#led pcb manufacturer

Explore tagged Tumblr posts

Text

4 Crucial Things to Consider While Choosing LED PCB Manufacturer

LEDs have revolutionized lighting. At the heart of their brilliance, is the PCB assembly. Electing the right LED PCB assembly manufacturer can make or break your project. This ensures quality, performance, and ultimately, success. So, before you dive into the luminous world of LED PCBs, this article sheds some light on the key factors to consider when making your purchase:

1. Experience Matters: You should choose a manufacturer with proven expertise in LED PCB assembly. The company you choose should have a track record of successful projects similar to yours. Experience means they will understand your specific needs and deliver assemblies that meet or exceed your expectations.

2. Material Matters: The heart of your PCB is its materials. Go for manufacturers

who ensure high-quality FR4 or metal-core PCBs for optimal thermal management and longevity. They must adhere to industry standards for materials and components to guarantee reliability and safety.

3. Thermal Management: LEDs are designed to generate heat, so proper thermal management plays a crucial role. Look for manufacturers who offer solutions like aluminium heat sinks. Their expertise in thermal management can extend the lifespan of your LED PCB and prevent overheating issues.

4. Price is Not Everything: Though cost is important, its priority is not over quality.

The cheapest option might have hidden costs in the long run. Choose a manufacturer who offers budget-friendly pricing while maintaining high-quality standards and reliable service.

If you are looking for an LED PCB manufacturer near you you can count on Hitech Circuits Co., Limited. They have more than 20 years of experience in the electronics manufacturing industry. They have a talented design team who follow advanced manufacturing techniques.

These guidelines help you illuminate your path to finding the perfect LED PCB assembly manufacturer. Your choice has a direct impact on the performance, lifespan, and success of your project.

2 notes

·

View notes

Text

Excellence Unleashed: Unrivaled PCB Manufacturer in China

Top-quality PCB manufacturing services from China's leading manufacturer. Get precision-engineered circuit boards for your electronic projects. Fast turnaround, competitive prices, and reliable delivery. Contact PCB Manufacturer in China today for all your PCB needs! Visit our site: https://www.readapcb.com/

#PCB Manufacturer in China#PCB manufacturing in China#pcb quick prototype#LED PCB manufacturer#PCB assembly in China#Aluminum pcb manufacturer#PCB design in China#HDI PCB manufacturer#Multilayer PCB manufacturing#PCBA manufacturing in China

0 notes

Text

J-Cube Technologies Inc.

J-Cube Technologies Inc. is an organization that specializes in the production of printed circuit boards (PCBs).

Our company is based in Montreal, Canada, and has been active in the industry for over a decade. Through our success in Asian infrastructure development and the expansion of our engineering and technical manufacturing expertise, we have grown to be a world-class provider of comprehensive and reliable electronic solutions.

#jcubetech#jcubetechca#J-Cube Technologies Inc#metal pcb#metal core pcb manufacturer#metal core printed circuit board#aluminum core pcb#mcpcb#LED MPCB#Ceramic PCB#mcpcb manufacturer#Quick turn mpcb#pcb core#Printed Circuit Board#Analog circuit#Bare board#Blind via#Component#Dip Trace#Schematic Capture#Library Pane#Schematic Pane

2 notes

·

View notes

Text

One-stop PCB assembly service and PCB manufacturing supplier -- Hitechpcba

As a leading one-stop electronics manufacturing services provider in China, Hitech Circuits Co., Limited offers high quality, cost effective and quick turn PCB board products, Printed Circuit board, PCB assembly, electronics assembly manufacturing, Electronic parts components sourcing services for your new products development.

With mature supply chain, talented design team, advanced manufacturing techniques and quality control systems, Hitech Circuits Co., Limited is able to provide one-stop electronics manufacturing services and solution for our customers to help them stand out in the marketplace.

4 notes

·

View notes

Text

Testing Cable Harness? Explore Quality Solutions Here!

Want to ensure your electrical systems are functioning flawlessly? Make it happen with our high-quality Testing Cable Harness. These cable harnesses are designed to meet your all-specific testing requirements. Visit Equip-Test to find out our collection and order the perfect testing cable harness that suits your needs.

