#MaterialHandling

Explore tagged Tumblr posts

Text

Chain Sling - Lifting Chains | Kito - Lifting Equipment

The Grade 100 chain sling was developed by Kito Chain Italia's long experience and accumulated technology. A range of solutions for lifting with chains.

2 notes

·

View notes

Text

ACE F150 4WD NextGen Pick and Carry Crane,- the perfect machine for all your lifting needs! With a maximum capacity of 15 tons and a range of features, you can trust this machine to get the job done quickly, efficiently, and safely.

#ACE#ACECranesIndia#acef150#f150crane#f15#mobilecranes#crane#hydracrane#4wd#nextgenpickncarrycrane#acecranes#cranes#lifting#machines#faranacrane#farana#newgenerationcrane#15toncrane#heavylifting#materialhandling#pickandcarry#construction

2 notes

·

View notes

Text

Discover top-notch Forklifts from reliable manufacturers and suppliers in UAE at TradersFind. Whether you need to lift, move, or store, our verified companies offer the best solutions tailored to your needs. 📦✨

Connect with us on WhatsApp at +971 56 977 3623 to discuss your Forklift requirements.

Visit TradersFind today and connect with the right manufacturers and suppliers to elevate your operations. https://www.tradersfind.com/category/forklift

Forklifts In UAE

#forklift#forklifttrucks#materialhandling#warehouseequipment#uaebusiness#tradersfind#logistics#supplychain#heavymachinery#industrialequipment#businessgrowth#forkliftrental#forkliftsales#warehousesolutions#b2bmarketplace#equipmentsuppliers#businessnetworking#liftandmove#uaelogistics#connectandgrow

2 notes

·

View notes

Text

Onshore Toyo

Elevate your lifting game and experience pure power in your hands with Toyo's game-changing Wire Rope Winches.

Designed with YOU in mind, these winches redefine convenience, control, and confidence in every lift.

🔗 Your Power, Your Control: With Toyo Wire Rope Winches, you're in charge. Feel the thrill of controlling heavy loads with precision, making lifting tasks a breeze.

⚙️ Effortless Mastery: Wave goodbye to manual labor. Toyo Wire Rope Winches bring ease to every lifting operation, letting you conquer challenges with efficiency.

🔄 Versatile Performance: From construction to logistics, Toyo's winches adapt to your needs, ensuring every lift is a success story waiting to happen.

🚀 Elevate Your Potential: Boost your lifting potential with Toyo Wire Rope Winches. Minimize effort, maximize productivity, and see your goals reach new heights. Ready to embark on a lifting journey like never before? Experience the power and control of Toyo Wire Rope Winches.

Get in touch today: 👉 WhatsApp: wa. me/966544580607

📞 Call: +966 54 458 0607

📧 Email: [email protected]

💻 Website: lifting.onshoretechnical.com

👉 Like 👍 | Share 🔁 | Comment 💬 | Tag your lifting partners! 🏆🔧

#ToyoLifting#WireRopeWinch#CustomerCentric#ElevateYourLift#EfficiencyBoost#PrecisionControl#IndustrialInnovation#LiftingSolutions#WorkplaceProductivity#ReliableTools#Toyo#Wirerope#IndustrialEquipment#MaterialHandling#Lifting#Winching#HeavyDuty#Manufacturing#Efficiency#Productivity#WorkplaceSafety#Reliability#Durability#Quality#Engineering#Logistics

