#Plastic Scrap Grinder

Explore tagged Tumblr posts

Text

Plastic Scrap Grinder Machine Manufacturer, Exporter Plastic Waste Crushing Machine https://www.invoitplast.com/plastic-scrap-grinder-machine/ Each part of this plastic scrap grinder machine is made from superior material, whether it is its body or sharp blades. Plastic Scrap Grinder Machine Manufacturer, Exporter - Plastic Waste Crushing Machine are best suitable for plastic grinding or crushing of Defected and rejected plastic products from Injection Moulding Machine, Blow Moulding Machine, Extrusion lines etc i.e. Chairs, Battery boxes, HDPE Drums, PVC Pipes & Fittings, Barrels, Jerry Cans, Household products, Plastic articles, Toys etc. Invoit Plast Machinery Pvt. Ltd. is also leading exporter of Plastic Scrap Grinder Machine to South #Africa, #Dubai UAE, #Nepal, #Bangladesh and #Qatar. Invoit Plast Machinery Pvt. Ltd. located in Ahmedabad, Gujarat, India., is manufacturer and supplier of Plastic Scrap Grinder Machine and to India specifically Hyderabad, Nasik, Chennai, Baroda, Bangalore and Rajkot.

5 notes

·

View notes

Text

Comprehensive Guide to Plastic Scrap Grinder Machine Prices in India

Plastic grinder machines are crucial in the recycling industry, playing a significant role in processing plastic waste into reusable material. Understanding the pricing of these machines in India is essential for businesses looking to invest in efficient recycling solutions. This article delves into the factors influencing the price of plastic scrap grinder machine and provides an overview of what you can expect when purchasing one in India.

Factors Influencing Plastic Grinder Machine Prices

Several factors influence the price of plastic grinder machines in India:

Machine Capacity: The capacity of the grinder, measured in kilograms per hour (kg/h), significantly affects the price. Higher capacity machines that can process more plastic waste will generally be more expensive.

Blade Quality and Type: The quality and type of blades used in the grinder impact the machine's price. Machines with high-quality, durable blades will cost more but offer better performance and longevity.

Motor Power: The power of the motor, usually measured in horsepower (HP), affects the machine's efficiency and price. More powerful motors can handle tougher materials and larger volumes, thus increasing the cost.

Build Quality: The materials used in the construction of the machine, such as high-grade steel, affect durability and price. Machines built with robust materials will last longer and withstand heavy use, justifying a higher price.

Features and Automation: Advanced features such as automated operation, adjustable settings, safety mechanisms, and ease of maintenance can add to the machine's cost. These features enhance usability and efficiency, making the investment worthwhile.

Brand and Manufacturer: Established brands with a reputation for quality and reliability, like Mechnocraft, often charge a premium for their products. Investing in a reputable brand ensures better customer support and product performance.

Price Range of Plastic Grinder Machines in India

Based on the above factors, plastic grinder machines in India can vary widely in price. Here’s a rough breakdown of the pricing:

Small Capacity Machines: These are suitable for small-scale operations and can process up to 50 kg/h. Prices typically range from ₹1,00,000 to ₹2,50,000.

Medium Capacity Machines: Ideal for medium-sized businesses, these machines can process between 50 to 200 kg/h. Prices generally range from ₹2,50,000 to ₹5,00,000.

Large Capacity Machines: Designed for large-scale operations, these machines can process over 200 kg/h. Prices start from ₹5,00,000 and can go up to ₹10,00,000 or more, depending on the specific features and capabilities.

Where to Buy Plastic Grinder Machines in India

India has several manufacturers and suppliers of plastic grinder machines. When looking to purchase, consider the following:

Local Manufacturers: Companies like Mechnocraft offer a range of high-quality plastic grinder machines with excellent customer support and after-sales service.

Online Marketplaces: Platforms like IndiaMART, TradeIndia, and Amazon India offer a variety of options from different manufacturers, providing a convenient way to compare prices and features.

Trade Shows and Expos: Attending industry trade shows and expos can provide insights into the latest models and technologies, allowing for informed purchasing decisions.

Conclusion

Investing in a plastic grinder machine is a crucial decision for businesses in the recycling industry. Understanding the factors that influence the price and knowing the typical price ranges can help you make an informed choice. For high-quality machines with reliable performance, consider contacting reputable manufacturers like Mechnocraft. Their expertise and range of products can provide the perfect solution tailored to your needs.

0 notes

Text

5 Essential Tips to Find the Best Plastic Scrap Grinder Supplier

Choosing the best supplier of plastic scrap grinder in India is important because it can have a major impact on the quality of your finished product. A good supplier will have:

· The right equipment and expertise ensure that your plastic scrap is ground correctly and efficiently.

