#asbestos gasket sheet

Explore tagged Tumblr posts

Text

Sealing Excellence- A Comprehensive Guide to Gaskets and Materials

Gaskets, often overlooked but indispensable, are the unsung heroes that ensure the smooth functioning of machinery and systems across various industries. This comprehensive guide unveils the world of gaskets and materials, shedding light on their critical role in maintaining seals, preventing leaks, and enhancing overall operational efficiency. Section 1: The Foundation – Understanding…

View On WordPress

#Asbestos Gasket Sheet#Asbestos Gaskets#Cylinder Head Facing Gasket#Gasket Material#Graphite Sheet#Industrial Gaskets

0 notes

Text

Sealing Excellence- A Comprehensive Guide to Gaskets and Materials

Gaskets, often overlooked but indispensable, are the unsung heroes that ensure the smooth functioning of machinery and systems across various industries. This comprehensive guide unveils the world of gaskets and materials, shedding light on their critical role in maintaining seals, preventing leaks, and enhancing overall operational efficiency.

Section 1: The Foundation - Understanding Gaskets

1.1 Definition and Function: Gaskets are sealing devices positioned between two mating surfaces to prevent leakage of fluids or gases. Their primary function is to create a barrier that withstands pressure, temperature, and environmental factors.

1.2 Types of Gaskets: Gaskets come in various types, each designed for specific applications. Common types include flat gaskets, spiral wound gaskets, ring gaskets, and asbestos gasket sheet, each with unique characteristics suited for different sealing requirements.

Section 2: Dive into Materials

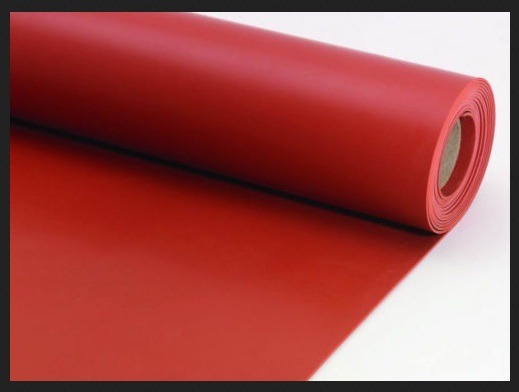

2.1 Rubber Gaskets: Natural rubber, synthetic rubbers like neoprene and silicone, are popular choices for gaskets due to their elasticity, flexibility, and resistance to certain chemicals.

2.2 Metal Gaskets: Materials such as stainless steel, copper, and aluminum are used for metal gaskets. These provide robustness, durability, and high-temperature resistance, making them ideal for demanding industrial gaskets applications.

2.3 Compressed Fiber Gaskets: Gaskets made from compressed fibers like asbestos-free materials or non-asbestos materials offer excellent sealing properties and are often chosen for their resistance to heat and pressure.

2.4 Graphite Gaskets: Known for their exceptional thermal conductivity and resistance to corrosive chemicals, graphite gaskets are preferred in high-temperature and high-pressure environments.

Section 3: Factors Influencing Material Selection

3.1 Temperature and Pressure: The operating conditions of a system, including temperature and pressure ranges, heavily influence the choice of gasket material. Matching these parameters ensures optimal performance and longevity.

3.2 Chemical Compatibility: Gaskets must be resistant to the specific chemicals they come into contact with. Selecting materials that are chemically compatible ensures the gasket's effectiveness over time.

3.3 Application-Specific Considerations: Whether it's a flange connection, pipe joint, or cylinder head, understanding the specific requirements of the application is crucial. Gasket materials must align with the mechanical and thermal demands of the system.

Section 4: Advancements in Gasket Technology

4.1 High-Performance Coatings: Innovative coatings enhance the properties of gasket materials, providing improved resistance to corrosion, wear, and extreme temperatures.

4.2 Nano-Material Integration: Incorporating nanotechnology into gasket manufacturing allows for the development of materials with enhanced strength, flexibility, and performance characteristics.

Conclusion:

In the dynamic landscape of industrial applications, gaskets and materials form the backbone of reliable and efficient systems. Understanding the nuances of gasket types and materials, and considering advancements in technology, is essential for engineers and manufacturers seeking optimal performance and longevity in their equipment. As industries evolve, the ongoing innovation and refinement of gasket materials will continue to contribute to the seamless operation of machinery across the globe.

