#plastic injection moulding machine manufacturer

Explore tagged Tumblr posts

Text

Top C-PVC Injection Moulding Machine for Reliable Production

Patel Plastic Machinery is providing top line C-PVC injection moulding machine designed to delivering reliable production. Our engineered efficiency and built quality to the handle unique properties of C-PVC make sure that high quality output with minimal waste. Our C-PVC injection moulding machine to producing complex component or simple parts that providing performance you need to stay ahead in the competitive market.

Patel Plastic Machinery are equipped with advance technology that allow for precise control over the moulding machine which guarantees superior product quality in every time. We are focusing on durability and ease to operate. Our machine built quality are providing long term value and reducing downtime. . Trust Patel Plastic Machinery to elevate your production capabilities and achieve consistent, high-quality results with every run.

If you want to improve your production advance C-PVC injection moulding machine? Then visit our website pplastmach.com to explore our full range of products and how we can help you achieve reliable and efficient manufacturing. Click the link below to get started today!

#plastic injection moulding machine#micro injection moulding machine#micro injection moulding machine manufacturer#micro injection moulding machine supplier#micro injection moulding machine in ahmedabad#micro injection moulding machine in india#pet preform injection moulding machine#plastic injection moulding machine in india#thin wall container injection moulding machine#plastic injection moulding machine manufacturer

0 notes

Text

The premier plastic injection moulding machine manufacturer stands out for their precision engineering, robust and durable machines, and commitment to innovation and sustainability.

0 notes

Text

Because the plant extension, the mold factory chagnged the new name as: Rost mold! We will be your reliable partner in China!

#injectionmold #plastmold #plasticmould #injectionmould #injectionmoulding #imm #inyeccionmold #bucketmold #chairmold #petmold #householdmold #dailyusemold #electricmold #autopartsmold #doublecolormold #irrigationmold

#injection molding#plastic molding#plastic#injection moulding machine#injection manufacturing company#injection mold

0 notes

Text

Introduction to Mould Manufacturing 2024

Plastic mould manufacturing is the process of creating mould or tools for the production of plastic parts. The mould are designed to shape and form plastic materials into specific shapes and sizes, allowing for the production of identical parts at a rapid pace. This process is widely used in various industries, including automotive, medical, and consumer goods.

The fundamental principle behind plastic mould manufacturing is to create a negative impression of the desired product, which is then used to cast the final product. The mould are made from high-quality materials such as steel or aluminum, which are capable of withstanding high temperatures and pressure. The mould are designed to accommodate the specific properties of the plastic material, including its melting point, viscosity, and shrinkage rate.

There are two primary types of plastic mould manufacturing: injection moulding and compression moulding. Injection moulding involves injecting molten plastic material into a mould cavity, which is then cooled and solidified to create the final product. This process is highly efficient and produces high-quality parts at a rapid pace. Compression moulding involves heating plastic pellets and then placing them into a heated mould cavity, which is then compressed to form the final product. This technique is used for larger parts or when the part requires greater strength and durability.

Plastic mould manufacturing has a wide range of applications, from the production of small plastic components to large automotive parts. The process allows for the creation of complex parts with intricate shapes and sizes. The ability to create identical parts at a rapid pace makes it an essential process in modern manufacturing.

In conclusion, plastic mould manufacturing is a crucial process in the manufacturing industry. It allows for the production of high-quality plastic parts at a rapid pace, making it a highly efficient and cost-effective process. The use of advanced technology and high-quality materials has made plastic mould manufacturing an essential process in various industries, including automotive, medical, and consumer goods.

Mould Manufacturing Process

The process of manufacturing a mould is a complex one, and it's important to note that not all plastic mould manufacturers use the same methods.

The most common method used by manufacturers is CNC machining, which involves using computer-controlled machines to carve out the shape of your product in thin layers. This technique has been around for decades and allows for greater precision than other methods like EDM (electrical discharge machining) or grinding.

Plastic mould manufacturing is a complex process that involves several steps to create high-quality mould for various industries. The process begins with designing the mould using computer-aided design (CAD) software. This software allows engineers to create a detailed 3D model of the mould, including all the intricate details required for the final product.

Once the design is complete, it's time to move onto the manufacturing stage. The first step in manufacturing is to create a mould base using steel or aluminum. This base is what will hold all the various components of the mould together. The base must be designed to withstand the high pressure and temperature required for the moulding process.

