#chocolate manufacturing

Explore tagged Tumblr posts

Text

Buy Dark Chocolate Online in the UAE from Zokolat Chocolates

Embark on a journey of decadence with Zokolat Chocolates, your go-to destination for premium dark chocolate online in UAE. Enjoy the convenience of ordering dark chocolate online in the UAE through our secure and user-friendly website.

VISIT US TO BUY - https://www.zokolat.com/product/candied-fruits-with-rise-crispies/

#zokolat chocolates#best chocolates in dubai#buy chocolates online#best dark chocolate#best milk chocolates#dark chocolates#online chocolate delivery in dubai#best dark chocolates#chocolate manufacturing#dark chocolate

0 notes

Text

This Chocotech Sucromaster® is used for the production of Hard Candies especially designed for Sugar and sugar-free masses, Milk hard caramels, laminated hard caramels, Medical hard candies, Aerated Hard Candies etc. Here the process consist of cooking, vacuuming, screw extraction of the mass, dynamic mixing, tempering and aerating where the high vacuum system guarantees low inversion and minimal aroma loss due to the low temperature of the mass. For More Information, Click here - https://vedicsystems.com/chocotech/

#chocotech cooker#chocotech#chocolate manufacturing#chocolate manufacturing machines#automation#vedicpacsystems#vedicsystems#food processing#automatic transmission#food machine#machine

0 notes

Text

Another weird question for y'all: If you are moderately allergic* to a thing and had been eating it anyway for years because you didn't know, and then when you figure out what you're allergic to you quit eating it at all, can you lose your ability to tolerate even a little bit of it? *a phrase which here means "probably severely allergic but can tolerate small amounts when on antihistamines"

#the person behind the yarn#allergy mention#food mention#I am not sure what I reacted to so severely today#and based on what I ate yesterday there's a chance my burger was cross contaminated with pickle juice#so I could be vinegared?#and it could be that this is just what vinegar allergic reactions are for me now#or it could be the german chocolate baking chocolate bar which I've never had before#or it could be my usual antihistamines but from a new manufacturer so new inactive ingredients#which means tonight instead of my usual double dose of off brand allegra I took benadryl#(DO NOT use my antihistamine usage as a guide. I take very high levels as directed by my doctors)#(seriously for most people this is both overkill and a bad idea)

22 notes

·

View notes

Text

it's been a while since i've cried hard enough to have a headache but. sure got there today, babes!

#ghost speaks#personal#ripped my favorite tights i've had for 5+ years and can't replace#can't return my glasses#got ptsd triggered by going past my old church because i took a wrong turn because i was. crying about not being able to return my glasses#have been crying for a solid 40 minutes straight#am still incredibly aware of how isolated and lonely i am#my parents are on vacation so i won't see a friendly face or get a hug till sunday night at the earliest#just. doing BAD#(well. there is the faint hope that the office manager will take pity on me since her office literally cannot manufacture lenses#that will meet my needs)#(but considering i spent a lot of the last hour yelling and begging out loud trying to work out a maximally sympathetic pitch)#(and also dreading 1-2 years of not having transition lenses because theirs fuck with my color vision)#(i'm not sure the hope makes things. better?)#i am gonna. make hot chocolate because it sounds like a marginal improvement over crying without that#the last time i couldn't stand up or i'd start crying harder was yesterday but boy did i not miss it#i thought i might feel better in the morning. ha. ha ha. ha#(like i know this is temporary i'm just. i just. i am so tired and SO stupidly ridiculously incredibly upset)#(like my emotional equilibrium right now is. not)

