#best injection moulding machine manufacturers in

Text

Craft precision with our leading injection moulding machine manufacturers in India. Our state-of-the-art machines are engineered to deliver superior performance, efficiency, and reliability.

#top injection moulding machine manufacturers in india#injection moulding machine manufacturers in india#best injection moulding machine in india

0 notes

Text

The Best News of Last Week

⚡ - Goodbye Fossil Fuels, Hello Renewables: The Energizing News You Need

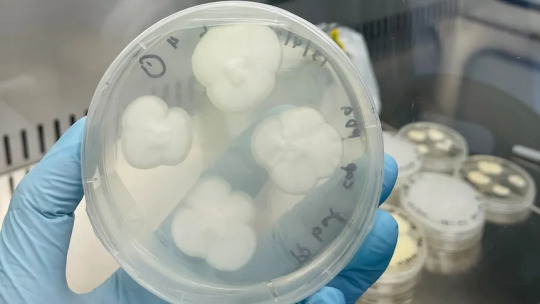

1. Fungi discovered that can eat plastic in just 140 days

Australian scientists have successfully used backyard mould to break down one of the world's most stubborn plastics — a discovery they hope could ease the burden of the global recycling crisis within years.

It took 90 days for the fungi to degrade 27 per cent of the plastic tested, and about 140 days to completely break it down, after the samples were exposed to ultraviolet rays or heat. We really see a solution within five years, according to environmental scientist Paul Harvey, an expert on global plastic pollution.

2. Topeka Zoo welcomes new African Lion as female sprouts mane

The Topeka Zoo has welcomed a new African Lion to its pride, a male, as one of its females started to sprout a mane following the 2021 passing of the pride’s last male.

The Topeka Zoo and Conservation Center announced on Thursday, April 13, that Tatu, a 4-year-old African Lion, has arrived in the Capital City. He comes to Topeka from the Denver Zoo and his arrival marks a time of growth for the zoo.

3. This barber opens his shop on his day off for children with special needs – and all of their haircuts are free

On his day off, Vernon Jackson still goes to work, opening up his Cincinnati barber shop, Noble Barber and Beauty, for VIP clients: children with special needs.

It's something he's done since 2021. "I was hearing so many horror stories that parents were going through with other barber shops and just the barbers or stylists having no patience with their child," Jackson told CBS News. "So I figured I would compromise by coming in on my day off so there were there would be no other barbers or stylists in the shop and I could give them the full attention that they need."

4. Renewables break energy records signalling ‘end of the fossil age’

Experts are calling time on the fossil age as new analysis shows wind and solar power produced a record amount of the world’s electricity last year.

The renewables generated 12 per cent of global electricity in 2022, up from 10 per cent the previous year, according to the report from clean energy think tank Ember. Last year, solar was the fastest-growing source of electricity for the 18th year in a row, rising by 24 per cent from 2021.

5. New nuclear medicine therapy cures human non-hodgkin lymphoma in preclinical model

A new nuclear medicine therapy can cure human non-Hodgkin lymphoma in an animal model A single dose of the radioimmunotherapy, was found to quickly eliminate tumour cells and extend the life of mice injected with cancerous cells for more than 221 days (the trial endpoint), compared to fewer than 60 days for other treatments and just 19 days in untreated control mice.

To explain it in simple terms because this is so freaking cool: There is a radioactive atom attached to a drug. The target cell eats the drug and the energy coming off of the radioactive atom kills the target cell

6. Colorado passes first US right to repair legislation for farmers

Colorado farmers will be able to legally fix their own equipment next year, with manufacturers including Deere & Co obliged to provide them with manuals for diagnostic software and other aids, under a measure passed by legislators in the first U.S. state to approve such a law.

Equipment makers have generally required customers to use their authorized dealers for repairs to machines such as combines and tractors.

7. When a softball player falls after hitting a grand slam, this is how her opponents reacted

youtube

----

That's it for this week :)

This newsletter will always be free. If you liked this post you can support me with a small kofi donation:

Buy me a coffee ❤️

Also don’t forget to reblog

1K notes

·

View notes

Text

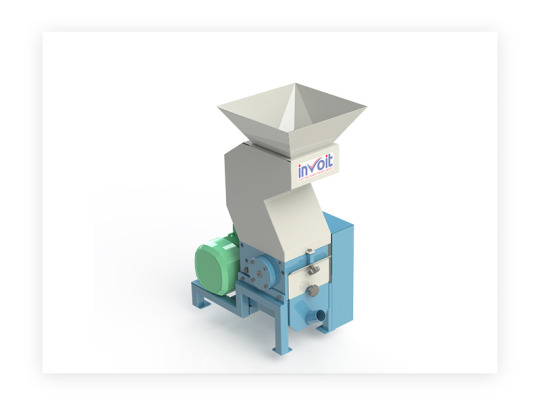

Plastic Scrap Grinder Machine Manufacturer, Exporter Plastic Waste Crushing Machine

https://www.invoitplast.com/plastic-scrap-grinder-machine/

Each part of this plastic scrap grinder machine is made from superior material, whether it is its body or sharp blades.

