#construction and manufacturing

Explore tagged Tumblr posts

Text

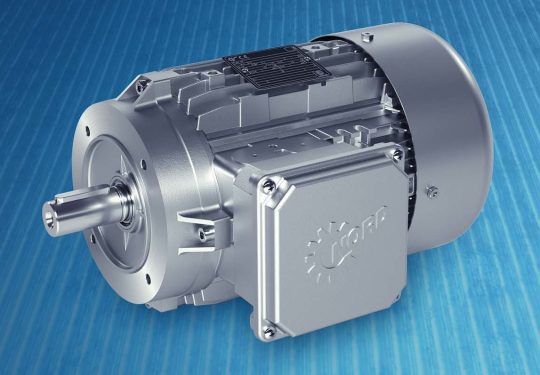

Unlocking Growth: Exploring the IE4 Permanent Magnet Synchronous Motor Market

The global economy is undergoing a significant shift towards sustainability and energy efficiency, driven by environmental concerns and regulatory mandates. In this transformative landscape, the IE4 Permanent Magnet Synchronous Motor (PMSM) market has emerged as a critical enabler of progress. According to a study by Next Move Strategy Consulting, the global IE4 Permanent Magnet Synchronous Motor Market size is predicted to reach USD 308.6 million with a CAGR of 8.97% by 2030. This underscores the growing importance of these advanced electric motors in various industries worldwide.

Request for a sample, here: https://www.nextmsc.com/ie4-permanent-magnet/request-sample

Understanding IE4 Permanent Magnet Synchronous Motors:

IE4 Permanent Magnet Synchronous Motors represent a paradigm shift in electric motor technology. Unlike conventional motors that rely on electromagnetic induction, PMSMs utilize permanent magnets to generate magnetic fields, resulting in higher efficiency, precision control, and reduced energy consumption. These motors are characterized by their synchronous operation, where the rotor rotates at the same speed as the magnetic field produced by the stator, enabling precise speed control and torque regulation.

Key Drivers of Market Growth:

The growth of the IE4 Permanent Magnet Synchronous Motor market is driven by several key factors. Firstly, stringent environmental regulations aimed at reducing carbon emissions and improving energy efficiency have prompted industries to adopt eco-friendly technologies, including high-efficiency electric motors. IE4 PMSMs offer significant energy savings compared to traditional motors, making them an attractive choice for applications where energy efficiency is paramount.

Moreover, the rapid expansion of industrial automation and the adoption of smart manufacturing technologies have fueled the demand for high-performance motors capable of delivering optimal efficiency and reliability. IE4 PMSMs are well-suited for use in robotics, CNC machines, conveyor systems, and other automated processes, where precision control and high torque density are essential.

Furthermore, the growing adoption of electric vehicles (EVs) and hybrid vehicles is driving demand for IE4 PMSMs in the automotive sector. These motors play a crucial role in powering electric propulsion systems, offering superior efficiency, power density, and torque characteristics compared to traditional internal combustion engines. As governments worldwide implement policies to reduce vehicle emissions and promote electric mobility, the demand for IE4 PMSMs in the automotive industry is expected to surge in the coming years.

Challenges and Opportunities:

Despite the promising growth prospects, the IE4 Permanent Magnet Synchronous Motor market faces several challenges. One of the primary challenges is the high initial cost associated with these motors, primarily due to the use of rare-earth magnets such as neodymium and dysprosium. The limited availability of these materials and their fluctuating prices pose a significant risk to manufacturers and end-users alike. However, ongoing research and development efforts aimed at alternative magnet materials, such as ferrite and samarium cobalt, are expected to mitigate this challenge in the long term.

Additionally, the complexity of motor design and integration presents challenges in terms of manufacturing, installation, and maintenance. IE4 PMSMs require sophisticated control systems and advanced manufacturing techniques to achieve optimal performance and efficiency. Moreover, the customization requirements for different applications and industries add further complexity to the production process, potentially increasing lead times and costs.