4 notes

·

View notes

Text

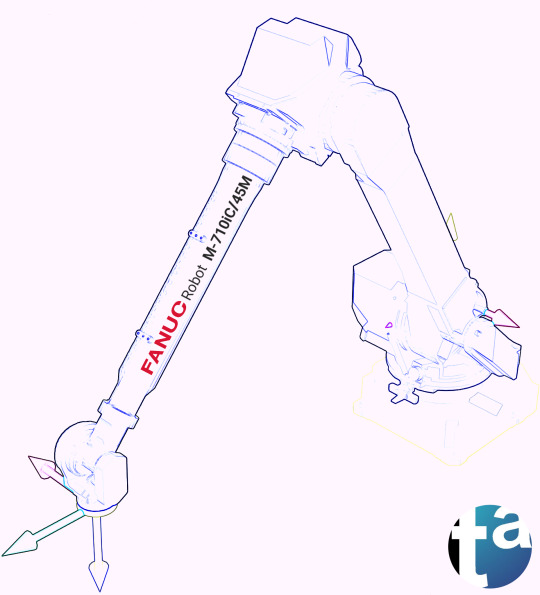

🦾 A007 - Palletizing Robot FANUC M-710iC/45M FanucAmerica Vision Reading QRCodes Automation Manipulator MaterialHandling Robotics ▸ TAEVision Engineering on Pinterest

Data A007 - Jul 17, 2023

#automation#robot#robotics#palletizing#FANUC#FanucAmerica#M-710iC/45M#FANUC M-710iC/45M#Vision Reading QRCodes#manipulator#MaterialHandling

5 notes

·

View notes

Text

Battery Scissor Lifts – Tallboy Lifts

In today’s fast-paced industrial and construction environments, efficiency and safety are top priorities. One piece of equipment that plays a crucial role in improving productivity is the Battery Scissor Lift. These lifts provide a reliable and eco-friendly alternative to traditional hydraulic or diesel-powered scissor lifts, making them a preferred choice for many industries.

Know more info:- https://www.tallboy.in/battery-scissor-lifts-tallboy-lifts

#batteryscissorlift#scissorlift#tallboylifts#liftingsolutions#constructionequipment#industrialequipment#ecoFriendlyequipment#workplatform#materialhandling#electriclift

0 notes

Text

https://www.techi.com/cartken-hauler-autonomous-robot-material-transport/

#Cartken#AutonomousRobots#AIinLogistics#LastMileDelivery#MaterialHandling#IndustrialAutomation#RoboticsTechnology#AIpowered#LogisticsInnovation#Automation#DeliveryRobots#AIinIndustry#TechInnovation#RoboticsInBusiness

0 notes

Text

Manually Transfer Trolley

Cubuilt Manually Transfer Trolley is a highly efficient and adaptable material handling solution, designed to easily move smaller loads across short distances. This trolley can be manually dragged along rails or towed by other trolleys, forklifts, winches, and trailers, making it a versatile tool for any industrial setting.

Why Choose Cubuilt Manually Transfer Trolley?

Efficient Material Movement: Ideal for transporting smaller loads, especially in confined spaces or narrow passageways. The trolley helps you move long loads through restrictive areas, enhancing workflow.

Space-Saving Design: Its compact structure makes it perfect for areas with limited floor space, unlike larger equipment like forklifts that require more room to operate.

Customizable Platform: The trolley can be tailored to fit specific load types, ensuring compatibility with various materials and industrial applications.

Cost-Effective Solution: Perfect for businesses needing a cost-efficient alternative to forklifts for smaller load handling, without sacrificing performance.

User-Friendly: It can be manually operated or towed by other equipment, providing flexibility for various operational needs.

The Cubuilt Manually Transfer Trolley is the ideal choice for companies seeking a versatile, space-efficient, and easy-to-use material handling solution.

Contact us :- https://cubuilt.com/products/manually-transfer-trolley/

#ManuallyTransferTrolley#MaterialHandling#EfficientLogistics#CompactDesign#SpaceSavingSolutions#MaterialShuttling#CustomTrolleys#IndustrialHandling#LoadMovement#ForkliftAlternative#WorkshopEquipment#ProductivityBooster#FactoryAutomation#WarehouseSolutions#EasyToManeuver#HeavyDutyTransport#IndustrialEquipment#CostEffectiveSolution#CustomizableTrolley#LogisticsSupport#IndustrialMachinery#TrolleySystems#MadeInIndia#EfficientHandling#ManufacturingInnovation#TransportSolutions#TrolleyHandling

0 notes

Text

Are Gas Forklifts the Same as LPG Forklifts? Here’s the Truth You Need to Know

When it comes to forklifts, the terminology you use matters — especially when making purchase decisions or advising clients. One of the most common areas of confusion is between “gas forklifts” and “LPG forklifts.” Are they the same? Let’s dive in. What Is an LPG Forklift? An LPG forklift runs on Liquefied Petroleum Gas, typically propane or a propane-butane mix. LPG is stored under pressure as…

#EGAN#forkliftmalaysia#forkliftnation#forklifts#gasforklifts#IndustrialEquipment#lovelaughlift#lpgforklifts#materialhandling

0 notes

Text

Ash handling is crucial in industries like power generation and cement production, requiring efficient systems to manage large volumes while minimizing wear and energy consumption. Two primary pneumatic conveying methods—dense phase and lean phase—offer distinct advantages. Dense phase systems operate at low velocity and high pressure, moving ash in compact slugs, reducing wear, and enhancing energy efficiency. In contrast, lean phase systems use high velocity and low pressure, keeping ash suspended in the air stream but causing more equipment wear. While dense phase is ideal for abrasive or fragile materials, lean phase suits lighter, non-abrasive ones. Selecting the right system depends on material properties, energy efficiency, and infrastructure constraints.

#AshHandling#PneumaticConveying#DensePhase#LeanPhase#IndustrialAutomation#MaterialHandling#EnergyEfficiency#BulkMaterialHandling#PowerPlantOperations#CementIndustry#ConveyingSystems#AshConveying#IndustrialProcessing#BulkHandling#EngineeringSolutions#EfficientTransport#IndustrialEquipment#ManufacturingProcess#SustainableEngineering#PlantMaintenance#IndustrialEfficiency#PowderHandling#AirConveying#SystemOptimization#HeavyIndustry#OperationalExcellence

0 notes

Text

SMD AGV Wheels – Precision Mobility for Automated Operations

AGVs ensure precise, efficient material handling in warehouses and factories. SMD's AGV wheels offer durability & reliable performance for seamless automation.

Key Characteristics & Features:

High Load Capacity for Industrial Applications

Low Friction & Smooth Operation for Maximum Efficiency

Maintenance-Free & Long Service Life

Precision Control for Accurate Navigation

Maximize AGV performance with Long Lasting & high-performance wheels.

#SMDGearbox#AGVWheel#AutomatedGuidedVehicle#SWTseries#MaterialHandling#IndustrialAutomation#WarehouseSolutions#ManufacturingExcellence

0 notes

Text

Who Benefits from Lakhotia's Heavy-Duty Conveyor Belts?

Lakhotia’s heavy-duty conveyor belts are designed to meet the toughest challenges in a variety of industries. Our belts provide unmatched strength, durability, and reliability, making them ideal for the most demanding material handling tasks.

📞 Call: +919025194360 🌐 Visit: www.lakhotiaindia.in

#HeavyDutyConveyorBelts#IndustrialSolutions#MaterialHandling#LakhotiaIndia#MiningConveyors#ConstructionBelts#SteelIndustry#BulkMaterialHandling#WarehouseLogistics#WasteManagement#RecyclingSolutions#ReliableConveyors#DurableBeltSystems#EfficientOperations#ToughConditions#EngineeringExcellence

0 notes

Text

Enhance Your Material Handling Efficiency with Grab Buckets

In industries where handling bulk materials is a daily necessity, grab buckets have become indispensable for improving efficiency and reducing manual labor. These heavy-duty lifting devices are widely utilized in ports, construction sites, steel plants, and waste management facilities for seamless handling of materials such as scrap, coal, sand, and gravel.

What is a Grab Bucket?

A grab bucket is a mechanical device designed to lift and transport bulk materials with ease. Operated using either a hydraulic or mechanical system, it efficiently opens and closes its jaws to securely grasp and release materials, ensuring smooth and efficient material handling.

