#commercial vehicle tracking system

Explore tagged Tumblr posts

Text

Boost Business Efficiency with Commercial Vehicle Tracking System

Looking for an effective commercial vehicle tracking system? Our blog explores the benefits of a commercial vehicle tracking system for businesses. Learn how to optimize fleet management and improve productivity. Discover key features and considerations for choosing the right commercial vehicle tracking system.

0 notes

Text

#lorry loads#freight transportation#trucking logistics#cargo hauling#haulage services#commercial vehicle operations#heavy load delivery#bulk goods shipment#oversize load transport#distribution trucking#logistics india#supply chain management india#freight forwarding india#transportation services india#warehousing india#distribution networks india#import export solutions india#third-party logistics india#cold chain logistics india#online lorry loads services#freight marketplace#truck load boards#digital logistics platform#transport automation#load matching#carrier connectivity#real-time tracking#capacity utilization#transportation management systems#house shifting services online india

0 notes

Text

#lorry loads#freight transportation#trucking logistics#cargo hauling#haulage services#commercial vehicle operations#heavy load delivery#bulk goods shipment#oversize load transport#distribution trucking#logistics india#supply chain management india#freight forwarding india#transportation services india#warehousing india#distribution networks india#import export solutions india#third-party logistics india#cold chain logistics india#online lorry loads services#freight marketplace#truck load boards#digital logistics platform#transport automation#load matching#carrier connectivity#real-time tracking#capacity utilization#transportation management systems#house shifting services online india

0 notes

Text

Enhancing Safety in the Mining Industry: The Role of Advanced Telematics Solutions

The mining industry faces significant challenges in ensuring the safety of its workforce amidst hazardous working conditions and complex operational environments. Despite stringent safety regulations and protocols, accidents and incidents continue to pose risks to personnel and assets. In this context, the adoption of advanced telematics solutions emerges as a critical strategy to enhance safety standards and mitigate risks within mining operations.

In this article, we will discuss the role of telematics technology, its key features, applications, and benefits in the mining industry.

Understanding the Role of Telematics Technology in the Mining Industry

Telematics systems employ a combination of hardware and software components to collect, transmit, and analyse data from vehicles and assets in real-time. The GPS tracking devices installed in vehicles capture location coordinates, speed, and route information, which is transmitted to a centralised platform via cellular or satellite networks. In addition, onboard sensors and diagnostics systems monitor vehicle performance metrics such as engine health, fuel consumption, and maintenance status.

This data is then processed and analysed using advanced algorithms and fleet telematic analytics tools to generate actionable insights and performance reports for fleet managers and stakeholders. By providing visibility into key operational parameters and safety metrics, mining telematics systems enable mining companies to proactively identify risks, implement preventive measures, and optimise resource allocation to enhance safety and efficiency across their operations.

Key Features of Telematics Fleet Management System for Mining Operations

Live Location Tracking: Track the real-time location of vehicles and equipment, enabling better fleet management and resource allocation.

Rash Driving Alerts: Receive alerts for instances of aggressive or unsafe driving behaviour, allowing for immediate intervention and corrective action.

Accident Detection: Detect accidents or collisions as they occur, enabling rapid response and assistance to affected personnel.

Autonomous Emergency Braking (AEB): Automatically apply brakes in emergency situations to prevent or mitigate collisions, enhancing overall safety on the road.

Tailgating Detection: Identify instances of tailgating, a common cause of accidents, and alert drivers to maintain safe following distances.

Overspeeding Monitoring: Monitor vehicle speed in real-time and receive alerts for instances of speeding, helping to prevent accidents and ensure compliance with safety regulations.

Drowsiness Detection: Detects signs of driver drowsiness or fatigue and provides timely alerts to prevent accidents caused by impaired alertness.

Distraction Monitoring: Monitor driver attentiveness and detect distractions such as mobile phone usage or inattentiveness, reducing the risk of accidents due to driver distraction.

Application of Telematics in the Mining Industry

Enhanced Driving Behavior Insights

Gain comprehensive insights into driving behaviour, empowering mining companies to identify and address unsafe practices effectively. By analysing factors such as speed, acceleration, and braking, organisations can develop targeted strategies to promote safer driving habits among their workforce.

Access to Incident Videos

Access to incident videos in real-time facilitates prompt response and investigation of accidents or incidents within mining operations. This capability enhances safety protocols by enabling timely review and analysis, ultimately contributing to the development of more robust risk management strategies.

Fleet Performance Optimization

Utilise data analytics to optimise fleet performance and efficiency in mining operations. By leveraging insights derived from telemetric fleet management systems, organisations can identify areas of inefficiency and implement corrective measures to reduce operational costs and enhance productivity across their fleet.

Benefits of Using Telematics in Mining Operations

Telematics technology finds various benefits in mining operations, contributing to enhanced safety, efficiency, and productivity. Some key benefits include:

Fleet Management: Telematics systems enable real-time vehicle tracking and equipment, allowing managers to monitor their location, speed, and status. This ensures efficient fleet management, optimal asset utilisation, and timely maintenance scheduling.

Remote Monitoring: Telematics enables remote monitoring of equipment performance and health, including engine diagnostics, fuel consumption, and maintenance alerts. This proactive approach helps prevent unexpected breakdowns, reduces downtime, and extends equipment lifespan.

Safety Enhancement: Integration with fatigue monitoring systems helps identify signs of driver fatigue, allowing for timely intervention to prevent accidents caused by drowsiness.

Data-Driven Decision-Making: Historical performance data and trend analysis provide valuable insights for long-term planning and strategic decision-making, driving continuous improvement initiatives.

Scalability: Telematics solutions are scalable and customizable to meet the evolving needs of mining operations, accommodating changes in fleet size, geographic expansion, and technological advancements.

Conclusion

To sum up, investing in mining telematics solutions is important for safeguarding worker wellbeing and enhancing operational efficiency in the mining industry. By leveraging telematics technology, mining companies can proactively identify and mitigate safety risks, optimise fleet performance, and ensure regulatory compliance.

#telematics in mining#telematics#mining telematics#applications of telematics#advantages of telematics#telematics solution providers in india#telematics vehicle tracking#truck fleet telematic#mining vehicle telematics#commercial fleet telematics#telematics software providers#telematics solutions#telematics data#telematics system#fleet telematics analytics#vehicle telematics data#mining telematics solution

0 notes

Text

Transforming the Trucking Industry with ELD Mandate and Advanced Technologies

In the ever-evolving landscape of the trucking industry, staying compliant with regulations while ensuring efficiency and safety is paramount. The Electronic Logging Device (ELD) Mandate, introduced by the Federal Motor Carrier Safety Administration (FMCSA), has significantly impacted how the industry operates. At Eld Mandate.biz, we understand these challenges and are committed to providing comprehensive solutions that not only meet regulatory requirements but also enhance fleet management and road safety.

Understanding the ELD Mandate

The ELD Mandate, which became effective in December 2017, requires commercial motor vehicles to use electronic logging systems (ELS) to record a driver’s Record of Duty Status (RODS). This regulation aims to improve compliance with the Hours of Service (HOS) rules, reduce paperwork, and enhance the efficiency of the trucking industry.

Our Solutions: ELDs, GPS Tracking, and More

At Eld Mandate.biz, we offer a range of solutions designed to help trucking companies comply with the ELD Mandate and enhance their operations:

Electronic Logging Devices (ELDs)

Our ELDs are FMCSA-compliant and come with advanced features such as real-time tracking, automated logs, and easy-to-use interfaces. These devices not only help drivers stay compliant with HOS regulations but also provide fleet managers with valuable insights into their operations.

GPS Tracking

Our GPS tracking solutions allow trucking companies to monitor their vehicles in real-time, enabling them to optimize routes, improve fuel efficiency, and enhance overall fleet management. With our online portal, fleet managers can access detailed information about their trucks' locations, speeds, and more.

### Fleet Management

Our comprehensive fleet management solutions go beyond ELDs and GPS tracking. We offer a range of tools and services, including proactive ELD monitoring, driver coaching, and compliance consulting. Our goal is to help our clients not only meet regulatory requirements but also operate more efficiently and safely.

Why Choose Eld Mandate.biz?

Compliance: Our solutions are fully compliant with FMCSA regulations, ensuring that your fleet stays on the right side of the law.

Advanced Technology: We leverage cutting-edge technology to provide our clients with the most accurate and reliable solutions.

Customer Support: Our team of experts is always available to assist you with any questions or issues you may have.

Conclusion The ELD Mandate has transformed the trucking industry, and at Eld Mandate.biz, we are committed to helping our clients navigate this new regulatory landscape. With our advanced ELDs, GPS tracking solutions, and fleet management services, we can help you achieve compliance, improve efficiency, and enhance road safety. Contact us today to learn more about how we can help your business thrive in the digital age of trucking.