Despite these challenges, the IE4 Permanent Magnet Synchronous Motor market presents significant opportunities for growth and innovation. The emergence of new applications and industries, such as renewable energy, robotics, and IoT, is driving demand for high-performance motors with enhanced efficiency, reliability, and durability. For instance, the rise of wind and solar power generation has created a growing need for IE4 PMSMs in wind turbines, solar tracking systems, and grid stabilization solutions. Similarly, the integration of robotics and IoT technologies in manufacturing, logistics, and healthcare sectors is driving demand for IE4 PMSMs in robotic arms, automated guided vehicles (AGVs), and medical devices.

Adoption Challenges in Traditional Industries: Despite the advantages of IE4 Permanent Magnet Synchronous Motors, the adoption rate in traditional industries such as HVAC, pumping systems, and material handling equipment has been relatively slow. This can be attributed to factors such as entrenched reliance on conventional motor technologies, lack of awareness about the benefits of PMSMs, and concerns about compatibility with existing infrastructure. Overcoming these adoption challenges will require targeted education and awareness campaigns, along with incentivization programs to encourage businesses to transition to more energy-efficient motor solutions.

Regulatory Compliance and Standards: Compliance with industry standards and regulations poses another challenge for the IE4 Permanent Magnet Synchronous Motor market. Manufacturers must ensure that their products meet stringent performance, safety, and efficiency standards set forth by regulatory bodies and industry associations. Failure to comply with these standards can result in costly recalls, penalties, and damage to brand reputation. Therefore, investing in research and development to develop motors that not only meet but exceed regulatory requirements will be essential for gaining a competitive edge in the market.

Inquire before buying, here: https://www.nextmsc.com/ie4-permanent-magnet/inquire-before-buying

Supply Chain Vulnerabilities: The IE4 Permanent Magnet Synchronous Motor market is susceptible to supply chain disruptions, particularly concerning the procurement of rare-earth magnets and other critical components. Dependence on a limited number of suppliers, geopolitical tensions, and trade restrictions can lead to shortages, price fluctuations, and delays in production. To mitigate supply chain vulnerabilities, manufacturers must diversify their supplier base, invest in vertical integration, and explore alternative sourcing options to ensure a reliable and resilient supply chain.

Technological Innovation and Advancements: Continuous technological innovation is imperative for driving growth and differentiation in the IE4 Permanent Magnet Synchronous Motor market. Manufacturers must invest in research and development to enhance motor efficiency, reliability, and performance while reducing costs and environmental impact. Advancements in materials science, motor design, power electronics, and digital control systems offer opportunities to develop next-generation PMSMs that meet the evolving needs of industries and consumers alike.

Lifecycle Sustainability and End-of-Life Management: Ensuring the sustainability of IE4 Permanent Magnet Synchronous Motors throughout their lifecycle presents both challenges and opportunities for manufacturers. From raw material extraction to manufacturing, use, and end-of-life disposal, minimizing environmental impact and maximizing resource efficiency are paramount. Implementing circular economy principles, such as remanufacturing, recycling, and responsible disposal, can help reduce waste and extend the lifespan of PMSMs, thereby contributing to a more sustainable and circular economy.

Market Fragmentation and Competition: The IE4 Permanent Magnet Synchronous Motor market is characterized by intense competition and market fragmentation, with numerous players vying for market share across different regions and industry verticals. As a result, manufacturers must differentiate their products through innovation, quality, and value-added services to stand out in the crowded marketplace. Strategic partnerships, mergers and acquisitions, and market consolidation may also be necessary to strengthen market position and achieve economies of scale.

Skills Gap and Talent Shortage: Addressing the skills gap and talent shortage in the IE4 Permanent Magnet Synchronous Motor industry is essential for driving innovation and sustaining market growth. As technology advances and the demand for specialized skills increases, manufacturers must invest in workforce development, training programs, and knowledge transfer initiatives to cultivate a skilled workforce capable of designing, manufacturing, and servicing advanced PMSM systems. Collaboration with educational institutions, vocational training centers, and industry associations can help bridge the skills gap and ensure a steady supply of talent for the future.