Next, the mould is assembled, which involves attaching various components such as the ejector pins, the sprue bushing, and the runner system. These components are essential for the mould to function correctly during the moulding process.

The next step is to machine the mould. This involves using specialized equipment to create the cavities and cores required for the final product. This process involves a high level of precision, and any errors or imperfections can result in a faulty mould.

Once the mould is machined, it's time to test it. This involves running a trial batch of plastic through the mould to ensure that it produces the desired product. Any issues with the mould or the moulding process can be addressed in this stage.

Finally, after the mould is tested and approved, it's ready for production. The mould is attached to an injection moulding machine, and plastic is injected into the cavities to create the final product. This process can be repeated thousands of times to create a large number of identical products.

Overall, plastic mould manufacturing is a complex and intricate process that requires a high level of skill and expertise. From designing the mould to running production, every step of the process must be executed with precision to ensure a high-quality final product.

1. Introduction

Mould manufacturing is an essential process in the production of various products, including automotive parts, consumer goods, and medical devices. Identifying different types of mould is crucial to ensure that the correct type is used for each product. In this guide, we will discuss the different types of mould prevalent in the mould manufacturing industry, their unique characteristics, materials they are best suited for, and the benefits and drawbacks of each type.

2. Types of Mould

Plastic Injection Mould:

Thermoset Compression Mould:

Blow Mould:

Rotational Mold:

3. Precautions and Safety Measures

Different types of mould have different safety considerations, but in general, it is important to wear appropriate personal protective equipment (PPE) when working with mould, such as gloves, goggles, and respirators. It is also important to follow proper handling and storage procedures to prevent mould contamination and ensure optimal mold performance.

Conclusion

Identifying different types of mould and understanding their unique characteristics, materials they are best suited for, and the benefits and drawbacks of each type is crucial to ensure that the correct type is used for each product. Proper maintenance and cleaning of mould are also essential to prevent mould contamination and ensure optimal mould performance. By implementing the knowledge gained in this guide, manufacturers can improve their mould manufacturing processes and produce high-quality products with greater efficiency and consistency.

#mold manufacturing#mould manufacturing#plastic molding#thermoset compression mould#cnc machining#injection molding#3d printing#manufacturing#compression molding#mumbai#india#blow mould#rotational molding

1 note

·

View note

Text

plastic injection moulding machine manufacturers in Delhi

Karan Hi-tech Machinery India Pvt. Ltd.is one of the largest company of plastic injection moulding machine in Delhi we are manufacturers suppliers and exporters plastic injection molding machines at affordable price

0 notes

Text

#Plastic Injection Machine#Plastic Injection Molding Machine#Plastic Injection Moulding Machine#Plastic Injection Molding Machine manufacturers

1 note

·

View note

Text

The Best News of Last Week

⚡ - Goodbye Fossil Fuels, Hello Renewables: The Energizing News You Need

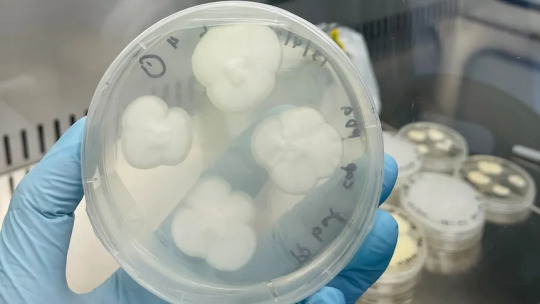

1. Fungi discovered that can eat plastic in just 140 days

Australian scientists have successfully used backyard mould to break down one of the world's most stubborn plastics — a discovery they hope could ease the burden of the global recycling crisis within years.

It took 90 days for the fungi to degrade 27 per cent of the plastic tested, and about 140 days to completely break it down, after the samples were exposed to ultraviolet rays or heat. We really see a solution within five years, according to environmental scientist Paul Harvey, an expert on global plastic pollution.

2. Topeka Zoo welcomes new African Lion as female sprouts mane

The Topeka Zoo has welcomed a new African Lion to its pride, a male, as one of its females started to sprout a mane following the 2021 passing of the pride’s last male.

