#telematics in mining

Explore tagged Tumblr posts

Text

Enhancing Safety in the Mining Industry: The Role of Advanced Telematics Solutions

The mining industry faces significant challenges in ensuring the safety of its workforce amidst hazardous working conditions and complex operational environments. Despite stringent safety regulations and protocols, accidents and incidents continue to pose risks to personnel and assets. In this context, the adoption of advanced telematics solutions emerges as a critical strategy to enhance safety standards and mitigate risks within mining operations.

In this article, we will discuss the role of telematics technology, its key features, applications, and benefits in the mining industry.

Understanding the Role of Telematics Technology in the Mining Industry

Telematics systems employ a combination of hardware and software components to collect, transmit, and analyse data from vehicles and assets in real-time. The GPS tracking devices installed in vehicles capture location coordinates, speed, and route information, which is transmitted to a centralised platform via cellular or satellite networks. In addition, onboard sensors and diagnostics systems monitor vehicle performance metrics such as engine health, fuel consumption, and maintenance status.

This data is then processed and analysed using advanced algorithms and fleet telematic analytics tools to generate actionable insights and performance reports for fleet managers and stakeholders. By providing visibility into key operational parameters and safety metrics, mining telematics systems enable mining companies to proactively identify risks, implement preventive measures, and optimise resource allocation to enhance safety and efficiency across their operations.

Key Features of Telematics Fleet Management System for Mining Operations

Live Location Tracking: Track the real-time location of vehicles and equipment, enabling better fleet management and resource allocation.

Rash Driving Alerts: Receive alerts for instances of aggressive or unsafe driving behaviour, allowing for immediate intervention and corrective action.

Accident Detection: Detect accidents or collisions as they occur, enabling rapid response and assistance to affected personnel.

Autonomous Emergency Braking (AEB): Automatically apply brakes in emergency situations to prevent or mitigate collisions, enhancing overall safety on the road.

Tailgating Detection: Identify instances of tailgating, a common cause of accidents, and alert drivers to maintain safe following distances.

Overspeeding Monitoring: Monitor vehicle speed in real-time and receive alerts for instances of speeding, helping to prevent accidents and ensure compliance with safety regulations.

Drowsiness Detection: Detects signs of driver drowsiness or fatigue and provides timely alerts to prevent accidents caused by impaired alertness.

Distraction Monitoring: Monitor driver attentiveness and detect distractions such as mobile phone usage or inattentiveness, reducing the risk of accidents due to driver distraction.

Application of Telematics in the Mining Industry

Enhanced Driving Behavior Insights

Gain comprehensive insights into driving behaviour, empowering mining companies to identify and address unsafe practices effectively. By analysing factors such as speed, acceleration, and braking, organisations can develop targeted strategies to promote safer driving habits among their workforce.

Access to Incident Videos

Access to incident videos in real-time facilitates prompt response and investigation of accidents or incidents within mining operations. This capability enhances safety protocols by enabling timely review and analysis, ultimately contributing to the development of more robust risk management strategies.

Fleet Performance Optimization

Utilise data analytics to optimise fleet performance and efficiency in mining operations. By leveraging insights derived from telemetric fleet management systems, organisations can identify areas of inefficiency and implement corrective measures to reduce operational costs and enhance productivity across their fleet.

Benefits of Using Telematics in Mining Operations

Telematics technology finds various benefits in mining operations, contributing to enhanced safety, efficiency, and productivity. Some key benefits include:

Fleet Management: Telematics systems enable real-time vehicle tracking and equipment, allowing managers to monitor their location, speed, and status. This ensures efficient fleet management, optimal asset utilisation, and timely maintenance scheduling.

Remote Monitoring: Telematics enables remote monitoring of equipment performance and health, including engine diagnostics, fuel consumption, and maintenance alerts. This proactive approach helps prevent unexpected breakdowns, reduces downtime, and extends equipment lifespan.

Safety Enhancement: Integration with fatigue monitoring systems helps identify signs of driver fatigue, allowing for timely intervention to prevent accidents caused by drowsiness.

Data-Driven Decision-Making: Historical performance data and trend analysis provide valuable insights for long-term planning and strategic decision-making, driving continuous improvement initiatives.

Scalability: Telematics solutions are scalable and customizable to meet the evolving needs of mining operations, accommodating changes in fleet size, geographic expansion, and technological advancements.

Conclusion

To sum up, investing in mining telematics solutions is important for safeguarding worker wellbeing and enhancing operational efficiency in the mining industry. By leveraging telematics technology, mining companies can proactively identify and mitigate safety risks, optimise fleet performance, and ensure regulatory compliance.

#telematics in mining#telematics#mining telematics#applications of telematics#advantages of telematics#telematics solution providers in india#telematics vehicle tracking#truck fleet telematic#mining vehicle telematics#commercial fleet telematics#telematics software providers#telematics solutions#telematics data#telematics system#fleet telematics analytics#vehicle telematics data#mining telematics solution

0 notes

Text

Driving the Future: How AI Demand Forecasting and Revolutionizing the Supply Chain matters?

At a time marked by digital concerns, artificial intelligence (AI) has become a game changer for companies that are competitive and reactive in complex markets. From the pattern forecast, with meticulous accuracy in optimal test logistics and processing, and proper forms, the operation is optimized. Add management of the downturn, and all the logistical sessions become not only more intelligent but also more versatile. This article explores the predictions of his tree in the fleets and telematic fleet strings in fleet management, which are converging with smart traders. At the heart of the supply chain, the ability to predict the customer request accurately.

The result is a superlative and minimized solution, an improvement in circulation, and essential savings. For industries as sales, production, and FMCG, it is not only useful - it is necessary. Artificial Intelligence in supply Chain extends beyond predictions. It is embedded in many layers of the string of success. The robotic system coordinates tasks, automates the execution of orders, and reduces human error in distribution centers.

The result is a string of supply chain that is more debt-free, better equipped, and more capable of responding to unexpected changes - a quality that has shown it to be impartial in the global market. The perks she extends beyond the supply chains in the most lamp field of business operations. The best company like Mined XAI refers to intelligence systems in various departments of the company, including marketing, HR, finance, and customer service. In marketing, help analyze customer behavior, customize the results, and plan campaigns.

AI for Enterprise: A Strategic Asset

Traditional methods and calculation sheets of AI for enterprise are often used in dynamic environments where consumer behavior remains unpredictable. One can the requirements requested which include a tool that utilizes automatic variables and real variables, contractors, and more accurate requirements, as well as its massive volume models from various sources, including past systems, customer reviews, inventor revisions, and trends. These models learn and adapt constantly, and refine their predictions as new data becomes available.

Their sensors monitor the health of cars and predict when maintenance is necessary, preventing costly downtime. I use real traffic and weather data to suggest the fastest and largest distribution compared to fuel economy. Their systems can identify the supply of priests; analyze the geopolitical risks, natural disasters, or real providers. The provider's quotes, leadership time, and performance data help make informed decisions for purchase.

To the ability to make information usable from large groups of data, AI demand is allowing the customers to make strategic decisions. Their systems may detect ineffectiveness, identify new opportunities, and suggest alternative screenings to keep the schedule on track. One of the most vulnerable applications of AI demand forecasting stream is in the fleet, where the real-time sensors and edge diagnostics are utilized to allow for fleet management.

The driver's behavior, including speed, braking, and slow movement, improves security and reduces fuel consumption. Generate an analysis of the fleet's use, which allows for dimensions supported by data on fleet expansion or consolidation. By analyzing telematic data, companies can optimize their logistics operations, which lead to improvements and reduced operational costs and efficiencies. The true power of these technologies lies in their synergy. Imagine a system that provides a peak in questions about a product next month.

Telematics and Fleet Management: The AI on the Road

The supply string system accelerates production and manages the inventory. Meanwhile, the Telematics Fleet Management prepares to meet increased demand or optimize real-time distribution socks. All this happens with minimal human intervention, led by honest learning. These integrated ecosystems were not the scientific manufacturing - they are already implemented by the Society of the Advantage, as seen in companies like Amazon and Wall Mart.

The principles and medium-sized companies also use the data platforms of a Telematics Fleet Management on the cloud, to stay competitive. Despite their potential length, the implementation of this in supply chains and companies includes challenges. There is a lack of professionals involved in the two technologies and the subsequent chain of operations. The Telematics Fleet Management system has reduced costs, full integration requires significant investments.

Conclusion< p> A prediction is required, as solutions at the level of fleet management radically modify the commercial landscape. These technologies enable operating companies to operate with accuracy and efficiency. As intensifying expectations and customer demands increase, investing in powerful tools is no longer a luxury - it is a necessity for development and growth. Companies that adopt this processing will now be what you drive tomorrow.

0 notes

Text

Global Loaders Market Size, Share, Trends & Forecast 2018–2032

🔍 What is the Global Loaders Market Size?

The global loaders market size was valued at USD 28.72 billion in 2018 and is projected to reach USD 50.70 billion by the end of 2032, exhibiting a steady CAGR of 4.1% during the forecast period.

🌍 Which Region Dominates the Loaders Market?

Asia Pacific dominated the global market with a share of 36.32% in 2018.

🚧 Why is the Loaders Market Growing?

Loaders play a crucial role in removing uneven rocks, dirt, sand, and mud at construction and mining sites, making surfaces even and strengthening the base for structures. The increasing number of mining sites and rising construction activities worldwide are boosting market growth.

📌 How is the Market Segmented?

By Loader Type:

Skid Steer

Backhoe

Wheeled

Crawler/Track

Mini Loaders

By Payload Capacity:

3–5 tons

6–10 tons

11–15 tons

15 tons and above

By Application:

Mining

Construction

Waste Management

Others

💡 What are the Latest & Future Trends?

The loaders market is witnessing demand for more fuel-efficient, versatile, and durable machines as infrastructure projects and mining activities expand globally. Innovations like hybrid engines, telematics, and smart operator controls will continue to shape the market.

👉 Read the full market insights: https://www.fortunebusinessinsights.com/industry-reports/loaders-market-101313

#Loaders#ConstructionEquipment#MiningMachinery#Infrastructure#HeavyMachinery#MaterialHandling#MarketTrends#ConstructionIndustry#UrbanDevelopment#EquipmentInnovation

0 notes

Text

Earthmoving Equipment Market: The Machinery Behind Modern Development

Heavy-duty earthmoving equipment forms the backbone of construction, mining, and infrastructure development projects. From road building to site excavation, these machines are designed to move vast amounts of material efficiently and safely.

As described in Business Market Insights, the market includes a wide range of machinery types such as excavators, bulldozers, loaders, and backhoes. These machines are used in construction, agriculture, mining, and forestry operations, and are selected based on project requirements, terrain, and load capacity.

Technological advances are shaping this industry in numerous ways. Automation, telematics, fuel efficiency, and hybrid or electric powertrains are becoming key features. Operators now benefit from improved comfort, safety, and real-time diagnostics—enhancing both productivity and sustainability.

As infrastructure investment continues across both emerging and developed regions, the demand for high-performance, environmentally responsible equipment is expected to remain strong. The market is also seeing growth in leasing and rental models, offering flexible options for contractors of all sizes.

0 notes

Text

Heavy Machinery, Big Impact: Trends in Earthmoving Equipment

The Earthmoving Equipment Market plays a pivotal role in shaping the infrastructure of modern civilization. From road construction and mining to urban development and disaster recovery, earthmoving machinery like excavators, bulldozers, loaders, and graders are the backbone of large-scale construction projects.

As infrastructure investment surges globally—especially in emerging economies—the demand for efficient, durable, and technologically advanced earthmoving equipment continues to rise.

Market Overview

Earthmoving equipment includes a range of heavy machinery used for tasks like digging, leveling, transporting, and grading soil or rock. These machines are essential in construction, mining, agriculture, and forestry, among other sectors.

Driven by urbanization, industrialization, and increased spending on infrastructure, the market is undergoing rapid technological transformation.

Key Market Trends and Drivers

Global Infrastructure Development Massive government investments in infrastructure projects—such as smart cities, highways, and rail corridors—are directly boosting equipment demand.

Technological Advancements The integration of IoT, GPS, telematics, and autonomous systems is revolutionizing earthmoving equipment, making machines smarter, safer, and more fuel-efficient.

Rental Services Expansion The high cost of equipment ownership has led many contractors to prefer leasing and rental models, boosting flexibility and market accessibility.

Growing Mining & Energy Sector Exploration of natural resources, especially in Asia-Pacific and Africa, is driving the need for robust earthmoving machines capable of working in harsh environments.

Emission Regulations and Electrification To comply with environmental regulations, manufacturers are introducing hybrid and electric-powered machines with lower emissions and better energy performance.

Challenges in the Market

High Maintenance & Operating Costs

Skilled Operator Shortage

Supply Chain Disruptions affecting raw materials and spare parts

Despite these hurdles, innovation and government initiatives are helping mitigate these issues, especially in developing markets.

Future Outlook

The future of the earthmoving equipment market lies in automation, electrification, and connectivity. Companies like Caterpillar, Komatsu, Volvo CE, JCB, and Hitachi are leading the way by investing in AI-driven analytics, autonomous fleets, and predictive maintenance.

As the global push for smarter, faster, and greener infrastructure continues, earthmoving equipment will remain an indispensable force behind progress.

#EarthmovingEquipment#HeavyMachinery#ConstructionEquipment#InfrastructureDevelopment#SmartConstruction

0 notes

Text

Heavy Construction Equipment Market, Size, Segment and Growth by Forecast Period: (2021-2031)

The Future of the Heavy Construction Equipment Market: Growth, Trends, and Opportunities

The heavy construction equipment market is on a steady growth trajectory, projected to reach US$ 338.06 billion by 2031, up from US$ 224.15 billion in 2024, with a CAGR of 6.16% from 2025 to 2031. This expansion is fueled by increasing infrastructure investments, urbanization, and advancements in construction technology. 📚Download Full PDF Sample Copy of Market Report @ https://wwcw.businessmarketinsights.com/sample/BMIRE00031135

Key Market Drivers

Government Infrastructure Projects – Countries like India, Brazil, and Mexico are heavily investing in transportation, renewable energy, and public infrastructure. The World Bank estimates over US$ 3.7 trillion is spent annually on infrastructure to support growing populations.

Rise in Clean Energy Investments – The shift toward sustainable energy is accelerating demand for construction machinery. The International Energy Agency (IEA) reports over US$ 3 trillion invested in 2024 in clean energy projects globally.

Technological Advancements – Automation, AI, and IoT are transforming heavy equipment, improving efficiency, safety, and remote monitoring.

Future Trends Shaping the Industry

Electric & Hybrid Equipment – With stricter emission norms, manufacturers are developing eco-friendly machinery.

Autonomous & Remote-Controlled Machines – AI-driven bulldozers, excavators, and drones are enhancing precision and reducing labor costs.

Rental & Leasing Models – Small contractors are increasingly opting for rental services to reduce capital expenditure.

3D Printing in Construction – Heavy equipment is being adapted for additive manufacturing in large-scale projects.

Opportunities for Stakeholders

Emerging Markets – Asia-Pacific and Africa offer significant growth potential due to rapid urbanization.

Smart Construction Technologies – Companies investing in AI and telematics will gain a competitive edge.

Sustainable Machinery – Demand for low-emission and energy-efficient equipment will rise with green building initiatives.

Heavy Construction Equipment Market: Segmentation, Drivers, and Opportunities

Market Segmentation Analysis

The heavy construction equipment market is analyzed based on type, propulsion type, power output, and end-use industry.

By Machinery Type

Earthmoving Equipment (e.g., excavators, bulldozers, loaders)

Material Handling Equipment

Heavy Construction Vehicles

Others

In 2024, the earthmoving equipment segment held the largest market share, driven by increasing infrastructure investments globally.

By Propulsion Type

Internal Combustion Engine (ICE) (Diesel/Gasoline)

Electric

The ICE segment dominated in 2024 due to its fuel efficiency and widespread availability in heavy-duty applications.

By Power Output

<100 HP

101–200 HP

201–400 HP (Largest market share in 2024)

>401 HP

By End-Use Industry

Building & Construction (Largest market share)

Forestry & Agriculture

Energy & Power

Mining

Others

Market Drivers and Opportunities

1. Rising Global Investments in Construction

Governments worldwide are increasing infrastructure spending, fueling demand for heavy construction equipment. Key developments include:

US: The Bipartisan Infrastructure Law allocated $1.2 trillion for infrastructure.

Europe: The EU Infrastructure Development Fund committed $828.8 billion.

Asia Pacific: The construction sector was valued at $4.36 trillion (2022), driven by rapid urbanization in India, China, and Southeast Asia.

2. Infrastructure Growth in Emerging Economies

Countries like China, India, Brazil, and Argentina are undertaking major projects:

China: Hong Kong-Zhuhai-Macau Bridge, Beijing Subway Expansion.

India: Smart Cities Mission, highway expansions.

Europe: Baltic Offshore Pipeline, Crossrail (UK).

These initiatives create significant opportunities for heavy construction equipment manufacturers.

Market Size and Share Analysis

Earthmoving Equipment Leads Market Growth

Germany’s Federal Transport Infrastructure Plan 2030 includes $280.68 billion in investments.

Companies like Volvo CE are introducing electric models (e.g., L120 Electric Wheel Loader) to meet sustainability demands.

ICE Segment Dominates Due to Reliability

Diesel-powered equipment remains preferred for heavy-duty applications due to fuel efficiency and established infrastructure.

Outlook

The market is expected to grow further, supported by government investments, urbanization, and technological advancements in electric and hybrid construction machinery.

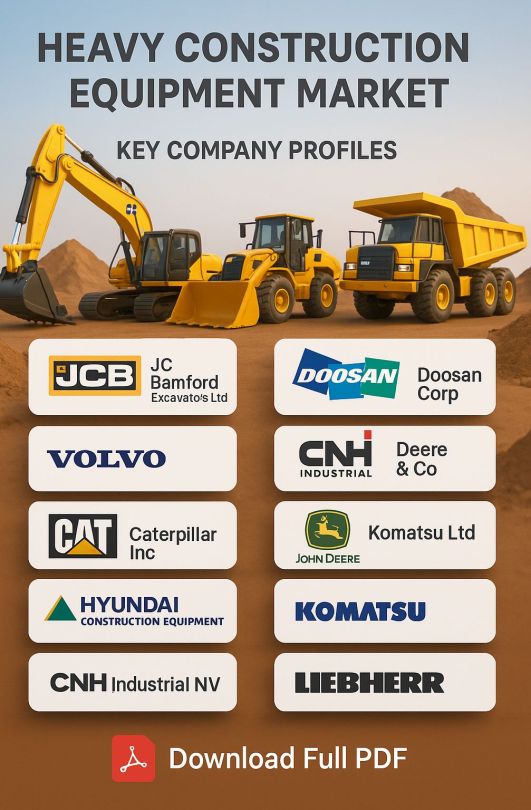

Market leaders and key company profiles JC BAMFORD EXCAVATORS LTD

AB VOLVO

CATERPILLAR INC

HITACHI LTD

HYUNDAI CONSTRUCTION EQUIPMENT CO LTD

DOOSAN CORP

CNH INDUSTRIAL NV

DEERE & CO

KOMATSU LTD

LIEBHERR Heavy Construction Equipment Market Report Coverage and Deliverables

The "Heavy Construction Equipment Market Size and Forecast (2021–2031)" report provides a detailed analysis of the market covering below areas:

Heavy Construction Equipment market size and forecast at global, regional, and country levels for all the key market segments covered under the scope

Heavy Construction Equipment market trends, as well as market dynamics such as drivers, restraints, and key opportunities

Detailed Porter's Five Forces and SWOT analysis

Heavy Construction Equipment market analysis covering key market trends, global and regional framework, major players, regulations, and recent market developments

Industry landscape and competition analysis covering market concentration, heat map analysis, prominent players, and recent developments for the Heavy Construction Equipment market

Detailed company profiles

The geographic scope of the Heavy Construction Equipment market report is divided into five regions: North America, Asia Pacific, Europe, Middle East & Africa, and South & Central America. The Heavy Construction Equipment market in Asia Pacific is expected to grow significantly during the forecast period.

The heavy construction equipment market in Asia Pacific is segmented into Australia, China, India, Japan, South Korea, Indonesia, Singapore, Malaysia, the Philippines, Vietnam, and the Rest of Asia Pacific. The construction sector in Asia Pacific recorded ~US$ 4.36 trillion of output in 2022, representing approximately 45% of the global construction sector. However, in January 2025, infrastructure investments related to transportation, renewable energy, and manufacturing reached US$ 21.9 billion in Singapore and Malaysia. Further, the government of New Zealand is emphasizing the development of infrastructure networks such as water and wastewater systems, road and rail networks, electricity transmission, and telecommunication infrastructure. Growing population and increasing urbanization are a few factors boosting the need to expand and upgrade important infrastructure facilities in the country. The government of New Zealand plans to offer ~US$ 47 billion for infrastructure development over the coming five years 2023-2027. The growing focus on infrastructure development is anticipated to propel the growth of construction activities, along with the application of heavy construction equipment, across the country in the coming years.

Heavy Construction Equipment Market Research Report Guidance

The report includes qualitative and quantitative data in the Heavy Construction Equipment market across type, vehicle type, end user and geography.

The report starts with the key takeaways (chapter 2), highlighting the key trends and outlook of the Heavy Construction Equipment market.

Chapter 3 includes the research methodology of the study.

Chapter 4 further includes ecosystem analysis along with Porter’s analysis.

Chapter 5 highlights the major industry dynamics in the Heavy Construction Equipment market, including factors that are driving the market, prevailing deterrents, potential opportunities as well as future trends. Impact analysis of these drivers and restraints is also covered in this section.

Chapter 6 discusses the Heavy Construction Equipment market scenario, in terms of historical market revenues, and forecast till the year 2031.

Chapters 7 to 9 covers Heavy Construction Equipment market segments by type, application and geography across North America, Europe, Asia Pacific, Middle East and Africa, South and Central America. They cover market volume revenue forecast, and factors driving the market.

Chapter 10 describes the competitive analysis along with the heat map analysis for the key players operating in the market.

Chapter 11 describes the industry landscape analysis. It provides detailed description of various business activities such as market initiatives, new developments, mergers, and joint ventures globally, along with a competitive landscape.

Chapter 12 provides detailed profiles of the major companies operating in the Heavy Construction Equipment market. The companies have been profiled on the basis of their key facts, business description, products and services, financial overview, SWOT analysis, and key developments.

Chapter 13, i.e., the appendix is inclusive of a brief overview of the company, list of abbreviations, and disclaimer.

Heavy Construction Equipment Market News and Key Development:

The Heavy Construction Equipment market is evaluated by gathering qualitative and quantitative data post primary and secondary research, which includes important corporate publications, association data, and databases. A few of the key developments in the Heavy Construction Equipment market are:

Hitachi Construction Machinery Co., Ltd. (TSE: 6305; “Hitachi Construction Machinery”) announced the establishment of Hitachi Construction Machinery Development Center India Private Limited (“Hitachi Construction Machinery Development Center India”), a consolidated subsidiary that will develop and design construction machinery in India, in late December to strengthen the product development capabilities of the Hitachi Construction Machinery Group. The company will target and hire exceptional talent within India in the fields of IT and mechanical engineering and expand to a scale of 200 engineers and designers by FY2027. (Source: Hitachi Construction Machinery Co., Ltd, Press release, December 2024)

HD Hyundai Construction Equipment North America has continued expansion of its HX crawler excavator product line with the availability of two new large frame mass excavators. The 82-ton HX800A L, and the 100-ton HX1000A L are designed to meet the needs of high-volume earthmoving, mining and quarrying applications. The HX800A L is powered by a 528 net hp (389 kW) engine, while the HX1000A L is equipped with a 620 net hp (420 kW) engine. (Source: HD Hyundai Construction Equipment, Press Release, August 2024)

About Us: Business Market Insights is a market research platform that provides subscription service for industry and company reports. Our research team has extensive professional expertise in domains such as Electronics & Semiconductor; Aerospace & Défense; Automotive & Transportation; Energy & Power; Healthcare; Manufacturing & Construction; Food & Beverages; Chemicals & Materials; and Technology, Media, & Telecommunications Author's Bio Akshay Senior Market Research Expert at Business Market Insights

0 notes

Text

Rough Terrain Crane Market Drivers Include Infrastructure Expansion and Off-Road Construction Needs

Infrastructure development initiatives across both developed and emerging economies are fueling the demand for robust, versatile lifting machinery. The Rough Terrain Crane Market is experiencing notable growth, largely driven by the pressing need for efficient equipment that can navigate off-road job sites and support large-scale construction efforts in remote or rugged areas.

Expanding Infrastructure Projects Fueling Market Demand

The surge in infrastructure spending, particularly in roads, bridges, airports, and urban transport corridors, is a primary driver for rough terrain crane deployment. Governments and private players are investing heavily in megaprojects that demand flexible, mobile cranes capable of traversing undeveloped sites. For example, India’s National Infrastructure Pipeline and the U.S. Infrastructure Investment and Jobs Act have allocated massive capital toward civil and industrial infrastructure, creating strong tailwinds for crane manufacturers.

Off-Road Construction Needs Boost Equipment Versatility

Unlike tower or truck-mounted cranes, rough terrain cranes are specifically designed for off-highway construction sites where uneven surfaces, mud, and obstacles pose operational challenges. These cranes feature all-wheel drive, compact chassis, and advanced suspension systems, making them indispensable in oil fields, dam construction, and mountainous projects. Their all-terrain mobility gives them a competitive edge in geographies with poor access roads or underdeveloped infrastructure.

Urbanization and Industrialization Accelerating Uptake

The global trend toward rapid urbanization, especially in Asia-Pacific, Africa, and Latin America, is another powerful market stimulant. With cities expanding outward and upward, there is a growing need for construction equipment that can perform reliably in variable terrain. Moreover, industrialization in these regions is resulting in the development of logistics parks, manufacturing hubs, and energy facilities—all requiring reliable lifting solutions in challenging work conditions.

Public-Private Partnerships and Government Support

Public-private partnerships (PPPs) have emerged as critical tools in unlocking large-scale infrastructure financing. These cooperative frameworks often involve long-term construction timelines in varying terrains, further increasing reliance on rough terrain cranes. In addition, regulatory push for faster project delivery—especially in transportation, energy, and water infrastructure—is prompting contractors to adopt equipment that ensures speed, safety, and efficiency.

Technological Integration Enhancing Performance

Market drivers also include the adoption of smart features that improve crane operability and maintenance. Leading manufacturers are incorporating telematics, remote diagnostics, and load-moment indicators, which not only enhance performance but also reduce downtime and improve job site safety. These technological upgrades make rough terrain cranes even more appealing to contractors managing complex infrastructure developments.

Regional Expansion Opportunities

Asia-Pacific holds a dominant share of the global market, driven by infrastructure-heavy economies like China, India, and Indonesia. Meanwhile, Africa and Latin America are emerging as high-growth regions, thanks to rising demand for energy infrastructure, mining, and port development. In North America and Europe, replacement cycles and upgrades in aging construction fleets are creating a stable demand base.

Challenges and Considerations

Despite strong growth indicators, certain constraints exist. High initial procurement costs and the need for skilled operators remain barriers, especially for smaller construction firms. However, rental models are mitigating these factors, allowing broader access to advanced crane technology without the capital burden of ownership.

Competitive Landscape

Leading players in the market—such as Tadano, Terex Corporation, Liebherr, and Zoomlion—are investing in R&D to deliver more fuel-efficient and terrain-adaptable models. These firms are also expanding their dealer networks and after-sales service infrastructure to gain competitive advantage in newly developing regions.

Conclusion: Preparing for the Next Wave

As infrastructure projects continue to diversify in scope and scale, the Rough Terrain Crane Market is expected to see sustained momentum. Manufacturers and contractors alike are aligning their strategies to meet the rising demand for machines that can function seamlessly across multiple terrains.

#RoughTerrainCranes#InfrastructureDevelopment#ConstructionEquipment#HeavyLiftingSolutions#Urbanization#OffRoadMachinery#CraneTechnology#SmartConstruction#MobilityEquipment#IndustrialGrowth#TelematicsInConstruction

0 notes

Text

Innovation Spotlight: Montra Electric Truck Is Changing the Future of Commercial EVs in India

Introduction:

Electric vehicles aren’t just the future they’re the now. At the heart of India’s green trucking revolution is Montra Electric, leading the way with cutting-edge EV tech and smarter, cleaner commercial trucks. Their newest innovations are setting fresh benchmarks in battery, safety, and environmental performance. Let’s dive into how they’re making it happen.

Cutting-Edge Technology that Keeps You Moving

In the world of electric commercial vehicles, battery power is king and Montra Electric is wearing the crown.

Their latest high-density battery systems mean:

Longer driving ranges

Faster charging times

Minimal downtime

This translates into greater efficiency, more trips per day, and a boost to your business all while being eco-conscious.

Smart Safety: Telematics That Think

Montra Electric isn’t just about power it’s about intelligence on the move.

With their advanced telematics system, you get:

Real-time location tracking

Live vehicle diagnostics (battery health, speed, temp, voltage)

Route playback & trip history

Driver performance insights

Fleet managers can optimize routes, track usage trends, and improve driver behavior all through a smart dashboard.

Built on Sustainability

Montra’s Rhino5536E is India’s first fully electric commercial truck with net-zero tailpipe emissions a true game-changer.

Environmental benefits include:

Lower air pollution

Reduced Scope 3 emissions (ESG compliant)

Super low maintenance and running costs

It’s not just a truck it’s a sustainability statement. For industries like mining, cement, and logistics, it’s a smarter, cleaner choice.

What’s Next for Montra Electric?

The innovation doesn’t stop here. Montra Electric is:

Working on autonomous driving tech

Expanding into electric tippers & intermediate commercial vehicles

Exploring battery swapping options

They’re not just keeping up they’re pushing ahead to create the next era of electric logistics in India.

Real Results, Happy Clients

Trusted by big names like TATA Steel, Hindustan Zinc, and Ultratech Cement, Montra’s trucks are already proving their worth—delivering low operating costs, reliable uptime, and green performance.

Conclusion:

Montra Electric Truck isn’t just about EVs it’s about driving India’s future forward. With every battery innovation, every telematics upgrade, and every clean mile driven they’re shaping a world where logistics meet sustainability.

Read the full article here: https://montraelectrictruck.com/blog/innovation-spotlight-ipltech-electric-latest-advancements-in-electric-vehicle-technology

0 notes

Text

Fuel Management Systems Market to Surpass US$ 1 Billion by 2034

The global fuel management systems (FMS) market was valued at US$ 624.4 million in 2023 and is expected to reach US$ 1.0 billion by 2034, growing at a CAGR of 4.6% from 2024 to 2034. As fuel expenses continue to dominate operational costs in fleet-heavy industries, the demand for effective, secure, and intelligent fuel management solutions has surged.

What is a Fuel Management System (FMS)?

A fuel management system is a combination of hardware and software technologies designed to track, monitor, and control fuel usage across vehicles and industrial equipment. These systems are essential in industries that depend on road, rail, air, or marine transportation, enabling businesses to minimize fuel waste, detect theft, and boost operational efficiency.

Analyst Viewpoint: A Growing Need for Fuel Intelligence

Two main trends are fueling the rise of FMS:

For example, in early 2022, petroleum/fuel accounted for 12% of recorded cargo thefts in the U.S., emphasizing the need for robust tracking mechanisms.

Technological Advancements in FMS

Modern FMS solutions increasingly incorporate IoT sensors, telematics, GPS, cloud integration, and AI algorithms to give fleet operators a detailed view of fuel consumption across sites and vehicles. These technologies offer real-time alerts, fuel trend analysis, and remote diagnostics.

Key technological advancements include:

For instance, in 2021, Fuel Me launched a mobile platform offering fuel purchasing and emergency services for the commercial transportation and construction sectors. Similarly, Aeris partnered with Omnicomm to combat fuel theft in India through smart monitoring solutions.

Regional Outlook: Asia Pacific Takes the Lead

Asia Pacific held the largest share of the global FMS market in 2023. The region’s rapid industrialization, increasing fleet sizes, and efforts to optimize fuel consumption have contributed to this dominance.

Key factors contributing to regional growth include:

As companies in Asia Pacific continue to adopt cutting-edge solutions to minimize fuel costs, the region is expected to maintain its leading position through 2034.

Key Players and Market Landscape

Prominent players in the FMS market are developing customized, integrated, and modular solutions to meet the growing needs of fleet operators. Key companies include:

These players are focusing on R&D investments, strategic partnerships, and region-specific launches to expand their customer base. For instance, Shell Fleet Solutions offers localized services in India tailored to reduce the total cost of fleet ownership.

Market Segmentation Overview

The FMS market can be segmented by process, application, end-user, and geography:

Future Outlook

With the rising emphasis on fuel efficiency, cost control, and security, the FMS market is well-positioned for steady growth through 2034. Companies across sectors—from logistics and mining to aviation and construction—are likely to continue investing in FMS as part of their digital transformation and sustainability strategies.

In the coming years, we can expect to see further integration of AI and machine learning, greater use of predictive analytics, and scalable SaaS platforms that cater to businesses of all sizes.

0 notes

Text

How Excavators Are Revolutionizing Modern Construction Projects

In today's rapidly evolving construction landscape, construction excavators have become the cornerstone of efficiency, precision, and safety. From urban infrastructure to large-scale mining and rural development, excavators have transformed how projects are executed—faster, safer, and more cost-effective than ever before.

Let’s explore how these powerful machines, especially industry leaders like Tata Hitachi construction excavators, are revolutionizing the construction industry across India and the world.

Speed and Efficiency on Site

One of the most significant ways excavators are changing the game is by dramatically increasing speed on job sites. Traditional earth-moving or digging methods involved intense manual labor or slower, less efficient machinery. Today’s construction excavators can dig, lift, and transport large volumes of material in a fraction of the time.

Excavators now come equipped with features such as automated digging cycles, real-time performance tracking, and advanced hydraulics—all of which reduce downtime and enhance productivity. For instance, Tata Hitachi construction excavators are designed with fuel-efficient engines and advanced hydraulic systems to ensure continuous, high-performance operation with reduced operating costs.

Versatility Across Applications

Modern excavators are not just for digging. With a wide range of attachments—such as breakers, augers, grapples, and rippers—excavators can perform multiple tasks like demolition, trenching, lifting, material handling, and grading.

Whether it's a compact mini excavator navigating tight urban spaces or a heavy-duty model clearing a mining site, construction excavators are now built for adaptability. This versatility significantly reduces the need for multiple types of equipment on-site, thereby cutting costs and improving logistics.

Tata Hitachi construction excavators, for example, offer machines across different tonnage classes, making them suitable for projects ranging from residential buildings to highway construction and quarry operations.

Enhanced Safety and Operator Comfort

Construction sites are inherently risky environments. Excavators are helping reduce these risks with technology that enhances both machine control and operator safety. Features such as rearview cameras, GPS-based guidance, and stability sensors ensure safer operation even in challenging terrain.

Additionally, manufacturers now focus heavily on operator comfort. Spacious, climate-controlled cabs with ergonomic controls help reduce fatigue and enhance focus. Tata Hitachi excavators, in particular, are known for their operator-centric design that includes low-vibration cabins, intuitive controls, and 360-degree visibility—ensuring safety and efficiency go hand-in-hand.

Integration with Smart Technologies

Another leap forward in how excavators are reshaping construction is their integration with smart technologies. Telematics systems now allow contractors to remotely monitor equipment health, fuel consumption, machine hours, and even real-time location.

Tata Hitachi's ConSite and InSite technologies are prime examples. These digital tools offer advanced analytics and predictive maintenance alerts, helping reduce breakdowns and optimize machine uptime. Such features are transforming excavators into intelligent worksite partners rather than just machines.

Eco-Friendly and Sustainable Options

With growing concerns over environmental sustainability, the shift toward energy-efficient and low-emission machinery is vital. Many modern construction excavators now feature engines compliant with the latest emission norms, idle shutdown functions, and energy-saving modes.

Tata Hitachi construction excavators are leading this transition in India. The brand showcased electric and hybrid models at EXCON 2023, signaling a strong move toward cleaner construction solutions. These machines are designed not only to minimize environmental impact but also to deliver significant fuel savings.

Conclusion

Construction excavators are no longer just tools—they are strategic assets that redefine how modern construction projects are planned and executed. Their speed, flexibility, safety features, and smart technologies make them indispensable on any job site.

As demand for efficient and sustainable infrastructure grows, Tata Hitachi construction excavators are helping companies meet these challenges head-on—delivering performance, precision, and productivity every step of the way.

0 notes

Text

Trailer Telematics Market : Size, Trends, and Growth Analysis 2032

The Trailer Telematics Market was valued at US$ 779.09 million in 2024 and is anticipated to grow at a CAGR of 10.90% from 2025 to 2032. This rapid market expansion is fueled by the global logistics sector’s increasing demand for real-time visibility, predictive analytics, and fleet safety optimization. Trailer telematics technologies are revolutionizing how logistics and transport companies manage assets—unlocking higher efficiency, security, and profitability.

Understanding Trailer Telematics

Trailer telematics systems integrate GPS, IoT sensors, cellular connectivity, and cloud platforms to monitor and transmit vital data from trailers. These systems track:

Real-time location

Vehicle speed and route history

Cargo condition (e.g., temperature, humidity)

Door open/close status

Brake health and tire pressure

Trailer utilization and idle time

This data allows fleet managers to monitor, control, and optimize operations remotely, reducing downtime, theft risk, fuel consumption, and cargo damage.

Key Drivers of Market Growth

1. Booming E-commerce and Logistics

The explosion in e-commerce and on-demand delivery services has intensified the need for fast, reliable, and transparent supply chain operations. Telematics solutions give companies the tools to manage complex logistics efficiently and meet growing customer expectations for real-time delivery tracking.

2. Need for Real-Time Visibility

Fleet operators are under pressure to know exactly where assets are and how they are performing at all times. Trailer telematics deliver location accuracy, status updates, and usage patterns that help in informed decision-making and route optimization.

3. Cargo Security and Regulatory Compliance

With increasing cargo theft incidents and tightening regulations around goods handling (especially cold chain logistics), companies are adopting telematics to ensure security and compliance. Real-time alerts for door breaches or temperature fluctuations can help prevent costly losses.

4. Predictive Maintenance and Asset Lifecycle Management

Advanced telematics systems support predictive maintenance by analyzing component health and usage patterns. This minimizes unplanned downtime, extends trailer lifespan, and reduces maintenance costs.

5. Environmental and Fuel Efficiency Goals

Fleet management increasingly incorporates sustainability goals. Telematics helps reduce fuel consumption by monitoring driver behavior, optimizing routes, and minimizing idling—supporting carbon reduction efforts.

Core Components of a Trailer Telematics System

GPS Modules – For accurate location tracking.

Telematics Control Unit (TCU) – Collects, processes, and transmits data.

Sensors – Monitor cargo temperature, trailer doors, braking systems, tire pressure, and more.

Connectivity – Typically cellular or satellite, enabling real-time communication.

Cloud Platform and Dashboard – For data visualization, analytics, and control via web or mobile apps.

Application Areas

Long-Haul Freight & Logistics Track trailer locations, monitor driver activity, and plan optimal routes for long-distance shipping.

Cold Chain Transportation Ensure temperature-sensitive goods (like food or pharmaceuticals) remain within required conditions with real-time temperature tracking.

Construction and Mining Manage heavy trailers and equipment on remote sites; monitor usage and geofence sensitive areas.

Rental & Leasing Fleets Monitor usage patterns, location history, and maintenance needs to enhance asset protection and ROI.

Public Sector and Emergency Services Governments and aid agencies use telematics to manage mobile equipment and ensure response efficiency.

Regional Insights

North America: Dominates the global market due to early technology adoption, advanced fleet infrastructure, and stringent cargo security regulations. The U.S. and Canada are major contributors.

Europe: Strong growth driven by environmental regulations, the rise of intermodal logistics, and data-driven fleet operations in countries like Germany, the UK, and France.

Asia-Pacific: Fastest-growing region fueled by expanding logistics networks in China, India, and Southeast Asia. Government investments in smart transportation and rising freight volumes are key factors.

Latin America & MEA: Emerging markets are showing increased interest in trailer telematics, especially in logistics-heavy economies like Brazil, Mexico, and the UAE. However, adoption is limited by cost sensitivity and connectivity challenges.

Leading Players in the Trailer Telematics Market

Geotab Inc.

A major telematics provider known for its open platform and scalable solutions. Offers real-time location tracking, driver behavior monitoring, and rich APIs for customization.

ORBCOMM Inc.

Specializes in IoT and M2M communication solutions, including satellite and cellular telematics for trailer, reefer, and intermodal container tracking.

Trimble Inc.

Offers logistics-focused telematics systems through its Transportation division. Provides advanced analytics, maintenance alerts, and real-time route optimization.

WABCO Holdings Inc.

A key player in smart braking, stability control, and trailer telematics. Known for integrating safety systems with tracking technology.

CalAmp Corp.

Delivers flexible, modular telematics devices and platforms for trailer management. Strong in sensor integration and cloud-based analytics.

Omnitracs LLC

Provides comprehensive fleet intelligence platforms with focus on routing, compliance, and driver productivity in trucking and logistics.

Spireon Inc.

Offers GPS-based trailer and asset tracking under the FleetLocate brand. Known for providing intuitive dashboards and actionable insights.

Verizon Connect

Delivers enterprise-level telematics and mobile workforce solutions. Provides real-time asset tracking, geofencing, and data analytics via the Verizon network.

Samsara Inc.

One of the fastest-growing players offering IoT-based solutions for real-time trailer tracking, video telematics, and AI-powered analytics across logistics and construction industries.

Market Trends

AI and Predictive Analytics: Telematics systems are integrating machine learning to predict failures, optimize fuel use, and automate decision-making.

5G and Edge Computing: High-speed data transmission and local processing enable richer real-time insights, even in remote areas.

Video Telematics Integration: Combining tracking with dashcams for enhanced driver safety and accident liability management.

Blockchain for Secure Tracking: Emerging applications in securing cargo chain of custody, especially in high-value or perishable goods.

Browse more Report:

Pharmaceutical Plastic Packaging Market

Pharmaceutical Analytical Testing Outsourcing Market

Non-invasive Helicobacter Pylori Testing Market

Neuroprotection Market

Neonicotinoid Pesticide Market

0 notes

Text

Construction Equipment Rental Market Drivers: Key Forces Powering Industry Growth and Transformation

The construction equipment rental market is undergoing a significant transformation driven by multiple economic, operational, and environmental factors. As global infrastructure projects continue to rise and companies prioritize cost-effective operations, the demand for rental equipment is expanding at a rapid pace. Businesses across construction, mining, and real estate sectors are increasingly relying on rental models for flexibility, affordability, and access to advanced machinery.

Cost Efficiency and Capital Optimization

One of the foremost drivers of the construction equipment rental market is the growing emphasis on cost efficiency. Purchasing construction machinery involves a substantial capital investment, often tied to long-term ownership costs including insurance, maintenance, and depreciation. Renting offers a viable alternative, especially for small to mid-sized contractors who may not have the financial bandwidth for outright purchases. This allows them to allocate their capital more effectively to other areas such as project management, labor, and technology adoption.

Additionally, rental agreements typically include maintenance services, reducing the operational burden on the contractors. This not only cuts down on unexpected repair costs but also ensures the equipment is in optimal working condition, minimizing project delays due to breakdowns.

Increased Infrastructure Development

A surge in global infrastructure development is another significant factor propelling the growth of the construction equipment rental market. Rapid urbanization, particularly in developing economies, has led to substantial investments in roads, bridges, airports, and residential complexes. These large-scale projects require various types of construction equipment such as excavators, loaders, cranes, and compactors — often for limited durations during specific project phases.

Renting becomes an ideal solution for such short-term needs, allowing construction firms to procure exactly what they need, when they need it. This strategic flexibility prevents idle equipment from occupying storage or consuming resources outside its period of utility.

Technological Advancements and Equipment Modernization

The market is also driven by the growing pace of technological innovation in construction machinery. Equipment manufacturers are consistently launching new models with features like telematics, GPS tracking, and fuel efficiency enhancements. These innovations, while valuable, often come at a premium cost.

Rental companies tend to update their fleet regularly, giving contractors access to the latest technology without the high cost of ownership. This not only improves operational efficiency but also helps firms comply with increasingly stringent environmental and safety regulations. Moreover, the access to modern equipment enhances productivity and reduces the risk of workplace injuries, making rental an even more attractive option.

Shift Toward Asset-Light Business Models

The construction industry is increasingly adopting asset-light business strategies to remain agile in a competitive environment. Renting rather than owning allows businesses to stay flexible and scale operations based on project needs. This is especially beneficial in fluctuating economic conditions, where long-term asset ownership might become a liability.

By choosing rental over purchase, construction firms can also test different models and brands before making permanent investment decisions. This trial-based approach helps them make informed decisions and better match equipment to job site requirements.

Environmental and Regulatory Pressures

Growing awareness around sustainability and environmental impact is influencing decisions in the construction industry. Rental companies, which often maintain a younger fleet of machines with better emissions control and fuel efficiency, offer a greener alternative compared to older owned equipment. This aligns well with government policies promoting eco-friendly construction practices.

Regulatory norms concerning emissions and noise levels are also stricter than ever. Renting from a provider that ensures compliance saves contractors the effort and cost of upgrading outdated machinery to meet legal standards.

Government Initiatives and Public Investments

In many regions, government-led initiatives to revamp infrastructure have led to increased spending on public projects. These initiatives act as strong catalysts for the construction equipment rental market. Contractors working on public infrastructure often face stringent deadlines and budget constraints — both of which are better managed through equipment rental.

Moreover, the government's promotion of public-private partnerships (PPPs) has led to more involvement from private construction firms in national development, further fueling the demand for efficient and timely equipment access through rental models.

Growing Demand in Emerging Markets

Emerging markets in Asia-Pacific, Latin America, and parts of Africa are witnessing fast-paced urban development and economic expansion. However, many local firms in these regions lack the financial resources for equipment ownership. Rental services fill this gap, enabling them to participate in growth opportunities without overextending their budgets.

These markets are also seeing an influx of global rental service providers looking to tap into unmet demand, which is improving the availability and variety of equipment choices for regional contractors.

In conclusion, the construction equipment rental market is experiencing strong momentum due to a confluence of cost, technology, policy, and market factors. As the industry continues to evolve, rental solutions will play an increasingly vital role in supporting efficient, scalable, and sustainable construction practices worldwide.

#ConstructionEquipmentRentalMarket#RentalMarketDrivers#InfrastructureDevelopment#ConstructionInnovation#EquipmentRentalTrends

0 notes

Text

Global Dump Trucks Market Size, Share, Trends & Forecast 2018–2032

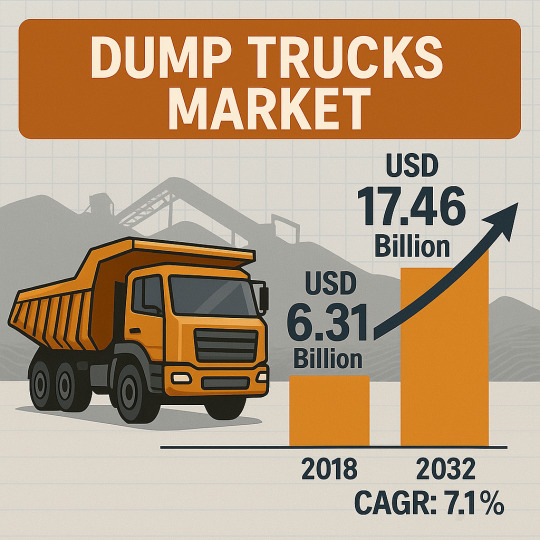

🔍 What is the Global Dump Trucks Market Size?

The global dump trucks market size was valued at USD 6.31 billion in 2018 and is projected to grow to USD 17.46 billion by 2032, exhibiting a solid CAGR of 7.1% during the forecast period.

🌍 Which Region Dominates the Dump Trucks Market?

Asia Pacific dominated the global market with a share of 36.93% in 2018.

🚜 Why is the Dump Trucks Market Growing?

The dump trucks market is expanding due to rising construction and mining activities worldwide. Growing urbanization, large-scale infrastructure projects, and the need for efficient material transportation are major factors fueling this growth.

📌 How is the Market Segmented?

By Type:

Articulated

Rigid

By End Use Application:

Mining

Construction

Waste Management

Others

💡 What are the Latest & Future Trends?

The demand for advanced, fuel-efficient dump trucks is increasing as governments and private sectors invest in sustainable urban development and mining. New tech like telematics and automation are expected to shape the future of the dump trucks industry.

👉 Read the full insights here: https://www.fortunebusinessinsights.com/industry-reports/dump-trucks-market-100953

#DumpTrucks#ConstructionEquipment#MiningIndustry#Infrastructure#Urbanization#HeavyMachinery#MarketTrends#MaterialHandling#ConstructionIndustry#Transportation

0 notes

Text

Earthmoving Equipment Market to 2031

From highways and airports to mining sites and real estate development, earthmoving equipment is fundamental to building the physical framework of modern civilization. This sector comprises a wide array of heavy machinery—excavators, bulldozers, loaders, graders, and backhoes—designed for excavation, transportation, and material handling. According to the Earthmoving Equipment Market Report, the market is poised for steady growth through 2031, propelled by infrastructure modernization and technological innovation.

The demand for heavy construction equipment is rising globally as countries invest in expanding their infrastructure. Urbanization, smart city initiatives, and large-scale projects like roads, bridges, dams, and airports are driving significant procurement of earthmoving machines.

Modern equipment is evolving to meet these demands more efficiently. Innovations in telematics, GPS-based control, autonomous driving systems, and IoT-enabled monitoring are transforming job sites. These technologies enable contractors to optimize fuel usage, predict maintenance needs, and enhance site safety.

One of the biggest shifts in the market is the growing focus on sustainability. Manufacturers are developing electric and hybrid models to reduce emissions and comply with stricter environmental regulations. These machines not only lower carbon footprints but also offer quieter operations—an important feature for urban construction zones.

Contractors are increasingly opting for rental services over ownership to reduce capital expenditure and maintenance responsibilities. The expanding rental market offers access to the latest models without long-term investment, improving operational flexibility and cost efficiency.

Emerging economies in Asia-Pacific and Latin America are key growth regions, driven by government-backed infrastructure initiatives. Meanwhile, developed markets like North America and Europe are focusing on replacing aging fleets with smart, efficient, and environmentally compliant machinery.

Automation is another transformative trend. Semi-autonomous graders and excavators are already being deployed, reducing operator fatigue and improving performance consistency. The integration of machine control systems with Building Information Modeling (BIM) ensures precision in excavation and grading, minimizing errors and material waste.

Furthermore, manufacturers are prioritizing operator comfort and safety. Modern cabins come equipped with ergonomic seats, climate control, touch-screen displays, and real-time diagnostics—resulting in better productivity and lower downtime.

As supply chains become more connected, data-driven asset management is emerging as a competitive advantage. Fleet managers can now track real-time data on fuel consumption, usage hours, and wear patterns to improve decision-making and reduce lifecycle costs.

With innovation and infrastructure demand working in tandem, the earthmoving equipment market will remain a pillar of global development—delivering machines that are smarter, cleaner, and more capable than ever before.

0 notes

Text

Loader Market Size, Share and Growth Analysis 2034

A loader is a highly versatile piece of heavy machinery widely used across industries like construction, mining, and agriculture to move and load materials such as soil, gravel, sand, and debris. It usually has a large bucket mounted at the front, designed to scoop, lift, and carry materials over short distances. Loaders come in different types—such as wheel loaders, skid steer loaders, and compact loaders—each suited for specific tasks and working conditions. Valued for their power, agility, and efficiency, loaders are essential for earthmoving, site preparation, and material handling, often operating alongside other equipment on large projects.

According to SPER Market Research, ‘Global Loader Market Size- By Type, By Engine, By Fuel - Regional Outlook, Competitive Strategies and Segment Forecast to 2034’ state that the Global Loader Market is predicted to reach 67.99 billion by 2034 with a CAGR 6.98%.

Drivers:

The increasing momentum of infrastructure development and construction activities, particularly in developing regions, is fueling the demand for loaders and other heavy equipment. Loaders are essential for clearing materials like sand, mud, and rocks to prepare construction sites, while continuous design enhancements improve operator comfort and efficiency. The rise of public-private partnerships and growth in residential, commercial, and industrial sectors further drive loader demand. Additionally, loaders are vital in logistics and agriculture for material handling and streamlining supply chains. Manufacturers are focusing on advanced technologies, automation, and electric models to boost performance, sustainability, and user experience, promoting consistent market growth.

Request a Free Sample Report: https://www.sperresearch.com/report-store/loader-market?sample=1

Restraints:

The loader market encounters several challenges that may hinder its growth and adoption. High upfront costs and ongoing maintenance expenses can discourage smaller contractors and businesses from purchasing advanced equipment. Fluctuating fuel prices and stricter environmental regulations also create operational and compliance difficulties, particularly for traditional internal combustion engine models. Integrating new technologies like automation, telematics, and electric powertrains often demands extensive training and adaptation for operators. Additionally, supply chain disruptions and raw material shortages can cause production delays. Together, these challenges present obstacles that manufacturers and users must overcome to fully leverage market potential. In 2024, the Asia Pacific loader market dominated the global landscape, propelled by fast economic growth and widespread urbanization in nations such as China, India, Thailand, and South Korea. These factors have greatly increased the need for construction machinery like loaders and excavators. Major infrastructure projects initiated by both government and private sectors focus on enhancing transportation systems and public amenities. For instance, India’s development of a new international airport near Mumbai aims to reduce congestion at the current facility. These large-scale projects continue to drive strong demand for heavy construction equipment. Some significant market players are Caterpillar, CNH Industrial N.V., Doosan Bobcat, Hitachi Construction Machinery Co., Ltd., Hyundai Construction Equipment Co., Ltd., J C Bamford Excavators Ltd., AB Volvo,

For More Information, refer to below link: –

Loader Market Share

Related Reports:

North America Extrusion Machinery Market Size

Thailand Construction Equipment Market Size

Follow Us –

LinkedIn | Instagram | Facebook | Twitter

Contact Us:

Sara Lopes, Business Consultant — USA

SPER Market Research

+1–347–460–2899

#Loader Market#Loader Market Share#Loader Market Size#Loader Market Revenue#Loader Market Analysis#Loader Market Segmentation#Loader Market Future Outlook#Loader Market forecast#LoaderMarket#ConstructionEquipment#WheelLoader#SkidSteerLoader#BackhoeLoader

0 notes

Text

Earthmoving Equipment Market Trends, Size, Segment and Growth by Forecast to (2021-2031)

Earthmoving Equipment Market Outlook:

The global earthmoving equipment market is projected to grow from US$ 97.49 billion in 2024 to US$ 148.2 billion by 2031, registering a CAGR of 6.2% between 2025 and 2031. 📚Download Full PDF Sample Copy of Market Report @ https://wwcw.businessmarketinsights.com/sample/BMIPUB00031689

Executive Summary and Global Market Insights:

The earthmoving equipment market is experiencing robust growth, driven primarily by rapid urbanization and accelerating infrastructure development across the globe. The increasing demand for highways, bridges, and smart urban infrastructure—especially in the Asia Pacific region—is propelling market expansion. Excavators dominate the product landscape, thanks to their flexibility and widespread application in both construction and mining.

