#battery pack assembly line

Explore tagged Tumblr posts

Text

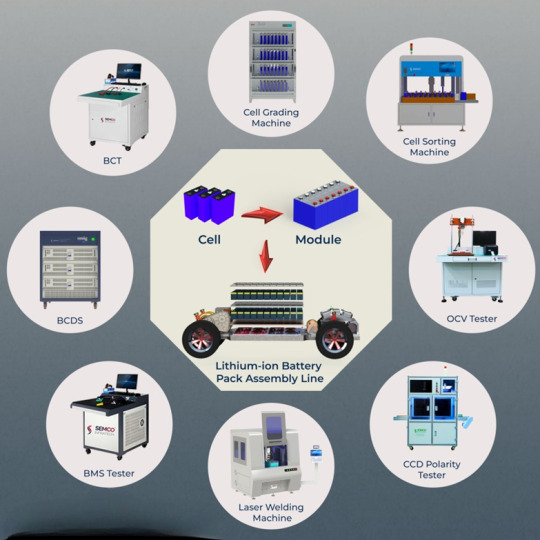

The Art of Battery Pack Assembly: Creating Power from Modules

The journey of a battery's transformation from a collection of individual cells to a powerful energy source involves several intricate steps. In this article, we focus on the final piece of this puzzle—the battery pack assembly process. In this process, the individual battery cells are ingeniously crafted into modules and eventually form a complete battery pack. Let's dive into the fascinating world of battery pack assembly line and see how this vital step is achieved.

Connecting Battery Cells: The First Step

The initial stage of battery pack assembly begins with the careful connection of battery cells. Each battery cell's surface is meticulously cleaned to ensure a pristine connection. This connection process involves linking battery cells and creating a structured arrangement. The configuration of these cells and the number of modules can vary significantly, depending on the specific application and battery model.

Battery cells are like the building blocks of energy storage. Their ability to store electrical energy makes them the core of the battery assembly process. Connecting them correctly is paramount in achieving the desired electrical performance.

Modularization: A Framework for Battery Pack Assembly

With the individual battery cells connected, the next step is modularization. In this phase, the connected battery cells are securely fastened into a module case. This module case typically comes with an adhesive coating to ensure a robust bond.

To create modules, electrical connections between the connected battery cells must be established. Depending on the specific design and requirements of the battery pack, this can be achieved through either a wiring harness or a busbar. After the electrical connections are made, the module is sealed with a cover, giving it its final structure. The number of modules created during this phase can vary depending on the application and battery model. These modules are like the building blocks of the battery pack, and each module forms an essential part of the larger energy storage system.

Component Assembly: The Key to Completing the Puzzle

The assembly process progresses as multiple modules are brought together to create a complete battery pack. These modules are carefully interconnected, ensuring that the electrical connections are secure, and the modules are correctly aligned. This intricate interconnection creates a cohesive unit, ready to provide power for a wide range of applications.

Each battery pack can be tailored to specific needs by adjusting the number of batteries and modules it contains. This customization is a remarkable aspect of battery pack assembly, as it allows manufacturers to create energy solutions that suit diverse applications, from electric vehicles to renewable energy systems.

The Vital Role of Battery Management Systems (BMS)

Once the battery pack is assembled, a crucial step remains – the application of the Battery Management System (BMS). The BMS plays a pivotal role in monitoring and managing the battery's health and performance. This system provides valuable insights into the battery's charging status and its expected service life.

A key component of the BMS is the Battery Monitoring Unit (CMU), which evaluates and balances the state of the battery cells. This balancing ensures that all cells in the battery pack are operating optimally, safeguarding their longevity and efficiency. The BMS offers real-time data, ensuring the battery remains in the best possible condition.

The application of BMS is a testament to the commitment to safety, performance, and longevity in battery manufacturing. It's a technology that helps optimize the use of energy storage solutions sustainably and efficiently.

Conclusion: Creating Power, One Module at a Time

The battery pack assembly process is a remarkable journey, where individual battery cells evolve into powerful energy solutions. This process highlights the importance of precision, customization, and the integration of cutting-edge technology. Battery packs assembled with care and expertise find applications in electric vehicles, consumer electronics, renewable energy systems, medical devices, and more.

As the world continues to transition towards cleaner, more sustainable energy solutions, the role of battery pack assembly grows in significance. With advancements in technology and research, we can expect battery packs to continue shaping a greener, brighter future for generations to come.

So, the next time you pick up your smartphone, drive an electric vehicle or enjoy the benefits of renewable energy, remember the meticulous craftsmanship that went into the creation of the battery pack, transforming it from individual cells into a powerful source of energy. It's a testament to human innovation and our commitment to a sustainable future.

#battery assembly line#battery assembly process#battery pack assembly line#battery pack assembly process#lithium-ion battery assembly line#lithium-ion battery assembly process#lithium-ion battery pack assembly line#lithium-ion battery pack assembly process

0 notes

Text

X-1 by Eugene F. Lally, Robot Shack / Robot Shop (1983), El Toro, CA. "The X-1 kit comes with everything needed, including the structure, to construct an economical personal robot with many functions and features. This is Robot Shop's top-of-the-line kit. Cost of the kit is $399.95 plus shipping. The battery pack is optional and costs $79.95. ... Included in the X-1 robot kit are: Body, frame, and skin panels.; Dual motor drive and gear reducer; Rubber drive wheels; On-board control panel; Function cycle timer; Noisemaker; Lighted robot heart/eyes; Body and skin features/markings; Wire and connectors; Assembly hardware; Assembly instructions." – The Personal Robot Book, by Text Marrs, 1985.

14 notes

·

View notes

Text

Robotic Automation Solutions & Fixtures for Smart Manufacturing

In today’s fast-paced world, industries are evolving to become smarter, safer, and more efficient. Robotic automation solutions are playing a key role in this transformation. Companies in India, especially in places like Pune, are adopting robotic solutions to enhance productivity and reduce errors.

Factories no longer rely solely on manual labor. With robots and machines working hand-in-hand, production speeds increase and errors decrease. If you’re looking for a reliable partner in robotic automation, you’ve come to the right place.

What Are Robotic Automation Solutions?

Robotic automation solutions refer to systems where robots and machines handle repetitive tasks in factories. These systems help improve accuracy and speed while reducing the chances of human error.

Here are some common robotic automation systems:

Robots for picking and placing materials

Automated welding machines

Assembly lines that run automatically

Quality-check machines

Special-purpose machines for unique tasks

Such systems are used where repetitive work needs to be done consistently and accurately.

Battery Assembly Line Solutions for EV Industry

As electric vehicles (EVs) continue to gain popularity, there’s a growing demand for battery assembly line solutions. These lines ensure the efficient and safe assembly of battery packs that power EVs.

Automated battery assembly lines help with:

Accurately stacking battery cells

Performing safety tests

Packing and labeling

These lines are designed for speed, safety, and precision. Robots handle repetitive tasks, ensuring the entire process remains error-free.

Heavy Fabrication Fixtures and Machines for Tough Jobs

Industries like automotive, railway, and construction require heavy fabrication fixtures to assemble large components accurately. Pune is home to several companies specializing in heavy fabrication fixtures and machine manufacturing.

Here’s how heavy fabrication fixtures are used:

Holding parts in place during welding and assembly

Ensuring the safety and accuracy of large-scale manufacturing

Making production processes faster and more efficient

These fixtures play an essential role in keeping the assembly lines running smoothly and safely.

Hydraulic Fixtures and Machines for Precision Tasks

In certain industries, high force is required for operations like testing engines or assembling large components. This is where hydraulic fixtures and machine manufacturers come into play.

Hydraulic fixtures are used for:

Testing engines under pressure

Fitting large parts together

Conducting precise pressure tests

These fixtures apply significant force while maintaining precision, making them ideal for heavy-duty tasks in various industries.