Plastic Scrap Grinder Machine Manufacturer, Exporter - Plastic Waste Crushing Machine are best suitable for plastic grinding or crushing of Defected and rejected plastic products from Injection Moulding Machine, Blow Moulding Machine, Extrusion lines etc i.e. Chairs, Battery boxes, HDPE Drums, PVC Pipes & Fittings, Barrels, Jerry Cans, Household products, Plastic articles, Toys etc.

Invoit Plast Machinery Pvt. Ltd. is also leading exporter of Plastic Scrap Grinder Machine to South #Africa, #Dubai UAE, #Nepal, #Bangladesh and #Qatar.

Invoit Plast Machinery Pvt. Ltd. located in Ahmedabad, Gujarat, India., is manufacturer and supplier of Plastic Scrap Grinder Machine and to India specifically Hyderabad, Nasik, Chennai, Baroda, Bangalore and Rajkot.

5 notes

·

View notes

Text

Plastic Injection Molding Shapes Tomorrow

Plastic material is melted and then injected into a mold cavity using the industrial process of plastic injection molding to produce a solid, three-dimensional item. This method enables the constant mass manufacture of intricate and accurate plastic components.

Important Elements in Plastic Injection Molding

Melting and injecting the plastic material into the mold consists of a hopper for loading plastic pellets, a barrel for heating the material, and a screw or plunger for forcing the molten plastic into the mold.

Mold: Molds can be created with one or more cavities and are commonly constructed of steel or aluminum depending on the needs of the production process.

Clamping Unit: During the injection process by the injection moulding manufacturer, the clamping unit guarantees that the mold stays tightly closed. The two mold parts are held together by a clamping mechanism, and the necessary force is applied by a hydraulic system.

Ejector System: The ejector system forces the final item out of the mold once the plastic has cooled and set inside the mold. The removal of the molded pieces is made simple and effective by this element.

The Technique of Plastic Injection Molding:

Mold Setup: The injection molding machine is ready for use after the mold has been put inside of it.

Pellets of plastic are fed into the machine's hopper during material loading.

Plastic pellets are heated and melted in the barrel of the injection machine before being injected. The molten plastic is then forcefully pumped into the mold cavity.

Cooling: The plastic inside the mold is solidified by cooling the mold. The thickness of the component and the material has an impact on the cooling time.

Ejection: The ejector mechanism forces the final object out of the mold once the plastic has hardened.

Plastic injection molding advantages:

Precision and Consistency: Plastic injection molding yields components with precise tolerances and reliable quality, making it the perfect process for high-precision goods.

Wide Material Variety: The technique is flexible in that it can handle a variety of thermoplastic and thermosetting materials.

Complex Geometries: Using alternative manufacturing processes would be difficult or impossible for the fabrication of elaborate and complex forms. Injection moulding is the best fit for this.

#Injection Moulding#Plastic Injection Molding#Injection Moulding manufacturer#Injection Moulding supplier#Injection Moulding China

2 notes

·

View notes

Photo

Are you looking for DIN 2738 ( P20 + Ni) Steels in India ?

Have you understand the advantages of using DIN 2738 Steel (P20 +Ni)?

Virat Special Steels announced as the largest stockiest of DIN 2738 ( P20 + Ni) which is supposed to be an upgraded version of the plastic mold steel 2311. Just like plastic mold steel 2311, DIN 2738 is also supplied in a pre hardened condition. The most specific use of DIN 2738 is that for the purpose of making plastic injection die molds.

Besides the fact that DIN 2738 is supplied in pre hardened condition, some of the other important characteristics of this steel are s follows:

In the state, when the same is supplied to the customers, the level of hardness of the steel is at 280-320 HB. The nickel content in the steel increases by 0.8% – 1.5% on further hardening.

This steel is micro alloyed.

The best characteristic of this steel, which makes it perfect for the making of plastic injection die molds, is the fact that it is very good in machining. As a result of this, it becomes absolutely suitable for various purposes like Texturing, polishing of the outsides of various products, provides excellent corrosion resistance to the products, etc.

Other than the making of plastic injection die molds, there are many other applications of this steel. Some of those applications have been discussed below:

This steel can be used for making dies for many different industries like the automotive industry, domestic goods industry, etc.

Plastic molds of various sizes, big as well as small, can be easily made from the use of DIN 1.2738 (AISI P20).