#Eld Mandate#Electronic Logging Device#keeptruckin#GPS tracking Online trucks#real time portal trucks#time portal proactive eld#Hours of Service#FMCSA (Federal Motor Carrier Safety Administration)#Commercial Motor Vehicle#Electronic logging system (ELS)#Fleet Management#Trucking Compliance#Road Safety

0 notes

Text

#gps tracker for commercial vehicles#gps tracking for commercial vehicles#GPS for commercial vehicles#Vehicle Tracking System#GPS vehicle tracking system

0 notes

Text

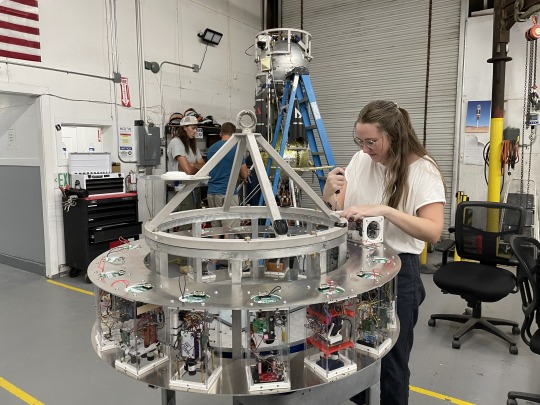

Student Experiments Soar!

youtube

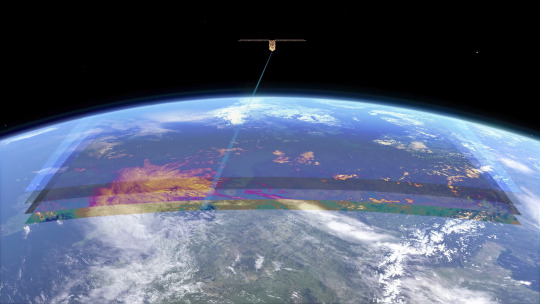

Have you ever wondered what it takes to get a technology ready for space? The NASA TechRise Student Challenge gives middle and high school students a chance to do just that – team up with their classmates to design an original science or technology project and bring that idea to life as a payload on a suborbital vehicle.

Since March 2021, with the help of teachers and technical advisors, students across the country have dreamed up experiments with the potential to impact space exploration and collect data about our planet.

So far, more than 180 TechRise experiments have flown on suborbital vehicles that expose them to the conditions of space. Flight testing is a big step along the path of space technology development and scientific discovery.

The 2023-2024 TechRise Challenge flight tests took place this summer, with 60 student teams selected to fly their experiments on one of two commercial suborbital flight platforms: a high-altitude balloon operated by World View, or the Xodiac rocket-powered lander operated by Astrobotic. Xodiac flew over the company’s Lunar Surface Proving Ground — a test field designed to simulate the Moon’s surface — in Mojave, California, while World View’s high-altitude balloon launched out of Page, Arizona.

Here are four innovative TechRise experiments built by students and tested aboard NASA-supported flights this summer:

1. Oobleck Reaches the Skies

Oobleck, which gets its name from Dr. Seuss, is a mixture of cornstarch and water that behaves as both a liquid and a solid. Inspired by in-class science experiments, high school students at Colegio Otoqui in Bayomón, Puerto Rico, tested how Oobleck’s properties at 80,000 feet aboard a high-altitude balloon are different from those on Earth’s surface. Using sensors and the organic elements to create Oobleck, students aimed to collect data on the fluid under different conditions to determine if it could be used as a system for impact absorption.

2. Terrestrial Magnetic Field

Middle school students at Phillips Academy International Baccalaureate School in Birmingham, Alabama, tested the Earth’s magnetic field strength during the ascent, float, and descent of the high-altitude balloon. The team hypothesized the magnetic field strength decreases as the distance from Earth’s surface increases.

3. Rocket Lander Flame Experiment

To understand the impact of dust, rocks, and other materials kicked up by a rocket plume when landing on the Moon, middle school students at Cliff Valley School in Atlanta, Georgia, tested the vibrations of the Xodiac rocket-powered lander using CO2 and vibration sensors. The team also used infrared (thermal) and visual light cameras to attempt to detect the hazards produced by the rocket plume on the simulated lunar surface, which is important to ensure a safe landing.

4. Rocket Navigation

Middle and high school students at Tiospaye Topa School in LaPlant, South Dakota, developed an experiment to track motion data with the help of a GPS tracker and magnetic radar. Using data from the rocket-powered lander flight, the team will create a map of the flight path as well as the magnetic field of the terrain. The students plan to use their map to explore developing their own rocket navigation system.

youtube

The 2024-2025 TechRise Challenge is now accepting proposals for technology and science to be tested on a high-altitude balloon! Not only does TechRise offer hands-on experience in a live testing scenario, but it also provides an opportunity to learn about teamwork, project management, and other real-world skills.

“The TechRise Challenge was a truly remarkable journey for our team,” said Roshni Ismail, the team lead and educator at Cliff Valley School. “Watching them transform through the discovery of new skills, problem-solving together while being driven by the chance of flying their creation on a [rocket-powered lander] with NASA has been exhilarating. They challenged themselves to learn through trial and error and worked long hours to overcome every obstacle. We are very grateful for this opportunity.”

Are you ready to bring your experiment design to the launchpad? If you are a sixth to 12th grade student, you can make a team under the guidance of an educator and submit your experiment ideas by November 1. Get ready to create!

Make sure to follow us on Tumblr for your regular dose of space!

613 notes

·

View notes

Text

What Is EV Charging Management Software?

Let’s get one thing out of the way EV charging isn’t just about plugging into a socket and walking away. Behind that simple user experience is a whole ecosystem that needs to run like a well-oiled (or should we say, well-charged) machine. That’s where EV charging management software steps in.

Think of it as the backend control room that powers everything from session tracking to billing, charger health, and even the queue at your nearest public station. Whether you’re managing a single station or hundreds across locations, this software is what keeps operations clean, trackable, and profitable.

Let’s break this down properly and make sense of what matters especially if you’re planning to get into the EV game with some business sense, not just shiny dashboards.

What is EV Charging Management Software, Really?

In simple words, EV Charging Management Software (CMS) is a centralized system that lets charging station owners, operators, and businesses manage, monitor, and monetize their EV charging infrastructure.

It does everything from:

Authorizing users and vehicles

Monitoring energy usage

Managing peak loads

Automating billing and invoicing

Handling remote diagnostics

And integrating with apps, wallets, and CRM tools

Without it, you'd be managing your EV chargers with spreadsheets, phone calls, and prayers.

Who Needs It?

If you're a fleet operator, public charging station owner, commercial building manager, or even a residential society exploring EV readiness this software isn't a luxury. It's survival gear.

And yes, government projects, retail malls, parking lots, and logistics parks are all getting in on it.

You want uptime, transparency, and ROI? You need a CMS that plays nice with your hardware and grows as your needs change.

What Problems Does It Solve?

Here’s where we skip the fluff and talk about real issues.

1. Energy Load Management

Uncontrolled EV charging can blow up your utility bill or trip the local transformer. CMS helps you control how much energy flows where and when without causing grid panic.

2. Charger Downtime

No operator wants to get that “your charger isn’t working” call at 2 AM. A solid CMS alerts you before users complain. Remote diagnostics and health checks are baked in.

3. User Authentication & Payments

Want to let only subscribed users charge? Want to integrate UPI, cards, or in-app wallets? A proper CMS does all that without you writing a single line of code.

4. Revenue Leakage

Imagine running a business where you're not sure who paid, how much power was delivered, or how many sessions failed. A CMS gives you transaction-level visibility. No guessing games.

5. Scalability

Planning to go from 5 chargers to 50? From 1 location to 12 cities? Your CMS better be ready before your Excel sheet dies of stress.

Must-Have Features (Beyond Just “Dashboard Looks Cool”)

A good EV CMS isn't just eye candy. Here's what you should be checking for:

OCPP Compliance: Plays well with most hardware brands

Dynamic Load Balancing: Keeps your power use smart and optimized

Real-time Monitoring: Know what’s happening where, second by second

Custom Pricing Models: Per minute, per kWh, time-of-day rates you control the game

Fleet & Group Management: Especially if you're running EV fleets or shared chargers

User Access Control: Set roles, permissions, and access levels

White-label Option: Your brand, your logo, your rules

So, Who’s Doing It Right?

There are plenty of software platforms out there that’ll promise the moon until you actually plug them in. But a few players are doing it with serious focus on customization, clean architecture, and real customer support.

Stellen Infotech: Quietly Building the Backbone for EV Ops

While most are busy chasing investor buzzwords, Stellen Infotech is quietly building robust, scalable, and adaptable EV charging software solutions for businesses that actually need to function in the real world.

They’re not just slapping a UI on top of code and calling it a platform. Their stack includes features like:

Custom-built integrations for fleets

White-labeled dashboards

Load optimization modules

Billing and invoicing flexibility

API support for third-party logistics, CRMs, or payment apps

The vibe? Practical tech that doesn’t crash when you scale or cry when you run 100 sessions a day. You’ll notice they’re not trying to be the flashiest just the most dependable in the room. And that’s honestly what most businesses want when dealing with critical infrastructure.

Can’t I Just Build This Myself?

Sure, if you’re sitting on a dev team with grid logic, payment gateway knowledge, OCPP expertise, and UI chops. Otherwise, you’ll spend 18 months burning money, and still end up with something half-baked.