#simple cable harness tester#test probes#flash programming#cable harness test modules#led probe#manufacturing pcb test equipment#testing cable harness

0 notes

Text

LED Wheel with Relays Circuit Art in Motion

PCB & PCBA(Quick quote):[email protected]

https://lnkd.in/gAhdxTUx

#pcb#pcb assembly#electronic#pcb design#electrical design#female led relationship#led zeppelin#hardware#pcb manufacturer#flex pcb

0 notes

Text

Copper Based PCB (Copper printed circuit board), Hitech Circuits – one of best PCB manufacturer in China

Hitechpcb is a professional PCB Manufacturer in Shenzhen, China. We have sufficient stocks of Copper based PCB material, that can ship copper based PCB to you on time. Also, now we can provide components sourcing and assembly services for our customer.

Email us Cynthia<[email protected]> if you are interested in PCB and PCBA service.

0 notes

Text

Медный сердечник PCB - медный фундамент + изоляция + медь

PCB с медным сердечником - это PCB с медной базой + изоляцией + слоем медной схемы, также известный как PCB с медной базой, PCB на медной основе и PCB с медной оболочкой.

ПХБ на основе меди - это металлический сердечник с медной пластиной. Если фундамент гибридного PCB представляет собой медную пластину, встроенную в пластину FR4, то это также PCB на основе меди.

#pcb fabrication#pcb assembly#pcb manufacturer#aluminium pcb#pcba manufacturing#pcb#flex pcb#flex circuit pcb#pcb design#led pcb#Copper core pcb

0 notes

Text

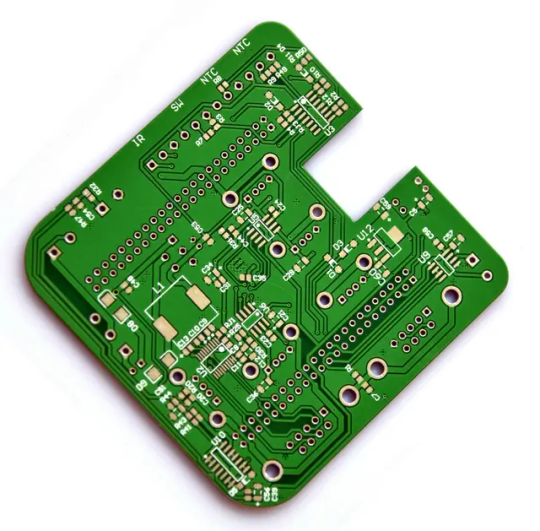

LED PCB Assembly

LED PCB Manufacturer & Assembly – One-stop service

What is the LED Circuit Board assembly?

Generally, LED PCB assembly is considered to be a circuit board that has the LED components soldered to it. The LED is soldered to the printed circuit board and features a chip that creates the light as electrically connected. A thermal heat sink and a ceramic base are used to bond the chip. Not all the PCB products can be used in Led industry, as an LED PCB is easy to create a high volume of heat, but making it hard to cool with traditional methods. For this reason, metal core PCB is widely used in LED application because of their enhanced ability to dissipate heat, especially aluminum pcb is often used to fabricate PCB for LED lights.

We’ve had great LED PCB assembly experiences with top LED chips to brand such as Cree, Luxeon, Osram, Nichia, Lumileds, MLS, EVERLIGHT, Samsung, LG, Seoul., etc. PCB LED lights can be incorporated into numerous lighting applications due to their combination of excellent energy efficiency, low cost and maximum design flexibility.

Application of LED PCB Assembly

Hitechpcba serves customers in different industries, providing highly reliable and innovative LED PCBs for various applications:

• Horticulture light LED PCB Assembly

• LED controller PCB Assembly

• Computer LED display and indicators

• LED lights PCB Assembly for medical use

• Automotive LED PCBs Assembly include PCBs for brake lights and headlights

• Street lighting LED PCB Assembly

• Flashlights and camping accessories

• Traffic light PCB Assembly

• Commercial lighting LED PCB Assembly

LED PCB Assembly specification

Number of layers for LED PCB

These layers are made up of aluminum and magnesium, but now have Copper base material and Ceramic base materials for LED PCB industry, we can meet it.

