#casting of cylinder liner

Explore tagged Tumblr posts

Text

Diesel and Marine Engine Cylinder Liners and Sleeves

A complete cylinder liner repair and reconditioning service is provided by RA Power Solutions. Your cylinder liners will be examined by our team of skilled engineers and technicians for any cracks, wear, or other damage. In order to verify that the cylinder liners meet or exceed factory requirements, we shall, if necessary, repair or replace them. Your cylinder liners will remain in good shape for many years to come since we also provide a 12-month warranty on our reconditioning services. For more information about babbitt white metal,rebabbitting of bearing, contact us by email at [email protected], 0124-425-1615, or +91-9810012383.

#cylinder liner repair#diesel engine repair#cylinder liners#cylinder liners and cylinder sleeves#casting of cylinder liner#diesel engines

0 notes

Text

youtube

Revitalize your engine's performance and safeguard its longevity with our expert Cylinder Liner Crack Repair using Metal Lock technology. Say goodbye to costly replacements and downtime caused by cracks. Our proven solution ensures seamless restoration, bolstering durability and efficiency. Don't let cracks compromise your engine's reliability. Act now to experience enhanced performance and peace of mind. Contact us today to schedule your Cylinder Liner Crack Repair and keep your machinery running smoothly for years. For more details on repair of cracked cylinder liner of the MAN main engine Email us at [email protected] or call +91 9810012383.

#Cylinder Liner Crack Repair by Metal Lock#Metal Lock and Metal Stitching#repair of cracked cylinder liner#crack repair of engine components#crack repair by metal lock#metal lock and metal stitching process#metal stitching and locking#repair broken cast iron cylinder liner#metal stitching of engine block#Youtube

0 notes

Text

weltop machinery Click here to quickly check the video, and we recommend this for you: https://weltop.en.made-in-china.com/product-group/obXTJvIlhgYV/Automatic-Long-Tube-Centrifugal-Casting-Machine-catalog-1.html?utm_source=facebook&utm_medium=free&utm_campaign=featured_video_pc&utm_content=YMNxeRbEJkpP_00&utm_term=wQYfXWHdCrUK

#centrifugal casting machine#casting machine#cylinder liner#cylinder sleeve#casting machine low-pressaluminium alloy

0 notes

Text

youtube

RA Power Solutions is the largest Allen cylinder manufacturer and producer. We have the manufacturing drawings available for most of the models of the popular engines. We also manufacture the cylinder liners as per the drawing and chemical composition of a cylinder liner provided by the clients. The liners can also be developed and manufactured as per the sample. For more details on cylinder liner manufacture and supplies, cast iron cylinder liner, and cast steel cylinder liner manufacturer email [email protected], and call +91 9810012383 or tel. +91-124-4251615.

#Allen cylinder manufacturer#cylinder liner manufacture and supplies#cast steel cylinder liner manufacturer#Cast Iron Cylinder Liner Manufacturer#Marine Engine Cylinder Liners#Cylinder Liner For Forging Press#Main Engine Cylinder Liner#Cylinder Liner Installation#Cast Iron Engine Cylinder Liner#Youtube

0 notes

Text

youtube

We manufacture cylinder liners and cylinder sleeves for all prominent marine and industrial diesel engine makes and models, including Daihatsu, Yanmar, Bergen, Niigata, Mirrlees, Alco, ABC, Crepelle, Nohab, and Allen. We follow OEM specifications while manufacturing cylinder sleeves and liners. The design or sample is used to create and produce cylinder liners.

Small quantities are also appropriate. Please email us at [email protected], or visit this link for additional information about cylinder liner manufacturers: https://turbineshaft.in/cylinder-liners-cylinder-sleeves.html

#cylinder liners#cylinder liners exporter#cylinder liner manufacturer#Cylinder Liner Installation#Diesel Engine Cylinder Liner Supplier#Cast Iron Engine Cylinder Liner#Main Engine Cylinder Liner#Aluminium Cylinder Liner Manufacturer#Compressor Cylinder Liner Producer#Cylinder Head Liner#Cylinder Liner Sleeve Manufacturer#Cylinder Liner And Sleeves#Youtube

1 note

·

View note

Text

The repair of a damaged engine block, turbocharger casing, and heavy cast iron parts can be successfully repaired by metal stitching, metal locking, and metal surgery process. For a detailed repair process of damaged casting by metal locking and metal stitching, email us at [email protected].

