#aluminium heat sink manufacturers

Explore tagged Tumblr posts

Text

#aluminium ips tube manufacturer#aluminium busbar manufacturer#heatsink extrusion manufacturers#aluminium heat sink manufacturers#aluminum led manufacturers#aluminium construction profiles#Aluminium Extrusion Profiles

0 notes

Text

What are all the types of aluminium fabrication?

Aluminum fabrication design encompasses a myriad of techniques and processes that transform raw aluminum into various finished products. Each method offers unique advantages, catering to diverse applications across industries ranging from aerospace to construction and automotive to electronics.

Extrusion stands as one of the most common aluminum fabrication techniques, involving the shaping of aluminum alloys by forcing them through a die. This process enables the creation of complex profiles with consistent cross-sectional shapes, ideal for applications requiring lightweight yet durable components such as window frames, structural beams, and heat sinks.

Sheet metal fabrication utilizes flat sheets of aluminum, which are cut, bent, and formed into desired shapes and sizes. From precision components for electronics to automotive body panels and aircraft fuselages, sheet metal fabrication offers versatility and efficiency in producing lightweight, corrosion-resistant parts with high structural integrity.

Casting processes, including sand casting, die casting, and investment casting, are employed to create intricate aluminum components with precise geometries. Sand casting is suitable for producing large, complex parts such as engine blocks and transmission housings, while die casting offers fast production of small to medium-sized components with tight tolerances. Investment casting, also known as lost-wax casting, enables the creation of finely detailed parts for aerospace, medical, and jewelry applications.

Welding plays a crucial role in aluminum fabrication, allowing for the joining of aluminum components through various techniques such as TIG (tungsten inert gas) welding, MIG (metal inert gas) welding, and resistance welding. TIG welding ensures precise control over the welding process, making it suitable for thin materials and intricate designs, while MIG welding offers higher deposition rates for thicker sections. Resistance welding methods like spot welding and seam welding are commonly used in automotive assembly and sheet metal fabrication.

The diverse types of aluminum fabrication techniques provide manufacturers and designers with a wealth of options to meet specific performance, cost, and design requirements. Whether it's extrusion, sheet metal fabrication, casting, or welding, each method contributes to the production of high-quality aluminum components for a wide range of applications. With expertise and quality materials from Alugrow Trading, manufacturers can leverage the full potential of aluminum fabrication to bring their designs to life.

Alugrow Trading

2 notes

·

View notes

Text

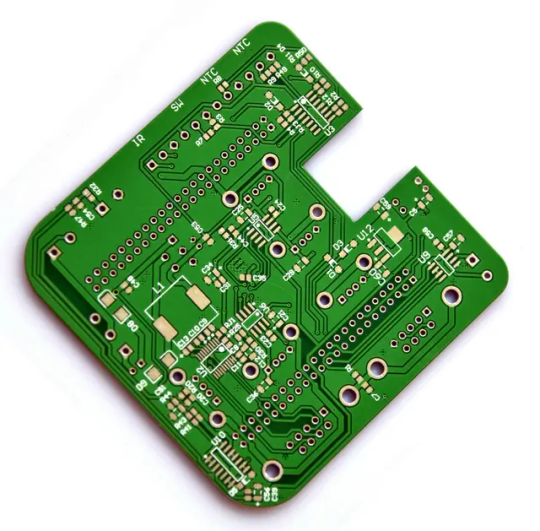

4 Crucial Things to Consider While Choosing LED PCB Manufacturer

LEDs have revolutionized lighting. At the heart of their brilliance, is the PCB assembly. Electing the right LED PCB assembly manufacturer can make or break your project. This ensures quality, performance, and ultimately, success. So, before you dive into the luminous world of LED PCBs, this article sheds some light on the key factors to consider when making your purchase:

1. Experience Matters: You should choose a manufacturer with proven expertise in LED PCB assembly. The company you choose should have a track record of successful projects similar to yours. Experience means they will understand your specific needs and deliver assemblies that meet or exceed your expectations.

2. Material Matters: The heart of your PCB is its materials. Go for manufacturers

who ensure high-quality FR4 or metal-core PCBs for optimal thermal management and longevity. They must adhere to industry standards for materials and components to guarantee reliability and safety.

3. Thermal Management: LEDs are designed to generate heat, so proper thermal management plays a crucial role. Look for manufacturers who offer solutions like aluminium heat sinks. Their expertise in thermal management can extend the lifespan of your LED PCB and prevent overheating issues.

4. Price is Not Everything: Though cost is important, its priority is not over quality.

The cheapest option might have hidden costs in the long run. Choose a manufacturer who offers budget-friendly pricing while maintaining high-quality standards and reliable service.

If you are looking for an LED PCB manufacturer near you you can count on Hitech Circuits Co., Limited. They have more than 20 years of experience in the electronics manufacturing industry. They have a talented design team who follow advanced manufacturing techniques.

These guidelines help you illuminate your path to finding the perfect LED PCB assembly manufacturer. Your choice has a direct impact on the performance, lifespan, and success of your project.

2 notes

·

View notes

Text

High-Quality Aluminium Extrusion Profiles in Australia for Every Industry

Discover the Best Aluminium Extrusion Profiles in Australia

Aluminium extrusion profiles have revolutionized various industries in Australia, offering lightweight, durable, and cost-effective solutions for construction, manufacturing, automotive, and more. Whether you need custom-designed profiles or standard extrusions, aluminium provides exceptional strength, corrosion resistance, and versatility. This article explores the advantages, applications, and how to choose the right aluminium extrusion profiles in Australia for your specific needs.

What Are Aluminium Extrusion Profiles?

Aluminium extrusion profiles are shaped aluminium sections created by pushing heated aluminium through a die to achieve a specific cross-sectional design. These profiles are widely used across industries due to their strength, flexibility, and sustainability. Aluminium extrusions are available in various shapes, including square, rectangular, T-slot, and custom designs, making them suitable for a broad range of applications.

Types of Aluminium Extrusion Profiles

Standard Extrusion Profiles These include common shapes such as angles, channels, tubes, and flat bars. They are widely used in construction, furniture, and industrial applications.

Custom Aluminium Extrusions For projects requiring unique specifications, custom aluminium extrusion profiles are designed to meet exact dimensions, tolerances, and finishes.

