#non asbestos gasket sheet

Explore tagged Tumblr posts

Text

0 notes

Text

Top 10 Benefits of CNAF Gaskets

1. Superior Sealability: CNAF gaskets provide a tight and reliable seal, preventing fluid and gas leakages.

2. High Temperature Resistance: These gaskets can withstand extreme heat conditions, making them suitable for applications involving steam and hot fluids.

3. Chemical Compatibility: CNAF gaskets are resistant to various chemicals, ensuring effective sealing without degradation.

4. Excellent Compression and Recovery: These gaskets deform to fill irregularities, maintaining consistent sealing performance even after compression.

5. Reduced Leakage: CNAF gaskets significantly minimize the risk of leakage, enhancing safety and reducing maintenance costs.

6. Easy Installation and Removal: These gaskets are easy to install and remove, saving time and effort during maintenance.

7. Cost-Effective Solution: CNAF gaskets offer affordability without compromising performance and durability.

8. Versatility: These gaskets can be used in diverse industries and applications, accommodating different fluids, temperatures, and pressures.

9. Longevity and Durability: CNAF gaskets are robust and resistant to wear, tear, and deformation, ensuring long-term reliability.

10. Environmental Friendliness: These gaskets are asbestos-free, providing a safe sealing solution and contributing to a healthier work environment.

In conclusion, Sealmax offers superior sealability, high temperature resistance, and chemical compatibility. With easy installation and cost-effectiveness, Sealmax provides durable and reliable sealing solutions. Choose Sealmax for quality gaskets that ensure leak-free operations.

0 notes

Text

#gaskets company in india#gasket sheet manufacturer#non asbestos gasket sheet#asbestos gasket sheet#spiral wound gasket#sheet gasket

0 notes

Text

Industrial Gaskets play a crucial role in the automotive industry as they are used to seal the gaps between two mating surfaces and prevent leaks of fluids, gases, or air.

#gaskets company in india#gasket sheet manufacturer#spiral gasket suppliers#industrial gasket#gasket sheets#gasket seal#gasket sheet suppliers#asbestos gasket#gasket manufacturer in india#non asbestos gasket

0 notes

Text

Searching for premium-quality compressed non-asbestos fibre gasket sheets (CNAF), that are specially made using aramid fibres and filler materials. Learn more!

0 notes

Text

Understanding Flange Metallic Gaskets

Understanding Flange Metallic Gaskets

Flange metallic gaskets are essential components in various industrial applications, particularly in the oil and gas industry. They are used to create a static seal between two flange faces, under different operating conditions, with varied pressure and temperature ratings.Get more news about Flange Metallic Gasket,you can vist our website!

Types of Flange Gaskets

There are several types of flange gaskets, each with its unique properties and applications. The most common types include non-asbestos gaskets, spiral wound gaskets, and ring joint gaskets.

Non-Asbestos Gaskets

Non-asbestos gaskets are the simplest type of gasket for flanges. They are produced by cutting graphite, organic, or inorganic non-asbestos sheets into shape. These gaskets suit low pressure, low temperature, and non-critical piping and plumbing applications. Non-asbestos gaskets have fully replaced asbestos gaskets due to the health risks associated with the production, use, and disposal of asbestos materials.

Spiral Wound Gaskets

Spiral wound gaskets feature a metal sealing element filled with graphite, PTFE, ceramic fibers, and non-asbestos fibers. These gaskets are classified as “semi-metallic” gaskets. They are ideal for standard flanges, heat exchangers, boiler handholes, manholes, and other high-temperature, high-pressure applications3.

Ring Joint Gaskets

Ring joint gaskets are used for RTJ flange faces. They are suitable for higher temperature and pressure oil and gas applications.

Conclusion

In conclusion, flange metallic gaskets play a crucial role in ensuring the integrity and efficiency of industrial systems. Selecting the right gasket type is vital for the safe and efficient operation of these systems.

0 notes

Text

Exploring Gaskets, Materials, and the Versatility of Graphite Sheets

Gaskets stand as silent sentinels, guarding the integrity of industrial systems by forming crucial seals against the elements. The materials from which these gaskets are crafted play a pivotal role in determining their performance and reliability. Among the diverse array of materials, graphite sheets have emerged as versatile contributors to effective sealing solutions. This exploration delves into the world of gaskets, the materials that shape them, and the unique characteristics of graphite sheets.