It is useful in the manufacturing of numerous dies and products like high finishing plastic die, Boaster plates used in presses, shoe / Sow blocks and die hammers, which are used for the making of drop hammers, press cassetes, forging dies, Upsetter blockers, and various other dies and molds made for different plastic products.

This steel has a very high demand in the market for the simple reason that this modern and upgraded version of plastic mold steel 2311, offers increased alloy element, which not only increases its hardness, but it also provides extra life. Thus, the parts manufactured through the use of this steel last for a much longer duration.

At the same time, the quality of polishing that is done on this steel is also very good. The hardness present in the steel is also uniform throughout the product. Almost all Leading steel company like Virat Special Steels is Stocking and supplying this product and the demand for the same is increasing on a constant basis.

Virat Special Steels is the largest stockist and supplier of P20 + Ni and P20 tool steel in flat, square and round bars. We provide steel in all sizes as your requirements. P20 Steels is available in flat, square and round shape.

Consult our team who will assist you for the PlasticMouldSteels query.

Learn more :

https://www.viratsteels.com/plastic-mould-steel.html

Any queries feel free to contact us :

[email protected] or on mobile number +91-9814021775

#viratsteels#plasticmouldsteels#metalworking#metallurgy#iso9001#engineering#steel#alloy steel#cold work steel#die steels#high speed steel#toolsteel#toolsteelsupplier#viratsteelindia#p20#p20ni#plasticmould#diesteel#nipponsteel#mouldsteelstockist#gurgaon#ludhiana#pune#india

2 notes

·

View notes

Text

Top C-PVC Injection Moulding Machine for Reliable Production

Patel Plastic Machinery is providing top line C-PVC injection moulding machine designed to delivering reliable production. Our engineered efficiency and built quality to the handle unique properties of C-PVC make sure that high quality output with minimal waste. Our C-PVC injection moulding machine to producing complex component or simple parts that providing performance you need to stay ahead in the competitive market.

Patel Plastic Machinery are equipped with advance technology that allow for precise control over the moulding machine which guarantees superior product quality in every time. We are focusing on durability and ease to operate. Our machine built quality are providing long term value and reducing downtime. . Trust Patel Plastic Machinery to elevate your production capabilities and achieve consistent, high-quality results with every run.

If you want to improve your production advance C-PVC injection moulding machine? Then visit our website pplastmach.com to explore our full range of products and how we can help you achieve reliable and efficient manufacturing. Click the link below to get started today!

#plastic injection moulding machine#micro injection moulding machine#micro injection moulding machine manufacturer#micro injection moulding machine supplier#micro injection moulding machine in ahmedabad#micro injection moulding machine in india#pet preform injection moulding machine#plastic injection moulding machine in india#thin wall container injection moulding machine#plastic injection moulding machine manufacturer

0 notes

Text

“Shaping Tomorrow: The Unsung Heroes of Modern Manufacturing”

Introduction to Injection Molding Machines

In the intricate world of manufacturing, there’s a silent force at work, tirelessly crafting the everyday items we often take for granted—injection molding machines. These machines are the backbone of the plastic industry, transforming raw materials into the essential products that shape our lives. Let’s embark on a journey to uncover the magic behind these incredible machines and their pivotal role in modern manufacturing.

The Heartbeat of Innovation

Injection molding machines are the unsung heroes of the plastic manufacturing industry. They operate by injecting molten plastic into a mold, where it cools and solidifies into the desired shape. This process is not only efficient but also incredibly versatile, allowing for the production of a wide range of products, from tiny medical components to large automotive parts.

Types of Injection Molding Machines

Hydraulic Injection Molding Machines:

Power and Versatility: These machines have been the industry standard for decades. They use hydraulic power to drive the molding process, making them capable of handling a wide range of materials and applications.

Cost-Effective for Large Parts: Ideal for producing large and heavy parts due to their high clamping force capabilities.

Considerations: While versatile, they can be less energy-efficient and require more maintenance compared to their electric counterparts.

Electric Injection Molding Machines:

Precision and Energy Efficiency: These machines are known for their high precision and energy efficiency. They use electric motors, resulting in reduced energy consumption and more precise control over the molding cycle.

Clean and Quiet: They generate less noise and produce fewer emissions, making them suitable for cleanroom environments.

Initial Investment: They often come with a higher upfront cost, but their long-term operational savings can outweigh the initial investment.

Hybrid Injection Molding Machines:

The Best of Both Worlds: Combining the strengths of hydraulic and electric machines, hybrids use electric servo motors for the injection process and hydraulic power for clamping and ejection.

Energy Savings: They offer energy efficiency without compromising on clamping force, making them an attractive option for manufacturers seeking a balance between performance and economy.

