#but single-treadle

Explore tagged Tumblr posts

Text

Today's fiber arts update: Guardy goes *AAAAA* about spinning tools.

I'm working on the third single of that merino yarn I'm making, and that leaves me with ample time to think - in this case about my wheel, and how it's simultaneously nearly perfect and a huge pain.

I love my wheel. It is small, it is a perfect combination of form and function, it is very familiar to me, and it cost me 40$. I love spinning on it.

But that 6:1 fixed ratio is a nightmare.

So sometimes I dream of a 14:1 wheel, leisurely spinning fine singles with some flavor of long draw, knowing that I'll get a yarn that'll hold together without having to treadle like I'm trying to set a speed record.

I'm gonna earn myself some extra money over the course of the holiday season, and I do want to put some of that into my hobbies, but I still neither have the extra space nor budget for an entire second wheel - and getting new parts made for old wheels is a complicated thing and I have no idea if I could even find someone to do that within Germany.

There isn't really a point to this aside from me being annoyed that my wheel limits my spinning speed so much.

#guardy's fiber arts tag#hand spinning#I can't even find a wheel model I'd *want*#it'd have to be a castle-style wheel with a wide variety of whorls and flyers available#a double drive wheel#but single-treadle#and decently small#and not too expensive#so basically#my wheel with a different ratio#:')

12 notes

·

View notes

Text

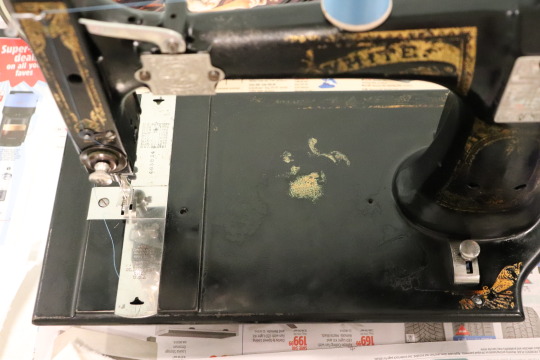

@once-a-polecat replied to your post “My uncle's friend asked if I wanted this machine...”:

So do Whites have the same parts availability as Singers? I see them around for a fraction of the price, I’ve just been holding out for a Singer because the parts are relatively easy to source. I’ve seen some really lovely White machines tho! I bet yours is going to look stunning when it’s cleaned up. That cabinet is {chefs kiss}

I don't know, I haven't looked into it because mine's not missing any pieces and still has all 6 bobbins.

I think that as long as you can verify that it has all the parts, and at least one or two bobbins, it probably won't need any new ones.. ever? The little rubber ring on the bobbin winder and the treadle drive belt degrade after a few decades and need replacing, but you can easily buy those, and everything else is highly unlikely to break from regular use.

The one thing I was worried about was accidentally stripping the screws while taking it apart for cleaning, and there was one screw that I didn't quite have the right size of screwdriver for and it started to look a bit ehhhh so I just didn't take that part off. It wasn't one of the really gunky ones anyways, and I did my best to clean around it, and may try again someday if I get more sizes of screwdriver. So I'd advise making sure you have all the right tools before starting and slathering all the stuck bits well in kroil (what the guy in a video I watched yesterday used) or wd-40 (what I used) or some such loosening thing.

It seems like it's very hard to find new bobbins, especially since there are different styles of shuttle and the bobbins are not interchangeable. Mine's a boat style and my bobbins wouldn't work in a bullet style from a couple years later.

While cleaning this thing it hasn't even crossed my mind to wonder where I'd find replacement parts because, well, what could possibly break? Nearly every single piece is cast iron or steel, and it's already been used SO much that the decals on the bottom are almost completely gone just from the amount of fabric that's run over it.

As mentioned in the previous post it's about 140 years old, was owned by a woman who made her living sewing on it for many decades, and it still works just fine! I haven't got the bobbin winder cleaned up yet and it's still off the cabinet, but I couldn't resist trying it out with just the hand wheel (using one of the bobbins that was wound long before I was born) once I got all the bits back on and yeah! Perfect stitches right away!

As long as it's kept well oiled it's just gonna keep on chugging along indefinitely.

Are you seeing these White machines in person at secondhand stores and such? If you can check to make sure they have bobbins and that no pieces are missing, I'd say grab one! Maybe keep some reference pics of working ones so you can look and see, or even better see if you can make a stitch with it before buying it, and presumably if it can do that even slowly and gunkily then it'll just need cleaning like this one did.

By all accounts they're REALLY good machines! I'm super excited to try mine out properly, and to post more about all the features. It has a lip around the bottom of the needle bar so that if some oil drips down it won't get on your needle! Genius!! Why doesn't every machine ever have that?! It's also fairly quiet AND you can adjust the bobbin tension right in the middle of a seam without disturbing the sewing or taking the shuttle out. Incredible.

The manual for mine says "The Best in the World" on it, and while that's just a normal Victorian thing to say about a product, I'm not about to argue with them. There are a few little things that I like better on Singers, such as the quality of the hinges that hold the machine to the cabinet, and the way the presser foot attaches, but all in all this White VSII is extremely goddamn good so far and I have no doubt that once I get the bobbin winder cleaned up it'll also work perfectly!

So yeah, GET ONE!

255 notes

·

View notes

Text

Supported Spindles: A Beginner's Jumping Off Point

I'm trying to put together an easy mostly-video post of how to learn supported spinning for my partner, but of course am publishing it for everyone. It's starting from the context of having some drop spindle experience, so that's what I'm assuming for the purpose of this short guide. I'm including some text information for easier referencing as well.

First--you might ask "Why spin supported at all?" That's a fair question. It's not the tool for everybody, but it fills some niches that drop spindles (and any other tool) don't, so it may be what you're looking for without you even knowing it. If you're not familiar with the wide variety of spinning tools and methods that exist, you probably don't know a ton about supported spindles. They can have many shapes and sizes, but the one thing they all have in common is that they must be in a bowl (or a spinning spoon, or some other similar curved, smooth item) to spin.

Each method and tool of spinning is suited to one thing or another, and supported spinning is suited to the following:

1) thinner yarns. While it's entirely possible to spin fine yarns on drop spindles, wheels, or what have you, supported spindles are MADE for fine spinning, and largely cannot deal with spinning thicker yarns. This makes supported spinning great for people who want to spin for 3 or 4 ply sock yarns, lace (normal lace but also the truly fine lace like wedding ring shawls), etc. However, even if you don't tend to use thin yarns, there are larger supported spindles that can handle a thicker single, so the boundaries can vary a lot.