EV management is not just a software challenge it’s a compliance, connectivity, and customer experience challenge. You’re better off working with a team that already figured that out.

What About Hardware Compatibility?

The good ones like Stellen’s platform are built to support OCPP 1.6 and 2.0, meaning they work with a wide range of chargers. You’re not locked into one brand or vendor, which is great because EV hardware isn’t cheap and upgrading just for software issues is bad business.

Final Thoughts: Where This Is Headed

EV charging isn't a novelty anymore. With mandates, subsidies, and rising fuel prices, we’re going to see charging stations pop up like ATMs did in the 2000s. But here’s the thing the ones who’ll stay profitable aren’t the ones who bought the fanciest chargers. It’s the ones who run them smartly.

That’s where EV charging management software earns its keep.

Whether you’re just setting up or scaling across cities, having a solid CMS isn’t optional it’s your operational backbone. Platforms like what Stellen Infotech offers are making this easier for businesses that don’t want to get stuck figuring out load curves and session reports at 11 PM.

And honestly? That’s the kind of tech backbone more EV businesses need not another flashy dashboard with no substance.

2 notes

·

View notes

Text

New SpaceTime out Monday

SpaceTime 20240826 Series 27 Episode 103

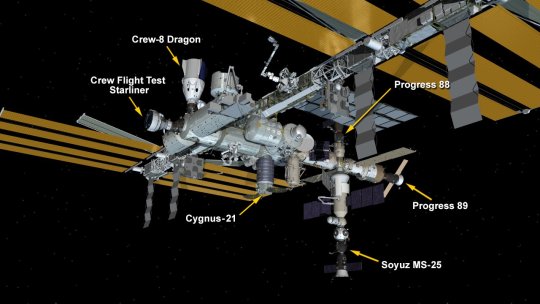

Starliner crew to return on Dragon

NASA has decided to return the stranded Starliner crew to Earth aboard rival SpaceX’ Dragon capsule because of ongoing concerns about the reliability of their Boeing spacecraft.

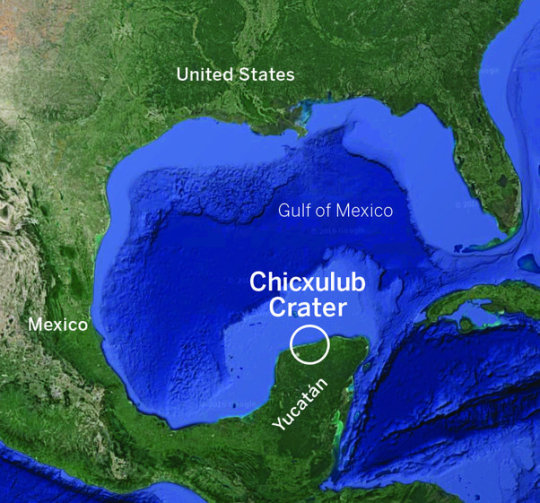

Tracking down the asteroid that killed the dinosaurs

A new study claims the asteroid which triggered the extinction of 75 percent of all life on Earth including all the non-avian dinosaurs 66 million years ago originated beyond the orbit of Jupiter during the early development of the solar system.

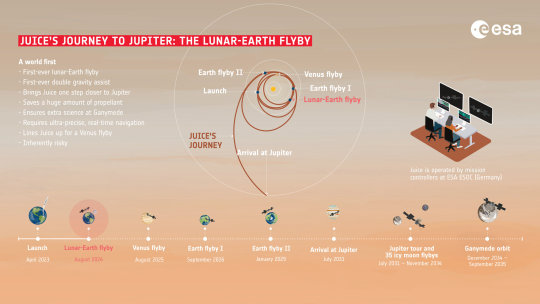

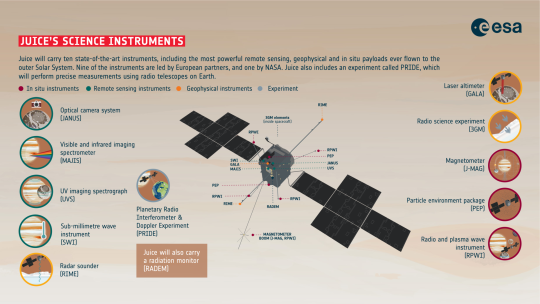

JUICE completes the first joint Lunar-Earth gravity assist flyby

The European Space Agency’s JUICE -- Jupiter Icy Moons Explorer – spacecraft has successfully completed the first ever joint Lunar-Earth gravity assist fly by flinging itself just as planned towards Venus.

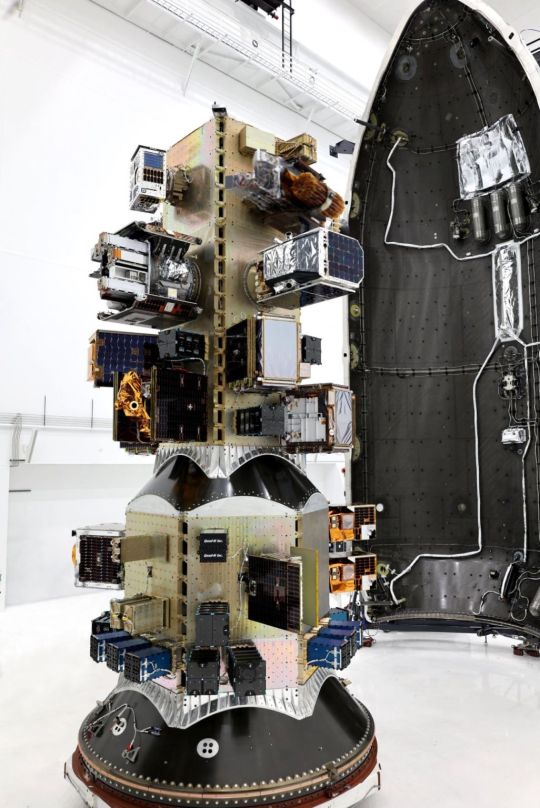

Three more Australian satellites sent into orbit

The latest trio flew up aboard SpaceX’s transporter 11 mission on a Falcon 9 rocket from Space Launch Complex 4E at Vandenberg Space Force Base in California. Transporter 11 is carrying 116 payloads, including CubeSats, microsats, and an orbital transfer vehicle carrying eight payloads.

The Science Report

Babies born to fathers of an older age more likely to have health complications at birth.

The bacteria that can produce rigid, heat stable plastics.

Tiny volcanic glass shards found in Tasmania came from a super-eruption in New Zealand.

Skeptics guide to body language

SpaceTime covers the latest news in astronomy & space sciences.

The show is available every Monday, Wednesday and Friday through Apple Podcasts (itunes), Stitcher, Google Podcast, Pocketcasts, SoundCloud, Bitez.com, YouTube, your favourite podcast download provider, and from www.spacetimewithstuartgary.com

SpaceTime is also broadcast through the National Science Foundation on Science Zone Radio and on both i-heart Radio and Tune-In Radio.

SpaceTime daily news blog: http://spacetimewithstuartgary.tumblr.com/

SpaceTime facebook: www.facebook.com/spacetimewithstuartgary

SpaceTime Instagram @spacetimewithstuartgary

SpaceTime twitter feed @stuartgary

SpaceTime YouTube: @SpaceTimewithStuartGary

SpaceTime -- A brief history

SpaceTime is Australia’s most popular and respected astronomy and space science news program – averaging over two million downloads every year. We’re also number five in the United States. The show reports on the latest stories and discoveries making news in astronomy, space flight, and science. SpaceTime features weekly interviews with leading Australian scientists about their research. The show began life in 1995 as ‘StarStuff’ on the Australian Broadcasting Corporation’s (ABC) NewsRadio network. Award winning investigative reporter Stuart Gary created the program during more than fifteen years as NewsRadio’s evening anchor and Science Editor. Gary’s always loved science. He studied astronomy at university and was invited to undertake a PHD in astrophysics, but instead focused on his career in journalism and radio broadcasting. Gary’s radio career stretches back some 34 years including 26 at the ABC. He worked as an announcer and music DJ in commercial radio, before becoming a journalist and eventually joining ABC News and Current Affairs. He was part of the team that set up ABC NewsRadio and became one of its first on air presenters. When asked to put his science background to use, Gary developed StarStuff which he wrote, produced and hosted, consistently achieving 9 per cent of the national Australian radio audience based on the ABC’s Nielsen ratings survey figures for the five major Australian metro markets: Sydney, Melbourne, Brisbane, Adelaide, and Perth. The StarStuff podcast was published on line by ABC Science -- achieving over 1.3 million downloads annually. However, after some 20 years, the show finally wrapped up in December 2015 following ABC funding cuts, and a redirection of available finances to increase sports and horse racing coverage. Rather than continue with the ABC, Gary resigned so that he could keep the show going independently. StarStuff was rebranded as “SpaceTime”, with the first episode being broadcast in February 2016. Over the years, SpaceTime has grown, more than doubling its former ABC audience numbers and expanding to include new segments such as the Science Report -- which provides a wrap of general science news, weekly skeptical science features, special reports looking at the latest computer and technology news, and Skywatch – which provides a monthly guide to the night skies. The show is published three times weekly (every Monday, Wednesday and Friday) and available from the United States National Science Foundation on Science Zone Radio, and through both i-heart Radio and Tune-In Radio.

