#high capacity cylinder liners

Explore tagged Tumblr posts

Text

Manufacture Cylinder Liners for High-Capacity Engines

With more than 40 years of expertise providing maintenance and overhaul services to diesel power plants all over the world, we are aware of the requirement for producing cylinder liners of the highest quality. We are aware of the many technical aspects that go into making cylinder liners. For more detail on cylinder liner repair email [email protected] or call +91 9582647131, tel. 124-425-1615.

#Cylinder Liner Manufacturer#Cylinder Liner Repair#Marine Engine Cylinder Liners#cylinder liners#cylinder liners and cylinder sleeves#Cylinder Liners of CAT 3616 Engine#cylinder sleeves manufactured#development of cylinder liners#Wartsila Cylinder Liners#high capacity cylinder liners#Cylinder liner machining

0 notes

Text

HDPE Thermoforming Plate Extrusion line

Jwell supply advanced extrusion system, it is suitable to produce HMW-HDPE material which have low MFI and high-strength into plate, the plates are mainly used to produce auto carriage board, pick-up's box liner, cover of truck, anti-rain cover etc. The plate thickness can reduce more than 30% when it has same impact strength, it reduce the production cost for manufacturers. Plate thickness 2-12mm, width 2000-3000mm. Main technical specification Model Products width(mm) Products thickness(mm) Capacity(kg/h) JW130+JW70 2200 1.5-12 600-700 JW150+JW90 2600 1.5-12 800-900 Note: The specifications are subject to change without prior notice. Product image display Transmission system The function of the drive system is to drive the screw and supply the torque and speed required by the screw in the extrusion process. It usually consists of a motor, a reducer and a bearing. Heating and cooling device Heating and cooling are necessary conditions for the plastic extrusion process to take place. 1. The extruder usually uses electric heating, which is divided into resistance heating and induction heating. The heating sheet is installed in the body, neck and head. The heating device heats the plastic in the cylinder externally to increase the temperature to reach the temperature required for the process operation. 2. The extruder cooling device is set to ensure that the plastic is in the temperature range required by the process. Specifically, it is to exclude the excess heat generated by the shear friction caused by screw rotation, so as to avoid the temperature being too high to make the plastic decompose, scorch, or shape difficult. The barrel cooling is divided into two types: water cooling and air cooling. Generally, small and medium-sized extruders are more suitable for air cooling, and large-sized ones are mostly water-cooled or combined with two forms of cooling. Read the full article

2 notes

·

View notes

Text

Premium Cylinder Liners for Enhanced Engine Performance

Essential parts of an engine's construction and cylinder liners greatly affect engine performance and lifetime. Often called engine sleeves, these liners offer a protective layer inside the engine's cylinders where combustion takes place. Maintaining ideal engine performance depends on heat dissipation, which the liners aid with, as well as from less friction and wear and strain. Premium-quality cylinder liners guarantee that the engine operates smoothly, effectively, and for a longer amount of time, whether the vehicle is commercial, industrial equipment, or personal car. One cannot emphasize their importance in improving general engine conditions.

Material Quality and Manufacturing Accuracy

The materials used and the manufacturing precision determine most of the lifetime and performance of cylinder liners. Usually formed from high-grade cast iron or alloyed steel, premium cylinder liners have excellent resistance to wear, heat, and corrosion, which makes these materials desirable. Including honing and precision polishing, the manufacturing process guarantees that the liners preserve an exact fit and excellent roundness. This accuracy reduces friction between the piston and the liner, producing smoother engine performance. Avoiding expensive repairs and guaranteeing long-term dependability depend on investments in premium cylinder liners.

Improved heat dissipation for best performance

Their capacity to improve heat dissipation is among the main benefits of premium cylinder liners. During combustion, engines produce a lot of heat; if this heat is not well controlled, overheating and damage may result. Premium liners improve engine performance by effectively transferring heat away from the combustion chamber, therefore preventing overheating. These liners lower component failure risk and enable the engine to function more effectively by preserving a balanced temperature. This is crucial for high-performance engines running under specific demanding conditions.

Reducing Wear and Tear in Highly Stressful Conditions

Particularly in commercial and industrial uses, engines bear great stress. This strain, over time, can cause internal components—especially the cylinder walls—to degrade. A protective barrier and premium cylinder liners help to lower engine wear and tear. Their new manufacturing methods and better materials guarantee that they may survive in high-stress conditions without sacrificing their structural integrity. Lowering the frequency of maintenance and replacements increases engine lifetime. Furthermore, by reducing wear, these liners preserve engine performance and fuel economy, thus saving long-term costs.

Long-Term Benefits and Cost-Effectiveness

Although premium cylinder liners would seem to be a major outlay, their long-term advantages much exceed their original cost. Over time, these liners save a great deal by shielding the engine from too much wear, enhancing fuel economy, and avoiding expensive repairs. Furthermore, premium liners are a great option for both personal and business automobiles because of their higher dependability and performance. Their longevity guarantees fewer replacements, which reduces maintenance expenses. Any engine owner would be wise to invest in these liners, given their low cost and improved engine performance they produce.