14 notes

·

View notes

Text

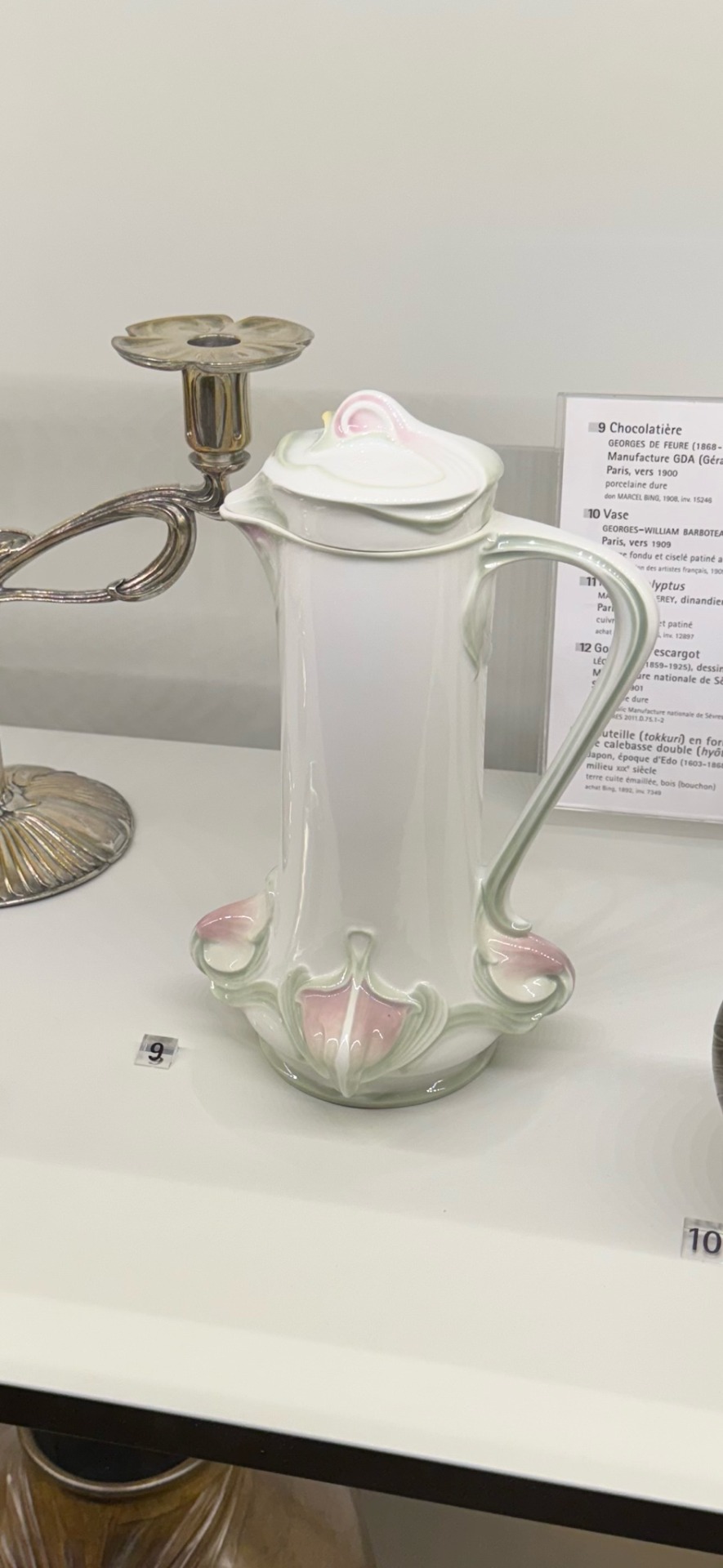

Chocolatière from 1900s, Musée des Arts Décoratifs, Paris

#art deco#art#decorative#museedesartsdecoratifs#museum#paris#object#design#1900s#france#manufacture#porcelain#faeriecore#faerie tales#faerie#tableware#hot chocolate

9 notes

·

View notes

Text

Pop n pop is a Assorted center-filled candy that surprises everyone with one bite. Magical Fruit Flavored Candy that make your kids want to crave more.

https://bakemate.in/

#bakemate#biscuit manufacturers#fmcg#biscuits#chocolate manufacturers#wafer biscuits suppliers and exporters to canada#candy

2 notes

·

View notes

Text

#JLMManufacturing #JLMManufacturingChocolateBridgeMix #ChocolateBridgeMixCandy #BridgeMix #BridgeMixChocolateCandyReview

I tried the JLM Manufacturing Chocolate Bridge Mix and these were pretty good.