#metal stitching#metal locking#damaged engine block#metal stitching locking#damaged casting by metal locking#cylinder liners#metal stitching process#crack repair#repair of crack and damaged cast#repair of damage casting

0 notes

Text

Thinking back on it, I'm realizing there aren't many straightforward idol anime I actually like. Like, Zombieland Saga is lots of fun, but the idol stuff is consistently the weakest part of it and I always feel myself tuning out whenever that's the focus. I guess I liked Heroines Run the Show before it went to shit in the back half? Does Ya Boi Kongming count? Symphogear, technically? Maybe Hanayamata? I dunno, I feel like all those shows have asterisks that keep them from being straightforward idol-y enough to qualify. Meanwhile, by far the most traditional idol show I've watched so far has been Shine Post, and hoooooooo boy did I end up hating that one.

I think the problem is, as I grow increasingly cynical and jaded in my old, withered age of 25 years old, the overwhelming positivity that defines the idol genre starts to feel forced and cloying. It's easy enough for "believe in yourself and try your best" to work as an overall theme if you're sincere enough to pull it off. But the second that theme becomes an obligation or an afterthought, it can very quickly turn a show into the most suffocating, shrink-wrapped piece of sanitized goop imaginable. It becomes a way for a story to avoid being about anything, spouting generic platitudes and cynically designed cuteness with all its edges sanded down and dull. When I look at the weaker idol anime I've watched, I don't see stories that come by their earnestness, well, earnestly. I see coldly calculated, market-tested corporate branding exercises that say nothing, express nothing, and don't dare step a single toe out of line. A plastic smile plastered across an empty styrofoam mannequin, babying its audience with lazy, simplified moralizing because it doesn't think they're capable of anything more complex than Teletubbies, and god forbid we lose a single audience member trying to actually make an artistic statement.

But that's the thing about Juuki Hanada as a writer.

When this man wants to get messy?

He gets fucking messy.

So much of what makes Hanada's writing so powerful, in comedy and drama alike, is how well he's able to let the reins go of his characters and let them crash into each other. Snappy one-liners and comebacks battling for dominance, chaotic personalities setting off fireworks of all kinds through their interactions, but also raw, ugly emotional confrontations that don't sugarcoat anything out of fear his audience isn't mature enough to handle it. Not all of his stuff is a masterpiece- I could spend hours talking about how badly Kyoukai no Kanata's plot falls apart in the second half, Steins;Gate gets more and more exhausting the more I think about it- but even his weakest works carry the unmistakable passion of a writer holding nothing back. And when he's firing on all cylinders? You might just end up with the single greatest coming-of-age tale this medium has ever produced.

And it turns out, that sensibility is exactly what a show like Love Live needs to succeed. Because even the most optimistic, inspirational story imaginable needs that edge to temper itself against. The sheer chaos of its lovable cast bouncing off each other isn't just what makes the comedy work so well, it's what lets these dramatic moments sting the way they need to. Because it's only in recognizing these harsher moments- failure, frustration, despair- that its triumphs are able to be so meaningful. I care about Muse because I've seen what it looks like when they fall short, and I care about Honoka because this show lets me see her at her lowest, at her most human and vulnerable. These characters aren't just plastic simulations of cute girls selling a fantasy; they feel like a real friend group, messy and anarchic and free. Free to express themselves with the full palette of the human experience, even the parts most of us would rather pretend didn't exist. And it makes their successes matter in a way they wouldn't if we didn't have that grounding in the unbearable chaos of being.

Love Live is not a deconstruction, or a subversion, or a dark parody or anything so gauche. It's nothing more of less than a straightforward, inspirational idol show. But it's a straightforward, inspirational idol show that knows it doesn't have to sacrifice its raw humanity to shine with the brightest stars in the sky. And that, folks, makes all the difference in the world.