Conclusion

Enhancement in engine performance, heat dissipation, and wear reduction in high-stress environments all depend on premium cylinder liners. Their premium components and exact production guarantees better fuel economy and a longer lifetime for your engine. Although the initial cost could be more than that of regular liners, their long-term advantages—fewer repairs and reduced maintenance costs—make them wise investments. Consider premium cylinder liners from thepartsxperts.com, where quality meets innovation for the best engine solutions if you want to improve the performance and lifetime of your engine.

For More Info:

cylinder liners

0 notes

Text

The Best Heat Pumps Australia

Heat pump water heaters transfer heat from the air to the water tank rather than using electricity directly, which means they use up to 75% less energy over time than traditional electric hot water systems. They also qualify for government financial incentives and rebates.

iStore best heat pumps Australia are designed with Australia's climate in mind and boast an impressive Coefficient of Performance. Their intelligent heating cycle automatically adjusts to your household's usage patterns, maximizing efficiency and reducing energy costs.

1. Chromagen 280L

The Chromagen Midea heat pump is an energy efficient hot water system that has a high Coefficient of Performance (COP). This means that it uses less electricity to produce more water, saving on running costs. It is also designed for Australian conditions and features a range of additional safety and convenience functions.

With a capacity of 170 litres, this system can provide enough hot water for households of four people. It can meet the hot water requirements of most Australian families, even in warmer climates.

It is competitively priced upfront and engineered to decrease monthly energy bills over time. It can be used in conjunction with photovoltaic solar panels to optimise self-consumption, energy savings, and carbon footprint reduction.

2. Airoheat 250L

Dux is a hot water leader when it comes to energy efficiency, as evidenced by their Airoheat heat pump range. The innovative technology can reduce greenhouse gas emissions by up to 60% compared with traditional systems. It also helps save Australians money and contributes to a sustainable future.

The Evo270 is a great choice for homes in any part of Australia, as it is able to operate in climate zones 1-7. It uses a glass liner tank that is durable and easy to maintain, and it can be boosted with an electric heat pump booster element.

Like other hot water heat pumps, this unit is eligible for a range of rebates and incentives, including Small-scale Technology Certificates (STCs) for renewable energy. Salmon Plumbing can help you determine if you are eligible for these benefits and ensure that you receive the best possible price. We also offer installation services. Our experts can advise you on the size of hot water system that you need to maximise your savings.

3. Rheem 325L

The Rheem MPi 325L Heat Pump is the perfect system for moderate to warmer climates and average size families. It uses next generation environmental heating technology which captures heat from the air to efficiently heat your water, so you can reduce energy usage and costs day and night. It also significantly reduces greenhouse gas emissions and over time. It has a large 325 litre capacity which enables the system to run at a constant optimised rate for your household. The system comes with a backup electric element so you can be confident your family will always have hot water.

The Rheem MPi Heat Pump is a great alternative to an electric hot water system and is available for purchase online with a 5 year cylinder warranty, 10 year collector(s) warranty, and 1 year parts including labour. Warranty terms are subject to change. Please see our Terms & Conditions for more information. Energy and greenhouse gas reductions based on Australian Government approved TRNSYS simulation modelling.

4. Thermal Ark Ark270

The Thermal Ark Ark270 is another great heat pump system that has some of the lowest upfront costs on this list. It uses the air outside your home to heat water and can operate in all Australian climates. It also has a number of operating modes to suit different needs, including vacation mode that saves energy by reducing the amount of hot water produced.

Unlike some heat pumps Australia that use natural gas to boost their energy output, the Ark270 is powered by electricity only. This makes it more affordable and more environmentally friendly. It can save heavy users hundreds of dollars a year on energy bills and is also eligible for government rebates.

Like the Chromogen 280L, this model has several customer-friendly features, including an easy-to-use controller and vacation mode that allows you to control the temperature of your hot water. It also has a long warranty and low noise levels. While the tank requires an anode replacement and checking of the pressure relief valve every so often, it is relatively easy to maintain.

#best heat pumps Australia#heat pumps Australia#heat pumps#heat pumps for hot water#heat pumps sydney

0 notes

Text

Twin Shaft Mixer Design

The ingenious twin shaft mixer design makes its mixing effect very good, especially for the viscous and stretchy materials, the mixing effect is more obvious.

Structure composition of twin shaft mixer:

Twin shaft concrete mixer is mainly composed of base frame, mixing tank, two mixing shafts, mixing blades, front and rear supporting body, gears, couplings, reducer, clutch, drive belt, motor, water pipe and cover and other components. The mixing parts are two synchronized spiral rotors with symmetrical shapes, and the two spiral shafts are synchronized in speed and opposite in direction during rotation.

