#compressed air systems installation

Explore tagged Tumblr posts

Text

Where should the air compressor in the factory be placed?

Compressed air systems are generally placed in compressor rooms. Generally, there are two situations, one is that it is installed in the same room as other equipment, or it can be a room specially designed for compressed air system. In both cases, the room needs to meet certain requirements to facilitate the installation and ergonomics of the compressor.

1. Where should the compressor be installed?

The main rule in the installation of compressed air systems is to arrange a single central area for the compressors.

Second, a separate area of the plant used for other purposes can also be used for compressor installation. Such installations should take into account certain risks and inconveniences. For example:Interference due to noise or ventilation requirements of the compressor; Physical risks and overheating risks; Condensate drain; Hazardous environments (e.g. dust or flammable substances); Space requirements and service accessibility for future expansion.

However, installation in a workshop or warehouse can facilitate the installation of energy recovery devices. It can also be installed outdoors under a roof if there are no facilities available for installing the compressor indoors. In this case, certain issues have to be taken into account: the risk of freezing of condensed water; rain and snow protection of air intakes, suction openings and vents; the required solid, level foundations(asphalt, concrete slab or flat tile bed); dust; the risk of flammable or corrosive substances and prevent other foreign matter from entering.

2. Compressor placement and design

Distribution system wiring should be performed for installations of compressed air equipment with long piping. Compressed air equipment is installed close to auxiliary equipment such as pumps and fans to facilitate servicing and maintenance; the building should be equipped with lifting equipment sized to handle the heaviest component of the compressor installation (usually the electric motor) and to have access to a forklift. It should also have enough floor space to install additional compressors for future expansion. Also, the clearance height must be sufficient to suspend an electric motor or similar equipment if required. Compressed air equipment should have floor drains or other means to handle condensate from compressors, aftercoolers, air receivers, dryers, etc.

Air compressors Supplier - Youteng

Wuxi Youteng Machinery Co., Ltd. was established in 2012, mainly engaged in air compression system, vacuum system design consulting, engineering project and repairing services etc. Our company mainly provides air compressor equipments and air compressor consumable material for compressors of world-famous brands. We also support OEM. In addition, The company has a number of experienced technicians to perform maintenance work on various air compressors, dryers and filters, which have a certain influence in China. At the same time, the company also participates in motor overhaul projects and maintains various motors. We have a complete service system and sufficient spare parts to relieve customers from worries.

#air compressor installation#compressor placement and design#compressed air systems installation#compressed air systems

0 notes

Text

Compressed Air Reticulation Service and Pipework Installation: Key to Efficient Operations

When it comes to industrial operations, having a reliable and efficient compressed air system is crucial. Whether it's for manufacturing, workshops, or other industries, the setup and maintenance of a good air reticulation system can have a huge impact on productivity. That’s where compressed air reticulation service and pipework installation come into play, ensuring that your air system operates smoothly and effectively.

What is Compressed Air Reticulation?

Compressed air reticulation refers to the network of pipes, hoses, and components that distribute compressed air to various parts of an industrial facility. This system needs to be well-designed to ensure that compressed air is delivered efficiently and without leaks. An effective reticulation system minimises air pressure drops and optimises the performance of your machinery.

Properly installed and maintained reticulation systems ensure that your business can run its processes seamlessly. If you’re experiencing issues with your air system, it could be time to invest in a compressed air reticulation service. These services involve the design, installation, and ongoing maintenance of your compressed air infrastructure, helping to prevent downtime and improve operational efficiency.

Importance of Pipework Installation in Compressed Air Systems

One of the core elements of a compressed air system is its pipework. The pipes play a critical role in distributing compressed air throughout the facility. The pipework installation process involves carefully laying out a network of pipes that connect the air compressor to various end-use points.

The installation process must be done with precision, as poor installation can lead to leaks, inefficiencies, and even system failures. Experienced professionals understand how to optimise the placement of pipes, select the right materials, and ensure everything is properly sealed.

Choosing the right pipe materials, such as steel, copper, or plastic, depends on factors like the size of the system, the pressure requirements, and the environment in which the system will be used. Additionally, the correct sizing of pipes is essential for maintaining consistent air pressure and minimising energy loss.

Why You Should Choose Professional Services

Both compressed air reticulation service and pipework installation require expertise to ensure long-term reliability and performance. Working with professionals ensures that your system is designed and installed according to industry standards, reducing the chances of system failure or costly repairs in the future.

Companies like Airquip and Pipetool offer comprehensive solutions for compressed air systems, from installation to ongoing maintenance. They provide tools and expertise to ensure that your pipework is installed correctly and that your compressed air reticulation system remains efficient for years to come.

Conclusion

A well-installed compressed air reticulation system and properly fitted pipework are essential for smooth, efficient operations in any industrial setting. To ensure the reliability of your system and avoid costly disruptions, it’s vital to seek professional services for both reticulation and pipework installation. With the right expertise and tools, you can maximize the performance and longevity of your compressed air infrastructure.

0 notes

Text

We also should really have checked that the old water tower was disconnected from the water system before we started filling it with compressed air.

Cold Air [Explained]

Transcript

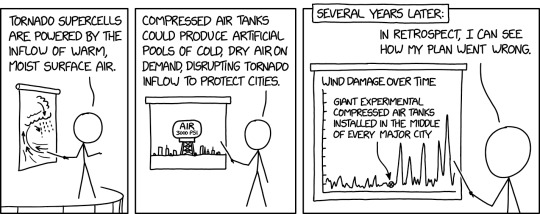

[Cueball is in front of a diagram of a tornado with a pointer in his right hand. The diagram has arrows flowing from the bottom toward the tornado at the top, and from the tornado toward the rain below it.] Cueball: Tornado supercells are powered by the inflow of warm, moist surface air.

[Cueball is now in front of a representation of his compressed air tank with a PSI of 3000 next to smaller buildings, appearing to be high-rise buildings or skyscrapers, on both sides of the tank.] Cueball: Compressed air tanks could produce artificial pools of cold, dry air on demand, disrupting tornado inflow to protect cities.

[Cueball is in front of a line graph labeled "Wind Damage over Time". Wind damage has spiked constantly after a point on the graph labeled "Giant experimental compressed air tanks installed in the middle of every major city"). In a frame in the top left corner, there is a label:] Several years later: Cueball: In retrospect, I can see how my plan went wrong.

298 notes

·

View notes

Text

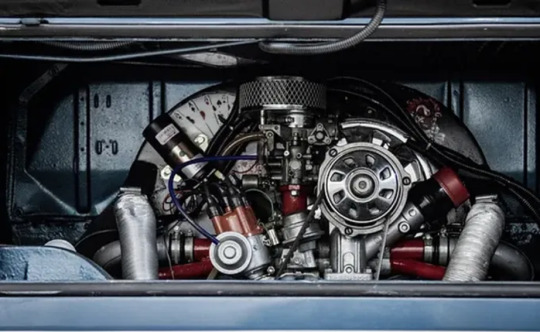

Chrysler 340 Six Pack!

This engine design was guided by none other than Tom Hoover, later known as ‘the father of the Hemi’. For 1970, as delivered in AAR Cuda and Dodge Challenger T/A for use in the SCCA Trans-Am Racing Series, the factory stock Six Pack 340 engine was a well-optioned animal straight out of the box. It meant business, leaving plenty of scope for modifications allowed within the racing regulations that would help it thrive in a Trans Am racing environment. There was no stone unturned, starting with a high nickel stress-relieved engine block, utilising thicker webbing in the pan rails and other areas to allow the option of installing four bolt main caps on 2,3 and 4. High-performance ‘J’ casting cylinder heads were utilised along with large diameter valves, working in tandem with a unique rocker arm/shaft/pushrod assembly. Within this cylinder head design, the pushrod holes were offset to allow more material for oversized porting on the intake runners. Forged crankshaft, heavy-duty conrods and high-performance pistons. A windage tray was also featured. A healthy 10.5 to 1 compression ratio complemented an aggressive 276/284 duration camshaft driven by a dual-row timing chain and the fire in the combustion chamber was ignited by dual points ignition with the spent gasses exiting through a free-flowing exhaust system.

One highlight of this engine combination was the Six Pack (or 6 barrel) carb set-up, running a trio of two-barrel Holleys sitting on top of a factory-fitted Edelbrock intake manifold. A 375 cfm centre carb acted as a primary, then at a given throttle percentage, the two 500 cfm outer carbs would open up and join the party to provide a whopping total of 1375 cfm in total air flow, along with an induction howl you’d never forget.