2) sitting down and/or being stationary. drop spindles are notable for being able to be used while walking or otherwise on the go, but supported spindles, since they must be in a bowl, are best used sitting, laying, or standing at a counter. I have read about them used walking via a spinning spoon tucked into the belt, but cannot attest to how practical that is myself. This makes supported spinning great for car/train/bus rides, waiting in line, watching tv, laying in bed, or anything like that.

3) small spaces. The most ergonomic way to spin supported is sitting comfortably cross legged or in a chair, with your elbows tucked in and your hands up. Your spinning is contained entirely to your lap, and (depending on your spinning style) you don't need to extend your arms out or do anything fancy. I've spun supported on a very cramped train without bothering the stranger sitting next to me all that much, which I've never been able to do with a drop spindle. For me this makes it much more suitable for public transit than drop spindles, but I think that comes down to how you use each tool rather than the tool itself.

4) low energy. Supported spinning doesn't take much energy, because you are doing very little moving (mostly your hands and forearms). It can be a great activity for when you're sick, or before bed when winding down. It's also worth trying if chronic illness or disability is stopping you from spinning on your other tools--I had to give up the drop spindle as my primary spinning tool because my shoulders are wrecked, and I can only treadle a spinning wheel on good days, but I can usually spin supported no matter what. (If supported isn't accessible for you, an espinner is your next best bet).

5) cool sound. Can't overstate this one. A wooden spindle in a wooden bowl sounds so good. Skip the metal or ball bearing tip if you want to hear it.

Without further ado, here's some videos I've compiled that covered things I thought were helpful. As a disclaimer, I seem to learn exclusively by doing things myself, so if these videos don't work for you, try looking up "supported spinning for beginner" or something similar. There are a lot of videos, and almost every single one has a different technique. Anyway, best first:

Video: Supported Spinning Tutorial by Lori Rhone (link)

youtube

Key things from this video:

get used to flicking the spindle without any fiber (just as you should with any spinning tool). try forming an O with your fingers to trap the spindle tip so it has something to fall against, flick as close to the tip as you can manage, etc.

they show a good variety of spinning bowls, especially objects that aren't intended to be spinning bowls (salt cellars, egg bowls, etc). if your spindle spins well in it, it's a spinning bowl. try out lots of stuff if you're having trouble finding a good one.

good posture and positioning--stay comfortable and keep your arms close to you, try to stop yourself from doing weird contortions, etc.

they discuss the importance of building a balanced cop, and show on another spindle how the cop they built maintains the general shape of the empty spindle. this isn't necessary, but it's good practice and certainly good to keep in mind. with drop spindles the added weight of the yarn is usually what determines a full spindle first, but with supported spindles the shape and size of the cop (or your own patience for spinning endless fine yarn) can be what does it instead.

+++

Video: The Basics of Supported Spindle by Amy King (link)

youtube

Key things from this video:

the variety of different shapes of supported spindles (there are even more shapes than what they've shown as well)

that you need to pair spindles and bowls--they don't all work with each other equally well or at all (purple--don't worry, I tested the spindle with the bowl I sent you, they like each other)

another method to park and draft on supported spindles, which is essentially the same as on drop spindles

their sweater is fantastic

+++

Video: Supported Spindles--a few tips for beginners by Nikolai Meriadoc (link)

youtube

Key things from this video:

if you have a good bowl to spin in but it's unstable, try putting it in another bowl or nestled in a blanket or something else. this can stabilize it a lot.

pre-drafting very finely can help. i forgot to go into it in the video but multiple passes where you go finer each time is usually the way to go if starting from roving or another commercial prep, in my opinion. you could also diz your fiber if you're going for a more worsted prep.

picking a fine fiber like merino, bfl, rambouillet, etc. can help you draft finer as well.

the angle at which you hold your fiber/yarn is important. it should be almost vertical while spinning, and horizontal while winding on.

+++

Hopefully that can get you all started ! There are also articles on the subject although I didn't include any as they weren't relevant for who I'm making this for, so be sure to look into them if that's something that would be helpful for you.

And remember:

This post isn't for radfems. It was made by and for trans people who love men <3

242 notes

·

View notes

Text

It’s an open question whether a full and unaverted look at death crushes the human psyche or liberates it. One could say that it’s the small ambitions of life that shred our souls, and that if we’re lucky enough to glimpse the gargoyles of our final descent and make it back alive, we are truly saved. Every object is a miracle compared to nothingness and every moment an infinity when correctly understood to be all we’ll ever get. Religion does its best to impart this through a lifetime of devotion, but one good look at death might be all you need.

When the American writer Herman Melville shipped out on a whale-hunting ship named the Acushnet in 1841, there was a black man aboard named John Backus who was famous for having once leapt out of a chase boat in panic. His fellow crew members had to suspend the hunt to save him. Acushnet means “peaceful resting place by the water” in Wampanoag, but in reality, each whale ship was its own brutal world. The industry killed men by the score, captains were often deranged sadists, and crew members would jump overboard at the first sight of land. Melville himself abandoned ship in the Marquesas Islands and was captured by cannibals, who held him for four months before giving him up to an Australian whaler.

John Backus is thought to be the basis for a character named Pippin in Melville’s epic novel Moby-Dick. Pip, as he is called, is a young black man who serves as cabin boy on the fictional whaleship the Pequod. One day, Pip is pressed into service on a chase boat, but as soon as a whale has been harpooned, Pip panics and jumps overboard. The harpooner, a man named Stubb, is forced to cut the line—and lose the whale—so that Pip won’t die. He warns Pip, however, that next time he will choose the whale.

“But we are all in the hands of the Gods,” as Melville observed. “Pip jumped again.” True to his word, Stubb does not cut the line, and the chase boat is quickly hauled out of sight by the whale. Pip finds himself in a warm, calm sea, swimming effortlessly but completely alone. There are three miles of water beneath him and the vaulting sky above and not a single living thing in sight. An hour passes, and by some freakish chance, the Pequod comes upon him, and the crew haul him aboard. Though Pip is alive, he has seen God and been rendered imbecile. “The sea had jeeringly kept his finite body up, but drowned the infinite of his soul,” Melville writes. “Not drowned entirely, though. Rather carried down alive to wondrous depths… He saw God’s foot upon the treadle of the loom, and spoke it; and therefore his shipmates called him mad. So man’s insanity is heaven’s sense.”

After that, Pip walked the decks of the Pequod offering a reward for himself, as if he were an escaped slave who needed to be caught and returned home.