Aluminum LED PCBs stand out among other PCBs because it has a good insulation characteristic and has a better machinery performance, the cheap cost is one important factor too.

Types of layers for LED PCB Assembly

Normally, the base layer is made using aluminum alloy metal.

This aluminum alloy substrate used in making the base makes it ideal for through-hole technology which transfers and dissipates heat.

A thermal insulation layer is made using some ceramic polymer which has good viscoelasticity characteristics.

It is highly heat resistant and protects the PCB against heat and mechanical stress.

The circuit layer, which is covered by a copper foil which can range from one to ten ounces.

LED Board type- single or in panel

Some boards are shapeless. For this reason, LED PCB panels are used. This reduces time, labor production and testing time.

Some LED PCB Assembly is done on a single board while others are done on panel boards.

LED PCB Assembly Process

Roughly, the PCBA process can be divided into theses phases: soldering paste printing > SMT (surface mounted technology) > reflow soldering > AOI (automated optical inspection)> THT (through-hole technology) > wave soldering > touch-up and cleaning > IC-programming > FCT (functional tests) > aging testing.

Below we show you the process.

Step1. Summarizing Project Information

Before contacting your supplier, make sure you have all the project information. Suppliers will need info following for quoting LED PCB assembly:

Gerber

BOM

LED PCB specification

Quotation quantity

Once you have gathered these information, you can contact us and request for a quote.

Of course, you can also provide the schematic, LED PCB Assembly pictures and even samples to us. The more details they have, the more accurate the supplier’s quotation will be.

Step2. Discussion and details about custom LED PCB Assembly

Different projects will have different requirements. Remember the special requirements mentioned in step 1? That’s going to be the focus of this session. Equipment and engineering capacity will not be identical between suppliers. Make sure your supplier has the equipment to produce and assemble major components and the corresponding testing capabilities.

For example, some vendors don’t have X-ray testing equipment, which means they can’t check the mount quality of BGA chips. Outsourcing this step will increase risk and cost. That’s what you don’t want.

Also, pay attention to time taken by the supplier to quote. Motherboards often contain hundreds or even thousands of components, and they are supplied by different manufacturers. To ensure the quality of the components, the supplier sourcing team will make multi-inquiries from these manufacturers or authorized suppliers to match customer’s requirement, which usually takes 2-3 business days, and even longer for some scarce chips. Therefore, if your project is complex and the supplier quotes you within few hours, double check with them.

Step3. Sample and feedback

After confirming the PI, the supplier will usually provide pre-production samples for your approval. At the same time, the supplier will also confirm with you the logistics plan of the bulk goods. Make sure they understand your shipping requirements, including details on packaging, customs clearance, taxes, etc.

For us to have a successful LED PCB Assembly process, its functions must be defined. Compliance requirement is defined to reduce the effect when components are selected.

The Bill of Materials is then generated from the information installed on the LED PCB.

All this information is used to assemble components which are identified from MOB to the LED PCB.

After that, the routing of traces is determined to each component, based on the size, shape of the circuit board and location of connectors.

Hitech Circuits is trusted by thousands of electronic engineers on their LED PCB assembly projects, from consumer, led bulb to precisely medical LED light, we can help you from the beginning of design stage; From commercial flood LED to industrial high power LED, from automotive LED to military LED, Venture is the perfect place for your LED PCB assembly requirement.

Hitech Circuits has been participated in hundreds and thousands of LED lighting projects, by providing LED PCB and also LED PCB assembly service.

Our LED PCB assembly had covered both ends of the Lighting Class LED size spectrum, assembling some of the largest (2 meter long boards) and some of the smallest LED Lighting applications which used in Medical Endoscopes.

LED PCB Assembly is very crucial in the current industrial development. Many electrical devises are being innovated and the old once being improved.

LED PCBs are useful due to the fact that they are made using materials that can transfer and dissipate heat. This characteristic increases device durability.

The world is changing with new technology, especially PCB technology that plays an essential role in the application of LED circuits. And the LED industry is taking advantage of this technology and growing faster.