The factory officially rated the engine at 290hp and 345ft/lbs of torque. The consensus is that it produced at least 330hp, particularly when you consider its claimed 14.4 second quarter-mile capability and 5.8 sec 0-to-60 mph times in a 3500 pound car. In race spec, the engine was de-stroked to just under the Trans-Am regulations 305cu limit and during the development phase across its racing lifespan, was rumoured to have produced between 460 and 500hp.

#Chrysler 340 Six Pack#Chrysler 340#chrysler#340 Six Pack#six pack#340#car#cars#muscle car#american muscle#mopar#moparperformance#moparnation#moparworld

61 notes

·

View notes

Text

***Educational Purposes Only***

Normal questions for phallo (my personal experience, and facts)

"Do you feel anything?" - yes, I feel everything from touch, stroking, temperature, pain, pressure, pleasure, gusts of cold air. They do disconnect and reconnect nerves, so it does take time (years) depending on how you heal to have complete sensation. But you always have sensation there even beforr you are fully healed. I found the Urethral Lengthening Procedure and the Implants (erectile device and prothetic testicle). It took probably 3 years after all of the procedures for me to have what is called "complete tactile function".

"How do you get erect?" - it's a pump, after they create the scrotum (they use the labia for this), you get your pump installed into your main hand side (ex. My pump is on the right testie), and the other testie is just an implant. I squeeze my pump (or my partner), and then saline water is pumped from the testicle into two tubes (one on each side on my penis). Creating a natural looking erection besides having to pump. It only takes about six pumps for me. Doesn't take much effort. I have a three part inflatable device.

"How do you "deflate"/ go down after an erection" -on the testie that is the pump, there is a small button above it, it is actually kind of a small box with a button on it. I hold the button for about 15 seconds and just let my erection naturally go down.

"How many surgeries does it take?" - well, I guess four in total. You have your hysterectomy (which included for me a complete oophorectomy as well, recent advancements in this procedure have made it so an oophorectomy is now optional), then your phalloplasty the building and attaching of the phallis and vaginectomy only at this part. The next surgery was to connect my urethral, called urethra lengthening. The last surgery was to install the penile pump and testicular implant.

"What are the chances it will fall off?" - less than 1% in the hands of a skilled surgeon. (My surgeon told me this information as the source) - note post operative care is the most important part of healing properly.

"Where did they take the skin?" - they took the skin for my phallis from my forearm and used a thin layer of the skin on my upper thigh to cover the tissue left exposed on my arm.

"Do you have any issues today?" - No issues, I've been finished for quite a bit now. I enjoy sex, it feels good. It looks good. I've never been clocked even naked in a locker room. I do dribble sometimes if I hurry while urinating, and I have to use a special technique to ensure 100% emptiness, but I can pee just fine. I found the installation of the pump helps me urinate easier than without.

"Can you ejaculate?" - Yup! I can, at least. I also have pre-ejaculate. I ejaculate almost everytime I orgasm. (With this said, the ability to ejaculate, amount of, and frequency of are all variable factors that can depend on person to person)

"Is the orgasm different?" -yes! It feels better to me. It could be comfort, but ejaculating does feel good when you orgasm. Ejaculating can vary from person to person. This ejacuate is not like cis men's, it is a clear fluid from the Skenes Glands.

"Did you have any major issues?" - not really, I did have to see a wound clinic for my implant surgery. I had wounds that needed care. I got a bladder infection with the catheter during the healing stage of urethral lengthening and had it removed after just over two weeks (it was supposed to be in for six weeks), as a reference though one of my urine bags broke and I had a plastic baggie to try to repair it until I could get a replacement (i had to wait hours), I also have a compromised immune system. For my arm, I wore my compression sleeve 100% of the time, and my arm healed extremely well and flat. You just need to listen to the rules and be sure not to break them.

"Do you have to do anything (e.g weekly)?" - sorta, I have to make sure I pump fully once a week.

"Any issues urinating?" - nope, takes some getting used to, though (standing). I find that I dribble, but it's only when I'm rushing when I shake. I still sit most of the time, it's even very common in cis men as an FYI. (I asked a large group of cismen)

"Does it look real?" -Yes, my wife said she never would have known I was trans until I told her. All penises look different. Even getting an erection looks natural.

"Did you have any corrective surgeries?" -No, I got pretty great results the first time. I do plan on going to closer, regular plastic surgeon to put in a larger implant as my left testicle (non-pumping side).

Have any of your own questions? Send me an ask, I'll be happy to answer!

Stay Golden Everyone ✌️💙💜

#pride month blog#trans ftm#transgender#transman#transman phalloplasty#phalloplasty#i love my phalloplasty penis#phallo#my experience with phallo#person#if i can help put info out there i would love that#phalloplasty education blog#phalloplasty experience blog#phallo education#phallo blog#/r phallo#ftm transition#ftm bottom surgery#ftm phalloplasty#phalloplasty blog#ask me things#lgbtq#educational purposes#educational blog

227 notes

·

View notes

Text

An old Suzuki Mightyboy turbo build article. Article is from a magazine from the early 90s.

The unique tuning is appealing

ALL THAT'S K

I won't lose to 660!

Mighty Boy TURBO by private tuning

550cc owners may be feeling a little sad with the arrival of the 660. But when it comes to tuning, the 550 is still very interesting. This time, we'll introduce you to the super energetic Mighty Boy, with its highly original tuning!

You can't judge people and cars by appearances...

At first glance, he looks like an ordinary guy, but when he gets behind the wheel on the circuit, he turns out to be a crazy fast racer... That's the kind of story you hear, you can't judge a person by their appearance. The same can be said about cars. This guy, MightyBoy, is a good example of that.

At first glance, it looks like a normal Mightyboy with a slightly large air intake.

When you drive it, full boost kicks in at 2000 rpm, and it accelerates with such force that you'll think, "Hey, wait a minute."

And it was no surprise. The engine in this car is an F5A with an intercooler and turbocharger. Moreover, the F5A has an increased displacement of 610cc, so it has a lot of torque even before the turbo kicks in. This engine hits full throttle at 2000rpm and keeps going all the way to 8000rpm, making it no ordinary engine.

my car. So tune it yourself

To explain in more detail about the tuning done by Mightyboy, the engine has been enlarged to 610cc by widening the bore to 65.5mm. A Tomei high compression piston is installed, and the compression ratio is about 9.0 with two Cook Sports(?) gaskets. The valve springs are normal.

The steering wheel is a Nismo Sunny wheel, and this is where you can really see the owner's personality.

The turbo system is equipped with a Mira TR-XX turbine and intercooler. The boost pressure is controlled by a homemade EVC at Lo (0.73kg/cm²) and Hi (1.2kg/cm²).

The levels can be switched by a switch on the shift lever. Other original features include a turbine cooling radiator and a fuel cooler mounted at the very back of the bonnet, making this an engine bay full of the owner's ideas.

Currently, the horsepower is kept at around 60hp, but this is set up with an emphasis on torque, considering that it will be used for daily commuting. This is still plenty fast, and it is apparently faster than the standard Works.

The suspension is in keeping with the power.

Naturally, the suspension has been strengthened to match the increased engine power, but this too has been tuned to the owner's own unique style, which is interesting.

The front shocks are standard, while the rear shocks are Kawasaki Z750FX (S&W) for motorcycles. The front springs are standard Grand Civic springs, while the rear springs are standard Alto springs. This suspension works really well, and it's great when cornering with the 13-inch Potenza.

It provides firm support with just the right amount of roll.

It's surprising that most of these tunings are done privately by the owners themselves. Tuning with a tuning kit specified by the manufacturer is easy and there's no such thing as a bad result. But a car that you build by trying out different things like Mightboy does is something you love like a part of yourself, and there's a joy in having a car that's unique and yours alone. I'd recommend this to anyone who's confident in their mechanics.

PIC CAPTIONS

▲The rear suspension fits the Z750 shock perfectly. The idea behind this is amazing.

▲This is the Lo/Hi switch for the homemade EVC. The main unit is located in the engine compartment.

▲▼The big air intake (for AE92) was not just for show. It covers the protrusion of the intercooler and also takes in a large amount of air to the intercooler.