· The exact specifications that you need for your project.

· They can also provide helpful advice and tips on how to get the most out of your plastic scrap grinder.

So, it’s important that you have the right supplier.

How To Choose the Right Supplier of Scrap Grinder?

We know that finding a perfect supplier can be a daunting task, but don’t worry we’ve listed some tips and advice to find the right one:

1. Research different brands and models: Research different brands and models of plastic scrap grinders online. Compare the features and prices of each model to help you determine which one is right for you.

2. Check customer reviews: Read customer reviews to get an idea of what others think of the plastic scrap grinder you’re interested in. This can help you make sure the machine is reliable and well-made.

3. Consider your budget: Consider your budget and find a plastic scrap grinder that fits within it. Be sure to factor in any additional costs for installation or maintenance.

4. Check for safety features: Make sure the plastic scrap grinder you choose has safety features like shields, shut-off switches, and emergency stops.

We hope these mentioned points will help you to find a trusted supplier of plastic scrap grinder in India.

0 notes

Text

Kitchen Witch Essentials

I want to preference this by saying your priorities of tools for your craft will vary as you get more experienced. If you get more into baking, you may choose to invest in a kitchen mixer. If your path goes more down drinks, you might want to get a French press. This list is for those starting out or looking to maintain general witchy cooking. Nothing on this list is mandatory, so don't feel like you need to go spend money just because it's on this list.

This list will also assume you have general kitchen stuff, like pots, pans, and knives. You may not have everything, but you have enough to cook.

Wooden Spoon

If for whatever reason you don't have a wooden spoon, and you want to do kitchen magic, I strongly recommend you go and get one. You can get them at any store that sells Kitchen Utensils, including the dollar store.

For some kitchen witches, the wooden spoon is like a magic wand. Allowing the witch to direct energy. Personally, I just enjoy using natural materials whenever I can. Also, it's just such a useful tool to have when cooking. You can stir your food on stove top, and since it's made of wood you don't need to worry about damaging non stick surfaces. If you're boiling pasta, stirring with a wooden spoon helps get rid of the foam overboil. You can also just leave the spoon over the pot to prevent pasta water overboiling. Baking bread? Flip the spoon around and use the handle to bring the dough together.

Some people choose to add sigils or other symbols onto their witchy spoons. If you decide to do this, please do not use paint or stain, as this can come off while cooking. Unless this will be a display only spoon, of course. Safest way is to laser burn a design. Check etsy for custom spoons.

Herbs/Spices you know the properties of

I'm sure you already have some non perishable Herbs or Spices in your pantry or spice rack. Black Pepper, Garlic powder, Cinnamon, Paprika, that kind of thing. I want you to pick one and deep dive into the history of that Herb/Spice. What it's been used for in the past, what are some common magical properties and associations; what do YOU associate with it. Write down the magical association, like protection, banish negativity, prosperity, ect. Start with one, work your way up to three. If you have trouble memorizing, keep a little cheat sheet near by.

Now when you add these seasonings, you know what energies you can add/attract with your food.

Mortar and Pestle

If you already have another way to grind spices, like a coffee grinder, this does not need to be a priority. And if you have arm or shoulder issues, I don't recommend using. The main benefit to using a mortar and pestle is the crushing style of grinding tends to release more aroma and flavor then the cutting style of a coffee grinder. If you plan to just use for dry spices, you won't need a very big or fancy one. 20 dollars should get you something small and solid.

Make sure you are getting one made of stone. I tried a wooden one and it's garbage. I use it to hold messy spoons. There are also metal ones, and while I've never tried one, I encourage caution. I worry about long term use stripping whatever coating is stopping it from rusting.

Jars

Glass Jars are so great to have in the kitchen. Leftover sauce? Put it in a jar. Suddenly made a jam? We got jars to put it in. Meal prep overnight oats? Jars are here for you! They're just great for storage. And you don't need to buy them. Lots of things come in jars; just give them a hot soapy soak, scrap the label off, wash and reuse. If you prefer mason jars, I recommend washing the lids by hand. The lids aren't meant to be reused for jarring, so they rust fairly quickly after a few washes. You can buy replacement lids, however.

Plastic Containers

Jars are great, but things get a little dicey when you want to put stuff in the freezer. Water likes to make sure everyone knows it's cold by puffing up bigger; like look at me, I'm freezing here! Which means, there's a chance your glass jar can shatter.

But freezing food is the best way to preserve food since you don't need to add anything like extra salt or sugar. So get some freezer safe containers. I love making batches of broth and stock, and freeze it for later. Or if we have a lot of leftovers, I'll freeze enough for a dinner another week, incase I don't have enough spoons to make dinner one evening. And don't worry, you can wash and reuse plastic containers too.