-- Sebastian Junger, In My Time of Dying

17 notes

·

View notes

Text

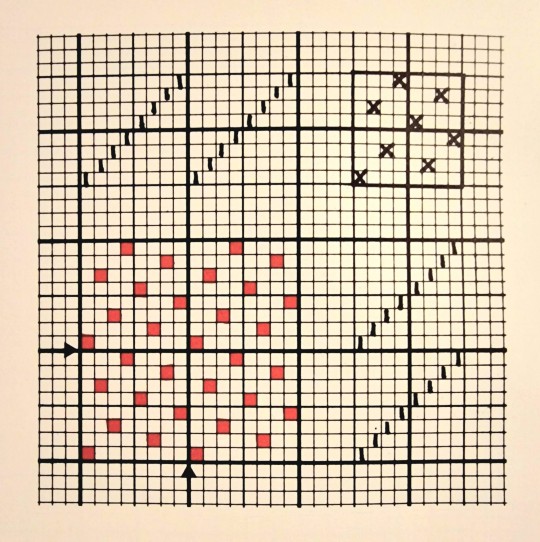

i have found the problems i was anticipating or maybe they have found me.

sidenote: was hoping this colour would be a little more olive and a little less military, i'll see what i can do about that. that'll be interesting.

anyways since everything was going very well i decided to change the tie-up to a satin - because i can weave that now!! exciting!!

as you can maybe tell from the photo, it works. but i have trouble with the last shaft, which wants to have its neutral position lower than everyone else. it's pulling down. i suspected this might be correlated with the cords of the last shaft/last treadle holes being taught, while all others have progressively more slack towards the front. so in rest position, these last cords are what hold the treadles up from the floor, the treadles rest on these cords, ergo the last shaft pulling down.

my non-weaving friend suggested yesterday that this might be an issue of me being perfectionistic and having reached a workable shed, to work with what i have achieved. that this tie-up may in fact be impossible to improve. however, i strongly feel it is not good enough to have a solution that: has a single treadle sticking up too high (making it difficult to operate) as well as a shed that is just barely workable. countermarch looms became widely used because they could do the exact thing i'm trying to do here (says allen fannin)

He also describes the issue i'm having quite nicely when talking about the balance required for the countermarch system and then he says this:

"[...] the weight of the treadles equalizes the pull on the ties to both the riser and sinker lamms, thereby canceling the resultant movement of a differential force between risers and sinkers."

when talking about how the treadles need be ≥ the weight of the harness.

overall i still don't feel like i quite understand. i suppose i can try taking out all the connections to the last shaft and see what happens. ok have tried that, 1 is still hanging low, 2 has joined it. uhm. conclusion?

the way i understand the countermarch system now, or try to picture it, is as a scale. the sinking and rising of each shaft is related to a piece of wood with a hole in the middle: when at rest, it should be horizontal. when you pull down on one end, the other rises and vice versa. to control this, both ends are attached to an upper and a lower lamm - one will raise the shed, one will lower it. which is pretty cool! because now you can make connections between these lamms and the treadles to store any combination of rising and sinking shafts. once i have done that tie-up, i can now step on the treadle, which will pull down the combination i have selected, which in turn brings up the remainder of the unconnected combination of lamms. yay, shed!

so anyways, i'm spending a lot of time sitting and staring and contemplating pivot points and feeling how much force it takes to lift pieces at different points and sighing a lot and generally feeling a little like the worlds dumbest creature. but we'll see.

in a way i am also happy to run into this issue, because if it just works, there's nothing to fix and i always feel like i don't really understand what's going on when that happens? i genuinely do prefer trying to work through issues rather than gliding along seamlessly (because that's where the learning happens yes, but also) because that is concrete, then the things i don't know take form and i can prod at their edges and try to get an idea of the shape of what i don't know. whereas if i'm unaware of not knowing something i certainly won't be able to do anything about it.

13 notes

·

View notes

Photo

Silk in Antiquity

Silk is a fabric first produced in Neolithic China from the filaments of the cocoon of the silk worm. It became a staple source of income for small farmers and, as weaving techniques improved, the reputation of Chinese silk spread so that it became highly desired across the empires of the ancient world. As China's most important export for much of its history, the material gave its name to the great trading network the Silk Road, which connected East Asia to Europe, India, and Africa. Not only used to make fine clothes, silk was used for fans, wall hangings, banners, and as a popular alternative to paper for writers and artists.

Origins & Cultivation

Silk is produced by silk worms (Bombyx mori) to form the cocoon within which the larvae develop. A single specimen is capable of producing a 0.025 mm thick thread over 900 metres (3,000 ft) long. Several such filaments are then twisted together to make a thread thick enough to be used to weave material. Fabrics were created using looms, and treadle-operated versions appear in, for example, the murals in tombs of the Han dynasty (206 BCE - 220 CE). The silk could be dyed and painted using such minerals and natural materials as cinnabar, red ochre, powdered silver, powdered clam shells, and indigo and other inks extracted from vegetable matter.

Sericulture - that is the cultivation of mulberry leaves, the tending of silkworms, the gathering of threads from their cocoons and the weaving of silk - first appears in the archaeological record of ancient China c. 3600 BCE. Excavations at Hemudu in Zhejiang province have revealed Neolithic tools for weaving and silk gauze. The earliest known examples of woven silk date to c. 2700 BCE and come from the site of Qianshanyang, also in Zhejiang. Recent archaeological evidence suggests that the Indus Valley civilization in the north of the Indian subcontinent was also making silk contemporary with the Neolithic Chinese. They used the Antheraea moth to produce silk threads for weaving.

However, silk production on a large scale and involving more sophisticated weaving techniques would only appear from the Chinese Shang and Zhou dynasties in the 2nd millennium BCE. Silk then became one of the most important manufactured and traded goods in ancient China, and finds of Shang dynasty (c. 1600 - 1046 BCE) silk in an Egyptian tomb are testimony to its esteemed value and use in early international trade.

Continue reading...

31 notes

·

View notes

Note

Describe his fashion house; its costumers, designs, changes and history, etc.

