#cylinder liner repair

Explore tagged Tumblr posts

Text

Cylinder Liners and Cylinder Sleeves Manufacturer | RA Power

RA Power Solutions' commitment to precision, durability, and innovation sets it apart as a reliable manufacturer of cylinder liners and sleeves. The company's dedication to quality control, advanced manufacturing techniques, and customization options make its products a preferred choice for those seeking top-tier components for internal combustion engines. As engines continue to evolve, RA Power Solutions remains at the forefront of providing cutting-edge solutions to meet the demands of the industry. To get more details, contact us at [email protected], 0124-425-1615, or +91-9810012383.

0 notes

Text

Diesel and Marine Engine Cylinder Liners and Sleeves

A complete cylinder liner repair and reconditioning service is provided by RA Power Solutions. Your cylinder liners will be examined by our team of skilled engineers and technicians for any cracks, wear, or other damage. In order to verify that the cylinder liners meet or exceed factory requirements, we shall, if necessary, repair or replace them. Your cylinder liners will remain in good shape for many years to come since we also provide a 12-month warranty on our reconditioning services. For more information about babbitt white metal,rebabbitting of bearing, contact us by email at [email protected], 0124-425-1615, or +91-9810012383.

#cylinder liner repair#diesel engine repair#cylinder liners#cylinder liners and cylinder sleeves#casting of cylinder liner#diesel engines

0 notes

Text

Manufacture Cylinder Liners for High-Capacity Engines

With more than 40 years of expertise providing maintenance and overhaul services to diesel power plants all over the world, we are aware of the requirement for producing cylinder liners of the highest quality. We are aware of the many technical aspects that go into making cylinder liners. For more detail on cylinder liner repair email [email protected] or call +91 9582647131, tel. 124-425-1615.

#Cylinder Liner Manufacturer#Cylinder Liner Repair#Marine Engine Cylinder Liners#cylinder liners#cylinder liners and cylinder sleeves#Cylinder Liners of CAT 3616 Engine#cylinder sleeves manufactured#development of cylinder liners#Wartsila Cylinder Liners#high capacity cylinder liners#Cylinder liner machining

0 notes

Text

The repair of a damaged engine block, turbocharger casing, and heavy cast iron parts can be successfully repaired by metal stitching, metal locking, and metal surgery process. For a detailed repair process of damaged casting by metal locking and metal stitching, email us at [email protected].

#metal stitching#metal locking#damaged engine block#metal stitching locking#damaged casting by metal locking#cylinder liners#metal stitching process#crack repair#repair of crack and damaged cast#repair of damage casting

0 notes

Text

Premium Cylinder Liners for Enhanced Engine Performance

Essential parts of an engine's construction and cylinder liners greatly affect engine performance and lifetime. Often called engine sleeves, these liners offer a protective layer inside the engine's cylinders where combustion takes place. Maintaining ideal engine performance depends on heat dissipation, which the liners aid with, as well as from less friction and wear and strain. Premium-quality cylinder liners guarantee that the engine operates smoothly, effectively, and for a longer amount of time, whether the vehicle is commercial, industrial equipment, or personal car. One cannot emphasize their importance in improving general engine conditions.

Material Quality and Manufacturing Accuracy

The materials used and the manufacturing precision determine most of the lifetime and performance of cylinder liners. Usually formed from high-grade cast iron or alloyed steel, premium cylinder liners have excellent resistance to wear, heat, and corrosion, which makes these materials desirable. Including honing and precision polishing, the manufacturing process guarantees that the liners preserve an exact fit and excellent roundness. This accuracy reduces friction between the piston and the liner, producing smoother engine performance. Avoiding expensive repairs and guaranteeing long-term dependability depend on investments in premium cylinder liners.