#science#space#astronomy#physics#news#nasa#astrophysics#esa#spacetimewithstuartgary#starstuff#spacetime#jwst#hubble space telescope#james webb space telescope

10 notes

·

View notes

Text

License Suspension in 2025 – What’s Changed and What to Do Next

License suspensions aren’t just legal setbacks — they can affect employment, insurance, and personal mobility. In 2025, the process for suspensions and reinstatements in Canada has become more structured, faster, and tech-driven.

1. Texting While Driving Now Leads to Instant Suspension Distracted driving is now classified as a major offense. First-time violators who text behind the wheel — especially in high-risk areas like school zones — can have their license suspended on the spot. This measure aims to improve road safety by discouraging mobile use entirely.

2. Insurance Notifications Are Automated Thanks to integrated provincial systems, insurers are instantly alerted when a suspension occurs. This can lead to increased premiums or canceled policies, making it critical to address suspensions quickly.

3. Online Learning Is Required Before Reinstatement Reinstating your license now typically includes completing an approved online safe driving course. Platforms such as licenseprep.ca help you prepare for any associated tests and understand the behaviours that led to your suspension.

4. Commercial Drivers Are Under Stricter Scrutiny Drivers with commercial licenses face even higher penalties. Even minor infractions can lead to extended suspensions or even permanent bans from operating heavy vehicles, affecting cross-province transport privileges.

5. Appeals and Reinstatement Requests Are Now Digital Paper forms are a thing of the past. You can now submit appeals, pay fees, and track reinstatement progress via digital portals, making the process much faster and more transparent.

#SuspendedLicenseCanada#DrivingRules2025#licenseprep#ReinstateLicense#DistractedDrivingCanada#CDLCompliance#DigitalDrivingSystem

2 notes

·

View notes

Text

Cancelled Missions: NASA's October 1977 Space Shuttle Flight Itinerary

"Soon after President Richard Nixon gave his blessing to the Space Shuttle Program on January 5, 1972, NASA scheduled its first orbital flight for 1977, then for March 1978. By early 1975, the date had slipped to March 1979. Funding shortfalls were to blame, as were the daunting engineering challenges of developing the world's first reusable orbital spaceship based on 1970s technology. The schedule slip was actually worse than NASA let on: as early as January 32, 1975, an internal NASA document (marked 'sensitive') gave a '90% probability date' for the first Shuttle launch of December 1979.

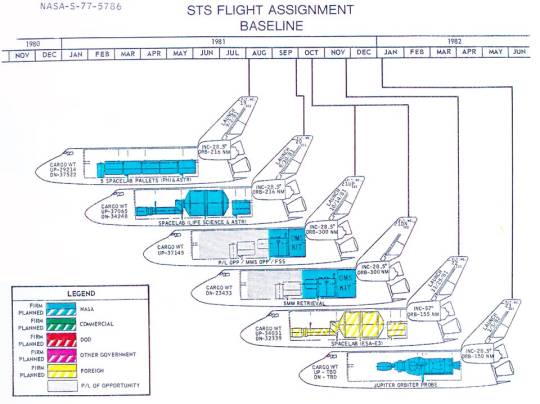

In October 1977, Chester Lee, director of Space Transportation System (STS) Operations at NASA Headquarters, distributed the first edition of the STS Flight Assignment Baseline, a launch schedule and payload manifest for the first 16 operational Shuttle missions. The document was in keeping with NASA's stated philosophy that reusable Shuttle Orbiters would fly on-time and often, like a fleet of cargo airplanes. The STS Utilization and Operations Office at NASA's Johnson Space Center (JSC) in Houston had prepared the document, which was meant to be revised quarterly as new customers chose the Space Shuttle as their cheap and reliable ride to space.

The JSC planners assumed that six Orbital Flight Test (OFT) missions would precede the first operational Shuttle flight. The OFT flights would see two-man crews (Commander and Pilot) put Orbiter Vehicle 102 (OV-102) through its paces in low-Earth orbit. The planners did not include the OFT schedule in their document, but the May 30, 1980 launch date for their first operational Shuttle mission suggests that they based their flight schedule on the March 1979 first OFT launch date.

Thirteen of the 16 operational flights would use OV-102 and three would use OV-101. NASA would christen OV-102 Columbia in February 1979, shortly before it rolled out of the Rockwell International plant in Palmdale, California.

As for OV-101, its name was changed from Constitution to Enterprise in mid-1976 at the insistence of Star Trek fans. Enterprise flew in Approach and Landing Test (ALT) flights at Edwards Air Force Base in California beginning on February 15, 1977. ALT flights, which saw the Orbiter carried by and dropped from a modified 747, ended soon after the NASA JSC planners released their document.

The first operational Space Shuttle mission, Flight 7 (May 30 - June 3, 1980), would see Columbia climb to a 225-nautical-mile (n-mi) orbit inclined 28.5° relative to Earth's equator (unless otherwise stated, all orbits are inclined at 28.5°, the latitude of Kennedy Space Center in Florida). The delta-winged Orbiter would carry a three-person crew in its two-deck crew compartment and the bus-sized Long Duration Exposure Facility (LDEF) in its 15-foot-wide, 60-foot-long payload bay.

Columbia would also carry a 'payload of opportunity' - that is, an unspecified payload. The presence of a payload of opportunity meant that the flight had available excess payload weight capacity. Payload mass up would total 27,925 pounds. Payload mass down after the Remote Manipulator System (RMS) arm hoisted LDEF out of Columbia's payload bay and released it into orbit would total 9080 pounds.

A page from the STS Flight Assignment Baseline document of October 1977 shows payloads and other features of the first five operational Space Shuttle missions plus Flight 12/Flight 12 Alternate

During Flight 8 (July 1-3, 1980), Columbia would orbit 160 n mi above the Earth. Three astronauts would release two satellites and their solid-propellant rocket stages: Tracking and Data Relay Satellite-A (TDRS-A) with a two-stage Interim Upper Stage (IUS) and the Satellite Business Systems-A (SBS-A) commercial communications satellite on a Spinning Solid Upper Stage-Delta-class (SSUS-D).

Prior to release, the crew would spin the SBS-A satellite about its long axis on a turntable to create gyroscopic stability and raise TDRS-A on a tilt-table. After release, their respective solid-propellant stages would propel them to their assigned slots in geostationary orbit (GEO), 19,323 n mi above the equator. Payload mass up would total 51,243 pounds; mass down, 8912 pounds, most of which would comprise reusable restraint and deployment hardware for the satellites.

The TDRS system, which would include three operational satellites and an orbiting spare, was meant to trim costs and improve communications coverage by replacing most of the ground-based Manned Space Flight Network (MSFN). Previous U.S. piloted missions had relied on MSFN ground stations to relay communications to and from the Mission Control Center (MCC) in Houston. Because spacecraft in low-Earth orbit could remain in range of a given ground station for only a few minutes at a time, astronauts were frequently out of contact with the MCC.

On Flight 9 (August 1-6, 1980), Columbia would climb to a 160-n-mi orbit. Three astronauts would deploy GOES-D, a National Oceanic and Atmospheric Administration (NOAA) weather satellite, and Anik-C/1, a Canadian communications satellite. Before release, the crew would raise the NOAA satellite and its SSUS-Atlas-class (SSUS-A) rocket stage on the tilt-table and spin up the Anik-C/1-SSUS-D combination on the turntable. In addition to the two named satellites, NASA JSC planners reckoned that Columbia could carry a 14,000-pound payload of opportunity. Payload mass up would total 36,017 pounds; mass down, 21,116 pounds.

Following Flight 9, NASA would withdraw Columbia from service for 12 weeks to permit conversion from OFT configuration to operational configuration. The JSC planners explained that the conversion would be deferred until after Flight 9 to ensure an on-time first operational flight and to save time by combining it with Columbia's preparations for the first Spacelab mission on Flight 11. The switch from OFT to operational configuration would entail removal of Development Flight Instrumentation (sensors for monitoring Orbiter systems and performance); replacement of Commander and Pilot ejection seats on the crew compartment upper deck (the flight deck) with fixed seats; power system upgrades; and installation of an airlock on the crew compartment lower deck (the mid-deck).

Flight 10 (November 14-16, 1980) would be a near-copy of Flight 8. A three-person Columbia crew would deploy TDRS-B/IUS and SBS-B/SSUS-D into a 160-n-mi-high orbit. The rocket stages would then boost the satellites to GEO. Cargo mass up would total 53,744 pounds; mass down, 11,443 pounds.

Flight 11 (December 18-25, 1980) would see the orbital debut of Spacelab. Columbia would orbit Earth 160 n mi high at 57° of inclination. NASA and the multinational European Space Research Organization (ESRO) agreed in August 1973 that Europe should develop and manufacture Spacelab pressurized modules and unpressurized pallets for use in the Space Shuttle Program. Initially dubbed the 'sortie lab,' Spacelab would operate only in the Orbiter payload bay; it was not intended as an independent space station, though many hoped that it would help to demonstrate that an Earth-orbiting station could be useful.