The Topeka Zoo and Conservation Center announced on Thursday, April 13, that Tatu, a 4-year-old African Lion, has arrived in the Capital City. He comes to Topeka from the Denver Zoo and his arrival marks a time of growth for the zoo.

3. This barber opens his shop on his day off for children with special needs – and all of their haircuts are free

On his day off, Vernon Jackson still goes to work, opening up his Cincinnati barber shop, Noble Barber and Beauty, for VIP clients: children with special needs.

It's something he's done since 2021. "I was hearing so many horror stories that parents were going through with other barber shops and just the barbers or stylists having no patience with their child," Jackson told CBS News. "So I figured I would compromise by coming in on my day off so there were there would be no other barbers or stylists in the shop and I could give them the full attention that they need."

4. Renewables break energy records signalling ‘end of the fossil age’

Experts are calling time on the fossil age as new analysis shows wind and solar power produced a record amount of the world’s electricity last year.

The renewables generated 12 per cent of global electricity in 2022, up from 10 per cent the previous year, according to the report from clean energy think tank Ember. Last year, solar was the fastest-growing source of electricity for the 18th year in a row, rising by 24 per cent from 2021.

5. New nuclear medicine therapy cures human non-hodgkin lymphoma in preclinical model

A new nuclear medicine therapy can cure human non-Hodgkin lymphoma in an animal model A single dose of the radioimmunotherapy, was found to quickly eliminate tumour cells and extend the life of mice injected with cancerous cells for more than 221 days (the trial endpoint), compared to fewer than 60 days for other treatments and just 19 days in untreated control mice.

To explain it in simple terms because this is so freaking cool: There is a radioactive atom attached to a drug. The target cell eats the drug and the energy coming off of the radioactive atom kills the target cell

6. Colorado passes first US right to repair legislation for farmers

Colorado farmers will be able to legally fix their own equipment next year, with manufacturers including Deere & Co obliged to provide them with manuals for diagnostic software and other aids, under a measure passed by legislators in the first U.S. state to approve such a law.

Equipment makers have generally required customers to use their authorized dealers for repairs to machines such as combines and tractors.

7. When a softball player falls after hitting a grand slam, this is how her opponents reacted

youtube

----

That's it for this week :)

This newsletter will always be free. If you liked this post you can support me with a small kofi donation:

Buy me a coffee ❤️

Also don’t forget to reblog

1K notes

·

View notes

Text

latest Freddie DeBoer seems odd. It's very focused on a sort of consumer-facing understanding of technology for a lot of its runtime. He's not wrong that the changes are smaller than they were in the 1800's but like. That's the low hanging fruit, we all know this, the jump from "not having trains" to "having trains" beats almost any improvement in "trains"

A major change technology has brought to the modern world imo is heavily streamlined manufacturing all across the industrial stack.

If you read like, Bunie Huang's Made in China blog series, in the early 2000's getting a piece of technology made required enormous in-person investment of time and effort working with your manufacturing teams across a pretty broad number of suppliers and industries, you had to get PCB's made, components sourced, moulds designed and set up for injection.

I know people manufacturing small to medium run commercial and industrial electronics, and I did that at my last job. You order machine populated PCB's from your favourite Chinese PCB solutions provider over a web form. If you need ten thousand buttons, you can get that delivered with three emails. Hell, if you want a custom genome to use for some experimental bioreactor, there's multiple competing suppliers who will mail you plasmids that you can customise from online templates and you don't even have to talk to anyone.

And that's just mass manufacturing. If you're making a few thousand of some high end medical equipment, or still in the development phase of design, you can order a titanium laser print to be delivered by the end of the week, or run off a dozen prototypes on your company's fleet of printers using body safe plastics.

Consumer needs don't change much because people are people, we have limited capacity to need things and do things. I've long said that no human can digest more than 50Mbps of media in real time, really. One home cook can only economise their movements so much. A food processor and a pressure cooker can save you some time but the solution to"I want to spend less time cooking at home" will eventually become "don't cook at home, lean on industrial manufacturing of food" and that's fine. There's only so much tech can improve your individual experience before you become the bottleneck.

Faster computers sure, means you can edit video on your phone a little quicker (also hey people ARE editing video on their phone, despite what this blog post says) but it also means Netflix can serve their 4 Petabytes of video library at 400+Gbps from a single server occupying less than 50 liters of space.