I'll also freeze food I notice is starting to go weird. If I buy a huge bag of baby spinach, but can't get through it all, I'll transfer it to a freezer bag. Adding frozen spinach to food as it cooks is one of the easiest ways to up your nutrients. You can also freeze other vegetables, just make sure you cut them up first.

Crock Pot/Slow Cooker

Every Witch Needs a Cauldron, and these are Electric Cauldrons. Prices vary mainly based on the size you want. There are different brands, different colors; you can even get some in the theme of your favorite fandom. But they all have the same 3 core settings: High, Low, and keep warm.

Slow cookers are....well, slow. Which is great for certain kinds of food that need to sit for a long time, like meats. But it's also great for Kitchen Witches with a lot going on. Non witches will "Set it and forget it" but it's a good idea to stir every once in a while. Which is where the magic comes in. So, if you're a scatter brained Witch, Like me, or have ADHD and have trouble focusing, an electric cauldron might be for you. Throw everything together in 15 minutes, then give it love and attention when you remember. Normally that happens when you start to smell the food.

Again, this is my preference. Some Kitchen Witches I know prefer to identify a specific pot as their cauldron. Some went and got an actual full size, cast iron cauldron; which is amazing but not feasible for most. I grew up using a slow cooker, so I'm very comfortable around one. But if it's not your thing; that's fine. Maybe your cauldron will be a rice cooker or a Boston Shaker.

#witch#kitchen witch#kitchen witchcraft#klickwitch#food and folklore#Food magic#magic#witchy#witch tips#pagan#February#kitchen magic#house witch

51 notes

·

View notes

Text

Exporter of LDPE Film Scrap Washing Line in Kuwait

R Mech Machines LLP is an Exporter of LDPE Film Scrap Washing Line in Kuwait. R Mech Machines LLP was established in 2008 in Ahmedabad, Gujarat, India. Our offerings encompass Plastic Scrap Turbo Washing Machines, Plastic Scrap Grinder Machines, Plastic Scrap Shredder Machines, Blade Sharpening Machines, Screw Press Squeezer Machines, Friction Washer Machines etc. Overview: We designed the LDPE washing system to clean contaminated film or thin materials. We design the grinding machine to create standardized particle sizes that are easy to wash and dry for film or thin materials. The high-speed turning of the rotor produces centrifugal force, which we utilize to remove dirt and sand from the washer. We use floating materials such as LDPE/HDPE/PP film/labels on the top and sink materials like PVC/PET/PC on the bottom. Both have separate discharge points to collect different materials based on density. Horizontal dryers and thermal drying systems control the moisture content of the finished product. At a moisture level of less than 5%, the material is appropriate for high-quality pelletizing. Features: Steel body structure User friendly Longer running life Smooth finish R Mech Machines LLP is an Exporter of LDPE Film Scrap Washing Line in Kuwait and places like Kuwait City, Mahboula, Ahmadi, Salmiya, Jabriya, Hawally, Zour, Sabah Al Salem, Al Farwaniyah. If you have any questions or need more information, feel free to reach out to us. Read the full article

#Ahmadi#Ahmedabad#AlFarwaniyah#BladeSharpeningMachines#cleancontaminatedfilm.dryingsystems#createstandardized#Exporter#ExporterofLDPEFilmScrapWashingLine#ExporterofLDPEFilmScrapWashingLineinKuwait#FrictionWasherMachines#Gujarat#Hawally#high-qualitypelletizing#high-speedturning#Horizontaldryers#India#Jabriya#Kuwait#KuwaitCity#LDPEFilmScrapWashingLine#LDPEFilmScrapWashingLineinKuwait#Longerrunninglife#Mahboula#Manufacturer#PlasticScrapGrinderMachines#PlasticScrapShredderMachines#PlasticScrapTurboWashingMachines#SabahAlSalem#Salmiya#ScrewPressSqueezerMachines

2 notes

·

View notes

Text

Answers to Common Plastic Granulator FAQs

Plastic granulators are widely utilized in plastics processing but also involve some common areas of concern. Here are answers to frequent questions about granulators:

How are granulators different from shredders or grinders?

Granulators use sharp rotating blades to cut plastics into uniform chips or particles. Shredders tear and grind plastics into uneven shapes.

What safety risks are involved?

Rotating blades pose injury hazards if not properly guarded. Other risks are dust explosions and noise. Proper precautions are essential.

What throughput can I expect?

Throughput depends on material, particle size, rotor speed and more. Typical rates range from 200 lb/hr for small units to over 2000 lb/hr for large granulators.

How much power do they require?

Common motors range from 5HP to over 100HP. Harder plastics need more power. Hydraulic drives offer variable speed control.

What maintenance is required?