T-Slot Aluminium Profiles T-slot extrusions are popular in modular framing systems, workstations, and automation setups due to their easy assembly and adaptability.

Architectural Aluminium Profiles Used in windows, doors, curtain walls, and facades, these profiles enhance structural integrity while providing a sleek and modern aesthetic.

Heat Sink Aluminium Profiles Engineered for electronic and industrial applications, heat sink extrusions dissipate heat efficiently, improving the performance of machinery and electronic devices.

Advantages of Aluminium Extrusion Profiles in Australia

Aluminium extrusion profiles offer numerous benefits, making them a preferred choice for diverse industries.

Strength and Durability

Aluminium provides excellent structural integrity while being lightweight, making it ideal for both heavy-duty and lightweight applications.

Corrosion Resistance

Aluminium naturally forms an oxide layer that protects it from rust and corrosion, making it suitable for outdoor and marine applications.

Cost-Effective and Sustainable

Aluminium is 100% recyclable and has a low production cost compared to other metals, making it an eco-friendly and economical choice.

Versatile and Customizable

With various finishes, coatings, and anodizing options available, aluminium extrusion profiles can be customized to match aesthetic and functional requirements.

High Thermal and Electrical Conductivity

Aluminium’s superior conductivity makes it an excellent choice for heat sinks, electrical enclosures, and energy-efficient applications.

Industries That Rely on Aluminium Extrusion Profiles in Australia

Construction and Architecture Aluminium extrusions are extensively used in building facades, roofing systems, window frames, and structural components.

Automotive and Transportation Lightweight aluminium profiles improve fuel efficiency and structural strength in vehicles, trailers, and rail applications.

Electronics and Electrical Industry Aluminium heat sinks and enclosures help regulate temperatures in electronic devices and power systems.

Manufacturing and Industrial Applications From conveyor systems to machine frames, aluminium extrusions provide durable and adaptable solutions for industrial setups.

Renewable Energy Solar panel frames and wind turbine components benefit from the durability and lightweight properties of aluminium extrusions.

How to Choose the Right Aluminium Extrusion Profiles in Australia

Determine Your Requirements Identify the dimensions, shape, and load-bearing capacity needed for your project.

Select the Right Alloy and Finish Different aluminium alloys provide varying levels of strength, corrosion resistance, and thermal conductivity. Choose the right finish, such as anodizing or powder coating, for added durability.

Consider Customization Options If your project requires unique specifications, opt for custom extrusion profiles to ensure the perfect fit.

Check Supplier Experience and Quality Standards Partnering with a reputable supplier ensures high-quality aluminium extrusions that meet Australian industry standards.

Conclusion: Get the Best Aluminium Extrusion Profiles in Australia

Aluminium extrusion profiles offer unmatched strength, durability, and flexibility across various industries in Australia. Whether you need standard extrusions or customized solutions, aluminium provides an efficient and sustainable choice for construction, manufacturing, and beyond. Finding the right supplier is crucial for ensuring quality and performance. If you’re looking for premium aluminium extrusion profiles, Contact us today! to discuss your project requirements and find the perfect solution.

Source From : High-Quality Aluminium Extrusion Profiles in Australia for Every Industry

0 notes

Text

PDTMC – Redefining Aluminium Extrusion Excellence in UAE

The United Arab Emirates (UAE) has positioned itself as a global leader in the aluminium industry, driven by innovation, sustainability, and cutting-edge technology. Among the Aluminium Extrusion Manufacturers in UAE, industry leaders are setting new benchmarks in precision, quality, and efficiency. Aluminium extrusion is widely used across various sectors, including construction, automotive, aerospace, and interior design, making it a crucial part of modern infrastructure. As the demand for aluminium extrusions continues to rise, manufacturers in the UAE are leveraging advanced technology and sustainable practices to stay ahead in the industry.

The Growing Demand for Aluminium Extrusion in UAE

The UAE’s rapid urbanization and infrastructural growth have significantly increased the demand for high-quality aluminium extrusions. Here’s why aluminium extrusion is essential for the region’s industries:

Sustainability & Recycling: Aluminium is 100% recyclable, making it a sustainable choice for eco-conscious industries.

Durability & Strength: Extruded aluminium profiles offer high strength while remaining lightweight, making them ideal for construction and automotive applications.

Versatility in Design: Aluminium extrusions can be customized into complex shapes, making them perfect for architectural and industrial use.

Energy Efficiency: Aluminium frames are widely used in modern energy-efficient buildings due to their thermal insulation properties.

What Sets UAE’s Aluminium Extrusion Manufacturers Apart?

The Best Aluminium Extrusion Manufacturers in UAE focus on advanced production techniques, stringent quality control, and global industry standards. Here are some key factors that set them apart:

State-of-the-Art Technology: Manufacturers leverage modern extrusion techniques, including automated processes and precision machining.

Adherence to International Standards: Companies comply with global quality and safety regulations, ensuring top-tier products.

Customization & Innovation: Clients benefit from highly customized extrusion solutions tailored to unique industry needs.

Fast & Efficient Production: The UAE’s aluminium manufacturers operate with high efficiency to meet growing regional and international demand.

Industries Benefiting from Aluminium Extrusion in UAE

Several industries heavily rely on Aluminium Extrusion Manufacturers in UAE to enhance their products and services. These include:

Construction & Architecture: Aluminium extrusions are widely used in windows, doors, curtain walls, and structural components.

Automotive & Transportation: Lightweight yet strong aluminium parts contribute to fuel efficiency and vehicle performance.

Aerospace Industry: The aerospace sector benefits from aluminium’s high strength-to-weight ratio for aircraft components.

Interior Design & Furniture: Aluminium extrusions are utilized for stylish, modern, and durable furniture designs.

Industrial & Engineering Applications: Extruded aluminium components are essential for machinery, heat sinks, and electrical applications.

Why Choose UAE for Aluminium Extrusion?

The UAE’s aluminium extrusion industry is backed by several competitive advantages, making it a global leader:

Strategic Location: The UAE serves as a global export hub, ensuring seamless distribution across markets.

Sustainable Manufacturing: Companies adopt eco-friendly production methods, reducing environmental impact.

High-Quality Raw Materials: The country has access to premium-quality aluminium, ensuring durable and efficient extrusions.

Strong Government Support: Industrial policies and initiatives encourage innovation and industry growth.