It seems disingenuous to act like consumer products feeling stagnant means technology is stagnant.

21 notes

·

View notes

Text

Effervescent tubes have revolutionised the pharmaceutical and nutraceutical industries, becoming the go-to solution for packaging effervescent tablets. As a prominent name in the sector, NBZ Healthcare, located in Mumbai, stands at the forefront of exceptionally effervescent tube manufacturing, ensuring quality and innovation.

In this article, we delve deep into the manufacturing of effervescent tubes, their applications, benefits, and the unparalleled expertise of NBZ Healthcare in this domain.

Understanding Effervescent Tubes

Effervescent tubes are specialised containers designed to store and preserve effervescent tablets. These tablets, when exposed to moisture or air, tend to lose their potency, necessitating robust, moisture-resistant packaging. Effervescent tubes, often crafted with airtight and tamper-proof caps, provide the ideal solution to ensure the longevity and effectiveness of these tablets.

Importance of Effervescent Tubes

Effervescent tubes are more than just packaging; they play a crucial role in the pharmaceutical and nutraceutical industries by:

1. Protecting Product Integrity:

- Shielding tablets from moisture and air.

- Preventing degradation of active ingredients.

2. Enhancing Consumer Experience:

- Easy to open and reseal.

- Portable and convenient for on-the-go consumption.

3. Ensuring Regulatory Compliance:

- Meeting stringent health and safety standards for pharmaceutical products.

4. Sustainability:

- With increasing focus on eco-friendly materials, many effervescent tubes are now designed to be recyclable or biodegradable.

Effervescent Tube Manufacturing Process

Effervescent tube manufacturing is a precise and technologically driven process. At NBZ Healthcare, we combine state-of-the-art machinery with strict quality control measures to produce exceptional effervescent tubes. Here’s an overview of the key stages:

1. Material Selection

- High-grade plastic materials such as polypropylene (PP) or polyethylene (PE) are used.

- Materials are selected based on moisture resistance, durability, and eco-friendliness.

2. Tube Extrusion

- Plastic granules are melted and extruded into tube-like shapes using extrusion machines.

- The dimensions and thickness are carefully controlled to meet industry standards.

3. Moulding

- Injection moulding is used to form the caps and closures of the tubes.

- Caps are designed to ensure an airtight seal and tamper resistance.

4. Printing and Branding

- Tubes are labelled or printed with product details, branding, and regulatory information.

- Advanced printing techniques ensure durability and clarity.

5. Quality Control

- Rigorous testing for moisture resistance, durability, and compatibility with effervescent tablets.

- Each tube undergoes inspection to ensure zero defects.

NBZ Healthcare: Redefining Effervescent Tube Manufacturing

As a leader in exceptionally effervescent tube manufacturing, NBZ Healthcare sets the benchmark for quality and innovation. Based in Mumbai, our facility is equipped with cutting-edge machinery and a dedicated team of professionals who prioritise precision and excellence.

What Sets NBZ Healthcare Apart?

1. Advanced Manufacturing Capabilities

- NBZ Healthcare utilises the latest extrusion and moulding technologies to produce high-quality tubes.

2. Customisation Options

- We offer custom designs, sizes, and branding options to cater to the unique needs of our clients.

3. Sustainable Practices

- Focused on reducing environmental impact, we incorporate eco-friendly materials and processes wherever possible.

4. Regulatory Compliance

- Our manufacturing processes comply with international standards, including ISO and FDA regulations.

5. Global Reach

- While based in Mumbai, NBZ Healthcare serves clients across India and internationally, ensuring timely delivery and exceptional service.

Applications of Effervescent Tubes

Effervescent tubes find applications in various sectors, including:

1. Pharmaceuticals:

- Storage of vitamins, supplements, and medications in effervescent tablet form.

2. Nutraceuticals:

- Packaging for dietary supplements and health-boosting effervescent tablets.

3. Food and Beverage:

- Containment of flavour-enhancing or health-focused effervescent powders and tablets.

4. Personal Care:

- Packaging for effervescent bath tablets or other similar products.

Innovations in Effervescent Tube Manufacturing

At NBZ Healthcare, innovation is at the heart of our operations. Here are some of the cutting-edge advancements we incorporate:

1. Smart Packaging Solutions

- Tubes embedded with QR codes or NFC tags for enhanced consumer engagement and traceability.