Section 1: The Art of Sealing - Gaskets Unveiled1.1 Definition and Purpose:Gaskets serve as essential components, creating a barrier between two mating surfaces to prevent leakage of fluids or gases.The primary purpose is to maintain the integrity of systems by withstanding pressure, temperature variations, and external environmental factors.1.2 Types of Gaskets:Flat gaskets, spiral wound gaskets, ring gaskets, and graphite sheet gaskets are among the diverse types, each tailored to specific applications and requirements.The choice of gasket type depends on factors such as pressure, temperature, and the characteristics of the surfaces being sealed.Section 2: Crafting Reliability - Gasket Materials Explored2.1 Rubber Gaskets:Materials like neoprene, EPDM, and silicone offer elasticity, flexibility, and resistance to various chemicals.Commonly used in applications requiring a dependable seal against water, weather, and mild chemicals.2.2 Metal Gaskets:Stainless steel, copper, and aluminum provide robustness and durability.Ideal for high-pressure and high-temperature environments, commonly found in industries such as oil and gas.2.3 Compressed Fiber Gaskets:Asbestos-free and non-asbestos materials, along with aramid fibers, offer excellent compressibility and chemical resistance.Well-suited for flange connections, pipe joints, and applications with moderate temperature and pressure.Section 3: The Graphite Advantage - Understanding Graphite Sheets3.1 Composition and Characteristics:Graphite sheets are composed of layers of graphite, providing exceptional thermal conductivity, chemical resistance, and sealing capabilities.The sheets are flexible, allowing them to conform to irregular surfaces, ensuring a tight seal.3.2 Applications:Graphite sheets find applications in high-temperature and high-pressure environments where traditional gasket materials may falter.Commonly used in heat exchangers, gaskets for engines, and sealing applications in the chemical processing industry.3.3 Benefits of Graphite Sheets:Thermal stability allows for reliable sealing in extreme temperature conditions.Chemical resistance ensures longevity in the presence of corrosive substances.Flexibility and conformability enable effective sealing on uneven or irregular surfaces.Conclusion:In the ever-evolving landscape of industrial engineering, the choice of gaskets and materials is paramount to the efficiency and longevity of systems. As we venture into the future, graphite sheets stand out as a remarkable solution, showcasing the adaptability and resilience required for sealing in the most demanding environments. The synergy between gaskets, materials, and innovative solutions like graphite sheets continues to shape a future where reliability and performance go hand in hand.Original Source: Industrial Gaskets

0 notes

Text

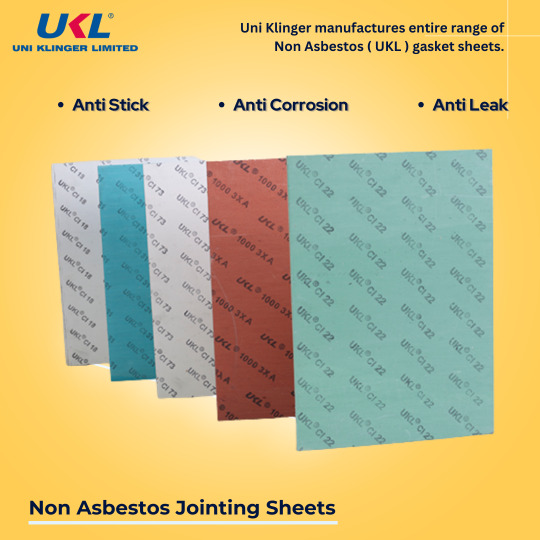

UKL - Compressed Non Asbestos Jointing Sheet

UKL non asbestos gasket sheets are manufactured in metallic & non metallic to cover a variety of applications in the industry. UKL Compressed Non Asbestos Jointing Sheet features are as follows:

Anti Stick

Anti Corrosion

Anti Leak

For more information,Visit: https://uniklinger.com/product/compressed-non-asbestos-jointing-sheet

#uniklinger#manufacturing#valves#engineering#ukl#steamengineering#gaskets#spiralwoundgasket#uniklingerlimited#uniklingercompany#nonasbestosgaskets#bestvalvemanufacturer#gasketsupplier#bestgasket#readygaskets#fluidsealing#industrysolution#sealinggaskets#sealwithuniklinger#jointing sheet

0 notes

Text

All the basics that you should know about stainless steel.

A flange is required whenever two tubes are connected to one another. It is utilized in the process of threading or welding the ends of two tubes together to create a single connected tube. Therefore, depending on the technique of attachment that is employed, fasteners can be generically categorized as either threaded attachment flanges or welding flanges. When it is time to link two tubes together, a flange junction has to be assembled using a gasket, many bolts and nuts, and a set of flanges.