As a full feature PCB solutions provider with more than a decade of experience, we're capable to provide LED PCB fabrication, components procurement and LED PCB assembly all under one roof. We can work with you to develop metal core PCB, aluminum circuit boards customized to your specific applications. We feature competitively priced PCBs made with standard FR-4 material that includes a thermal aluminum clad layer that will efficiently dissipate heat, keep all LED PCB components cool and significantly enhance the performance of your products.

LED Pcb Board, LED pcb Assembly

LED with its advantages of high brightness, high efficiency, low heat, long life, is considered the most development potential in the 21st century lighting. In the market and policy driven by the rapid development of the domestic LED industry blowout has formed a relatively complete industrial chain, including the production of epitaxial wafers, chip preparation, packaging, integration, LED application. In 2010, China's LED industry scale, up from $ 827 billion in 2019 to 220 billion yuan, an annual growth rate of over 70%, higher than the 50% level of growth of the global LED lighting industry output value. Among them, the middle and lower reaches of the most complete industrial chain, accounting for 90% of the overall percentage of the GDP.Chinahas become the world's leading LED manufacturing base and important application market.

To further promote the technological innovation of the LED industry, construction and wide application of independent industry chain, China Electronic Appliance Corporation and industry associations to organize the theme of "Focus on the core energy LED Exhibition will be held November 9-11, 2010 in Shanghai International Expo Center and the 78th China Electronics Fair over the same period will be held will create from raw materials, epitaxial wafers, chip, LED bracket, LED accessories, LED packaging and supporting materials, the LED backlight upstream firm to the upstream and downstream enterprises of the display, lighting, landscaping, decorative lighting, traffic lights, automotive lighting, special lighting, to the equipment, instrumentation, software, finance, consulting and other service enterprises and technological exchanges and market trading platform, help the domestic industry sustained and healthy development, and promote the steady expansion of the LED application market.

In the LED industry chain upstream of the epitaxial wafers and LED chips accounted for 70% of the profits of the whole industry, and technology-intensive, capital-intensive, where the core technology of the LED. Well-known epitaxial wafer and chip production enterprises will be exhibited a number of energy-efficient, low heat, cost-effective LED products, many of whom have excellent products of international advanced level.

LED electronic pcb assembly manufacturing 100% Original LED Chip with one-stop in-house pcba services

0 notes

Text

Por que escolher o substrato de alumínio PCB para aplicações de LED?

O substrato de alumínio para PCB é um tipo de placa de circuito baseada em metal que utiliza o alumínio como seu material principal. Ao contrário das PCBs tradicionais que usam FR4 ou outros materiais não metálicos, o substrato de alumínio oferece condutividade térmica e resistência mecânica superiores. O principal objetivo do uso de um substrato de alumínio para PCB é melhorar a dissipação de calor em componentes eletrônicos que geram calor significativo durante a operação. Esse tipo de substrato é particularmente útil em aplicações em que a manutenção de baixas temperaturas operacionais é fundamental para evitar danos e garantir a longevidade.

No setor de eletrônicos, os substratos de alumínio para placas de circuito impresso são comumente encontrados em sistemas de iluminação LED de alta potência, conversores de energia e eletrônicos automotivos, onde o gerenciamento de calor é uma consideração fundamental. Ao proporcionar uma condutividade térmica eficiente, o substrato de alumínio ajuda a proteger componentes sensíveis, permitindo maior desempenho e maior durabilidade. Sua capacidade de suportar temperaturas mais altas faz com que seja a escolha preferida de muitos engenheiros que projetam dispositivos eletrônicos sensíveis ao calor ou de alta potência.

Principais usos do substrato de alumínio para PCB

Iluminação por LED: Uma das aplicações mais importantes do substrato de alumínio para PCB é em sistemas de iluminação LED. Os componentes de LED geram calor significativo durante a operação e, sem a dissipação de calor adequada, sua eficiência e vida útil podem ser drasticamente reduzidas. A alta condutividade térmica do substrato de alumínio pcb ajuda a transferir o calor para longe dos LEDs, garantindo um desempenho estável. Os substratos de alumínio permitem que os LEDs funcionem em temperaturas mais baixas, o que não apenas melhora a eficiência energética, mas também aumenta a vida útil do sistema de iluminação. É por isso que os substratos de alumínio para placas de circuito impresso são amplamente usados em painéis de LED, luzes de rua e faróis automotivos, onde o gerenciamento do calor é crucial para a confiabilidade.