This was both soft, chewy, crunchy, and easy to eat.

This chocolate tasted not artificial tasting to me and was creamy.

The bridge mix had raisins, malted milk balls, chocolate coated cream pieces, and peanuts

These had a light sweet and salty to me.

I would eat these again.

Got at Gordons.

#JLM Manufacturing#JLM Manufacturing Chocolate Bridge Mix#Chocolate Bridge Mix Candy#Bridge Mix#Bridge Mix Chocolate Candy Review

5 notes

·

View notes

Text

Easter 2023

#my photography#my photos#photography#easter#chocolate#easter bunny#chocolate bunny#i'd seen smaller ones from the same manufacturer#but didn't know the huge ones existed.#madge's

3 notes

·

View notes

Text

i really need to cut out refined sugar

#like im actually addicted to it its so bad#i do use it as a coping mechanism i think anytime i feel sad or depressed or stressed#its such an unhealthy coping mechanism#my friend is in a similar situation and recently cut out chocolate to prove to herself that she could and that she had enough self control#so i might ask her for some advice#i like to think that most of my dietary habits are pretty good. like i dont drink a lot of alcohol (most of the time). i dont smoke.#i cook from scratch most of the time. i dont eat a lot of salty food. i eat a lot of fruit and veg etc#its just refined sugars like chocolates and biscuits that are my poison fr#and also hidden sugars cause manufacturers straight up put it in everything these days like a lot of baked beans have added sugar in them

2 notes

·

View notes

Text

#random wikipedia articles#wikipedia#white chocolate#chocolate#white chocolate is made with coco butter not coco solids#invented in 1936#started being manufactured in the USA in 1984

0 notes

Text

Elevate your chocolate journey today and discover the epitome of luxury and refinement in every delightful sip. Experience the bliss of premium drinking chocolate online shop in Dubai - start your indulgent experience with Zokolat Chocolates now.

#zokolat chocolates#best chocolates in dubai#buy chocolates online#best dark chocolate#best dark chocolates#best milk chocolates#dark chocolates#online chocolate delivery in dubai#chocolate manufacturing#dark chocolate

0 notes

Text

The Role of Plastic Injection Mold Design in Creating Plastic Chocolate Molds

The art of chocolate-making has evolved significantly with the advent of advanced manufacturing techniques. One critical component in the production of beautifully shaped and precise chocolate products is the use of plastic chocolate molds. These molds, crafted through meticulous plastic injection mold design, ensure consistency, quality, and creativity in chocolate production.

What are Plastic Chocolate Molds?

Plastic chocolate molds are specialized tools used to shape molten chocolate into various forms, from simple bars to intricate designs. These molds are typically made from durable, food-grade plastic that can withstand the heat of molten chocolate while providing a smooth surface for easy release. Their widespread use in both artisanal and industrial chocolate-making underscores their importance in achieving professional-grade results.

The Importance of Plastic Injection Mold Design

The creation of plastic chocolate molds begins with plastic injection mold design. This process involves designing and manufacturing the mold cavities that will be used to shape the plastic. A well-executed design ensures the final product—in this case, the chocolate mold—is functional, durable, and precise.

Key Elements of Plastic Injection Mold Design:

Precision Engineering: The mold must be designed to exact specifications, ensuring the chocolate mold produces consistent shapes every time.

Material Selection: High-quality, food-safe materials are essential for creating molds that meet hygiene and safety standards.

Thermal Properties: The design must account for the heat resistance of the plastic to ensure it performs well under the conditions of chocolate production.

Ease of Use: A well-designed mold allows for easy demolding, minimizing damage to delicate chocolate creations.

Benefits of Using Plastic Chocolate Molds

Consistency: Plastic chocolate molds ensure uniformity in size and shape, making them ideal for mass production.

