#pcba circuit board

Explore tagged Tumblr posts

Text

Why PCB Assembly is Critical to the Success of Your Circuit Card Designs?

In the world of electronics, planning an productive and solid circuit card is as it were half the fight. The prepare that changes your conceptual plan into a useful and tough item is PCB Assembly (PCBA). This significant stage includes assembling all the electronic components onto the PCBA Circuit Board to guarantee it performs as expecting. Here’s why PCB Assembling plays a essential part in the victory of your circuit card designs.

1. Precision in Circuit Card Assembly

Circuit card designs include complicated formats of components and associations. Circuit Card Assembly, or the prepare of fastening components onto a printed circuit board (PCB), requires supreme accuracy. Indeed a minor blunder amid Assembly can lead to useful disappointments, execution debasement, or indeed disastrous breakdowns. Progressed Assembly procedures, such as Surface Mount Technology (SMT) and Through-Hole Technology (THT), guarantee tall accuracy and compatibility with complex designs, shielding the execution of your circuit card.

2. Unwavering quality of the Last Product

The strength and unwavering quality of electronic gadgets depend intensely on the quality of their PCB Assembly. Legitimate assembling guarantees solid associations, negligible flag obstructions, and resistance to natural variables like warm, stickiness, and vibration. When high-quality materials and assembling forms are utilized, your circuit card designs are more likely to withstand thorough utilization, subsequently improving their life expectancy and client satisfaction.

3. Performance Optimization

PCBA Circuit Board are indispensably to the by and large execution of electronic gadgets. Indeed a well-designed circuit card can come up short to convey ideal execution if the Assembly prepare is substandard. Legitimate fastening strategies, exact component situation, and vigorous testing amid the PCB Assembly stage guarantee the circuitry works proficiently. By dispensing with potential powerless focuses, the last item accomplishes way better execution metrics.

4. Cost Efficiency and Scalability

Investing in high-quality PCB Assembly not as it were ensures the usefulness of the item but too diminishes long-term costs. Defective assembling can lead to tall rates of item returns, guarantee claims, and support costs. Besides, a streamlined Circuit Card Assembly prepare permits for versatility, making it less demanding to move from prototyping to mass generation without compromising quality.

5. Integration with Progressed Technologies

Modern electronic designs regularly include components like microcontrollers, sensors, and coordinates circuits, all of which require exact dealing with. The PCBA Circuit Board needs to coordinated these components consistently to work accurately. High-end PCB Assembling administrations guarantee legitimate arrangement and integration, clearing the way for inventive and complex applications.

Conclusion

In pith, the victory of your circuit card designs depends essentially on the PCB Assembly handle. Guaranteeing that the assembling is exact, solid, and adjusted with your plan determinations changes your concept into a item prepared for the showcase. With quality Circuit Card Assembling, you can convey strong, high-performing hardware that stand out in the competitive scene.

0 notes

Text

PC Board Assembly vs. PCBA Circuit Board: Key Differences in the Assembly of Printed Circuit Boards

The world of electronics is brimming with specialized terms. “PC board assembly” and “PCBA circuit board” are among these two respective common confusions. Though they seem interchangeable, they are far apart when it comes to the real and much-needed understanding of the difference between the two. Let’s take a trip into this exciting world of printed circuit boards (PCBs) and find out how these two important steps differ. To read more click on the link now.

0 notes

Text

Unveiling PCB Assembly Cables: Bridging the Gap in Electronic Design

In the world of electronics, the assembly of Printed Circuit Boards (PCBs) is a complex process that requires precise attention to detail. One crucial aspect often overlooked in the PCB assembly process is the role of PCB assembly cables. These cables are vital for connecting and integrating different electronic components and systems, ensuring that your devices operate efficiently and reliably. If you’re curious about PCB assembly cables and their significance, this blog post will provide a comprehensive overview, including their types, applications, and considerations for choosing the right cables for your project.

What are PCB Assembly Cables?