Choosing the Right Aluminium Extrusion Manufacturer in UAE

Selecting the right Aluminium Extrusion Manufacturers in UAE is crucial for quality and reliability. When choosing a manufacturer, consider:

Experience & Reputation: Established companies with proven industry experience offer the best quality and service.

Technological Capabilities: Look for manufacturers using advanced extrusion and finishing techniques.

Customization Options: A good manufacturer provides tailored solutions to meet specific project requirements.

Sustainability Practices: Choose companies committed to eco-friendly production methods.

With a rapidly growing aluminium industry, the UAE is at the forefront of innovation and quality in aluminium extrusion. As one of the most trusted Aluminium Extrusion Manufacturers in UAE, PDTMC continues to redefine industry standards by offering high-quality, customized solutions for various sectors. Whether you require durable materials for construction, lightweight automotive components, or specialized industrial applications, we delivers you excellence at every step.For businesses seeking a reliable aluminium extrusion partner, consider PDTMC as your best option.

0 notes

Text

Aluminium Extrusion: Smart Solution for Product’s Innovation

Aluminium extrusions are among the most adaptable and valuable materials used across industries, offering unmatched versatility, lightweight properties, and impressive strength-to-weight ratios. As industries evolve to demand efficient, sustainable, and high-performing materials, aluminium extrusions have become a cornerstone in aluminium extrusion diverse applications, from construction to aerospace. Below, we explore their extensive uses and why they are an excellent choice for your products.

The Versatility and Applications of Aluminium Extrusions

1. Aluminium Extrusions in Construction: Building Durability and Efficiency

The construction industry heavily relies on aluminium extrusions for their superior properties, making them indispensable for modern infrastructure. Key applications include:

Framing Systems: Aluminium extrusions are widely used in door, window, and curtain wall frames. Their lightweight nature simplifies installation, reduces labor costs, and accelerates on-site assembly.

Corrosion Resistance: Ideal for outdoor applications, aluminium ensures durability and longevity, even in harsh environmental conditions. This property makes it an excellent choice for facades and cladding systems.

Design Versatility: Extruded aluminium can be customized into complex shapes, enabling architects to achieve both functional and aesthetic goals.

For example, Eleanor Extrusion India provided tailored aluminium profiles for a large-scale commercial building project. Our extrusions were used in curtain walls and window frames, ensuring both aesthetic appeal and structural integrity. This project highlighted our ability to deliver high-quality, durable solutions for the construction industry.

2. Transforming the Automotive Industry with Aluminium Extrusions

The automotive sector has gained popularity of aluminium extrusions for their contribution to vehicle performance and efficiency. Specific uses include:

Structural Components: Car frames, chassis, and suspension systems benefit from the lightweight yet strong nature of aluminium extrusions, reducing overall vehicle weight.

Fuel Efficiency: By minimizing weight, aluminium improves fuel economy and lowers emissions, aligning with global sustainability goals.

Crash Safety: Aluminium’s ability to absorb energy during impacts enhances passenger safety, making it a preferred material for automotive design.

3. Aerospace and Aviation: Elevating Performance with Aluminium

In the aerospace and aviation industries, aluminium extrusions are indispensable due to their remarkable balance of strength and weight. Key applications include:

Aircraft Frames: Components such as fuselage frames and wing structures rely on aluminium for structural integrity.

Landing Gear: Lightweight materials reduce overall aircraft weight, improving flight efficiency and fuel economy.

Heat Resistance: Aluminium’s thermal properties ensure reliable performance in extreme environments.

4. Supporting Electronics with Aluminium’s Thermal Properties

The electronics industry harnesses aluminium extrusions for their excellent heat dissipation capabilities. Common uses include:

Heat Sinks: Aluminium extrusions efficiently transfer heat away from electronic components, ensuring optimal performance and longevity.

Device Housings: Enclosures made from aluminium provide both protection and thermal management for sensitive electronic devices.

Cable Management Systems: Durable, lightweight profiles support efficient routing and protection of cables in complex systems.

5. Revolutionizing Furniture Design with Aluminium Extrusions

Modern furniture manufacturers are increasingly incorporating aluminium extrusions into their designs, thanks to their aesthetic and functional benefits:

Sleek Designs: Aluminium’s smooth finish and versatile shapes enhance the visual appeal of office furniture and modular systems.

Durability: Corrosion-resistant properties ensure outdoor furniture retains its quality over time.

Ease of Assembly: Lightweight and customizable, aluminium extrusions streamline furniture production and assembly processes.

This blog was originally published here

0 notes

Text

Brighten Your Production with V and F Sheet Metal Expertise

Lighting manufacturers seeking reliable sheet metal and fabrication partners should consider V and F Sheet Metal. They possess a long history of serving the UK lighting industry. They understand the sector's unique requirements. Therefore, they offer a tailored service. V and F maintain a comprehensive stock of materials. This includes aluminium and steel. They hold materials for gear plates and reflectors. Moreover, they stock heat sinks and ceiling adaptor plates. Mounting brackets are also readily available.

V and F utilise advanced manufacturing technologies. Consequently, they achieve precise outcomes. They operate a Trumpf 3030 fibre laser cutting machine. This ensures accurate cutting of complex shapes. They also employ Trumpf 200R and 3000R CNC punch presses. These machines handle high-volume production. Furthermore, they use CNC bending for precise forming. This allows them to create intricate components.

Beyond cutting and forming, V and F provide welding services. They offer stud welding for secure fastenings. Additionally, they offer spot welding for efficient assembly. These capabilities enhance their production flexibility. They provide end-to-end sheet metal and fabrication solutions.

V and F’s experience benefits lighting companies. For example, they understand the importance of tight tolerances. They also understand the need for consistent production. Subsequently, they ensure reliable supply. V and F help streamline manufacturing processes. They enable lighting manufacturers to focus on their core business.

0 notes

Text

What is Precision Sheet Metal Fabrication? A Complete Guide

Precision sheet metal fabrication is a specialized manufacturing process that involves cutting, bending, and assembling thin metal sheets to create precise components for various industries. This process ensures high accuracy, durability, and efficiency, making it essential for applications in automotive, aerospace, electronics, and construction.

Understanding Precision Sheet Metal Fabrication

Precision sheet metal fabrication refers to the advanced methods used to shape and form metal sheets into intricate designs with exact tolerances. This process utilizes cutting-edge technology, including CNC machines, laser cutting, waterjet cutting, and robotic welding, to ensure high-quality results.