Customization: With the flexibility of plastic injection mold design, manufacturers can create custom molds for unique shapes and branding.

Cost-Effectiveness: Plastic molds are durable and reusable, offering excellent value for both small-scale chocolatiers and large manufacturers.

Creative Freedom: The precision of plastic injection mold design enables intricate and innovative designs, adding aesthetic appeal to chocolate products.

How Plastic Injection Mold Design Impacts Chocolate Production

A well-thought-out plastic injection mold design streamlines the production process, reducing waste and improving efficiency. For example, the inclusion of cooling channels in the mold design can help speed up the cooling process of molten chocolate, enabling faster production cycles. Additionally, careful consideration of cavity alignment and release mechanisms ensures the chocolate comes out cleanly, reducing the need for manual adjustments or rework.

Trends in Plastic Chocolate Mold Manufacturing

As technology advances, manufacturers are exploring new ways to enhance plastic injection mold design. Innovations like 3D printing allow for rapid prototyping and testing of mold designs, while sustainable materials are becoming increasingly popular for eco-conscious brands. These trends not only improve the production process but also align with consumer demand for environmentally friendly practices.

Conclusion

The creation of plastic chocolate molds is a testament to the sophistication of plastic injection mold design. By combining precision engineering with high-quality materials, manufacturers can produce molds that meet the demands of chocolatiers worldwide. Whether for artisanal creations or large-scale production, the right plastic chocolate mold can elevate the quality and appeal of chocolate products, ensuring sweet success for every maker.

#plastic injection mold design#plastic chocolate molds#plastic moulding manufacturers#injection frisbee#plastic injection molding manufacturer#best injection molding company#plastic injection mould manufacturer#injection molding solutions#injection molding maker

0 notes

Text

L'Injection Plastique au Service des Fabricants d'Emballage de Chocolat

L'emballage joue un rôle crucial dans l'industrie du chocolat, non seulement pour protéger le produit, mais aussi pour attirer les consommateurs grâce à un design attrayant. Parmi les technologies les plus utilisées dans la fabrication de ces emballages, l'injection plastique se distingue par sa polyvalence et son efficacité. Dans cet article, nous explorons comment les fabricant emballage chocolat utilisent l'injection plastique pour répondre aux besoins de ce marché exigeant.

Pourquoi l'emballage est essentiel dans l'industrie du chocolat

L'emballage d'un produit chocolaté remplit plusieurs fonctions clés :

Protection : Il préserve le chocolat des agressions extérieures telles que l'humidité, la lumière et les variations de température.

Attrait visuel : Un emballage bien conçu attire l'œil des consommateurs et renforce l'image de marque.

Praticité : Les consommateurs recherchent des emballages faciles à ouvrir et à refermer, adaptés à leurs besoins quotidiens.

Durabilité : Avec une sensibilisation croissante aux questions environnementales, les emballages doivent être conçus dans une optique de durabilité et de recyclabilité.

L'injection plastique : une technologie clé pour les fabricants d'emballage

L'injection plastique est une méthode de fabrication qui consiste à injecter du plastique fondu dans un moule pour créer des objets aux formes précises. Cette technique est particulièrement prisée par les fabricants d'emballage de chocolat pour plusieurs raisons :

Flexibilité de conception : L'injection plastique permet de créer des emballages aux designs variés et innovants, adaptés aux besoins spécifiques des clients.

Production en grande série : Cette technologie est idéale pour produire rapidement et efficacement de grandes quantités d'emballages.

Réduction des coûts : Bien que l'investissement initial dans les moules puisse être élevé, les économies réalisées sur le long terme en font une option rentable.

Personnalisation : Les fabricants peuvent intégrer des logos, des motifs ou des textures directement dans les moules, offrant ainsi des possibilités infinies de personnalisation.

Les applications de l'injection plastique dans l'emballage de chocolat

L'injection plastique permet de créer une large gamme de solutions d'emballage pour le chocolat, notamment :

Boîtes et coques rigides : Utilisées pour les chocolats haut de gamme, elles offrent une présentation élégante tout en protégeant efficacement le produit.