Key tasks include blade sharpening or replacement, belt tightening, lubrication, cleaning out material buildup and inspection of screens and bearings.

What are common problems and troubleshooting tips?

Issues like irregular particle size, overheating, vibration, jamming or speed fluctuations generally point to worn blades, blocked screens, buildup or improper settings.

What safety features are recommended?

Lockable hoppers, emergency stops, machine guards, dust collection and noise reduction measures should be used.

With proper selection, operation and maintenance, plastic granulators can reliably and efficiently process plastic scrap for recycling or reuse in production.

2 notes

·

View notes

Text

https://baobikhangloi.com.vn/mang-phu-nong-nghiep-duc-lo-san

Perforated agricultural film products Between the conventional coating and the perforated film, users often choose the non-perforated type because they are significantly cheaper. Pre-perforated coatings are more expensive not because the cost of the perforating equipment is too high, but because this perforation will slow down the overall system productivity considerably. However, in our opinion, the high price of these products is completely worth the performance they bring. If you've ever used mulch for your growing work, you'll understand that punching holes for seeds or seedlings is a tedious and time-consuming task. Before the advent of perforated mulch, farmers around the world thought of many ways that this perforation could be done faster and easier.

On the smallest and simplest scale, they use knives, scissors or any other sharp object to make a cross in the membrane, then fold the excess plastic underneath to create holes shaped like square. This manual folding of 4 pieces of plastic takes a lot of time, the strength of the film is also weakened and it is easy to tear at the location of the cuts.

More advanced cutting tools for making circular holes in the coating have also been invented. Old milk cans are drilled with 2 small holes and inserted electrical wires to make handles, then hot coals are inserted. When the can of milk is hot enough, the farmer carries it away and places it on top of the mulch already spread in the garden, in the places where they want to drill holes. The plastic at this location will melt into the shape of the bottom of the box, and another farmer can go behind to collect the excess plastic. Plants or seeds can also be transplanted at this time.

In the same way as above, there are places where it is very popular to use wire mesh frames in old car air filters, especially those of light trucks and pickup trucks. The sharp edges on the mesh combined with the temperature of the coal inside will cut through the plastic film more easily. Instead of coal, one can also use kerosene or scrap plastic, or whatever as long as they are capable of burning for a long time.

Some people also use old PVC pipes, using a grinder to cut the pipe edges into a serrated shape to create a hole punching mold. When we forcefully press the water pipe into the covered ground, we will also get round holes like other methods. However, in hard areas, the plastic saw teeth will easily wear or break. Currently, metal punching tools with a similar design have also been sold a lot on e-commerce platforms. There are even variations that use electricity from the battery to heat. However, no matter how creative these tools are, they are still manual, still consuming a lot of labor to perform on large agricultural lands. To cater for farming on such a scale, automatic agricultural film punching machines have been built. They are integrated right on the film production line, to produce pre-perforated agricultural films. Machined perforated agricultural film will have holes with uniform size and spacing according to pre-set parameters. These distances will be calculated to leave the most reasonable space for the growth of the plant's roots. Currently, our Khang Loi company has invested in machinery system to produce perforated agricultural films, perforated on both transparent films and 2-layer films with one black side and one side. grey. Although our large format plastic films or agricultural mulch can reach up to 8 meters wide, our mulch punching machine currently only works on films up to a maximum size of 8 feet. 3 meters. We will give you the option of 1 to 4 rows of holes. Each hole is 8cm in diameter and the distance between holes is customizable. Our perforated agricultural film products use virgin resin as the main material, blended with special additive formulations to increase UV resistance and durability. Flexibility is also an advantage worth mentioning. This property makes our products resistant to the tension that occurs during installation, and is compatible with all mechanical punching operations, seeding operations, seedling without worrying about damage. membrane will be torn. If you have a need or need more advice on the product, please contact us at 0902.732.168, or leave us a message in the contact section. Thank you very much!

2 notes

·

View notes

Text

0 notes

Text

Our Plastic Scrap Grinder Machine is widely appreciated by the clients for its features like Size, operation and maintenance, high speed grinding and production, Strength level and performance.

