#biological engineering

Explore tagged Tumblr posts

Text

GUYS

THEY MADE WOOLLY MICE

THEY'RE SO CUTE

#i don't actually know what to tag this#mice#woolly mice#woolly mammoth#science#biology#biological engineering#<- i think?

109 notes

·

View notes

Text

Translating MIT research into real-world results

New Post has been published on https://thedigitalinsider.com/translating-mit-research-into-real-world-results/

Translating MIT research into real-world results

Inventive solutions to some of the world’s most critical problems are being discovered in labs, classrooms, and centers across MIT every day. Many of these solutions move from the lab to the commercial world with the help of over 85 Institute resources that comprise MIT’s robust innovation and entrepreneurship (I&E) ecosystem. The Abdul Latif Jameel Water and Food Systems Lab (J-WAFS) draws on MIT’s wealth of I&E knowledge and experience to help researchers commercialize their breakthrough technologies through the J-WAFS Solutions grant program. By collaborating with I&E programs on campus, J-WAFS prepares MIT researchers for the commercial world, where their novel innovations aim to improve productivity, accessibility, and sustainability of water and food systems, creating economic, environmental, and societal benefits along the way.

The J-WAFS Solutions program launched in 2015 with support from Community Jameel, an international organization that advances science and learning for communities to thrive. Since 2015, J-WAFS Solutions has supported 19 projects with one-year grants of up to $150,000, with some projects receiving renewal grants for a second year of support. Solutions projects all address challenges related to water or food. Modeled after the esteemed grant program of MIT’s Deshpande Center for Technological Innovation, and initially administered by Deshpande Center staff, the J-WAFS Solutions program follows a similar approach by supporting projects that have already completed the basic research and proof-of-concept phases. With technologies that are one to three years away from commercialization, grantees work on identifying their potential markets and learn to focus on how their technology can meet the needs of future customers.

“Ingenuity thrives at MIT, driving inventions that can be translated into real-world applications for widespread adoption, implantation, and use,” says J-WAFS Director Professor John H. Lienhard V. “But successful commercialization of MIT technology requires engineers to focus on many challenges beyond making the technology work. MIT’s I&E network offers a variety of programs that help researchers develop technology readiness, investigate markets, conduct customer discovery, and initiate product design and development,” Lienhard adds. “With this strong I&E framework, many J-WAFS Solutions teams have established startup companies by the completion of the grant. J-WAFS-supported technologies have had powerful, positive effects on human welfare. Together, the J-WAFS Solutions program and MIT’s I&E ecosystem demonstrate how academic research can evolve into business innovations that make a better world,” Lienhard says.

Creating I&E collaborations

In addition to support for furthering research, J-WAFS Solutions grants allow faculty, students, postdocs, and research staff to learn the fundamentals of how to transform their work into commercial products and companies. As part of the grant requirements, researchers must interact with mentors through MIT Venture Mentoring Service (VMS). VMS connects MIT entrepreneurs with teams of carefully selected professionals who provide free and confidential mentorship, guidance, and other services to help advance ideas into for-profit, for-benefit, or nonprofit ventures. Since 2000, VMS has mentored over 4,600 MIT entrepreneurs across all industries, through a dynamic and accomplished group of nearly 200 mentors who volunteer their time so that others may succeed. The mentors provide impartial and unbiased advice to members of the MIT community, including MIT alumni in the Boston area. J-WAFS Solutions teams have been guided by 21 mentors from numerous companies and nonprofits. Mentors often attend project events and progress meetings throughout the grant period.

“Working with VMS has provided me and my organization with a valuable sounding board for a range of topics, big and small,” says Eric Verploegen PhD ’08, former research engineer in MIT’s D-Lab and founder of J-WAFS spinout CoolVeg. Along with professors Leon Glicksman and Daniel Frey, Verploegen received a J-WAFS Solutions grant in 2021 to commercialize cold-storage chambers that use evaporative cooling to help farmers preserve fruits and vegetables in rural off-grid communities. Verploegen started CoolVeg in 2022 to increase access and adoption of open-source, evaporative cooling technologies through collaborations with businesses, research institutions, nongovernmental organizations, and government agencies. “Working as a solo founder at my nonprofit venture, it is always great to have avenues to get feedback on communications approaches, overall strategy, and operational issues that my mentors have experience with,” Verploegen says. Three years after the initial Solutions grant, one of the VMS mentors assigned to the evaporative cooling team still acts as a mentor to Verploegen today.