#anime#tabw#the anime binge watcher#love live! school idol project#love live!#love live#2013 aniwatch

12 notes

·

View notes

Text

Merrily We Roll Along review summary Part 2

Robert Hofler, The Wrap

‘Merrily We Roll Along’ Broadway Review: Daniel Radcliffe and Jonathan Groff Lead a Riveting Revival

The troubled Stephen Sondheim musical finally finds its perfect cast

Watching the show on Broadway, I found myself concentrating less on Mendez and Radcliffe’s back-to-back screeds and drawn more to Groff, who almost singlehandedly, and in a very quiet way, makes this revival drive forward while going backward on all eight cylinders. He plays off the over-the-top performances of his two costars — who bring a sly Oliver-and-Hardy chemistry to the stage, Radcliffe being Stan to Mendez’s Ollie. Mendez entertains us with her nasty one-liners and Radcliffe stops the show with his powerful, yet nuanced rendition of “Franklin Shepard, Inc.”

Charley and Mary are telling us in no uncertain terms that Franklin is a major sell-out, but Groff doesn’t play him as a jerk. Instead, he makes the character the quiet eye of the hurricane of resentment (justified or not) swirling around him. For the first time ever, I actually felt the need to protect the guy from his two best friends. After all, there are much, much worse things in life than ending up a successful Hollywood producer of shlock movies. Franklin never sexually harasses anyone, uses the wrong pronoun or votes Republican. By today’s standards, he’d be a pillar of virtue in the film community.

Groff’s portrayal of this unsympathetic character (until well into the second act) recalls the equally inspired casting of Jim Parsons as the bitchy Michael in the first Broadway production of “The Boys in the Band.” Groff and Parsons’ innate likeability gives each actor more than a few minutes of stage time to take an audience by the hand and lead us on their respective character’s journey.

Given a choice to see a show called “Musical Husbands” and “Take a Left,” I’d buy a ticket to “Musical Husbands.” Better yet, I recommend getting a ticket to see this wonderful “Merrily” revival and buy another the following week to enjoy it even more the second time.

Patrick Ryan, USA Today

More than 40 years after notoriously flopping on Broadway, “Merrily We Roll Along” is back with a splendid and shattering revival at the Hudson Theatre starring Jonathan Groff, Lindsay Mendez and Daniel Radcliffe.

Groff, who last appeared on Broadway in the original cast of “Hamilton,” has never been better than he is here, imbuing a tricky character with tearful sincerity and charm.

"It's our time, breathe it in," Frank sings at the end of the show, as he readies to take on the world with Charley and Mary by his side. The same could be said of "Merrily," which four decades later, finally feels right on time.

David Gordon, What’s On Stage

Sitting comfortably in the Hudson Theatre, this Merrily is one of those transcendent productions I’ll look back on fondly forever.

Radcliffe’s Charley is adorably filled with nervous energy, and he continues to blow the roof off the joint with “Franklin Shepard, Inc.”. Groff beautifully grounds Frank in the reality of a man who has gotten everything he wanted, only to realise that the most important things in his life have completely disappeared. Mendez lives and breathes every single emotional beat to its fullest potential, making a meal out of Furth’s sardonic quips. Watching them sing “Old Friends” transported me to a plane of musical-comedy heaven which I have not visited in a long time, and their idealistic “Our Time” is a genuine tearjerker.

Friedman’s production is a theatrical miracle, finding the heart at the center of this story of dreams, regrets, and good things going, going, gone. Somewhere, its creators are bursting with pride to see their vision fully realised, at long last.

Steven Siskin, NY Stage Review

If Mendez and Radcliffe were already perfect downtown—or perhaps even on the first day in the rehearsal room—Jonathan Groff’s Franklin Shephard has taken a different path. To say the role is difficult is an understatement; like Robert (a.k.a. Bobby baby) in the Sondheim-Furth Company, Franklin is trapped. He stands in the precise center of a crowd that his character dominates, unable to break through his walled-off personality to relate to anyone, imploring somebody—anybody—to “make me aware of being alive.” Groff brought an intriguing element to his performance last winter, not shying away from displaying a Franklin who was cold, cruel, and unlikable. He has now found a way to add a core of desperate sadness and a sense of loss, which makes him the most effective Franklin of the half-dozen I’ve seen.