0 notes

Text

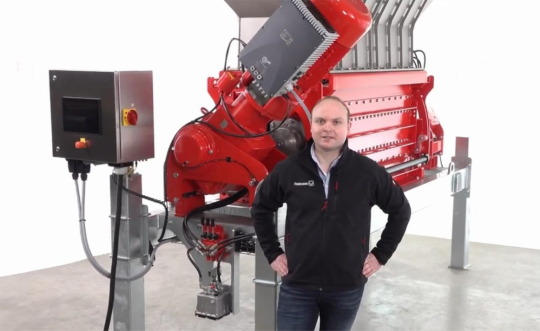

New Food Waste Grinder to optimize Pumping Throughput

Focused on improving the waste-handling capabilities of the food industry, animal processing, and related waste-handling facilities, Vogelsang USA is bringing its largest format grinding system, the RedUnit XRL260. Nicknamed “Big Red,” Vogelsang’s largest hopper-fed grinder to date is designed specifically to reduce large quantities of solid waste material quickly. The RedUnit XRL260 features two 50hp geared motors capable of handling up to 130 cubic yards of solid waste per hour (100 m3/h). The 5’ x 2’ inlet handles whole hogs and higher volumes of waste material. Existing installations have been able to increase throughput by 50-100% while reducing power consumption by as much as 50-60%. Notable installations have been: - Rendering plants: handling hogs, calves, and poultry – increased throughput by as much as 100% - Biowaste, Process, and Post-Consumer: This includes organic waste, scraps, pits, and tops, as well as post-consumer waste with metal and plastic—50% energy savings compared to a hammermill. - Slaughterhouse: bones innards, offal, skulls – lowered energy costs by 60%, increased protein output - Pet Food: handled pallet-sized frozen blocks of animal waste – increased throughput by 100%, easy feeding improved operations. Among the most notable features of the XRL260 is its side-entry maintenance design, specifically engineered to provide quick and safe access to the grinder's cutting elements. A “side flap” is easily opened to remove foreign objects, typically allowing one person to dismantle the one-piece cutting rotors. This ensures maximum uptime and quick, cost-effective maintenance. Operational features: - Lateral service hatches provide direct access to rotors to streamline maintenance and allow the easy removal of foreign bodies. - Elimination of elaborate clearing systems - Independent rotor direction and speed to adjust to any type of materials Part of the new service concept from Vogelsang: - Side panels easily lift up for removal of foreign bodies and maintenance. - Direct access to rotors with maintenance that can be done by only one person if necessary. - Ripper rotors can be easily removed for quick cleaning, ultimately extending the lifetime value of the machine https://news.vogelsang.info/en/redunit-xrl-260 Read the full article

0 notes

Text

Ilmenite Market Exploration: Unraveling Market Segmentation and Demographics

Ilmenite: A Primary Source of Titanium Dioxide Formation and Deposits Ilmenite, also known as manaccanite, is a titanium-iron oxide mineral with the formula FeTiO3. It is a weakly magnetic black or steel-gray solid. Ilmenite forms in igneous and metamorphic rocks as a primary mineral. It crystallizes in the trigonal-hexagonal system and most often occurs in a massive, granular or lamellar forms. Ilmenite forms as a volcanic and hypabyssal rock-forming mineral. Hydrothermal solutions also deposit ilmenite in veins and breccia zones. Major ilmenite deposits are found in Australia, South Africa, Canada, Ukraine and India. The largest deposits are located near Beach Lake in Ontario, Canada and near Prairie Lake in Australia. Chemical Composition and Properties Chemically, ilmenite is an iron(II) titanium oxide. It typically contains 50-52% TiO2 and 32-38% FeO. Ilmenite also contains small amounts of MgO, MnO and calcium contaminants. The mineral is black to steel-gray colored with a submetallic to dull luster. It has a hardness of 5-6.5 on the Mohs scale and a moderate specific gravity ranging from 4.7-5 g/cm3. Ilmenite is weakly magnetic due to its iron content. It tends to alter to leucoxene, pseudobrookite and rutile under weathering conditions near the Earth's surface. When heated in air, ilmenite oxidizes to a mixture of iron oxide and titanium dioxide. Economic Significance and Uses Ilmenite is the primary industrial source of titanium dioxide, which is also known as titanium white. Titanium dioxide has a variety of applications due to its brightness and very high refractive index. It is widely used as a pigment in paints, plastics, paper, inks, foods and other materials. Titanium dioxide imparts a brilliant white color and opacity to products while remaining non-toxic. As a pigment, it is valued for its hiding power and tinting strength. Globally, titanium dioxide demand exceeds 6 million metric tons per year. The paint and plastics industries combined account for approximately 90% of titanium dioxide usage. Mining and Refining Processes Mining ilmenite deposits involves open pit or underground methods based on the deposit type and economics. At the mining site, overburden rock is first removed to access the ilmenite orebody. The run of mine ore is dug out using heavy earthmoving equipment like hydraulic excavators and trucks. The ore is hauled to a processing facility where it undergoes size reduction using crushers and grinders. Magnetic separation is employed to concentrate the ilmenite content. This separates the weakly magnetic ilmenite from non-magnetic gangue minerals like silicates, quartz and iron sulfides. Outlook and Sustainability Issues Global ilmenite reserves are sufficient to meet demand for many decades at current production levels. Major producers like Rio Tinto, Vale, Chemours and others are engaged in exploration to discover new reserves and expand mining operations. Efforts are also on to produce titanium metal and alloys from ilmenite. Recycling of titanium scrap helps manage resources and reduce mining impacts. However, issues like land use, emissions, water usage and waste generation during mining and processing require ongoing attention. Industry-wide programs focus on environmental stewardship and sustainability performance. Minimizing energy consumption through efficient processes also benefits producers. On the whole, ilmenite will continue supplying the titanium needs of various industries into the foreseeable future.