Another Solutions grant requirement is for teams to participate in the Spark program — a free, three-week course that provides an entry point for researchers to explore the potential value of their innovation. Spark is part of the National Science Foundation’s (NSF) Innovation Corps (I-Corps), which is an “immersive, entrepreneurial training program that facilitates the transformation of invention to impact.” In 2018, MIT received an award from the NSF, establishing the New England Regional Innovation Corps Node (NE I-Corps) to deliver I-Corps training to participants across New England. Trainings are open to researchers, engineers, scientists, and others who want to engage in a customer discovery process for their technology. Offered regularly throughout the year, the Spark course helps participants identify markets and explore customer needs in order to understand how their technologies can be positioned competitively in their target markets. They learn to assess barriers to adoption, as well as potential regulatory issues or other challenges to commercialization. NE-I-Corps reports that since its start, over 1,200 researchers from MIT have completed the program and have gone on to launch 175 ventures, raising over $3.3 billion in funding from grants and investors, and creating over 1,800 jobs.

Constantinos Katsimpouras, a research scientist in the Department of Chemical Engineering, went through the NE I-Corps Spark program to better understand the customer base for a technology he developed with professors Gregory Stephanopoulos and Anthony Sinskey. The group received a J-WAFS Solutions grant in 2021 for their microbial platform that converts food waste from the dairy industry into valuable products. “As a scientist with no prior experience in entrepreneurship, the program introduced me to important concepts and tools for conducting customer interviews and adopting a new mindset,” notes Katsimpouras. “Most importantly, it encouraged me to get out of the building and engage in interviews with potential customers and stakeholders, providing me with invaluable insights and a deeper understanding of my industry,” he adds. These interviews also helped connect the team with companies willing to provide resources to test and improve their technology — a critical step to the scale-up of any lab invention.

In the case of Professor Cem Tasan’s research group in the Department of Materials Science and Engineering, the I-Corps program led them to the J-WAFS Solutions grant, instead of the other way around. Tasan is currently working with postdoc Onur Guvenc on a J-WAFS Solutions project to manufacture formable sheet metal by consolidating steel scrap without melting, thereby reducing water use compared to traditional steel processing. Before applying for the Solutions grant, Guvenc took part in NE I-Corps. Like Katsimpouras, Guvenc benefited from the interaction with industry. “This program required me to step out of the lab and engage with potential customers, allowing me to learn about their immediate challenges and test my initial assumptions about the market,” Guvenc recalls. “My interviews with industry professionals also made me aware of the connection between water consumption and steelmaking processes, which ultimately led to the J-WAFS 2023 Solutions Grant,” says Guvenc.

After completing the Spark program, participants may be eligible to apply for the Fusion program, which provides microgrants of up to $1,500 to conduct further customer discovery. The Fusion program is self-paced, requiring teams to conduct 12 additional customer interviews and craft a final presentation summarizing their key learnings. Professor Patrick Doyle’s J-WAFS Solutions team completed the Spark and Fusion programs at MIT. Most recently, their team was accepted to join the NSF I-Corps National program with a $50,000 award. The intensive program requires teams to complete an additional 100 customer discovery interviews over seven weeks. Located in the Department of Chemical Engineering, the Doyle lab is working on a sustainable microparticle hydrogel system to rapidly remove micropollutants from water. The team’s focus has expanded to higher value purifications in amino acid and biopharmaceutical manufacturing applications. Devashish Gokhale PhD ’24 worked with Doyle on much of the underlying science.

“Our platform technology could potentially be used for selective separations in very diverse market segments, ranging from individual consumers to large industries and government bodies with varied use-cases,” Gokhale explains. He goes on to say, “The I-Corps Spark program added significant value by providing me with an effective framework to approach this problem … I was assigned a mentor who provided critical feedback, teaching me how to formulate effective questions and identify promising opportunities.” Gokhale says that by the end of Spark, the team was able to identify the best target markets for their products. He also says that the program provided valuable seminars on topics like intellectual property, which was helpful in subsequent discussions the team had with MIT’s Technology Licensing Office.