2. Enhanced Moisture Resistance

- Using desiccant-lined caps and advanced sealing technologies to further improve moisture protection.

3. Eco-Friendly Materials

- Transitioning to biodegradable plastics and exploring sustainable alternatives like biopolymers.

4. Automation and AI Integration

- Automated production lines ensure consistency and reduce manufacturing errors.

- AI systems monitor quality in real-time for enhanced accuracy.

Challenges in Effervescent Tube Manufacturing

While effervescent tube manufacturing offers immense potential, it comes with its own set of challenges, such as:

1. Material Costs:

- Balancing quality and affordability when sourcing raw materials.

2. Environmental Concerns:

- Reducing the carbon footprint of manufacturing processes.

3. Regulatory Compliance:

- Adhering to diverse regulatory standards across different markets.

4. Consumer Expectations:

- Meeting the growing demand for sustainable and innovative packaging solutions.

The Future of Effervescent Tube Manufacturing

The demand for effervescent tubes is expected to rise significantly as more consumers turn to effervescent products for their convenience and efficiency. NBZ Healthcare is well-positioned to lead this growth, with a focus on:

1. Sustainability Initiatives

- Introducing greener manufacturing processes and materials.

2. Global Expansion

- Reaching untapped markets to provide high-quality effervescent tubes worldwide.

3. Product Diversification

- Expanding into new applications and industries beyond pharmaceuticals and nutraceuticals.

4. Technological Upgrades

- Adopting emerging technologies to enhance efficiency and product quality.

Why Choose NBZ Healthcare for Effervescent Tubes?

At NBZ Healthcare, we combine years of expertise with a commitment to innovation and customer satisfaction. When you partner with us, you’re choosing:

- Unmatched Quality: Every tube is crafted with precision and care.

- Custom Solutions: Tailored to your product’s specific needs.

- Reliable Service: Consistent and timely delivery of all orders.

- Sustainable Values: Supporting environmentally responsible practices.

Conclusion

Effervescent tubes play a pivotal role in preserving the efficacy and quality of effervescent tablets. With NBZ Healthcare’s expertise in exceptionally effervescent tube manufacturing, businesses can rely on robust, high-quality packaging solutions tailored to their needs.

As a Mumbai-based pioneer in the industry, NBZ Healthcare continues to set the standard for excellence, innovation, and sustainability. Whether you’re in the pharmaceutical, nutraceutical, or any related industry, NBZ Healthcare is your trusted partner for exceptional effervescent tube solutions.

Reach out to us today and experience the difference in quality and service!

2 notes

·

View notes

Text

What Industries Is Injection Molding(Moulding) Applicable To?

Injection moulding is a common manufacturing process by injecting molten plastic material into a mould so that it can be formed into the desired product shape upon cooling.

Injection moulding process has the advantages of low cost, high production efficiency and stable product quality to make it widely used in various industries. In this vast injection moulding market, there are three industries are particularly eye-catching, which are extensively used for production and manufacturing due to their specific needs and product characteristics.

1.Household Appliance Manufacturing Industry

As an indispensable part of people's daily life, the market demand for household appliances is stable and continuously growing. The injection moulding process plays a pivotal role in the manufacturing of household appliances, from the outer shell to the internal components, injection moulding technology provides key support. Most of the exterior and structural components of home appliances, such as TV remote controls, refrigerators, TV sets, air-conditioning panels, and washing machine shells, are manufactured by injection molding process.

2.Automotive Components Industry & Transportation Sector

With the booming development of the automotive industry, the auto components and parts market has ushered in unprecedented development opportunities. Components and parts such as automotive dashboards, door interior panels, bumpers, and lamp housings as well as a wide range of pipework and connections are made through the injection moulding process. These parts require not only high precision and good mechanical properties, but also need to meet the strict appearance requirements, which injection moulding process is precisely by virtue of its unique advantages, in this field to occupy a place. In addition, with the rise of new energy vehicles, injection moulded parts play an important role in the manufacturing of key components such as battery packs and motor housings.

3.Medical Device Industry

With the increasing emphasis on health, the market demand for medical devices continues to grow. In medical device manufacturing, the injection moulding process is used to produce disposable medical devices such as syringes, infusion tubes and surgical instruments. These products require strict quality control and hygiene standards, and injection moulding process ensures product safety and effectiveness.