0 notes

Text

Rotomoulding & Pulveriser Machine Manufacturer — Navconic

Manufactures Moulding Machine and Rotomould which are similar to Rotomoulding and Rotational Moulding Machine as well as Plastic Moulding Machine, Moulded Plastic.

PRODUCTS of Rotomoulding Machine

Rotomoulding Machine Manufacturer

Bi-Axial Machine

Close oven rock n roll machine

Open Fired Rock N Roll Machine

Pulveriser Machines Manufacturer

PVC Pulveriser

Rotomoulding Pulveriser Manufacturer

Extruder Lldpe Rotomoulding Manufacturer

Plastic Recycling Machine Manufacturer

Scrap Grinder machines

Scrap Grinder machines

Roto MouldsManufacturer and exporter of Rotomoulding and Rotational Moulding Machines, Moulded Plastic Products, Injection Moulds, Blow Moulds, Investment Die Casting Moulds.

For More Details Click here: https://www.navconic.com

0 notes

Text

Plastic Scrap Shredder and Grinder Machine in Tamil Nadu

#plasticrecyclingmachine #hdperecycling #plasticrecycling #wasteplasticrecycling #wovensacksrecycling #mlpscraprecycling #Ahmedabad #Gujarat #india

0 notes

Text

What is Plastic Grinder Machine?

What is Plastic Grinder Machine?

Plastic waste is a growing concern worldwide due to its detrimental impact on the environment. In recent years, the use of plastic grinder machines has gained popularity as a solution to this problem. These machines help to break down plastic waste into smaller pieces, allowing for efficient recycling, manufacturing of new products, and energy recovery. With various sizes and designs available, plastic grinder machines have become an essential tool in many industries, including recycling, manufacturing, and construction. In this context, it is important to understand the function and benefits of plastic grinder machines in reducing plastic waste and preserving the environment.

It is also known as plastic crusher machine. Plastic grinder machines typically use rotating blades to shred the plastic material into smaller pieces. The size and shape of the particles produced depend on the size and shape of the blades and the mesh size of the screen through which the particles pass. Some plastic grinder machines also use cooling systems to prevent the plastic from melting due to the heat generated during the grinding process.

What kind of Plastic is used in PGM?

Plastic grinding machine prices are affordable and these are designed to process various types of plastic waste, including:

- Polyethylene (PE): This is the most common type of plastic used in plastic grinding machines. It is a lightweight and flexible plastic commonly used for packaging, such as plastic bags and bottles.

- Polypropylene (PP): This is a durable and heat-resistant plastic commonly used in automotive parts, appliances, and packaging.

- Polystyrene (PS): This is a lightweight and rigid plastic commonly used in disposable cups, plates, and packaging.

- PVC (Polyvinyl chloride): This is a strong and durable plastic commonly used in construction materials, such as pipes, flooring, and window frames.

- PET (Polyethylene terephthalate): This is a strong and transparent plastic commonly used in beverage bottles and food packaging.

- Nylon: This is a strong and heat-resistant plastic commonly used in automotive parts, electrical equipment, and textiles.

The type of plastic used by plastic grinding machine manufacturers depends on the application and the type of waste being processed. It is important to select the appropriate type of plastic to ensure efficient processing and to avoid contamination that could affect the quality of the final product.

How Plastic Grinder Machine Works?

The operation of a plastic scrap grinder machine can vary depending on the specific type of machine, but generally, the working principle involves the following steps:

- Sorting and Feeding: The plastic waste is sorted to remove any non-plastic materials, such as metal, paper, or glass. Then, the plastic waste is fed into the hopper of the grinder machine.

- Grinding or Shredding: Once the plastic waste is fed into the machine, it goes through a grinding or shredding process. This involves the use of sharp blades or rotating cutters that cut or shred the plastic waste into smaller pieces or particles.

- Screening: The ground or shredded plastic particles are passed through a screen or mesh that separates the particles based on size. This helps to ensure that the resulting particles are of a consistent size suitable for the intended application.

- Collection: The ground or shredded plastic particles are collected and stored for further processing, such as recycling, energy recovery, or manufacturing of new products.