Conclusion:

In conclusion, the IE4 Permanent Magnet Synchronous Motor market is poised for substantial growth and innovation in the coming years. With increasing emphasis on energy efficiency, sustainability, and technological advancement, IE4 PMSMs are expected to play a pivotal role in powering the industries of the future. By leveraging their superior efficiency, reliability, and performance, these advanced electric motors are unlocking new opportunities for growth and transformation across various sectors. However, addressing the challenges associated with cost, materials, and complexity will be crucial for realizing the full potential of IE4 PMSMs and driving widespread adoption. As manufacturers, researchers, and policymakers collaborate to overcome these challenges, the IE4 Permanent Magnet Synchronous Motor market will continue to evolve and thrive, shaping a more sustainable and efficient future for generations to come.

#IE4 Permanent Magnet Synchronous Motor#construction and manufacturing#market research#market trends#business insights

0 notes

Text

Retconned Wardi firearms- a basic handgun, a highly decorative ceremonial handgun (belonging to Faiza), and a lance-gun.

Gun tech has officially been nerfed down to hand cannons (press F) (this has been a long time coming but I'd been fallacy of sunk costs-ing myself out of retconning).

Handguns are held similarly to a shotgun, with the butt pressed into the user's shoulder, one hand gripping under the barrel, and the other free to ignite the gunpowder. These represent the most advanced firearms in contemporary usage, both in make and in their use of uniform iron projectiles built to match the gun's bore for greater range and efficiency. Lance-guns are the more basal form, usually larger and mounted with the pole held over the shoulder, and are most effectively used by two people (one to hold and aim, one to light the gunpowder).

The spread of firearms is currently mostly limited to the Eastern Inner Seaway peoples (with some additional distribution via overland trade), and actual manufacture of hand cannons and gunpowder at Significant scale is limited to the region's core powers.

The reason for this limited spread is partially due to specific elements of the technology's history. Gunpowder was first synthesized by Burri alchemists and considered to be the discovery of the legendary divine weapon + solar fire of the deity Inanariya, and its formula (along with techniques for ideally refining its components) remained a closely guarded state secret. It was used predominantly in priestly contexts to generate flame and explosive sounds (in conjunction with earlier practices of generating multicolored flames with use of other chemicals), then integrated into combustible weaponry in the forms of fire lances, which would eventually develop into early handcannons.

The treatment of gunpowder as a guarded sacred or semi-sacred substance continued with Wardi adoption, where knowledge of its making is considered a closed rite. It's name (inya tsatsul or just tsatsul, a derived adoption of the Burri iñazatsūya) still reflects a divine solar association (the Burri word means 'sun's thunder', the Wardi 'inya' invokes the sun, 'tsatsul' is an adapted loanword and has no meaning independent of the substance itself), though its priestly use is now predominantly associated with the firearm'ed Odonii (rather than priests of the solar Face Inyamache). The composition of gunpowder can no longer be regarded as a Secret by any means, though efforts to obscure the methods of its creation are still moderately successful and has kept knowledge of gunpowder manufacture more limited than the total sphere of firearm usage itself.

The actual strongest limiting factor of firearm usage is the rarity of natural saltpeter deposits necessary for making gunpowder. The practice of actively producing saltpeter via nitraries has not been developed anywhere in the setting, and all is instead obtained via natural sources. These sources are rare and limited within the current spread of firearm technology, and result in gunpowder being a limited and expensive substance to produce. The weapons themselves are also very expensive to manufacture (a good quality steel SWORD is far too material-cost prohibitive for most people to own), particularly high quality firearms designed for use with standardized ammunition.

These guns are also very basal, and logistical difficulties in their use (weight, very slow loading and firing speed, high visibility, Relatively low reach and accuracy) along with the restrictive cost of production has kept firearms far from rendering conventional weaponry, armor, and projectiles obsolete (even within the societies that have access to them). They are still, however, very devastating in use within their contemporary context, particularly in that high quality guns have a longer range than the best arrow-based projectiles, and utterly negate most contemporary forms of armor at close range.