The show plays like wildfire, ignited from that first blast of overture from that band. It’s a win-win, or perhaps a win-win-win-win. A win for Merrily, yes; a win for Radcliffe, Mendez, and Goff; and a win mostly for Maria Friedman, who created this production with significant success back in 2012 and—in three or four steps along the way—has continued to add layers of sheen so that it no longer plays like an excellent production of a troubled musical but an excellent show all around.

Melissa Rose Bernardo, NY Stage Review

Thankfully, Friedman has found three actors whose charm and genuine connection overrides their characters’ most unpalatable qualities. And since the NYTW production, their performances have only deepened. Groff (Spring Awakening, Hamilton) is perfection as the successful but hollow composer-turned-corporation Frank

9 notes

·

View notes

Text

Premium Cylinder Liners for Enhanced Engine Performance

Essential parts of an engine's construction and cylinder liners greatly affect engine performance and lifetime. Often called engine sleeves, these liners offer a protective layer inside the engine's cylinders where combustion takes place. Maintaining ideal engine performance depends on heat dissipation, which the liners aid with, as well as from less friction and wear and strain. Premium-quality cylinder liners guarantee that the engine operates smoothly, effectively, and for a longer amount of time, whether the vehicle is commercial, industrial equipment, or personal car. One cannot emphasize their importance in improving general engine conditions.

Material Quality and Manufacturing Accuracy

The materials used and the manufacturing precision determine most of the lifetime and performance of cylinder liners. Usually formed from high-grade cast iron or alloyed steel, premium cylinder liners have excellent resistance to wear, heat, and corrosion, which makes these materials desirable. Including honing and precision polishing, the manufacturing process guarantees that the liners preserve an exact fit and excellent roundness. This accuracy reduces friction between the piston and the liner, producing smoother engine performance. Avoiding expensive repairs and guaranteeing long-term dependability depend on investments in premium cylinder liners.

Improved heat dissipation for best performance

Their capacity to improve heat dissipation is among the main benefits of premium cylinder liners. During combustion, engines produce a lot of heat; if this heat is not well controlled, overheating and damage may result. Premium liners improve engine performance by effectively transferring heat away from the combustion chamber, therefore preventing overheating. These liners lower component failure risk and enable the engine to function more effectively by preserving a balanced temperature. This is crucial for high-performance engines running under specific demanding conditions.

Reducing Wear and Tear in Highly Stressful Conditions

Particularly in commercial and industrial uses, engines bear great stress. This strain, over time, can cause internal components—especially the cylinder walls—to degrade. A protective barrier and premium cylinder liners help to lower engine wear and tear. Their new manufacturing methods and better materials guarantee that they may survive in high-stress conditions without sacrificing their structural integrity. Lowering the frequency of maintenance and replacements increases engine lifetime. Furthermore, by reducing wear, these liners preserve engine performance and fuel economy, thus saving long-term costs.

Long-Term Benefits and Cost-Effectiveness

Although premium cylinder liners would seem to be a major outlay, their long-term advantages much exceed their original cost. Over time, these liners save a great deal by shielding the engine from too much wear, enhancing fuel economy, and avoiding expensive repairs. Furthermore, premium liners are a great option for both personal and business automobiles because of their higher dependability and performance. Their longevity guarantees fewer replacements, which reduces maintenance expenses. Any engine owner would be wise to invest in these liners, given their low cost and improved engine performance they produce.

Conclusion

Enhancement in engine performance, heat dissipation, and wear reduction in high-stress environments all depend on premium cylinder liners. Their premium components and exact production guarantees better fuel economy and a longer lifetime for your engine. Although the initial cost could be more than that of regular liners, their long-term advantages—fewer repairs and reduced maintenance costs—make them wise investments. Consider premium cylinder liners from thepartsxperts.com, where quality meets innovation for the best engine solutions if you want to improve the performance and lifetime of your engine.