Another member of Doyle’s team, Arjav Shah, a recent PhD from MIT’s Department of Chemical Engineering and a current MBA candidate at the MIT Sloan School of Management, is spearheading the team’s commercialization plans. Shah attended Fusion last fall and hopes to lead efforts to incorporate a startup company called hydroGel. “I admire the hypothesis-driven approach of the I-Corps program,” says Shah. “It has enabled us to identify our customers’ biggest pain points, which will hopefully lead us to finding a product-market fit.” He adds “based on our learnings from the program, we have been able to pivot to impact-driven, higher-value applications in the food processing and biopharmaceutical industries.” Postdoc Luca Mazzaferro will lead the technical team at hydroGel alongside Shah.

In a different project, Qinmin Zheng, a postdoc in the Department of Civil and Environmental Engineering, is working with Professor Andrew Whittle and Lecturer Fábio Duarte. Zheng plans to take the Fusion course this fall to advance their J-WAFS Solutions project that aims to commercialize a novel sensor to quantify the relative abundance of major algal species and provide early detection of harmful algal blooms. After completing Spark, Zheng says he’s “excited to participate in the Fusion program, and potentially the National I-Corps program, to further explore market opportunities and minimize risks in our future product development.”

Economic and societal benefits

Commercializing technologies developed at MIT is one of the ways J-WAFS helps ensure that MIT research advances will have real-world impacts in water and food systems. Since its inception, the J-WAFS Solutions program has awarded 28 grants (including renewals), which have supported 19 projects that address a wide range of global water and food challenges. The program has distributed over $4 million to 24 professors, 11 research staff, 15 postdocs, and 30 students across MIT. Nearly half of all J-WAFS Solutions projects have resulted in spinout companies or commercialized products, including eight companies to date plus two open-source technologies.

Nona Technologies is an example of a J-WAFS spinout that is helping the world by developing new approaches to produce freshwater for drinking. Desalination — the process of removing salts from seawater — typically requires a large-scale technology called reverse osmosis. But Nona created a desalination device that can work in remote off-grid locations. By separating salt and bacteria from water using electric current through a process called ion concentration polarization (ICP), their technology also reduces overall energy consumption. The novel method was developed by Jongyoon Han, professor of electrical engineering and biological engineering, and research scientist Junghyo Yoon. Along with Bruce Crawford, a Sloan MBA alum, Han and Yoon created Nona Technologies to bring their lightweight, energy-efficient desalination technology to the market.

“My feeling early on was that once you have technology, commercialization will take care of itself,” admits Crawford. The team completed both the Spark and Fusion programs and quickly realized that much more work would be required. “Even in our first 24 interviews, we learned that the two first markets we envisioned would not be viable in the near term, and we also got our first hints at the beachhead we ultimately selected,” says Crawford. Nona Technologies has since won MIT’s $100K Entrepreneurship Competition, received media attention from outlets like Newsweek and Fortune, and hired a team that continues to further the technology for deployment in resource-limited areas where clean drinking water may be scarce.

Food-borne diseases sicken millions of people worldwide each year, but J-WAFS researchers are addressing this issue by integrating molecular engineering, nanotechnology, and artificial intelligence to revolutionize food pathogen testing. Professors Tim Swager and Alexander Klibanov, of the Department of Chemistry, were awarded one of the first J-WAFS Solutions grants for their sensor that targets food safety pathogens. The sensor uses specialized droplets that behave like a dynamic lens, changing in the presence of target bacteria in order to detect dangerous bacterial contamination in food. In 2018, Swager launched Xibus Systems Inc. to bring the sensor to market and advance food safety for greater public health, sustainability, and economic security.

“Our involvement with the J-WAFS Solutions Program has been vital,” says Swager. “It has provided us with a bridge between the academic world and the business world and allowed us to perform more detailed work to create a usable application,” he adds. In 2022, Xibus developed a product called XiSafe, which enables the detection of contaminants like salmonella and listeria faster and with higher sensitivity than other food testing products. The innovation could save food processors billions of dollars worldwide and prevent thousands of food-borne fatalities annually.