Improved heat dissipation for best performance

Their capacity to improve heat dissipation is among the main benefits of premium cylinder liners. During combustion, engines produce a lot of heat; if this heat is not well controlled, overheating and damage may result. Premium liners improve engine performance by effectively transferring heat away from the combustion chamber, therefore preventing overheating. These liners lower component failure risk and enable the engine to function more effectively by preserving a balanced temperature. This is crucial for high-performance engines running under specific demanding conditions.

Reducing Wear and Tear in Highly Stressful Conditions

Particularly in commercial and industrial uses, engines bear great stress. This strain, over time, can cause internal components—especially the cylinder walls—to degrade. A protective barrier and premium cylinder liners help to lower engine wear and tear. Their new manufacturing methods and better materials guarantee that they may survive in high-stress conditions without sacrificing their structural integrity. Lowering the frequency of maintenance and replacements increases engine lifetime. Furthermore, by reducing wear, these liners preserve engine performance and fuel economy, thus saving long-term costs.

Long-Term Benefits and Cost-Effectiveness

Although premium cylinder liners would seem to be a major outlay, their long-term advantages much exceed their original cost. Over time, these liners save a great deal by shielding the engine from too much wear, enhancing fuel economy, and avoiding expensive repairs. Furthermore, premium liners are a great option for both personal and business automobiles because of their higher dependability and performance. Their longevity guarantees fewer replacements, which reduces maintenance expenses. Any engine owner would be wise to invest in these liners, given their low cost and improved engine performance they produce.

Conclusion

Enhancement in engine performance, heat dissipation, and wear reduction in high-stress environments all depend on premium cylinder liners. Their premium components and exact production guarantees better fuel economy and a longer lifetime for your engine. Although the initial cost could be more than that of regular liners, their long-term advantages—fewer repairs and reduced maintenance costs—make them wise investments. Consider premium cylinder liners from thepartsxperts.com, where quality meets innovation for the best engine solutions if you want to improve the performance and lifetime of your engine.

For More Info:

cylinder liners

0 notes

Text

Crack Repair By Metal Stitching And Metal Locking

RA Power Solutions Pvt Ltd is the only company in the world, that can undertake repair of damaged, cast components and crack repair onsite, even while sailing of the vessel. The video shows successful repair of the main engine block and cylinder liners which developed cracks. Our expert technicians specialize in repairing badly damaged castings or cracks. For more details, please email us at [email protected], or [email protected], or call us at +91 9582647131 or +91 9810012383.

#white metal babbitt bearings#crack repairs of damage casting#onsite crackrepair#damaged engine block repair

0 notes

Text

Caterpillar Engine Parts: A Comprehensive Guide to Quality and Performance

Caterpillar Inc., a global leader in the manufacturing of construction and mining equipment, has long been synonymous with durability and performance. Their engines are the backbone of many industries, providing power to a wide range of machinery and vehicles. This article will explore Caterpillar engine parts, highlighting their importance, various types, and tips for maintenance to ensure optimal performance.

The Importance of Quality Engine Parts

Caterpillar engines are known for their reliability and efficiency. However, the performance of these engines heavily depends on the quality of the parts used. Using genuine Caterpillar engine parts ensures that the machinery operates at its best, reduces the likelihood of breakdowns, and extends the lifespan of the equipment.

Why Choose Genuine Caterpillar Parts?

Reliability: Genuine Caterpillar parts are designed and manufactured to meet the highest standards, ensuring they perform under the most demanding conditions.

Compatibility: Original parts are engineered specifically for Caterpillar engines, guaranteeing a perfect fit and optimal performance.

Warranty Protection: Using genuine parts maintains the warranty of the equipment, providing peace of mind to the owners.

Long-term Cost Savings: Although genuine parts may have a higher upfront cost, their durability and performance reduce maintenance costs over time, leading to long-term savings.

Types of Caterpillar Engine Parts

Caterpillar engines comprise numerous parts, each playing a critical role in the engine's operation. Here are some of the essential components:

Pistons and Rings

Pistons are crucial for converting the energy produced by fuel combustion into mechanical work. Caterpillar pistons are designed for maximum strength and durability. The piston rings ensure a tight seal within the combustion chamber, preventing oil from entering and maintaining compression.