QUESTIONS ABOUT CUNT FAGULA. accepting

so this is a post that's been on my to-do list from the start! this is a lot to get into, so i'm gonna break it up into parts, starting with:

PART I: HISTORY & DEVELOPMENT.

the start of the fashion house was very, very small. it was literally just lola, and he first started off hand-sewing until he had the money to spare on a sewing machine (a singer treadle machine). he learned to sew by apprenticing with a tailor, where he also learned some of the finer details of what goes into garment-making.

initially, he just made clothes for himself, but once he had his sewing machine, he started visiting the black-owned boutiques and selling some pieces through them. while new orleans was considerably more progressive in terms of racial equality than a lot of places, particularly in the south, racism was still very much present, and he didn't really want to even attempt to deal with the white-owned boutiques, even though there were more of them and they got more business, and he personally benefited from lightskinned privilege.

soon, he had a deal with one specific boutique, where he would sell his pieces through them, which continued for a while even after he had enough money for a space for his atelier (workshop). at this point, he began dealing more in couture (high-end custom pieces) and began hiring employees. he started with a single seamstress, which was enough, for a while, but between the two of them, only so much could get done in a day, so he brought on more seamstresses over time.

at a certain point, things just sort of took off. he eventually brought on another designer, and then another, usually those who he'd already employed as seamstresses. lola always had final say on every design, and that continues today, but he was able to engage in more business with more than just himself producing designs.

at the time when business was really taking off and lola had more money than he knew what to do with, he moved the atelier to a location where a boutique could be established at the front of the house, as well as provide more space for the atelier itself. the boutique serves a few purposes; pieces that were started but for whatever reason were never picked up by the client are sometimes sold here, but this is rare, considering the amount of money that goes into it (the lowest end would be daywear costing around $10,000, and the most he's ever charged for a single piece was a wedding dress that cost around $16,000,000, which doesn't include the accessories). seasonal collections are also sold here, and only a limited number of pieces are produced per design, keeping the brand highly exclusive and allowing him to charge exorbitant rates. clients are also seen in the boutique for fittings and alterations.

another development would be the type of items produced. initially, it was just clothing (shirts, blouses, dresses, pants, etc), but lola wanted to branch out into everything. over time, they began creating shoes, handbags, and jewelry -- the jewelry, i should mention, is only created to pair with custom pieces. the same techniques and artisans are used to make any metalwork that is worked directly into certain pieces (which lola himself is personally very prone to including in his own designs).

lola began to favor immortals for his artisans, since their skills could be honed far past that of any mortal, and he would never have to replace them, so there are several vampires working for the house, among others, doing the most complicated work, such as embroidery, featherwork, and metalwork. it should be noted that they're not the only ones doing this work, but they oversee everything in their respective wheelhouses.

while still human, lourdes had been making plans to move the atelier to paris and beginning the process of becoming a haute couture house (haute couture is regulated by the french government and has highly specific requirements). however, considering the small pool of haute couture houses and the heavy regulations, he felt it would be unwise to put himself under such scrutiny once he became a vampire, which is perhaps the only thing he laments in that regard, as haute couture is essentially the highest level of prestige for a fashion house. still, his brand is held in extremely high regard, particularly for the exclusivity and unique ornate designs.

#lore.🥀#when i tell u i've learned so much about high fashion.........#i've always been interested in fashion#but i didn't know about the intricacies of couture before considering making it lola's profession a few years ago

5 notes

·

View notes

Text

“The impact of both new technology and the growing influx of immigrant workers can best be seen in the New England textile mills. In the 1820s and 1830s, young women from the farm country of New England went to work in the massive brick textile factories springing up along the Merrimack River near Lowell, Massachusetts, and other New England towns. In 1820, Lowell--then called Chelmsford--was a sleepy village of about 200 farm families, located about 25 miles northwest of Boston. Six years later, it had grown into a town of 2,500 and was incorporated as the town of Lowell. In 1830, the population surged to 6,000, and tripled to 18,000 just six years later. By 1850, Lowell boasted a population of 33,000.

What created this booming growth was the rise of the textile industry. Other New England mill towns also grew, but Lowell quickly became the center of the New England textile industry and drew workers--mostly single women as young as 16 or 17--from across New England. These women generally came from the middle ranks of farm families, those that were neither impoverished nor wealthy. The desire to be financially and socially independent, to finance an education, or to simply experience the pleasures of living and working in a larger town drew many young farm women to the mills. Some women did contribute their earnings to their families, but mostly they worked in the mills to earn their own income.

…Mill owners insisted that their female hands be in their boarding houses by 10 o’clock each evening, and they urged boarding house keepers, usually older women, to report any violators to the management. In the early years, women were required to attend church services regularly, and some mill owners even deducted pew rent from the women’s earnings and paid it directly to local churches. These close living and working arrangements created a camaraderie among the women workers, a community of like-minded women who eagerly wanted to improve their minds and their lives. Throughout the 1830s and 1840s, they organized and attended lectures, language classes, sewing groups, and literary ‘improvement circles’--after working a 12-hour day. From one of these circles was born the Lowell Offering, the first journal ever written by and for mill women. The journal published poetry, short stories, and commentary penned by the female workers.

Workers also organized themselves into labor-reform groups to crusade for better working conditions and shorter workdays. As technological innovations enabled women to work faster and produce more, mill owners assigned more machines to workers--without raising wages. For example, at Hamilton Company, one of the mills in Lowell, the average number of looms per weaver more than doubled between 1840 and 1854. The workload for spinners increased as well. Workers were expected to operate more machines at a faster rate. But wages remained the same--although the company reaped higher profits from the workers’ increased productivity.

…In 1846, Elias Howe introduced the first sewing machine. Five years later, in 1851, the addition of a foot treadle for easier operation made the machine an indispensable tool. But instead of easing the sewer’s burden, the sewing machine increased it. Hand sewers could no longer compete with the sewing machine. In one day, one sewing machine operator could do as much work as six hand sewers. Hand sewers were forced to buy or rent sewing machines, or work in garment factories, where they had no control over their wages or hours.

To make matters worse, seamstresses, like the mill workers of New England, were expected to work faster and produce more while working for the same wages. New technology, such as the sewing machine or improved looms, enabled consumers to buy manufactured goods at reasonable prices--but at the expense of factory workers, who were not paid a fair wage for operating this new technology.

…Despite the long hours and low wages, women still preferred working in factories to being domestic servants. At least factory workers had some free time; servants were on call 24 hours a day. Domestics worked up to 16 hours a day, with one afternoon off each week. They earned $1 to $1.25 a week plus board. Servants’ duties varied according to their employers’ requirements and the number of other servants employed in the house. But in general, the work was very demanding. Domestics devoted entire days to washing, baking, ironing and cleaning each room. They were accustomed to heavy physical work--cleaning out fireplaces or emptying chamber pots--and trudging up and down staircases several times a day.

Besides enduring the back-breaking work, servants also had to endure the snobbery of their social ‘superiors.’ During the colonial era, servants were treated as part of the family and joined in all household activities. By the mid-19th century, however, they were regarded as mere hired hands, and were viewed as an inferior class. The Boston census of 1845 categorized servants as part of the ‘unclassified residue of the population.’ No wonder that young women wanted to avoid the social stigma of being a domestic.”