Typical metals used in this process include:

Aluminium – Lightweight and corrosion-resistant

Stainless Steel – Strong, durable, and heat-resistant

Copper & Brass – Great for electrical applications

Carbon Steel – Offers strength and versatility

Key Processes in Precision Sheet Metal Fabrication

Cutting

Techniques like laser cutting, plasma cutting, and waterjet cutting help achieve precise shapes with minimal material waste.

Bending

Using press brakes and CNC bending machines, metal sheets are shaped into desired forms without compromising structural integrity.

Welding & Assembly

MIG, TIG, and robotic welding ensure strong and seamless joints, creating high-quality finished products.

Finishing & Coating

Powder coating, anodizing, and electroplating enhance durability and aesthetics, providing a corrosion-resistant surface.

Benefits of Precision Sheet Metal Fabrication

✔ High Accuracy & Consistency – Advanced machinery ensures uniformity across all parts.

✔ Cost-Effective Production – Reduces material waste and improves production efficiency.

✔ Versatile Applications – Used in industries like medical devices, telecommunications, and defence.

✔ Custom Fabrication – Tailored solutions meet specific design and functional requirements.

Applications of Precision Sheet Metal Fabrication

🔹 Aerospace Industry – Lightweight and durable components for aircraft manufacturing.

🔹 Automotive Sector – Precision parts for engines, frames, and body panels.

🔹 Electronics Industry – Metal casings, enclosures, and heat sinks.

🔹 Construction & Architecture – Custom metalwork for buildings and structures.

Conclusion

Precision sheet metal fabrication plays a vital role in modern manufacturing, ensuring high-quality, durable, and cost-effective metal components. Whether you need customized metal enclosures, automotive parts, or aerospace components, precision fabrication guarantees the best results.

Contact us today to discuss your fabrication needs and get expert solutions tailored to your industry.

Visit us today to explore our advanced manufacturing capabilities and see how we can bring your project to life!

0 notes

Text

Revolutionizing Power Distribution with Aluminium Profiles: Key Benefits and Innovations

In recent years, the power distribution industry has undergone significant transformation, with technological advancements driving efficiency, safety, and sustainability. One key material that has played a crucial role in this revolution is Aluminium Profiles for power distribution. These profiles offer a range of benefits, making them indispensable in modern electrical infrastructure. At Dhaatu Fabex, we specialize in manufacturing high-quality aluminium profiles that are engineered to meet the specific needs of power distribution systems. Let’s explore the key benefits and innovations in this space.

1. Enhanced Durability and Corrosion Resistance

Aluminium profiles are known for their exceptional durability and corrosion resistance. In power distribution, where components are exposed to various environmental conditions, corrosion can cause significant damage to materials over time. Aluminium, however, is naturally resistant to corrosion, making it an ideal choice for components used in power transmission and distribution systems. At Dhaatu Fabex, our aluminium profiles are designed to withstand harsh conditions, ensuring longer service life and reliability.

2. Lightweight yet Strong

One of the standout features of aluminium profiles is their lightweight nature, which does not compromise on strength. Power distribution systems require materials that can support heavy loads without being too cumbersome to handle or install. Aluminium profiles provide an optimal solution by being lightweight, reducing installation time and costs while still offering the necessary strength to support power cables and other critical components.

Easy handling and installation

Reduced transportation costs

Ideal for both large and small-scale projects

3. Sustainability and Environmental Benefits

As the world moves towards more sustainable practices, aluminium has become the material of choice for green energy solutions, including power distribution. Aluminium profiles are recyclable, which makes them a more eco-friendly alternative to traditional materials. Using Aluminium Profiles for power distribution reduces the overall environmental impact, making power systems more sustainable. At Dhaatu Fabex, we are committed to offering products that align with the global push for sustainability, contributing to a greener future.

4. Cost-Effectiveness and Efficiency

Aluminium profiles are cost-effective in comparison to other materials like copper or steel, offering a balance between performance and price. They are easy to fabricate, reducing manufacturing costs, and their excellent conductivity properties improve the efficiency of power distribution systems. By choosing Dhaatu Fabex’s aluminium profiles, companies can save on material costs while improving the overall performance of their power distribution infrastructure.

Lower material costs than alternatives

Increased energy efficiency

Faster fabrication and manufacturing times

Innovation at Dhaatu Fabex

At Dhaatu Fabex, we continuously innovate and optimize our manufacturing processes to provide the highest quality Aluminium Profiles for power distribution. Our profiles are designed with precision, ensuring that they meet the specific needs of power distribution systems. With a focus on quality, durability, and sustainability, we offer a wide range of solutions to suit various applications in the power sector.

For more information on how our aluminium profiles can enhance your power distribution systems, visit our website at www.dhaatufabex.com.

Conclusion: Aluminium profiles are reshaping the landscape of power distribution, providing numerous benefits such as durability, strength, sustainability, and cost-efficiency. At Dhaatu Fabex, we are proud to be at the forefront of this revolution, delivering high-quality aluminium profiles that empower industries to build more reliable, efficient, and eco-friendly power distribution systems.

#Aluminium Profiles For power Distribution#aluminium heat sink manufacturers#heatsink extrusion manufacturers#premium aluminium sliding doors#aluminium window profile manufacturers#Aircraft Aluminium Extrusions Suppliers

0 notes

Text

The Advantages and Applications of Aluminium CNC Machining Parts

The Advantages and Applications of Aluminium CNC Machining Parts Aluminium CNC machining has revolutionized the manufacturing industry, offering unparalleled precision and efficiency in the production of aluminium parts and components. This article explores the benefits, applications, and processes involved in aluminium CNC machining.Get more news about aluminium cnc machining parts discount,you can vist our website!