Mechanical part design of twin shaft mixer:

Transmission system: including electric motor, reducer, gears and bearings, etc. It is used to transmit power and ensure the normal rotation of the mixing cylinder. The selection of motor is based on the production capacity of the concrete mixer and the working environment for comprehensive consideration, while the selection of reducer is based on the reduction ratio and torque size and other factors.

Mixing system: it consists of mixing drum, mixing blades and feeding inlet, etc. The volume of mixing drum is suitable for the production demand, and the number, shape and arrangement of blades ensure that the concrete can be fully mixed.

Hydraulic system: It is mainly used to control the opening and closing of feeding port, discharging port and tilting angle of mixing cylinder, etc. The flow rate and pressure are suitable for the production demand, and the control mode is flexible and convenient.

Design Consideration of twin shaft mixer:

Strength and durability: the design takes into account the strength and durability of the material to ensure that the mixer can run stably for a long time.

Repair and maintenance: the design pays attention to the convenience of repair and maintenance so as to facilitate timely repair in case of failure.

Transportation and installation: the design takes into account factors such as transportation and installation of the mixer to ensure that the mixer can be used normally on site.

Advantages of twin shaft mixer:

Strong mixing capacity: the mixing capacity of twin shaft concrete mixer is strong, and it is effective in mixing dry-hard, semi-dry-hard, plastic and various proportions of concrete.

Short mixing time: the main mixing zone is located in the circumferential direction of the mixer, which can make full use of the mixing space, so that the aggregate, cement and water can reach the average and optimal mixing form in a short time, saving energy.

Environmental protection: the whole mixing and conveying process is carried out in the sealed space, which will not cause dust leakage, clean and environmental protection.

Convenient maintenance: adopting advanced anti-locking shaft system and high-pressure water curtain cleaning system, it is easy to maintain and repair.

Low wear and tear of mixing blades: most of the concrete is piled up between the two mixing shafts during the mixing process, which reduces the wear and tear between the mixing arms, blades and bottom liner.

Low noise: low mixing noise and good working environment.

To summarize, with its unique design and significant advantages, twin shaft mixer occupies an important position in the field of concrete mixing equipment.

This resource is from https://www.concretebatchplant24.com/twin-shaft-mixer-design.html Should you be interested in buying our product, please contact us at: Haomei Machinery Equipment Co.,ltd Whatsapp/Wechat: 0086 181 3788 9531 Email: [email protected]

0 notes

Text

STORAGE OF RENEWABLE ENERGY [CNG] AT HIGH PRESSURES

In 2022, India became the fourth largest country in the world by valuation of the automotive industry. With this massive influx of automobiles, India is leaning towards Compressed Natural Gas (CNG) as a significant renewable energy variant. CNG as a fuel helps curtail emissions from traditional fuels such as diesel and petrol. India’s projected sales of CNG vehicles will increase from 863.22 thousand units in 2021 to 1,463.46 thousand units by 2029.

Government Initiatives to Promote CNG Vehicles:

Individual states are investing heavily to build a CNG infrastructure.

Keeping the price of CNG lower than traditional fuels prompt customers to see it as a cost-saving option.

SATAT Scheme for producing automobile-grade CNG from biogas generated from waste.

The segment was dominated by passenger vehicles; sales of CNG accounted for 12.1 percent of sales at 177,410 units as against 120,070 units in 2021; carmakers are betting on CNG in a big way as it gives owners a more affordable driving option. The top CNG car manufacturers are Maruti Suzuki, Tata Motors, Hyundai, Bajaj & Mahindra.

Infrastructure:

One of the critical elements to support this boost in sales will be technology in the form of safer storage for this flammable gas at higher pressures. CNG is stored at 250 barg pressures in the cascades at filling stations and transferred into smaller cylinders, cars, buses, etc.

CNG Cylinder Types and Manufacturers:

CNG tanks can be categorized into Type 1, Type 2, Type 3, and Type 4. The type is determined primarily based on design, production method, and liner material. Generally, in India, Type 1 Cylinder comprises all steel, which is relatively economical and heavier. The varying capacity of 30 L, 60 L, and 90 L cylinders are used in 3-wheelers, cars, trucks, and buses.

Use of Compressor:

A high-pressure compressor is used in a very critical stage of the manufacturing process. The air leakage test is one of the final, conclusive tests wherein the cylinder's integrity is checked before it is given a clean chit for dispatch. Compressed air at 400 barg pressures and 200 m3/hr flows are generally required for the process.

COMPRESSORS SOLUTIONS FROM ELGI SAUER RANGE FOR CNG CYLINDER TESTING APPLICATION:

Suction pressure: max. 16 bar g Final pressure: max. 500 bar g Volume Flow Rate: max. 500 m3/ h Rated Power: max. 75 kW for Air

ORKAN series compressors are based on a flexible modular system and cover a wide output range.

High-pressure air compressors up to 500 barg

Real gas boosters with inlet pressures of up to 16 barg

Hermetically gas-tight designs with magnetic coupling

Standard products for air, nitrogen, helium, CNG, and hydrogen

Ex-proof versions acc. to ISO 80079-34:2018 and the European ATEX directive 2014 / 34 / EU

Magnetic coupling drives for Gas Boosters.