Módulos de potência e eletrônicos de potência: Em módulos de potência e dispositivos eletrônicos de alta potência, como conversores e amplificadores de potência, o gerenciamento de calor é uma grande preocupação. O substrato de alumínio da placa de circuito impresso oferece uma solução eficaz, permitindo a dissipação eficiente do calor. Como esses dispositivos de potência geram calor durante a operação, o substrato de alumínio conduz rapidamente o calor para longe dos componentes, evitando o superaquecimento. Isso garante uma operação estável, aumenta a durabilidade e reduz o risco de danos térmicos. Essas qualidades tornam os substratos de alumínio pcb ideais para eletrônica de potência industrial, sistemas de energia renovável e outras aplicações de alta potência.

Fatores que afetam o preço do substrato de alumínio para PCB

Custos dos materiais: Um dos principais fatores que influenciam o preço de um substrato de alumínio para PCB é o custo das matérias-primas. Em geral, o alumínio é mais acessível do que outros metais, mas as flutuações nos preços globais do alumínio podem afetar o custo geral do substrato. Além disso, a espessura da camada de cobre usada na construção da PCB afeta significativamente o preço. Uma camada de cobre mais espessa melhora a condutividade e a durabilidade da placa, mas também aumenta os custos do material. Portanto, o preço final de um substrato de PCB de alumínio varia de acordo com o tipo e a espessura do alumínio e do cobre usados.

Processo de fabricação: As técnicas de fabricação empregadas por diferentes fornecedores podem levar a variações nos preços. Alguns fabricantes usam processos mais avançados ou precisos que melhoram a qualidade, o desempenho térmico ou a durabilidade do substrato. Esses processos aprimorados podem incluir melhores técnicas de gravação ou laminação de alta precisão, o que pode aumentar os custos de produção. Os fornecedores com tecnologia de ponta ou controle de qualidade rigoroso geralmente cobram mais pelos substratos de alumínio para placas de circuito impresso. No entanto, esses custos mais altos geralmente se traduzem em melhor desempenho e confiabilidade, especialmente em aplicações críticas como eletrônica de potência ou iluminação LED.

Volume do pedido: O volume do pedido também desempenha um papel importante na determinação do preço dos substratos de alumínio para placas de circuito impresso. Os pedidos em massa tendem a se beneficiar das economias de escala, reduzindo o custo por unidade à medida que a produção aumenta. Os fabricantes de grande porte podem distribuir seus custos fixos por uma quantidade maior, o que lhes permite oferecer preços mais competitivos para pedidos de grande volume. Por outro lado, pedidos menores ou personalizados podem incorrer em custos de produção mais altos, resultando em um preço mais alto por unidade. Para empresas que precisam de um grande número de substratos para produção em massa, a compra em massa é uma estratégia econômica.

Comparação entre PCB de alumínio e FR4

Desempenho térmico: Uma das diferenças mais significativas entre um substrato de PCB de alumínio e o FR4 está em seu desempenho térmico. As PCBs de alumínio são projetadas especificamente para oferecer dissipação de calor superior, o que as torna altamente eficazes em aplicações em que o gerenciamento térmico é fundamental. O núcleo de alumínio permite a transferência eficiente de calor para longe dos componentes eletrônicos sensíveis, o que reduz o risco de superaquecimento e prolonga a vida útil do dispositivo. Por outro lado, o FR4, que é feito de vidro trançado e resina epóxi, tem condutividade térmica limitada. Embora o FR4 seja adequado para aplicações de baixa potência, ele tem dificuldades em ambientes de alta potência, onde o calor excessivo pode danificar os componentes.