For More Info:

cylinder liners

0 notes

Text

Automotive Cylinder Liner - Know the Revenue and Profit-Sources of the Industry

A cylinder liner is a sleeve used to protect the cylinder of an engine. The cylinder liner is usually made of metal, and is placed inside the cylinder of the engine. The cylinder liner helps to protect the cylinder from the wear and tear of the engine.

Unlock Growth Potential in Your Industry – Get Your Sample Report Now@https://www.globalinsightservices.com/reports/automotive-cylinder-liner-market/?utm_source=PranaliP-organic

Key Trends

Some of the key trends in automotive cylinder liner technology include the use of new materials, coatings and manufacturing processes.

Materials:

There has been a shift away from traditional materials such as cast iron and steel towards more advanced materials such as aluminum and composites. These materials offer superior performance in terms of weight, strength and heat resistance.

Coatings:

A variety of coatings are being used to improve the performance of cylinder liners. These include thermal barrier coatings, wear-resistant coatings and lubricant-infused coatings.

Manufacturing processes:

New manufacturing processes such as powder metallurgy and additive manufacturing are being used to produce cylinder liners with improved properties.

0 notes

Text

Understand the selection of materials and coatings for Mazda cylinder liners, including the traditional gray cast iron and the innovative Nikasil and Alusil coatings, designed for enhanced durability and engine performance.

0 notes

Text

For more details regarding crack repair of aluminium and cast iron by metal lock & metal stitching, please email us at [email protected], or [email protected], or call us at +91 9582647131 or +91 9810012383.

#Bronze and Cast Iron Component By Metal Lock#Metal Lock & Metal Stitching#crack repair of aluminium#Crack Repair By Metal Stitching#Metal Stitching of Cylinder Liner#Crack In Main Engine Liner

0 notes

Text

Debugging double-station automatic long tube centrifugal casting machine

#cylinder sleeve#cylinder liner#centrifugal casting machine#casting machine low-pressaluminium alloy#castingequipmentcentrifugal casting machine#horizontal casting machine#engine

0 notes

Text

Crack Repair By Metal Stitching And Metal Locking

RA Power Solutions Pvt Ltd is the only company in the world, that can undertake repair of damaged, cast components and crack repair onsite, even while sailing of the vessel. The video shows successful repair of the main engine block and cylinder liners which developed cracks. Our expert technicians specialize in repairing badly damaged castings or cracks. For more details, please email us at [email protected], or [email protected], or call us at +91 9582647131 or +91 9810012383.

#white metal babbitt bearings#crack repairs of damage casting#onsite crackrepair#damaged engine block repair

0 notes

Text

Automotive Cylinder Liner Market Competitive Analysis and Forecast 2023-2033

Market Definition

A cylinder liner is a sleeve used to protect the cylinder of an engine. The cylinder liner is usually made of metal, and is placed inside the cylinder of the engine. The cylinder liner helps to protect the cylinder from the wear and tear of the engine.

Market Outlook

Some of the key trends in automotive cylinder liner technology include the use of new materials, coatings and manufacturing processes.

Materials:

There has been a shift away from traditional materials such as cast iron and steel towards more advanced materials such as aluminum and composites. These materials offer superior performance in terms of weight, strength and heat resistance.

Coatings:

A variety of coatings are being used to improve the performance of cylinder liners. These include thermal barrier coatings, wear-resistant coatings and lubricant-infused coatings.

Manufacturing processes:

New manufacturing processes such as powder metallurgy and additive manufacturing are being used to produce cylinder liners with improved properties.

The automotive cylinder liner market is primarily driven by the increasing demand for vehicles and the need for cylinder liners to protect the engine from wear and tear. The cylinder liner market is also driven by the increasing demand for aftermarket parts and services, as well as the need for replacement parts. Other factors that are driving the automotive cylinder liner market include the increasing popularity of aftermarket modifications and the need for cylinder liners to meet the demands of high-performance engines.