Orkan gas boosters feature Sauer's first magnetic coupling drive for hermetically gas-tight compressors. It guarantees absolute gas tightness, is extremely low maintenance, and operates with maximum reliability.

CubeCooler

The new CubeCooler enables re-cooling temperatures more than 30% lower than conventional cooler configurations. Coolers have been arranged radially around the combined fan and flywheel for a high cooling capacity like this.

for visit : https://www.elgisauer.com/blogs/storage-of-renewable-energy-cng-at-high-pressures/

0 notes

Text

4 Stroke 7.5 HP Petrol Engine: A Review of Soberoses' Powerful and Reliable Motor

The 4 Stroke 7.5 HP is a powerful engine.5 HP 4kW Petrol Engine by Soberoses is a powerful and reliable motor engine designed to handle heavy loads. With its impressive features such as stable operation, humanized functions, large fuel tank, and good heat dissipation, this petrol engine offers convenience and efficiency for a variety of applications. In this review, I will share my personal experience with this product and provide an overall assessment of its performance. I recently purchased the Soberoses 4 Stroke 7.5 HP 4kW Petrol Engine for my farm, and I must say, it has exceeded my expectations. The engine's running power of 4000W and rated speed of 3600 rpm provide sufficient power to run various appliances and equipment on my farm. From powering lamps and refrigerators to operating high-current electric tools, this petrol engine handles it all effortlessly.One feature that I particularly appreciate is the stable operation of the engine. With its high-quality starter and cast iron cylinder liner, I have experienced smooth and uninterrupted performance. I no longer have to worry about the engine jamming or facing any unexpected issues during operation.The humanized functions of this petrol engine are also worth mentioning. The low oil alarm light and automatic shutdown feature ensure that the engine operates reliably for a long time. I no longer have to constantly check the oil levels as the alarm system alerts me when it's time for a refill. Additionally, the high-quality muffler significantly reduces noise levels, creating a comfortable working environment.The large fuel tank capacity of 3.6L is a great advantage, as it allows me to work for extended periods without constantly refueling. This saves me valuable time and energy, especially during long hours of farm work.Furthermore, the good heat dissipation system of the petrol engine is impressive. The forced air cooling system and heat dissipation holes effectively regulate the motor temperature, preventing overheating and extending the engine's service life. This feature also ensures safety during prolonged use. 4 Stroke 7.5 HP: Sufficient Power for Heavy LoadsCredit - Amazon.comBuy On AmazonThe 4 Stroke 7 has one of the key aspects.5 HP 4kW Petrol Engine is its impressive power output. With a running power of 4000W and a rated speed of 3600 rpm, this engine is capable of handling heavy loads with ease. Whether you need to power lamps, refrigerators, household air conditioners, or high-current electric tools, this petrol engine has the power to get the job done.4 Stroke 7.5 HP: Stable and Effective OperationCredit - Amazon.comBuy On AmazonIts stable operation is another important feature of this petrol engine. With a high-quality starter and cast iron cylinder liner, the engine works smoothly and effectively, avoiding any potential jamming issues. This ensures that you can rely on this engine for consistent performance, even in demanding situations.Humanized Functions for Convenience and SafetyCredit - Amazon.comBuy On AmazonThe 4 Stroke 7 is mentioned again.5 HP 4kW Petrol Engine is designed with humanized functions to enhance convenience and safety. It features a low oil alarm light and automatic shutdown system, which ensures that the engine operates reliably over the long term. Additionally, the high-quality muffler significantly reduces noise levels, creating a more comfortable working environment.Large Fuel Tank for Extended UseCredit - Amazon.comWith a capacity of 3, the generous fuel tank is worth mentioning.6L, this petrol engine allows for extended periods of use without frequent refueling. This is particularly beneficial for tasks that require continuous power for an extended duration. By minimizing the need for refueling, this engine saves you time and energy, allowing you to focus on the task at hand.4 Stroke 7.5 HP: Effective Heat Dissipation for LongevityCredit - Amazon.comThe 4 Stroke 7 is referred to once more.5 HP 4kW Petrol Engine is equipped with a forced air cooling system and heat dissipation holes, ensuring effective heat dissipation. This not only helps to reduce the motor temperature but also prolongs the engine's service life. By minimizing heat buildup, this engine minimizes safety hazards and ensures reliable performance for years to come.4 Stroke 7.5 HP: Customer ReviewsCredit - Amazon.comAt this time, there are no available customer reviews. We encourage you to check back later for feedback from satisfied customers who have experienced the benefits of the 4 Stroke 7.5 HP 4kW Petrol Engine. Pros: - Sufficient power - The 4 Stroke 7.5 HP petrol engine has a running power of 4000W, making it capable of handling heavy loads from various household appliances and high-current electric tools. - Stable operation - With its high-quality starter and cast iron cylinder liner, this petrol engine ensures stable and efficient performance, minimizing the risk of jamming. - Humanized functions - The engine features a low oil alarm light and automatic shutdown, providing long-term reliable operation. The high-quality muffler also reduces noise levels, creating a comfortable working environment. Cons: - Limited fuel tank capacity - Although the petrol engine has a generous fuel tank capacity of 3.6L, it may require frequent refueling during extended usage, which can be time-consuming. - No specific product rating mentioned - The product description does not mention the rating given by customers who have purchased and used the petrol engine, making it difficult to gauge its overall performance and reliability. - Lack of detailed product reviews - The product description does not provide any specific details about customer reviews, making it challenging to gather information about the experiences and satisfaction levels of previous buyers. Read also: - 750W Petrol Generator - Power Up Anywhere with the POLLOR - Reliable and Efficient Portable Power: Wolf 2000w Petrol Inverter Generator - Versatile and Reliable Backup Power Solution for Camping and Emergencies - Portable and Efficient Power Solution: Spark Petrol Inverter Generator W2000i Conclusion Overall, the Soberoses 4 Stroke 7.5 HP 4kW Petrol Engine has proven to be a reliable and efficient motor engine for my farm. Its powerful performance, stable operation, humanized functions, large fuel tank capacity, and good heat dissipation make it an excellent choice for various applications. I highly recommend this petrol engine to anyone in need of a dependable power source for their home backup, pumps, vehicles, or farm equipment. With its reasonable price of £135.00, it offers great value for the money. Questions & Answers: Question: How long can the petrol engine run without refueling?Answer: The petrol engine has a fuel tank capacity of 3.6L, which allows it to work for extended periods without the need for frequent refueling. However, the exact duration depends on the load and usage conditions.Question: Is the petrol engine easy to start?Answer: Yes, the petrol engine is equipped with a high-quality starter, ensuring easy and convenient starting.Question: Does the petrol engine produce excessive noise?Answer: No, the petrol engine features a high-quality muffler that greatly reduces noise levels, providing a comfortable working environment. Buy On Amazon Read the full article