In addition, the injection moulding process is also widely used in the electrical and electronic industry, consumer electronics, packaging industry, toy manufacturing, construction materials, industrial parts, furniture and household furnishings and agriculture, among many others.

4.Electrical & Electronic Industry

In the manufacturing process of electronic products, many components such as housings, cases, sockets, connectors, cables, switches and holders for electronic circuit boards need to be manufactured by injection moulding process. Injection moulding process can achieve precise control of product appearance, size and structure, to meet the requirements of electronic products for appearance quality, functionality and reliability.

5.Consumer Electronics Industry

In the electronics industry, injection moulded parts are equally widely used. From mobile phone housings, computer components including keyboards and mice to remote controls and battery cases, the injection moulding process offers a wide variety of appearance and structure options for electronic products. These components not only need to have good mechanical properties and appearance, but also need to have excellent electrical insulation properties to ensure the stable operation of electronic products. Injection moulding technology occupies an important position in the manufacture of electronic products due to its advantages of high precision and low cost.

6.Construction Sector

In the construction field, injection moulded parts also have a wide range of applications, the drainage systems, door and window frames, pvc pipes, valves, wire troughs, insulation materials and other construction materials and accessories are mostly manufactured by injection moulding process. These components are not only high-strength and corrosion-resistant, but also weather-resistant and easy to install, meeting the construction industry's requirements for material performance and ease of use and improve construction efficiency and aesthetics. The application of injection moulding technology in the construction field not only improves the performance and quality of construction materials, but also promotes the sustainable development of the construction industry.

7.Packaging Industry

The packaging and container industry is also one of the key application areas for injection moulding processes. Plastic bottles, food boxes, cosmetic bottles, plastic bags and other packaging containers are mostly manufactured by injection moulding process to meet food safety and aesthetic requirements. These containers need to be well-sealed, drop-resistant, retain freshness and recyclable to ensure that the products are safe and environmentally friendly. Injection moulding processes can offer flexible design and manufacturing options to adapt to different packaging needs and provide strong support for the development of the packaging industry.

These areas above are just a few examples of the application areas of the injection moulding process. In the toy industry, injection moulded parts are used to manufacture a variety of plastic toys; In the textile and clothing industry, injection moulded parts are used to manufacture accessories such as zips and buttons; In the agricultural sector, injection moulded parts are used to manufacture agricultural tools and equipment such as sprayers and watering cans; Even in the aerospace sector, injection moulded parts are also used to manufacture parts for aircraft and spacecraft. It can be said that injection moulded parts have penetrated into almost every corner of our life.

In summary, injection moulded parts play an important role in several industries by virtue of their high precision, low cost and wide applicability. The application of injection moulding process in these areas not only improves production efficiency, but also meets the needs of product diversification and individualisation. With the continuous progress of science and technology and the continuous improvement of people's requirements on product quality, injection moulding technology will continue to be widely used and developed in various fields.

#design#autos#business#prototyping#prototype#prototype machining#rapid prototyping#cnc machining#precision machining#machining parts#injection molding#plastic injection molding#injection moulding machine#injection moulding#plastic injection#injection molded#injection molding parts#injection molded parts

2 notes

·

View notes

Text

Buy Advanced Thin Wall Container Injection Moulding Machine

Patel Plastics Machinery is specializes in high performance injection molding machines that design for thin wall container production. those machines are manufactured to compete demand and modern manufacturing. they providing rapid cycle times and exceptional precision to make sure that consistent quality in thin wall container production. Patel Plastics Machinery specialized in this field to their innovative design and optimal efficiency or reduce material wastege their machines is high volume production environment.

Patel Plastics Machinery their thin wall container injection molding machines are equipped advance features,high sped injection, pricise system and robust construction to continous operation. Those machine are manufacturing thin wall containers with thin and uniform wall or these container are significant weight reduce with maintaining strength and durability. Patel Plastics Machinery commitment to technological advancement and customer satisfaction and make sure that their injection molding machine are not only compete industry standard they make first choice of reliable and efficient solution for thin wall container production challenges.

if you seeking high performance injection molding machines designed for thin wall container production then visit our website PPLastMach.com . discover the advance features high speed injection molding machine that was precise, robust, efficient and reliable or manufacturing with reduce waste material then Patel Plastics Machinery compete your requiredment.