- Harriet Sigerman, “‘I Never Worked So Hard’: Weavers, Stitchers, and Domestics.’” in An Unfinished Battle: American Women, 1848-1865

#harriet sigerman#history#american#class#servants#gender#19th century#1840s#1850s#an unfinished battle

27 notes

·

View notes

Text

flicked cheviot in a shoebox, loaded onto my petlyn hackle, dizzed into a rough roving, a spun into singles with about 36gm on each bobbin. I'm hoping that the rough 90gm of 3ply I get from this will be enough for socks but the spinning didn't take too long (short forward draw, about 2 treadles to an inch and a half on a whorl ratio of 8.7:1 giving a tpi of 11.6) so I am tempted to do my three pairs originally planned (cheviot, suffolk, romney, covering downs, downs-like, and non-downs for socks).

I tried dizzing the cheviot off a drum carder and was unimpressed with the results but I'm using that to practice my grist and I'll end up dyeing some for sampling. The romney and the suffolk have both been combed into tops but I have more to do before I have enough to start spinning with (I've only combed 75gm of the suffolk, and I want 150).

7 notes

·

View notes

Text

-

Author: Avalanumbres

Group: C

Prompts: A new hobby. Lady Belle, Peasant!Rumple. Another kid.

-

Stone Seekers: Waters of Avonlea

Something wet dripped down Gideon’s face as he ran through the streets of his seaport home. When the moisture hit his lips he licked them and tasted salt. Not blood then, that relieved him. His father would kill him if he injured himself. Assuming the angry pirates chasing after him didn't do it first.

“Street rat!” One shouted. “Stop, thief!”

Gideon had one advantage over the larger men. He knew these roads. Fast as lightning, he darted through a crowd, turned left into a narrow alley, and came out in the market. There he resumed a normal gait, pretended to study a few random items on vendors’ carts, and listened as the angry sailors passed him by.

“Hot day today,” he told the costermonger while wiping his brow.

The woman humphed.

“Papa would like two of these, please.”

The seller glanced at the small golden pears in Gideon's hand. “One copper.”

Gideon handed over the coin and strode off toward his home.

Rumplestiltskin and his son lived in a single-room shack with a sagging roof and a packed dirt floor. The space was filled by three objects: a bed, a small washtub for dying wool, and a spinning wheel. Everything else existed in their lives by either coincidence or through the process of creating items to sell. They had little, yet their lives were filled with love and joy.

It was lonely at times, moreso for Gideon’s father, who pined endlessly for the woman he’d fallen in love with more than ten years ago. Belle was Gideon's mother, but wasn't a part of their lives. She lived in the castle beyond the walled part of the city. On occasion, she left her father’s protection to wander the markets. On those rare days she always sought out the spinner’s stall. The family’s reunions were brief and both parents clung to the hope that they would see each other again soon. Gideon, on the other hand, felt little for his mother beyond the knowledge that she made his father’s heart sing. Rumplestiltskin’s happiness meant everything to his son and so he’d adopted his father’s dream of a permanent reunion. In fact, that was the very reason he was in this mess right now.

“Hello, Papa,” Gideon shoved the door back into its frame and held out the pears. “I got us something sweet to end our dinner.”

At the wheel, Rumplestiltskin took his foot from the treadle and looked up, eyes skimming past the fruit to a small bag Gideon clutched to his chest. “My favorite. Thank you. They look delicious.”

The boy sighed as he squeezed his slender frame between the wheel and the wash basin, then dropped to the bed. “You only like them because they are yellow and mother always wears a golden dress to come see you.”

The assumption brought an image of Belle to Rumplestiltskin’s mind, one of warm light caressing a satin gown. From where they had hidden for their lovemaking, a ray from the sun reached out to touch Belle’s tousled hair and made the blue in her eyes sparkle. She told him about the baby that day and their lives had changed forever.

“The fact that they remind me of your mum has little to do with why I like them.” Rumplestiltskin returned to spinning for a moment, then stopped the wheel to turn a knowing frown toward his son. “And what else did you acquire while you were meant to be at your lessons?”

“I went to my lessons, “ Gideon protested.

“For how much of the day?”

Now that his father's full attention was on him, Gideon felt compelled to tell the truth. “Half,’ he grumbled.

“Son, the money I make from dying and spinning pays for that education.” Rumplestiltskin reached for his walking stick and used it to pull himself to his feet. “I wish you wouldn't throw it away so easily.”

“I’m not throwing it away, Papa. Not this time.” Gideon’s eyes lit up as they tracked his father’s movements. “I met another kid on the way to classes today and I learned of a way we can leave this life behind us!”

“By starting a new hobby of thievery?” Rumplestiltskin leaned heavily on his walking stick. He could only blame himself for his son’s behavior, though it’s origin baffled him. He eyed the bag again. “Magical endings always come at a great price.”

“This isn't like your story,” his son insisted, oblivious to the price his parents paid for the magic that kept him a secret. “This is different. If we can help gather these stones we can save the land from a horrible evil. You can be a hero and earn the right to ask for Mother’s hand! No more pining for her at your wheel or daydreaming while you dye the wool. No more secret meetings in the market! You could be married! We could all be together. Forever.”

“And just what do we have to do to earn this great gift?”

Gideon rose from the bed and stepped into the light by the window. With hesitation he began to untie the strings of his leather satchel. “We need to find the rest of these before-”

A terrible crashing erupted from the world beyond, followed by blood-curdling shrieks that grew closer with great rapidity. The noise triggered Gideon’s reflexes, making him draw the string taut and clutch the treasure back against his chest.

“Something’s happening.” Rumplestiltskin rushed to the door and flung it open, took two stumbling steps and then froze. There, directly in front of him, was Belle, golden skirts hiked up as high as she could manage and eyes wide with terror.

“Belle!” The fear that struck him wasn’t for himself, but for the woman he could never live without. “Belle!”

She ran to his side and reached out to help him find balance. “Giant Calixclaws have entered the city from the sea,” she told him. “They’re headed this way.”

“You have to get behind the walls,” Rumple insisted.

Belle shook her head, then turned her gaze to some point down the road. “There’s no time.”

Gideon drew a dagger from his belt and strode forward. “You run, I’ll stay and protect our home.”

“You can’t do that, son. Better to find safety.”

Gideon shook his head. “I can do this. It’s me they want anyway.”

“You?” Belle whimpered. “Gideon… Why?”

He turned, gave her his most triumphant smile, and adjusted his grip on the bag he’d carried from the sea. “I have the Water Stone.”

“Magic,” Rumplestiltskin spat. “Leave that behind and run. Now. Please, son.”