0 notes

Text

Cylinder Liners and Cylinder Sleeves Manufacturer | RA Power

RA Power Solutions' commitment to precision, durability, and innovation sets it apart as a reliable manufacturer of cylinder liners and sleeves. The company's dedication to quality control, advanced manufacturing techniques, and customization options make its products a preferred choice for those seeking top-tier components for internal combustion engines. As engines continue to evolve, RA Power Solutions remains at the forefront of providing cutting-edge solutions to meet the demands of the industry. To get more details, contact us at [email protected], 0124-425-1615, or +91-9810012383.

0 notes

Text

CNG cylinder

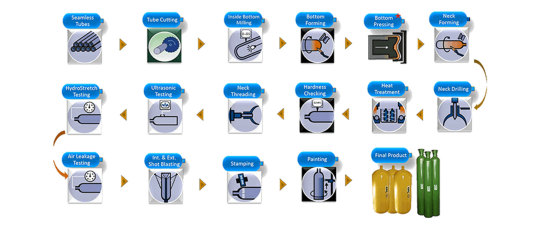

Type 1 CNG CYLINDERS

Type 1 CNG Cylinders for LIGHT-DUTY VEHICLES, MEDIUM AND HEAVY-DUTY VEHICLES Type 1 CNG cylinders are made of steel. Available Capacity (L), 30, 35, 40, 50, 60, 70, 80, 90. DSW CNG cylinders are manufactured conforming to specific country national standards or International standards like ISO: 11439, ECER 110, GB17258, ISO: 11120 Compressed Natural Gas cylinders (CNG cylinders) are a popular alternative with truck, transit, and refuse fleets.

Category: cng cylinders for vehicleTags: CNG Gas Cylinder, Compressed Gas Cylinder

Description

ISO11439 Type 1 CNG CYLINDERS

Type 1 CNG cylinders are used regularly in science and engineering buildings, machine shops, and retail and campus dining. Researchers, staff, and contractors store and use various compressed gases for different reasons. Compressed natural gas (CNG) is a fuel gas mainly composed of methane (CH4), compressed to less than 1% of the volume it occupies at standard atmospheric pressure.

CNG TANK SIZES

what is a Type 1 gas cylinder?

Type 1 CNG gas cylinders: Type 1 cylinders feature an all-steel shell construction, featuring no composite materials in their design.

Type 1 CNG Cylinder, which can store natural gas under pressure 20MPa or 25MPa made of 4130X seamless steel tube with ISO9809-1/ISO9809-3/EN/DOT approval. which are explosive pressure vessels containing flammable and explosive gases. The storage pressure for automotive cylinders is 20MPa.