Technological advancements are reshaping the industry, with automation, telematics, and the adoption of electric and eco-friendly machinery enhancing operational efficiency and sustainability. Despite these advancements, high capital costs and the growing popularity of equipment rental services present challenges, particularly for small and medium-sized manufacturers.

Regionally, North America and Europe maintain steady growth trajectories, supported by modernization and infrastructure upgrades. Meanwhile, emerging economies in Latin America and Africa offer significant growth potential as construction activities intensify.

Key Market Driver – Urbanization:

Urbanization remains a central growth engine for the earthmoving equipment market. As global populations increasingly migrate toward urban centers, the demand for residential developments, commercial infrastructure, and public utilities—such as metro systems and roadways—continues to rise. This is especially prominent in developing regions like Asia Pacific and Africa, where construction activity is surging to meet the needs of expanding urban populations.

In addition, urban redevelopment initiatives in developed economies, including those in North America and Europe, are bolstering the need for earthmoving equipment. The rise of smart cities, which emphasize integrated, technology-driven infrastructure, ensures ongoing demand for machinery such as bulldozers, backhoes, and loaders. Collectively, these trends underscore urbanization as a pivotal force shaping the future of the earthmoving equipment market.

Earthmoving Equipment Market Segmentation Analysis

The earthmoving equipment market analysis is derived from three primary segments: product type, power output, and end-user industry.

By Product Type

The market is segmented into:

Excavators

Loaders

Bulldozers

Backhoe Loaders

Others

In 2024, excavators dominated the market due to their versatility and widespread usage across construction, mining, and infrastructure development projects. Their ability to perform multiple functions—such as digging, lifting, and material handling—makes them a preferred choice over other types of earthmoving equipment.

By Power Output

The market is categorized into:

Below 100 HP

101–200 HP

Above 200 HP

The 101–200 HP segment led the market in 2024. This mid-range power band offers an optimal balance between performance and cost-efficiency, making it ideal for diverse applications in construction. In markets like India, this segment holds around 38% share, underscoring its dominance due to superior engine capabilities, fuel efficiency, and adaptability across varied terrain and project sizes.

By End-User Industry

End users of earthmoving equipment include:

Construction

Mining

Agriculture & Forestry

Others

The construction segment held the largest market share in 2024. The dominance of this segment is driven by the expanding demand for earthmoving equipment in residential, commercial, and public infrastructure projects worldwide. Equipment is essential for foundational work, site preparation, and the transport of heavy materials—making construction the most critical application area.

Market Drivers and Opportunities

1. Rapid Urbanization and Infrastructure Investment

Global urbanization continues to be a significant growth catalyst for the earthmoving equipment market. The migration of populations to urban centers fuels demand for housing, commercial buildings, and public infrastructure such as roads and metros. This trend is particularly evident in emerging economies like India and China, where urban expansion drives massive construction activity. Additionally, developed regions in Europe and North America are investing in urban redevelopment and smart cities, reinforcing long-term equipment demand.

Parallelly, governments worldwide are increasing investments in large-scale infrastructure projects to boost economic growth. Projects involving highways, bridges, airports, and rail networks require heavy-duty machinery, thereby fueling demand. Public-private partnerships and sustainable infrastructure development further contribute to this growth trend.

2. Rising Demand for Sustainable Equipment

The shift toward environmental sustainability is creating significant opportunities for manufacturers. There is increasing demand for electric and hybrid earthmoving equipment that reduces carbon emissions and operational noise—especially in urban projects. Regulatory pressures, such as stricter emission norms in Europe and North America, are accelerating the adoption of eco-friendly technologies.

Manufacturers investing in R&D to create energy-efficient, low-emission machinery are gaining competitive advantages and appealing to environmentally conscious clients. The demand for sustainable solutions aligns with global climate commitments, creating new revenue channels and expanding the market’s future potential.

Conclusion

The earthmoving equipment market in 2024 is primarily led by excavators, the 101–200 HP power category, and the construction industry. Urbanization, infrastructure spending, and sustainability initiatives are key drivers, with the potential for further growth driven by technological advancements and environmental regulations. As global development accelerates, the demand for efficient, versatile, and eco-conscious equipment is expected to rise steadily.

Market leaders and key company profiles Caterpillar Inc.

Komatsu Ltd.

John Deere

XCMG Group

Liebherr Group

SANY Group

Volvo Construction Equipment

Hitachi Construction Machinery

JCB

Doosan Bobcat Earthmoving Equipment Market Report Coverage and Deliverables

The "earthmoving equipment Market Size and Forecast (2021–2031)" report provides a detailed analysis of the market covering below areas:

Medical earthmoving equipment market size and forecast at global, regional, and country levels for all the key market segments covered under the scope

Medical earthmoving equipment market trends, as well as market dynamics such as drivers, restraints, and key opportunities

Detailed Porter's Five Forces and SWOT analysis

Medical earthmoving equipment market analysis covering key market trends, global and regional framework, major players, regulations, and recent market developments

Industry landscape and competition analysis covering market concentration, heat map analysis, prominent players, and recent developments for the earthmoving equipment market

Detailed company profiles

Geographical Scope and Regional Insights – Earthmoving Equipment Market

The earthmoving equipment market is analyzed across five key regions: North America, Asia Pacific, Europe, the Middle East & Africa, and South & Central America. Among these, the Asia Pacific region is anticipated to experience significant growth during the forecast period.

The global earthmoving equipment market exhibits distinct regional characteristics shaped by diverse infrastructure development priorities, economic landscapes, and industrial expansion. Asia Pacific leads as the dominant region, driven by rapid urbanization, rising construction activity, and large-scale infrastructure and mining projects—particularly in high-growth economies such as China and India.

North America represents a mature but steadily advancing market, fueled by smart city initiatives, infrastructure revitalization programs, and the integration of cutting-edge technologies in construction machinery. In Europe, environmental regulations and sustainability goals are shaping market trends, with a rising preference for electric and hybrid earthmoving equipment to align with stringent emission standards and green construction mandates.

Earthmoving Equipment Market Report Structure

The market research report delivers a comprehensive mix of qualitative and quantitative insights across key segments including product type, portability, technology, application, end-user, and geography.

Chapter 2 outlines the key takeaways, including market trends and forward-looking insights.

Chapter 3 presents the research methodology adopted for the analysis.

Chapter 4 provides an ecosystem overview and Porter’s Five Forces analysis.

Chapter 5 discusses major industry dynamics—highlighting market drivers, restraints, opportunities, and emerging trends, along with their impact.

Chapter 6 details the historical performance and forecast of market revenues through 2031.

Chapters 7 to 10 focus on segmental analysis by product type, power output, end-user industry, and regional markets—covering North America, Europe, Asia

About Us: Business Market Insights is a market research platform that provides subscription service for industry and company reports. Our research team has extensive professional expertise in domains such as Electronics & Semiconductor; Aerospace & Défense; Automotive & Transportation; Energy & Power; Healthcare; Manufacturing & Construction; Food & Beverages; Chemicals & Materials; and Technology, Media, & Telecommunications Author's Bio Akshay Senior Market Research Expert at Business Market Insights

0 notes