Cylinder Liners

Cylinder liners provide a smooth surface for the pistons to move within the engine block. They must withstand high pressure and temperature, making Caterpillar's hardened steel liners an excellent choice for ensuring engine longevity.

Bearings

Bearings reduce friction between moving parts and support the engine's rotating components. Caterpillar bearings are precision-engineered to handle extreme loads and offer high resistance to wear and tear.

Gaskets and Seals

Gaskets and seals prevent leaks and maintain the engine's integrity. Caterpillar's high-quality materials ensure a secure fit, preventing oil, coolant, and air leaks that can compromise engine performance.

Turbochargers

Turbochargers boost the engine's power output by increasing the air intake into the combustion chamber. Caterpillar turbochargers are designed to provide optimal airflow, enhancing engine efficiency and performance.

Fuel Injectors

Fuel injectors deliver fuel into the engine's combustion chamber with precision. Caterpillar injectors are known for their accuracy and durability, ensuring efficient fuel consumption and reduced emissions.

Camshafts and Crankshafts

The camshaft controls the opening and closing of engine valves, while the crankshaft converts linear motion into rotational motion. Caterpillar's camshafts and crankshafts are built for high strength and precision, ensuring smooth engine operation.

Maintenance Tips for Caterpillar Engines

Proper maintenance of Caterpillar engines is crucial to ensure they operate efficiently and last longer. Here are some tips to keep your engine in top shape:

Regular Inspections

Routine inspections help identify potential issues before they become major problems. Check for leaks, unusual noises, and wear signs on belts and hoses.

Use Genuine Parts

Always use genuine Caterpillar parts for replacements and repairs. This ensures compatibility and maintains the integrity of the engine.

Follow Manufacturer Guidelines

Adhere to Caterpillar's maintenance guidelines, including recommended oil changes, filter replacements, and service intervals. This ensures the engine operates within optimal parameters.

Monitor Fluid Levels

Regularly check and maintain appropriate levels of oil, coolant, and other essential fluids. This helps prevent overheating and reduces wear on engine components.

Keep the Engine Clean

Dirt and debris can affect engine performance. Clean the engine regularly to prevent clogging and ensure efficient operation.

For More Info:-

Detroit Diesel Parts

Parts for Caterpillar Engines

0 notes

Text

Advantages and Uses of Rubber Rollers in Manufacturing

What is a Rubber Roller?

A rubber roller is a machine part composed of an inner round shaft or tube covered by an outer layer of elastomer compounds. The inner shaft is made of steel, aluminum alloys, or other strong and rigid material composites. On the other hand, the outer layer is typically fabricated from a polymer such as polyurethane, silicone, EPDM, neoprene, and natural rubber. Rubber rollers are used in different manufacturing processes for performing operations such as:

Pressing

Laminating

Driving

Deflecting

Feeding

Printing

Pushing and Pulling

Film Processing

Material Conveying

Squeezing and Wringing

Straightening

Cooling and Uncooling

Rubber rollers benefit from elastomers' advantageous qualities, which include high coefficient of friction, resilient to abrasion and chemicals, impact strength, shock absorption, compression and deflection, and adjustable hardness. Comparing them to metal rollers, these characteristics allow them to handle produced products without harming the product or the item itself. Furthermore, in most situations, it takes less time and money to reassemble or repair the rubber covering than it does to repair the metal core, extending its useful life. When good surface durability and moderate to medium hardness are required, they are the recommended machine parts. Rubber rollers that have been properly designed and engineered can endure the deteriorating forces caused by mechanical and thermal causes.