Benefits of Aluminium CNC Machining High Precision and Accuracy: CNC (Computer Numerical Control) machining allows for the production of highly precise and accurate parts. The use of computer-controlled machines ensures that each part is manufactured to exact specifications, reducing the risk of human error. Material Properties: Aluminium is a popular choice for CNC machining due to its excellent mechanical properties. It is lightweight, has high thermal and electrical conductivity, and is resistant to corrosion. These properties make it ideal for a wide range of applications. Cost-Effective: Aluminium is relatively inexpensive compared to other metals, making it a cost-effective option for manufacturing. Additionally, CNC machining reduces material waste, further lowering production costs. Versatility: Aluminium can be easily machined into complex shapes and designs. This versatility allows for the creation of intricate parts that would be difficult or impossible to produce using traditional manufacturing methods. Speed and Efficiency: CNC machines can operate continuously, 24/7, without the need for breaks. This results in faster production times and increased efficiency, allowing manufacturers to meet tight deadlines and high-volume orders. Applications of Aluminium CNC Machining Parts Aerospace Industry: Aluminium CNC machined parts are widely used in the aerospace industry due to their lightweight and high-strength properties. Components such as aircraft frames, engine parts, and landing gear are often made from aluminium. Automotive Industry: The automotive industry relies on aluminium CNC machining for the production of various parts, including engine components, transmission parts, and structural elements. The lightweight nature of aluminium helps improve fuel efficiency and reduce emissions. Electronics Industry: Aluminium’s excellent thermal conductivity makes it an ideal material for electronic components. CNC machined aluminium parts are used in the production of heat sinks, housings, and connectors for electronic devices. Medical Industry: The medical industry benefits from the precision and accuracy of aluminium CNC machining. Surgical instruments, prosthetic devices, and medical equipment components are often made from aluminium due to its biocompatibility and corrosion resistance. Industrial Equipment: Aluminium CNC machined parts are used in various industrial applications, including machinery, tools, and equipment. The durability and versatility of aluminium make it suitable for a wide range of industrial uses. The CNC Machining Process Design and Programming: The CNC machining process begins with the creation of a digital design using CAD (Computer-Aided Design) software. This design is then converted into a CNC program that controls the machining operations.

Machining Operations: The CNC machine performs various operations such as milling, turning, drilling, and tapping to shape the aluminium into the desired part. The machine follows the programmed instructions with high precision. Quality Control: After machining, the parts undergo rigorous quality control checks to ensure they meet the required specifications. This may include dimensional inspections, surface finish evaluations, and material property tests. Finishing and Assembly: The final step involves any necessary finishing processes, such as anodizing or painting, to enhance the appearance and durability of the parts. The parts are then assembled into the final product. In conclusion, aluminium CNC machining offers numerous advantages, including high precision, cost-effectiveness, and versatility. Its applications span across various industries, making it an essential manufacturing process in today’s world.

0 notes

Text

The Comprehensive Guide to Aluminium Die Casting for Manufacturers

Introduction

Aluminium die casting is a manufacturing process that involves forcing molten aluminium into a mold cavity under high pressure. This method is widely used due to its ability to produce complex shapes with high dimensional accuracy and excellent surface finish. For manufacturers, understanding the intricacies of aluminium die casting manufacturers is crucial for optimizing production, ensuring quality, and maintaining cost-effectiveness. This blog delves into the key aspects of aluminium die casting, including its benefits, the process, applications, and best practices for manufacturers.

Benefits of Aluminium Die Casting

High Strength-to-Weight Ratio: Aluminium's inherent properties make it an ideal material for die casting. It provides a high strength-to-weight ratio, making it suitable for applications where durability and lightness are essential.

Excellent Thermal and Electrical Conductivity: Aluminium is an excellent conductor of heat and electricity, making die-cast aluminium components suitable for electrical and electronic applications.

Corrosion Resistance: Aluminium naturally forms a protective oxide layer, which enhances its resistance to corrosion. This property extends the lifespan of die-cast parts, especially in harsh environments.

Complex Geometries and Thin Walls: Aluminium die casting allows for the production of complex geometries and thin-walled parts that would be challenging or impossible to achieve with other manufacturing processes.

High Production Rates: Die casting is a highly efficient process with rapid production rates, making it suitable for high-volume manufacturing. The repeatability of the process ensures consistent quality across large production runs.

The Aluminium Die Casting Process

The aluminium die casting process can be broken down into several key stages:

Mold Preparation: The die, typically made from steel, is designed and prepared. It consists of two halves, the cover die and the ejector die. The mold is preheated and coated with a lubricant to facilitate the ejection of the cast part and to control temperature.

Melting and Injection: Aluminium ingots are melted in a furnace until they reach a liquid state. The molten aluminium is then injected into the mold cavity under high pressure, typically ranging from 1,500 to 25,000 psi. This high pressure ensures the molten metal fills the mold cavity completely, capturing intricate details and producing a dense, strong part.

Cooling and Solidification: Once the molten aluminium fills the mold cavity, it is allowed to cool and solidify. Cooling rates can be controlled to influence the mechanical properties and grain structure of the final part.

Ejection and Finishing: After solidification, the die halves are separated, and the cast part is ejected using ejector pins. The part is then subjected to various finishing processes such as trimming, deburring, and machining to achieve the desired specifications.

Quality Inspection: The finished part undergoes rigorous quality inspection to ensure it meets the required standards and specifications. This may involve dimensional checks, surface finish inspection, and testing for mechanical properties.

Applications of Aluminium Die Casting

Aluminium die casting is utilized across a wide range of industries due to its versatility and reliability. Some key applications include:

Automotive Industry: Aluminium die-cast parts are extensively used in the automotive industry for engine components, transmission housings, and structural parts. The lightweight nature of aluminium helps in improving fuel efficiency and reducing emissions.

Electronics and Telecommunications: The excellent thermal and electrical conductivity of aluminium makes it ideal for electronic housings, heat sinks, and connectors.

Aerospace and Defense: The aerospace and defense industries rely on aluminium die casting for components that require high strength, precision, and resistance to extreme conditions.

Consumer Goods: From household appliances to power tools, aluminium die-cast parts are found in numerous consumer products due to their durability and aesthetic appeal.

Industrial Machinery: Aluminium die casting is used to manufacture various components for industrial machinery, including pump housings, valve bodies, and motor housings.

Best Practices for Aluminium Die Casting Manufacturers

To achieve optimal results in aluminium die casting, manufacturers should adhere to the following best practices:

Design for Manufacturability (DFM): Collaborate with design engineers to ensure parts are designed with manufacturability in mind. This includes considering factors such as draft angles, wall thickness, and the placement of ribs and fillets to facilitate smooth production and minimize defects.

Material Selection: Choose the appropriate aluminium alloy based on the specific requirements of the application. Factors to consider include mechanical properties, corrosion resistance, and cost.