#micro injection moulding machine in ahmedabad#plastic injection moulding machine#micro injection moulding machine#pet preform injection moulding machine#thin wall container injection moulding machine#plastic injection moulding machine in india#micro injection moulding machine supplier#micro injection moulding machine in india#micro injection moulding machine manufacturer#plastic injection moulding machine manufacturer

0 notes

Text

Innovations, especially in plastic injection moulding machine manufacturers have transformed production processes, making it possible to produce complex, durable, and high-quality parts quickly and efficiently

0 notes

Text

Plastic Scrap Grinder Machine Manufacturer, Exporter Plastic Waste Crushing Machine https://www.invoitplast.com/plastic-scrap-grinder-machine/ Each part of this plastic scrap grinder machine is made from superior material, whether it is its body or sharp blades. Plastic Scrap Grinder Machine Manufacturer, Exporter - Plastic Waste Crushing Machine are best suitable for plastic grinding or crushing of Defected and rejected plastic products from Injection Moulding Machine, Blow Moulding Machine, Extrusion lines etc i.e. Chairs, Battery boxes, HDPE Drums, PVC Pipes & Fittings, Barrels, Jerry Cans, Household products, Plastic articles, Toys etc. Invoit Plast Machinery Pvt. Ltd. is also leading exporter of Plastic Scrap Grinder Machine to South #Africa, #Dubai UAE, #Nepal, #Bangladesh and #Qatar. Invoit Plast Machinery Pvt. Ltd. located in Ahmedabad, Gujarat, India., is manufacturer and supplier of Plastic Scrap Grinder Machine and to India specifically Hyderabad, Nasik, Chennai, Baroda, Bangalore and Rajkot.

5 notes

·

View notes

Text

Plastic Injection Molding Shapes Tomorrow

Plastic material is melted and then injected into a mold cavity using the industrial process of plastic injection molding to produce a solid, three-dimensional item. This method enables the constant mass manufacture of intricate and accurate plastic components.

Important Elements in Plastic Injection Molding

Melting and injecting the plastic material into the mold consists of a hopper for loading plastic pellets, a barrel for heating the material, and a screw or plunger for forcing the molten plastic into the mold.

Mold: Molds can be created with one or more cavities and are commonly constructed of steel or aluminum depending on the needs of the production process.

Clamping Unit: During the injection process by the injection moulding manufacturer, the clamping unit guarantees that the mold stays tightly closed. The two mold parts are held together by a clamping mechanism, and the necessary force is applied by a hydraulic system.

Ejector System: The ejector system forces the final item out of the mold once the plastic has cooled and set inside the mold. The removal of the molded pieces is made simple and effective by this element.

The Technique of Plastic Injection Molding:

Mold Setup: The injection molding machine is ready for use after the mold has been put inside of it.

Pellets of plastic are fed into the machine's hopper during material loading.

Plastic pellets are heated and melted in the barrel of the injection machine before being injected. The molten plastic is then forcefully pumped into the mold cavity.

Cooling: The plastic inside the mold is solidified by cooling the mold. The thickness of the component and the material has an impact on the cooling time.

Ejection: The ejector mechanism forces the final object out of the mold once the plastic has hardened.

Plastic injection molding advantages:

Precision and Consistency: Plastic injection molding yields components with precise tolerances and reliable quality, making it the perfect process for high-precision goods.

Wide Material Variety: The technique is flexible in that it can handle a variety of thermoplastic and thermosetting materials.

Complex Geometries: Using alternative manufacturing processes would be difficult or impossible for the fabrication of elaborate and complex forms. Injection moulding is the best fit for this.

#Injection Moulding#Plastic Injection Molding#Injection Moulding manufacturer#Injection Moulding supplier#Injection Moulding China

2 notes

·

View notes

Text

Karan Hi-tech Machinery India Pvt. Ltd.is one of the largest company of plastic injection moulding machine in delhi we are manufacturers suppliers and exporters plastic injection molding machines at affordable price

#Plastic injection moulding machine#Plastic injection moulding machine Price#Plastic injection moulding machine suppliers in Delhi#Plastic injection moulding machine manufacturers in delhi

1 note

·

View note