3 notes

·

View notes

Text

I flew the most secret MiG fighter in the world for the US Air Force: Red Eagle pilot gives the low-down on America’s MiG-21 ‘Fishbed’

Hush KitMarch 16, 2021

Name: Brian McCoy

Rank: Captain

Service: United States Air Force

How did the MiG-21 differ from the F-5E?

The biggest difference for the pilot would have to be familiarity. The F-5E is essentially a beefed-up, fighter version of the Northrop T-38 Talon … an aircraft every USAF pilot had experience in during basic flight training.

First Impressions?

Small airplane! Small cockpit, archaic instrument panel, high canopy rails.

How would you rate the cockpit for the following:

a. Ergonomics?

Ergonomics wasn’t yet a thing when the ‘Fishbed’ was designed.

b. Pilot’s view?

Outward visibility contends for the worst single problem encountered by the Fishbed pilot during air combat manoeuvring. Fighting the MiG-21 required deliberate manoeuvring simply to keep the adversary in sight … regardless of the tactical advisability of such manoeuvring.

The blind zone behind the pilot (due to the ejection seat and structural members behind the seat) extends at least 40 degrees either side of the tail. The wings are not visible to the pilot – neither is the vertical tail.

The blind zone under the high canopy rails extends about 70 degrees either side as measured from the pilot’s butt centerline (aircraft structure).

The blind zone out front is about 10 degrees either side of the nose (tall instrument panel; poorly-placed gun camera; combining glass supports; thick, translucent Pexiglass sheet placed in front of pilot as protection from B-52 tail gunner).

c. Comfort

i. While not really a concern for the designers, it’s not any more uncomfortable than other fighter designs from the era. And they did paint the instrument panel a soothing shade of green specifically to calm the pilot.

d. Instrumentation

i. Primarily the instruments we used were factory-installed … with Cyrillic characters and metric system measures and graduations – neither of which were familiar to the average American fighter pilot. Luckily our outstanding maintenance professionals placed green arcs for normal operating ranges and red radials for system limits. At some point, numbers are numbers.

Our jets had American altimeters, airspeed indicators, radios, transponders, oxygen regulators and drag chutes (for the Soviet jets … F-7 jets came from the factory with drag chutes).

Yes, the ejection system was factory installed. For the older Soviet jets, that meant a 57mm mortar shell fired to propel the ejection seat (and pilot) from the aircraft. It also brought along the forward-hinged canopy which attached to the headrest of the pilot’s seat and then folded down in front of the pilot as a shield from windblast. (The canopy and related support members probably weighed 250 – 400 pounds!) The later F-7 jets featured a rocket-propelled seat that had nearly 0/0 capability (the pilot was on his own against the breeze). The fabulous ACES-II ejection seat installed in the F-15 and F-16 aircraft (among others) used similar rocket tubes that fired sequentially to keep the G-loading associated with riding the seat during ejection down to a maximum of about 16 G’s. The F-7 rocket tubes fired all at once … giving the ejectee a spine-compressing 21 G “boost” from the aircraft.

Against the F-16?

a. In WVR: Which aircraft would have the advantage and why?

i. The F-16 holds every advantage: Higher thrust-to-weight ratio, vastly better outward visibility, higher instantaneous turn rate, much higher sustained turn rate, better weapons, much better cannon and gunsight, better man/machine interface, better acceleration … the only potential advantage the ‘Fishbed’ pilot might enjoy is if the speeds in the fight slow below 250 KIAS – well below. The slower the fight gets, the more the advantage swings to the MiG.

b. Which set-ups and altitudes would the MiG-21 favour?

i. Offensive perch at 1,000 foot range in solid gun tracking solution … LOL.

ii. Side-by-side, line-abreast 500’ spread, 150 KIAS (or less), 20,000 feet MSL.

c. How should the MiG-21 pilot fight?

i. Call for help, stay close to the Viper, get slow (and hope the Viper follows suit), keep pointing the nose at the Viper to threaten him, call for help, look for any opportunity to leave the fight, consider pre-emptive ejection, call for help!”

d. Who would you put your money on?

i. It might be obvious that I’m leaning toward the F-16.

ii. But this question opens a line of consideration I’ve encountered several times on related FB posts … the idea that the superior aircraft always – and almost automatically – wins. For nearly eight years I flew nothing but air-to-air in engagements ranging from 1v1’s to Red/Green/Maple Flag exercises. I’ve led small missions and those Flag exercises. Debriefed both using high technology or chalkboards in as much detail as the situation required to illustrate the learning points involved. I estimate I’ve been in 4,500 engagements during those years. As I learned more and more about air combat and experienced varied tactics, aircraft capabilities (or lack thereof) and the occasional imposition of simple luck … the more I came to realise the skill, daring and bravado of the pilot in that other airplane was far more important in determining an engagement’s outcome than the type aircraft he was strapped into.

iii. But I’d rather be in the F-16 for such a fight.

About 60 – 70% of our ‘adversaries’ paid attention in our pre-mission briefings and avoided fighting in such a way as to maximise our limited list of potential advantages. They kept their energy up, kept their distance, threatened us enough to force us to bleed energy and then killed us quickly and cleanly. We lost nearly all of these sorts of engagements – just as intended!

The Hush-Kit Book of Warplanes will feature the finest cuts from Hush-Kit along with exclusive new articles, explosive photography and gorgeous bespoke illustrations. Pre-order our Hush-Kit Book of Warplanes here. Until Tuesday 6th April we are running a bank holiday weekend promo code. The code is CRACKING20 and is valid for 20% off pledges and pre-orders on The Hush-Kit Book of Warplanes

20 – 25% of our adversaries either ignored our briefings or intentionally sought to see what happens when they ‘stepped into the phone booth’ with us. We’d win well over half of such fights … pretty good considering we almost always started out defensively.

The rest either had a bad day, didn’t have a plan, or were so overcome by the situation that they forgot what to do. We knew what to do.

iii. We normally started on the DEFENSIVE perch, allowing frontline pilots the opportunity to watch the threat aircraft do it’s thing while they were looking out their front windows … much easier than assessing performance while looking over their shoulders.

iv. I had memorable engagements against F-15’s, F-16’s, A-4M’s … but perhaps especially against the original F/A-18.

Best thing about the MiG-21?

a. Simplicity

Worst thing about the MiG-21?

a. Toss-up between abysmal outward visibility, incredible susceptibility to battle damage and astounding energy bleed-off during heavy manoeuvring.

How would you rate the MiG-21 in the following areas:

a. Instantaneous turn rate

i. Totally dependent on airspeed. Nothing special until below 250 KIAS – then it became startling. The rate did not increase at the lower speeds … it simply did not fall off as much as expected.

b. Sustained turn rate

i. Woeful. A 4+G level turn in full AB bled a bit over 1 knot per degree of heading change. Impossible to assess a “sustained turn rate” with bleed off like that.

c. Weapons platform

i. Keep in mind we flew very early export model ‘Fishbeds’ – MiG-21 F-13’s and F-7’s. Not the most advanced Fishbeds built.

ii. We simulated carriage of the IR-guided AA-2 Atoll … a direct copy of the AIM-9B Sidewinder. Not an impressive missile. Fishbeds also carry the AA-8 Aphid IR missile … a short range missile with impressive cornering capability.

iii. As a gun platform the Fishbed suffers from an incredibly unstable gunsight … useless above 2.5-3 G’s. The gun itself suffered from poor rate of fire and low muzzle velocity … but at least it didn’t carry many rounds.

d. Acceleration

i. Acceleration of the early-model Fishbed was actually quite good. Less than late- model F-16’s but on par with F-15C’s.

e. Top Speed

i. We lived with a self-imposed limit of 600 KIAS … enough for perhaps Mach 1.3 at altitude. It’s reportedly a Mach 2 capable airframe. I see no reason to doubt that capability.