Two-Platen Injection Molding Machines:

Space and Flexibility: Featuring a unique design with two platens that move horizontally, these machines save space and offer greater flexibility in mold design and production.

The Science of Precision

Precision injection molding is a specialized process that focuses on producing highly accurate and consistent plastic components with tight tolerances. This is crucial for industries like medical devices, electronics, and automotive, where exact specifications are paramount. Advanced machinery and techniques control every aspect of the process, ensuring that each part meets the highest standards of quality.

The Future of Injection Molding

As technology advances, so does the world of injection molding. Innovations in materials, machine design, and process control are paving the way for even more efficient and sustainable manufacturing practices. The future holds exciting possibilities, from biodegradable plastics to smart manufacturing systems that can adapt in real-time to changing production needs.

Conclusion

Injection molding machines are more than just tools—they are the heart of modern manufacturing, driving innovation and efficiency across countless industries. By understanding the different types of machines and their unique capabilities, we can appreciate the incredible precision and versatility they bring to the table. As we look to the future, these machines will continue to play a crucial role in crafting the products that shape our world.

To Know More About Injection Moulding Machine Dealers in Lucknow click on the Link Below:

https://eshikarastogi.pashium.in/5-top-plastic-injuction-moulding-machine-dealers-in-lucknow

1 note

·

View note

Text

Moulding Tolerances and Surface Finish: Expectations in On-Demand Production

In on-demand production, moulding tolerances and surface finish play a crucial role in determining the quality and performance of the final product. For manufacturers, designers, and engineers, understanding these aspects is key to ensuring smooth and successful project outcomes.

Exploring Moulding in On-Demand Manufacturing

On-demand manufacturing has transformed the moulding landscape, providing unmatched flexibility, speed, and precision. This method allows for the rapid creation of moulded components without the need for extensive tooling or large inventories.

Advantages of On-Demand Moulding

With on-demand manufacturing, moulds can be created swiftly, reducing lead times from weeks to mere days. This rapid process accelerates production cycles and offers the flexibility to modify or iterate designs without incurring hefty tooling costs. The process minimizes the need for large-scale tooling investments and eliminates the burden of storing large inventories. Advanced technologies and precise tooling used in moulding ensure the consistent production of high-quality, reliable parts. Moreover, production levels can be adjusted easily, scaling up or down as demand fluctuates, leading to efficient use of resources.

Common Moulding Techniques in On-Demand Manufacturing

Injection Moulding: Ideal for mass-producing complex parts with stringent tolerances.

CNC Machining: Suitable for creating small to medium-sized components with detailed geometries.

3D Printing: Facilitates rapid prototyping and the production of intricate, custom parts.

Reaction Injection Moulding (RIM): Best suited for producing large, lightweight parts with smooth surfaces.

Materials Used in On-Demand Moulding

Plastics: Including thermoplastics, thermosets, and elastomers for diverse applications.

Metals: Such as aluminum and steel for creating strong, durable components.

Composites: Including carbon fiber and glass fiber for high-performance needs.

Applications of On-Demand Moulding

Aerospace: Creation of lightweight, high-performance components for aircraft and spacecraft.

Automotive: Facilitating rapid prototyping and the production of complex automotive parts.

Medical: Producing precise, customized parts for medical devices and equipment.

Consumer Products: Enabling the quick production of customized components for various industries.

By embracing on-demand manufacturing for moulding, businesses can enhance their production efficiency, lower costs, and expedite the introduction of innovative products to the market.

Moulding Tolerances: Defining the Precision

Moulding tolerances refer to the permissible deviations in the dimensions of parts produced through processes like injection moulding. These tolerances are critical for ensuring that components fit, function, and assemble correctly. On-demand production often delivers tighter tolerances compared to traditional methods, thanks to the use of advanced technologies and precise tooling.

Surface Finish: Balancing Aesthetics and Functionality

Surface finish is a crucial element in moulding that affects both the look and performance of the final product. On-demand manufacturing provides a range of surface finish options, including textured, smooth, or matte finishes. The selected finish can influence the product’s durability, resistance to corrosion, and overall user experience.

Key Factors Impacting Moulding Tolerances and Surface Finish

Several factors play a role in determining moulding tolerances and surface finish in on-demand production:

Material Choice: Different materials shrink at different rates, affecting tolerances and finish.

Tooling Quality: High-quality tooling ensures accurate dimensions and superior surface finishes.

Manufacturing Process: Techniques like injection moulding, CNC machining, and 3D printing each offer unique capabilities in terms of tolerance and surface finish.

Design Complexity: More intricate designs can sometimes challenge the achievement of precise tolerances and surface finishes.