Their boy was about to protest again, but instead he fell silent and tipped his head to one side. The ruckus from down the lane was changing. The sounds of splitting wood and shattering glass had been replaced with something more akin to the crunch of a breaking seashell. “Do you hear that?”

Both parents nodded, but neither could speak. Their attention was on the giant claw reaching up from behind the milner’s home. It rose into the air, then slammed down, splintering the tiny structure into bits that covered the street. The empty space was then replaced by their enemy.

“Giant crabs,” Gideon whispered, swallowing hard. After taking a deep breath he squared his shoulders and stretched himself to his full height. “I’ll have them for dinner.”

“Gideon!” Both parents reached for him, but he slipped away. After just two strides he stood under the creature’s belly and stabbed upward, using all of his strength. He heard a crack and stared up at the orange-pink carapace. The tip of his blade was wedged in the belly of the beast but would go no further. It would also not come out.

Belle tried rushing to Gideon’s side, but Rumplestiltskin held her back, begging her not to leave him. While he pleaded, a cloaked form appeared behind the legs of the Calixclaw. Small and powerful, this newcomer yielded a sword with such precision that each swing sliced a leg of the crab. The beast shrieked again and again, then finally stumbled.

The warrior waved Gideon back, screaming. “Get out of the way!”

He did as he was told, scrambling through his retreat with just enough time to spare. Following one more swing from the sword, their maritime foe thrashed mightily, then collapsed to the ground, dead.

“Gotta aim for the weak points,” the newcomer told him, lowering her cloak’s hood to reveal her wavy, golden hair. She turned to Rumplestiltskin and gave him a wide grin. “A staff fighter, huh? Good. We’ll need all the help we can get. Come on.” With that she took off, expecting the others to follow.

“Who was that?” Belle squinted after the girl, even as her son urged her along.

“Alice,” Gideon said. “And she’ll help me explain everything once you are safe.”

-

15 notes

·

View notes

Text

Fiber arts update!

The postal service gods have smiled upon me and gotten me my wheel a day early, huzzah!

I might just be developing kit-based stockholm syndrome, but putting this thing together was actually kinda fun. Easier than the loom and, hilariously, less frustrating than the fucking bobbin winder, even if it did take absolutely forever. Also, I like the way it sounds (or... doesn't sound like much, as the case may be), I like the way it looks, I like how sturdy it is. And I think I'm starting to really enjoy the way it spins, too.

On the other hand? I have thoughts.

Why is there no convenient place to put fiber. Why are the sliding hooks so goddamn hard to operate smoothly. And, honestly, I don't mind the double treadle, but I also still do not understand why it exists. It makes direction control harder, with no notable upside that I can see.

I'm also fighting a desperate battle against the concept of scotch tension. I mean, I did pick a single drive wheel kind of deliberately, because there's upsides to it that double drive does not have (like how the drive band isn't a non-euclidean nightmare of horribleness)... but goddamn it, I really didn't appreciate the smooth, incredibly even take-up of my old wheel enough until now. You put the tension somewhere, and unless something catches in the orifice, that's the tension you're gonna get, no ifs and buts. The Kiwi 3, meanwhile, likes to periodically tug at my fiber and it's weirding me the fuck out. At least tension's about as easy to adjust as my double-drive wheel (which, thanks to its center-screw setup, is probably a great deal easier than average for double-drive), but also just as finicky.

The "no convenient place to put fiber" thing is annoying, though. The vintage wheel has all kinds of bits and bobs that you can fix your WIP to in a pinch, plus a nice handy distaff, while the Kiwi 3 spins, and anything beyond that single function is kind of a "not my goddamn job" kinda deal.

I do appreciate the orifice hook slot, though.

I have also somehow STILL MISPLACED the orifice hook about half a dozen times in the last few hours. I am incorrigible.

The most interesting takeaway is that I was kinda scared that I'd get a new spinning wheel and realize that my old one is crap. This is definitely not what happened. Despite all my grumbling, I do like the Kiwi and I'm very happy to have it, but I'm also realizing all the upsides of the vintage wheel that I took for granted. Like how easy it is to get it started in the right direction with barely a tap of my foot, (almost) no matter which position it's in. The even take-up. The feather-light tension. The distaff. The nub I can wrap my spin around when taking a break. The fact that, when I stop treadling, both flyer and bobbin stop at the same time.

On the other hand, I will admit to never taking the bobbin off of that vintage wheel unless I absolutely have to. To wind off, I usually just lower the tension all the way and let the bobbin free-spin, because fuck that. And the Kiwi also doesn't make me smack my shins into a wooden base on a regular basis. AND I got the high-speed whorl for it so now I have ratios from 5.5:1 all the way to 15:1, and it's glorious. Plus, it's a whole lot quieter. And as much as I don't like the specific way they set up the sliding hooks, they're still much, much more pleasant than the double-threaded nightmare I had to pull off on the vintage wheel half the time.

TL;DR: new wheel good, once I get my blending board and really figure out the tension on the Kiwi, I'll be so fucking powerful you folks

18 notes

·

View notes

Text

strangers have been kind to me lately

i contacted a seller C. off craigslist regarding her spinning wheel and when I asked for more pictures she asked me if it was my first wheel and when I said yes she had me call her; we talked for half an hour about types of tension systems as i took notes and we decided this wasn't the wheel for me but she'd send me some resources and she did. and we've been emailing back and forth about different wheels ("you should be okay learning on scotch or double drive but i dont know whether you prefer single or double treadle") and whether or not they might work for me ("I don't know how they're claiming it's an ashford. doesn't look like any Ashford I've ever seen") and if she has any friends who might have something to sell. she is thrilled that a person under 50 is interested in textiles and has kept me from spending hundreds of dollars on things I'd ultimately regret. (she keeps telling God to bless me and it makes me physically recoil but it's okay. I'm safe over the phone, over email. maybe she wouldn't hate me if she knew. maybe ill meet her at a fiber festival one day and it'll be okay.)

this older lady S. stopped me on my way to the grocery store and said there's a cat there! and of course I took off my big headphones to look. (I had a neighbor once ask me for a cup of sugar and she knew me as that person who always stops to pet the neighborhood cats) and sure enough. a terrified little creature screaming from under a car. a few people stopped with us but everyone is going somewhere so they all made excuses eventually -- but me and S. wouldn't just leave this little thing that clearly had never been outside before and didn't know not to fling itself into the middle of the street. so I held the kitten in my arms and we walked up and down the block until we found some volunteers for a local dv shelter who gave us a box and a blanket and we figured well. one of us needs to take it home. and S. walked with me the whole time but I got the sense that maybe her housing situation wasn't the most stable -- so we exchanged contact information and the kitten is now comfy and cozy in my lap while i sit on the floor in my tiny bathroom. and S. called me that night to make sure I'd managed everything and to let me know again that if I needed any help just to give her a call.

my vet let me bring her (the kitten) by to scan for a microchip (no chip) and they all oohed and aahed over her as she tore her way out of the cardboard carrier so I would once again cradle her in my arms. nothing makes you more popular than walking through the city with a kitten in your arms. not even carrying a pigeon (although children like that a lot). one person in particular stopped me and carefully didn't gender me as they introduced me to their wife and two small children and told a personal story that I won't relate here but -- well. strangers have been kind to me lately and I feel that kindness can be multidirectional.