Read what fighting these MiGs was like from an F-15 pilot here

f. Take-off characteristics

i. Tonopah Test Range Airfield sits at about 5,600 feet above sea level – enough altitude to seriously reduce takeoff performance. We never flew the Bandits from a lower field elevation.

ii. Temperature varied considerably at TNX – also effecting flight performance drastically.

iii. Taking the runway, I’d lock the nosewheel in the straight-ahead position and select nosewheel braking to aid in any abort situation. Once cleared for takeoff (except for that ONE time!), I’d run the power up to MILITARY while holding the brakes. When prepared to launch, I’d simply release brakes and note the acceleration sensation at the small of my back. After perhaps 2 seconds of acceleration at just MIL, I’d thumb the release and select MAXIMUM power. The afterburner lightoff process took a few seconds (and featured a very good opportunity for the engine to cease operating altogether), caused several expected engine instrument fluctuations and normally resulted in much higher thrust output. (Sensing the differing acceleration rates of the two power settings gave me another check for normal engine operation.) Once lit, the afterburner made things happen much more quickly.

iv. The MiG-21 typically rolled about 3,500 to 5,000 feet before attaining takeoff speed at about 150 KIAS. Climbout was always in full afterburner until reaching 10,000 feet MSL. (This was to get us as quickly as possible out of the more dangerous low altitude ejection envelope.) We typically climbed out at 300 KIAS with a very steep climb angle.

v. The aircraft was designed to takeoff from even unprepared fields, climb quickly to high altitude, accelerate to supersonic speed … and run down attacking B-52 bombers. I never took off from a plowed field, so I can’t verify that specific capability – but the airplane’s delta wing made it very capable of quick climbs and rapid acceleration.

g. Landing characteristics

i. Oh, boy! Do we have to do this?

ii. First of all, refer back to the section where I discussed the limited forward visibility. Nowhere is that more relevant than during each mission’s landing phase.

Pilots had to fly the overhead traffic pattern looking obliquely forward during the final turn. This is completely natural and how every final turn is flown in every fighter jet.

When rolled out on final, that same oblique viewpoint (out both sides now) has to be used to fine-tune runway alignment … and it works okay. But the normal down-the-runway cues most guys use for rounding out and flaring to land are hidden, so peripheral vision has to substitute perceived sink rate to help ‘feel’ for the runway. This skillset needed some development. (It wasn’t as bad as the wall in front of Charles Lindbergh in the ‘Spirit of St. Louis’ … but it wasn’t as good as looking through your car’s windshield, either.)

iii. The engine’s extremely slow windup makes the landing pattern the most dangerous phase of flight for the unwary or careless ‘Fishbed’ pilot.

Idle to MILITARY power took as much as 13 seconds … almost a quarter of a minute!! Imagine a ‘Fishbed’ pilot allowing the engine’s rpm to decay all the way to idle while at low altitude, low airspeed and high sink rates – as normally occur during any routine traffic pattern.

One of the signs of low thrust availability came anytime engine rpm dropped below 80% N1.

a. The extended windup time was less than the 13-second Idle to MIL marathon … but even 5 or 6 seconds waiting for useable thrust could be critical.

b. The exhaust nozzle opened fully right around that 80% N1 reading, dropping the effective thrust to nearly nothing. That was the true danger of allowing the engine rpm to decay.

c. Instructor pilots flying chase aircraft (AT-38B’s) could visually monitor the exhaust nozzle during traffic patterns with new pilots so as to provide warning and guidance in case of decayed engine rpm … or other issues with transitioning pilots’ traffic pattern work.

An AT-38B Talon aircraft flies over the plains during a 479th Tactical Training Wing Lead-In Fighter Training (LIFT) flight near Holloman Air Force Base. Training on the Talon, LIFT pilots and weapons systems officers become familiar with fighter tactics and maneuvers which they will eventually use tactics and maneuvers which they will eventually use when flying more technologically advanced aircraft.

d. While potentially dangerous, this condition was easily avoided by simply not allowing the engine rpm to slow below the 80% N1 level. As a result, we flew wimpy wide traffic patterns with very gradual turns and descents.

iv. The Fishbed was actually easy to fly through it’s landing pattern … so long as the pilot was aware of and prepared for the unusual and potentially dangerous pitfalls unique to the aircraft.

v. Being a single-engine aircraft, we spent a lot of time thinking about and training for flameout recoveries. Our glide profile was flown at 250 KIAS … the same speed we used for other emergency recoveries.

vi. While TNX was our prime recovery field, flight conditions at the time of the emergency could make landing there impossible due to distance. There were several contingency landing possibilities in the area – like old, inactive runways or dry lake beds. (Necessity is the mother of invention.)

vii. We used drag chutes on every landing to extend brake and tire life.

Read what fighting these MiGs was like from an F-15 pilot here

h. Climb rate

i. The aircraft could climb rapidly and steeply to whatever altitude was required. Once level, the Fishbed could quickly accelerate to supersonic speed.

i. Range

i. This is an astonishingly short-ranged aircraft … even for a fighter. I’ve taken off from TNX, climbed to meet an adversary almost directly overhead the runway, fought three engagements and left the range with need to land immediately due to fuel considerations … ten minutes after takeoff!

ii. I flew 287 ‘Fishbed’ sorties in my Constant Peg career – logging 134.5 hours … a bit under 0.47 hours per sortie. We weren’t trying for long sorties and made liberal use of afterburner, so your results may vary.

iii. We never flew the Bandit jets with external fuel tanks or in a cross-country fuel-efficient mode … at least not while I was there.

j. Sensors

i. Mark-1 eyeballs were our best set of sensors – by far! Our best-in-the-business GCI controllers were a close second.

ii. There was no onboard Airborne Intercept search-and-track radar.

iii. There was no IRSTS.

iv. There was a range-only radar system that displayed information on a meter equipped with lights to indicate “In Range.” It was a pathetic system useful only when I pointed the jet straight down to get altitude verification. I suppose it may have been effective against relatively cooperative, bomber-sized targets.

Biggest myth about the MiG-21?

a. That it is not an effective combat machine. With well over 11,000 copies built over a very long production run, it remained deadly due to sheer numbers for decades.

What should I have asked you?

a. How many times did the MiG-21 try to kill you? [Tried hard only once]

b. Would you willingly fly the MiG-21 into combat? [No.]

c. Was the MiG-21 easy to taxi? [Not Day One … or Day Two]

Describe you most memorable exercise in the MiG-21?

a. Describe a typical MiG-21 fight

b. How did the Soviets fight and where did this knowledge about their tactics come from?

i. I’m unsure of the remaining classification status of some aspects of this sort of information and not comfortable discussing it. It’s probably now unclassified since the USSR is out of business but I’d prefer to leave this topic alone.

c. Which model of MiG-21 was it and where did it come from?

i. We flew the MiG-21 F-13 (an early export model best known for combat operations versus United States aircraft in Southeast Asia.) We also flew later license-built (?) F-7 aircraft. Where these aircraft came from is frankly more than I personally know or am willing to discuss.

d. What was life like between missions? How did the desire for secrecy change things in your life?

i. We left Nellis AFB every morning via MAC-owned/operated C-12 executive transport aircraft (Beechcraft King Airs). We returned almost every evening after the day’s flight operations were complete. This travel was required to enable face-to-face debriefings with our adversary aircrews. Non-pilot personnel typically traveled to Tonopah on Monday mornings and returned to Nellis Friday afternoons. There were adequate dormitory, mess hall and recreational facilities to accommodate all assigned personnel. Pilots each had a full-time dorm room in case they needed to remain overnight.

ii. Details of our squadron’s operations were classified – but the fact that something special was going on was not a closely-guarded secret. We were treated with something like lofty respect by the Nellis fighter community – and granted unquestioned ‘expert’ status in matters regarding adversary aircraft.

iii. I could not share specific information with my family. If I’d been killed while flying a MIG – my family would have been told a cover story.

iv. One night at home my heart nearly stopped during a local news broadcast clearly showing a MiG-21 taking off at Tonopah! I couldn’t say a word about what I’d seen on the TV … thankfully my young family couldn’t tell a MiG-21 from a B-29 … but my jaw dropping to the floor might have drawn attention.

Tell me something I don’t know about the MiG-21

a. It accelerates right with the MiG-27 … knot for knot!

Describe the MiG-21 in three words

a. Surprisingly nimble $hitheap!

Quickest way to lose a fight with a MiG-21?

a. Failure to pick him up visually before he’s in firing position. With a wingspan under 24’ … it’s very hard to see!

b. Slowing down with him (assuming he’s willing and able to fight at very slow speed)

Against the F-15

a. How does the MiG-21 compare to the F-15 in WVR?

i. Each of the advantages enjoyed by the F-16 in the previous discussion also apply to the F-15’s advantages (except that acceleration is basically a draw) – with the additional factor that the Eagle is even better than the ‘Fishbed’ at slow speeds. The MiG is considerably smaller and much harder to see and perhaps keep track of in a visual fight.

b. What was your most challenging opponent in BFM/DACT and why?

i. Not really a definitive single answer to this question – owing to the pilot skill factor brought up above.

ii. Need to mention that most Constant Peg engagements went according to plan.