Some plastic grinder machines may include additional steps, such as washing or drying the plastic waste, depending on the specific application. Additionally, some machines may include cooling systems to prevent the plastic from melting due to the heat generated during the grinding process.

Manufacturing Process of PGM

The manufacturing process of a plastic waste grinding machine can vary depending on the specific type and design of the machine. However, some common steps involved in the manufacturing process include:

- Design and Engineering: The design and engineering of the plastic grinding machine are carried out based on the specific application and requirements of the machine. This involves determining the size, capacity, and features of the machine, such as the type of blades or cutters, the motor power, and the control systems.

- Material Selection and Preparation: The materials for the machine, such as steel, aluminum, and plastic, are selected based on the desired properties, such as strength, durability, and weight. The materials are then prepared for manufacturing, such as cutting and shaping.

- Fabrication and Assembly: The machine parts are fabricated using cutting, welding, and machining processes. The parts are then assembled together to form the final machine. Quality control checks are carried out throughout the process to ensure that the parts and assembly meet the specifications and standards.

- Testing and Calibration: The completed machine is tested and calibrated to ensure that it meets the performance and safety requirements. The testing involves checking the machine's speed, power, and functionality, as well as ensuring that the safety features, such as emergency stop buttons and safety guards, are working correctly.

- Packaging and Shipping: The final step is packaging the machine for shipment to the customer. The machine is typically disassembled for ease of shipping and reassembled on-site by the customer or a technician.

The manufacturing process of a plastic crusher machine requires specialized knowledge and expertise in mechanical engineering, fabrication, and assembly. It is essential to ensure that the machine meets the required performance and safety standards to ensure efficient and safe operation.

Uses of PGM

Plastic grinder machine or Plastic bottle crusher machines have a wide range of uses across various industries, including:

Recycling: Plastic grinding machines are commonly used in the recycling industry to process plastic waste into smaller particles suitable for further processing, such as melting and molding into new products.

Manufacturing: Plastic grinding machines are used in the manufacturing industry to process plastic waste into raw materials for the production of new plastic products, such as bags, toys, and packaging.

Energy Recovery: Plastic grinding machines can be used to grind plastic waste into small particles suitable for energy recovery processes, such as incineration or gasification.

Landscaping: Ground plastic particles can be used in landscaping applications, such as mulching or as a soil amendment.

Construction: Ground plastic particles can be used in construction materials, such as asphalt or concrete, to improve their strength and durability.

Agriculture: Ground plastic particles can be used in agriculture applications, such as for soil stabilization or as a component in animal feed.

The uses of plastic grinding machines are diverse and can vary depending on the type of plastic waste being processed and the desired end product. By processing plastic waste into small particles, plastic grinding machines help to reduce waste and promote sustainability.

Advantages/ Benefits of PGM

Plastic grinding machines are used to reduce plastic waste into small particles or flakes, which can be reused in various applications. Some of the advantages of plastic grinding machines include:

Cost-effective: Plastic grinding machines are a cost-effective way of reducing plastic waste into reusable flakes or particles. They are less expensive compared to other recycling equipment, such as shredders or granulators.

Efficient: Plastic grinding machines are efficient in reducing the size of plastic waste into small particles or flakes. They can process large quantities of plastic waste in a short amount of time.

Versatile: Plastic grinding machines can be used to grind various types of plastic waste, including PET, PVC, HDPE, and LDPE, among others.

Environmentally friendly: Plastic grinding machines contribute to environmental sustainability by reducing the amount of plastic waste that ends up in landfills or oceans.

Easy maintenance: Plastic grinding machines are easy to maintain, with simple and straightforward maintenance procedures.

Flexibility: Plastic grinding machines can be used in different industries, such as packaging, construction, automotive, and electronics, among others.

Overall, plastic crusher machines are a useful tool in reducing plastic waste and promoting sustainability.

Disadvantages of PGM

While the mini plastic crusher machines have several advantages, they also have some disadvantages. Here are some of the disadvantages of plastic grinding machines:

Noise pollution: Plastic grinding machines produce a lot of noise during operation, which can be a nuisance for workers and people in the vicinity.

Dust pollution: Plastic grinding machines can generate a lot of dust during operation, which can be harmful to the health of workers and people in the vicinity.

Maintenance costs: While plastic grinding machines are generally easy to maintain, they can still require periodic maintenance and repairs, which can be costly.

Energy consumption: Plastic grinding machines require a lot of energy to operate, which can lead to high energy bills and increased carbon emissions.

Limited capacity: Some plastic grinding machines have a limited capacity, which can make it difficult to process large quantities of plastic waste.

Wear and tear: Plastic grinding machines can experience wear and tear over time, which can reduce their efficiency and lifespan.