Original Source: Gasket and Materials

#gasket sheet#industrial#gaskets#gasket material#Rubber Gasket Sheet#Asbestos Gasket Sheet#Gasket Material#Graphite Sheet#Asbestos Gaskets#Silicone Sheets#Gland Packing

0 notes

Text

0 notes

Text

Sealing Solutions Redefined- Exploring Gaskets, Materials, and the Innovation of Silicone Sheets

In the intricate machinery of various industries, the humble gasket stands as a guardian, ensuring tight seals and preventing leaks that could disrupt operations. At the heart of these sealing solutions lie carefully selected materials, each chosen for its unique properties and suitability for specific applications. Among these materials, silicone sheets have emerged as a versatile option,…

View On WordPress

2 notes

·

View notes

Text

What to Consider When Choosing Your Gasket Material and Type

A gasket may be a combination of materials, which is employed to stop any fluid entry between two static components. The success of the industrial gasket and materials depends on the sort of fabric utilized in the manufacturing process. counting on the sort of application, a spread of materials are wont to produce gaskets of…

A gasket may be a combination of materials, which is employed to stop any fluid entry between two static components. The success of the industrial gasket and materials depends on the sort of fabric utilized in the manufacturing process. counting on the sort of application, a spread of materials are wont to produce gaskets of the many shapes and sizes. Gaskets also are chosen supported factors like application temperature, pressure, electrical conduciveness, and resistance to extreme environments.

Types of Gasket Materials

While the materials wont to produce gaskets are numerous, on a general basis, they will be segregated into 3 types:

Fibrous materials

Elastometric materials

Metallic materials

Fibrous materials: These materials are made using organic fibers. The gasket sheet is skilled as a binding solution to assist develop the gasket material. they need excellent absorption properties and are flexible enough to be made into various shapes. Some common samples of fibrous gasket materials are:

Asbestos– In fibrous materials, asbestos is perhaps the foremost recognizable and popular material. It is often used for sealing applications during a sort of environment. Asbestos maintains its shape and strength up to 450oF. It doesn’t emit any toxic odor and is safe to handle.

Carbon fibers- As a cloth, carbon fiber has the power to face up harsh chemical environments. It is often used for applications that have high temperatures and pressures. it’s seen as a perfect material because of its low permeability. However, it’s not suitable for oxidization.

Aramid- An artificial fiber, aramid has been used as a substitute for asbestos. it’s a high resistance towards heat and organic solvents. Though it doesn’t have a freezing point, it does tend to degrade when temperatures reach 500oC. However, it doesn’t react well to salts and acids, also as direct contact with UV rays.

Elastometric materials: because the name suggests, these materials are produced using elastomers with various composites. This makes them extremely popular materials for a spread of industries thanks to their high performance and quality. a couple of well-known elastomers are given below:

Silicone- Perhaps the foremost recognized material for gaskets, silicone is well-known for its waterproof properties. It works effectively in extreme temperatures and is immune to UV and ozone elements. Silicone is often easily molded or cut using water jet cutting systems counting on the sort of application.

Rubber- As an organic material, natural rubber has good resistance to heat, and functions wells as a cushioning pad. When utilized in gaskets, it can recover to its original shape from medium temperatures. It is often wont to protect gaskets from alkalis, mild acids, and inorganic salts.

Neoprene- this will be used as an appropriate option for rubber. The advantage that neoprene has is that while it’s almost like rubber in terms of its resistance to acids and alkalis, it also can work against oils, petroleum, and other fuels. However, it’s not recommended to be used against hydrocarbons.

Metallic materials: Usually, the various sorts of metals wont to produce gaskets are a variety of steels, alloys, titanium, copper, and aluminum.

Carbon Steel– this is often one of the favored metallic choices for gaskets. The larger the quantity of carbon within the alloy, the harder and stronger it becomes. Unfortunately, the carbon content has got to be balanced with other metal properties otherwise it can lower the general freezing point.

Aluminum– Aluminum is understood for its lightweight, machinability, and high resistance to corrosion. Aluminum alloys are an honest choice for gaskets thanks to their weldability and strength.

Titanium– Considered to be almost like 304 chrome steel, titanium is understood for its lightweight, strength, and corrosion resistance. It is often used for very high temperatures, and it’s perfect for oxidizing media.

An understanding of the varied sorts of gasket materials used can assist you to decide the proper type to use in your industrial application.

Original Source: Industrial Gaskets

#gaskets#industrial#gasket material#gasket sheet#Asbestos Gaskets#Gasket Material#Rubber Gasket Sheet#Ready Cut Gaskets#Industrial Gaskets

2 notes

·

View notes

Text

#gaskets company in india#gasket sheet manufacturer#non asbestos gasket sheet#asbestos gasket sheet#spiral wound gasket#sheet gasket

0 notes

Text

Top 10 Benefits of CNAF Gaskets

1. Superior Sealability: CNAF gaskets provide a tight and reliable seal, preventing fluid and gas leakages.

2. High Temperature Resistance: These gaskets can withstand extreme heat conditions, making them suitable for applications involving steam and hot fluids.