Suitable applications include: Scuba Modified atmosphere packaging (MAP) Laboratory Onsite industrial/manufacturing

There are four categories available in CNG gas cylinders. The first category is seamless alloy steel cylinders (CNG-1). CNG-2 is a composite gas cylinder with steel or aluminum lining and a barrel reinforced with long fibers impregnated with “hoop winding” resin. The third category is composite gas cylinders with aluminum liner plus carbon fiber fully wound and glass fiber ring wound reinforcement (CNG-3). The fourth category is the composite gas cylinder with plastic liner plus carbon fiber full winding and glass fiber ring winding reinforcement (CNG-4).

Each of these Compressed Gas cylinders has its advantages and disadvantages, and it depends.

The main cylinders used worldwide are steel cylinders, generally made from high-quality chromium-molybdenum steel, and the ISO 11439 and ECE R110 standards can meet the requirements of most countries.

A complete automotive CNG cylinder has a cap, a valve, and a safety relief device. The cap protects the valve, and the safety relief device on the valve should be of the rupture disc-fusible plug combination type.

0 notes

Text

Australia's Best Value Ute: Discover the 2023 Mazda BT-50

The Mazda BT-50 is gaining attention as the best value ute available in Sydney today. This truck stands out with its powerful diesel engine, comfortable interior, and modern technology.

Sydney's Best Value Ute:

Powerful Towing Capability

Great utes need outstanding towing capabilities, and the BT-50 delivers. The 3.0-litre 4-cylinder turbo diesel engine has a powerful design with a towing capacity of 3,500 kg. While powerful, it's also fuel efficient. This truck has an average combined fuel consumption rate of 7.7L/100km.

Exterior Design

The standard 17" alloy wheels enhance this truck's traction and style. Mazda has added LED headlamps for improved visibility, with automatic on and off functions. The standard roof rack has mounting points, making it an easy place to secure cargo. The XTR-LE variant has a strong and stylish sports bar. The polished stainless steel is made of the highest quality materials and includes an integrated LED stoplight. Additionally, the tub liner is made with heavy-duty materials, keeping the tub protected from scratches and dents.

Interior Style

The standard XT cab chassis variant seats five passengers. The interior is comfortable with cloth seats and smart storage options, with two cupholders in the front and two in the back. The GT Pickup variant elevates the soft surfaces, adding leather seats and wrapping the steering wheel in leather as well. The GT Pickup also adds heated front seats for enhanced comfort in cold weather conditions.

Safety Assist Features

Today, a vehicle really meant for modern utility requires advanced safety assist features that make everyday driving easier. The BT-50 is well-equipped with standard features like attention assist, automatic emergency braking, and brake assist. The blind spot monitoring feature will watch your sides and alert you when the system detects danger. This makes changing lanes on busy roadways a lot safer. Mazda has also included features like a forward collision warning and lane departure warning. There are also automatic high beam controls, which will lower your high beams to reduce glare for oncoming traffic. The BT-50's reverse camera makes backing in and out of tight parking spaces a breeze. This truck also watches the back for you with a rear cross-traffic alert.

Modern Infotainment Features

The BT-50 is well-equipped with comforting entertainment options for long days spent in the truck. The vehicle's touchscreen comes in either a 7" or 9" inch model. It includes wireless Apple Car Play or Android Auto, so you can easily connect your smartphone. The standard truck has a six-speaker audio system, providing a great experience for listening to your favourite music. Bluetooth technology allows the driver to use their phone hands-free. There are also audio controls mounted on the steering wheel so you never have to worry about distractions from your phone. The BT-50 is a ute with many variants, making it easier for drivers to select the features they want most. Every version of this truck is powerful and well-equipped with modern technology. Drivers prioritising power will want to learn more about this option.

0 notes

Text

Diesel and Marine Engine Cylinder Liners and Sleeves

A complete cylinder liner repair and reconditioning service is provided by RA Power Solutions. Your cylinder liners will be examined by our team of skilled engineers and technicians for any cracks, wear, or other damage. In order to verify that the cylinder liners meet or exceed factory requirements, we shall, if necessary, repair or replace them. Your cylinder liners will remain in good shape for many years to come since we also provide a 12-month warranty on our reconditioning services. For more information about babbitt white metal,rebabbitting of bearing, contact us by email at [email protected], 0124-425-1615, or +91-9810012383.

#cylinder liner repair#diesel engine repair#cylinder liners#cylinder liners and cylinder sleeves#casting of cylinder liner#diesel engines