J-WAFS Solutions companies have raised nearly $66 million in venture capital and other funding. Just this past June, J-WAFS spinout SiTration announced that it raised an $11.8 million seed round. Jeffrey Grossman, a professor in MIT’s Department of Materials Science and Engineering, was another early J-WAFS Solutions grantee for his work on low-cost energy-efficient filters for desalination. The project enabled the development of nanoporous membranes and resulted in two spinout companies, Via Separations and SiTration. SiTration was co-founded by Brendan Smith PhD ’18, who was a part of the original J-WAFS team. Smith is CEO of the company and has overseen the advancement of the membrane technology, which has gone on to reduce cost and resource consumption in industrial wastewater treatment, advanced manufacturing, and resource extraction of materials such as lithium, cobalt, and nickel from recycled electric vehicle batteries. The company also recently announced that it is working with the mining company Rio Tinto to handle harmful wastewater generated at mines.

But it’s not just J-WAFS spinout companies that are producing real-world results. Products like the ECC Vial — a portable, low-cost method for E. coli detection in water — have been brought to the market and helped thousands of people. The test kit was developed by MIT D-Lab Lecturer Susan Murcott and Professor Jeffrey Ravel of the MIT History Section. The duo received a J-WAFS Solutions grant in 2018 to promote safely managed drinking water and improved public health in Nepal, where it is difficult to identify which wells are contaminated by E. coli. By the end of their grant period, the team had manufactured approximately 3,200 units, of which 2,350 were distributed — enough to help 12,000 people in Nepal. The researchers also trained local Nepalese on best manufacturing practices.

“It’s very important, in my life experience, to follow your dream and to serve others,” says Murcott. Economic success is important to the health of any venture, whether it’s a company or a product, but equally important is the social impact — a philosophy that J-WAFS research strives to uphold. “Do something because it’s worth doing and because it changes people’s lives and saves lives,” Murcott adds.

As J-WAFS prepares to celebrate its 10th anniversary this year, we look forward to continued collaboration with MIT’s many I&E programs to advance knowledge and develop solutions that will have tangible effects on the world’s water and food systems.

Learn more about the J-WAFS Solutions program and about innovation and entrepreneurship at MIT.

#000#2022#2023#Accessibility#adoption#Advice#agriculture#amp#anniversary#applications#approach#architecture#artificial#Artificial Intelligence#attention#Bacteria#batteries#billion#Biological engineering#Biology#board#bridge#Building#Business#CEO#chemical#Chemical engineering#chemistry#Civil and environmental engineering#climate change

4 notes

·

View notes

Text

Two women can give birth!

Only women can do this!

2 notes

·

View notes

Text

I've been thinking a bit

Fuck gender, like why can't everyone be the same gender, it would fix so much; sexism, homophobia, confused on sexuality, transphobia and bathrooms, even clothing, makeup and "gender colors" (fun fact, when gender colors was invented pink was for boys and blue for girls and when you think abit it makes sense), like i wouldn't have to want to be a pretty girl with ass if everyone was pretty girl with huge ass, why aren't we biologically engineering people who have both reproductive organs?!?

#lgbtqia#pansexual#bisexual#transgender#genuine question#biology#biological engineering#genderfluid#gender equality#anti homophobia#why haven't we done this#like actually

4 notes

·

View notes

Text

The recent creation of Robots from Human Cells may change medicine and possibly lead to the ability to create biological artificial life. Yet all of its applications have not been discovered yet.

Scientists have created tiny living robots from human cells that can move around in a lab dish and may one day be able to help heal wounds or damaged tissue, according to a new study.

The scientists used adult human cells from the trachea from a diversity of anonymous donors. The anthrobots were not full-fledged organisms because they didn’t have a full life cycle

#science article#biology#biotechnology#cells#robot design#medical research#human biology#biological engineering

2 notes

·

View notes

Text

Can Biological Engineering Change the World? (New York Times)

Excerpt from this New York Times story:

Science is always focused on breakthroughs and the next big thing. And, too often, there is loads of hype about what benefits to society a particular breakthrough might bring.

But when I saw the image of Albert Einstein peering out of a petri dish in the office of Christopher Voigt, the chairman of the Department of Biological Engineering at Massachusetts Institute of Technology, I knew that he was on to something very big. Something that is almost certainly going to affect our children in the decades to come.

The image in the petri dish was built by tiny, living organisms whose DNA had been manipulated by Dr. Voigt and his students so that they were directed to line up in a formation that resembled Einstein’s face.