#I'd consider the setting to be like.....most closely analogous to like 3rd-1st century BCE earth (in terms of the average scale of#societies + Most of its technology (aside from major exceptions like this) + trade interconnectivity)#There are VERY few Very Big states capable of mass-manufacturing and resource extraction (like nothing the size of#the Roman empire has Ever existed in this setting. The biggest empires aren't even close. Cynozepal has a pretty massive territorial#span so is probably the closest thing but its actual control is highly fragmented along disconnected central hubs)#There's significant seaway trade connections but the Vast majority of transmission of goods is localized (even moreso over land)#So point being firearms have developed '''''earlier''''''' than in IRL history but the conditions that enabled very rapid spread are#not really present (though it's fairly inevitable that they'll become widespread over the next few centuries)#Also the likely trajectory of adaptation is going to be the development of Plate armor (which could absorb/block shots#from some types of firearms More advanced than these).#The types of armor used in this particular region is mostly lamellar/scale/padded fabric/leather and rarely involves#full body protection (using a shield to compensate) so developing thicker and fully protective armor would be the next logical#step in the arms race#I think it would be a fun constructed history for armor technology to outpace these simple firearms enough that they end up largely#abandoned in favor of re-specializing in close combat but I don't really care to plan out the far future that much

77 notes

·

View notes

Text

Swiss researchers develop robotic additive manufacturing method that uses earth-based materials—and not cement

Researchers at ETH Zurich, a university in Switzerland, have developed a new robotic additive manufacturing method to help make the construction industry more sustainable. Unlike concrete 3D printing, the process does not require cement.

According to a press statement from ETH Zurich, the robotic printing process, called impact printing, uses cheap, abundant, and low-carbon earth-based materials such as clay or excavated earth. Currently, the robotic additive manufacturing method uses a mix of excavated materials, silt, and clay. Most of the custom material is common waste product sourced locally from Eberhard Unternehmungen, a Swiss construction company. In the future, the process could use other materials.

With ETH Zurich’s method, a robot deposits material from above, gradually building a wall. On impact, the pieces of material bond together, with minimal additives. Whereas concrete 3D printing creates layers, ETH Zurich’s method extrudes and drops the material one bit at a time at velocities of up to 10 meters per second. The fast speed allows the material to bond quickly.

youtube

ETH Zurich’s process can build full-scale, freeform structures, including one- or two-story walls and columns. The printing tool has been used to build structures as tall as almost 10 feet. The process results in walls with a bumpy texture, but robotic surface finishing methods can achieve a smoother finish.

The custom printing tool can be integrated with multiple robotic platforms. As a result, the tool can build walls in both offsite facilities and onsite construction projects. At ETH Zurich’s Robotic Fabrication Laboratory, the tool has been integrated with a high-payload gantry system. The hardware can be mounted on an autonomous legged excavator to build walls on sites with variable terrain.

ETH Zurich says it aims to increase the cost competitiveness of sustainable building materials through efficient and automated production.

#solarpunk#solarpunk business#solarpunk business models#solar punk#solarpunk innovation#earth based construction#switzerland#3D printing#additive manufacturing#Youtube

34 notes

·

View notes

Text

the gendering of baby clothes is obviously profoundly stupid. however, having a boy has made me realize that construction equipment is actually very cool. all the machines are gigantic and they do cool stuff and I pay more attention to them now when I spot them in the wild.

#sorry the connection here is that#he has lots of inherited outfits with construction equipment printed all over them#baby clothes manufacturers are like here is your interest set: construction. dinosaurs. sharks.

16 notes

·

View notes

Text

Have a read…this will help with your understanding of how corporate or legacy media outlets have skewed reporting on Gaza since the latest phase of the siege has unfolded before our eyes.

5 notes

·

View notes

Text

My cat tree needed some new posts so in addition to doing that I cleaned and recovered it over the weekend and Theda was so mad the whole time.

All of my cats were confused, but Theda was mad. I stole her cat tree!! Mother is evil!!!!!! Every time I added a new layer she had to climb on it, regardless of it was screwed down yet.

She’s finally at peace again. In time I may be forgiven.