Rubber Rollers' Benefits

The elastic qualities of rubber, which no metal can match, are the reason rubber rollers are utilised. Scratches, dents, corrosion, and cracks are all common and easy ways for metals to get damaged. Furthermore, metals' roughness and texture cause abrasions and deterioration on any surface they come in contact with. Though more costly and scarce, alternative materials such as fiber-reinforced composites can offer superior quality. Their availability is limited, and their cost is usually higher. The most cost-effective approach is to use rubber rollers, which have special mechanical qualities that are both physical and mental, including:

high coefficient of friction surface: In dry, clean environments, the coefficient of friction between steel surfaces is between 0.5 and 0.8. This produces a similar value of roughly 0.45 for aluminium to steel as well. The coefficient of friction of rubber, on the other hand, varies from 0.6 to 1.2 depending on the material. For transporting equipment like rollers, rubber is a good lining material because of this. When transporting items on an uneven plane, a high coefficient of friction keeps the objects from sliding.

Retains its shape in the face of impact: Rubbers are known for their good impact strength due to their flexibility. With ease, they can take in energy and spread it over a greater surface area before reverting to their previous form. This keeps the roller from breaking down too soon by preventing surface cracks and indentations.

Superior resistance to chemicals: Certain varieties of rubber have varying levels of chemical resistance. Rust can permanently harm a roller, thus it can be avoided by covering the roller core. Though significantly more expensive than rubber linings, stainless steel is the most often used metal roller choice that can withstand chemical attacks.

The replaceable lining preserves the robust roller core without causing any structural damage, as the rubber lining sustains the most damage during operation. By taking out and replacing the worn rubber liner, the roller core is easily serviceable. The roller core's and the equipment's overall lifespan are increased in this way. Furthermore, it averts costly maintenance such as cylinder or roller replacement. For optimal performance and longevity, it is advisable to work with a reputable rubber roller manufacturer to ensure the highest quality materials and workmanship.

#rubberroller#rubberrollermanufacturers#industrialproducts#manufacturers#anarrubtechpvtltd#anarrubtech

0 notes

Text

Understanding the Importance of Bunker and Marine Lubricants

The maritime industry is a cornerstone of global trade, and maintaining the efficiency and longevity of ships is paramount. A crucial aspect of this maintenance involves the use of high-quality bunker and marine lubricants. At Gujmar Group, we specialize in providing top-tier marine lubricants that ensure optimal performance and longevity of marine engines and machinery.

Why Bunker and Marine Lubricants Matter

Bunker and marine lubricants are essential for several reasons. They reduce friction between moving parts, minimize wear and tear, and protect against corrosion. This is vital in the harsh marine environment where saltwater and varying temperatures can take a toll on engine components. By using high-quality lubricants, ship operators can ensure smoother operations, lower maintenance costs, and longer engine life.

Types of Marine Lubricants

1. Cylinder Oils : These are used in the cylinders of marine engines to provide a protective film between the piston and the cylinder liner, reducing wear and maintaining efficiency.

2. System Oils : These lubricants are used in the entire engine system, including the bearings, to ensure smooth operation and protect against corrosion and wear.

3. Gear Oils : Designed specifically for marine gear systems, these oils reduce friction and wear, ensuring the longevity of the gear mechanisms.

At Gujmar Group, we offer a wide range of bunker and marine lubricants tailored to meet the specific needs of different types of marine engines and machinery. Our products are formulated to provide excellent protection, enhance performance, and comply with international standards.

Comprehensive Marine Services

In addition to our top-notch lubricants, Gujmar Group is recognized as a leading ship supplier and ship chandler in India. We offer a comprehensive range of marine services to meet the diverse needs of the maritime industry. Our services include:

- Marine Paints : High-quality marine coatings to protect ships from corrosion and fouling.

- Ship Provisions : Supplying a wide variety of food, beverages, and other necessities to ships.

- Ship Repair : Expert repair services to ensure your vessel is always in top condition.

- Ship Stores Suppliers : Providing essential supplies and equipment for everyday operations.

Why Choose Gujmar Group?