I've posted about the kitten everywhere I can think of and this afternoon I got a call from J. who contacts everyone who lists a found pet in our county to let them know not to go to the county's services with the animal because of their shady practices, etc., and we spoke for something like two hours about rescuing pets and her whole life story and parts of mine and the disintegrating government at all its various levels and she thanked me for talking to her and for "getting it" because sometimes when she tries to inform people they tell her to never speak to them again and I think now if I ever needed help in fighting a local public official (either in court or in an actual physical fight) I would know who to call.

I miss working retail so deeply -- the skill I have cultivated that is interacting with these strangers in a way that makes them feel I am listening so that I have the opportunity to actually listen. in laughing lightly and nodding at the right moments and being earnest in both my knowledge and lack thereof. I like to think that mostly people like to be kind but sometimes they don't get the opportunity.

but also (kitten in my lap) it's easier to be kind to a kitten or a well spoken curious young person that goes mm yes yes to you on the phone than it is to be Kind generally and I am still learning. and this moment of having a kitten asleep in my lap has come for me in period of pretty awful lethargic depression where I've slept through the majority of my hours and I am learning to not look away from the things that make my stomach curl and my heart thump simply because they make me uncomfortable and I am afraid for the physical safety of myself and my friends now and in the near future. but. I like to think that people mostly want to be kind. I hope.

4 notes

·

View notes

Text

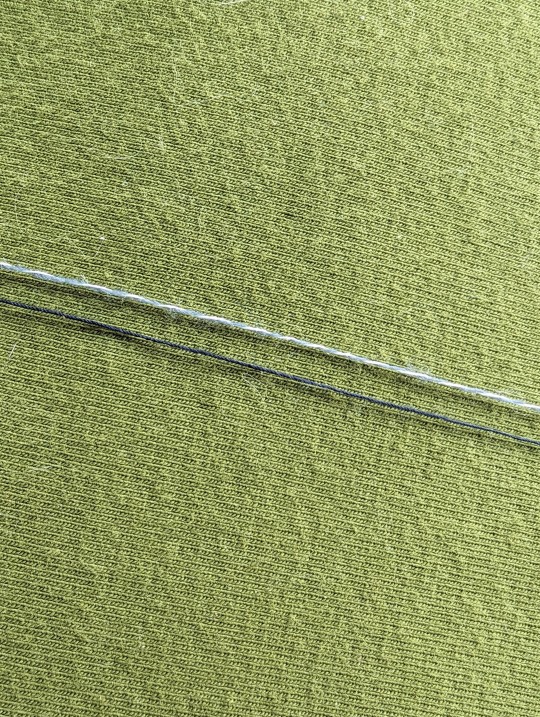

wip wednesday: project shaming edition

i finally remembered wip wednesday, and it's even still wednesday! great job, me, very proud of you.

first, the good. i have yet to spin the second bobbin of my first pipy project, but that's fine—treadle wheels are mostly a weekend thing for me, and i felt crappy last weekend and barely got out of bed. i feel like it'll get done this weekend, no worries. and i'm going to ignore that realistically, i'm going to start spinning up the polwarth i dyed basically as soon as i can, because i'm greedy. surely the limit is one active spinning project per wheel, right?

anyhow, starting 'as soon as i can' is, basically, after i finish this set of socks.

are these socks exciting? no. am i enjoying knitting them? they're fine, i guess. i'm not sure that i love hobbii's sock yarn, and it wants desperately to spiral, for some reason. but the socks will serve their purpose, and that's why i knit socks with novelty yarn, so whatever. i'm getting a lot of very important youtube videos watched.

unfortunately, that's it for the good, and next up we have this hideously orange jumper. it's so orange that neither my phone nor my computer can figure out what to do with it. when it looks right on one, it looks red on the other; when it looks right on the other, it looks like bizarre orange that's both too bright and too dull. this picture looks equivalently bad on both devices, so it's what i'm using.

it's just a mindless no-pattern raglan with hobbii unicorn solids. it looks small, but it's just squished on the needles—it's adult sized, and the body will be something like 470 stitches around. this isn't really sparking joy, though it is, again, good television knitting, and i think that it will be well loved when i'm finished. which might be 2025.

and then the...mixed emotions. i spun this yarn. i'm knitting it into a shawl for my wife. i love both the yarn and the wife. but i'm a little wary of the project itself, because it's not great for mindless knitting (or at least isn't great yet), and also, frankly, i'm so aware that it's silly, you know? will anyone ever wear this shawl? i honestly have no idea. but here's the yarn.

that second picture is one strand of the yarn, one of sewing thread. the yarn is one ply of handspun rambouillet and one of commercial silk, plied loosely together. i went with this because while this is by no stretch of the imagination an orenburg shawl, galina khmeleva says that this is how they're traditionally done: loosely plied, one ply cashmere, one ply commercial silk. i figure if it's good enough for them, it's good enough for me—and also, ok, easier than spinning another 1200 metres of singles for this.

i've started the very beginning of the shawl, and have every intention of finishing it, but haven't gotten far. you can just see the lace on the outer panels starting to form.

i love this shawl. i'm going to finish this shawl. now that i'm thinking about it, though, it might be more of a summer knitting project than a winter one. i'm putting off starting a cowl, which would be a little more practical in the immediate future. i'll see how i feel when i'm done the socks, i guess.