ESRO merged with the European Launcher Development Organization in 1975 to form the European Space Agency (ESA). Columbia's five-person crew for Flight 11 would probably include scientists and at least one astronaut from an ESA member country.

Flight 12 (January 30 - February 1, 1981), a near-copy of Flights 8 and 10, would see Columbia's three-person crew deploy TDRS-C/IUS and Anik-C/2/SSUS-D into 160-n-mi-high orbit. Payload mass up would total 53,744 pounds; mass down, 11,443 pounds.

JSC planners inserted an optional 'Flight 12 Alternate' (January 30 - February 4, 1981) into their schedule which, if flown, would replace Flight 12. Columbia would orbit 160 n mi above the Earth. Its three-person crew would deploy Anik-C/2 on a SSUS-D stage. The mission's main purpose, however, would be to create a backup launch opportunity for an Intelsat V-class satellite already scheduled for launch on a U.S. Atlas-Centaur or European Ariane I rocket. An SSUS-A stage would boost the Intelsat V from Shuttle orbit to GEO.

NASA JSC assumed that, besides the satellites, stages, and their support hardware, Columbia would for Flight 12 Alternate tote an attached payload of opportunity that would need to operate in space for five days to provide useful data (hence the mission's planned duration). Payload mass up would total 37,067 pounds; mass down, 17,347 pounds.

Space Shuttle Flights 13 through 18 would include the first orbital mission of the OV-101 Enterprise (Flight 17), during which astronauts would retrieve the LDEF payload deployed during Flight 7.

Flight 13 (March 3-8, 1981) would see three astronauts on board Columbia release NOAA's GOES-E satellite attached to an SSUS-D stage into a 160-n-mi-high orbit. OV-102 would have room for two payloads of opportunity: one attached at the front of the payload bay and one deployed from a turntable aft of the GOES-E/SSUS-D combination. Payload mass up would total 38,549 pounds; mass down, 23,647 pounds.

Flight 14 would last 12 days, making it the longest described in the STS Flight Assignment Baseline document. Scheduled for launch on April 7, 1981, it would carry a 'train' of four unpressurized Spacelab experiment pallets and an 'Igloo,' a small pressurized compartment for pallet support equipment. The Igloo, though pressurized, would not be accessible to the five-person crew. OV-102 would orbit 225 n mi high at an inclination of 57°. Mass up would total 31,833 pounds; mass down, 28,450 pounds.

Flight 15 (May 13-15, 1981) would be a near-copy of Flights 8, 10, and 12. OV-102 would transport to orbit a payload totaling 53,744 pounds; payload mass down would total 11,443 pounds. The JSC planners noted the possibility that none of the potential payloads for Flight 15 — TDRS-D and SBS-C or Anik-C/3 — would need to be launched as early as May 1981. TDRS-D was meant as an orbiting spare; if the first three TDRS operated as planned, its launch could be postponed. Likewise, SBS-C and Anik-C/3 were each a backup for the previously launched satellites in their series.

Flight 16 (June 16-23, 1981) would be a five-person Spacelab pressurized module flight aboard OV-102 in 160-n-mi-high orbit. Payloads of opportunity totaling about 18,000 pounds might accompany the Spacelab module; for planning purposes, a satellite and SSUS-D on a turntable behind the module was assumed. Payload mass up would total 35,676 pounds; mass down, 27,995 pounds.

Flight 17, scheduled for July 16-20, 1981, would see the space debut of Enterprise and the retrieval of the LDEF released during Flight 7. OV-101 would climb to a roughly 200-n-mi-high orbit (LDEF's altitude after 13.5 months of orbital decay would determine the mission's precise altitude).

Before rendezvous with LDEF, Flight 17's three-man crew would release an Intelsat V/SSUS-A and a satellite payload of opportunity. After the satellites were sent on their way, the astronauts would pilot Enterprise to a rendezvous with LDEF, snare it with the RMS, and secure it in the payload bay. Mass up would total 26,564 pounds; mass down, 26,369 pounds.

For Flight 18 (July 29-August 5, 1981), Columbia would carry to a 160-n-mi-high orbit a Spacelab pallet dedicated to materials processing in the vacuum and microgravity of space. The three-person flight might also include the first acknowledged Department of Defense (DOD) payload of the Space Shuttle Program, a U.S. Air Force pallet designated STP-P80-1. JSC called the payload 'Planned' rather than 'Firm' and noted somewhat cryptically that it was the Teal Ruby experiment 'accommodated from OFT [Orbital Flight Test].'

The presence of the Earth-directed Teal Ruby sensor payload would account for Flight 18's planned 57° orbital inclination, which would take it over most of Earth's densely populated areas. Payload mass up might total 32,548 pounds; mass down, 23,827 pounds.

Space Shuttle Flights 20 through 23 would include the first mission to make use of an OMS kit to increase its orbital altitude (Flight 21), the first European Space Agency-sponsored Spacelab mission (Flight 22), and the launch of the Jupiter Orbiter and Probe spacecraft (Flight 23)

Flight 19 (September 2-9, 1981) would see five Spacelab experiment pallets fill Columbia's payload bay. Five astronauts would operate the experiments, which would emphasize physics and astronomy. The Orbiter would circle Earth in a 216-n-mi-high orbit. Payload mass up would total 29,214 pounds; mass down, 27,522 pounds.

Flight 20 (September 30-October 6, 1981), the second Enterprise mission, would see five astronauts conduct life science and astronomy experiments in a 216-n-mi-high orbit using a Spacelab pressurized module and an unpressurized pallet. JSC planners acknowledged that the mission's down payload mass (34,248 pounds) might be 'excessive,' but noted that their estimate was 'based on preliminary payload data.' Mass up would total 37,065 pounds.

On Flight 21, scheduled for launch on October 14, 1981, Columbia would carry the first Orbital Maneuvering System (OMS) Kit at the aft end of its payload bay. The OMS Kit would carry enough supplemental propellants for the Orbiter's twin rear-mounted OMS engines to perform a velocity change of 500 feet per second. This would enable OV-102 to rendezvous with and retrieve the Solar Maximum Mission (SMM) satellite in a 300-n-mi-high orbit.

Three astronauts would fly the five-day mission, which would attain the highest orbital altitude of any flight in the STS Flight Assignment Baseline document. JSC planners noted that the Multi-mission Modular Spacecraft (MMS) support hardware meant to carry SMM back to Earth could also transport an MMS-type satellite into orbit. Payload mass up would total 37,145 pounds; mass down, 23,433 pounds.

On Flight 22 (November 25 - December 2, 1981), Enterprise might carry an ESA-sponsored Spacelab mission with a five-person crew, a pressurized lab module, and a pallet to a 155-to-177-n-mi orbit inclined at 57°. Payload mass up might total 34,031 pounds; mass down, 32,339 pounds.

During Flight 23 (January 5-6, 1982), the last described in the STS Flight Assignment Baseline document, three astronauts would deploy into a 150-to-160-n-mi-high orbit the Jupiter Orbiter and Probe (JOP) spacecraft on a stack of three IUSs. President Jimmy Carter had requested new-start funds for JOP in his Fiscal Year 1978 NASA budget, which had taken effect on October 1, 1977. Because JOP was so new when they prepared their document, JSC planners declined to estimate up/down payload masses.

Flight 23 formed an anchor point for the Shuttle schedule because JOP had a launch window dictated by the movements of the planets. If the automated explorer did not leave for Jupiter between January 2 and 12, 1982, it would mean a 13-month delay while Earth and Jupiter moved into position for another launch attempt.

Almost nothing in the October 1977 STS Flight Assignment Baseline document occurred as planned. It was not even updated quarterly; no update had been issued as of mid-November 1978, by which time the target launch dates for the first Space Shuttle orbital mission and the first operational Shuttle flight had slipped officially to September 28, 1979 and February 27, 1981, respectively.

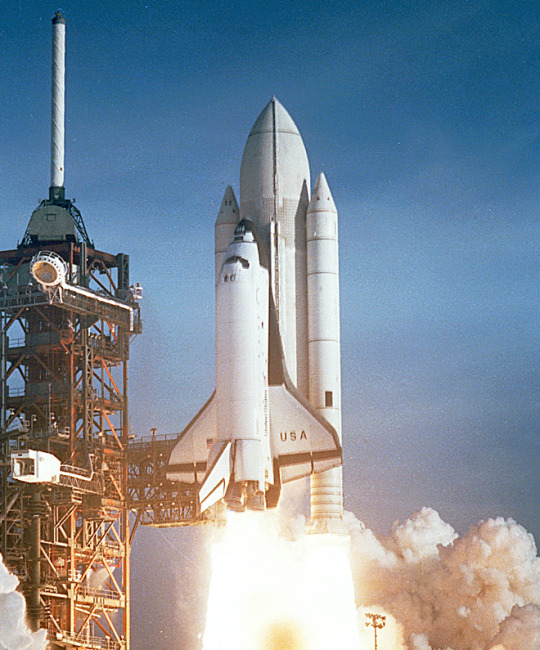

The Space Shuttle Orbiter Columbia lifts off at the start of STS-1.