The key restraints and challenges in the Automotive Cylinder Liner market are as follows:

1. Stringent emission norms:

The automotive industry is subject to stringent emission norms globally. The cylinder liner must meet these emission norms while also providing good wear resistance and corrosion resistance. This is a challenge for the manufacturers of automotive cylinder liners.

2. Cost:

Automotive cylinder liners are made of materials such as cast iron, aluminum, or steel. The cost of these materials is high, which in turn increases the cost of the automotive cylinder liner. This is a challenge for the manufacturers as they need to maintain a balance between cost and quality.

3. Availability of raw materials:

The raw materials used for the manufacturing of automotive cylinder liners are cast iron, aluminum, and steel. These materials are not easily available, which poses a challenge for the manufacturers.

To Know More: https://www.globalinsightservices.com/reports/automotive-cylinder-liner-market/

Research Objectives

Estimates and forecast the overall market size for the total market, across product, service type, type, end-user, and region

Detailed information and key takeaways on qualitative and quantitative trends, dynamics, business framework, competitive landscape, and company profiling

Identify factors influencing market growth and challenges, opportunities, drivers and restraints

Identify factors that could limit company participation in identified international markets to help properly calibrate market share expectations and growth rates

Trace and evaluate key development strategies like acquisitions, product launches, mergers, collaborations, business expansions, agreements, partnerships, and R&D activities

Thoroughly analyze smaller market segments strategically, focusing on their potential, individual patterns of growth, and impact on the overall market

To thoroughly outline the competitive landscape within the market, including an assessment of business and corporate strategies, aimed at monitoring and dissecting competitive advancements.

Identify the primary market participants, based on their business objectives, regional footprint, product offerings, and strategic initiatives

Request Sample: https://www.globalinsightservices.com/request-sample/GIS22434//

Market Segmentation

The Automotive Cylinder Liner Market is segmented by type, material type, vehicle type, and region. On the basis of liner type the market is segmented as dry and wet. On the basis of material type the market is segmented as aluminum alloy, steel, cast iron, and others. On the basis of vehicle type the market is segmented as passenger cars and commercial vehicles. By region, the market is classified into North America, Europe, Asia-Pacific, and rest of the world.

Request Customization@ https://www.globalinsightservices.com/request-customization/GIS22434/

Major Players

The key players in the Automotive Cylinder Liner Market are Aichi Machine Industry Co., Ltd., Bryan Automotive, Darton International, Inc., MAHLE GmbH, Melling, Nippon Piston Ring Co., Ltd., Tenneco Inc., TPR CO.,LTD., Westwood Cylinder Liners Ltd., and ZYNP (Anhui) Co., Ltd.

Request Discounted Pricing@ https://www.globalinsightservices.com/request-special-pricing/GIS22434/

Research Scope

Scope – Highlights, Trends, Insights. Attractiveness, Forecast

Market Sizing – Product Type, End User, Offering Type, Technology, Region, Country, Others

Market Dynamics – Market Segmentation, Demand and Supply, Bargaining Power of Buyers and Sellers, Drivers, Restraints, Opportunities, Threat Analysis, Impact Analysis, Porters 5 Forces, Ansoff Analysis, Supply Chain

Business Framework – Case Studies, Regulatory Landscape, Pricing, Policies and Regulations, New Product Launches. M&As, Recent Developments

Competitive Landscape – Market Share Analysis, Market Leaders, Emerging Players, Vendor Benchmarking, Developmental Strategy Benchmarking, PESTLE Analysis, Value Chain Analysis

Company Profiles – Overview, Business Segments, Business Performance, Product Offering, Key Developmental Strategies, SWOT Analysis

Buy your copy here: https://www.globalinsightservices.com/checkout/single_user/GIS22434/

With Global Insight Services, you receive:

10-year forecast to help you make strategic decisions

In-depth segmentation which can be customized as per your requirements

Free consultation with lead analyst of the report

Infographic excel data pack, easy to analyze big data

Robust and transparent research methodology

Unmatched data quality and after sales service

Contact Us:

Global Insight Services LLC 16192, Coastal Highway, Lewes DE 19958 E-mail: [email protected] Phone: +1-833-761-1700 Website: https://www.globalinsightservices.com/