Key Features of Grab Buckets

High Load Capacity – Capable of handling large volumes of bulk materials effortlessly.

Durable Construction – Built with high-quality steel to withstand heavy loads and extreme working conditions.

Precision Control – Ensures accurate material handling with minimal spillage.

Customizable Options – Available in various sizes and configurations to meet different industrial needs.

Hydraulic & Mechanical Variants – Choose the option that best fits your operational requirements.

Applications of Grab Buckets

Steel & Scrap Industries – Facilitates the efficient lifting and transportation of scrap metal.

Ports & Shipping Yards – Essential for loading and unloading bulk cargo.

Construction & Mining – Handles gravel, sand, and stones efficiently.

Waste Management – Streamlines the movement and processing of waste materials.

Power Plants – Ensures safe and effective transportation of coal and other raw materials.

Why Choose LeisterTech Grab Buckets?

LeisterTech is a trusted provider of high-performance grab buckets designed to meet the rigorous demands of industrial material handling. Our grab buckets are engineered for efficiency, durability, and reliability, ensuring seamless operations in heavy-duty environments.

Benefits of LeisterTech Grab Buckets

Enhanced Efficiency – Reduces handling time and lowers labor costs.

Robust Build – Designed for long-lasting and consistent performance.

Versatile Applications – Suitable for a wide range of industries.

Professional Support – Backed by expert maintenance and technical assistance.

Upgrade Your Material Handling with LeisterTech!

If you're looking for a high-quality grab bucket to enhance your industrial operations, LeisterTech has the perfect solution for you. Contact us today to discuss your specific requirements and find the ideal fit for your industry.

☎ Call us at: +91 93289 16310 / +91 99091 79617 📧 Email us at: [email protected] 🌍 Visit our website: LeisterTech.com

Boost your material handling efficiency with LeisterTech’s premium grab buckets!

#GrabBuckets#MaterialHandling#IndustrialEquipment#BulkMaterialHandling#LeisterTech#HeavyDutyMachinery#ConstructionEquipment#ScrapHandling#WasteManagement#SteelIndustry

0 notes

Text

Mastering Safe Operations with Expert Training! Safety in Material Handling Equipment Operation isn’t just a practice—it’s a necessity! CORE EHS recently conducted an in-depth training session in Aurangabad, empowering engineers, supervisors, and operators from the manufacturing industry with critical skills for safe and efficient equipment handling. From risk assessment to hands-on techniques, our expert trainer ensured that safety remains a top priority in every operation. Because proper training prevents accidents before they happen! How does your team prioritize safety in material handling? Let’s talk!

#SafetyFirst#MaterialHandling#EquipmentSafety#WorkplaceSafety#SafeOperations#PreventAccidents#SafetyCulture#RiskManagement#SafetyInAction#HealthAndSafety#EmployeeWellbeing

0 notes

Text

High-Performance Busbar Systems | KITO – Reliable Power Distribution Solutions

KITO's Busbar systems offer a highly efficient, space-saving, and reliable solution for power distribution in industrial and commercial setups. Designed for optimal conductivity, durability, and easy installation, our Busbars ensure seamless energy flow with minimal power loss. Whether for factories, data centers, or commercial buildings, KITO provides customized Busbar solutions tailored to meet modern energy demands. Upgrade to a smarter power distribution system today!

#kito india#kitoindia#materialhandling#liftingequipment#industrialtrolley#industrialequipment#busbar#busbarsolutions

0 notes

Text

TAEVision 3D Mechanical Design MaterialHandling ForkLift Trucks ATLAS TOYOTA Toyota-Lift of Minnesota @ToyotaEquipment Toyota ▸ TAEVision Engineering on Pinterest ▸ TAEVision Engineering on Google Photos

Data 037 - Jul 16, 2023

#TAEVision#engineering#3d#mechanicaldesign#MaterialHandling#forklift#trucks#ATLAS TOYOTA#TOYOTA#Toyota-Lift of Minnesota#ToyotaEquipment

2 notes

·

View notes