I was in Dr. Voigt’s office reporting an article on the role that re-engineering nature might play in helping fight climate change. (Read the full piece here.)

And what Dr. Voigt was demonstrating — in images created more than a decade ago during an early stage of his research — is that bacteria and other living things are as programmable as computer code. Life itself could be turned into a modifiable tool of production.

It is compelling proof that the fast-growing field of biological engineering is going to change the world. In very big ways.

I ended up in Dr. Voigt’s lab because one of his former graduate students, Karsten Temme, had worked with him to decode the genetics of a bacteria to help researchers fully understand what is known as nitrogen fixing, the process that nature uses to turn nitrogen in the atmosphere into food for plants.

For decades, farmers in the United States and around the world have been using chemical fertilizers to supplement this natural process and greatly expand the amount of food they produce.

But chemical fertilizer has turned out to be a big problem for the climate. To make it, manufacturers burn an enormous amount of natural gas, producing carbon dioxide that warms the planet.

This manufactured fertilizer helps feed the world. But its production, distribution and the environmental impact of its use is responsible for the equivalent of an estimated 1 billion metric tons of carbon dioxide each year, which is more than the emissions from the remaining coal-burning power plants in the United States.

And making matters worse, once this chemical fertilizer is spread on fields, a large amount of it runs off into area streams and rivers, causing algae blooms and killing aquatic life, and more of it evaporates as nitrous oxide, which is a more potent greenhouse gas than carbon dioxide.

To tackle this problem, Dr. Temme joined Dr. Voigt and a third colleague to form Pivot Bio, a company that has changed the DNA of bacteria to direct it to turn nitrogen from the atmosphere into more nutrients for corn plants than it would naturally.

After the bacteria is coated onto corn seeds, it reduces the amount of chemical fertilizers that farmers use, cutting their greenhouse gas emissions. Just five years after Pivot’s product was introduced to the market, it is being used on about 5 percent of the corn crops in the United States.

1 note

·

View note

Text

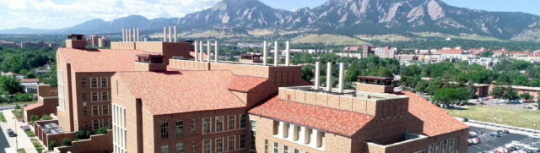

The Department of Chemical and Biological Engineering is committed to providing a welcoming and inclusive learning, teaching and working environment for all students, faculty, staff and guests. The diversity of our community is central to our success as a world-class center of teaching, learning and research.

We are firm in our commitment that all people have the right to be free from harassment and discrimination. To that end, any discrimination against students, faculty, or staff based on protected class identity is in opposition to our values, which are in accordance with the CU Boulder Discrimination & Harassment Policy.

The department recognizes that science and engineering have not traditionally been open, welcoming and accessible spaces for many people, and we are committed to increasing inclusion, diversity and equity in chemical and biological engineering education and research.

In service to these commitments, the department will:

Invite and host speakers with diverse backgrounds as part of the undergraduate curriculum and seminar series

Integrate implicit bias and bystander intervention training for students, faculty and staff

Address diversity and ethics in undergraduate and graduate coursework

Increase efforts to inclusively recruit and retain students, faculty and staff

Leverage the recommendations of the department's Diversity, Equity, & Inclusion committee to continuously improve the overall climate for diversity, equity and inclusion at all levels

Creating a safe, welcoming and rich academic environment is an ongoing process that requires the engagement, commitment and input of all students, faculty and staff within our community.

0 notes

Text

The rapid forward march of genetics opened stunning new vistas of human biological engineering.