The first Shuttle flight, designated STS-1, did not in fact lift off until April 12, 1981. As in the STS Flight Assignment Baseline document, OV-102 Columbia performed the OFT missions; OFT concluded, however, after only four flights. After the seven-day STS-4 mission (June 27 - July 4, 1982), President Ronald Reagan declared the Shuttle operational.

The first operational flight, also using Columbia, was STS-5 (November 11-16, 1982). The mission launched SBS-3 and Anik-C/3; because of Shuttle delays, the other SBS and Anik-C satellites planned for Shuttle launch had already reached space atop expendable rockets.

To the chagrin of many Star Trek fans, Enterprise never reached space. NASA decided that it would be less costly to convert Structural Test Article-099 into a flight-worthy Orbiter than to refit Enterprise for spaceflight after the ALT series. OV-099, christened Challenger, first reached space on mission STS-6 (April 4-9, 1983), which saw deployment of the first TDRS satellite.

NASA put OV-101 Enterprise to work in a variety of tests and rehearsals (such as the 'fit check' shown in the image above), but did not convert it into a spaceflight-worthy Orbiter.

The voluminous Spacelab pressurized module first reached orbit on board Columbia on mission STS-9 (November 28- December 8,1983). The 10-day Spacelab 1 mission included ESA researcher Ulf Merbold and NASA scientist-astronauts Owen Garriott and Robert Parker. Garriott, selected to be an astronaut in 1965, had flown for 59 days on board the Skylab space station in 1973. Parker had been selected in 1967, but STS-9 was his first spaceflight.

The 21,500-pound LDEF reached Earth orbit on board Challenger on STS-41C, the 11th Space Shuttle mission (April 6-13, 1984). During the same mission, astronauts captured, repaired, and released the SMM satellite, which had reached orbit on 14 February 1980 and malfunctioned in January 1981. Challenger reached SMM without an OMS kit; in fact, no OMS kit ever reached space.

STS Flight Assignment Baseline document assumed that 22 Shuttle flights (six OFT and 16 operational) would occur before January 1982. In fact, the 22nd Shuttle flight did not begin until October 1985, when Challenger carried eight astronauts and the West German Spacelab D1 into space (STS-61A, October 30 - November 6, 1985). Three months later (28 January 1986), Challenger was destroyed at the start of STS-51L, the Shuttle Program's 25th mission.

In addition to seven astronauts — NASA's first in-flight fatalities — Challenger took with it TDRS-B, NASA's second TDRS satellite. The Shuttle would not fly again until September 1988 (STS-26, September 29 - October 3, 1988). On that mission, OV-103 Discovery deployed TDRS-C. The TDRS system would not include the three satellites necessary for global coverage until TDRS-D reached orbit on board Discovery on mission STS-29 (13-18 March 1989).

Following the Challenger accident, NASA abandoned — though not without some resistance — the pretense that it operated a fleet of cargo planes. The space agency had at one time aimed for 60 Shuttle flights per year; between 1988 and 2003, the Shuttle Program managed about six per year. The most flights the Shuttle fleet accomplished in a year was nine in 1985.

Shuttle delays meant that JOP, renamed Galileo, missed its early January 1982 launch window. It was eventually rescheduled for May 1986, but the Challenger accident intervened. Galileo finally left Earth orbit on 18 October 1989 following deployment from OV-104 Atlantis during STS-34 (October 18-23, 1989).

Between the time JOP/Galileo received its first funding and the Challenger explosion, NASA, the White House, and Congress had sparred over how the Jupiter spacecraft would depart Earth orbit. Eventually, they settled on the powerful liquid-propellant Centaur-G' rocket stage.

Citing new concern for safety following Challenger, NASA canceled Centaur G'. Galileo had to rely on the less-powerful IUS, which meant that it could not travel directly to Jupiter; it had instead to perform gravity-assist flybys of Venus and Earth to reach its exploration target. Galileo did not reach the Jupiter system until December 1995.

LDEF had been scheduled for retrieval in March 1985, less than a year after deployment, but flight delays and the Challenger accident postponed its return to Earth by nearly six years. On mission STS-32 (January 9-20, 1990), astronauts on board Columbia retrieved LDEF, the orbit of which had decayed to 178 n mi. LDEF remains the largest object ever retrieved in space and returned to Earth.

During reentry at the end of mission STS-107 (16 January-1 February 2003), Columbia broke apart over northeast Texas, killing its international crew of seven astronauts. This precipitated cancellation of the Space Shuttle Program by President George W. Bush, who announced his decision on 14 January 2004.

The end of the Space Shuttle Program was originally scheduled for 2010, immediately following the planned completion of the International Space Station. In the event, STS-135, the final Space Shuttle mission, took place four years ago (July 2011), three months after the 30th anniversary of STS-1. The Orbiter Atlantis lifted off on 8 July with a four-person crew — the smallest since STS-6. It docked with the International Space Station to deliver supplies and spares and landed in Florida 13 days later."

Article by David S. F. Portree: link

source, source

NASA ID: S77-5784, S77-5785, S77-5758

#STS-1#STS-2#STS-3#STS-4#STS-5#STS-6#STS-7#STS-8#STS-9#STS-10#STS-11#STS-12#STS-13#STS-14#STS-15#STS-16#STS-17#STS-18#STS-19#STS-20#STS-21#STS-22#STS-23#Space Shuttle Columbia#Columbia#OV-102#Space Shuttle Enterprise#Enterprise#OV-101#cancelled

29 notes

·

View notes

Text

Puma Mitsubishi Lancer Evo V

Mitsubishi TEST&SERVICE

Debuted in the second race. In qualifying, he suddenly took the first corner of R. In the finals, he was at the top for a while. 4th place in qualifying (1st in class), 4th in final (1st in class). Driver: Akihiko Nakatani/Sakae Obata.

③Suspension damper is KYB. The spring is Ralliart. ④Safety fuel tank is made by ATN. Capacity is 120ℓ. ⑤The steering wheel is MOMO buckskin. ⑥ The meter is Pi system. On the left is the Omori boost gauge. ⑦The door hinges are carved out because they hit the roll cage. (8, 9) was originally a work RS-Z (8JX 17). The tires are 225/45R17 ADVAN. 1⑩ Replace the radiator with one made by Denso. (11) The oil cooler is genuine. (12) Aero mirror is Valdisport. ⑬The rear is equipped with a differential cooler. LSD is Ralliart (viscous only in the center). (14)The roll bar passes through the bulkhead. The tower bar is Valdisport. There was a WRC plan for the ECU, but the current one is the original. Commercialization is also under consideration. (15)The muffler is thin, about 80mm. (16)The yellow part on the console is the starter, and the one below is the water spray. (17) The roll cage is for FIA-approved rallies. (18) shift is a sword. The knob is a small screwdriver, which is my preference. (19) seats are Valdisport Type II. (20) The roll cage looks like a bird cage. Please compare it with the Impreza on the right.

In the second race, they defeated the Nissan Development Team's GT-R. The tire size/tread has been expanded since Evo IV, reducing the time by approximately 2 seconds.

Exceeded IV in all aspects. There are no flaws!

``The new EVO V has solved all the shortcomings of the EVO IV . In particular, thanks to the wider tread, cornering speed has improved dramatically. It has become my specialty.'' Mr. Yamada of Test & Service maintains the ``Puma Evo,'' which achieved amazing times and came close to the G T-R. When building the vehicle, they placed emphasis on improving the suspension, which is subject to increased strain due to the increased cornering force. Therefore, in testing and service, even if a high input value is added, it cannot be accepted.

I decided to build a strong body. However, the main difference from the Impreza is that instead of welding reinforcement such as adding more spots, the main reinforcement is the extensive use of a strong roll bar that penetrates the body and is also used in WRC. Looking at each part, there are only a few welded parts. The weight is also 30kg more than the standard. This idea is common to the EVO era. With the reinforcement so far, the driver

``I can feel the movement of my feet''

It seems that the comments are satisfying. The engine has a proven track record of being packed to the hilt, starting with the Evo, and is powerful and stable enough to keep its rivals at bay. The cooling performance seems to be high, and the original oil cooler is used as is. “If we keep boiling it down like this, we can last for at least one fight.”

Nakatani seemed to be breathing heavily.

PROVA Eifel Dunlop GC8 Impreza

Debuted in last year's final race! Suddenly took first place in qualifying. This year, he will participate in the second race. 12th place in qualifying (8th in class), retired in finals. Driver: Kazuo Shimizu/Tsutomu Shibuya.

④ The fuel tank is 120ℓ. (5, 6, 7) All aero parts are Prova. The side duct is effective in cooling the brakes. ⑧⑨ The tires are DL/Formula R (205/ 50R16) and the Enkei Sports 7.5J x 16. (10) differential cooler is made by Calsonic. (11) The Prova damper and spring are Swift from Tokyo Spring. (12) Two oil coolers are installed on the engine and one on the transmission. In particular, the latter has a high calorific value and is a must-have item. The radiator is also a large capacity type. ⑬The steering wheel is Impul 913 special. (14)The engine is STi tuned. Management is the same as for WRC cars. The roll cage has been changed and the battery has been made smaller. (15)The seat is full carbon made by Mooncraft. (16) The roll cage is very simple. (17,18) meter is Pi system. On the console, from the right, there is a transmission oil pump, a differential oil pump, and a reserve tank switch for using up to the last liter. Below is a display switch for the Pi data logger. ⑲The square plate visible at the back of the rear center section is the weight. (20) The rear suspension mounting area has been fully reinforced with welding.