Best Practices for Optimal Moulding Results

To achieve the best possible moulding tolerances and surface finishes in on-demand production:

Collaborate with Experienced Partners: Work with skilled manufacturers and designers to optimize design and material selection.

Set Clear Expectations: Define tolerance and surface finish requirements upfront.

Choose Compatible Materials: Select materials that meet the desired tolerance and finish standards.

Mechkonnect Industrial Solutions Pvt Ltd: Your Trusted Partner

Mechkonnect Industrial Solutions Pvt Ltd specializes in moulding and on-demand manufacturing, offering expertise in injection moulding, CNC machining, and 3D printing. By leveraging cutting-edge technologies and maintaining close collaboration with clients, Mechkonnect ensures precise moulding tolerances and high-quality surface finishes. Whether you need rapid prototyping or large-scale production, Mechkonnect’s on-demand manufacturing solutions deliver accuracy, quality, and reliability, turning your vision into reality with exceptional efficiency. Partner with Mechkonnect to bring your projects to life with unmatched precision and speed.

0 notes

Text

Kyodo India: A Blessing for Manufacturing and Pharmaceutical Industries in India

Introduction:

There have been some revolutionary inventions in the manufacturing industry of the world which made mass manufacturing possible and available for everyone. For over 40 years, Kyodo India has been assisting the manufacturing industry with its superior innovation and consistently high quality in providing state-of-the-art mass manufacturing solutions across various business sectors which include manufacturing, pharmaceuticals, medical equipment and more. We at Kyodo India are dedicated to promote manufacturing excellence, technological advancement, and customer satisfaction which has positioned us as a trusted, reliable and profitable partner for several kinds of businesses operating on a worldwide scale. All of our products have been a blessing for many manufacturing industries and your business can become the next which can produce ample amounts if quantity to supply against the never-ending demands of the market.

Optimize Your Production with Our Purging Compounds Solutions

In the manufacturing business, the most important elements are maintaining the efficiency and cleanliness of machinery to produce good quality products punctually. Our Asaclean Purging Compound is considered the best purging compound internationally in several countries and is specifically designed to effectively clean injection moulding machines and extruders to produce the same high-quality products without any downtime or variance in appearance. This purging compound for injection moulding and extruders has the ability to remove unwanted and unnecessary residual material which also prevents contamination and significantly reduces waste of imperfect finished goods. Hence, the benefits include the following:

• Reduced Scrap Rates: By ensuring the necessary effective cleaning, it can significantly minimize material waste.

• Lower Maintenance Costs: Asaclean Purging compounds decrease machine cleaning and maintenance needs.

• Improved Product Quality: It also prevents raw materials contamination and confirms a high-quality production run.

Enhance Efficiency with Quick Muold Change Systems & Hydraulic Clamping Systems

Time is considered an indispensable element in the manufacturing business, and our Quick Mould Change System is thoughtfully engineered to maximize the output without hampering the time taken for production. By offering swift and secure mould changes ways, we significantly minimize downtime and boost the productivity output of finished goods. When manufacturing is paired with our Hydraulic Clamping System, it grants a robust and reliable clamping solution for your business operations to achieve unprecedented levels of efficiency in manufacturing. The key advantages of Quick Mould Change System and Hydraulic Clamping System include the following:

• Faster Production Cycles: Quick mould changes reduce idle time and produce products faster.

• Enhanced Safety: This is a safe and secure clamping systems which reduces the risk of accidents.

• Increased Flexibility: With these businesses can adapt effectively to many different production requirements.

Superior Magnetic Solutions for Precision and Strength in Manufacturing

We at Kyodo India offer the most advanced magnetic solutions that is currently fulfilling many and various industrial needs of production an =d manufacturing. Our powerful Neodymium Magnets and Alnico Magnets are known worldwide for their exceptional magnetic strength and tremendous resistance to demagnetization. These magnets are considered extremely crucial for several applications such as magnetic welding clamps that provides a secure and precise holding which is necessary for high-quality welding operations. The benefits of our Magnetic Solutions are:

• Strong Magnetic Force: This ensures reliable holding power and strength for heavy-duty production tasks.

• Durability: Our magnets are resistant to demagnetization which confirms a long-term use of them.

• Versatility: These are highly suitable for a wide range of industrial applications to improve manufacturing.

Maintaining Clean and Safe Production Environments

It is also very crucial to keep a clean and static-free environment in both manufacturing and pharmaceutical industries to produce the finished products which is why our Dust Ionizer and Static Charge Eliminator are carefully designed by top engineers to maintain such clean and relevant environments. By eliminating the hazardous dust and static charges, these devices prevent any type of contamination and protect sensitive equipment to maintain effectiveness. Key benefits of our Dust Ionizer and Static Charge Eliminator include:

• Enhanced Product Quality: This can reduce many kinds of defects caused by dust and static in production runs.