Mold Maintenance: Regular maintenance of the die is crucial to prolong its lifespan and maintain the quality of the cast parts. This includes cleaning, lubrication, and timely repairs.

Process Control: Implement robust process control measures to monitor and control variables such as injection pressure, temperature, and cooling rates. This ensures consistent quality and reduces the likelihood of defects.

Quality Assurance: Establish a comprehensive quality assurance program that includes inspection and testing at various stages of production. This helps in identifying and addressing issues early, ensuring that only parts that meet the required standards are delivered to customers.

Sustainability Practices: Embrace sustainable practices such as recycling aluminium scrap and minimizing energy consumption. Aluminium is highly recyclable, and incorporating recycled material can reduce costs and environmental impact.

Conclusion

Aluminium die casting is a versatile and efficient manufacturing process that offers numerous benefits to manufacturers. By understanding the intricacies of the process, selecting the right materials, and adhering to best practices, manufacturers can produce high-quality parts that meet the demanding requirements of various industries. As technology advances and new applications emerge, aluminium die casting will continue to play a pivotal role in modern manufacturing.

0 notes

Text

Alloy 6063 Aluminium Plates Stockist and Supplier Mumbai India

Aluminium alloy 6063 is highly regarded for its exceptional extrudability and corrosion resistance, making it a preferred choice for architectural, automotive, and industrial applications. In Mumbai, a dynamic centre of industrial activity, alloy 6063 aluminium plates are sought after for their versatility in design and durability in diverse environmental conditions.

Introduction to Alloy 6063 Aluminium Plates

Alloy 6063 belongs to the 6000 series of aluminium alloys, renowned for their combination of strength, formability, and surface finish quality. It is composed primarily of aluminium, magnesium, and silicon, which enhance its mechanical properties and corrosion resistance. This alloy is particularly favoured for its ability to be easily extruded into complex shapes, making it ideal for applications requiring intricate designs and aesthetic appeal.

Properties that Define Alloy 6063

Extrudability: Alloy 6063 is highly extrudable, allowing manufacturers to create intricate profiles and shapes with ease, making it popular in architectural applications.

Corrosion Resistance: The alloy's composition provides excellent resistance to corrosion, making it suitable for outdoor applications and structures exposed to varying weather conditions.

Aesthetic Appeal: It can be anodized to enhance its surface hardness and durability while also offering a range of attractive finishes to suit architectural preferences.

Lightweight: Like other aluminium alloys, 6063 offers a high strength-to-weight ratio, contributing to lighter structures and easier installation.

Applications Across Various Industries

Architectural: Widely used in window and door frames, curtain walls, and structural components due to its aesthetic appeal and durability.

Automotive: Utilized in trim components, interior fittings, and body structures where lightweight and corrosion resistance are essential.

Industrial: Applied in machinery components, heat sinks, and furniture frames where both strength and aesthetics are critical.

Advantages of Choosing Alloy 6063 Aluminium Plates

Design Flexibility: Allows for intricate and complex shapes, enhancing architectural and design possibilities.

Durability: Resistant to corrosion, fading, and degradation, ensuring longevity and minimal maintenance requirements.

Environmentally Friendly: Aluminium is recyclable, promoting sustainability and reducing carbon footprint.

Procuring Alloy 6063 Aluminium Plates in Mumbai

In Mumbai, numerous stockists specialize in alloy 6063 aluminium plates, offering a range of dimensions and specifications to meet diverse customer requirements. These suppliers ensure timely delivery and quality assurance, catering to both small-scale projects and large-scale developments with precision and reliability.

Alloy 6063 aluminium plates exemplify innovation and functionality in modern industrial applications. Their unique properties, including extrudability, corrosion resistance, and aesthetic appeal, make them indispensable across architectural, automotive, and industrial sectors. In Mumbai, a hub of industrial excellence, alloy 6063 aluminium plates continue to set benchmarks for quality and performance, contributing to sustainable and aesthetically pleasing solutions.

0 notes

Text

Aluminium Extrusion: Smart Solution for Product’s Innovation

Aluminium extrusions are among the most adaptable and valuable materials used across industries, offering unmatched versatility, lightweight properties, and impressive strength-to-weight ratios. As industries evolve to demand efficient, sustainable, and high-performing materials, aluminium extrusions have become a cornerstone in aluminium extrusion diverse applications, from construction to aerospace. Below, we explore their extensive uses and why they are an excellent choice for your products.

The Versatility and Applications of Aluminium Extrusions

1. Aluminium Extrusions in Construction: Building Durability and Efficiency

The construction industry heavily relies on aluminium extrusions for their superior properties, making them indispensable for modern infrastructure. Key applications include:

Framing Systems: Aluminium extrusions are widely used in door, window, and curtain wall frames. Their lightweight nature simplifies installation, reduces labor costs, and accelerates on-site assembly.

Corrosion Resistance: Ideal for outdoor applications, aluminium ensures durability and longevity, even in harsh environmental conditions. This property makes it an excellent choice for facades and cladding systems.

Design Versatility: Extruded aluminium can be customized into complex shapes, enabling architects to achieve both functional and aesthetic goals.

For example, Eleanor Extrusion India provided tailored aluminium profiles for a large-scale commercial building project. Our extrusions were used in curtain walls and window frames, ensuring both aesthetic appeal and structural integrity. This project highlighted our ability to deliver high-quality, durable solutions for the construction industry.

2. Transforming the Automotive Industry with Aluminium Extrusions

The automotive sector has gained popularity of aluminium extrusions for their contribution to vehicle performance and efficiency. Specific uses include:

Structural Components: Car frames, chassis, and suspension systems benefit from the lightweight yet strong nature of aluminium extrusions, reducing overall vehicle weight.

Fuel Efficiency: By minimizing weight, aluminium improves fuel economy and lowers emissions, aligning with global sustainability goals.

Crash Safety: Aluminium’s ability to absorb energy during impacts enhances passenger safety, making it a preferred material for automotive design.

3. Aerospace and Aviation: Elevating Performance with Aluminium

In the aerospace and aviation industries, aluminium extrusions are indispensable due to their remarkable balance of strength and weight. Key applications include:

Aircraft Frames: Components such as fuselage frames and wing structures rely on aluminium for structural integrity.