This is the first car that Fuji Heavy Industries has officially started working on, from rally to circuit. Once you get used to the world of racing, it can be intimidating.

Unexpected or unexpected. 4 doors are more rigid than 2 doors

``Thanks to the horizontally opposed engine, everything is symmetrical, which means excellent weight balance.This is the lifeblood and appeal of this car.Also, by making full use of the four-wheel drive provided, cornering performance is improved. However, it's the direction of the settings. Thanks to this, the advantage is that you can turn with the same feeling whether it's a rainy day or a sunny day.'' Mr. Fukushima from Bulova Race Garage will be participating in the race. However, the design is older than its rivals, and it seems that the body rigidity is completely lacking, so strengthening it is necessary for the vehicle.

The most important item in production. especially the way it twists

It is said that reinforcement has been focused on the suspension mounting area (to increase suspension rigidity). Also, since last year, the use of flashy two-doors has been allowed in Super Taikyu, but the only reason why four-doors are still used is because they are highly rigid.

The roll cage isn't used much either visually. This was done to reduce weight, and only the minimum necessary parts were included after thorough body reinforcement. The weight was 30kg lighter than the standard, and 30kg was placed as weight on the passenger seat and rear center to thoroughly improve the weight balance. The body is completely finished, but is this it?

Their problem is the engine. It's a little lacking in power. If I go up a little bit more, I can catch up with EVO. It seems like STi's hard work will determine what happens next.

11 notes

·

View notes

Text

#lorry loads#freight transportation#trucking logistics#cargo hauling#haulage services#commercial vehicle operation#heavy load delivery#bulk goods shipment#oversize load transport#distribution trucking#logistics india#supply chain management india#freight forwarding india#transportation services india#warehousing india#distribution networks india#import export solutions india#thirdparty logistics india#cold chain logistics india#online lorry loads services#freight marketplace#truck load boards#digital logistics platform#transport automation#load matching#carrier connectivity#real-time tracking#capacity utilization#transportation management systems

0 notes

Text

#lorry loads#freight transportation#trucking logistics#cargo hauling#haulage services#commercial vehicle operations#heavy load delivery#bulk goods shipment#oversize load transport#distribution trucking#logistics india#supply chain management india#freight forwarding india#transportation services india#warehousing india#distribution networks india#import export solutions india#third-party logistics india#cold chain logistics india#online lorry loads services#freight marketplace#truck load boards#digital logistics platform#transport automation#load matching#carrier connectivity#real-time tracking#capacity utilization#transportation management systems#house shifting services online india

0 notes

Text

Dubai’s Premier Movers — Expert On-Demand Moving & Removals Services

In today’s fast-paced world, convenience and efficiency are non-negotiable. That’s why our service is built on a simple promise: providing Dubai’s Premier Movers with expert, on-demand moving and removals services that cater to your every need — whenever and wherever you need us. Whether you’re relocating your home, office, or simply need to transport a few items, our on-demand model delivers unparalleled flexibility, speed, and professionalism.

The On-Demand Advantage

Instant Booking & Flexibility

In an era where time is of the essence, our on-demand moving services ensure you’re never left waiting. With our instant booking system, you can schedule your move at a time that suits your busy lifestyle. Gone are the days of rigid scheduling — our flexible platform allows you to book a move as quickly as you need it, whether it’s at the crack of dawn or in the middle of a hectic day.

Our digital platform is designed with you in mind, offering:

Real-Time Availability: See immediate service availability in your area.

Instant Confirmations: Get rapid feedback and secure your booking without delay.

Customisable Options: Choose services that best suit your unique moving requirements, from apartment removals and home moving to office relocation.

Advanced Technology Integration

Leveraging cutting-edge technology, we streamline every aspect of the moving process. Our system integrates:

GPS Tracking: Monitor your belongings in real time as they travel to your new destination.

Automated Scheduling: Efficiently manage your move with dynamic scheduling that adapts to real-time conditions.

Mobile App Access: Book, track, and communicate with our team directly from your smartphone, ensuring a seamless experience from start to finish.

This blend of technology and on-demand service not only boosts efficiency but also enhances your overall experience by ensuring transparency, reliability, and exceptional service quality.

Comprehensive Moving Solutions

Residential Moving & Removals

Whether you’re moving into a new apartment or a spacious villa, our residential moving services cover every detail. Our expert team handles:

Apartment Removals: Specialising in high-rise buildings with tailored solutions for tight spaces.

Home Removals: From full-scale home moving to selective removals, we provide a personalised approach that meets your unique needs.

Furniture Removals: Professional packing, handling, and transportation of your prized furniture items, ensuring they arrive intact and ready for your new home.

Our residential services are crafted to minimise stress and ensure that your move is smooth and hassle-free. With our on-demand model, you can even arrange for last-minute moves without compromising on quality.

Commercial Moving & Office Relocation

For businesses, time is money. Our on-demand commercial moving solutions are designed to minimise downtime and ensure a swift transition, keeping your business operations running smoothly. Our services include:

Office Removals & Moving: From small offices to large corporate spaces, we ensure your equipment and furniture are handled with care.

Office Shifting & Relocation: Comprehensive solutions that include packing, transportation, and reinstallation of office equipment.

Commercial Moving: Tailored services that cater to the unique demands of commercial relocations, ensuring efficiency and minimal disruption.

Our experienced professionals are adept at handling the complexities of commercial moves. We work around your schedule, ensuring your business remains operational throughout the transition.

Specialised Removals

Sometimes, moving requires specialised care. Our services extend beyond standard household or office moves to include:

Car Delivery: Safe and secure transport of your vehicles to your new location.

Bike Delivery: Quick and efficient handling of bikes, ensuring they arrive in pristine condition.

House Shifting: Expertise in handling delicate or oversized items, ensuring a smooth transfer regardless of the distance or complexity.

Our specialised removal services are perfect for those who require a unique or tailored approach. With our on-demand service, even these specialised needs are met with the same high standard of professionalism and care.

How Our On-Demand Model Works

1. Seamless Online Booking

The journey to a hassle-free move begins online. Our user-friendly website and mobile app make it easy to:

Select Your Service: Choose from a range of moving and removal services tailored to your needs.

Get Instant Quotes: Receive transparent pricing instantly, so there are no surprises later.

Schedule Your Move: Pick a date and time that works best for you, with options for last-minute bookings.

2. Tailored Service Selection

Every move is unique, and so is our approach. Our system allows you to:

Customise Your Package: Add on extra services like packing, temporary storage, or specialised handling based on your needs.

Select Add-Ons: Opt for additional services like furniture removals or office relocation to ensure a complete and stress-free move.

Receive a Personalised Itinerary: Get a detailed plan of your move, complete with real-time updates and clear instructions.

3. Expert Movers at Your Service

Our team of professional movers is the backbone of our service. Trained in the latest moving techniques and equipped with advanced tools, they:

Handle with Care: Ensure every item is securely packed and transported.

Optimise Routes: Use real-time traffic data to choose the best routes, ensuring timely deliveries.

Maintain Communication: Stay in constant touch throughout the move, providing you with updates and addressing any concerns promptly.

4. Post-Move Support

Even after the move is complete, our support continues. We offer:

Unpacking Services: Assistance with unpacking and organising your new space.

Follow-Up Calls: Ensuring you’re settled in and satisfied with our service.

Feedback Opportunities: Helping us continually refine our service based on your valuable insights.

Why Choose Our On-Demand Moving Services in Dubai?

Reliability You Can Trust

Dubai is a bustling metropolis with diverse moving needs. Our on-demand service is designed to meet those needs with unmatched reliability. We understand that:

Every Move is Critical: Whether it’s a last-minute relocation or a planned move, we treat every move with the utmost importance.

Time is of the Essence: Our streamlined process and professional team ensure your move is executed swiftly without compromising on quality.

Quality Matters: We maintain the highest standards in both service quality and customer satisfaction, making us the go-to choice for Dubai’s premier movers.

Convenience at Your Fingertips

Our on-demand model transforms the traditional moving process by:

Eliminating Hassles: From scheduling conflicts to last-minute changes, our digital platform adapts to your needs.

Providing Real-Time Solutions: With instant booking and on-the-go tracking, you’re always in control of your move.

Ensuring Transparency: Our clear pricing and detailed itineraries mean there are no hidden fees or surprises.

Comprehensive & Versatile Service Offerings

No matter the size or complexity of your move, we have the solution. Our extensive range of services covers:

Residential Moving: From home removals to apartment moving, our services are designed to cater to every household.

Commercial Solutions: Efficient and precise services for office removals, office moving, and commercial relocations.