#wip wednesday#knitting#spinning#hand spinning#fiber arts#fibre arts#fiber crafts#fibre crafts#handspun#handspun yarn#handspinning#smartest raccoon i know#i really want to find a way to consolidate tags#but also i keep looking in the tags and there's not much there#so i also want people to use more tags#it's a real conundrum#i need to figure out what's up with my phone's camera too#all of a sudden it can't handle reds or blues?#which is sort of bad#since reds and blues are...minorly important colours

46 notes

·

View notes

Text

PINNED POST

who am i?

someone who’s been sewing since being voluntold into the puppet factory at age 7. (yes i did grow up in a circus.) a legal adult for decades now but immature enough to get away with calling myself a boy until i die. trans man who dresses like an off duty drag queen. undiagnosed autistic with sensory intolerance for synthetic fibers. proud of my weight gain and not shy to block fatphobic bigots. too arthritic to give a shit about typos or capitalizing. former professional alterations-er. white usamerican who believes strongly in class solidarity across all lines. faggot.

what will you find here?

ive never been good at keeping my tumblr self organized but i’m really going to try to keep this one focused. at first i’ll be posting project round ups and picture tutorials as i work through the immense backlog of my stash, but i’d like to answer questions and help folks troubleshoot their own sewing, fitting, and mending problems. theoretically i’d like to do video tutorials but i dont have the time or equipment. certainly some anti-oppression based political analysis and references to the leather community will filter through, and probably some garden and pet pictures. i’m going to be coaching my life and business partner through making their first clothes pretty soon here so that will be posted in some form as well. tips for adapting clothes for sensory issues and physical mobility based disabilities. me fixating on pattern matching to a truly asinine degree. all black projects covered in cat and dog hair that are really hard to photograph well ¯\_(ツ)_/¯

what do i make?

ive made everything from thirty foot puppet costumes to these-jncos-arent-wide-enough industrial high fashion jeans to back support corsets and more but currently my own projects are all about providing me with a wardrobe that a) keeps me warm b) doesnt trigger any sensory issues c) makes me look like hot shit. you could call what i’m working on a capsule wardrobe but really i’d just call myself broke. my idea of looking like hot shit involves seamlessly blending the fashions of a sixty year old redneck who goes to town twice a year, and the hardest fem at goth night.

what am i interested in?

i really like historical fashion, especially viking and pre-viking era scandinavian, medieval british isles, and irish/scottish/english/american from about 1800-1960. (NOT saying that other places dont have incredible clothes and fashion traditions, but sewing is pretty much the backbone of my ancestor work—not nec. reverence bc not all of my ancestors deserve it frankly (though some do) but connection and understanding—so i focus my research and construction where my own ancestors were (if you call yourself folkish you can fuck off and die in a dumpster fire right now and if you dont, dont bother googling they dont deserve your attention)). i often take historical undergarments and adapt them for contemporary outerwear, or blend methods of fit or construction that were traditionally used exclusively for either mens or womens fashion in a single garment. somehow i ended up specializing in flattening out princess seams.

perks

follow me and maybe i’ll get someone to video me using the treadle machine which has belonged to my great grandma, my gay great uncle, my gay great uncle’s widower, my mom, and myself

new build project masterlist

alterations project masterlist

tags masterlist

“you’re really into anti-oppression, why aren’t you adding image descriptions?”

a couple reasons. as i mentioned i have a host of disabilities (physical and otherwise). my dayjob involves a lot of computer work, sewing is really hard on my hands and body, i cant always look at screen for very long, and if i made myself wait to post until i could do image descriptions, i would never post at all. i don’t think requiring disabled folks to do things they can’t is the best approach to radical hospitality. if anyone feels moved to add image descriptions to anything i do, i will reblog their post with the tag ‘image descriptions added.’ my main aim in starting this blog is to share my knowledge with trans/disabled folks and other people that experience gender dysphoria, body dysmorphia, sensory issues, or physical difficulties getting clothes on and off without pain. the typed writeup that will accompany each picture tutorial is my best attempt at sharing my knowledge and processes with anyone who uses a screen reader

11 notes

·

View notes

Text

Picked up this roving from my stash and decided to just spin a tiny bit as is to see how muddy it might spin and like within 3 treadles I knew I wanted singles. The way the colour blends while being spun as is is really nice, but once you ply it those colours become lost. The staple length is quite long too, so even when I pull the singles quite hard it doesn't stretch or fall apart so it seems more than stable to be on its lonesome.

2 notes

·

View notes

Text

It's very likely we will be moving within the year, and I am now pressuring myself to get the One Big Project done before we do so.

My baby girl, a 1910 White Rotary Treadle Sewing Machine.

She was a steal on ebay, at a measily 35$ for a working sewing machine, but no base or cabinet. And then the treadle base was one without the original cabinet and no machine, also in working order, for another 125$ plus 75$ in shipping for a large cast iron base that weighs easily over 60lbs.

I did get a walnut slab for free from my father before cutting contact, so I suppose I can finally say he did one decent thing for me in my life.

The true problem, is that the wood was green when I received it, and has since bowed and cracked. I tried to fix it, but I'm not a woodworker and quite frankly, did a piss poor job.

So I have two large hurdles to get her all put together and working.

I need to get her serviced and cleaned. All her parts work, she moves, and all her bells and whistles are accounted for. I even have the original box with additional feet and needles.

I need to get this wood actually prepared and ready for use.

So the worry now, is finding local craftsmen who are able to do these things better than my poor attempts with minimal knowledge. I do know how to maintain my girl once she's been properly cleaned, but I'm too scared to try and take her apart to full clean and check all the parts myself.

So I've sent off several e-mails to local small businesses, asking about their services and if they believe they can help with my issues.

There is a local man moving into retirement from a life in machining for large companies who has a passion for vintage machines, which I am beyond chuffed about. He's got a blog detailing some of the machines he's worked on, including an absolute gorgeous 1800s Singer. One can only dream of having one in such good condition as those pictures. So I'm certain he'll be the perfect pick for my darling, as she's a simple little machine, and already in good condition.

According to his site, his full service is 100$ plus applicable taxes, and if she needs parts, full cost plus time for the install. I'll likely end up tipping him as well, given he seems like a lovely man.

The wood however is proving more of an issue.

There is one company that seems the best choice, a local cabinetry company that also offers lumber prep on the side. However, they only have pricing listed per foot, and I'm rather certain they will also include labor costs which is not listed at all. They do allow you to bring your own wood, however, and I don't need a full cabinet, just the rescue of this lovely piece of walnut that I have tortured over the past year trying to fix.

All in all, though, even if it's a bit pricier than I expect, the cost of a 1910 White Rotary Treadle Sewing Machine, with all my love, sweat and tears poured into it, will still come out to under 500$, which is quite the steal for a vintage lady that will last not only me, but perhaps future generations as well.

Oh, and my unidentified spinning wheel only requires a single 80$ fly wheel, and a bit of wood glue to fix up. Also rather chuffed about getting her into working condition too.

Pictures will come later, however. I do plan on doing a full detailed post of them both, and my journey with them.

Once I move, though- then we'll be looking at looms. That will be a high price point no matter what I choose to go with, and I'm trembling imagining it.

2 notes

·

View notes