Plateaux thermoformés : Ces supports permettent de maintenir les pralines et autres chocolats en place, évitant ainsi qu'ils ne s'abîment pendant le transport.

Capsules et fermetures : Pour les emballages refermables, l'injection plastique permet de produire des systèmes de fermeture précis et faciles à utiliser.

Accessoires promotionnels : L'injection plastique est également utilisée pour créer des objets promotionnels associés aux chocolats, comme des figurines ou des décorations.

Vers une production durable : le rôle des matériaux

Face aux préoccupations environnementales croissantes, les fabricants d'emballage de chocolat cherchent à adopter des solutions plus durables. L'injection plastique évolue pour répondre à ces exigences, notamment par :

L'utilisation de plastiques recyclés : De plus en plus de fabricants intègrent des matériaux recyclés dans leurs processus de production.

Le développement de plastiques biodégradables : Ces matériaux offrent une alternative écologique, réduisant l'impact environnemental des emballages.

L'optimisation des designs : Des emballages plus légers et plus compacts permettent de réduire la consommation de matière première tout en maintenant la fonctionnalité.

Conclusion

L'injection plastique joue un rôle fondamental dans la conception et la production d'emballages pour l'industrie du chocolat. Grâce à cette technologie, les fabricants d'emballage de chocolat peuvent répondre aux attentes des consommateurs en matière de qualité, de design et de durabilité. En s'appuyant sur des matériaux innovants et des procédés optimisés, ils participent également à la transition vers une industrie plus respectueuse de l'environnement. Que ce soit pour des boîtes luxueuses ou des solutions pratiques et écologiques, l'injection plastique reste une alliée incontournable dans ce secteur gourmand.

#moulage par injection#injection plastique#pommeau de douche anti calcaire#pommeaux douche#plastic molds for chocolate making#plastic moulding manufacturers#pièces en plastique de moulage par injection#pommeaux de douche#moule injection plastique#moules d’injection

0 notes

Text

Crunchy or Smooth? Try Our Premium Peanut Butter

Are you looking for best peanut butter manufacturer in India then Sonya Foods is premium peanut butter manufacturer. Sonya Foods is provide premium quality butter made from the finest roasted peanuts. Our products are rich protein and it’s free from preservative and available in smooth and crunchy variants.

SonyaFood known that great peanut butter start with great ingredients. That why we sourcing peanut from trusted farmer and we are flowing accurate quality control processes to delivered product that smooth, flavourful and packed with protein. If you want classic spread or something with twist then SonyaFood is providing variety option to suit your plate.

Our wide range of product that compete to every taste and providing something for everyone. SonyaFood we believe that great peanut butter starts with great ingredients. Visit our website sonyafoods.com for our delicious offer and that why SonyaFood is best peanut manufacturer in India.

#peanut butter#peanut butter manufacturer#peanut butter supplier#chocolate peanut butter#crunchy peanut butter#chocolate peanut butter manufacturer#chocolate peanut butter supplier#almond butter manufacturer#crunchy peanut butter manufacturer#peanut butter in ahmedabad

0 notes

Text

Chocolate wrapping has come a long way from the simple hand-wrapping techniques of the past to the fully automated, high-tech machines of today. Over the years, the packaging process has evolved to meet increasing demand, enhance product presentation, and ensure extended shelf life. In this blog, we’ll take a fascinating journey through the history of chocolate wrapping and explore how cutting-edge technology is shaping the future of confectionery packaging.

1 note

·

View note

Text

BBL Foods 5 roll refiner machinery is stated to present top notch outcomes because of its uniform molecular size. Always do not forget this technique for sensitive chocolates, coatings, spreads and creams. It`s top notch how this material, presenting precision insulation, reduces power consumption, saving cash and time.

#biscuit machine manufacturer#5 roll refiner machinery#food manufacturing consultants#chocolate machines manufacturer#chocolate moulding machines#pasta line supplier

0 notes