In a 1v1 between an F-5E and a MiG-21 which aircraft would you rather be in and why?

a. If life and death is not on the line, I’d prefer to be in the MiG-21. Knowing what I know, I can control the fight, bring it to a situation I can completely control and confidently maneuver to win the fight … decisively.

b. If life and death is on the line … give me the F-5E. (Damn few ‘Fishbed’ pilots realise they can fight that jet down to 30 KIAS. The better survivability of the F-5E can’t be denied.)

What was Constant Peg and how did it work?

a. Constant Peg was a flight program utilising actual threat aircraft to expose frontline American fighter crews to the sight of an aircraft they’d expect to kill. There was some exposure to fighting that aircraft – with the expectation that they would not encounter more skilled pilots anywhere else.

b. Normally selected units deploying to Nellis for Red Flag exercises were given the opportunity to spend part of their time with us.

i. They would operate out of Nellis – just as they did for Red Flag.

ii. We’d inbrief them into our program – usually on a Saturday.

During this inbrief each pilot would sign a sheet informing them of the penalties for divulging information about our program.

We’d also brief them about the aircraft they’d be flying against. (This was when we’d tell them not to go into the phone booth with the ‘Fishbed’!)

iii. We would wait on the ground until GCI told us our adversaries were inbound to our operating areas at the extreme northwest corner of the vast Nellis airspace complex. Our flight time was extremely limited, so saving fuel was a primary … and constant! … concern.

iv. Immediately after takeoff (we most often took off in pairs), we’d run a Soviet-style tactic for our adversaries to practice their radar work. They’d also run a stern-conversion on us to get us quickly together to get on with the meat of our mission.

v. Participating pilots had to first experience a Performance Profile mission with one of our pilots. This was a sophisticated ‘show and tell’ mission where the Red Eagle pilot described identifying features of his aircraft (without actually naming the aircraft … never know who’s listening!), coordinated a drag race to compare acceleration capabilities and led an advanced-handling demonstration.

vi. Once completing a PP with a ‘Fishbed’ pilot, our adversaries normally got a second PP with a Flogger pilot.

vii. After flying a PP with both aircraft, they were cleared to fly BFM missions with us.

BFM missions with the ‘Fishbed’ were full-up fights. We’d normally begin out front in the defensive position … allowing our adversary to watch us do our thing out their front window. Most of the time we’d start at about 20,000 feet, with about 400-450 knots on both jets and the adversary about 9,000 feet behind at the MiG’s 4:30 or 7:30 position. We’d usually get two long or three short engagements before the ‘Fishbed’ was out of fuel.

Who would win Eurofighter Typhoon versus Dassault Rafale? Analysis here

BFM missions with the Flogger were not very challenging for our adversaries … the Flogger couldn’t turn well at all. But seeing that in person was an important thing to learn.

viii. Once completing BFM missions with both aircraft, adversary pilots moved on to DACT missions – normally against one ‘Fishbed’ and one ‘Flogger’. (We rarely flew DACT sorties since so much emphasis was put on the BFM missions.)

c. We also participated in actual Red Flag missions – either with the Bandit aircraft or our AT-38B’s … or sometimes with both! (Our participation limited the Red Flag scenario to American participants only – due to the classification of our program.)

Why were you chosen for this effort and how would you describe the other individuals in your team?

a. I sometimes wonder why I was selected for this program. I volunteered, had built a solid reputation within the USAF fighter community and had appropriate experience that allowed me to be considered. Only Aggressors, Fighter Weapon School graduates and former Topgun Instructors were considered to become Bandits! I was an Aggressor. Bottom line? I got lucky!!

i. Even with those prerequisites, a prospective Red Eagle had to pass muster with the current Red Eagles. One vote, “No” … and you were out.

ii. Three personal interviews took place: two with individual General Officers – in their offices. Not intimidating at all! The third … and most important … was with the Red Eagle Operations Officer. Fail that one – and the outcome of the other interviews didn’t matter.

iii. Needed a security clearance a notch above Top Secret to play. Not routine.

b. Everyone that wore a Red Eagle patch was absolutely top-notch! The pilots I flew with – USAF, USN and USMC – were extremely skilled aviators. I’d go to war with any one of them … or all of them! Red Eagle GCI controllers were the absolute best. Our maintenance folks were beyond comparison … best in the business! They could build an airplane from spare parts without any problems – or they could fashion parts if none existed! We pilots routinely placed our lives in their hands without batting an eye. We also entrusted our lives to the Life Support technicians that worked directly for me (I was the Squadron Life Support Officer) but needed no direction from me. (There were two ejections while I was there … both pilots survived without meaningful injuries – thanks in part to the efforts of my guys.) We had dedicated professionals manning the firetrucks, security posts, refueling trucks, cooking our meals, cleaning our rooms, filling out our paperwork … at every level of effort – amazing, hand-picked personnel volunteered to pull classified duty at a classified location for several days each week away from home. I’m still impressed by the numbers of highly-qualified people that supported our unique mission. And kept it all secret until the program was declassified in 2006!

13 notes

·

View notes

Text

Essential Auxiliary Machinery on Ship

1. Generators

Generators are the heartbeat of a ship’s electrical system. They provide electrical power for various onboard systems, such as lighting, navigation equipment, communication systems, and HVAC (Heating, Ventilation, and Air Conditioning). Depending on the ship’s size and power requirements, multiple generators may be installed to ensure redundancy and continuous power supply during extended voyages.

2. Boilers

Boilers are essential for producing steam, which is utilized for various purposes on board. Steam is used for heating fuel oil and other fluids, running steam turbines for power generation, and operating various machinery and auxiliary machinery equipment, such as steam-driven pumps and winches.

3. Air Compressors

Air compressors generate compressed air used to power pneumatic tools, such as wrenches and chipping hammers, and operate pneumatic control systems. They also provide compressed air for starting main engines and auxiliary engines.

4. Purifiers

Fuel and lube oil purifiers play a critical role in maintaining the quality of fuels and lubricants used onboard. These machines remove impurities, water, and solids from fuel and oil, ensuring smooth engine operation and prolonging the life of critical machinery.

5. Refrigeration and Air Conditioning Systems

Refrigeration and air conditioning systems are vital for maintaining the temperature of provisions, perishable cargo, and living spaces. These systems use refrigerants and cooling coils to control temperature, humidity, and air quality throughout the ship.

6. Ballast Water Treatment Systems

To maintain stability and maneuverability, ships require ballast water to be pumped in or out as cargo is loaded or unloaded. Ballast water treatment systems are responsible for purifying and treating the ballast water to prevent the spread of invasive species and maintain marine ecosystem health.

7. Sewage Treatment Plants

Sewage treatment plants are responsible for processing and treating wastewater generated onboard. They help ensure that treated effluent meets international environmental standards before it is discharged into the sea.

8. Bilge Water Separators

Bilge water separators remove oil and other contaminants from the bilge water, a mix of seawater and oil that collects in the lower parts of the ship. The clean water is then discharged, while the separated oil is collected for proper disposal.

9. Incinerators

Incinerators are used to burn solid waste generated onboard, such as paper, cardboard, and non-recyclable plastics. Proper incineration reduces waste volume and ensures compliance with environmental regulations.

10. Water Makers

Water makers use reverse osmosis or distillation processes to convert seawater into potable water for drinking, cooking, and various onboard applications. They are especially vital for long voyages where access to freshwater sources may be limited.

Conclusion

The auxiliary machinery found on ships plays a crucial role in maintaining the vessel’s efficiency, safety, and comfort during journeys at sea. From power generation to waste management and water purification, each system contributes to the smooth operation and sustainability of modern ships. The continuous advancement of auxiliary machinery technology further enhances the capabilities and environmental performance of ships, making them safer, greener, and more reliable for maritime transportation across the globe.