Gujmar Group stands out as one of the top ship chandlers in India. Our commitment to quality and customer satisfaction has made us the best ship supply company in India. We are also among the leading marine fuel suppliers in India, providing high-quality marine fuels to ensure efficient and reliable ship operations.

Our extensive network and expertise allow us to offer unparalleled services to our clients, making us the preferred choice for all your maritime needs. Whether you need bunker and marine lubricants, ship repairs, or provisions, Gujmar Group is your trusted partner.

Conclusion

Choosing the right bunker and marine lubricants is crucial for the efficient and reliable operation of your ship. At Gujmar Group, we provide a comprehensive range of high-quality lubricants and marine services to meet all your needs. Trust us to keep your vessel in peak condition and ensure smooth sailing on every voyage.

Visit Gujmar Group to learn more about our products and services, and discover why we are the best choice for ship suppliers and marine services in India.

#Ship Supplier#Ship Chandler#Marine Services#Marine Paints#Ship Provisions#Ship Repair#Top ship chandlers in India#Best ship supply company in India#Marine fuel suppliers in India#Ship Stores suppliers in India

0 notes

Text

Twin Shaft Mixer Design

The ingenious twin shaft mixer design makes its mixing effect very good, especially for the viscous and stretchy materials, the mixing effect is more obvious.

Structure composition of twin shaft mixer:

Twin shaft concrete mixer is mainly composed of base frame, mixing tank, two mixing shafts, mixing blades, front and rear supporting body, gears, couplings, reducer, clutch, drive belt, motor, water pipe and cover and other components. The mixing parts are two synchronized spiral rotors with symmetrical shapes, and the two spiral shafts are synchronized in speed and opposite in direction during rotation.

Mechanical part design of twin shaft mixer:

Transmission system: including electric motor, reducer, gears and bearings, etc. It is used to transmit power and ensure the normal rotation of the mixing cylinder. The selection of motor is based on the production capacity of the concrete mixer and the working environment for comprehensive consideration, while the selection of reducer is based on the reduction ratio and torque size and other factors.

Mixing system: it consists of mixing drum, mixing blades and feeding inlet, etc. The volume of mixing drum is suitable for the production demand, and the number, shape and arrangement of blades ensure that the concrete can be fully mixed.

Hydraulic system: It is mainly used to control the opening and closing of feeding port, discharging port and tilting angle of mixing cylinder, etc. The flow rate and pressure are suitable for the production demand, and the control mode is flexible and convenient.

Design Consideration of twin shaft mixer:

Strength and durability: the design takes into account the strength and durability of the material to ensure that the mixer can run stably for a long time.

Repair and maintenance: the design pays attention to the convenience of repair and maintenance so as to facilitate timely repair in case of failure.

Transportation and installation: the design takes into account factors such as transportation and installation of the mixer to ensure that the mixer can be used normally on site.

Advantages of twin shaft mixer:

Strong mixing capacity: the mixing capacity of twin shaft concrete mixer is strong, and it is effective in mixing dry-hard, semi-dry-hard, plastic and various proportions of concrete.

Short mixing time: the main mixing zone is located in the circumferential direction of the mixer, which can make full use of the mixing space, so that the aggregate, cement and water can reach the average and optimal mixing form in a short time, saving energy.

Environmental protection: the whole mixing and conveying process is carried out in the sealed space, which will not cause dust leakage, clean and environmental protection.

Convenient maintenance: adopting advanced anti-locking shaft system and high-pressure water curtain cleaning system, it is easy to maintain and repair.

Low wear and tear of mixing blades: most of the concrete is piled up between the two mixing shafts during the mixing process, which reduces the wear and tear between the mixing arms, blades and bottom liner.

Low noise: low mixing noise and good working environment.

To summarize, with its unique design and significant advantages, twin shaft mixer occupies an important position in the field of concrete mixing equipment.