#theda bara true millennial kitten#I had one basket and the cats were obsessed with it#so I decided to buy a second when I ordered more posts#then I discovered the first basket was like#horrifically filthy on the inside#soooo now they once again have just one basket#I did keep the metal structure in case I get super ambitious and decide to try and make my own basket#I basically know how it’s constructed but whether my sewing machines can do it is another question#I bought four yards of fleece assuming it would be overkill#but honestly? this was more or less the correct amount of kill#I have some leftover but not that much#I love that this cat tree manufacturer sells replacement parts#tbh not that much cheaper to buy five posts compared to buying a new tree#but so so so much less waste#and this is a good quality tree

7 notes

·

View notes

Text

#future#digital art#technology#artwork#futurism#motorbike#my art#motorsports#motorcycle#moto#moto love#cyberpunk aesthetic#cybernetics#cyberpunk#cyberpunk art#bikelife#industrial#manufacturing#construction#factory

3 notes

·

View notes

Text

"Manufacturing Processes Used by Mild Steel Dowel Bars Manufacturers in Sweden"

INTRODUCTION

Mild steel dowel bars are indispensable in the construction industry, especially for enhancing the durability and stability of concrete structures. Known for their exceptional strength and adaptability, these bars play a crucial role in ensuring efficient load transfer across joints in pavements, slabs, and other structural applications. This article explores the intricate manufacturing processes employed by Mild Steel Dowel Bars Manufacturers in Sweden, focusing on precision, quality, and innovation.

1. Raw Material Selection

The manufacturing process begins with selecting high-quality mild steel, known for its optimal balance of strength and ductility. Manufacturers in Sweden adhere to stringent quality standards to ensure that the raw material meets the requirements for construction-grade dowel bars.

2. Cutting and Sizing

Once the raw mild steel is procured, it is cut into specific lengths based on the application requirements. Precision cutting ensures uniformity, which is essential for effective load transfer and durability in concrete structures. Advanced cutting tools, including laser and hydraulic cutters, are often used to achieve accuracy.

3. Surface Preparation

Surface preparation is a vital step in the manufacturing process. The steel is cleaned to remove impurities, such as rust, grease, or mill scale, that may affect its bonding with concrete or its durability. Abrasive blasting or chemical treatments are commonly used for thorough cleaning.

4. Heat Treatment for Strength Enhancement

To enhance the mechanical properties of mild steel, manufacturers employ heat treatment techniques. This process improves the tensile strength and resilience of the bars, making them suitable for high-stress applications. Controlled heating and cooling cycles ensure uniformity and consistent quality.

5. Corrosion-Resistance Coating

Mild steel is susceptible to corrosion, especially in harsh weather conditions or when exposed to moisture. To mitigate this, manufacturers in Sweden apply protective coatings, such as epoxy or galvanization. These coatings not only extend the lifespan of the dowel bars but also ensure compliance with environmental and safety standards.

6. Straightening and Finishing

After heat treatment and coating, the bars are straightened to ensure they meet precise alignment specifications. Advanced machinery is used for this step, eliminating any deformations and achieving a smooth, uniform surface.

7. Quality Inspection and Testing

Quality assurance is a cornerstone of the manufacturing process. Mild Steel Dowel Bars Manufacturers in Sweden conduct rigorous testing to ensure that the bars meet international construction standards. Key tests include tensile strength analysis, corrosion resistance evaluation, and dimensional accuracy checks.

8. Packaging and Distribution

Once the dowel bars pass all quality checks, they are packaged using materials that protect them during transportation and storage. Proper labeling and documentation ensure that the bars reach their destination with traceability and compliance intact.

Advantages of Swedish Manufacturing Processes

Precision Engineering: Swedish manufacturers utilize advanced machinery and technology to achieve unmatched precision in dowel bar production.

Sustainability Practices: The focus on eco-friendly methods, such as recycling and reducing waste, aligns with Sweden's commitment to sustainability.

Compliance with Global Standards: By adhering to stringent international construction norms, Swedish manufacturers ensure that their products are recognized worldwide for quality and reliability.

Conclusion

The meticulous manufacturing processes employed by Mild Steel Dowel Bars Manufacturers in Sweden highlight their dedication to quality and innovation. From raw material selection to final packaging, each step ensures that the dowel bars are robust, durable, and suited for a wide range of construction applications. These processes set a benchmark for the global industry, making Sweden a leader in the production of high-quality mild steel dowel bars.