Why Pune is a Hub for Robotic Automation and Fixture Manufacturing

Pune has become a major industrial hub for manufacturing and technology in India. Here’s why Pune is the go-to location for robotic automation solutions and hydraulic fixtures:

Skilled Workforce – Access to trained engineers who understand automation technology

Full Support – From design to assembly, Pune offers a complete solution for automation and fixtures

Connectivity – Well-connected to major cities like Mumbai, making it easier to source and deliver components

These factors make Pune an ideal place for companies offering robotic automation solutions and heavy fabrication fixture manufacturing.

Industries That Benefit from Robotic Automation

Robotic automation is used across various industries to improve efficiency:

Automotive Manufacturing – From Body-in-White (BIW) assembly to painting, robotic automation helps in building vehicles with speed and precision.

Pharmaceuticals – In this sector, robots handle packaging and labeling in clean rooms.

Electronics – PCB inspection and assembly are made quicker and more accurate with robotic automation.

Warehousing – Robots are used for sorting and pick-and-place tasks in distribution centers.

Consumer Goods – Automated systems package and palletize products efficiently.

Choosing the Right Partner for Robotic Automation

Selecting the right robotic automation solutions provider is essential for your business. Here are some factors to consider:

Experience – Ensure the provider has experience in your specific industry.

Customization – The system should be tailored to meet your specific needs.

After-Sales Support – Ongoing maintenance and support are crucial for smooth operations.

Technology Integration – Make sure the new system integrates well with your existing technology.

Quality Standards – The system should meet industry standards for safety and quality.

A reliable robotic automation solutions provider will help make your factory more efficient and smarter.

FAQs – Robotic Automation and Fixture Manufacturing

Q1. What are robotic automation solutions? Robotic automation solutions involve using robots and machines to automate repetitive tasks, reducing human error and increasing speed and accuracy.

Q2. Why are battery assembly line solutions important for EV manufacturers? Battery assembly line solutions help EV manufacturers stack battery cells accurately and test them for safety. Automation ensures speed and precision in the process.

Q3. What is the role of heavy fabrication fixtures in manufacturing? Heavy fabrication fixtures are used in industries like automotive and construction to hold large parts in place during assembly or welding. They ensure safety and precision.

Q4. How do hydraulic fixtures work in industrial applications? Hydraulic fixtures apply strong clamping force during tasks like engine testing and pressure testing. These fixtures ensure accuracy and precision while handling high forces.

Q5. Why is Pune a hub for robotic automation and fixtures? Pune is home to a skilled workforce and well-established companies that specialize in robotic automation solutions and heavy fabrication fixture manufacturing, making it an ideal location for such industries.

Conclusion – Embrace the Future of Smart Manufacturing

The future of manufacturing lies in robotic automation. Whether you're looking for battery assembly line solutions, heavy fabrication fixtures, or hydraulic fixtures, automation can help make your processes faster, safer, and more efficient.

If you want to take your factory to the next level, invest in the right robotic automation solutions provider and join the industry revolution.

#robotics#robotics engineering#robotics innovation#automation#techinnovation#parc robotics#battery manufacturer#battery supplier

0 notes

Text

Five Important Factors for making Battery Pack Molds

Battery packs are small energy storage systems that incorporate many batteries within a protective a home. They are crucial for delivering portable power for a wide range of applications, including electronic devices and electric vehicles. Their importance arises from their ability to efficiently store and transmit energy, allowing diverse devices and systems to function seamlessly.

Plastic injection molding is the supported process for producing battery packs due to its versatility and efficiency. This manufacturing technology enables the manufacture of complicated and complex mold designs with high precision.

In this post, we will look at a variety of factors to consider when constructing a battery pack mold to ensure high-quality and durable components.

1. Material Selection

Material selection in battery pack mold-making entails selecting the best thermoplastic that meets the specific needs of the battery design. It covers discussions about thermal conductivity, impact resistance, and chemical compatibility with battery components.

Choosing a material with high thermal conductivity, such as PEEK, for a lithium-ion battery mold is critical since it regulates heat during operation and extends the mold’s life, assuring consistent and reliable performance. It provides efficient heat dissipation, inhibits chemical reactions, and increases the overall durability of the mold.

2. Design for Venting

The venting design includes channels or vents in the mold that allow air and gas to circulate during the injection molding process. It regulates air traps, provides consistent filling of the mold cavity, and eliminates defects like as air pockets and inadequate filling, which can jeopardize the structural integrity of battery pack components.

Consider an electric vehicle battery mold with complex geometry. Effective venting channels carefully inserted in the mold allow trapped air to escape, reducing faults such as voids and ensuring the production of perfect battery components.

3. Precision and Tolerance

Precision defines a level of accuracy and consistency in making components within prescribed tolerances. However, there are some considerations you should make to guarantee that each battery pack matches the exact dimensions criteria, which contributes to the overall product quality.

Consider a medical device battery mold, which requires precise dimensions to achieve a perfect fit with the device. It ensures that each battery component fits correctly and meets the high-quality standards required for medical applications.

4. Parting Line and Ejection

In the manufacture of battery pack molds, the parting line indicates the point at which the mold halves separate. On the other side, ejection refers to systems that remove molded components from the mold. They protect molded components and maintain constant production cycles, which are essential for smooth and efficient manufacturing.

For example, a mobile device battery mold contains exquisite complexities. Its clearly defined separation line and efficient ejection system ensure that delicate components are neither distorted or damaged during the demolding process, resulting in immaculate battery packs.

5. Durability and wear resistance

Refers to the mold’s capacity to survive the rigors of multiple molding cycles without degradation. This includes selecting materials and coatings that can withstand the mechanical loads and wear that come with high-volume manufacture.

Consider an industrial equipment battery mold that produces components for heavy-duty use. The use of wear-resistant coatings on crucial mold surfaces extends mold life, resulting in continued production. Manufacturers can reduce downtime and maintenance costs and increase productivity by using wear-resistant materials and coatings.

The Best Battery Pack Assembly Line: Technical Features

1. Square Battery Assembly Line:

Core procedures: primarily winding or stacking procedures that include electrode preparation, cell encapsulation (aluminum/steel shell), top cover welding, etc. Hot press forming machines, cell insertion machines, ultrasonic welding machines, and other pieces of equipment are used.

Advantages: High compatibility, adaptability to various sizes and customizing requirements; simple structure, high energy density (for example, blade battery).

2. Cylindrical Battery Assembly Line

Core processes include fully automatic winding, supporting tab welding, liquid injection, sealing, and other equipment. A classic example is the 4680 cylindrical battery manufacturing line.

Advantages: mature process, high automation, great yield and consistency, wide heat dissipation area, and short single-cell manufacturing cycle.

Challenges include complex module design and limited space use; big cylindrical batteries (e.g., 4680) must overcome technological barriers such as welding and shell strength.

3. Pouch Battery Assembly Line

Core Processes: Key equipment for stacking technology comprises tab welding machines, aluminum film punching and shell insertion machines, top and side sealing machines, and so on, all of which use high-precision linear or rotary production line layouts.

Advantages: Highest energy density (5-10% higher than square cells at the cell level), excellent safety (simple pressure relief in the event of thermal runaway), and adaptability to future solid-state battery technology pathways.

Challenges: low domestic aluminum film output, dependency on imports, stacking efficiency lower than winding (many semi-manual processes), low shell strength necessitating additional module materials, and lagging CTP technology deployment.

Conclusion

To achieve consistent, high-quality production, battery pack mold-makers must pay close attention to material selection, venting design, precision, parting line alignment, and durability. If you’re seeking battery pack mold services in Pune, several local manufacturers offer specialized solutions for lithium-ion and lead-acid battery casings, injection molding, and related tooling.

Creating high-quality battery pack molds entails more than just shaping plastic; it requires precision, durability, and performance. From selecting the appropriate materials and planning for heat dissipation to assuring manufacturing accuracy, every decision has a direct impact on the finished battery pack’s safety and efficiency.