This resource is from https://www.concretebatchplant24.com/twin-shaft-mixer-design.html Should you be interested in buying our product, please contact us at: Haomei Machinery Equipment Co.,ltd Whatsapp/Wechat: 0086 181 3788 9531 Email: [email protected]

0 notes

Text

Repairing Cylinder Liners with Cracks

We can typically repair a cylinder liner in a matter of days, compared to the weeks or even months it can take to replace a cylinder liner. Cylinder liner repair can be performed without having to remove the engine from the vehicle. This means that you can get your vehicle back on the road quickly and without a lot of inconvenience. Cylinder liner deglazing is the process of removing carbon deposits and other contaminants from the surface of the cylinder liner. For more information about cylinder liners, cylinder liners exporter, and Cylinder Sleeves Manufacturer contact us at [email protected], 0124-425-1615, or +91-9810012383.

#Cylinder liner repair#cylinder liners exporter#cylinder liners#Cylinder Sleeves Manufacturer#engine cylinder liner

0 notes

Text

SKL Engine Cylinder Liner Manufacturer

The cylinder liners and cylinder sleeves manufactured by us as the outcome of our four decades of manufacturing expertise and development of in-house facilities. All cylinder liners and cylinder sleeves up to 1500 mm in length are centrifugally cast and machined in-house to maintain the tolerances and finish of OEM quality and international standards. The SKL engine cylinder liner of high capacity popular make and model of diesel engine are available in stock. We develop and manufacture cylinder liners and cylinder sleeves as per the drawing or sample submitted by the client. For any information here you can connect with us at [email protected], 0124-4251615, or +91- 9810012383.

#crankshaft grinders#cylinder liners#cylinder liners and cylinder sleeves#SKL engine cylinder liner#onsite crankshaft grinding machine#crankshaft repair#cylinder liner repair#cylinder liners exporter#cylinder liner exporter#cylinder sleeves#skl engine cylinder liners exporters

0 notes

Text

For more details on repair of engine blocks, metal surgery, and MAN engine cylinder liners please email us at [email protected], or [email protected], or call us at +91 9582647131 or +91 9810012383.

#Crack Repair of Cylinder Liners#Crack Repair of Cylinder Liners By Metal Locking#cylinder liners crack repair#Main Engine Cylinder Liner#main engine cylinder liner repair#MPI Test Of Cylinder Liner#Crack Liner Repair By Metal Stitching#MAN engine cylinder liners#metal surgery

0 notes

Text

Marine Diesel Engine Overhaul Repair and Maintenance Service

Marine diesel engine maintenance is the process of regularly inspecting, repairing, and replacing parts of the diesel engine in order to ensure its safe and efficient operation. Proper maintenance is essential for ensuring the reliability and longevity of the engine, as well as meeting regulatory requirements for marine vessel operation.

The following are some of the key aspects of marine diesel engine maintenance:

Regular inspections: Regular inspections help to identify any potential problems early, allowing for prompt repairs and minimizing the risk of breakdowns.

Lubrication: Lubrication is critical for reducing friction and wears on the engine components. The oil and filters must be changed regularly to maintain the engine's performance and longevity.

Cooling system maintenance: The cooling system must be kept clean and free from debris to ensure efficient heat transfer from the engine.

Fuel system maintenance: The fuel system must be kept clean and free from contaminants to ensure the reliable and efficient operation of the engine.

Exhaust system maintenance: The exhaust system must be regularly inspected and cleaned to ensure proper operation and to meet environmental regulations.

Regular overhauls: Regular overhauls help to restore the engine to its original condition and extend its lifespan.

Regular and proper maintenance of marine diesel engines is crucial for ensuring their reliability and longevity, as well as reducing the risk of unexpected breakdowns and costly repairs.

You can reach our team at RA Power Solutions by emailing [email protected] or [email protected], and by calling +91-9582647131 or 09810012383.

#Marine Diesel Engine Overhaul#diesel engine repair#diesel engine overhaul service#onsite marine diesel engine repair#onsite marine engine#cylinder liners#maintenance and repair#diesel engine repair and overhaul#onsite crankshaft repair#onsite crankshaft grinding#engine repair and overhaul#overhaul services#Cummins engine#Wartsila#Marine Diesel Engine#repair of crankshafts onsite#grinding of onsite crankshaft#crankshaft of Wartsila 12V32#Wartsila diesel engine crankshaft#ship auxiliary engine overhaul#diesel engines and spares#auxiliary engines#Daihatsu engine#Wartsila and Caterpillar engine

0 notes

Text

John-Deere 3029, 4039, 4045, 6059, 6068 Engines (Saran)-499999CD Disassembly

This article describes the disassembly of John-Deere 3029, 4039, 4045, 6059, 6068 Engines (Saran)-499999CD

John Deere Service Advisor Electronic Data Link EDL2 Diagnostic Adapter High Quality

ENGINE DISASSEMBLY SEQUENCE

The following sequence is suggested when complete

disassembly for overhaul is required. Refer to the

appropriate repair group when removing individual

engine components.

1. Drain all coolant and engine oil. Check engine oilfor metal contaminates (see Groups 25 and 30).

2. Remove fan belts, fan, and alternator (seeGroup 30).

3. Remove turbocharger (if equipped) and exhaust manifold (see Group 35).

4. Remove rocker arm cover with vent tube. On engines having an Option Code label on rocker arm cover, be careful not to damage label (see Group 05).

5. Remove water manifold with thermostats (see Group 30).

6. Remove oil cooler piping and water pump (seeGroups 25 and 30).(Continued on next page)

7. Remove dipstick, oil filter, and engine oil cooler.

Discard standard-flow oil cooler if oil contained metal

particles (see Group 25).

8. Remove oil pressure regulating valve assembly(see Group 25).

9. Remove fuel filter, fuel transfer pump, and fuel lines (see Group 40).

10. Remove injection lines, injection pump, andinjection nozzles (see Group 40).

11. Remove starting motor.

12. Remove rocker arm assembly and push rods.Keep rods in sequence (see Group 05). Check forbent push rods and condition of wear pad contactsurfaces on rockers.

13. Remove cylinder head. Check piston protrusion.Verify piston height selection (see Groups 05 and10).

14. Remove cam followers. Keep in same sequence as removed (see Group 20).

03.2024 John Deere Service Advisor 5.3.235 AG/CF Diagnostic Software

15. Remove oil pan (see Group 25).

16. Remove flywheel and flywheel housing (see Group 15).

17. Remove crankshaft pulley (see Group 15).

18. Remove timing gear cover (see Group 20).

19. Remove oil pump drive gear, outlet tube (and its O-ring in block) and pump body (see Group 25).

20. Remove oil slinger, timing gears and camshaft.Perform wear checks (see roup 20).

21. Remove balancer shafts (4-cylinder only, if equipped), see Group 20.

22. Remove engine front plate (see Group 20).

23. Remove lube oil system by-pass valve (see Group 25).

24. Stamp cylinder number on rod (if required). Remove pistons and rods. Perform wear checks with “PLASTIGAGE”. On 4 and 6-cylinder engines, remove two at a time (see Group 10).

25. Remove main bearings and crankshaft. Perform wear checks with PLASTIGAGE” (see Group 15).

26. Remove cylinder liners and mark each one with cylinder number from which removed (see Group 10).

27. Remove piston cooling orifices (see Groups 10 and 15).

28. Remove balancer shaft and camshaft bushings (if equipped), see Group 20.

29. Remove cylinder block plugs and serial number plate (as required) when block is to be put in a “hot tank” (see Group 10).