Conclusion

In the face of mounting concerns over the impact of plastic waste on the environment, recycling has become more important than ever before. While recycling is an essential part of the solution, it's not always easy or cost-effective. This is where the plastic grinding machine comes in.

The plastic grinding machine is an innovative piece of equipment that has revolutionized the recycling process. Its ability to grind down plastic waste into small particles makes recycling more efficient and cost-effective, which in turn reduces the amount of plastic waste in landfills and oceans. This not only helps to conserve natural resources, but it also decreases carbon emissions.

Plastic waste is a significant environmental concern, as it takes hundreds of years to decompose, and even then, it releases harmful toxins into the environment. The impact of plastic pollution is felt across the globe, from the world's oceans to our communities, and it's up to all of us to take action to mitigate it. In this circumstance, PGM is perfect escape to save us all from the pollution.

So, if you're looking for a way to make a positive impact on the environment, consider investing in a plastic grinding machine or supporting businesses that use them in their recycling efforts. Together, we can create a more sustainable future for generations to come.

0 notes

Text

Scrap Grinder Supplier in Jammu

Scrap Grinder Supplier in Jammu: Invoit Plast Machinery Pvt. Ltd. Plastic processing machine manufacturer, supplier, and exporter Invoit Plast Machinery Pvt. Ltd. A scrap grinder, also known as a plastic grinder or shredder, is a machine designed to reduce plastic and other materials into smaller, more manageable pieces. Its primary function is to process and recycle various forms of industrial scrap, post-consumer waste, or rejected products into reusable raw materials. Applications of Scrap Grinders Scrap grinders are versatile machines with a wide range of applications: Plastic Recycling: Plastic recycling plants commonly use them to grind plastic waste into granules for manufacturing new plastic products. Rubber Recycling: In the rubber industry, they use scrap grinders to recycle rubber waste into reusable materials. Paper Shredding: They play a role in recycling paper products, reducing the need for cutting down more trees. Electronic Waste: Scrap grinders can process electronic components to recover valuable metals and components. Wood Recycling: In the woodworking industry, scrap grinders help convert wood waste into useful wood chips or sawdust. Metal Recycling: Some scrap grinders are adapted to process metal scrap, aiding in the recovery of valuable metals. Textile Recycling: In the textile industry, they shred textiles into fibers that can be used in new fabric production. We Provide Scrap Grinder Supplier in Jammu Including Srinagar, Udhampur, Anantnag, Kathua, Rajouri, Baramulla, Pulwama, Doda, Ganderbal, Kupwara, Kishtwar, Kulgam, Leh, Akhnoor, Budgam, Gulmarg, Arnia, Khour, Katra, Sonamarg, Bijbehara, Ranbir Singh Pora, and Bhaderwah. Read the full article

0 notes

Text

Plastic Pulverizer Machine

MF series plastic grinder pulverizer machine is a prefect machine for processing and grinding thermoplastics material, such as PVC, PE, PP, EVA, PLA, ABS etc, with high output and thin powder.

This pulverizer machine for plastic series is disc-type plastic grinding mill series, which has the advantages of high-yield and low-power.

Plastic Grinder Pulverizer Machine Features

Focused on generating plastic powder from plastic granules and scraps. The whole system consists of a feeding hopper, grinding chamber, vertex receptacle, shaking filter, regrinding system, dust cleaner.

Both the board and the cutting blade are made of abrasion-resistant steel, which has excellent efficiency after warm treatment.

Straightforward exchangeable of premium knives, and also it can be used consistently after grinding.

As the new disc design is used, our plastic pulveriser machine has the features of high yield and strong resistance. The life of the grinding disc is double that of the ordinary.

QINGCHENYU plastic pulverizer machine has low power intake, high yield, a good-designed framework as well as simple installation.

Professional bearings & high rotation rate. One drive motor ensures the efficient grinding crash, which greatly saves the time and operation of machinery and control engineering.

The installation and maintenance of our pulverizer machine for plastic are easy. Simply open the door to cover clean-up. Milling process of the whole seal, without dust leakage. Full automatic feeding, the materials and sorting. Grinding gap adjustment is simple, use the plug-foot bolts and adjustments can be fine-tuning (10-120 mesh).

The host used the water and wind double system; Rational design of a smaller cross-section of the grinding chamber, grinding is almost flat vertical surface. Material entered the grinding chamber as soon as caught, ground, and then rapidly removed, which eliminates the grinding chamber of the surge in materials, heating materials to avoid decomposition, resulting in improved production.

In virtue of automated feeding, automated splitting up as well as automated discharging, this plastic pulveriser machine is completely air-proof and with no dirt leakage.

The powder excellence can be readjusted because the device has 10-120 meshes to choose from. It just needs to use a filler gauge and change screw to understand precise modification.

0 notes