"In the Name of Eugenics: Genetics and the Uses of Human Heredity" - Daniel J. Kevles

#book quote#in the name of eugenics#daniel j kevles#nonfiction#genetics#scientific advancements#vistas#genetic engineering#biological engineering#human genetics

0 notes

Text

#radical feminism#womens rights#feminism#gender critical women#radical feminist safe#adult human female#biological women#rad fem#trans exclusionary radical feminist#terfsafe#women’s issues#inventions#history#womens history#technology#medicine#education#entertainment#home cooking#engineering

2K notes

·

View notes

Text

ive been sitting on this gay sonic mlp concept for months im gonna be sick to my stomach am i cooking or am i cooked chat

#when genetically engineering alicorns isnt biologically possible so they gotta get a little ermmm creative dot dot dot#BLANK FLANK!!!!!#this is so dumb im ending it all#sth#sonic#sonic the hedgehog#shadow the hedgehog#sonadow#sonic x shadow#sonic au#mlp#sonic mlp au#my little pony#mlp fim#my art

553 notes

·

View notes

Text

read some Batkid reverse, Talon Dick and it made me think of how the batfam would try to take his medical information like these owls when they get him

But also to be real this is how would they get his weight

#These batkid revers talon dick are so funny because#Everyone think you know how to handle a biologically engineered assassin child just because you been an assassin child hfbhfvh#Damian wayne welcome to parenthood your first assignment is assassin child with occasional zoomies#damian wayne#dick grayson#Dc#batfam

225 notes

·

View notes

Text

My favorite dynamic

Og images below the cut

#I actually really love these two#I need to talk abt them more#I especially love maudi. He's auditor's biological son. But made by accident#Auditor was trying to clone himself amd put im the wrong commands and ended up giving himself a son HABSBABBDD#Charlie is a generically engineered cat person made by a random as science facility. They were made for combat#Deimos and Sanford found her as a baby and took her in#Btw... If u even care.....#Oc: maudi#Oc: Charlie#madness combat#madcom#madness combat oc#madcom oc#art#artists on tumblr#artwork#digital art#digital drawing#digital illustration#my art#digital doodle#shitpost

44 notes

·

View notes

Text

LOVE writing kidfics with all my blorbos, regardless of whether they'd be "good" parents or not.

Of course I'm giving babies to characters that would canonically be great parents, but I'm also giving babies to my morally questionable blorbos and making them do this

#tbh this is about Wander [over yonder] and the tf2 mercs respectively#although im kinda vindicated by comic 7 since SOLDIER is canonically a dad now#If Soldier and Scout are allowed to have canon biological children#Then *I* can give my ot3 (Medic Heavy and Engineer) a baby that Medic found while dumpster diving

10 notes

·

View notes

Link

The Department of Chemical and Biological Engineering is committed to providing a welcoming and inclusive learning, teaching and working environment for all students, faculty, staff and guests. The diversity of our community is central to our success as a world-class center of teaching, learning and research.

We are firm in our commitment that all people have the right to be free from harassment and discrimination. To that end, any discrimination against students, faculty, or staff based on protected class identity is in opposition to our values, which are in accordance with the CU Boulder Discrimination & Harassment Policy.

The department recognizes that science and engineering have not traditionally been open, welcoming and accessible spaces for many people, and we are committed to increasing inclusion, diversity and equity in chemical and biological engineering education and research.

In service to these commitments, the department will:

Invite and host speakers with diverse backgrounds as part of the undergraduate curriculum and seminar series

Integrate implicit bias and bystander intervention training for students, faculty and staff

Address diversity and ethics in undergraduate and graduate coursework

Increase efforts to inclusively recruit and retain students, faculty and staff

Leverage the recommendations of the department's Diversity, Equity, & Inclusion committee to continuously improve the overall climate for diversity, equity and inclusion at all levels

Creating a safe, welcoming and rich academic environment is an ongoing process that requires the engagement, commitment and input of all students, faculty and staff within our community.

#engineering#chemical engineering#chemical and biological engineering#biological engineering#k12 academics

0 notes

Text

Santa x Reader (yes really) fic inspired by https://www.tumblr.com/ntls-24722/770636181074477056/centaur-claus by @ntls-24722.

Word count: ~13,700

#my writing#x reader#i'm....hesitant to tag it as much else#don't get me wrong i'm very proud of this but also a bit self-conscious#in some ways it seems in alignment with my usual silliness#but in other ways it feels wildly random and out of pocket#but is it really that much weirder than killer robots; dummies; biologically engineered creatures; giant spiders?#who really knows at this point#centaur claus

7 notes

·

View notes

Text

#college#university#college majors#majors#engineering#computer science#physical science#biological sciences#social sciences#education#music major#art major#college life#student life#college student#collegeblr#collegebound#student#poll#polls#tumblr polls#pollblr#augmented polls

16 notes

·

View notes