3 notes

·

View notes

Text

#art#indeedgoodman#model#fyp#tree#branches#forest#palm trees#trees and forests#trees#construction#manufacturing#services#modern architecture#contractor#renovation#design

7 notes

·

View notes

Text

iron worker

15 notes

·

View notes

Text

construction - jersey city, new jersey - yashica mg-1 & 400 iso color film - developed at eliz digital & scanned with minolta dimage dual iii

#35mm#construction#building#concrete#architecture#infrastructure#engineering#technology#manufacturing#35mm photography#film photography#city photography#urban landscape#neon#hi viz#people#machines#machinery#mechanical#jersey city#new jersey

14 notes

·

View notes

Text

#branding#furniture#interior design#manufacturer#woodbine#delhi#gurugram#styleblogger#decor#supplier#Furniture Replica#Renovation#Civil#Construction

2 notes

·

View notes

Text

Vipul Infra Systems Pvt. Ltd. is the Best PEB manufacturer In India specializing in pre-engineered buildings and industrial sheds. Known for quality and innovation, they deliver customized, durable, and efficient solutions.

#peb manufacturers#pre engineered building#pre engineered steel buildings#industrial sheds#warehouse construction

2 notes

·

View notes

Text

Save Big on GI Flanges-Get Lowest Prices with Udhhyog

In today's competitive industrial landscape, procurement efficiency is essential, especially when it comes to sourcing critical components like GI flanges. If you're looking for GI flanges at the lowest price, Udhhyog is here to help you save big while ensuring you receive top-quality products.

Understanding GI Flanges

Galvanized Iron (GI) flanges are essential components in piping systems, providing a reliable connection between pipes and fittings. They are favored for their corrosion resistance, which makes them ideal for various applications, including plumbing, water supply, and industrial processes. GI flanges are available in different types, such as slip-on, weld neck, and blind flanges, each serving specific purposes.

Why Choose Udhhyog for Your GI Flanges?

At Udhhyog, we understand the needs of Micro, Small, and Medium Enterprises (MSMEs) across India. We are dedicated to providing high-quality GI flanges at the lowest prices without compromising on quality. Here are a few reasons why Udhhyog stands out as your go-to supplier:

Quality Assurance: Our GI flanges are manufactured to meet international standards, ensuring durability and reliability in your applications. We prioritize quality to provide you with products that stand the test of time.

Competitive Pricing: We leverage our industry expertise and efficient supply chain management to offer the lowest prices for GI flanges in the market. With Udhhyog, you can procure the best without breaking the bank.

Wide Selection: Whether you need slip-on flanges, blind flanges, or any other type, Udhhyog has a comprehensive range of GI flanges to meet your specific requirements.

Fast Delivery: We understand that time is of the essence in your projects. Our streamlined logistics ensure that your orders are delivered promptly, allowing you to keep your operations running smoothly.

Flexible Credit Options: To support MSMEs, we offer a 45-day credit period, helping you manage cash flow effectively while ensuring you have access to the materials you need.

Applications of GI Flanges

GI flanges are commonly used in various industries, including:

Construction: For joining pipes in building projects.

Water Treatment: Ensuring secure connections in water supply systems.

Chemical Processing: Used in pipelines that transport chemicals and other fluids.

HVAC Systems: Connecting ducts and ensuring efficient airflow.

How to Order GI Flanges from Udhhyog

Ordering your GI flanges from Udhhyog is a seamless process. Simply visit our website and browse our range of products. You can easily find GI flanges at the lowest prices by following these steps:

Select Your Product: Choose the type and size of GI flanges you need.

Add to Cart: Once you've made your selection, add the items to your cart.

Checkout: Complete your purchase using our secure payment options.

Delivery: Sit back and relax as we process your order and deliver it to your doorstep.

#GFlanges#GIFlanges#Flanges#FlangeManufacturing#PipingSolutions#IndustrialSupplies#PipeFittings#LowestPrices#AffordableFlanges#SaveBig#CostEffective#BudgetFriendly#Industry-Specific Hashtags#Construction#WaterSupply#ChemicalProcessing#HVAC#IndustrialEquipment#Udhhyog#Engineering#Manufacturing#QualityControl#MSME#SupplyChain

5 notes

·

View notes