3. Chemical Compatibility: CNAF gaskets are resistant to various chemicals, ensuring effective sealing without degradation.

4. Excellent Compression and Recovery: These gaskets deform to fill irregularities, maintaining consistent sealing performance even after compression.

5. Reduced Leakage: CNAF gaskets significantly minimize the risk of leakage, enhancing safety and reducing maintenance costs.

6. Easy Installation and Removal: These gaskets are easy to install and remove, saving time and effort during maintenance.

7. Cost-Effective Solution: CNAF gaskets offer affordability without compromising performance and durability.

8. Versatility: These gaskets can be used in diverse industries and applications, accommodating different fluids, temperatures, and pressures.

9. Longevity and Durability: CNAF gaskets are robust and resistant to wear, tear, and deformation, ensuring long-term reliability.

10. Environmental Friendliness: These gaskets are asbestos-free, providing a safe sealing solution and contributing to a healthier work environment.

In conclusion, Sealmax offers superior sealability, high temperature resistance, and chemical compatibility. With easy installation and cost-effectiveness, Sealmax provides durable and reliable sealing solutions. Choose Sealmax for quality gaskets that ensure leak-free operations.

0 notes

Text

Non Asbestos Gasket Sheet in Saudi Arabia

We are No.1 Non Asbestos Gasket / Gasket sheet manufacturers and suppliers in UAE, Oman, Saudi Arabia, Kuwait, Qatar, Iran, Iraq, Kazakhstan, Bahrain, Jordan, Egypt, Nigeria, Yemen, Singapore, Malaysia, and India Read more...

0 notes

Text

What to Consider When Choosing Your Gasket Material and Type

A gasket may be a combination of materials, which is employed to stop any fluid entry between two static components. The success of the industrial gasket and materials depends on the sort of fabric utilized in the manufacturing process. counting on the sort of application, a spread of materials are wont to produce gaskets of… A gasket may be a combination of materials, which is employed to stop…

View On WordPress

#Asbestos Gaskets#Gasket Material#industrial gasket and materials#Industrial Gaskets#Klinger Gasket#Rubber Gasket Sheet

0 notes

Text

Exploring Gaskets, Materials, and the Versatility of Graphite Sheets

Gaskets stand as silent sentinels, guarding the integrity of industrial systems by forming crucial seals against the elements. The materials from which these gaskets are crafted play a pivotal role in determining their performance and reliability. Among the diverse array of materials, graphite sheets have emerged as versatile contributors to effective sealing solutions. This exploration delves into the world of gaskets, the materials that shape them, and the unique characteristics of graphite sheets.

Section 1: The Art of Sealing - Gaskets Unveiled1.1 Definition and Purpose:Gaskets serve as essential components, creating a barrier between two mating surfaces to prevent leakage of fluids or gases.The primary purpose is to maintain the integrity of systems by withstanding pressure, temperature variations, and external environmental factors.1.2 Types of Gaskets:Flat gaskets, spiral wound gaskets, ring gaskets, and graphite sheet gaskets are among the diverse types, each tailored to specific applications and requirements.The choice of gasket type depends on factors such as pressure, temperature, and the characteristics of the surfaces being sealed.Section 2: Crafting Reliability - Gasket Materials Explored2.1 Rubber Gaskets:Materials like neoprene, EPDM, and silicone offer elasticity, flexibility, and resistance to various chemicals.Commonly used in applications requiring a dependable seal against water, weather, and mild chemicals.2.2 Metal Gaskets:Stainless steel, copper, and aluminum provide robustness and durability.Ideal for high-pressure and high-temperature environments, commonly found in industries such as oil and gas.2.3 Compressed Fiber Gaskets:Asbestos-free and non-asbestos materials, along with aramid fibers, offer excellent compressibility and chemical resistance.Well-suited for flange connections, pipe joints, and applications with moderate temperature and pressure.Section 3: The Graphite Advantage - Understanding Graphite Sheets3.1 Composition and Characteristics:Graphite sheets are composed of layers of graphite, providing exceptional thermal conductivity, chemical resistance, and sealing capabilities.The sheets are flexible, allowing them to conform to irregular surfaces, ensuring a tight seal.3.2 Applications:Graphite sheets find applications in high-temperature and high-pressure environments where traditional gasket materials may falter.Commonly used in heat exchangers, gaskets for engines, and sealing applications in the chemical processing industry.3.3 Benefits of Graphite Sheets:Thermal stability allows for reliable sealing in extreme temperature conditions.Chemical resistance ensures longevity in the presence of corrosive substances.Flexibility and conformability enable effective sealing on uneven or irregular surfaces.Conclusion:In the ever-evolving landscape of industrial engineering, the choice of gaskets and materials is paramount to the efficiency and longevity of systems. As we venture into the future, graphite sheets stand out as a remarkable solution, showcasing the adaptability and resilience required for sealing in the most demanding environments. The synergy between gaskets, materials, and innovative solutions like graphite sheets continues to shape a future where reliability and performance go hand in hand.Original Source: Industrial Gaskets