To begin, place the gasket so that it is sandwiched between the mating sides of your seal. The screws then need to be tightened. When the gasket's surface pressure reaches a certain value, it deforms to completely conceal any inconsistencies in the sealing surface. The makers of PVC coated stainless steel tubing have consistently been a dependable resource.

Flange joints are a type of interchangeable connection. Flanges for both containers and tubes are available as interchangeable parts. Stainless steel sanitary tubing suppliers might be of great assistance.

There are three different types of sealing faces, depending on the pressure and the type of media being sealed against: planar sealing faces for low pressure, uneven sealing faces for moderate pressure, and tongue and groove sealing faces for high pressure and combustible, explosive, and toxic media. One such choice is ss capillary tubes manufacturers in India.

Different flanges can withstand different pressures and media, as you know. It turns out that the gasket utilized in the connection is crucial. Non-metallic plates in particular have been used to produce an abundance of gaskets. The stainless steel coil tubing manufacturers has been outstanding.

Asbestos rubber sheets, asbestos plates, polyethylene table sheets, and so on all have sizes that are specified in various standards. A latex gasket, for example, can only withstand temperatures up to 120? Asbestos with a high acid-resistance content has been widely used in harsh environments. Copper, aluminum, 10 steel, or stainless steel sheet metal is necessary in the event of increased pressure. India is home to a plethora of top-notch stainless steel boiler tube manufacturers.

Despite their apparent simplicity, fasteners have become more important in virtually every industry because of the vital roles they play. The two are joined by the fasteners. These days, the majority of individuals prefer to make use of them.

Flange, in reality, follows its own set of guidelines. The three systems in question are the DIN system, the ANSI scheme, and the JIS system. Similar pressure thresholds and sealing face types are needed for both systems. Stainless steel condenser tube manufacturers are highly sought after by a majority of customers nowadays.

Furthermore, the latter method is not generally accepted. Additionally, the GB standard, the chemical standard, the mechanical standard, and the pressure vessel benchmark should all be followed during production of the flanges. Industrial processes rely heavily on pipes and tubes as well. These technological advancements accommodate for human limitations by carrying out activities that humans are unable do.

0 notes

Text

Moving into the flanged stainless steel realm.

When joining two tubes, a flange is an essential component. In most cases, it joins the ends of two tubes with a threaded connection or some other type of welding. Therefore, there are primarily two types of fasteners: threaded attachment flanges and welding flanges. Flanges, a gasket, and a number of bolts and nuts are needed whenever two tubes are ready to be linked together via a flange junction.

The first step is to place the gasket in between the seals. Once that's done, you may tighten the bolts. When the surface pressure of a gasket reaches a critical point, it deforms to fill in any gaps or imperfections in the sealing surface, thereby sealing the joint. Duplex pipe suppliers have proven invaluable.

One sort of removable connection is a flange junction. It appears that there are two sorts of removable parts, namely container flanges and tube flanges. You can benefit greatly from working with Duplex tube suppliers.

There are three different types of sealing faces, each suited to a different pressure range and set of circumstances: planar sealing faces for low pressure, uneven sealing faces for moderate pressure, and tongue and groove sealing faces for high pressure and combustible, explosive, or poisonous material. Most of the time, Indian factories that make Duplex flanges are reliable.

It's well knowledge that different types of flanges can withstand varying amounts of pressure and media. The gasket used in the connection really plays a crucial role. Gaskets made from non-metallic plates have been mass-produced. The company that makes forged parts has been doing a fantastic job. Duplex pipe fittings are actually very good.

Asbestos rubber sheets, asbestos plates, polyethylene workbooks, and so on all have sizes that are specified by various norms. A typical latex gasket, for instance, has a temperature limit of 120? In corrosive environments, acid-resistant asbestos has seen extensive application. Copper, aluminum, 10 steel, or some other type of stainless steel sheet may be used if the pressure is high enough. You might be able to get a wide selection of Duplex round bar.

Despite their apparent simplicity, fasteners serve important purposes and have grown in prominence across practically all sectors of the economy. Vehicles and machinery are joined together by fasteners. Most people in the modern world like to make use of them. Duplex forged fittings made of stainless steel are highly recommended.

In fact, flange is a technique in and of itself. Indeed, these are the DIN system, the ANSI scheme, and the JIS system. The previous systems' pressure requirements and sealing face types are identical. Most customers today choose Copper nickel plate.

The third option is also not often used. In addition, the GB standard, the specific chemical standard, the mechanical requirement, and the pressure vessel benchmark must all be followed while fabricating flanges. Pipes and tubes are the backbone of the manufacturing sector. These innovations have made up for human shortcomings by doing work that people can't. The quality of the A193 grade B7 bolts has been excellent.