#generator parts#ship machinery parts#navigation equipment#Auxiliary Machinery Equipment#Ship Machinery Parts#Auxiliary Machinery#Generator Parts#Automation#Navigation#pumps#automation systems

2 notes

·

View notes

Text

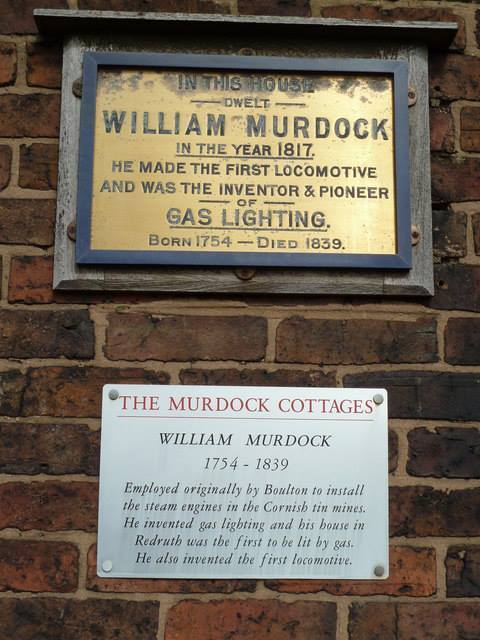

On August 21st 1754 William Murdock, the Scottish engineer, was born.

The son of John Murdock, a former artillery gunner and a Millwright and tenant of Bello Mill on the estate of James Boswell in Auchinleck, William was educated until the age of ten at the Old Cumnock Kirk School before attending Auchinleck school under William Halbert, author of a highly regarded arithmetic textbook. There he excelled in mathematics.

Murdock was a brilliant Scottish engineer and inventor. He probably doesn’t get the recognition he deserves due to the work of one of his mentors, James Watt.

In 1777 he walked from his home in Ayrshire to Birmingham to follow his dream of working with and Watt and Matthew Boulton

Down south it is thought his name was anglicized to Murdoch, but I’m happy to keep it as the original for this post. He remained an employee of Boulton and Watt for ten years and later a partner of Boulton and Watt until the 1830s and his reputation as an independent inventor has tended to be obscured by the reputations of those two men and the firm they founded.

The invention for which Murdock is best known is the use of coal gas for lighting purposes. Several independent inquirers into the constituents of Newcastle coal had arrived at the conclusion that nearly one-third of the substance was driven off in vapor by the application of heat, and that the vapor so driven off was inflammable. But no suggestion had been made to apply this vapor for lighting purposes until Murdock took the matter in hand. Murdock tested the effects of different types of coal from all over Britain, setting up an iron retort in the back yard of his home from which a metal tube ran into the living room. On July 29th, 1792, he presided at the lighting of a gas flame within the room. It would be several years, however, before Murdock took his invention beyond this rudimentary stage.

Murdock moved to Soho in 1798, too and it was there he resumed his experiments with coal gas. He knew he still had a long way to go in devising storage methods, mantles to give effective light, and gas purification systems, as well as safety measures. Boulton and Watt took great interest in Murdock’s progress, but were reluctant to apply for patents because they were currently engaged in litigation over their steam engine patents. They finally overcame their reluctance, however, and by 1803 the Soho factory was entirely illuminated by gas. The “Soho stink,” as Murdock called the odour of the gas, was eliminated after a time and factories as well as private homes began to install the system.

Murdock’s catalogue of inventions and ideas also includes: a method of harnessing compressed air that he used to work the bells in his Birmingham home; a high-pressure steam engine that could propel shot; a cylindrical crown saw that could be used to bore steam pipes for water and cut columns out of solid blocks of stone; an iron cement, the basic formula of which is still in use today, and; a method of transmitting letters and packages through a tube exhausted by an air pump.

Murdock took little interest in developments after 1810, by which time the gas industry was in the hands of businessmen scrambling for position and setting up rival gas companies in every city. In that year Murdock became a partner in the Soho company and remained so until he retired in 1830. He died in Birmingham on November 15th, 1839, and is buried near his former employers and mentors, Boulton and Watt.

The second pic is Boulton, Watt and Murdoch featured in a gilded statue in central Birmingham, doesn’t it look great!

6 notes

·

View notes

Text

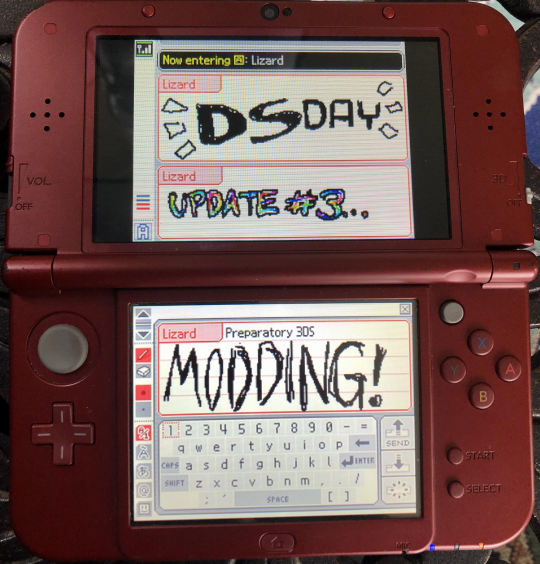

I'm using the ample time before my DS Day to prepare. I have modded both of the New 3DS systems mentioned in Update #1. It really was easy! Use this guide to try it for yourself.

I made this Deltarune Castle Town theme:

You can download it here.

Add Maypop Castle Town.zip to the /Themes folder on your SD Card. I'm using Anemone to apply themes, since that's what the guide's script installs. I may also make one of UT!Toriel's house.

I reorganized the home screens on both of them to look exactly like in the above video. The organization is necessary because there are so many apps now and probably more to come. I also installed PictoChat because DS Day is not complete without it.

As for the DSi systems, neither of them can turn on as of now. The blue one's charging light comes on when I plug it in, and when I press Power, the power light comes on, as do the screens, but it turns off immediately after the screens fade to white. The black one got to the Health & Safety screen after I plugged it in but turned off shortly after. It does not turn on at all now, and when I plug it in, the charging light flashes.

According to some cursory research (I visited a few Reddit threads), the battery is likely to be the problem. I plan to buy a new battery and try it on both to see if that fixes them. If it fixes both, I will buy a second battery.

Then, I'll move on to the L and R buttons. People on this page suggest blowing on them really hard. Others suggest using compressed air instead to avoid accidentally spitting on the DSi. Still others say that only cleaning them with isopropyl alcohol worked. I will start with whichever of the two solutions I already have the materials for.

#DS Day#retro gaming#3ds hacking#deltarune#196#2024-01-07#Remade the post with less tags because apparently only the first five tags are searchable.#Also I don't upload videos to this site often but it sure is buggy!

4 notes

·

View notes

Text

Industrial Applications of Mild Steel Pipes

Mild Steel (MS) pipes are widely used in industrial applications due to their exceptional strength, durability, and affordability. As a reliable MS Pipe dealer in Gujarat, Tube Trading Co., understands the importance of these versatile pipes in a range of sectors. In this article, we will explore the industrial applications of MS pipes and highlight their significance as a Square pipe distributor in Vadodara.

Construction Industry:

The construction industry heavily relies on the utilization of mild steel pipes for various applications. These pipes are commonly employed in plumbing systems, water distribution networks, and sewage lines. The corrosion resistance and durability of MS pipes make them particularly suitable for underground installations. Moreover, they are extensively used for structural purposes in the construction of frameworks for buildings, bridges, and other infrastructure projects. The square-shaped MS pipes supplied by Tube Trading Co. - an excellent Square pipe distributor in Vadodara, make them highly suitable for creating sturdy supports, columns, and frames, enhancing the overall strength and stability of structures.

Oil and Gas Industry:

The oil and gas industry heavily relies on mild steel pipes for efficient resource transportation. These pipes are crucial for conveying petroleum products, natural gas, and various chemicals. The strength, reliability, and cost-effectiveness of MS pipes make them an excellent choice for pipelines in the industry. They possess the ability to withstand high-pressure applications, making them suitable for both onshore and offshore operations. The most trusted and noteworthy MS Pipe dealer in Gujarat - Tube Trading Co. caters to the demand for quality pipes in the oil and gas sector, ensuring the seamless flow of resources and contributing to the industry's overall productivity.

Automotive Manufacturing:

MS pipes are widely used in the automotive sector for manufacturing exhaust systems and chassis components. The excellent weldability of MS pipes allows for easy fabrication, enabling the production of customized exhaust systems that meet specific performance requirements. Additionally, the durability and strength of MS pipes make them suitable for creating sturdy chassis components, ensuring the safety and structural integrity of vehicles.