0 notes

Text

The primary function of an industrial gasket is to create a reliable and durable seal between two surfaces, ensuring that there is no leakage or seepage of fluids or gases. For more information check out this blog.

#Gasket Sheets#Gasket sheet Manufacturer in India#gasket seal#gasket sheet suppliers#asbestos gasket

0 notes

Text

Rigid Mica Sheets Insulation | Axim Mica

Mica Sheets are the foundation from which mica parts are made. Depending on your application, the correct mica sheet for an application depends on the material: Muscovite, or Phlogopite. Depending on the level of heat resistance needed, the thickness of mica sheet will also vary. Mica sheets are not uniform, and they can be ordered in various sizes and different degrees of smoothness based on the needs of the customer.

Mica Sheets Application:

Ax-THERM M & P mica sheets are used for high-performance thermal and electrical insulation in a broad range of industries such as

Heating elements for electrical & thermo mechanical equipment

Construction of induction, arc or high frequency furnaces

High voltage applications

High thermal applications

Industrial sealing & gasket industries (e.g. oil & gas distribution)

Ax-THERM M & P mica sheets are the ideal alternative for asbestos insulations.

Good resistance to high temperatures & chemicals, low heat conductivity, high dielectric strength, good high-voltage proof performance. Fire resistance classification UL94 (94 V-0), BS 479 (class 1), NBN 21-203 (A1).

2 notes

·

View notes

Text

Flange Gaskets: A Critical Component in Piping Systems

Flange gaskets are essential components in piping systems, used to create a seal between two flanges that are bolted together. These gaskets prevent leaks and ensure the integrity of the piping system.

Types of Flange Gaskets

There are numerous types of flange gaskets available, each with its own unique properties and applications. Some common types include:

Flat gaskets: These are the simplest type of gasket, made from a flat sheet of material.

Compressed fiber gaskets: These gaskets are made from compressed fibers, such as asbestos or graphite.

Metallic gaskets: Metallic gaskets are made from various metals, such as copper, aluminum, or stainless steel.

Spiral wound gaskets: These gaskets are made from a metal strip wound into a spiral shape, often with an inner core of graphite or PTFE.

Expansion joint gaskets: These gaskets are designed to accommodate thermal expansion and contraction in piping systems.

Factors to Consider When Selecting Flange Gaskets

When selecting flange gaskets, several factors must be considered:

Pressure: The gasket must be able to withstand the operating pressure of the piping system.

Temperature: The gasket must be compatible with the temperature range of the fluid being transported.

Chemical compatibility: The gasket material must be resistant to the chemicals being handled.

Flange type: The type of flange (e.g., slip-on, weld neck) will determine the appropriate gasket type.

Joint sealing requirements: The gasket must be able to create a reliable seal under the specific conditions of the application.

Platinex Piping Solutions

Platinex is a renowned brand offering high-quality stainless steel piping solutions, including flange gaskets. Manufactured by Ratnamani Metals and Tubes Limited (RMTL), a leading Indian stainless steel company, Platinex flange gaskets are known for their:

Superior quality: Platinex gaskets are manufactured using advanced techniques and adhere to strict quality standards.

Wide range of materials: They offer a variety of gasket materials to suit different applications.

Customizable solutions: Platinex can provide customized gaskets to meet specific requirements.

Additional Manufacturers and Suppliers

Apart from Platinex, there are several other reputable manufacturers and suppliers of flange gaskets:

Parker Hannifin: A global leader in motion and control technologies, Parker Hannifin offers a wide range of gaskets and seals.

Garlock: A leading manufacturer of gaskets and seals for various industries.

Flexitallic: A global supplier of high-performance gaskets and sealing solutions.

Local Plumbing Supply Stores: Consider local plumbing supply stores for smaller quantities or specific regional requirements.

By carefully considering these factors and selecting the appropriate flange gasket, you can ensure the integrity and reliability of your piping system.

0 notes