30. Clean out liner bores (upper and lower areas) with nylon brush (see Group 10).

31. Measure cylinder block (see Groups 10, 15, and 20)

02.2024 John Deere Parts ADVISOR EPC(CF& AG& CCE)

0 notes

Text

Rules are Rules

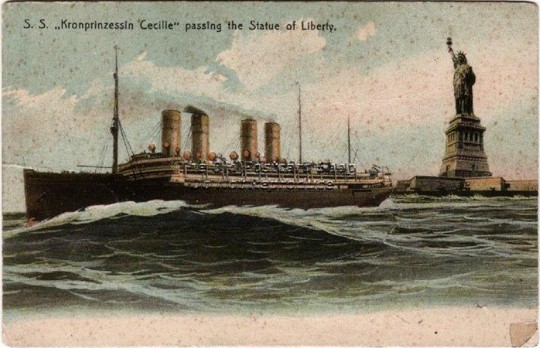

The US Army transport ship USS Mount Vernon (ID-4508) was originally the huge German passenger liner S.S. Kronprinzesin Cecilie, built in Stettin, Germany, in 1906. As a US Army ship she had an eventful history including a humorous event at Mare Island Naval Shipyard.

When World War I broke out in 1914 the S.S. Kronprinzesin Cecilie and 113 Austrian and German merchant vessels sought shelter in US Ports from the English and French fleets who would have hunted them down and sunk them. Those ships sat unused until the US entered the war in 1917 at which time they were all seized in a coordinated action. Aware of the pending seizure, all the ships were sabotaged by their crews on orders from the German High Command to prevent their use against Germany. It did not work, even though the S.S. Kronprinzesin Cecilie’s huge cast cylinders for her steam engines were smashed, US naval personnel pioneered a process to weld repair the castings returning her and others like her to service much quicker than the German’s anticipated. Together with other US flag ships, they carried two million American servicemen to France leading to the defeat of the Germans by Allied Forces.

The Mount Vernon made the first of nine trips across the Atlantic, hauling troops to and from the battlefields in October of 1917. Then one year later Mount Vernon was headed for the US with a load of wounded soldiers. 200 miles off the French port of Brest gun crews sighted a submarine periscope. It was too late to take evasive action as a torpedo slammed into her side and water began rushing in. The captain reversed course and personnel manned lifeboats to abandon ship if necessary as he steamed back towards Brest with damage control parties fighting the flooding. She made it to safety and was quickly repaired and put back in service. Then in 1919 with war over she was sent out to the Pacific.

On 17 October 1919 Mount Vernon was transferred to operation by the Army Transport Service where the ship was assigned to the Army's Pacific fleet based at Fort Mason in San Francisco. She steamed through the Panama Canal and into San Francisco Bay on Monday, November 10, 1919. At 706 ft long and 32,000 tons displacement she was the largest ship ever to transit the canal or sail into San Francisco Bay. Her mission was to sail to Vladivostok, Russia to return US troops and repatriate German prisoners of war and Czechoslovak troops who had been fighting the Russian Bolsheviks. But before she headed to Russia, she went to Mare Island for repairs. The process for ships heading to the shipyard was for the Mare Island Pilot to board the ship out in the Carquinez Straits and guide it to the pier through the narrow channel in the Mare Island Straits. No doubt the pilot was looking forward to the opportunity to guide this massive ship up the waterway. People would talk about it for years, and they did, but probably not for the reasons he supposed.

When the massive ship arrived off the Mare Island Straits her Army Captain did not pause as expected and, instead, he proceeded up the Strait to a position opposite the shipyard. Alarmed by the sudden appearance of the huge ship, Mare Island officials radioed her advising the captain that he was not authorized to proceed up the channel without the Mare Island pilot on board. In response, the Army Captain swung the giant ship around and sailed back down the channel to await the pilot out in the Carquinez Straits. Once the Mare Island pilot was on the bridge of the Mount Vernon, she then proceeded yet again up the straits to the shipyard. Fortunately for the pilot, the trip was as uneventful as the first or he never would have heard the end of it (he probably never did anyway).

Dennis Kelly

#mare island#naval history#san francisco bay#us navy#vallejo#world war 1#world war i#world war one#bay area#California#northbay#solano#sonoma#napa#wine country#military#tourism

0 notes