Landing Gear: Lightweight materials reduce overall aircraft weight, improving flight efficiency and fuel economy.

Heat Resistance: Aluminium’s thermal properties ensure reliable performance in extreme environments.

4. Supporting Electronics with Aluminium’s Thermal Properties

The electronics industry harnesses aluminium extrusions for their excellent heat dissipation capabilities. Common uses include:

Heat Sinks: Aluminium extrusions efficiently transfer heat away from electronic components, ensuring optimal performance and longevity.

Device Housings: Enclosures made from aluminium provide both protection and thermal management for sensitive electronic devices.

Cable Management Systems: Durable, lightweight profiles support efficient routing and protection of cables in complex systems.

5. Revolutionizing Furniture Design with Aluminium Extrusions

Modern furniture manufacturers are increasingly incorporating aluminium extrusions into their designs, thanks to their aesthetic and functional benefits:

Sleek Designs: Aluminium’s smooth finish and versatile shapes enhance the visual appeal of office furniture and modular systems.

Durability: Corrosion-resistant properties ensure outdoor furniture retains its quality over time.

Ease of Assembly: Lightweight and customizable, aluminium extrusions streamline furniture production and assembly processes.

This blog was originally published here

#aluminium extrusion solutions#eleanor industries#aluminium extrusion manufacturers#aluminium extrusion profiles#aluminium extrusion manufacturing company

1 note

·

View note

Text

Aluminum Matrix Composites, Global Top 13 Players, Market Share and Ranking (2023)

Aluminum Matrix Composites Market Summary

Aluminum Matrix Composites is a heterogeneous mixture of aluminum metal and alloys as the matrix and metal or non-metal particles/fibers as the reinforcement phase. It is widely used in automotive parts (such as engines, brake discs, gearboxes, etc.), aerospace fields (such as helicopter landing gear, aircraft support frames, etc.), and military/defense (such as heat sinks, heat sinks and substrates, etc.).

According to the new market research report "Global Aluminum Matrix Composites Market Report 2024-2030", published by QYResearch, the global Aluminum Matrix Composites market size is projected to reach USD 2059 million by 2030, at a CAGR of 5.4% during the forecast period.

Figure. Global Aluminum Matrix Composites Market Size (US$ Million), 2019-2030

Figure. Global Aluminum Matrix Composites Top 13 Players Ranking and Market Share (Ranking is based on the revenue of 2023, continually updated)

According to QYResearch Top Players Research Center, the global key manufacturers of @Aluminum Matrix Composites include DWA Aluminium Composites, Alvant, Triton Systems, Materion, CPS Technologies, Denka, Japan Fine Ceramics, 3M, Coherent, Grinm Metal, etc. In 2023, the global top five players had a share approximately 70.0% in terms of revenue.

Figure. Aluminum Matrix Composites, Global Market Size, Split by Product Segment

In terms of product type, currently Particle Reinforced is the largest segment, hold a share of 67.1%.

Figure. Aluminum Matrix Composites, Global Market Size, Split by Application Segment

In terms of product application, currently Aerospace is the largest segment, hold a share of 40.2%.

Figure. Aluminum Matrix Composites, Global Market Size, Split by Region

Market Drivers:

1. Downstream demand growth drives the development of the composite materials industry: Aluminum-based composite materials have the advantages of light weight, high specific strength, high specific modulus and good wear resistance. They overcome the shortcomings of a single material and give full play to the advantages of the matrix material and the reinforcing material. As the production process of aluminum-based composite materials is gradually improved and the cost is controlled, the industry is expected to show a booming trend and gradually expand in the application fields of new energy vehicles, aerospace, national defense, nuclear industry and electronics.

2. Technological upgrading will accelerate the development of the aluminum-based composite materials industry: Aluminum-based composite materials are gradually maturing in manufacturing equipment and production technology/processes, which will greatly improve the production and preparation process of aluminum-based composite materials.

3. Technological progress: With the continuous improvement of the manufacturing and processing technology of aluminum-based composite materials, its performance has been improved and the scope of application has been expanded.

4. Expansion of emerging application fields: In emerging fields such as 3D printing, electronics, optics, construction and shipbuilding, there is great potential, which will help the growth of the market size.

Trend:

1. Aluminum-based nanocomposites: By introducing nanoparticles into the metal body, the thermal stability and other properties of the material can be improved. At the same time, the nanocomposites also have excellent properties such as electrical conductivity and thermal conductivity.

2. Lightweight and high strength: Aluminum-based composites are widely used in the fields of automobiles, aerospace, etc. By using lightweight composite materials, the weight of the material structure can be reduced and fuel efficiency can be improved. At the same time, reasonable design of the manufacturing process will be able to achieve the requirements of high strength and high stiffness.

3. Multifunctional aluminum-based composites: In addition to the existing high strength, high modulus and other functions, by adding functional additives such as conductive materials and flame retardants, the thermal conductivity, flame retardancy, biocompatibility and flame retardancy of the composite materials can be achieved.

About The Authors

Jiashi Dong

Lead Author

Email: [email protected]

QYResearch Nanning Branch Analyst, as a member of the QYResearch Semiconductor Equipment and Materials Department, his main research areas include automotive electronics, semiconductor equipment, materials and thermally conductive powders. Some subdivided research topics include automotive diodes, automotive inductors, automotive lidar, radio frequency power supplies, plastic sealing machines, high-purity non-ferrous metals, battery materials, precursors, electroplating equipment, thermal conductive ball aluminum, semiconductor chemical plating solutions, semiconductor coating devices, etc. At the same time, he is also engaged in the development of market segment reports and participates in the writing of customized projects.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 17 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

Aluminum Nitride Ceramic PCB

Aluminum Nitride (AlN) is currently the best ceramic substrate material accessible. Its properties of high thermal conductivity (170 W/mK) combined with being a strong dielectric and a low expansion rate (CTE) make it the material of choice today as a substrate or package for high-power LEDs, ICs, sensors and many other components and circuits.

Reasons why you should choose Aluminum Nitride PCB for your project

Aluminum Nitride (AlN) PCBs offers several compelling reasons, especially in applications where thermal management, high-frequency performance, and reliability are critical. Here are some key reasons to consider using AlN PCBs:

·Exceptional Thermal Conductivity: AlN ceramics have excellent thermal conductivity properties, making them highly effective at dissipating heat generated by electronic components. This property is crucial for maintaining component reliability, extending the lifespan of electronics, and preventing overheating-related failures.