Agriculture and Irrigation:

Mild steel pipes are an integral part of irrigation systems in the agriculture sector. These pipes are used to transport water from sources such as wells, rivers, or reservoirs to fields for crop irrigation. MS pipes are durable and resistant to harsh environmental conditions, making them suitable for both above-ground and underground installations. They are also utilized in the construction of fencing structures, greenhouses, and enclosures for livestock. Square pipes, distributed by Tube Trading Co. - a reliable MS Pipe dealer in Gujarat, are commonly employed to create robust support frames for agricultural structures, ensuring their stability and longevity.

Manufacturing and Engineering:

Mild steel pipes are widely utilized in the manufacturing sector for diverse purposes. They play a crucial role in the fabrication of machinery, equipment, and conveyor systems. MS pipes are employed as conduits for the efficient transport of fluids, gases, and other materials within manufacturing plants. Due to their strength and ductility, these pipes are reliable for conveying compressed air, hydraulic fluids, and various chemicals. Furthermore, in the automotive industry, MS pipes find extensive usage in the production of exhaust systems, roll cages, and chassis components, thanks to their durability and affordability.

Infrastructure Development:

MS pipes play a significant role in infrastructure development projects. They are used for the construction of bridges, flyovers, and elevated highways, providing structural support and facilitating the transportation of people and goods. MS pipes are also employed in the installation of underground utility networks, including water supply, sewage, and gas pipelines.

Choosing the right-sized mild steel pipes for your project:

Choosing the right-sized mild steel pipes for your project is crucial to ensure proper functionality, structural integrity, and cost-effectiveness. Let’s explore some key factors to consider while choosing the right-sized MS pipes:

Flow Requirements: Determine the flow rate or volume of fluids or gases that will pass through the pipe. Calculate the required pipe diameter based on the desired flow velocity and pressure drop. This will help you choose a pipe size that can handle the anticipated flow without causing excessive pressure loss.

Load-Bearing Capacity: Assess the load-bearing requirements of your project. Consider the weight or load that the pipe will need to support, whether it's structural loads, machinery, or equipment. Larger-diameter pipes with thicker walls generally have a higher load-bearing capacity, providing greater strength and stability.

Material Compatibility: Ensure that the chosen mild steel pipe is compatible with the fluids or gases that will be conveyed. Consider factors such as corrosion resistance, chemical compatibility, and temperature limitations. Mild steel pipes are generally suitable for a wide range of applications, but if you anticipate exposure to corrosive environments, you may need to consider additional protective coatings or alternative materials.

Installation Considerations: Evaluate the available space and installation requirements. Consider factors such as the pipe's length, flexibility, and ease of joining. Determine whether you need straight lengths or require bends, fittings, or connectors to navigate through the project site. Ensure that the chosen pipe size can be accommodated within the available space without hindering the overall functionality of the system.

Standards and Regulations: Comply with industry standards and regulations governing pipe sizing for specific applications. Different industries and regions may have specific guidelines regarding pipe size selection. Familiarize yourself with relevant codes and standards to ensure compliance and to guarantee the safety and efficiency of your project.

Cost Considerations: Evaluate the cost implications associated with different pipe sizes. Larger-diameter pipes with thicker walls tend to be more expensive than smaller ones. Consider the balance between cost and performance to ensure that you select a pipe size that meets your project requirements while optimizing your budget.

Consultation and Expert Advice: If you are uncertain about the appropriate pipe size for your project, it is advisable to consult with experienced engineers, contractors, or MS pipe dealers. They can provide valuable insights and help you make an informed decision based on the specific needs and constraints of your project.

Final Thoughts:

Mild steel (MS) pipes have become indispensable in numerous industrial applications due to their versatility, reliability, and cost-effectiveness. In Gujarat, a state experiencing rapid industrial growth, Square pipe distributors in Vadodara serve as crucial suppliers, fulfilling the demand for quality pipes, including square pipes. The construction industry benefits from mild steel pipes for plumbing and structural applications, while the manufacturing sector relies on them for machinery fabrication. In agriculture, these pipes find extensive usage in irrigation systems and the construction of agricultural structures. Furthermore, the oil and gas industry heavily depends on MS pipes for efficient resource transportation. The widespread utilization of mild steel pipes underscores their importance in driving industrial development and infrastructure growth.

#distributor#Jindal pipes#steel industry#steel companies#industrial#seamless pipes#piping material#plumbing industry#construction structure#manufacturer#construction sites

7 notes

·

View notes

Text

THE ULTIMATE GUIDE TO PRESSES, SHEARS, LASER CUTTERS AND PUNCHES

In the world of metal fabrication, several key machines play a vital role in shaping and cutting metal with precision and efficiency. This ultimate guide provides comprehensive knowledge and insights into the essential products of the industry: Press Brake, Press Brake Tools, Shearing Machine, Laser Cutting Machine, and Power Press. Whether you are a beginner or an experienced professional, this guide will equip you with the necessary information to understand, select, and optimize the use of these machines for your metalworking needs.

Press Brake:

1.What is a Press Brake?

A press brake is a key equipment used in the field of metal fabrication for bending and folding metal sheets. It utilizes pressure to bend the metal sheet into the desired shape. It is commonly used to create bent parts, enclosures, tubing, and other metal components.

A press brake consists of an upper die and a lower die, with the upper die fixed to the frame and the lower die movable through a hydraulic system or mechanical drive system. The metal sheet is placed between the two dies and then bent into the desired angle and shape by applying pressure.

Press brakes typically have the following features and capabilities:

(1)Bending capacity: Press brakes can achieve bends at different angles and radii to meet various workpiece requirements.

(2)Precision: High precision bending results can be achieved by adjusting the position of the upper and lower dies.

(3)Automation: Some modern press brakes are equipped with CNC systems, allowing for automated operation and programming.

(4)Versatility: Press brakes can be used for various bending tasks and different types of metal materials by changing different tools and dies.

(5)Safety: Press brakes are typically equipped with safety devices such as light curtains, protective covers, and emergency stop buttons to ensure operator safety.

Press brakes are widely used in industries such as automotive manufacturing, aerospace, construction, electronics, and more. They are essential equipment for achieving precise and efficient metal fabrication.

2.Types of Press Brakes

There are several types of press brakes commonly used in metal fabrication:

Mechanical Press Brake: Uses a mechanical flywheel and clutch system for bending.

Hydraulic Press Brake: Utilizes hydraulic cylinders for precise bending control.

Servo-Electric Press Brake: Uses electric servo motors for high precision bending.

Pneumatic Press Brake: Relies on compressed air for lighter applications.

CNC Press Brake: Equipped with computerized controls for automated and precise bending operations.

The choice of press brake depends on factors such as material type, thickness, bending requirements, and production volume.

3.Components and Working Principles

A press brake consists of several key components that work together to perform the bending operation. Here are the main components and their functions:

Frame: The frame provides structural support and stability to the press brake.

Bed: The bed is a flat surface where the material to be bent is placed.

Ram: The ram is the moving part of the press brake that applies force to the material for bending.

Die: The die is a tool that shapes the material by providing a specific bending angle.

Punch: The punch is another tool that presses against the material, working in conjunction with the die to bend it.

Backgauge : The backgauge is an adjustable device that positions the material accurately for consistent bending.

4.Key Features and Benefits

Material Placement: The operator places the metal sheet or plate on the bed of the press brake.

Tool Setup: The appropriate die and punch are selected and installed on the press brake.

Backgauge Adjustment: The backgauge is adjusted to position the material correctly for the desired bend.

Bending Process: The ram moves downward, applying force to the material, which is sandwiched between the punch and the die. This bending action creates the desired angle in the material.

Material Removal: Once the bending is complete, the operator removes the bent material from the press brake.

5.Applications and Industries

Press brakes are widely used in various industries for different applications, including:

Metal Fabrication: Press brakes are commonly used in metal fabrication shops to bend and shape metal sheets and plates for various products such as enclosures, brackets, frames, and panels.

Automotive Industry: Press brakes are used in the automotive industry for manufacturing components like chassis, brackets, and body panels.

Aerospace Industry: Press brakes are utilized in the aerospace industry for bending and forming metal parts used in aircraft structures and components.

Construction and Architecture: Press brakes are used in the construction and architectural sectors for bending metal components used in building structures, facades, and decorative elements.

Electronics and Appliances: Press brakes are employed in the manufacturing of electronic enclosures, appliance components, and consumer products.