0 notes

Text

Different Types Of Strainers In Pipeline

Different Types Of Strainers In Pipeline Are you looking to learn about the different types of strainers used in pipeline systems? If so, you’ve come to the right place. Understanding the different types of strainers and their applications can help you choose the right strainer for your pipeline system, ensuring that it functions optimally while minimizing maintenance costs. Working Pressure and Temperature Ranges of Strainers The first thing to consider when choosing a strainer is its working pressure and temperature ranges. Strainers with an open area ratio of two to four times the cross-section of the inlet pipe are recommended. Additionally, the critical velocities of the straining medium should be known, as the higher the screen velocity, the larger the differential pressure drop. What is a Strainer Valve? A strainer valve is an important piece of equipment that protects a pipeline system by removing unwanted debris that can clog up components and damage equipment. The size of a strainer’s mesh is determined by the size of the particles that need to be filtered, with larger mesh sizes being able to filter larger particles. Mesh-lined strainers are the most common type and can achieve fine straining, but are more expensive. Basket Strainer Basket strainers are used to protect downstream equipment by preventing solids and debris from entering the system. When selecting a basket strainer, it is important to consider the type of liquid and pressure that will be encountered. These are the most commonly used in food and beverage processing. Y-Type Strainer A Y-type strainer is characterized by two metal plates held together by bolts or gaskets, with a perforated sheet and wire-mesh lining. It is used to filter liquids through pipelines and can work in both vacuum and suction conditions, but has a lower dirt-holding capacity and requires more frequent cleaning. Temporary Strainers Temporary strainers are used to remove debris from pipelines during the startup of new pipelines or during the cleaning and modification of existing systems. They are designed to function at high differential pressures and are installed upstream of pumps and other equipment to protect them from debris and foreign objects. Special Type Strainers Special type strainers are designed to remove solid matter from a pipeline and feature a perforated metal mesh as the straining element. They are used for specific applications, such as wide differential strainers, jacketed strainers, magnetic strainers, micronic strainers, offset strainers, and reducing strainers. Conclusion In conclusion, understanding the different types of strainers and their applications is important in choosing the right strainer for your pipeline system. Basket strainers, Y-type strainers, temporary strainers, and special type strainers all have specific uses and are made of different materials. By selecting the right strainer, you can protect your downstream equipment, minimize maintenance costs, and ensure your pipeline system functions optimally. MAN 7S35MC-MK7 Cylinder Liner from Decho Marine Services Decho Marine Services (China) Tingting +86 159-6706-1188 [email protected] from Decho Marine Services Decho Marine Services (China) Tingting +86 159-6706-1188 [email protected]

0 notes

Text

HDPE Thermoforming Plate Extrusion line

Jwell supply advanced extrusion system, it is suitable to produce HMW-HDPE material which have low MFI and high-strength into plate, the plates are mainly used to produce auto carriage board, pick-up's box liner, cover of truck, anti-rain cover etc. The plate thickness can reduce more than 30% when it has same impact strength, it reduce the production cost for manufacturers. Plate thickness 2-12mm, width 2000-3000mm. Main technical specification Model Products width(mm) Products thickness(mm) Capacity(kg/h) JW130+JW70 2200 1.5-12 600-700 JW150+JW90 2600 1.5-12 800-900 Note: The specifications are subject to change without prior notice. Product image display Transmission system The function of the drive system is to drive the screw and supply the torque and speed required by the screw in the extrusion process. It usually consists of a motor, a reducer and a bearing. Heating and cooling device Heating and cooling are necessary conditions for the plastic extrusion process to take place. 1. The extruder usually uses electric heating, which is divided into resistance heating and induction heating. The heating sheet is installed in the body, neck and head. The heating device heats the plastic in the cylinder externally to increase the temperature to reach the temperature required for the process operation. 2. The extruder cooling device is set to ensure that the plastic is in the temperature range required by the process. Specifically, it is to exclude the excess heat generated by the shear friction caused by screw rotation, so as to avoid the temperature being too high to make the plastic decompose, scorch, or shape difficult. The barrel cooling is divided into two types: water cooling and air cooling. Generally, small and medium-sized extruders are more suitable for air cooling, and large-sized ones are mostly water-cooled or combined with two forms of cooling. Read the full article

0 notes

Text

Engine Cylinder Sleeves

Engine Cylinder Sleeves UAE, USA & Engine Cylinder Liner

Engine Cylinder Sleeves and Engine Cylinder Liner Manufacturer and Supplier in the USA, UAE and is renowned in the engine remanufacturing industry is Jaidarshan Indocraft. With years of experience in the industry, we have been manufacturing sleeves for a wide range of applications, including automotive, tractor, Power Generation, HVAC, marine, and other high-performance racing and engine applications. Backed with years of experience and in-depth knowledge, we can customize cylinder sleeves as per specific customer needs.

Our Range of High Performance Cylinder Liners and Sleeves

Specialist Cylinder Liner Manufacturer and Suppliers in the USA Optimum Cylinder Liners for high-performance engines

A cylinder liner is a cylindrical part fitted into a diesel engine block that forms a cylindrical space in which the piston requites smoothly. One of the most crucial functional parts is the formation of an engine. Usually, Cylinder liners are made of Cast Iron, Cast Steel, Nickel, and Nickel Chrome CI. Usually, the liner will wear and tear over time and needs to be replaced. The temperature of the liner is hotter than the jacket. For higher efficiency and performance, engine sleeves or Cylinder Liners are used.

One-Stop Solution for Engine Cylinder Sleeves

Our Cylinder Engine Liners are made with cast iron alloyed with Moly , Nickel , chromium, vanadium, and molybdenum, which improves corrosion resistance and enhances the wear resistance capacity. Engine liners are used at high temperatures and high pressure. Piston and piston rings are sliding at high speeds, which causes wear and tear. Usually, the liners wear off with consistent use and need an extra quality product that lasts longer. We manufacture – wet liners and dry liners that are used in engines.

As a Cylinder Liner Supplier in USA, we deliver high-performance products and efficient Dry Cylinder Liner and Wet Cylinder liners for military and commercial class vessels to perform rigorous operating conditions.

Our Cylinder Liner Dry and Wet

Provides different liners and sleeves with sustainable material and a high-end appearance to survive with long life. All you need to do is to provide the corresponding product name and get a quotation.

Compatible with almost all engines

Simple structure

Convenient processing

Convenient processing

Types of wet cylinders and sleeves that are highly sustainable with service life up to 300,000 km. Provide corresponding product codes to get quotations.

Comes with cooling water gap between engine block and liners

Manufacturer to incorporate cooling passages.

Provides better cooling and more even temperature distribution

Leading Cylinder Liner Supplier

Jai Darshan Indocraft is a leading manufacturer and supplier of Cylinder Liners and Sleeves, pistons, and other spare parts. We have been providing superior grade high-performance products to meet the demand of industries.

We are a Cylinder Liner Dry and Wet manufacturer in India, with state of the art manufacturing facility and testing chemical compositions. We ensure that each batch complies with the right formulation and gives out proper liner properties.

Call us now – +91 93779 67468 or more information enquire us at [email protected]

0 notes

Text

What are the compound fertilizer granulation equipment?

Building an npk production line requires a compound fertilizer granulator. There are many compound fertilizer processing and granulating equipment. Some companies are not clear how to choose a suitable compound fertilizer granulator. What are the compound fertilizer granulating equipment introduced today? There are three main types of compound fertilizer granulators: rotary drum granulator, disc granulator machine and double roller granulator. What is the difference between these compound fertilizer granulators? What are the advantages and disadvantages of each?

The disc granulator machine mainly uses the rolling of the disc surface and the granulation of the granules themselves, and is used in conjunction with the upper mixer to achieve a high ball forming rate. The investment cost of granulator equipment is low, and the production capacity is strong, but the dust of open-air granulation is relatively large.

The barrel of the rotary drum granulator equipment is lined with a special rubber plate or an acid-resistant stainless steel liner to realize automatic scar removal and tumor removal, and the traditional scraper device is eliminated. A drum granulator is a forming machine that can shape materials into specific shapes. The main working method is granule wet granulation. With a certain amount of water or steam, the basic fertilizer can fully react after being humidified in the cylinder. Under certain liquid phase conditions, with the help of the rotary motion of the cylinder, the extrusion force between the material particles is agglomerated into balls. The investment cost of fertilizer equipment is high, the production capacity is strong, and the dust of drum granulation is relatively small.

The double roller granulator is produced by a non-drying normal temperature process, and it is formed at one time. The equipment has low investment, quick effect and good economic benefit. The complete set of equipment is compact in layout, scientific and reasonable, and advanced in technology. Energy saving and consumption reduction, no waste discharge, stable operation, reliable operation and convenient maintenance. Wide adaptability of raw materials, suitable for granulation of raw materials such as compound fertilizer, medicine, chemical industry, feed, etc., and the product granulation rate is high. Various concentrations and types of compound fertilizers (including organic fertilizers, inorganic fertilizers, biological fertilizers, magnetic fertilizers, etc.) can be produced.

1 note

·

View note

Photo

The Jaguar E-Type, or the Jaguar XK-E for the North American market, is a British sports car that was manufactured by Jaguar Cars Ltd between 1961 and 1975. Its combination of beauty, high performance, and competitive pricing established the model as an icon of the motoring world. The E-Type's claimed 150 mph (241 km/h) top speed, sub-7-second 0 to 60 mph (97 km/h) acceleration, unitary construction, disc brakes, rack-and-pinion steering, and independent front and rear suspension distinguished the car and spurred industry-wide changes. The E-Type was based on Jaguar's D-Type racing car , which had won the 24 Hours of Le Mans three consecutive years beginning 1955,and employed what was, for the early 1960s, a novel racing design principle, with a front subframe carrying the engine, front suspension and front bodywork bolted directly to the body tub. No ladder frame chassis, as was common at the time, was needed and as such the first cars weighed only 1315 kg (2900 lb) The E-Type was fitted with the in-line 6-Cylinder 3.8L or 4.2L SOHC Engine. The V12 Version had a Jaguar designed engine The all-aluminium block was fitted with removable wet iron liners, complete with single overhead camshaft aluminium heads with two valves per cylinder. It was regarded as one of the premier power plants of the 1970s and 1980s. Production cars had the SOHC engine at 5.3L, 6.0L or 7.0L capacity. The Racing version had the DOHC 7.0L V12 Engine

9 notes

·

View notes