• Improved Safety: It minimizes the risk of accidental or hazardous static discharge, which can damage equipment or cause fires.

• Cleaner Work Environment: It creates and promotes a healthier and more efficient workspace for workers to produce more.

Manufacturing and Production Excellence in Pharmaceutical Solutions

Kyodo India is an experienced corporation and excellent choice for the pharmaceutical industry because we offer the best range of products and services to them for more quality production. We supply high-quality pharmaceutical dosage forms and active pharma ingredients (APIs) to help this industry produce more without compromising on high-quality finished products. Many similar businesses have chosen us for years and made us a reliable and active pharma ingredients manufacturer that guarantees to meet the highest standards of purity and efficacy in pharmaceutical solutions. Our expertise also extends to delivering top-tier medical equipment as well, making us a highly sought-after medical equipment supplier in Delhi. The benefits of pharmaceutical solutions include the following:

• High-Quality Ingredients: We ensure the high-quality production of safe, effective and useful pharmaceutical products.

• Regulatory Compliance: We always adhere to the required and legal industry standards in the pharmaceutical sector.

• Comprehensive Support: We offer a wide range of equipment and ingredients to support all various pharmaceutical needs.

Some of the Best-Selling Products from our Portfolio

• Asaclean Purging Compound: It is used for efficient cleaning of injection moulding machines and extruders.

• Quick Mould Change Systems: These are used to streamline mould changes to improve the efficiency of productivity.

• Hydraulic Clamping Systems: These can secure and efficient clamping solutions for many diverse production applications.

• Neodymium and Alnico Magnets: These are high-performance magnets for various uses like magnetic welding clamps.

• Dust Ionizers and Static Charge Eliminators: This helps in maintaining clean and static-free production environments.

• Pharmaceutical Dosage Forms and APIs: These are high-quality ingredients and formulations for the pharmaceutical industry.

Conclusion: Choose Kyodo India and Bid Farewell to Manufacturing Problems

Kyodo India is a dedicated company with over 4 decades of experience in providing the best manufacturing solutions to several manufacturing and pharmaceutical industries. With the help of our innovative, reliable, and high-quality solutions many manufacturing industries have been able to reach new heights of success and profitability. All of our products are thoughtfully, methodically and innovatively designed to improve effectiveness, efficiency, reduce downtime, and guarantee the highest standards of quality production and safety. By partnering with Kyodo India, you are investing in your business to get a large sum of return with a wealth of manufacturing expertise and a comprehensive range of products customised to meet your specific manufacturing needs for more production and more profit.

To learn more about our products and services, and to discover how Kyodo India can boost your manufacturing and pharmaceutical requirements, please visit our official website https://kyodoindia.com/ or contact our customer service team from the Contact Us page. Kyodo India – The Manufacturing Partner Your Business Deserves.

#pharmaceutical dosage forms#medical equipment suppliers in delhi#Asaclean Purging Compound#purging compund#Quick DIE Change System#magnetic clamp#purging compound for extruders#purging compound for injection moulding#magnetic welding clamps#quick mold change system#hydraulic clamping system#neodymium magnets#Alnico Magnets

0 notes

Text

What Commonly Used Injection Molding Materials Have: An Insight into Their Properties and Applications.

Injection molding is a widely utilized manufacturing process that involves injecting molten material into a mold to create a wide array of products. The choice of material is crucial as it influences the properties, cost, and applications of the final product.

Here, we delve into some of the most used injection molding materials, exploring their characteristics and common applications.

1. Polypropylene (PP)

Characteristics:

Polypropylene is a type of plastic that is very versatile. It is lightweight, resists chemicals well, and can handle repeated stress without breaking. This makes it perfect for uses that need to be durable.

Applications:

PP is often used in packaging, car parts, everyday products, and medical devices. Repeated bending makes it great for items like living hinges that need to bend a lot.

2.Acrylonitrile Butadiene Styrene (ABS)

Characteristics:

ABS is a type of plastic made by mixing styrene and acrylonitrile with polybutadiene. This makes it very strong, tough, and keeps its shape well.

Applications:

ABS is commonly used in car parts, electronic cases, everyday items, and toys. Its strength and easy shaping also make it popular for 3D printing.

3. Polyethylene (PE)

Characteristics:

Polyethylene comes in different types like HDPE and LDPE. It resists chemicals, insulates electricity, and is flexible. HDPE is harder and more rigid, while LDPE is softer, more flexible, and melts at a lower temperature.

Applications:

PE is used for many items like containers, bottles, plastic bags, and toys. It is also great for medical and food packaging because it is safe and non-reactive.