Resistência e peso: Outra distinção importante entre o alumínio e o FR4 é a resistência e o peso. Os substratos de alumínio para Pcb são conhecidos por sua combinação de leveza e durabilidade. O alumínio não é apenas mais leve que o FR4, mas também mais forte, oferecendo maior estabilidade mecânica e resiliência. Isso torna as PCBs de alumínio mais adequadas para aplicações que exigem resistência física robusta, como eletrônica automotiva e industrial, em que as placas podem ser expostas a condições adversas. Por outro lado, o FR4 é mais pesado e menos durável, mas continua sendo uma opção confiável e econômica para aplicações eletrônicas padrão em que a resistência não é um fator crítico.

Diferentes aplicações: A escolha entre substrato de alumínio para pcb e FR4 depende muito da aplicação específica. O FR4 é amplamente usado em eletrônicos convencionais, como aparelhos de consumo, telecomunicações e circuitos de uso geral, pois é econômico e suficiente para operações de baixo calor e baixo consumo de energia. Entretanto, os substratos de alumínio para placas de circuito impresso são a opção ideal para ambientes de alta temperatura e alta potência. Eles são particularmente predominantes em iluminação LED, eletrônica de potência e sistemas automotivos, onde a dissipação eficiente de calor é essencial para manter o desempenho e evitar falhas nos componentes. Assim, enquanto o FR4 se destaca em aplicações padrão, as PCBs de alumínio brilham em condições térmicas e mecânicas mais exigentes.

Placa PCB de alumínio para aplicações de LED

Papel detalhado na dissipação de calor e na vida útil: Nos sistemas de iluminação LED, o gerenciamento eficiente do calor é fundamental para manter o desempenho e a longevidade, o que torna o substrato de alumínio da placa de circuito impresso uma escolha preferencial. Os LEDs geram uma quantidade significativa de calor durante a operação e, se não for dissipado adequadamente, esse calor pode degradar a eficiência do LED e reduzir sua vida útil. Os substratos de alumínio desempenham um papel fundamental ao fornecer um caminho térmico direto para que o calor escape dos componentes do LED. O núcleo de alumínio tem alta condutividade térmica, o que permite que ele transfira rapidamente o calor dos LEDs e o dissipe no ambiente. Isso não apenas mantém os chips de LED mais frios, mas também garante que o sistema geral funcione de forma mais confiável. Ao evitar o superaquecimento, o substrato de alumínio da placa de circuito impresso aumenta significativamente a vida útil dos produtos de LED, reduzindo os custos de manutenção e melhorando a eficiência energética.

Uso em vários sistemas de iluminação por LED: A versatilidade dos substratos de alumínio pcb levou ao seu uso generalizado em uma variedade de sistemas de iluminação LED. Eles são comumente usados em aplicações de LED de alta potência em que a dissipação de calor é fundamental, como em luzes de rua, holofotes e luzes de compartimento alto. Nesses sistemas, o substrato de alumínio garante que os LEDs mantenham temperaturas operacionais ideais, mesmo em ambientes adversos. Além disso, eles são utilizados na iluminação de fundo de LEDs para televisores e monitores, em que a manutenção de baixas temperaturas é essencial para preservar a qualidade da imagem e evitar a degradação das cores com o passar do tempo. Os substratos de alumínio para Pcb também são encontrados em faróis de LED automotivos, onde o gerenciamento eficiente do calor é necessário para garantir o desempenho e a segurança. Sua capacidade de lidar com altas temperaturas e, ao mesmo tempo, permanecer leve e durável torna as PCBs de alumínio indispensáveis em aplicações de LED de alta potência e sensíveis ao calor.

O que é uma PCB de material à base de alumínio?

Estrutura de uma PCB à base de alumínio: uma PCB de material à base de alumínio, comumente chamada de PCB de alumínio, consiste em várias camadas importantes que trabalham juntas para oferecer funcionalidade elétrica e gerenciamento térmico eficiente. A estrutura central normalmente inclui uma camada espessa de alumínio que serve como substrato, uma camada de isolamento dielétrico e uma camada de cobre para conexões elétricas. A camada de alumínio fornece uma base sólida e excelente condutividade térmica, enquanto a camada dielétrica é projetada para suportar altas temperaturas e garantir o isolamento elétrico entre o circuito de cobre e a base de alumínio. Essa construção multicamada permite que as PCBs de alumínio dissipem com eficiência o calor gerado pelos componentes eletrônicos, tornando-as particularmente adequadas para aplicações de alta potência e alta temperatura, como iluminação LED, amplificadores de potência e eletrônicos automotivos.