Press Brake Tools:

1.Importance of Press Brake Tools

Press brake tools play a crucial role in the performance and efficiency of press brake machines. Here are some key points highlighting the importance of press brake tools:

(1) Precision Bending: Press brake tools are designed to provide precise and accurate bending angles. They ensure consistent results and help meet the required specifications for the final product. The quality and precision of the tools directly impact the overall quality of the bent parts.

(2) Versatility: Press brake tools come in various shapes, sizes, and configurations to accommodate different bending requirements. They can be customized or interchanged to achieve different bending angles, radii, or complex shapes. This versatility allows manufacturers to produce a wide range of products using the same machine.

(3) Durability and Longevity: Press brake tools are made from high-quality materials such as hardened steel or special alloys, which make them highly durable and resistant to wear and tear. Proper maintenance and regular tool inspections ensure their longevity, reducing the need for frequent replacements.

(4) Efficiency and Productivity: Well-designed press brake tools optimize the bending process, reducing setup time, and increasing productivity. They enable faster bending cycles, allowing manufacturers to produce more parts in less time. Efficient tooling also minimizes material waste and improves overall production efficiency.

(5) Cost Savings: Using the right press brake tools can lead to cost savings in multiple ways. Accurate bending reduces material waste, saving on raw material costs. Efficient tooling reduces setup time and increases machine productivity, maximizing the output per hour. Additionally, durable tools have a longer lifespan, reducing the frequency of replacements and maintenance costs.

(6) Safety: Press brake tools are designed with safety features in mind. They provide proper clamping and holding mechanisms to secure the material during bending, minimizing the risk of accidents. Additionally, using high-quality tools reduces the chances of tool failure or breakage, ensuring operator safety.

(7) In summary, press brake tools are vital for achieving precise and accurate bending results, improving productivity, reducing costs, and ensuring operator safety. Selecting the right tools and maintaining them properly is essential for the efficient operation of press brake machines.

2.Types of Press Brake Tools (including ARC Press Brake Tools)

There are several types of press brake tools available, each designed for specific bending applications. Here are some common types of press brake tools:

V-Die: V-dies are the most commonly used press brake tools. They consist of a bottom die with a V-shaped groove and a punch with a matching V-shaped tip. V-dies are versatile and can be used for a wide range of bending angles and materials.

(1) Bottoming Die: Bottoming dies, also known as flat dies, have a flat surface instead of a V-shaped groove. They are used for achieving sharp bends or bending thicker materials where a tighter radius is required.

(2) Gooseneck Punch: Gooseneck punches have a curved shape that allows for deep and offset bends. They are commonly used for bending channels, boxes, and other complex shapes.

(3) Hemming Tool: Hemming tools are used for creating hems or flanges on the edge of a sheet metal part. They consist of a punch and die set that folds the material over itself to create a secure edge.

(4) Radius Tool: Radius tools, also known as radius punches or radius dies, are used for creating curved bends with a specific radius. They are available in various sizes to accommodate different bending requirements.

(5) Multi-V Die: Multi-V dies have multiple V-shaped grooves of different sizes on a single die. They allow for quick and easy tool changes without the need for separate dies for different bending angles.

(6) ARC Press Brake Tools: ARC press brake tools are specialized tools used for bending sheet metal into arc shapes. They are designed to create precise and consistent curved bends, commonly used in applications such as cylindrical parts, tubes, or curved profiles.

ARC press brake tools typically consist of a bottom die with a curved groove and a punch with a matching curved tip. They enable the accurate and repeatable bending of sheet metal into various arc shapes.

3.Material Selection and Coatings

When it comes to press brake tools, material selection and coatings play an important role in their performance and longevity. Here's a brief overview of material selection and coatings for press brake tools:

Material Selection:

(1) Tool Steel: Tool steel, such as D2 or A2, is commonly used for press brake tools due to its high hardness, wear resistance, and toughness.

(2) Carbide: Carbide inserts or tips are used for heavy-duty applications or when bending abrasive materials. Carbide provides excellent wear resistance but is more brittle than tool steel.

(3) High-Speed Steel (HSS): HSS is another option for press brake tools. It offers good toughness and wear resistance, but not as high as tool steel.

Coatings:

(4) Nitride Coating: Nitride coatings, such as TiN (Titanium Nitride) or TiCN (Titanium Carbonitride), improve the surface hardness and wear resistance of the tool. They are suitable for general-purpose bending applications.

(5) DLC Coating: DLC (Diamond-Like Carbon) coatings provide excellent hardness, low friction, and high wear resistance. They are ideal for bending stainless steel and other difficult-to-form materials.

(6) PVD Coating: Physical Vapor Deposition (PVD) coatings, like TiAlN (Titanium Aluminum Nitride), enhance the tool's performance by reducing friction and increasing wear resistance.

(7) Chrome Plating: Chrome plating is a common coating for press brake tools. It provides good corrosion resistance and reduces friction during bending operations.

The selection of material and coating depends on factors such as the type of material being bent, the bending application, and the desired tool life. It's important to choose the right combination of material and coating to ensure optimal performance and durability of the press brake tools.

4.Tooling Configurations and Considerations

When it comes to press brake tools, the tooling configurations and considerations are crucial for achieving accurate and efficient bending operations. Here are some important aspects to consider:

Tooling Configurations:

(1) V-Die: The V-die is the female tool that provides the desired bend shape. It comes in various widths and angles to accommodate different material thicknesses and bending requirements.

(2) Punch: The punch is the male tool that contacts the material and applies force to create the bend. It also comes in different shapes and sizes to achieve specific bend angles and radii.

(3) Multi-V Die: Multi-V dies have multiple V-shaped grooves of different widths and angles. They allow for bending different material thicknesses and angles without changing the die.

(4) Gooseneck Punch: Gooseneck punches have a curved shape that allows for deep or offset bends where space is limited.

(5) Hemming Tools: Hemming tools are used for creating hemmed edges or flanges on sheet metal.

Considerations:

(1) Material Thickness: The tooling configuration should be selected based on the material thickness being bent. Thicker materials may require larger tooling to accommodate the increased force and prevent tool damage.

(2) Material Type: Different materials have varying properties, such as hardness and ductility, which can affect the tooling selection. Harder materials may require tougher tooling materials or coatings.

(3) Bend Angle and Radius: The desired bend angle and radius dictate the selection of punch and die configurations. Sharp bends require smaller punch radii, while larger radii are needed for gentler bends.

(4) Tooling Alignment: Proper alignment between the punch and die is essential for achieving accurate and consistent bends. Misalignment can result in uneven bends or tool damage.

(5) Tooling Maintenance: Regular inspection and maintenance of the tooling are necessary to ensure optimal performance and longevity. This includes cleaning, lubrication, and replacement of worn-out components.

By considering the tooling configurations and these important factors, you can select the appropriate press brake tools for your specific bending requirements. This will help you achieve precise and efficient bending operations while prolonging the tooling life.

5.Tool Maintenance and Longevity

(1) Regular cleaning: Clean the press brake tools regularly to remove debris, dirt, and metal shavings. Use appropriate cleaning agents and tools to avoid damaging the tool surfaces. Ensure that the tools are completely dry before storing them.

(2) Lubrication: Apply lubrication to the press brake tools as recommended by the manufacturer. Lubrication helps reduce friction and wear, improving the tool's lifespan. Follow the manufacturer's guidelines for the type and frequency of lubrication.

(3) Inspection and repair: Regularly inspect the press brake tools for signs of wear, damage, or deformation. Check for any cracks, chips, or excessive wear on the cutting edges. If any issues are detected, promptly repair or replace the damaged parts to prevent further damage and ensure accurate bending results.

(4) Proper storage: Store the press brake tools in a clean and dry environment to prevent corrosion and damage. Use dedicated tool racks or boxes to keep the tools organized and protected. Avoid placing heavy objects on top of the tools to prevent deformation.

(5) Operator training: Proper training of operators is essential for tool maintenance and longevity. Educate operators on the correct usage techniques, operating limits, and safety precautions. Encourage operators to report any issues or abnormalities with the tools promptly.

By following these maintenance tips, you can extend the lifespan of your press brake tools and ensure consistent and accurate bending operations. Regular maintenance not only improves tool performance but also contributes to the overall safety and efficiency of the bending process.

6.Advanced Tooling Technologies and Innovations

Advanced tooling technologies and innovations have significantly improved the performance and capabilities of press brake tools. Here are some key advancements in press brake tooling: