#basic oxygen furnace

Explore tagged Tumblr posts

Text

basic oxygen furnace

24 notes

·

View notes

Text

Basic Oxygen Furnace (BOF) steel making involves blowing oxygen through molten pig iron that is heated to more than 1,600℃ to convert it into steel. Different types of refractories play an important role to maximize furnace life and yield. IFGL Refractories offers specialized BOF refractory solutions for enhanced furnace performance.

#steelmanufacturing#steelindustries#ifglrefractories#refractory solutions#bof refractories#basic oxygen furnace

0 notes

Text

random pet peeve:

the odorless deadly chemical which can be in your house if you have a leaky stove or furnace is CO: Carbon Monoxide.

You have carbon monoxide detectors for that, because it's deadly and can build up without you noticing.

That deadly gas is NOT CO2. CO2 is Carbon Dioxide. You breathe it out, it feeds plants, it's what makes soda drinks fizzy.

So you don't usually have a "CO2 detector" in your home (they exist, though).

Now don't get me wrong: CO2 isn't super healthy either, but since humans emit CO2, we're pretty good at handling low levels of it. Too much of it will asphyxiate you, but that's super rare. It really needs to happen because of things like "nearby volcanic eruptions" and "deep lake water disruptions". Basically CO2 kills you by getting in the way of oxygen that you're trying to breathe in, and it kills you the same way any other gas does: you can't breathe in much oxygen if all the air is something besides oxygen.

CO (Carbon Monoxide), on the other hand, directly fucks up your hemoglobin. You breathe it in, and your blood starts carrying carbon monoxide around, rather than oxygen (in) and carbon dioxide (out). It basically suffocates you at the blood level, rather than the lungs level: You can breathe in all the oxygen you want, but if your blood can't move oxygen, you die.

This also bypasses the "I NEED TO BREATHE!" feeling. You don't notice that your blood is failing to move oxygen, you just get headaches, dizzy, nauseous, and confused, then die.

So, to sum up:

Carbon Dioxide (CO2): Relatively common, makes drinks fizzy, not dangerous unless there's a a ton of it. If you walk into a room full of CO2, you start choking because you can't breathe.

Carbon Monoxide (CO): Rare poisonous gas, comes from leaky combustion appliances, quite dangerous. If you walk into a room full of CO, you get a headache, act weird, then die.

1K notes

·

View notes

Text

Alright I NEED to know the biology lore of how can ghasts live in what is basically a fire dimension with no water, that probably smells like toxic as heck (because of all the combustion), and that is basically a big cave that probably makes it a giant furnace. Heck, even the implications of how the player can stand it either.

Because if that thing thrives on water it must be a water/air amphibian (y'know, instead of land), or be able to survive with mostly carbon (because the nether is in constant combustion, there must be oxygen as well as a shit ton of CO2).

Along with the amphibian speculation some ppl think it may have slimy/soft skin, but we have seen ghasts swimming in lava or under lava waterfalls, so there must be some draconic features like hard scales that cover it up, like the lava snail could he need lots of iron or use it somewhere on its body? But also we know the nether probably has little to no iron, it's mostly gold, and quartz, but maybe, similar to mars, all the iron is found in netherrack (because of its reddish color).

So maybe it was a creature that lived close to volcanic places on the over world? Both in high places and underwater, to explain his ability to fly.

Do you think it started out as a small cephalopod that had a really light body? Or even a jellyfish?

Like, imagine if that skin was more like a jellyfish's bell, and somehow it has a high body temperature by itself, so when getting out of the water they naturally float like hot-air balloons.

So, maybe they don't live that deep underwater, or slowly evolved to live in less pressurized environments until they escaped water.

Considering they have both eyes on front and also a mouth there too, they may be closer to octopus than squids, and look more like the martians in the war of the worlds book. But not that ugly.

Maybe the ghast is a giant octopus that is horizontal like a cuttlefish. And what if it also lost the ability to camouflage? And that's why they're pale white, my headcanon is that they're actually transparentish in the way polar bear fur is transparent. And high temperature environments made them lose their color changing skills because their skin had a higher priority of becoming harder?

Along with the volcanic thing maybe they can stand the nether because they need lots of minerals to thrive? And the nether is basically an infinite cave. Now I need to know how pressurized is the deep ocean and also if the nether has a high or low pressure too, and if that's the case how could a ghast withstand the shift from there to floating in the over world?

Of the ghast was or used to be an over world creature how did the interdimentional migration work? Were they brought there because of commerce? As transportation? (In the Minecraft movie we see the piglins using it to fly), if they are highly adapted to the nether that means they must have been there for a long time, but also we know nether portals are made by intelligent creatures like us or the piglins, so it could have happened more than 50,000 years ago or even a million if that's the case, since homo erectus or before?, or are there rare instances of natural portals occurring?

What of the ghast is like those creatures that live exclusively on a specific part or island on earth and can't be found anywhere else? And a natural portal occurred and then a constant swapping led them to getting trapped there or something forced them to, like a predator? Although I don't think the over world has anything that Could be threatening to them, not even the warden since they can fly.

Or maybe they ARE nether creatures, and the ancient nether was way different, maybe even colder, and more humid. We know we can't place water there, but we can have cauldrons, also, the presence of life and fungi there must be a sign that there must be a kind of humidity somehow, maybe not water by now, maybe a different liquid.

AAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAA there's so many interesting stuff to speculate about this creature and maybe I'm going a bit too nerdly but that new addition alone was THAT good to the game, can't wait to befriend a ghast myself.

#ghast#Minecraft#ghastling#minecraft live#minecraft live 2025#the nether#biology#worldbuilding#speculative biology#fantasy#science fiction#sci fi

61 notes

·

View notes

Note

Been waiting to share this but I can’t be normal.

Hello ninjago headcanon blog! I like musing about Kai and Nya and how their powers work :3… this might be a bit long:

I actually choose to believe that despite each of them having a mastery of only one element, considering Nya and Kai have blood of two elements in them, they still feel an affinity and connection to the other element. For example; Kai is a great fire wielder who hates deep water but rain is one of his favourite things in the world, and most times it feels so familial and close that it might be his mother hugging him. Nya is a remarkable water bender who is attached to her element, but she’s always been enticed by the way fire dances and moves, and in the blacksmith shop, she used to love watching it melt the metal and be near the furnaces because the warmth felt so correct to her.

However!! There are drawbacks of being basically double blooded in terms of elements? Like-

Waterbenders/ Masters of Water are meant to be able to breathe underwater BUT Nya should be able to breathe underwater for an undefined amount of time- as much as she wants- but she can’t. Instead, she can hold her breath for longer than the average person (1hr) but begins to feel the effects of oxygen deprivation at the 1/2hr mark.

Fire Masters are meant to be able to withstand immense heat- Kai’s fireproof… but never fully (up to a certain temperature). And when he stops being fireproof he feels the full brunt of that burn (say, he can withstand like. 1000°C which is a good temperature for forging copper and bronze- which he grew up doing unharmed- but when my guy tries to walk through fire like he should be able to! he experiences the effects as if he wasn’t able to withstand heat at all)

Being children of two elements puts them in deep connection with both, but it can also be a disadvantage, especially when the two elements are OPPOSITES.

wow. i genuinely have no idea what to say to this aside from the fact it’s very cool.

#ninjago#ninjago headcanons#headcanon#ninjago kai#kai smith#kai jiang#ninjago nya#nya smith#nya jiang

37 notes

·

View notes

Note

Wouldn't it be hilarious if stone monkeys actually can give birth or lay stone eggs naturally? Like... if they have a partner it'll be a regular old birth the same as how MK and the twins came into the world... but say a stone monkey didn't have a partner. Stone Monkey are a rare and critically endangered species afterall (even if they don't have the protections of an endangered species).

So what if, as a biological advantage, a stone monkey actually can lay a stone egg and give birth to a little baby stone monkey the same way as how Wukong and Macaque were born. But it's risky since creating life without a partner is beyond dangerous and most don't survive to even see the egg hatch, so most can only have one at a time and have to REALLY want a kid since, well, they'd basically be trading their life for the kids'. A kid that probably wouldn't even be hatched until long after their parent is dead.

I think with Wukong, it'd be a bit different because, well, 7 times over immortal monkey. But he'd still experience the negative effects and basically be completely vulnerable for a long time afterwards if he ever did it.

Just a little headcanon I thought up that I thought you'd be interested in.

Oh like parthenogenesis! Like some reptiles do when theres no available mates. I figure in a similar sense, the baby Stone Monkey would be a near-genetic clone of the parent; with the environment the "womb" is in adding life energy/qi/dao and affecting the appearance/abilities of the developing monkey within. Wukong likely popped out the way he did cus his egg was at the top of a mountain - his egg absorbing the violent life energy of what was once an active volcano over thousands of years.

Considering a certain few lines in Jttw, it's suggested that Wukong and Macaque are the last of their kind (with Six Eared being a variant/subspecies) - or they're just the only ones in that hemisphere. Like ancient human relatives the great Stone Monkeys became lost to time or were drowned in the Great Flood, or in the case of the Gibbon and Baboon; left Earth entirely.

The idea of a Stone Monkey deciding one day "I want a baby" and their body taking from there if there wasn't a viable mating option is really interesting. Their body's becoming like golems, weathered down into boulders if damage comes to them. And also very sad cus they know that theres a really good chance that they will never meet their baby. :(

Though imagine what the potiential "trigger" for it could be...

Guanyin: "The Monkey King is currently held beneath the Five Point Mountain. It will act as his prison for the next five centuries." Gold Star: "Ah. Make sure he's watered frequently and has plenty of oxygen." Guanyin: "But of course, it is only humane. However, doesn't he possess many forms of immortality?" Gold Star: *is so old that he witnessed the first Stone Monkeys, some even developing on his planet* Gold Star: "Not unless you want him to make another of himself." Guanyin: "Pardon?" Gold Star: "In my observations; when a Stone Monkey without a mate wished to reproduce, they would bury themselves and abstain from all biological needs until their bodies returned to the stone from whence they came. A new stone egg formed within their body as if it were a womb. The process is very taxing, and many died if another was not present to "wake" them afterwards. Though even in the case of parental death; the egg within the body would live on to hatch forth an infant to be raised by the familial troop." Guanyin, panicking: "I... I will be back in a moment." Wukong, beneath the mountain: "...why am I thinking about having kids?" Guanyin: *busts in holding molten copper and iron cus it was the only thing next to her at the time*

Of course it is unlikely for Wukong to actually *die* if his body decided to Copy/Paste him into an egg. But the possible way it could occur to him accidentally in any universe would be scary.

Like say... being trapped in a (newly) air-tightened Furnace by spiteful past enemy...

Lets just say I thought of another way that Luzhen is created >:)

Macaque: *pops open the lid to the airless Furnace* "Oh thank Buddha! You're intact. Drink some water dummy." Wukong, "awakened" by the fresh air and water: "...I think I'm pregnant." Macaque: "Uh... congrats?" Wukong: "No, like. Being cooked in there with no air made me pregnant." Macaque, only vaguely familar with their species: "...we should really ask Gold Star about this."

Luzhen in the TMKATI au would be celebrated as an adored, if not odd, new member to the family. His egg pops out after a long time of just sitting in SWK's body like his swallowed a rock. Luzhen "hatched" in a way that triggered something akin to labor. After all, Wukong's egg split open his Rock-mother (possibly the body of his parent) when it was his time to hatch. Wukong decides it is the worst pain he's ever felt in all his immortal life. Luzhen blinks slowly when his shell finally cracked all the way, confused on where he was.

The bit of dao Luzhen absorbed from his enviroment allowed him to develop just a tiny difference to his father; a pair of moon-silver eyes. Macaque smugly declares Luzhen's beautiful eyes are clearly a trait he inherited from him - and likely *did* depending on if any part of Macaque ended up in the Furnace with Wukong too. Like lets say the bones from an arm grapsing deperately before the lid of the Furnace slammed shut...

Hilariously, if Sun Wukong couldn't breath and/or wasn't able to crawl towards the Wind Trigram his first time cooking in the Furnace; there was a good chance that Lao Tzu would have opened the Furnance to a statue-like Monkey King with an egg inside of it. Wukong finally reawakening 500 years later with a heavy stomach and *many* questions.

#lego monkie kid#lmk#sun wukong#jttw theories#jttw#journey to the west#pregnancy tw#stone egg#death tw#liu er mihou#six eared macaque#celestial primates#sun luzhen#lmk sun luzhen#lmk character ideas#jttw stone egged au

94 notes

·

View notes

Text

My personal murder method headcanons

Yep. Self-explanatory.

Also warning cuz I am gonna use She/Her pronouns for one or two of the characters.

Flumpty

He crushes your head like an empty soda can.

If he finds you might be useful, he just sends you into a coma instead.

Golden Flumpty

Makes their victims commit suicide by invading their minds.

Birthday Boy Blam

The simple way for a simple guy

He just stabs you multiple times lol

Same goes for Kevin Jr

He can also bite your head off

Redman

He paralyzes your legs and drags you into the lava or furnace to burn you alive.

Eyesaur

They normally just crush or trample you

However they can also use their hand-tail to knock you back so hard you splatter on the wall

Beaver

He straight-up claws your face off.

Owl

She pecks at you brutally until you die.

Beavowl

They just maul and stab you to death lol

Spider Flumpty

I HAD to include one of the clones cuz I had the PERFECT idea while I was drifting off to sleep.

So basically, she'll either make your death quick or drawn-out.

For the drawn-out death, she bites you and injects you with venom, watching as you slowly die to the poison in your blood system. And then she will rip you apart.

If you're lucky, she'll just put your head into her mouth and snap your neck.

Grunkfuss

I saved the best and I mean THE BEST for last.

As one of the more sadistic ones when it comes to killing, he makes SURE that your death is as horrible as possible.

He will use a variety of ways to kill you, primarily the boa method (Which is wrapping his arms around you so tightly you die from lack of oxygen) or ripping you to shreds with just his teeth. Hell, he’ll even slam your body around or spin his third set of teeth tremendously fast in order to blend you to death.

He'll only stop attacking once your breathing ceases, you finally stop bleeding, and/or your head comes off.

He can also let you try to run and hide, knowing you can't escape from him. You'll die anyway.

The rest of the gang have to play rock-paper-scissors to decide who cleans up the blood and guts Grunkfuss painted the rooms with.

#one night at flumpty's#one night at flumptys#one night at flumpty’s oc#onaf#onaf oc#onaf headcanons

8 notes

·

View notes

Text

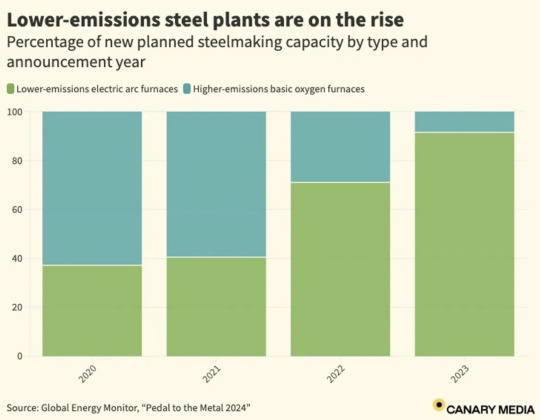

Excerpt from this story from Canary Media:

One of the world’s dirtiest industries is beginning to embrace cleaner methods.

Most planned new steelmaking capacity will use lower-emissions electric arc furnace technology rather than the historically dominant but emissions-intensive basic oxygen furnaces, per a new report from the nonprofit Global Energy Monitor.

Steel is, quite literally, a pillar of our world. It props up skyscrapers, reinforces bridges, and is crucial to cars, planes, trains, and ships. It’s also incredibly dirty: As much as 11 percent of global carbon dioxide emissions come from the iron and steel industries.

The primary steelmaking process generally starts with producing iron in a superhot and extremely carbon-intensive coal-based blast furnace. The resulting iron is then typically put into a basic oxygen furnace, where it becomes steel.

But recent trends suggest that more-sustainable electric arc furnaces (EAF) are starting to replace basic oxygen furnaces, helping slash emissions. In 2023, nearly all newly announced steelmaking capacity — 93 percent — planned to use EAFs, per the Global Energy Monitor report.

As it stands, about 32 percent of global steelmaking happens in these lower-emissions electric furnaces, but that’s set to rise to more than 36 percent by the end of the decade as more EAFs come online and more oxygen furnaces retire, per the report. That growth rate nearly puts the industry on track to meet the International Energy Agency’s target for EAFs to make up 37 percent of steelmaking by 2030.

The picture is less clear for iron production, the step in the steelmaking process that is responsible for the��vast majority of carbon emissions.

More than 90 percent of the world’s iron is still made in extremely dirty coal-based blast furnaces. The primary alternative to these furnaces, direct reduction iron (DRI), is beginning to gain ground. But coal-based blast furnace capacity is still being built faster than DRI capacity.

5 notes

·

View notes

Text

#Steel slag roads#Green roads India#Sustainable infrastructure#Eco-friendly roads#Slag road construction#Steel slag use#Green construction India#Slag in infrastructure#Waste to roads

1 note

·

View note

Text

Inspired by this post by striderl, here are the explanations for my characters' serials.

Cygnus (5022)

Inspired by a Cheapshow (podcast) episode in which a character mangled some bingo calls, calling 22 as 'two little swans' instead of the traditional 'two little ducks'. Instantly I knew I had to use that for a character somehow: give them a serial ending in 22 and call them Cygnus (the genus of swans).

The 'Fifty' came later just because I liked the sound of 'Fifty-Twenty-Two'.

Phaeton (1842)

This one actually gets explained in-universe. As Phaeton is a human, they weren't automatically assigned a serial, so they had the opportunity to choose their own one. Phaeton chose 1842 because the atomic numbers of hydrogen, oxygen and molybdenum are 1, 8 and 42. The chemical abbreviations of those elements are H, O and Mo, which can be put together to spell Homo (the genus of humans).

In this way, Phaeton and Cygnus have 'matching' serials; Cygnus's name is an organic genus derived from their serial, whereas Phaeton's serial is digits derived from their organic genus.

Engineer 1668 (lead engineer on the TV Titan's maintenance crew)

It's the melting point (in degrees Celsius) of titanium. (Geddit, titan-ium?)

I wanted to use the Kelvin temperature because Kelvin seems more Science than Celsius, but 1668°C is 1941°K, and 1668 was just a more pleasing number.

Agent 1791 (TV Titan's identity pre-upgrade)

(Yes, the Titan's not actually my character, but [fart])

It's the year of discovery of the element titanium. (Although it was initially named maccanite, and didn't receive the name titanium until 1795.)

Primus (1153) and Icarus (1566) (TV Matriarch's bodyguards)

(Also not actually my characters. But also it appears to be fanon that these two are the Matriarch's bodyguards at all! We've never seen them since their first appearance.)

I devised their nicknames and serials concurrently; I wanted to give them serials that Phaeton could turn into nicknames.

I decided I wanted one of them to be called Primus, so I looked up 4-digit primes looking for one that was both 'pleasing' and was splittable into a pair of 2-digit primes.

For Icarus I looked up asteroid names and numbers until I found one that was both a reasonable character name and had a pleasing number.

Fornax (4304)

The number was just one I found pleasing. The hard part was later coming up with a nickname, after I decided I'd got attached to this character enough to name them.

I initially wanted to carry over Cygnus's theme of 'bird name that's also a constellation'. Unfortunately the birb constellations don't have terribly pleasing names. Besides Cygnus, there's Apus (bird of paradise), Aquila (eagle), Columba (pigeon), Corvus (crow), Grus (crane), Pavo (peafowl), Phoenix (not a real birb), and Tucana (toucan).

Corvus is admittedly kinda cool-sounding, but was a bit too close to Cygnus for my liking. I initially wanted to go with Grus, because I noticed that so far all my named TVs had names ending in -us (Cygnus, Primus, Icarus) and I wanted to continue that theme, but I just couldn't make myself like it as a name, plus it just didn't feel like something Phaeton would pick for them.

In the end I threw out the bird link and kept just the constellation link. Phaeton chooses Fornax as a name just because of that and because 'four' and 'for' sound similar.

(Fornax means 'furnace', and Phaeton means 'one who shines'. So the trio are basically called Shiny, Swan and Oven.)

Other engineers

I literally used random.org to generate numbers, and picked the first 15 that fulfilled my criterion of 'last digit can't be 0' (see link below for why not).

I wanted to give myself a little challenge of coming up with nicknames for existing numbers that I didn't pick, instead of picking numbers that would fit a specific name.

I ended up with two characters with serials ending in 07, so they'll get nicknames to tell them apart. 5007 and 9807 both work on the Titan's propulsion systems and are collectively referred to as 'the Sevens'; 5007 is nicknamed 'Stannum' (Latin for tin, which has atomic number 50) and 9807 is nicknamed 'Ianthe' (for the asteroid 98-Ianthe).

Engineer 9779 is nicknamed Palindrome for obvious reasons.

Unfortunately, one of the numbers random.org gave me was 6918. I considered not using that one, because people will likely assume I added the 69 to be funny, then I thought 'nah, just add it, things like this would be inevitable with procgenned serials'.

There are two engineers with nearly identical serials (because that happens with true randomness): 7672 and 7678. They'll probably get nicknames at some point.

That's the Doylist explanation. The Watsonian explanation of how TV serials are generated is in this post I made earlier this year.

9 notes

·

View notes

Text

The Importance of Steel Factory in Modern Industry

Steel Factory play a pivotal role in modern infrastructure and industrial development. As the backbone of construction, manufacturing, transportation, and various other sectors, steel production is essential to creating the durable materials that shape our daily lives. From skyscrapers to automobiles, bridges to household appliances, steel is an indispensable resource that drives economic growth and innovation.

What is a Steel Factory?

A steel factory, also known as a steel mill, is a facility where raw materials such as iron ore, coal, and limestone are transformed into steel. These factories are responsible for producing different types of steel, each with varying characteristics and properties depending on its intended use. Steel factories utilize a combination of processes, including melting, casting, rolling, and shaping, to produce steel in the form of sheets, bars, coils, or beams.

There are two primary types of steel mills:

Integrated Steel Mills: These plants handle the entire production process, from refining raw materials to producing finished steel.

Mini Mills: These focus on recycling scrap steel and refining it into new steel products, contributing to sustainable manufacturing practices.

The Steel Production Process

The production of Steel Factory involves several key steps. The most common method is the Basic Oxygen Furnace (BOF) process, while the Electric Arc Furnace (EAF) method is used in mini mills for recycling scrap metal.

Ironmaking: The first step involves extracting iron from iron ore in a blast furnace. The furnace heats the ore along with coke (a carbon-rich substance derived from coal) and limestone, producing molten iron and slag (a by-product used in other industries).

Steelmaking: In the steelmaking phase, molten iron is combined with scrap metal and oxygen to reduce carbon content and impurities. This process, typically done in a basic oxygen furnace, creates liquid steel.

Casting: The liquid steel is then poured into molds to create solid shapes, which can include slabs, billets, and blooms. These are the raw forms of steel that will be further processed.

Rolling and Shaping: After cooling, the steel is rolled into thinner sheets or shaped into desired forms, such as bars or beams. These products are then ready for industrial use.

Finishing: Depending on the intended use of the steel, additional processes such as heat treatment, coating, or surface treatments may be applied to enhance durability, corrosion resistance, and aesthetic appeal.

The Role of Steel Factories in Infrastructure

Steel is a foundational material in modern infrastructure. Steel Factory supply the structural components needed for building everything from bridges to high-rise buildings. Steel’s strength, flexibility, and resilience make it the ideal material for supporting heavy loads and withstanding environmental stressors.

Construction: Steel beams, girders, and rebar are essential components in large-scale construction projects, providing stability to buildings and bridges.

Transportation: Steel factories produce materials for the automotive, shipbuilding, and railway industries. From the frames of vehicles to the tracks that trains run on, steel is integral to modern transportation systems.

Energy: Steel is used in the construction of oil rigs, wind turbines, and pipelines, playing a crucial role in energy infrastructure.

Steel Factories and Sustainability

As concerns about climate change and environmental degradation grow, steel factories are making significant strides toward sustainability. Many steel producers are shifting towards eco-friendly methods, such as using Electric Arc Furnaces to recycle scrap metal and adopting cleaner technologies that reduce emissions.

Innovations in Steel Manufacturing

Steel Factory are at the forefront of technological innovation. Advances in automation, artificial intelligence, and robotics have transformed the industry, increasing efficiency and reducing costs. Some key innovations include:

High-Strength Steel: New steel alloys are being developed that offer higher strength while using less material, making them more environmentally friendly and cost-effective.

3D Printing with Steel: The rise of additive manufacturing has introduced the possibility of 3D printing with steel, which could revolutionize industries such as aerospace and automotive engineering.

Smart Factories: The integration of IoT (Internet of Things) devices allows for better monitoring of equipment and processes in steel mills, optimizing production and minimizing downtime.

Conclusion

Steel Factory are the cornerstone of industrial progress. They provide the raw materials necessary for countless industries, from construction to transportation and energy. As technological advancements and environmental concerns shape the future of steel production, these factories continue to adapt and innovate, ensuring that steel remains a vital part of modern life.

The next time you see a skyscraper, drive a car, or walk across a bridge, remember that it all started in a steel factory—a place where raw materials are transformed into the building blocks of our world.

Metal Berg Manufacturing Company Factory

Block 16 Plot 283, Green Estate, Amuwo Odofin Estate 102102, Lagos, Nigeria

+234 803 044 2676

2 notes

·

View notes

Text

High-temperature flames are used to create a wide variety of materials -- but once you start a fire, it can be difficult to control how the flame interacts with the material you are trying to process. Researchers have now developed a technique that utilizes a molecule-thin protective layer to control how the flame's heat interacts with the material -- taming the fire and allowing users to finely tune the characteristics of the processed material. "Fire is a valuable engineering tool -- after all, a blast furnace is only an intense fire," says Martin Thuo, corresponding author of a paper on the work and a professor of materials science and engineering at North Carolina State University. "However, once you start a fire, you often have little control over how it behaves. "Our technique, which we call inverse thermal degradation (ITD), employs a nanoscale thin film over a targeted material. The thin film changes in response to the heat of the fire, and regulates the amount of oxygen that can access the material. That means we can control the rate at which the material heats up -- which, in turn, influences the chemical reactions taking place within the material. Basically, we can fine-tune how and where the fire changes the material."

Read more.

#Materials Science#Science#Nanotechnology#Flames#Thin films#North Carolina State University#Coatings#Glass#Carbon

7 notes

·

View notes

Text

So most of this is true. We are very good at making things boil to create steam to make the spinny thing give us power. But. We are also very good at making things EXPLODE to make the spinny thing give us power.

This was touched on briefly in regards to internal combustion engines, but this is true for any gas turbine engine. If you cram a bunch of oxygen into a small space and add some fuel and then EXPLODE it, you get a lot of hot air pushing out of that area really quickly, which will make your turbine spin as well. This is a gas turbine, most commonly seen in jet engines, but there are also industrial gas engines (as seen at natural gas power plants, for example) that are basically GIANT jet engines that don't fly.

Part of the reason natural gas is more efficient for energy generation is because you don't have to heat the water to make the steam to turn the turbine to get the power, you just explode the gas. You also get a lot fewer problems with the turbine when steam isn't involved, because steam has a habit of causing pitting on the turbine blades if it isn't dry enough. (Yeah, dry steam is a thing. Try not to think about it too hard else you'll break your brain.) This means having to replace the turbine a lot more often--which is fine if your cooling loop is separate from your primary heating loop, like in most types of nuclear reactors, but if you've got a boiling water reactor, your turbine is exposed to irradiated steam so maintenance becomes a lot harder.

All that being said--we have been using water and wind to generate power for thousands of years. Not electricity, but power, which is really what we're talking about when we talk about making the spinny thing go. Because the spinny thing is creating mechanical power, which is then used to make an electric engine go WEEEEEEEE to give us electric power. But mechanical power can be used directly for things like pumping water or grinding grain or operating bellows to fuel really huge blast furnaces for smelting iron.

Humans have been really good at finding ways to make mechanical power and reduce the amount of energy we are personally required to put into getting that mechanical power. Because humans are relatively weak and generally lazy in the sense that we're always looking for an easier way to do something difficult.

Steam power, in the grand scheme of things, is relatively new, and frankly it took a lot of trial and error (and explosions) before it could be used reliably and efficiently, which is also partly why we don't see things like steam powered cars or nuclear powered jet engines (though they tried, for both). It just isn't efficient or practical. And inherently one of the ways to make steam power more efficient is to pressurize all that lovely boiling water (whatever the heat source), which is where the explosions come in. Think about a bottle of soda exploding, but now imagine that with a giant metal tank and boiling water, and you have the horror of late 19th century steam power. The number of trains and ships that exploded was not inconsequential. There was an entire insurance company created just to deal with steam boilers because no one else wanted to touch them. The American Society of Mechanical Engineers was basically created because a bunch of engineers got together and said "right, there has to be some way to do this without blowing people up" and the pressure vessel regulations came into existence. But that was in 1880, and if you look at the development of steam powered energy, not much has changed except the source of the heat.

(Yes, Vitruvius created a bladeless radial steam engine in ~30 BCE, but you'll note that it never really took off, mostly because it lacked a good way to do anything with all the spinning, like turning a gear shaft.)

So yes. Nuclear power is really no different from coal power, they just use different sources to make sources hot. And steam power is great, but at the end of the day, we have come up with lots of better ways to create power. Steam is just the best way we've found so far to create a lot of power all at once. And with nuclear power in particular, we can get a lot of electrical power out of the system with very little energy being put into it. One uranium fuel pellet that can fit in your hand is equivalent to 40 tons of coal, the size of a large dump truck.

So if you need lots of electrical power, steam is one of your best options. But if you're just looking for mechanical power, there are lots of better options.

nuclear power is impressive until you get up to why. "we use the most precisely engineered machinery ever created to split atoms to release energy" oh yeah how come? "boil water to turn a fan" get the fuck out

#power generation#making things explode#nuclear power generation#humans are inherently lazy#mechanical power#electrical power#spinny things make both

73K notes

·

View notes

Text

Rethinking Green Energy’s Workhorse: A Fresh Look at the Alkaline Electrolyser

The race to decarbonize the planet is not a distant dream anymore—it’s a present-day engineering challenge. While flashy technologies like hydrogen fuel cells and carbon capture grab headlines, one technology quietly shoulders the bulk of clean hydrogen production today: the Alkaline electrolyser. Reliable, time-tested, and surprisingly versatile, this underdog of the hydrogen economy deserves a more thoughtful look, especially in an era driven by net-zero ambitions.

In this blog, we’ll step away from surface-level discussions and dive deep into the why, how, and what-next of the Alkaline electrolyser—and why its legacy might just be the foundation of our sustainable future.

The Basics: What Is an Alkaline Electrolyser?

At its core, an Alkaline electrolyser splits water (H₂O) into hydrogen (H₂) and oxygen (O₂) using electricity. It does this through electrolysis, a process that involves applying direct current to electrodes immersed in a liquid alkaline electrolyte—usually potassium hydroxide (KOH) or sodium hydroxide (NaOH). This causes hydrogen ions to migrate and collect at the cathode while oxygen is released at the anode.

This may sound basic, but don’t be fooled. The beauty of the alkaline system lies in its simplicity, durability, and scalability. Developed over a century ago, this technology has been a workhorse in industries like chemical manufacturing and metallurgy, and it's now making a huge comeback thanks to the green hydrogen boom.

Why the Renewed Interest?

In a world leaning into green hydrogen as a fuel of the future, choosing the right electrolyser technology is critical. PEM (Proton Exchange Membrane) and Solid Oxide Electrolysers are newer, flashier options, but they come with higher costs and complex material requirements.

So why is the Alkaline electrolyser still relevant?

Mature Technology: It’s been tested in real industrial settings for decades, making it extremely reliable.

Low Capital Cost: Compared to PEM, alkaline systems are cheaper to produce and maintain.

Easier Maintenance: Less wear-and-tear, no rare-earth catalysts, and off-the-shelf components.

When paired with renewable power (solar or wind), this technology becomes an economical pathway to producing green hydrogen—fuel made without emitting carbon dioxide.

A Human Story: From Coal to Clean

Let’s bring this closer to home.

Imagine a mid-sized steel manufacturing plant in Pune, India. For decades, it ran on coal-fired blast furnaces, emitting thousands of tons of CO₂ every year. Local air quality declined, asthma cases increased, and the plant’s electricity bill became unbearable.

Now fast-forward to today. That same plant has replaced a section of its fossil-fuel-based hydrogen supply chain with an onsite Alkaline electrolyser powered by solar panels on its roof. The result? A 65% reduction in carbon emissions from hydrogen processes. Families living near the plant breathe easier, and the company earns carbon credits while improving its public image.

This isn't fiction—it’s happening around the world.

Technical Deep Dive: How It Stacks Up

Feature

Alkaline Electrolyser

PEM Electrolyser

Solid Oxide

Electrolyte

KOH or NaOH

Polymer membrane

Ceramic

Operating Temp

60–80°C

50–80°C

600–800°C

Current Density

Lower

Higher

Moderate

Hydrogen Purity

High

Very High

Very High

Cost

Low

High

High

Durability

High

Medium

Low

While PEM may win on compactness and efficiency in small-scale applications (like mobility), alkaline systems dominate where scalability, cost, and reliability are more important—especially in large industrial setups.

The Environmental Payoff

Green hydrogen made from an Alkaline electrolyser has profound environmental implications:

Zero CO₂ Emissions: When powered by renewable energy, the process is virtually carbon-free.

Water Use Efficiency: Newer systems reclaim wastewater for electrolysis, reducing water stress.

Low Toxicity: The alkaline solution is safer and easier to dispose of compared to acidic electrolytes.

And let’s not forget the larger context. By replacing hydrogen produced from natural gas (grey hydrogen), we avoid nearly 10 tons of CO₂ per ton of hydrogen—a giant leap for any industry.

Challenges? Yes, But Not Deal-Breakers

Like any technology, the Alkaline electrolyser has limitations:

Response Time: It doesn’t ramp up or down as quickly as PEM systems, making it less suitable for intermittent renewable sources—unless paired with battery storage or grid-buffering.

Larger Footprint: Alkaline systems require more space, which may be an issue in urban setups.

Hydrogen Purity: Although high, it may require post-purification for applications like fuel cells.

However, ongoing R&D is addressing these challenges through innovations like:

Advanced catalysts to improve efficiency

Modular designs for faster deployment

AI-integrated systems for predictive maintenance and load balancing

Looking Ahead: Where Does It Fit in a Green Future?

By 2030, global green hydrogen demand is expected to grow more than 5-fold. While many newer technologies are being explored, the industrial world won’t wait for perfection. They need solutions that work now—and the Alkaline electrolyser is that solution.

From steel and ammonia to refineries and data centers looking to decarbonize backup power systems, this humble piece of electrochemical machinery will be central in redefining global energy.

Final Thoughts: It’s Time to Respect the Classics

In a world obsessed with disruption, it's easy to overlook the value of refinement. The Alkaline electrolyser may not grab headlines, but its reliability, cost-effectiveness, and green potential make it indispensable in our collective march toward a cleaner planet.

When you think about innovation, don’t always think “new.” Sometimes, innovation is about using the right tool better, smarter, and more sustainably.

And sometimes, that tool is a 100-year-old electrolyser quietly reinventing the future.

0 notes

Text

Comprehensive Analysis of Single-stage Double-suction Centrifugal Fans

The single-stage double-suction centrifugal fan is a specially designed centrifugal fan featuring a double-sided air intake structure and a single-stage impeller, suitable for high-flow ventilation requirements. The following will provide a comprehensive introduction from aspects such as structural features, working principle, performance parameters, application scenarios, installation and maintenance, as well as market conditions.

I. Structure and Working Principle

Structural features

The single-stage double-suction centrifugal fan has the following significant structural features:

Double-sided intake design : The impeller has suction ports on both sides, and the gas enters the impeller simultaneously from both sides to form a symmetrical flow

Double-bearing structure : With double-bearing design, high reliability in operation, safe and stable

Axial force balance : Due to the symmetrical intake on both sides, the axial force on the impeller is basically eliminated, and the wear of the two bearings is basically the same

Working Principle

The working principle of the single-stage double-suction centrifugal fan is based on the principle of centrifugal force:

Intake stage : Gas enters the center area of the impeller simultaneously from the suction ports on both sides of the fan

Acceleration phase : The high-speed rotating impeller accelerates the gas under the effect of centrifugal force and throws it towards the outer edge of the impeller

Pressure conversion : The gas slows down in the volute, kinetic energy is converted into pressure energy, and is finally discharged from the air outlet

Ii. Performance Characteristics and Technical Parameters

Performance advantages

The single-stage double-suction centrifugal fan has the following outstanding performance characteristics:

The performance characteristics illustrate the advantages

High FLOW Up to twice the FLOW rate of single suction to meet high flow rate requirements

Run SMOOTHLY Axial force automatic balance reduce bearing load, extend service life

High EFFICIENCY ENERGY SAVING The optimized design impeller and flow channel reduce energy consumption, low operating cost

Iii. Application Fields

Single-stage double-suction centrifugal fans, with their large flow rate and stable performance, are widely used in the following fields:

Commercial and public buildings

Ventilation systems for hotels, conference venues, cinemas, theaters and large shopping malls

Circulate the air in coordination with the central air conditioning system

Industrial field

Ventilation in industrial plants and transportation of process gases

Emissions of harmful gases from chemical plants and pharmaceutical factories

Metallurgical blast furnace air blowing and oxygen steelmaking

Blowers and combustion-supporting fans for industrial furnaces

Summary

Single-stage double-suction centrifugal fans, with their double-sided air intake design, high flow rate characteristics and stable operation performance, have become ideal ventilation equipment for many industrial, commercial and environmental protection fields. The axial force balance brought by its symmetrical structure and the double-support design ensure long-term reliable operation, making it particularly suitable for occasions that require large flow ventilation. When selecting a model, factors such as flow rate, pressure, medium characteristics and installation environment should be comprehensively considered, and products from reputable brands should be chosen. Correct installation and regular maintenance are the keys to ensuring the efficient and stable operation of the fan. With the increasing requirements for energy conservation and environmental protection, high-efficiency and energy-saving single-stage double-suction centrifugal fans will become the mainstream choice in the future market.

E-mail: [email protected]

0 notes

Text

Sustainable Steel Market : Trends, Share, and Growth Drivers

The sustainable steel market is expected to grow from an estimated USD 331.5 million in 2024 to USD 708.2 million in 2033, at a CAGR of 8.80%. Growing sustainable steel market : The market is fueled by higher global demand for environment-friendly and energy-efficient alternatives during the production of steel. In addition, this demand is augmented by increased stringency in regulations related to carbon emissions. End. It would thus be possible to reduce the environmental footprint with the shift taking place from old-fashioned ways of steel production, more energy-intensive, to sustainable ones, like using recycled steel, and increasing popularity of "green steel.

The report, additionally, offers a comprehensive SWOT analysis and Porter’s Five Forces analysis to offer a better understanding of the competitive landscape of the industry. It also covers strategies adopted by prominent players such as mergers and acquisitions, collaborations, joint ventures, product launches, and brand promotions, among others. The report aims to offer the readers a holistic understanding of the relevant features of the industry.

Claim Your FREE Sample Copy with Table of content@ https://www.emergenresearch.com/request-sample/3213

The leading market contenders listed in the report are: SSAB, Tata Steel, ArcelorMittal, Nucor, U.S. Steel, Baosteel, POSCO, JFE Steel, Hyundai Steel, Thyssenkrupp

The research study examines historic data from 2018 and 2020 to draw forecasts until 2030. The timeline makes the report an invaluable resource for readers, investors, and stakeholders looking for key insights in readily accessible documents with the information presented in the form of tables, charts, and graphs. To Visit Full Report & Table of Contents Sustainable Steel Market: https://www.emergenresearch.com/industry-report/sustainable-steel-market

Market Overview: The report bifurcates the Sustainable Steel market on the basis of different product types, applications, end-user industries, and key regions of the world where the market has already established its presence. The report accurately offers insights into the supply-demand ratio and production and consumption volume of each segment. Segments Covered in this report are:

End-User Application Outlook (Revenue, USD Million; 2020-2033)

Transportation

Building and Construction

Furniture and Appliances

Mechanical Equipment and Tools

Packaging

Others

Product Type Outlook (Revenue, USD Million; 2020-2033)

Recycled Steel

Green Steel

Technology Outlook (Revenue, USD Million; 2020-2033)

Sustainable Steel

Electric Arc Furnace (EAF)

Blast Furnace-Basic Oxygen Furnace (BF-BOF)

Others

Green Steel

Electric Arc Furnace (EAF)

Renewable Electric Arc Furnace (R-EAF)

Hydrogen Direct Reduced Iron Electric Arc Furnace (H2 DRI-EAF)

Others

The research report offers a comprehensive regional analysis of the market with regards to production and consumption patterns, import/export, market size and share in terms of volume and value, supply and demand dynamics, and presence of prominent players in each market. Get An Impressive Discount On This Report@ https://www.emergenresearch.com/request-discount/3213

Regional Analysis Covers: North America (U.S., Canada) Europe (U.K., Italy, Germany, France, Rest of EU) Asia Pacific (India, Japan, China, South Korea, Australia, Rest of APAC) Latin America (Chile, Brazil, Argentina, Rest of Latin America) Middle East & Africa (Saudi Arabia, U.A.E., South Africa, Rest of MEA)

Key reasons to buy the Global Sustainable Steel Market report:

The latest report comprehensively studies the global Sustainable Steel market size and provides useful inference on numerous aspects of the market, such as the current business trends, market share, product offerings, and product share.

The report offers an insightful analysis of the regional outlook of the market.

It offers a detailed account of the end-use applications of the products & services offered by this industry.

The report holistically covers the latest developments taking place in this industry. Therefore, it lists the most effective business strategies implemented by the market rivals for ideal business expansion.

Request Customization as per your specific requirement@ https://www.emergenresearch.com/request-for-customization/3213

About Us:

Emergen Research is a market research and consulting company that provides syndicated research reports, customized research reports, and consulting services. Our solutions purely focus on your purpose to locate, target, and analyse consumer behavior shifts across demographics, across industries, and help clients make smarter business decisions. We offer market intelligence studies ensuring relevant and fact-based research across multiple industries, including Healthcare, Touch Points, Chemicals, Types, and Energy. We consistently update our research offerings to ensure our clients are aware of the latest trends existent in the market. Emergen Research has a strong base of experienced analysts from varied areas of expertise. Our industry experience and ability to develop a concrete solution to any research problems provides our clients with the ability to secure an edge over their respective competitors.

Contact Us:

Eric Lee

Corporate Sales Specialist

Emergen Research | Web: www.emergenresearch.com

Direct Line: +1 (604) 757-9756

E-mail: [email protected]

Visit for More Insights: https://www.emergenresearch.com/insights

Explore Our Custom Intelligence services | Growth Consulting Services

Trending Titles: Nanoceramics Powder Market | Minimal Residual Disease Testing Market

Latest Report: Molecular Sieves Market | Microfluidics Prototype Market

0 notes