Função em aplicações de alta potência e alta temperatura: A estrutura exclusiva das PCBs à base de alumínio permite que elas tenham um desempenho excepcional em ambientes em que o gerenciamento de calor é fundamental. Em aplicações de alta potência, os componentes geram calor significativo durante a operação, o que pode levar à degradação do desempenho ou à falha se não forem gerenciados adequadamente. As PCBs de alumínio são projetadas para transferir o calor para longe desses componentes de forma rápida e eficiente, evitando pontos quentes e garantindo uma operação confiável. Esse recurso é especialmente importante em aplicações como sistemas de iluminação LED, em que a exposição prolongada a altas temperaturas pode reduzir a eficiência e a vida útil. Ao manter temperaturas operacionais ideais, as PCBs de alumínio ajudam a aumentar a durabilidade e o desempenho dos dispositivos eletrônicos.

Por que usar alumínio em PCBs?: A escolha do alumínio como material de base na fabricação de PCBs é motivada por suas propriedades excepcionais que atendem às necessidades das aplicações eletrônicas modernas. Uma das vantagens mais significativas do alumínio é sua capacidade superior de dissipação de calor. O alumínio tem uma alta condutividade térmica, o que lhe permite conduzir e dispersar o calor com muito mais eficácia do que os materiais tradicionais, como o FR4. Essa propriedade é fundamental para evitar o superaquecimento em aplicações de alta potência, aumentando assim a vida útil dos componentes eletrônicos.

Além disso, o alumínio oferece resistência mecânica substancial, o que o torna uma opção robusta para aplicações que podem ser expostas a estresse físico ou a condições ambientais adversas. Sua natureza leve contribui para a portabilidade e a eficiência gerais do dispositivo, pois não acrescenta peso desnecessário ao produto final. Essas características fazem do alumínio um material ideal para a fabricação de PCBs, especialmente em setores que exigem alta confiabilidade e desempenho sob estresse térmico e mecânico. Como resultado, as PCBs baseadas em alumínio são cada vez mais favorecidas em vários setores, incluindo o automotivo, o de telecomunicações e o de eletrônicos de consumo, em que o gerenciamento eficiente do calor e a durabilidade são fundamentais.

Nós Hitech Circuits estamos sempre dedicados a fornecer preços competitivos, boa qualidade e prazo de entrega rápido para nossos clientes. Se você tiver alguma necessidade de PCI, não hesite em contactar-me.

#LED#PCB#pcb assembly#pcb design#pcb factory#aluminum pcb#pcb fabrication#pcb manufacturer#https://hitechcircuits.com/

0 notes

Text

0 notes

Text

Unlocking the Power of Ceramic PCBs: A Game changer in Electronics

Ceramic PCBs (Printed Circuit Boards) are a game-changer in electronics. Unlike regular PCBs made from fiberglass, these use a ceramic base, offering better heat management and durability. They perform exceptionally well in high-temperature and high-power settings.

Why Choose Ceramic PCBs?

Ceramic PCBs have many benefits. They handle heat efficiently, making them perfect for power electronics, LED lights, and car systems. Their strong build means they can withstand tough environments, ensuring your devices last longer and work more reliably.

Applications of Ceramic PCBs

Ceramic PCBs from Hitech Circuits Co. Limited are used in various industries. From aerospace and telecommunications to medical devices and renewable energy, these boards meet diverse needs. With our expertise, Ceramic PCBs provide top-notch performance in any application.

The Hitech Circuits Co. Limited Advantage

At Hitech Circuits Co. Limited, quality and innovation are our priorities. Our modern manufacturing facilities and skilled team ensure every Ceramic PCB meets the highest standards. With years of experience and a focus on customer satisfaction, we are your trusted source for advanced Ceramic PCB solutions.