0 notes

Text

#avoidplastics#FollowTrafficRules#ourbestqualityproduct#ontimematerialdispatch#bestproducts#goodwillenginnering

#DrugFreeSociety#metalgasket

Metallic Gaskets are used for sealing higher temperature and pressure applications, where non-asbestos materials will fail. Typical applications are for heat exchangers, compressors, condensers, pumps, and valves.

Metal gaskets are manufactured from a material such as Soft iron, Low Carbon steel, Stainless Steel, Monel, and Inconel. These gaskets are also known as ring gaskets or RTJ gaskets

here are 3 main classifications of gasket: metallic, semi-metallic and non-metallic.

Metallic Gaskets. These gaskets are made from one metal or a combination of several metals. ...

Semi-metallic Gaskets. These gaskets are made from a combination of metallic and non-metallic components.

Gaskets are mechanical seals that inhibit leakage by filling the gaps between static mating surfaces. Both polished and unpolished surfaces, particularly metal surfaces, have an inherent roughness or microscopic asperity that creates spaces where fluids can pass through.

A gasket is a seal that is manufactured to fit between two or more surfaces, such as two lengths of piping. The gasket is designed prevent leakage whilst being subjected to varying levels of compression.

Metal Gasket Materials – The manufacturing of metal gaskets can be done using multiple materials including Stainless Steel, Copper, Cast Steel, Monel, Inconel, Brass, Bronze, 17-4, among many others. They also can be combined with various rubber products.

Gaskets are normally made from a flat material, a sheet such as paper, rubber, silicone, metal, cork, felt, neoprene, nitrile rubber, fiberglass, polytetrafluoroethylene (otherwise known as PTFE or Teflon) or a plastic polymer (such as polychlorotrifluoroethylene).

A combination of cork and rubber, for example neoprene or nitrile, yields a gasket resistant to solvents, oils, and fuels. Some of the materials used in the formulations and grades include: Cork & Neoprene Blend. Cork & Viton Blend.

#avoidplastics#FollowTrafficRules#ourbestqualityproduct#ontimematerialdispatch#bestproducts#goodwillenginnering#DrugFreeSociety#metalgasket#Metallic Gaskets are used for sealing higher temperature and pressure applications#where non-asbestos materials will fail. Typical applications are for heat exchangers#compressors#condensers#pumps#and valves.#Metal gaskets are manufactured from a material such as Soft iron#Low Carbon steel#Stainless Steel#Monel#and Inconel. These gaskets are also known as ring gaskets or RTJ gaskets#here are 3 main classifications of gasket: metallic#semi-metallic and non-metallic.#Metallic Gaskets. These gaskets are made from one metal or a combination of several metals. ...#Semi-metallic Gaskets. These gaskets are made from a combination of metallic and non-metallic components.#Gaskets are mechanical seals that inhibit leakage by filling the gaps between static mating surfaces. Both polished and unpolished surfaces#particularly metal surfaces#have an inherent roughness or microscopic asperity that creates spaces where fluids can pass through.#A gasket is a seal that is manufactured to fit between two or more surfaces#such as two lengths of piping. The gasket is designed prevent leakage whilst being subjected to varying levels of compression.#Metal Gasket Materials – The manufacturing of metal gaskets can be done using multiple materials including Stainless Steel#Copper

0 notes

Text

Asbestos gaskets are made from a naturally occurring mineral that has heat-resistant properties. Asbestos fibers are woven together to form a strong and durable material that can withstand high temperatures and pressure. Superlitejointings is a manufacturer of asbestos gaskets that are commonly used in industrial applications.

#non-asbestos gasket#Industrial Gasket#gaskets company in India#gasket sheet manufacturer#Gasket Sheet#Gasket Seal#asbestos gasket

0 notes

Text

Gasket sheet manufacturers in UAE

We are No.1 Non Asbestos Gasket / Gasket sheet manufacturers and suppliers in UAE, Oman, Saudi Arabia, Kuwait, Qatar, Iran, Iraq, Kazakhstan, Bahrain, Jordan, Egypt, Nigeria, Yemen, Singapore, Malaysia and India

0 notes

Text

How do stainless steel flanges connect and seal?

Stainless steel is one of the strongest construction metal materials, with anti-corrosion, anti-rust, wear-resistant and other characteristics.