·High-Frequency Performance: AlN PCBs exhibit low signal loss and minimal signal distortion, making them well-suited for high-frequency and microwave applications. They provide reliable signal transmission and are ideal for RF (Radio Frequency) circuits, microwave antennas, and advanced communication systems.

·Electrical Insulation: AlN ceramics possess excellent electrical insulation properties. They have a high dielectric strength, preventing electrical leakage and ensuring the isolation of electrical components and signals. This insulation is essential for maintaining signal integrity and preventing unintended electrical connections.

·Mechanical Strength: AlN ceramic substrates have good mechanical strength, with the ability to withstand mechanical stresses during manufacturing, assembly, and operation. This mechanical robustness contributes to the overall reliability of electronic systems.

·Compatibility with Semiconductor Devices: The thermal expansion coefficient of AlN is relatively close to that of silicon, a common material used in semiconductor devices. This compatibility allows for efficient heat transfer from semiconductor components, reducing the risk of thermal stress and enhancing their performance and longevity.

·High-Power and High-Temperature Applications: AlN PCBs are well-suited for high-power electronic components and high-temperature environments. They can efficiently dissipate heat from power amplifiers, voltage regulators, LEDs, and other heat-generating devices.

·Longevity and Reliability: The superior thermal management provided by AlN PCBs contributes to the longevity and reliability of electronic systems, reducing the risk of premature component failures due to overheating.

·Wide Range of Applications: AlN PCBs find application in various industries, including aerospace and defense, telecommunications, medical devices, automotive, and industrial electronics. They are versatile and suitable for demanding electronic applications.

·Customization: AlN PCBs can be customized to meet specific design requirements, including layer count, dimensions, and design layout, ensuring that they are tailored to the needs of the application.

·Efficient Heat Dissipation: The exceptional heat dissipation properties of AlN PCBs allow for the effective management of thermal issues without the need for additional cooling mechanisms, such as heat sinks or fans.

In conclusion, choosing Aluminum Nitride (AlN) PCBs offers lots of advantages, including superior thermal conductivity, high-frequency performance, electrical insulation, and mechanical strength. These properties make them a preferred choice in applications where traditional PCB materials may not meet the stringent requirements for thermal management and reliability. At Hitech Circuits, we supply both Aluminium Nitride PCB (AlN) processed by thick film process (Silver/silver palladium metalization) as well as Direct Plated Copper Technologies (DPC), with copper tracks and pads.

#AINPCB #ceramicpcb

0 notes

Text

How Can a Fanless Computer Remain Cool?

Compared to a conventional fanned Personal computer, particularly small kind factor fanned PCs, a fanless computer doesn’t necessarily look dramatically diverse. Even so, there are numerous subtle stuff occurring that protect against these calm, unassuming components of equipment from burning up up. Just how does a fanless Personal computer stay amazing?

Fanless computers often awesome in accordance with the theory of conduction – that may be, some thing popular dissipating heating into its setting through actual physical speak to. Warmth conduction is a all-natural occurrence, but the amount heating is dissipated might be significantly affected by style.

The fundamental strategy is to place heating-undefinedmaking components, just like the computer’s Central processing unit, in contact with a heat kitchen sink. A heat sink will allow the temperature produced by the constituents to flow through it and finally to the encircling air flow. When designing a heat kitchen sink assemblage, it is crucial that you look at what resources you will use and just how all of its components will interface with one another. See our Tech Benefit online video about how fanless cooling down works listed below, and look at on to learn more.

Temperature basins certainly are a core part for helping a fanless Laptop or computer remain awesome. What is the most effective materials to get a temperature drain? It makes sense that a temperature sink needs to be constructed from a temperature conductor. A lot likewise a power conductor offers a pathway for your circulation of power existing, a heating conductor is actually a materials in which temperature can stream conveniently. If anything very hot (say for example a Processor) is in touch with one particular end of the heating conductor and something relatively cold (such as the oxygen away from Laptop or computer) is in contact with the other aspect, heat will rapidly circulation from the source of heat with the conductor. Aluminium and copper are the business-undefinedbeloved conductors utilized for heating basins.

Most OnLogic temperature sink assemblies comprise of two major parts: an light weight aluminum prohibit fitted along with the Processor, and the case top. Temperature is transferred through the Processor in the aluminum prevent, then your cover, and lastly the nearby oxygen. There needs to be successful heating carrying out interfaces between every one of these elements to be able to efficiently cool the system.

Creating an efficient program for warmth shift is attained differently internally and away from the Computer. Air flow itself is a terrible temperature conductor,fanless mini PC so on the inside of the PC it is vital that you get rid of the maximum amount of atmosphere as is possible in between the Processor and heat sink.

Merely installing the high temperature drain in the Central processing unit is not really enough because minute imperfections depart oxygen pockets at the program stage. The most prevalent way of getting around this can be introducing thermal mixture, that is a greater conductor than atmosphere. The thermal paste fills all of the spaces that could otherwise have oxygen within them.

Common sense Source ML300 LidOn the beyond the Personal computer, heat has been dissipated directly into the atmosphere so an alternative technique is necessary. A frequent layout is a lid protected in specially-manufactured ridges. These ridges boost the overall surface subjected to the atmosphere, properly introducing far more passageways for temperature to escape. Should you look closely, at times even ridges could have ridges more increasing the surface area.

These concepts can assist you stay away from a number of pitfalls when constructing or employing a fanless Computer. As an example, although temperature paste is a better conductor than air, it is a reasonably poor one particular compared to copper or lightweight aluminum. This means that you ought to just use adequate to complete the gaps where it really is essential. Anymore so you are creating a energy shield that could overheat your computer.

Another frequent complication in order to avoid is setting something on top of a fanless personal computer. A good single notepad can capture a budget of heat about the Personal computers lid, preventing the pc from cooling. You must also think about the atmosphere all around the Computer. When the around air is unable to rotate (as it could be inside a confined space) or too slim (like at substantial elevations) it will have significantly less prospect of hauling heating outside the Computer.

related articles:

So How Exactly Does A Fanless Pc Work?

How to decide on the very best Smaller Laptop or computer For Yourself

The Great things about a Fanless Business Computer

0 notes