0 notes

Text

Rules are Rules

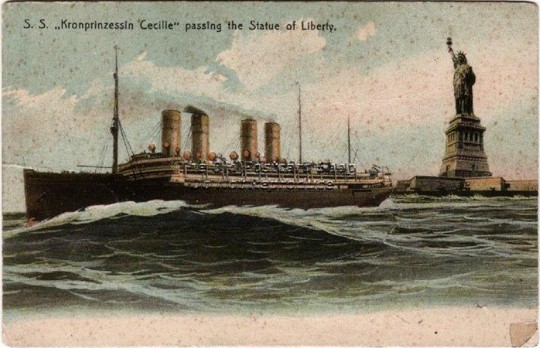

The US Army transport ship USS Mount Vernon (ID-4508) was originally the huge German passenger liner S.S. Kronprinzesin Cecilie, built in Stettin, Germany, in 1906. As a US Army ship she had an eventful history including a humorous event at Mare Island Naval Shipyard.

When World War I broke out in 1914 the S.S. Kronprinzesin Cecilie and 113 Austrian and German merchant vessels sought shelter in US Ports from the English and French fleets who would have hunted them down and sunk them. Those ships sat unused until the US entered the war in 1917 at which time they were all seized in a coordinated action. Aware of the pending seizure, all the ships were sabotaged by their crews on orders from the German High Command to prevent their use against Germany. It did not work, even though the S.S. Kronprinzesin Cecilie’s huge cast cylinders for her steam engines were smashed, US naval personnel pioneered a process to weld repair the castings returning her and others like her to service much quicker than the German’s anticipated. Together with other US flag ships, they carried two million American servicemen to France leading to the defeat of the Germans by Allied Forces.

The Mount Vernon made the first of nine trips across the Atlantic, hauling troops to and from the battlefields in October of 1917. Then one year later Mount Vernon was headed for the US with a load of wounded soldiers. 200 miles off the French port of Brest gun crews sighted a submarine periscope. It was too late to take evasive action as a torpedo slammed into her side and water began rushing in. The captain reversed course and personnel manned lifeboats to abandon ship if necessary as he steamed back towards Brest with damage control parties fighting the flooding. She made it to safety and was quickly repaired and put back in service. Then in 1919 with war over she was sent out to the Pacific.

On 17 October 1919 Mount Vernon was transferred to operation by the Army Transport Service where the ship was assigned to the Army's Pacific fleet based at Fort Mason in San Francisco. She steamed through the Panama Canal and into San Francisco Bay on Monday, November 10, 1919. At 706 ft long and 32,000 tons displacement she was the largest ship ever to transit the canal or sail into San Francisco Bay. Her mission was to sail to Vladivostok, Russia to return US troops and repatriate German prisoners of war and Czechoslovak troops who had been fighting the Russian Bolsheviks. But before she headed to Russia, she went to Mare Island for repairs. The process for ships heading to the shipyard was for the Mare Island Pilot to board the ship out in the Carquinez Straits and guide it to the pier through the narrow channel in the Mare Island Straits. No doubt the pilot was looking forward to the opportunity to guide this massive ship up the waterway. People would talk about it for years, and they did, but probably not for the reasons he supposed.

When the massive ship arrived off the Mare Island Straits her Army Captain did not pause as expected and, instead, he proceeded up the Strait to a position opposite the shipyard. Alarmed by the sudden appearance of the huge ship, Mare Island officials radioed her advising the captain that he was not authorized to proceed up the channel without the Mare Island pilot on board. In response, the Army Captain swung the giant ship around and sailed back down the channel to await the pilot out in the Carquinez Straits. Once the Mare Island pilot was on the bridge of the Mount Vernon, she then proceeded yet again up the straits to the shipyard. Fortunately for the pilot, the trip was as uneventful as the first or he never would have heard the end of it (he probably never did anyway).

Dennis Kelly

#mare island#naval history#san francisco bay#us navy#vallejo#world war 1#world war i#world war one#bay area#California#northbay#solano#sonoma#napa#wine country#military#tourism

0 notes