Stainless steel flanges are highly resistant to corrosion, and chrome-containing stainless steel stamped flanges combine mechanical strength with high elongation, making parts easy to machine and manufacture to meet the needs of architects and structural designers. All metals react with oxygen in the atmosphere to form oxide films on their surfaces.

The flange gasket is to achieve the sealing effect of the flange. A gasket is a ring made of a plastically deformable material with a certain strength. Gaskets are usually cut from non-metallic sheets or manufactured to specified dimensions in specialized factories, and materials include asbestos rubber sheets, asbestos sheets, PTFE sheets, polyethylene sheets and thin metal sheets. There are also sheets (tin, stainless steel), which are metal-coated gaskets wrapped in a non-metallic material such as asbestos. According to different pressure levels, flange gaskets also have different materials, ranging from low-pressure asbestos gaskets, high-pressure asbestos gaskets, PTFE gaskets to metal gaskets.

Flange connection is to use flanges to connect the pipes or fittings to be connected, and the joints can be disassembled. The connection method is more inclusive, and can be connected with the pipe fittings by hot melt or bonded. Some pipes and fittings that are not suitable for hot melt or electrofusion connection can be connected by flange connection. For example, ppr pipe, metal pipe and other pipes are not suitable for hot melt connection. Flanged connections are easy to use and can withstand higher pressures. Flange connections are widely used in industrial pipelines.

0 notes

Text

Sealing Excellence- A Comprehensive Guide to Gaskets and Materials

Gaskets, often overlooked but indispensable, are the unsung heroes that ensure the smooth functioning of machinery and systems across various industries. This comprehensive guide unveils the world of gaskets and materials, shedding light on their critical role in maintaining seals, preventing leaks, and enhancing overall operational efficiency.

Section 1: The Foundation - Understanding Gaskets

1.1 Definition and Function: Gaskets are sealing devices positioned between two mating surfaces to prevent leakage of fluids or gases. Their primary function is to create a barrier that withstands pressure, temperature, and environmental factors.

1.2 Types of Gaskets: Gaskets come in various types, each designed for specific applications. Common types include flat gaskets, spiral wound gaskets, ring gaskets, and asbestos gasket sheet, each with unique characteristics suited for different sealing requirements.

Section 2: Dive into Materials

2.1 Rubber Gaskets: Natural rubber, synthetic rubbers like neoprene and silicone, are popular choices for gaskets due to their elasticity, flexibility, and resistance to certain chemicals.

2.2 Metal Gaskets: Materials such as stainless steel, copper, and aluminum are used for metal gaskets. These provide robustness, durability, and high-temperature resistance, making them ideal for demanding industrial gaskets applications.

2.3 Compressed Fiber Gaskets: Gaskets made from compressed fibers like asbestos-free materials or non-asbestos materials offer excellent sealing properties and are often chosen for their resistance to heat and pressure.

2.4 Graphite Gaskets: Known for their exceptional thermal conductivity and resistance to corrosive chemicals, graphite gaskets are preferred in high-temperature and high-pressure environments.

Section 3: Factors Influencing Material Selection

3.1 Temperature and Pressure: The operating conditions of a system, including temperature and pressure ranges, heavily influence the choice of gasket material. Matching these parameters ensures optimal performance and longevity.

3.2 Chemical Compatibility: Gaskets must be resistant to the specific chemicals they come into contact with. Selecting materials that are chemically compatible ensures the gasket's effectiveness over time.

3.3 Application-Specific Considerations: Whether it's a flange connection, pipe joint, or cylinder head, understanding the specific requirements of the application is crucial. Gasket materials must align with the mechanical and thermal demands of the system.

Section 4: Advancements in Gasket Technology

4.1 High-Performance Coatings: Innovative coatings enhance the properties of gasket materials, providing improved resistance to corrosion, wear, and extreme temperatures.

4.2 Nano-Material Integration: Incorporating nanotechnology into gasket manufacturing allows for the development of materials with enhanced strength, flexibility, and performance characteristics.

Conclusion:

In the dynamic landscape of industrial applications, gaskets and materials form the backbone of reliable and efficient systems. Understanding the nuances of gasket types and materials, and considering advancements in technology, is essential for engineers and manufacturers seeking optimal performance and longevity in their equipment. As industries evolve, the ongoing innovation and refinement of gasket materials will continue to contribute to the seamless operation of machinery across the globe.

Original Source: Gasket and Materials

#gasket sheet#industrial#gaskets#gasket material#Rubber Gasket Sheet#Asbestos Gasket Sheet#Gasket Material#Graphite Sheet#Asbestos Gaskets#Silicone Sheets#Gland Packing

0 notes