustion process in a car's engine requires a precise mixture of air and fuel to produce power. High-performance Car Air Filters optimize this mixture by allowing a greater volume of clean air to flow into the engine. Unlike standard filters, which may become clogged with contaminants over time, high-performance filters are designed to maintain consistent airflow. This unrestricted airflow ensures that the engine receives the right amount of oxygen, which is essential for efficient combustion.

Efficient combustion results in improved fuel efficiency. When the air-fuel mixture is precisely balanced, the engine burns fuel more effectively, extracting the maximum energy from each drop of gasoline or diesel. As a result, you get more miles per gallon, saving money on fuel costs while reducing your carbon footprint. This improved fuel efficiency is not only economically beneficial but also environmentally responsible, contributing to reduced greenhouse gas emissions.

High-performance air filters achieve their superior filtration capabilities through advanced materials and design. Many of these filters use synthetic filter media, which is more efficient at trapping microscopic particles and contaminants. This design helps protect the engine from harmful debris that can cause wear and tear, while still delivering a higher volume of clean air.

Furthermore, high-performance air filters are often washable and reusable, which is another aspect of their eco-friendly nature. This not only reduces the frequency of filter replacement but also minimizes the impact of disposable filters on the environment. By choosing a washable high-performance filter, you contribute to reducing the amount of filter waste that ends up in landfills.

Apart from improving fuel efficiency, high-performance air filters can also enhance engine power and responsiveness. With more oxygen-rich air entering the engine, it can generate greater horsepower and torque. This means that you not only save on fuel costs but also enjoy a more spirited and dynamic driving experience.

High-performance air filters, including quality Aftermarket Filters, play a significant role in improving fuel efficiency in vehicles. Their ability to provide a consistent and unrestricted flow of clean air to the engine results in more efficient combustion, better mileage, and cost savings for the vehicle owner. Additionally, high-performance filters are eco-friendly, reducing waste and contributing to a cleaner environment. So, if you're looking to enhance your car's performance and save on fuel costs, upgrading to a high-performance air filter is a wise choice.

#Aftermarket Filters#Car Air Filters#Cabin filters#Fuel Filter#Filtration Solutions#Hydraulic Filters#Air Oil Separator#Performance Filters

0 notes