4. Polycarbonate (PC)

Characteristics:

Polycarbonate is a strong type of plastic known for being tough and clear. It can be shaped easily and is used in many ways.

Applications:

Polycarbonate is often used in eyeglass lenses, medical tools, car parts, and electronics. Its clearness and strength make it perfect for things that need to be strong and easy to see through.

5. Polystyrene (PS)

Characteristics:

Polystyrene is a type of man-made plastic that comes in two types: solid and foam. It is light, stiff, and cheap to make.

Applications:

PS is used in things like disposable utensils, plastic models, CD cases, and foam packaging. The foam kind, called expanded polystyrene (EPS), is common in insulation and packing materials.

6. Nylon (Polyamide - PA)

Characteristics:

Nylon is a man-made material that is strong and flexible. It can handle being pulled hard, resist wear and tear, and is good with heat and chemicals.

Applications:

Nylon is used in cars, machines, everyday items, and clothes. It is tough and strong, perfect for parts that get a lot of use and pressure.

7.Polyethylene Terephthalate (PET)

Characteristics:

PET is a thermoplastic polymer resin of the polyester family. It is known for its strength, thermostability, and resistance to moisture.

Applications:

PET is widely used in beverage bottles, food packaging, and synthetic fibers. Its recyclability makes it a popular choice for environmentally conscious manufacturers.

Different materials used in injection molding have special qualities that suit various needs. For example, polypropylene is versatile and tough, while polycarbonate is strong and clear. Knowing these traits helps manufacturers pick the best material for their specific use, ensuring good performance, cost-efficiency, and eco-friendliness. As technology and materials improve, more options for injection molding become available, opening new possibilities for innovation in manufacturing.

There are 7 Most Common Injection Moulding Gate Types - Choosing a Gate for Your Project

An injection molding gate is a specially designed opening that controls how molten plastic flows into the mold. Its main job is to manage the amount and direction of the plastic as it fills the mold. There are different kinds of gates, such as edge gates, sub gates, and direct sprue gates, each with its own unique features and uses. We will look at these types more closely below.

Most common types of injection moulding gate:

Edge Gates

Tunnel / Submarine (Sub) Gates

Cashew Gates

Sprue or Direct Gates

Fan Gates

Diaphragm Gates

Pin Gates

Inject moulding is a prototyping tool made by HLH Rapid. Before beginning production, our engineers choose the ideal gate for your design and build bespoke moulds and parts based on your CAD drawings. Simply use our site contact form to send us your CAD designs and project specifics, including quantity, material, and any surface finishing. In a span of 24 to 48 hours, our staff will furnish an estimate.

Do you want to learn about Injection Molding or need a Free Quote? Submit your CAD drawings and project details, including quantity, material, and surface finish, through our site contact form. Our team will send you a quote within 24-48 hours.

0 notes

Text

Plastic Scrap Grinder Machine Manufacturer, Exporter

Plastic Scrap Grinder Machine Manufacturer, Exporter

Plastic Waste Crushing Machine Manufacturer, Exporter

https://www.invoitplast.com/plastic-scrap-grinder-machine/

Our Plastic Scrap Grinder Machine is a special addition for your delight with its high performance and cost effectiveness.

They are best suitable for plastic grinding or crushing of Defected and rejected plastic products from Injection Moulding Machine, Blow Moulding Machine, Extrusion lines etc i.e. Chairs, Battery boxes, HDPE Drums, PVC Pipes & Fittings, Barrels, Jerry Cans, Household products, Plastic articles, Toys etc.

2 notes

·

View notes

Text

Phoenix Moulds is a specialist in making moulds related to manufacturing and design.

We design and manufacture moulds that are tested and approved by international standards. We specialize in manufacturing, designing and developing all kinds of injection moulds. We make moulds for agriculture, plumbing, drainage, SWR, electrical, roof water and many other industries. We also work for categories in various polymers like PVC, PP, CPVC, ABS, EE, TPR, PP-R HDPE and PP-R etc. Our manufacturing units are equipped with advanced computer softwares and tools & hardware related to the machines.

0 notes

Text

Unparalleled Vibration Control with Dynemech - Precision Vibration Engineering for Enhanced Productivity and Efficiency

Are you in need of top-notch vibration control goods and services that provide unparalleled precise machinery alignment, increased lifespan, and reduced expenses? There is no need to search any longer! Dynemech Anti Vibration Technology is committed to delivering the best , well researched & effective solutions in the market, supported by our unparalleled expertise and commitment to excellence.

Dynemech, a leading indigenous manufacturer of vibration dampening technology, offers a comprehensive range of innovative anti-vibration solutions engineered to deliver unmatched precision in operational accuracy, prolong the working life of the machine, and reduce maintenance costs. Our products are designed to provide accurate levelling, alignment, and vibration management, resulting in improved machine performance across industrial and manufacturing sectors.