Specialisd Removals: Including vehicle transport and specialised care for oversised or delicate items.

Innovation Driven by Technology

Our commitment to technology ensures that you receive:

Enhanced Efficiency: Automated scheduling and route optimisation reduce waiting times and improve service delivery.

Improved Communication: Stay connected with our team through our mobile app, ensuring a smooth and transparent moving process.

Real-Time Updates: Track every step of your move with GPS tracking and instant notifications.

Real-Life On-Demand Success Story

Imagine a scenario where you’re planning a last-minute move due to an unexpected job transfer in Dubai. You need to vacate your apartment quickly and move into a new home that’s conveniently located near your new office. With traditional moving services, coordinating such a move could be stressful and time-consuming.

However, with our on-demand model, here’s how the process unfolds:

Immediate Online Booking: You log into our mobile app and select the service you need — apartment removals. The app shows real-time availability, and you quickly confirm your booking for the same day.

Tailored Moving Plan: Once your booking is confirmed, you receive a personalised itinerary. The app notifies you of the estimated arrival time of our expert movers and provides clear instructions on how to prepare for the move.

Efficient Execution: Our professional team arrives promptly, handling everything from packing to furniture removals with the utmost care. They navigate the busy streets of Dubai using the best routes provided by our automated system, ensuring that your belongings are delivered safely and on time.

Seamless Transition: Upon arrival at your new location, the team assists with the setup, and you’re quickly settled into your new home with minimal disruption to your schedule.

This real-life success story underscores the efficiency and reliability of our on-demand moving services, proving that even under tight time constraints, we deliver excellence.

Final Thoughts

Dubai’s dynamic lifestyle demands a moving service that is as fast, efficient, and adaptable as its residents. Our on-demand moving and removals services are tailored to meet these exact requirements. We combine technology, expertise, and a commitment to customer satisfaction to provide a moving experience that is truly stress-free.

By choosing us, you’re not just booking a move — you’re partnering with Dubai’s premier movers, dedicated to making your relocation as seamless as possible. Whether it’s a residential move, a commercial relocation, or a specialised removal, our team is ready to serve you at a moment’s notice.

Experience the future of moving with our on-demand services, where every detail is managed with precision, every move is executed with care, and every customer is treated like a priority.

Ready to move? Book Your On-Demand Move Today and discover why we’re Dubai’s top choice for professional, reliable, and efficient moving and removals services.

Embrace the convenience, efficiency, and reliability of on-demand moving in Dubai. Let our expert team transform your moving experience into one that is smooth, prompt, and completely tailored to your needs. Whether it’s a residential or commercial move, we’re here to deliver excellence every step of the way.

Dubai’s Premier Movers — where your move is just a click away. Call Anymove for a Free Quotation: 058 805 4207

#dubai#moving#relocation#moving company#packers and movers#movers near me#packing services#packingandmoving

2 notes

·

View notes

Text

How to Find Truck Loads for Owner Operators

More than 70% of transported goods are moved by trucks in the United States. More than 90% of companies in the United States long-distance freight trucking industry are owner-operators. Getting frequent, reliable, and well-paying truck loads is crucial for the smooth running of any trucking business. In the past, owner-operators had to constantly check physical load boards, wait in truck shops, or make several calls a day in order to get loads. Times have now changed. The internet, smartphones, apps, etc. offer an advantage to finding a reliable source to get truck loads. If you are still in the researching phase of becoming a new owner operator please see our full guide on how to start a trucking business in 2024.

Below are a few ways in which an owner-operator can find loads:

Load boards

Load boards are the most common way to find loads. This is especially a reliable option for a new business to get rolling quick. A Load board is essentially an online site that provides a shared platform for shippers and truckers/owner-operators. The shippers post information of the load such as the origin, distance, destination and other important details, and owner operators can apply to pick up transport those loads. Load boards can be very helpful if the business is not leased onto a dedicated carrier.

Load board apps are also available on smartphones that provides multiple listings to help owner-operators find suitable loads. Load boards differ from one service provider to another. While some may provide the services for free, others charge a fee to access the boards. We discuss the best load board sites for owner operators:

Paid load board websites that also offer free trial:

Direct Freight - https://www.directfreight.com/home/

DAT - https://www.dat.com/load-boards

Get loaded - http://www.getloaded.com/

Truckers Edge - https://www.truckersedge.net/

Load Match - https://www.loadmatch.com/

Free load board websites:

Trucker Path - https://truckerpath.com/truckloads/free-load-board/

Trulos - http://www.trulos.com/

DSSLN - http://www.dssln.com/

Freight Finder - https://www.freightfinder.com/

Load up - http://www.usacanadaloadup.com/

Apps:

Trucker Path

DAT

Truckloads & Freight

All the websites or apps above should give a start to owner operators on how to find truck loads with a load board. Other options apart from public load boards are below.

Lease-on

Some companies have a private load board. These are specifically for owner-operators to lease-on with that company. This option provides the owner-operator with the stability of a big company – which is an added advantage for a new owner-operator. It also gives the freedom to choose the freight directly from a load board. Some companies also offer discounts on operating expenses to owner-operators. Hence, it helps the owner-operator utilize its purchasing power. Owner-operators may also get paid a fuel surcharge versus per mile.

Freight brokers

Freight brokers help finding loads. Choosing a freight broker can be a handy option if an owner-operator is not looking to lease-on with a trucking company. A freight broker eases the process by doing most of the leg-work. This includes dispatching loads, tracking shipments, payrolls, invoicing, etc. A freight broker assists a shipper in finding a carrier that is qualified to move its load. Once a deal is negotiated, the broker connects the shipper with the owner-operator. The broker negotiates the highest amount with the shipper for the load, and connects the shipper with a carrier that is willing to move it at the lowest amount. The margin is called a spread, and is charged by the broker as a fee for the service provided. The spread is usually 15-25% of the profit.

For example, an owner-operator agrees to move a load for $6000. A freight broker negotiates with the shipper for $7000 to do the trip. The margin of $1000 is the spread, goes directly to the freight broker.

A freight broker can be an individual or a company. When looking for one to partner with, it is recommended to find ones who are registered with the FMCSA and cover insurance costs. It is a great option for beginner owner-operators who are yet to get a strong foothold in the industry. It is important to have clarity regarding the impact of the spread on the profits made for a business.

Dispatchers

A dispatcher manages the flow of the freight for efficient movement of the truck load. This is done by avoiding empty miles in the trips. Doing so helps in maximizing profits for owner-operators. One of the keys to smooth functioning of this service is constant communication with the owner-operator. A dispatcher ensures compliance and usually provides customer service. In addition to finding loads for the owner-operator, dispatchers also aid in various backend operations. This includes all associated paperwork like tax records, permits, insurance, etc. Some dispatchers provide end to end services. This means the dispatcher takes care of finding and managing the loads, as well as ensuring timely payment from the shipper. The fee is charged either at a flat rate, or as a certain percentage of the load. An owner-operator can hire an individual dispatcher or a trucking dispatch service provider. This is another way for owner operators to find truck loads.

Government Contracts

Federal, state, and local governments often outsource their transportation requirements. To be considered as an option for moving government loads, an owner-operator has to register on the U.S. General Services Administration (GSA) website as a company. Registering as a government contractor can help an owner-operator find loads in their own city/area. Obtaining contracts can vary depending upon the security clearance required for winning the bids. A contract with government entities like the US postal service or getting the business’ name on the GSA list can bring in steady work-flow and also offer great pay. Government contracts are a great option for finding loads for an owner operator.

Prospecting

Prospecting is the continual process of finding loads. It revolves around researching shippers in the local area. The owner-operator should research the number of shippers, the kind of loads needed to move, destinations catered to, etc. This will help the owner-operator determine a prospect shipper to get loads from. The process requires the owner-operator to connect with the prospect shipper by reaching out to them. In the communication, an owner-operator can enquire about the shipper���s requirement and any trips suitable for the owner-operator to undertake. It also helps in finding any future opportunities that the shipper might offer. This requires a bit more work for the owner operator but also provides a good opportunity to find more loads.

Networking

Just like any other business, networking can be a key step for ensuring an owner-operator’s visibility and possible growth in the industry. Creating friendships can lead to prospective clients. Getting involved in associations like the American Association of Owner Operators (AAOO) or other local events can help in professional connections that may be a great pathway for getting loads. It not only helps in staying informed about news in the trucking industry, but also helps in tips and guidelines to grow business.Owner operators should choose a strategy or combination of strategies above to determine what works best for the business. At first, an owner-operator might not have a lot of load options to choose from. The owner-operator may have to take up any available job to keep the business running. Though overwhelming at first, it gets easier with each trip. Owner Operators need the best technology and ELD Mandate provides some of the best products from Asset Trackers, Dash Cams, ELDs, Tablets and Data for all owner operators.

#Eld Mandate#Electronic Logging Device#keeptruckin#GPS tracking Online trucks#real time portal trucks#time portal proactive eld#Hours of Service#FMCSA (Federal Motor Carrier Safety Administration)#Commercial Motor Vehicle#Electronic logging system (ELS)#Fleet Management#Trucking Compliance#Road Safety

0 notes