Businesses may prevent costly mistakes and deliver dependable products at scale by prioritizing smart design, selecting the appropriate thermoplastics, and collaborating with professional mold makers.

Are you ready to improve your battery pack production with precision and efficiency? Collaborate with OPM, where innovation meets excellence. We are now excited to serve clients all over the world. Contact us today by email at [email protected] or call us at +91-9900299893 to learn more about custom-made solutions that will boost your battery pack production.

#battery pack mold#Plastic injection molding#battery pack mold-making#battery pack mold services in Pune

0 notes

Text

Laser Welding Machine Market Drivers Showcase Demand Across Medical Devices, Aerospace, and Manufacturing Sectors

Laser Welding Machine Market have steadily emerged as a transformative force across industries, revolutionizing how materials are joined with precision and efficiency. These high-tech systems are increasingly favored over traditional welding methods due to their speed, accuracy, automation capabilities, and ability to weld difficult materials. As industries like automotive, aerospace, electronics, and medical devices push for cleaner, stronger, and more efficient joining methods, the demand for laser welding machines continues to rise.

1. Growing Demand in Automotive and Aerospace Industries

The automotive and aerospace sectors are primary consumers of laser welding machines. The constant push for lighter, more fuel-efficient vehicles drives the need for precision welding techniques capable of working with lightweight alloys and complex geometries. In automotive manufacturing, laser welding enables high-speed processing and produces consistent, strong joints that are essential for structural integrity. Likewise, the aerospace industry values the ability to weld materials such as titanium and nickel alloys, where exactness is critical. These requirements make laser welding machines indispensable in modern assembly lines.

2. Technological Advancements and Innovation

Recent advancements in laser technologies—such as fiber lasers, hybrid laser systems, and real-time monitoring tools—have dramatically enhanced the efficiency, adaptability, and cost-effectiveness of laser welding machines. Smart manufacturing and Industry 4.0 trends are also propelling the integration of AI and IoT features into welding systems. These innovations allow for automation, predictive maintenance, quality assurance, and real-time data analytics, all of which optimize production and reduce downtime. As manufacturers seek greater operational intelligence, these high-tech capabilities drive market growth.

3. Rising Adoption in Medical Device Manufacturing

Miniaturization and precision are critical in medical device manufacturing. Laser welding meets these demands by providing non-contact, sterile, and micro-welding solutions, essential for assembling devices like pacemakers, surgical tools, and catheters. The growing global healthcare demand and medical device innovation pipeline are prompting manufacturers to invest in advanced welding systems that ensure both accuracy and regulatory compliance. As the medical device market expands, so does the laser welding machine market.

4. Shift Towards Electric Vehicles (EVs)

The global transition from internal combustion engines to electric vehicles has introduced new welding requirements. EVs rely heavily on battery packs, which require intricate and robust welds. Laser welding is ideal for battery module assembly because it offers the precision and thermal control necessary for working with sensitive materials and intricate designs. Additionally, the rising focus on sustainability and energy efficiency further cements the role of laser welding in the EV ecosystem.

5. Increased Focus on Automation and Labor Cost Reduction

Global manufacturers are under constant pressure to improve efficiency and cut costs. Laser welding machines offer a highly automated solution that reduces the reliance on skilled labor and minimizes human error. As labor costs rise globally and skilled welders become harder to find, automated laser welding systems provide a cost-effective, scalable solution. This shift toward automation is particularly prominent in high-volume production environments, such as consumer electronics and heavy machinery.

6. Government Incentives and Infrastructure Development

Many governments worldwide are supporting manufacturing modernization through subsidies, tax incentives, and infrastructure investments. Initiatives like "Make in India" and “Made in China 2025” are spurring investments in advanced machinery, including laser welding systems. Moreover, public-private partnerships and funding for research and development further accelerate the adoption of cutting-edge welding technology, particularly in developing economies.

Conclusion

The laser welding machine market is being propelled by a confluence of factors: rising industrial demands, technological progress, the shift toward EVs, and a greater push for automation. As industries become more reliant on advanced materials and precise fabrication techniques, laser welding machines are positioned as a cornerstone of future manufacturing strategies. With continued innovation and growing global demand, the laser welding machine industry is expected to witness sustained and dynamic growth in the coming years.

0 notes

Text

Automated Guided Vehicle (AGV) Market: Key Drivers of Growth and Technological Advancements

The Automated Guided Vehicle (AGV) market has been experiencing rapid growth in recent years, driven by advancements in technology, increasing demand for automation, and the rising need for efficient material handling solutions across various industries. AGVs are autonomous, mobile robots used for transporting materials without human intervention. These vehicles are equipped with a variety of sensors, cameras, and navigation technologies, such as LiDAR, to move autonomously along pre-determined paths within a facility. The market for AGVs is expanding due to several key drivers, which are discussed in detail below.

1. Rising Demand for Automation in Manufacturing

One of the most significant drivers of the AGV market is the growing demand for automation in manufacturing industries. The need for increased efficiency, productivity, and cost reduction in production processes has led many businesses to adopt automated solutions. AGVs are ideal for streamlining operations, such as material transportation, assembly line supply, and warehouse management, making them essential in sectors like automotive, electronics, and consumer goods manufacturing. Automation also reduces the reliance on manual labor, which can be prone to errors, fatigue, and injuries, ultimately improving workplace safety.

Additionally, as manufacturers move toward lean manufacturing practices, AGVs support the just-in-time inventory systems that help reduce the cost of storing inventory. This demand for streamlined production processes continues to fuel the adoption of AGVs as a key part of automation strategies.

2. Improvement in AGV Technology

The AGV market is also driven by continuous improvements in AGV technology. With advancements in sensors, control systems, and software, AGVs are becoming more efficient, versatile, and intelligent. The integration of machine learning and artificial intelligence (AI) is enhancing the decision-making capabilities of AGVs, allowing them to better navigate dynamic environments and optimize routes for efficiency. Furthermore, the development of wireless communication technologies enables AGVs to integrate seamlessly with existing infrastructure and other automated systems within a facility, such as conveyors and robotic arms.

The increased capabilities of AGVs, such as the ability to transport larger loads, navigate in more complex environments, and interact with humans in a safe manner, make them more attractive to industries looking for robust automation solutions.

3. Cost-Effectiveness and Return on Investment (ROI)

Although the initial investment in AGVs can be significant, the long-term cost savings they offer are a major driver of market growth. AGVs help reduce operational costs by minimizing the need for manual labor and reducing the risk of workplace accidents, which can be expensive for companies. Moreover, AGVs are highly efficient in terms of energy consumption, as many of them are powered by batteries that are easily recharged during downtime. These vehicles can work around the clock, increasing productivity and helping businesses achieve higher throughput with fewer resources.

The significant ROI associated with AGV deployment—due to savings on labor, enhanced throughput, and reduced maintenance costs—makes AGVs an attractive investment, particularly for large-scale industries like warehousing and logistics.

4. Growth of E-commerce and Logistics

The exponential growth of the e-commerce industry has been another key driver of the AGV market. As e-commerce companies like Amazon and Alibaba continue to expand, there is an increasing need for efficient and fast material handling and order fulfillment. AGVs play a critical role in this process by automating the movement of goods within warehouses and distribution centers, speeding up the picking, packing, and shipping processes.

Furthermore, the rise of omnichannel retail, where products are sold through both online and offline channels, has placed greater pressure on logistics and supply chain operations to ensure rapid order processing and delivery. AGVs are capable of increasing the speed and accuracy of material handling, thus supporting the efficiency demands of modern logistics operations.

5. Labor Shortages and Workforce Challenges

Another key driver for the adoption of AGVs is the growing challenge of labor shortages, particularly in industries such as logistics, warehousing, and manufacturing. As the global workforce ages and fewer young people enter manual labor-intensive fields, companies are finding it increasingly difficult to hire and retain skilled workers. AGVs help mitigate this issue by automating labor-intensive tasks, reducing the dependence on human workers.

In addition, the COVID-19 pandemic highlighted the importance of minimizing human contact in industrial settings, accelerating the shift toward automation. AGVs, which require minimal human intervention, can help mitigate labor-related challenges, ensuring continuity of operations in the face of workforce disruptions.

6. Regulatory Support and Industry Standards

The AGV market is also supported by regulatory frameworks and industry standards that promote workplace safety and automation. Governments and regulatory bodies are increasingly recognizing the value of automation in improving safety standards, particularly in industries with high accident rates, such as manufacturing and warehousing. For example, safety certifications and standards like ISO 3691-4 for AGVs ensure that these vehicles operate in a safe manner, further encouraging businesses to adopt AGVs.

In addition, many countries offer incentives and grants for businesses investing in automation technologies, including AGVs, which makes it easier for companies to justify the initial investment.

7. Customization and Flexibility in AGV Solutions

The versatility and adaptability of AGVs are also driving their adoption across various industries. AGVs come in different sizes, configurations, and payload capacities, allowing businesses to customize solutions that meet their specific operational needs. Whether it’s a simple tow tractor or a more complex, multi-functional vehicle, AGVs can be tailored to meet the unique requirements of industries such as healthcare, food and beverage, and pharmaceuticals. This flexibility makes AGVs suitable for a wide range of applications, further fueling their market growth.

Conclusion

The AGV market is expanding rapidly due to a combination of factors, including increased automation demand, technological advancements, cost-effectiveness, and labor shortages. As industries continue to prioritize efficiency, safety, and productivity, AGVs are poised to play an integral role in transforming operations across manufacturing, logistics, and warehousing sectors. With ongoing innovations in AGV technology and favorable regulatory conditions, the market is expected to see sustained growth in the coming years.

0 notes

Text

Understanding Kelvin Probes: FAQs for Precision Testing

Kelvin Probes excels in precision testing across industries. Here are the 10 best FAQs based on the real scenarios to help you understand Kelvin Probes and how they make our lives simpler.

How do Kelvin Probes ensure smartphone reliability?

Micro-resistances on circuit boards are measured during the smartphone manufacturing process to identify flaws early and guarantee seamless operation for millions of users.

Can Kelvin Probes efficiently test battery packs for electric vehicles?

Yes, using the four-wire approach, Kelvin Probes can efficiently measure the terminal resistance of EV batteries, which is important for preserving EV range and driving safety.

What makes Kelvin Probes essential for evaluating aerospace components?

Aerospace engineers use Kelvin Probes to confirm low-resistance connections in navigation systems, guaranteeing that the aircraft functions perfectly at 30,000 feet.

How do Kelvin Probes help in PCB assembly lines?

Kelvin Probes identify faulty solder junctions during PCB production, averting expensive recalls (imagine a game console breaking mid-match).

Where can I buy Kelvin Probes for automotive testing?

You can buy the highest standard Kelvin Probes at Equip - Test for automotive testing.

Are Kelvin Probes used in the renewable energy systems?

Yes, Kelvin Probes are used in renewable energy systems for optimal energy output with minimal loss of power efficiency.

Can biomedical equipment be tested using Kelvin Probes?

In medical devices where accuracy is essential, such as defibrillators or ECG monitors, Kelvin probes are essential for guaranteeing the dependability of vital connections.

8. How should I proceed if my Kelvin Probe readings appear to be inconsistent?

Inadequate connections or probe wear may cause inconsistent results. Accuracy can be increased by routine calibration and clean contact points.

9. How do Kelvin Probes contribute to safety checks in the railway industry?

Kelvin Probes help test electrical connections within signaling systems, ensuring reliable communication and safe train operation.

10. Why should I choose Kelvin Probes over other resistance measurement tools?

Kelvin Probes are perfect for applications needing high precision because their four-wire technique reduces errors brought on by lead resistance.

#test probes#simple cable harness tester#sockets#manufacturing pcb test equipment#kelvin probe#pogo contacts#equip-test

0 notes

Text

Akira Batteries: Pioneering the Future of Energy Storage as Leading Lithium-ion Battery Manufacturers in India

Driving India’s Electric Revolution with Advanced Energy Solutions

As India accelerates toward a sustainable transportation future, the demand for high-performance energy storage solutions continues to grow exponentially. Akira Batteries has established itself among the premier lithium-ion battery manufacturers in India, developing advanced power systems that are transforming mobility across the subcontinent. Our cutting-edge manufacturing facilities combine precision engineering with stringent quality control to create batteries that deliver exceptional performance, longevity, and safety for diverse electric vehicle applications.

Technological Excellence in Battery Innovation

Advanced Cell Chemistry for Superior Performance

At the core of our success lies proprietary cell formulations specifically engineered for India’s unique operating conditions. Unlike many lithium-ion battery manufacturers in India that rely on imported technology, Akira has developed specialized cathode and electrolyte compositions that optimize performance across extreme temperature ranges and challenging road conditions. This tailored approach ensures consistent power delivery and reliable operation in environments ranging from the humid coastal regions to the arid northwest.

State-of-the-Art Manufacturing Processes

Our production facilities incorporate automated assembly lines with precision equipment for cell fabrication, module assembly, and pack integration. Each manufacturing stage undergoes comprehensive quality verification through advanced testing protocols, ensuring every battery meets our exacting standards for capacity, voltage stability, and charge acceptance. This meticulous attention to production quality distinguishes Akira among lithium-ion battery manufacturers in India.

Application-Specific Battery Solutions

E-Bike and Scooter Power Systems

Our dedicated two-wheeler battery line features compact, lightweight designs optimized for efficient energy density and rapid charging capability. These integrated systems include sophisticated battery management technology that maximizes range while protecting cells from harmful discharge patterns, extending overall lifespan and maintaining consistent performance throughout thousands of cycles.

Electric Vehicle Battery Packs

For larger electric vehicles, we offer scalable battery systems engineered for optimal weight distribution, thermal management, and structural integration. These advanced packs incorporate redundant safety features, intelligent monitoring systems, and modular architecture that enables straightforward servicing and potential capacity upgrades as technology evolves.

Commitment to Sustainability and Safety

Environmentally Responsible Production

As responsible lithium-ion battery manufacturers in India, we implement comprehensive sustainability practices throughout our operations. Our manufacturing processes minimize waste generation, utilize energy-efficient equipment, and incorporate material recovery systems that reduce environmental impact while conserving valuable resources. This commitment extends to our supply chain partnerships, where we prioritize ethically sourced materials and transparent production practices.

Multilayered Safety Engineering

Safety remains our paramount concern, with multiple protective features integrated into every battery:

Advanced thermal management systems prevent overheating during charging and high-demand operation

Sophisticated cell balancing technology ensures uniform performance across all cells

Reinforced enclosures protect internal components from physical damage

Intelligent monitoring continuously evaluates operating parameters to prevent unsafe conditions

Driving Innovation Through Research

Our dedicated R&D center continues to push the boundaries of lithium-ion technology, exploring next-generation materials and cell architectures that promise even greater energy density, faster charging capabilities, and extended cycle life. This ongoing investment in research ensures Akira remains at the forefront of battery innovation in India’s rapidly evolving electric mobility landscape.

Partner with India’s Energy Storage Leaders

As one of the most trusted lithium-ion battery manufacturers in India, Akira Batteries offers unparalleled expertise in energy storage solutions. Our comprehensive approach—from initial concept development through manufacturing to after-sales support—provides partners with complete confidence in the performance, reliability, and safety of our battery systems.

Experience the Akira advantage and discover how our advanced lithium-ion technologies can power your electric mobility solutions with superior efficiency, reliability, and sustainability for a cleaner, greener future.

Original Source:- https://ruchiragreen.blogspot.com/2025/03/akira-batteries-pioneering-future-of.html

0 notes

Text

Welding Market - Forecast (2024 - 2030)

Request Sample :

In March 2024, the United States Department of Energy (DOE) announced up to $6 billion for 33 initiatives aimed at transforming America’s industrial sector, strengthening domestic manufacturing, and reducing greenhouse gas emissions. This transformative federal investment is matched by the selected projects, which will increase welding activities and contribute to market growth. Furthermore, the welding industry has seen considerable technological breakthroughs in recent years, including the introduction of new techniques and equipment such as robotic and laser welding. For example, in November 2022, Comau SpA installed an automated welding system for Beijing Foton Daimler Automotive Co. (BFDA) The company stated that its welding technique will assist BFDA in meeting both present and future objectives, including a 50,000-unit annual production capacity target. These innovations improve productivity, quality, and safety, resulting in increased industrial usage.

Report Coverage

The report “Welding Market– Forecast (2024–2029)”, by IndustryARC, covers an in-depth analysis of the following segments of the welding market.

By Product Type: Equipment/Accessories (Welding Machines, Gas Cylinders & Regulators, Welding Helmets, Welding Goggles, Welding Gloves, Others), Consumables (Electrodes & Filler Materials, Gases, Fluxes & Wires, Others)

By Mechanization: Manual/Mechanized Welding, Automatic Welding, Robotic Welding

By Technique: Arc Welding, Resistance Welding, Oxy Fuel Welding, Others (Laser Beam Welding, Ultrasonic Welding, etc.)

By End-Use Industry: Automotive & Transportation, Aerospace & Defense, Building & Construction, Energy, Heavy Machinery, Others

By Geography: Korea, China, Japan, USA, EU, Others

Inquiry Before Buying :

Key Takeaways

The shift towards environmentally friendly welding consumables is on the rise. Companies like, Ultrasonic Metal Welding, and Voestalpine Böhler Welding, ITW Welding are developing green consumables. More brands are expected to prioritize sustainable products, appealing to environmentally sensitive customers, and adhering to rules.

The welding market witnesses a growing trend in the adoption of automation and robotics. For example, in September 2023, Neuromeka demonstrated a 3D Vision Collaborative Robot for Welding at FABTECH. With the advent of advanced robots such as Novarc Technologies’ “Spool Welding Robot,” a single human welder can achieve a 3–5x boost in pipe welding output.

The accelerated development of the electric vehicle sector presents opportunities for welding technology, particularly in battery manufacturing and assembly. For example, the Brazilian Association of Electric Vehicles (ABVE) projects a 60% increase in fully electric and hybrid car sales in Brazil in 2024 compared to 2023. Many welds are required in EV battery packs to join different parts, such as cells and connections. Busbars, collector plates, and tabs are a few examples of these connections.

By Product Type — Segment Analysis

Consumables dominated the welding market in 2023. The consumables segment is further divided into electrodes, filler materials, gases, fluxes, and wires. Welding electrodes and filler materials are critical components of the welding process that influence the quality and longevity of the finished weld. Matching the right welding electrodes and filler materials is crucial for certain applications. Companies are extending their line of filler metals, driving up the market for welding consumables. For example, in August 2021, ESAB launched a new line of B3 SC electrodes and fluxes for SMAW, GTAW, and SAW for 2.25% Cr 1% Mo alloyed steels, SA-387 Grade 22, A335 Grade P22, and comparable materials. The new B3 SC filler metals have modernized formulas optimized for applications that demand exceptional toughness in both post-weld heat treatment and after-step cooling treatment.

By Mechanization — Segment Analysis

Automatic Welding dominated the welding market in 2023. Owing to its use, especially in industrial and manufacturing sectors where precision and productivity are paramount, automatic welding is advancing mechanization. Automatic welding technologies’ popularity has been gradually expanding as sensors and automation software have advanced. For example, John Deere, an American manufacturer corporation that manufactures agricultural machinery is using Intel’s AI technology to assist fix a costly, long-standing issue in the industrial welding process. As a result, new welding technologies, such as hybrid welding, additive manufacturing, or other ways, are opening up new possibilities in welding and attaching complex materials.

Schedule A Call:

By Technique — Segment Analysis

Arc Welding dominated the welding market in 2023. According to TWI Ltd, a multinational engineering and technology firm, arc welding procedures continue to be the primary source of material joining, accounting for 80% of all welding in India. Arc welding requires less expensive equipment and consumables. Arc welding is popular because it can join a wide range of metals and thicknesses, making it useful in a variety of applications such as construction, automotive, shipbuilding, pipeline welding, and fabrication. Arc welding equipment is also available in manual and automatic forms, giving it the flexibility to meet the needs of various production environments and requirements.

By End-Use Industry — Segment Analysis

Building & Construction dominated the welding market in 2023. Welding products are used to weld complex and huge buildings in the construction industry. The market’s expansion is being driven by the rapidly industrializing Asia Pacific region and other developing countries worldwide during the forecast period. India’s real estate and construction industries are thriving, and there is always a need for welding services for residential, commercial, and industrial projects. For example, in March 2022, the Airports Authority of India (AAI) began developing new and existing airports, with a projected capital investment of approximately Rs. 25,000 crores over the next five years. This includes building new terminals, expanding and modifying existing terminals, Airport Navigation Services (ANS) infrastructure, control towers, and technical blocks, among other things. These infrastructure projects will focus on modernizing and expanding ports, enhancing port connectivity, boosting port-linked industries, and developing coastal communities, all of which will spur demand for welding.

By Geography — Segment Analysis

China dominated the dominated the welding market in 2023. The region’s dominance is attributed to the flourishing manufacturing sectors, rapid urbanization, and extensive infrastructural developments. For instance, In January 2022, China unveiled plans to develop its construction industry during the 14th Five-Year Plan (2021–2025), paving a pillar of the country’s economy on a greener, smarter, and safer path. According to the OECD TiVA database, China is the world’s sole manufacturing superpower, and in terms of gross production, China’s share is 3 times the US’ share, 6 times Japan’s in 2023. With production hubs for electronics, automotive, construction, and shipbuilding, China has a consistently high demand for welding consumables.

Buy Now :

Drivers — Welding Market

• Large-scale infrastructure projects are necessitating substantial welding operations as a result of rising industrialization

The welding and cutting business has enormous potential for expansion primarily due to the growing emphasis on infrastructure development projects. Large-scale welding projects include the construction of buildings, bridges, ships, offshore oil platforms, and oil and gas pipelines. For example, in March 2023, US President-elect Joe Biden’s $7 trillion “Build Back Better” proposal featured huge new infrastructure spending aimed at revolutionizing the country’s old and underutilized infrastructure networks.

Infrastructure development will also play an important part in implementing the €1 trillion European Green Deal. According to the China National Bureau of Statistics, the total projected investment in recently started projects during the period climbed by 23.3% in 2022 on an annual basis. To guarantee that these welding projects are finished safely, effectively, and within the allotted time and budget, a great deal of planning, coordination, and execution is needed. This rising industrialization and accompanying infrastructure development drive the demand for welding operations across various sectors.

• The surging automotive and transportation sector

The automobile industry is a major contributor to welding market growth. To create various types of cars and parts, complex welding techniques and equipment are required. Rapid urbanization is driving up global demand for automobiles in developing countries like China, India, Brazil, and Russia. For instance, the automotive industry in India produced a total of 2,59,31,867 vehicles including Passenger Vehicles, Commercial Vehicles, Three Wheelers, Three Wheelers, and Quadricycles in in FY-2022–23, as against 2,30,40,066 units in FY-2021–22.

According to the European Automobile Manufacturers’ Association (ACEA), worldwide car manufacturing reached approximately 76 million units in 2023, a significant 10.2% rise from the year before. This boom was fueled by positive production trends that occurred across the globe. As of June 2023, the EU Commission had chosen 107 transport infrastructure projects to receive nearly €6 billion in EU funding from the Connecting Europe Facility (CEF), the EU’s strategic investment instrument in transport infrastructure. The need for specialized automotive welding technology and services therefore drives the welding market along with the production of various vehicle segments.

Challenges — Welding Market

• Shortage of skilled workers and high labor cost

According to the American Welding Society, the US will require more than 360,000 welders by 2027 and the current welder shortage is mostly caused by the expansion of the new industry and the resulting requirement for skilled labor. According to data from the Weld Australia 2023 member poll, there will be a minimum of 70,000 welders shortage in Australia by 2030. This lack of welders is endangering industries across the globe and pushing down welding revenue. Manufacturing requires welding, and since there has been a labor shortage in the welding sector for several years, there are a lot of worries about this sector. The demand for qualified welders has consistently outpaced supply.

Several causes are listed as contributing to the skills gap, including retired workers, an increasing sector, and young men’s and women’s preconceptions about working in manufacturing. However, one of the leading contributors is an aging workforce. For example, the Bureau of Labor Statistics predicts that welder positions will rise by 2% between 2022 and 2031, which is significantly less than the average for all occupations. The global welding market is facing issues as older tradespeople, many of whom belong to the baby boomer generation, are retiring at a faster rate than firms can replace them.

• Deployment of sustainable manufacturing strategies

Environmental concerns are becoming increasingly important in all industries, including welding. Implementing eco-friendly methods such as using renewable energy, decreasing waste through effective material management, and using environmentally friendly welding technology will help to reduce the industry’s environmental impact while promoting sustainability. For example, Metal Active Gas (MAG) welding is one of the most sustainable welding procedures. It is extremely efficient, clean, fast, precise, and adaptable in practice. Laser gas metal arc welding is another eco-friendly welding process.

Metalworkers face several hurdles while implementing green welding methods. Managing implementation concerns is one of the most difficult challenges. The transition from traditional welding processes to more sustainable ones takes time, effort, and investment in new equipment and training. Another problem is achieving a balance between environmental effects and productivity. Green welding approaches frequently necessitate slower welding speeds or lower heat inputs, which can impact efficiency and project timeframes. Metalworkers must discover strategies to address these issues while also reducing the environmental impact of their work.

Market Landscape

Technology launches, acquisitions, and R&D activities are key strategies adopted by players in the welding market. Major players in the welding market are the Lincoln Electric Company, ACRO Automation Systems, Inc., Miller Electric Mfg. LLC, Kobe Steel, Ltd., Hyundai Welding Co., Ltd., Voestalpine AG, Air Liquide, Ador Welding Ltd., Tianjin Bridge Welding Materials Group Co., Ltd., Gedik Welding among others.

Developments:

In April 2024, Kemppi launched the Minarc T 223 ACDC GM, which is a portable multi-voltage welding equipment that provides high-quality AC/DC TIG welding and excellent weld cleaning.

In February 2023, Miller Electric Mfg. LLC, one of the well-known manufacturers of welding equipment and consumable products, has unveiled its Copilot collaborative welding system. This system will enable welders to achieve higher welding quality and optimize the usage of consumables, allowing users to meet increased demand.

In February 2023, TriMas, a manufacturer of a wide range of products primarily for the consumer, aerospace, and industrial markets, agreed to acquire Weldmac Manufacturing, a manufacturer of metal fabricated assemblies and components for aerospace and military. Weldmac made roughly $33 million in revenue in fiscal year 2022.

For more Automation and Instrumentation Market reports, please click here

0 notes

Text

Piece Counting Weighing Scale by UP Scales – Accurate, Reliable, and Efficient

Are you looking for a high-precision weighing solution for your business? The Piece Counting Weighing Scale by UP Scales is the ultimate tool for accurate piece counting, inventory management, and weight measurement. Designed for industries like manufacturing, logistics, and retail, this scale ensures precision, reliability, and efficiency in every operation.

Explore the features, benefits, and technical specifications of this advanced weighing scale, and learn why UP Scales is the trusted choice for businesses across India.

Why Choose the Piece Counting Weighing Scale by UP Scales?

The Piece Counting Weighing Scale is packed with advanced features to meet the diverse needs of modern businesses. Here’s why it stands out:

High Precision Counting: With a resolution of up to 1/100,000, this scale ensures accurate piece counting, minimizing errors in inventory management.

Versatile Applications: Ideal for piece counting, inventory control, stock room management, shipping departments, and component supply.

User-Friendly Interface: Equipped with a 28-key keypad and LED display, the scale is easy to operate, even for beginners.

Overload Protection: Built-in overload protection ensures safe weighing and extends the scale’s lifespan.

Customizable Settings: Set High, Low, and OK piece count parameters for quality control and check weighing.

Label Printing Option: Print labels directly from the scale, including shop details, date/time, product name, unit weight, total weight, and number of pieces.

Technical Specifications

Order CodeCapacity (kg)Division (g)DisplayPlatterAccessoriesCAX5C30K1230.2LEDHigh PlatterPole Dating, High Platter*CAX5C30K1350.6LEDClose PlatterThermal PrinterCAX5C31K14101.0LEDHigh PlatterRSS20 Clean*CAX5C32K16202.0LEDHigh Platter40 Memory Class / Time*CAX5C33K18305.0LEDHigh Platter-

Power Source: AC110V/220V/240V ±10% / DC50/44M Rechargeable Battery Dimensions: 429 x 351 x 426 mm / Bus Size: 483 x 410 x 255 mm Gross Weight: 6.5 kg

Applications of the Piece Counting Weighing Scale

Piece Counting: Accurately count small parts and components in manufacturing and assembly lines.

Inventory Control: Maintain precise inventory records to reduce discrepancies and optimize stock levels.

Stock Room Management: Efficiently manage stock rooms with accurate weight and count data.

Shipping Departments: Ensure correct package counts and weights for outgoing shipments.

Component Supply: Verify the quantity and weight of components supplied to production lines.

Why Choose UP Scales?

UP Scales is a trusted name in the weighing industry, known for delivering high-quality, reliable, and accurate weighing solutions. Here’s why businesses prefer UP Scales:

Government Calibration Verification Certificate: Our scales come with a Government Calibration Verification Certificate and stamping by the Legal Metrology Department, ensuring compliance with legal standards.

1-Year On-Site Warranty: We offer a 1-year on-site warranty, ensuring prompt technical support and maintenance.

Same-Day Free Delivery & Installation: Enjoy same-day free delivery and installation services in Delhi NCR, minimizing downtime and getting your operations up and running quickly.

Expert Customer Support: Our team is always ready to assist you with any queries or technical issues. Call us at 9899008683 for immediate support.

FAQs About the Piece Counting Weighing Scale

1. What is the maximum capacity and accuracy of the scale?

The scale offers capacities ranging from 3 kg to 40 kg and accuracies from 0.1 g to 5 g, depending on the model.

2. Is the scale compliant with legal metrology standards?

Yes, the scale comes with a Government Calibration Verification Certificate and stamping by the Legal Metrology Department.

3. Does the scale come with a warranty?

Yes, UP Scales provides a 1-year on-site warranty for the Piece Counting Weighing Scale.

4. Can the scale be used for inventory management?

Absolutely! The scale is perfect for inventory control, stock room management, and shipping departments.

5. Do you offer delivery and installation services?

Yes, we provide same-day free delivery and installation services in Delhi NCR.

Get Your Piece Counting Weighing Scale Today!

Ready to streamline your business operations with the Piece Counting Weighing Scale by UP Scales? Visit our product page to learn more and place your order: https://upscales.buyweighingmachine.com/product-categories/piece-counting-weighing-scale

For any inquiries or assistance, feel free to call us at 9899008683. Our team is here to help you choose the perfect weighing solution for your needs.

0 notes

Text

How a Lithium-ion Battery Assembly Line Works?

As the demand for electric vehicles (EVs) and energy storage solutions surges, the efficiency of lithium-ion battery assembly lines plays a crucial role in determining the success of battery manufacturers. A well-optimized assembly line ensures high precision, consistency, and cost-effectiveness. But how does the process work? Let’s dive into the key stages of a lithium-ion battery assembly line.

Cell Grading: The Foundation of Excellence

Cell grading is a crucial first step in the process when each battery cell is carefully examined to ascertain its performance parameters. To produce a thorough "report card" for every cell, capacity, and internal resistance are carefully examined. This methodical procedure guarantees uniformity and groups cells according to their performance attributes, establishing the groundwork for the best possible utilization of a battery pack.

Cell Sorting: Precision in Pairing

After grading, cells are sorted based on their specifications, optimizing the performance of the final battery pack. By ensuring that the batteries in a pack are precisely matched, this precision matching maximizes performance and prolongs battery life. To fully utilize each cell's potential within the battery pack's overall power, this phase must be carefully planned.

OCV Testing Machines

Open Circuit Voltage (OCV) testing machines measure the voltage of cells to ensure they meet the required standards before assembly.

CCD Polarity Tester

This equipment is used for precise alignment and assembly of battery components, enhancing the overall efficiency of the production process.

BMS Testing: The Guardian of Performance

At the heart of the battery pack lies the Battery Management System (BMS), serving as its vigilant guardian. Before integration, the BMS undergoes rigorous testing to validate its functionality and its ability to effectively communicate with the individual cells. This crucial step ensures that the BMS is equipped to monitor and regulate the health and performance of the battery pack with unwavering precision.

Cell Welding: Where Precision Meets Connectivity

As the testing cells await their transformation into a unified force, the delicate process of cell welding takes center stage. Automated robotic arms execute this task with precision, forging strong and reliable electrical connections between the cells. The seamless integration achieved through cell welding forms the foundational framework for the battery pack, ensuring its resilience and efficiency.

Battery Pack Testing or Aging: Trials of Endurance

The culmination of the assembly line journey leads to the final stage – rigorous testing of the complete battery pack. Depending on its intended application, this phase may encompass charging/discharging cycles to simulate real-world usage or accelerated aging tests to evaluate long-term performance and safety. Through these trials of endurance, the battery pack's resilience and reliability are put to the test, ensuring its readiness for the demands of modern life.

Battery Comprehensive Testing

Finally, comprehensive testing machines assess the battery packs' overall functionality, safety, and longevity before they are ready for deployment. The integration of these advanced machines not only streamlines the production process but also ensures that you deliver high-quality, reliable battery packs that power the future of transportation.

Conclusion: Precision, Innovation, and Reliability

From the meticulous grading of individual cells to the comprehensive testing of the assembled battery pack, the cell-to-battery assembly line embodies a fusion of precision, innovation, and reliability. Each step in this intricate process plays a pivotal role in shaping the quality, safety, and performance of the batteries that power our modern world. Behind every seamless charge and every enduring power source lies a journey of expertise and dedication, culminating in the creation of batteries that stand as pillars of energy in our technologically driven lives.

#Lithium-ion battery assembly line#Lithium-ion battery manufacturing process#Battery cell assembly#Lithium-ion battery production#Battery manufacturing equipment#Battery cell grading process#Battery cell sorting techniques#Battery management system testing#Cell welding in battery manufacturing#Battery pack aging tests#Comprehensive battery testing procedures

0 notes

Text

Automotive Packaging Solutions: Enhancing Efficiency and Protection in the Supply Chain

Introduction

The automotive industry relies on a complex supply chain that spans multiple continents, with manufacturers sourcing components from various suppliers before assembling the final product. To ensure the safe transit of delicate parts, automotive packaging solutions play a crucial role in protecting valuable components from damage, contamination, and inefficiencies. As automotive production evolves, so does the need for smarter, more durable, and sustainable packaging solutions.

This article explores the importance of automotive packaging solutions, the different types available, and how the industry is adapting to new challenges in logistics and sustainability.

Why Automotive Packaging Solutions Matter

Automobile manufacturers and suppliers handle a diverse range of parts, from large body panels to small electrical components. Without proper packaging, these components are at risk of damage due to:

Mechanical impact during handling and transportation

Moisture and corrosion, especially for metal components

Electrostatic discharge (ESD), which can affect sensitive electronic parts

Improper stacking and storage, leading to deformation or inefficiency

High-quality automotive packaging solutions address these risks, ensuring that parts arrive at their destination in optimal condition while minimizing waste and unnecessary costs.

Types of Automotive Packaging Solutions

To meet the varied needs of the automotive sector, packaging solutions come in different forms, each designed for specific applications:

1. Returnable Packaging Solutions

Returnable or reusable packaging systems are gaining popularity in the automotive industry due to their cost-effectiveness and sustainability. These packaging options include:

Plastic totes and bins: Ideal for transporting small parts like screws, nuts, and bolts.

Foldable bulk containers: Used for larger components such as engine parts or transmission units.

Steel racks and pallets: Perfect for heavy and oversized automotive components.

These solutions help manufacturers reduce packaging waste, lower costs, and improve supply chain efficiency.

2. Custom Foam Inserts and Protective Cushioning

Delicate components such as sensors, electronics, and fragile automotive parts require cushioning to absorb shock and vibrations. Foam inserts, air pockets, and honeycomb core packaging provide impact resistance, ensuring safe transportation.

3. Corrosion-Resistant Packaging

Many automotive parts, particularly those made of steel or aluminum, require protection against oxidation and rust. Corrosion-resistant packaging includes:

Vacuum-sealed pouches to remove oxygen exposure.

VCI (Volatile Corrosion Inhibitor) bags that prevent rust formation.

Desiccant packs to absorb moisture and maintain a dry environment.

4. ESD-Safe Packaging for Electronics

Modern vehicles rely heavily on electronic components, including control modules, sensors, and lithium-ion batteries. Electrostatic discharge (ESD) can damage these parts, making specialized ESD-safe packaging essential. Materials like conductive plastics, ESD shielding bags, and foam-lined trays protect sensitive electronics from static buildup.

5. Partition Sheets and Layer Pads

Partition sheets and layer pads are widely used in automotive packaging to separate components, prevent shifting during transport, and maximize stacking efficiency. Made from durable materials like corrugated plastic or honeycomb-core polypropylene, these solutions offer both strength and reusability.

Key Benefits of Advanced Automotive Packaging Solutions

Investing in the right automotive packaging solutions offers several advantages, including:

1. Reduced Damage and Product Loss

Proper packaging prevents dents, scratches, and breakage, reducing the risk of costly replacements and delays in production.

2. Improved Supply Chain Efficiency

Standardized, stackable, and returnable packaging enhances logistics efficiency, making it easier to load, unload, and store components.

3. Cost Savings in the Long Run

Although some automotive packaging solutions require higher initial investment, they result in long-term savings through durability, reduced waste, and lower material handling costs.

4. Sustainability and Reduced Environmental Impact

As the automotive industry moves toward greener practices, sustainable packaging options are gaining importance. Recyclable, reusable, and biodegradable materials contribute to a circular economy, reducing waste and carbon footprint.

5. Compliance with Industry Regulations

Many countries and automotive manufacturers have strict packaging regulations regarding hazardous materials, weight limitations, and environmental impact. Using compliant automotive packaging solutions ensures smooth operations without regulatory issues.

The Future of Automotive Packaging

The automotive industry is evolving, and so are its packaging needs. Some key trends shaping the future include:

Smart Packaging: Integration of RFID tags and QR codes to track shipments and manage inventory more efficiently.

Lightweight and High-Strength Materials: Advanced composites that offer both durability and weight reduction for lower shipping costs.

Greater Focus on Circular Economy: Manufacturers are increasingly prioritizing packaging that can be reused, repurposed, or recycled to minimize environmental impact.

Automation and Robotics in Packaging: Automated systems for loading, unloading, and packaging optimization are making processes faster and more efficient.

Conclusion

Automotive packaging solutions are a crucial part of the supply chain, ensuring that components remain undamaged, logistics remain efficient, and manufacturers reduce waste and costs. Whether it’s returnable packaging, protective cushioning, or corrosion-resistant materials, selecting the right packaging solution is vital for the success of the automotive industry.

With a growing emphasis on sustainability and efficiency, companies must continue to innovate and adopt automotive packaging solutions that align with modern industry demands.

0 notes

Text

How Alligator Automations Helps in Reducing Manual Labour Through Technology

Automation has become a core driver of productivity, shifting from a futuristic idea to an essential part of modern industry. Tasks once handled manually, especially repetitive ones, are now managed by intelligent machines, revolutionizing manufacturing, packing, and distribution processes. Alligator Automations is a leader in this shift, delivering cutting-edge solutions that streamline industrial workflows. Imagine a busy factory floor: products moving on conveyors, robots assembling intricate devices, and a synchronized packaging system—all showcasing automation’s potential. This vision of seamless collaboration between humans and machines has now become a reality due to companies like Alligator Automations.

From Humble Beginnings to Industry Leaders

Founded in 2008, Alligator Automations started with competition-based robotics and has evolved into a major player in end-of-line packaging automation. Committed to driving innovation, we provide automated solutions to diverse sectors like automotive, food and beverage, FMCG, agriculture and many more, positioning ourselves as a leader in industrial transformation.

How Alligator Automations Reduces Manual Labour in Key Areas

Advanced Palletizing Systems: Handling heavy palletizing loads manually is labour-intensive and risky. Alligator Automations’ robotic palletizers streamline this process, reducing worker strain and injuries while adapting to varied product shapes and weights. With robotic precision, companies can achieve high palletizing efficiency with minimal labour.

Automated Sorting & Product Handling: Our advanced systems use vision recognition to automate sorting, a valuable feature for industries like food and beverage, chemical, retail and many more, which demand high precision and hygiene. Automation enhances sorting accuracy, reduces manual input, and improves operational speed.

Bulk Material Bagging Solutions: For sectors like agriculture and construction, Alligator’s automated bagging systems manage bulk materials quickly and efficiently, reducing contamination, spillage, and wastage. This enhances productivity and safety on bagging lines, thus reducing manual labour through technology.

Improved Safety & Cost Savings: Automation reduces repetitive tasks and heavy lifting, lowering workplace injuries and labour costs. Alligator’s robotics improve safety and meet industry standards, making the work environment secure and efficient.

Data-Driven Production Insights: Alligator Automations’ IoT-enabled systems track real-time productivity, helping businesses optimize operations and asset maintenance. This AI-driven monitoring minimizes human oversight, ensuring seamless and efficient process control.

Applications Across Industries

Alligator Automations’ solutions cater to diverse industries, from FMCG and food production to warehousing, agriculture to automotive and many more. These automation solutions address unique pain points and labour-intensive tasks in each sector, allowing companies to scale their operations efficiently. For example:

Food & Beverages: Automation solutions like automatic bagging, secondary packaging, and intralogistic conveyor systems ensure compliance with food safety and quality standards.

Cement: Transitioning to automated packaging increases precision and operational speed.

Chemicals & Fertilizers: Safe handling systems reduce risks associated with hazardous materials.

Tyre Industries: Specialized systems streamline tyre manufacturing and handling.

Petrochemical, FMCG, Agro Commodities, Appliances, Automobile, E-commerce, Oil & Paints, Papers & Battery, and Seed industries benefit from enhanced packaging, palletizing, and intralogistics solutions tailored for high efficiency, safety, and reliability in each application.

Embrace Future-Ready Production with Alligator Automations

As labour shortages and operational costs rise, adopting automation becomes not just beneficial but essential. Alligator Automations empowers industries to enhance productivity, safety, and precision. By transitioning to automated systems, companies can significantly cut down on manual labour, streamline processes, and gain a competitive edge in today’s technology-driven market.

For an in-depth assessment and solution tailored to your production line, reach out to Alligator Automations today and explore the future of intelligent, labour-free automation.

#alligator automations#bagging machine#agatha harkness#packaging machine manufacturer#automatic conveyor systems

0 notes

Text

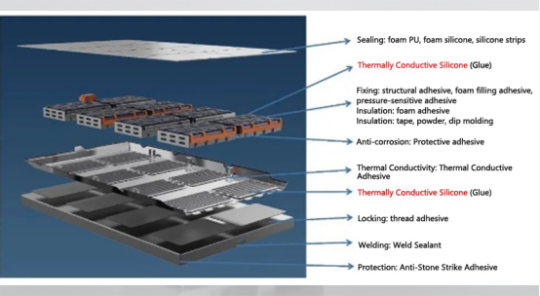

Empowering lithium battery production line, revealing Second Intelligent's “smart” engine

● New Energy Power Battery Core Coating Project ●

Thanks to the explosive development of the new energy automobile industry, the lithium battery also ushered in a period of rapid development. Shenzhen Second Intelligent Equipment Co., Ltd (Second Intelligent) lithium battery gluing machine equipment is based on the new energy lithium battery packaging section, through the core, side plate, end plate, insulating sheet, etc. to glue to achieve bonding, sealing, thermal conductivity and other functions, its performance requirements and stability have reached the international leading level.

In 2023, Second Intelligent provided more than 20 sets of gluing machine equipments for 3 production lines of a new energy power battery manufacturer, which helped it to further improve the production efficiency, meet the market demand for production capacity, and escort the stability of product quality, and helped the customer to rapidly expand the market share!

New energy, new opportunities!

With the new energy vehicle market penetration rate continues to increase corresponds to the global power battery manufacturing continues to expand. Currently, the demand for power batteries is “blowout” explosive growth. Industry data predicts that the global electric vehicle sales of 23.3 million units in 2025, corresponding to the demand for power batteries amounted to 1,691GWh.

2021-2025 power battery demand CAGR of nearly 48%.

| Adhesive technology in the battery system application point

The power battery is the "heart" of new energy vehicles. It refers to the rechargeable battery system used in new energy vehicles to provide power sources. The battery cell is the smallest unit of a battery system. Multiple battery cells form a module, and multiple modules form a battery pack. This is the basic structure of automotive power batteries.

Behind the rapid development of the industry is the continuous technological refinement of the manufacturing process and supporting equipment. Among the many key processes and materials, new energy power battery cell gluing as one of the most important processes in the assembly process, how to improve the precision of gluing,

Stability and automation has become the focus of industry attention.

To solve the reliability of new energy vehicle batteries, it is necessary to deal with the “core gluing” problem. Therefore, the well-known brands of new energy power battery cell suppliers in all aspects of the screening is very strict.

New energy power battery market demand soars, and lithium-ion coating machine as an important battery core production equipment, its market demand is also increasing. At present, in the domestic new energy automobile industry chain rapid development background, lithium-ion coating machine development trend is good.

| Choosing Second Intelligent to build new energy power battery cell coating project together

After seventeen years of technological precipitation and innovation, customizable solutions, professional design, fast delivery and excellent service, Second Intelligent has gradually established a brand image of high quality, credibility and service in the industry. Against this background, the new energy power battery manufacturer finally chose Second Intelligent.

The new energy power battery manufacturer finally selected Second Intelligent as the new energy power battery core coating supplier, the two sides of the team strong combination, around the site environment and process technology needs, from the early equipment program planning to the late equipment on-line always maintain close communication and cooperation.

Since December 2022, after receiving the customer's new energy power battery cell coating project procurement needs, the team composed of R&D, engineering, after-sales, project and sales of Second Intelligent, responded to the customer's needs in a timely manner, decomposed the customer's needs, carried out product validation, and efficiently linked the functions of various sections within the company, closely communicated with the customer and finalized the program.

Communicate closely with the customer and finalize the details of the program. Second Intelligent team and customer team keep online meeting about 2 times a week to continuously optimize the solution design.