Dynemech offers a wide range of products for vibration isolation, including but not limited to vibration isolation plates, precision wedge mounts, taper shim levelling mounts, circular bolt supported mounts, level grip mounts, auto-levelling pneumatic mounts, shock isolators, spring elements with viscous damping, anti-vibration tables with honeycomb tabletops, pneumatically vibration-isolated workstations with steel cabinets and casters, and precision metrology equipment anti-vibration tables.

These tried and tested solutions are widely applicable to various applications, such as plastic injection moulding machines, CNC VMC, mechanical power presses, textile machines, forging hammers, CNC milling, generators, compressors, HVAC systems, punching presses, stamping, and shearing machines.

Dynemech's anti-vibration solutions are meticulously designed to enhance machine performance, prolong machinery lifespan, and minimize maintenance expenses, hence leading to profitable production and cost-effectiveness for manufacturing units.

Don't just take our word for it! Listen to testimonials from our contented clientele who have directly encountered the advantages of our vibration control solutions.

"The utilization of Dynemech pads in our CNC machines leads to improved accuracy and reduced tool deterioration, resulting in a substantial increase in productivity." - Manufacturing Industry Leader

Contact:

Dynеmеch Systеms Pvt Ltd.

Mob: +91-9810760131 ; +91-9911145131

Email: Salеs@dynеmеch.com www.vibrationmountsindia.com | www.vibrationdampingpads.com

#VibrationControl#PrecisionEngineering#AntiVibration#MachineryAlignment#MaintenanceCostReduction#IndustrialSolutions#VibrationIsolation#WedgeMounts#TaperShimMounts

0 notes

Text

How Injection Moulding Specialists Works: Definition and Process.

Injection moulding is the process of manufacturing a wide variety of parts and items, keeping expenses under control, and using plastic. Though the process was invented in the early 19th century till date it is accepted as the best process to manufacture complex parts at an affordable expense. Due to its versatility and flexibility, the finished products of Injection Moulding Specialists are widely used in different kinds of industries around the world. Industries like aviation industries, medical industries, and even the automotive industries are using the parts produced by injection moulding machines.

Pros of Injection Moulding

The Injection Moulding Specialists is accepted as one of the most effective processes of manufacturing techniques having many advantages. But since it’s a manufacturing process there are certain measures you should consider before selecting the right approach for you. The pros of injection moulding are discussed below:

Durability: The parts that are produced by the injection moulding process provide advanced reliability and durability of the product. Fillers can be added to the products to reduce the density of the plastic and make the product stronger.

Impeccable Precision: The material is injected into the moulding machine and then shaped by the mold, which can be done repeatedly reduces the chance of imperfection in the shapes. Due to its high level of accuracy in producing product parts, it is highly in demand in the automotive and aerospace industries.

Cost Efficiency: Injection Moulding Specialist is considered the most cost-effective process of manufacturing parts or items. The cost of the product depends on the complexity of the design and the materials you are going to use for the product. Upon comparing you will find that injection moulding is capable of providing the maximum number of products with the money you can allot for that particular product.

Eco-friendly: The injection moulding process does not produce any waste while doing any production hence it is considered the most eco-friendly process and can be useful in maintaining the environment. In this process, the materials that become residue can be reused during the next manufacturing process.

How the Specialist do the Work

The Injection Moulding Specialist process may look simple to you but it is a very complicated process that requires the right expertise and equipment. In terms of work, the process is divided into two steps that can make you understand the working process. The process can be described as follows:

The injection moulding machine can be divided into three parts; they are the heated barrel, the hopper, and the screw. The machine works by taking plastic granules or powder as a material and turning it into shapes according to the required dimensions.

The feed hopper receives the materials and then with the help of a screw it starts generating heat by the process of friction. The plastic material after reaching the required temperature is then injected into the mold cavity where it is cool down and takes the shapes according to the need.

How to Use Injection Moulding

The basic principle behind the Injection Moulding Specialist process is very complicated though it may look very simple. The process requires the right equipment and the right expertise to complete the process correctly. If you can execute the process correctly then injection moulding will provide you excellent results even for the most complex and challenging parts.

0 notes

Text

plastic injection moulding machine

Patel Plastic Machinery MFG. is one of the best plastic injection moulding machine manufacturing industries in India is located in Ahmedabad, Gujarat. We are also supplier of plastic injection moulding machine in all over india.

#plastic injection moulding machine#plastic injection moulding machine manufacturer#plastic injection moulding machine supplier#plastic injection moulding machine in india#plastic injection moulding machine in ahmedabd

0 notes