Conclusion

Discover the unmatched performance and reliability of Ceramic PCBs with Hitech Circuits Co. Limited. Enhance your electronic designs with our cutting-edge circuit boards and explore new possibilities in technology. Choose Hitech Circuits Co. Limited for Ceramic PCBs that set new standards in the electronics industry.

0 notes

Text

LED PCB

LED PCBs are engineered to power and control light-emitting diodes efficiently. Our LED PCBs feature thermally conductive materials for effective heat dissipation, ensuring optimal LED performance and longevity. Precision manufacturing and design expertise make our LED PCBs ideal for various lighting applications, from commercial displays to automotive lighting systems. Read More: https://sqpcb.com/products/led-pcb

#PCB Supplier#PCB Manufacturer#Custom Circuit Boards#Multi Circuit Boards#Aluminum base PCB#Multilayer PCB#aluminium pcb board#Customize Pcb#customized pcb boards#pcb board#printed circuit board#circuit board#Pcb manufacturing#Assembly pcb#pcb china#special pcb#LED PCB#rigid flex pcb

0 notes

Text

XDPCBA.cn: Exploring the Advantages and Applications of Flex PCB in Modern Electronics

Flex PCB, also known as flexible printed circuit boards, have revolutionized the world of modern electronics with their numerous advantages and wide-ranging applications. These lightweight and versatile circuit boards offer a host of benefits that traditional rigid PCBs simply cannot match.

One of the key advantages of flex PCB is its flexibility, allowing it to be bent, folded, or twisted to fit into tight spaces or unconventional shapes. This flexibility enables designers to create innovative and compact electronic devices that were previously impossible with rigid boards. From wearable technology to medical devices and automotive applications, flex PCBs have opened up new possibilities for product design.

In addition to their flexibility, flex PCBs offer enhanced durability and reliability. Their ability to withstand vibrations, shocks, and extreme temperatures makes them ideal for applications in harsh environments where traditional circuit boards may fail. This durability ensures the longevity and performance of electronic devices even in demanding conditions.

Another notable advantage of flex PCBs is their lightweight nature. Compared to rigid boards, they are significantly lighter due to their thin profile and absence of bulky connectors or cables. This weight reduction not only contributes to overall product weight savings but also allows for greater design freedom by eliminating space constraints.

The applications of flex PCBs are vast and diverse. They are widely used in consumer electronics such as smartphones, tablets, and wearables where space optimization is crucial. Additionally, industries like aerospace, automotive manufacturing, healthcare equipment, and industrial automation rely on flex PCBs for their unique properties.

In conclusion, the advantages offered by flex PCB technology have propelled it into becoming an indispensable component in modern electronics. Its flexibility, durability, lightweight nature along with its wide range of applications make it a preferred choice for designers seeking innovative solutions in electronic product development.

#pcb plate#pcb board#pcb circuit#pcb factory#circuit board#fpc#flex pcb#aluminum pcb#led pcb#led circuit board#pcb & pcba#pcb assembly#pcba board manufacture#pcba assembly manufacture#pcba service#pcb board manufacture#pcba oem#pcba shenzhen#pcba supplier#pcba pcb assembly#pcba circuit board#ems pcba#smt pcba#pcba smt assembly

0 notes

Text

Durable Battery Probes for Top-Tier Testing

Get an edge with electronic testing with our durable Battery Probes. Built for accurate connections and consistent performance, these probes are guaranteed to deliver optimal results. Discover our comprehensive selection online and order today to ensure efficiency for all your electronic requirements! For additional details, feel free to call us at +361 533 3165.

#simple cable harness tester#test probes#flash programming#cable harness test modules#manufacturing pcb test equipment#led probe#sockets#kelvin probe

0 notes

Link

Techno Advance System offers all type of PCB Assembly & Soldering Job Work in Gandhinagar, Ahmedabad, and Mumbai, India. Need efficient LED job work PCB assembly services in Ahmedabad or Gandhinagar? Look no further! Our skilled technicians provide reliable and affordable services to meet your needs. Contact us today!

#pcbassembly#pcb assembly manufacturers#pcb manufacturer#pcb assembly contract manufacturer#pcb assembly#LED tube Light suppliers#led tube light

1 note

·

View note