PCB assembly cables, often referred to as cable assemblies or wire harnesses, are integral to the interconnection of various components within an electronic device. These cables facilitate communication and power transfer between PCBs and other system elements, such as sensors, connectors, and displays. They are designed to ensure that electronic systems function as intended by providing reliable and efficient connections.

Key Functions of PCB Assembly Cables:

Signal Transmission: PCB assembly cable carry electrical signals between different parts of a system, ensuring accurate data transfer and communication.

Power Distribution: These cables deliver power from the power supply to various components, maintaining the required voltage and current levels.

Mechanical Support: By securing connections and reducing stress on PCB connectors, assembly cables help prevent damage and ensure durability.

Types of PCB Assembly Cables

There are several types of PCB assembly cables, each suited to different applications and requirements. Here’s a look at some common types:

Flat Ribbon Cables:

Description: These cables consist of multiple wires arranged parallel to each other and encased in a flat, flexible insulation.

Applications: Often used in applications where space is limited and a large number of connections are needed, such as in computer motherboards and internal devices.

Round Cables:

Description: These cables feature a round cross-section and can include multiple wires insulated individually or as a bundle.

Applications: Common in power distribution and general-purpose connections where flexibility and durability are required.

Flexible Flat Cables (FFC):

Description: FFCs are thin, flexible cables that consist of flat conductors and are ideal for space-constrained applications.

Applications: Frequently used in compact electronic devices such as smartphones, cameras, and portable electronics.

Coaxial Cables:

Description: Coaxial cables have a central conductor surrounded by an insulating layer and an outer conductive shield.

Applications: Used for high-frequency signal transmission, such as in RF applications, video signals, and data communication.

Custom Cable Assemblies:

Description: Custom cables are designed and manufactured according to specific requirements and specifications provided by the client.

Applications: Ideal for specialized applications where off-the-shelf solutions are not suitable.

Applications of PCB Assembly Cables

PCB assembly cables find applications across a wide range of industries and devices. Some common areas include:

Consumer Electronics:

Devices: Smartphones, tablets, laptops, and gaming consoles.

Role: Connect internal components like displays, processors, and batteries.

Automotive Industry:

Devices: In-vehicle infotainment systems, engine control units, and sensors.

Role: Facilitate communication and power distribution within vehicle electronics.

Medical Devices:

Devices: Diagnostic equipment, patient monitoring systems, and imaging devices.

Role: Ensure reliable connections for data transfer and power supply in critical medical applications.

Industrial Equipment:

Devices: Manufacturing machinery, robotics, and control systems.

Role: Provide robust and durable connections to withstand harsh operating conditions.

Telecommunications:

Devices: Networking equipment, routers, and signal processors.

Role: Enable high-speed data transmission and connectivity.

Choosing the Right PCB Assembly Cable

Selecting the appropriate PCB assembly cable is essential for ensuring the reliability and performance of your electronic devices. Here are some factors to consider:

Application Requirements:

Considerations: Determine the specific requirements of your application, such as signal type, power needs, and environmental conditions.

Cable Specifications:

Factors: Evaluate cable specifications including gauge, insulation type, shielding, and flexibility based on your design requirements.

Durability and Reliability:

Assessment: Ensure the cables are durable and reliable, particularly in harsh environments or critical applications.

Custom vs. Standard Solutions:

Decision: Decide whether off-the-shelf cables are sufficient or if custom solutions are needed to meet specific design constraints.

Quality and Compliance:

Standards: Choose cables that meet industry standards and certifications to ensure MT PCB Assembly quality and compliance.

PCB assembly cables are crucial components in the electronic design and assembly process, playing a vital role in connecting various parts of a system and ensuring seamless operation. Understanding the different types of cables, their applications, and the factors to consider when selecting them can significantly impact the performance and reliability of your electronic devices.

By focusing on quality and choosing the right cables for your specific needs, you can ensure that your PCB assemblies operate efficiently and effectively, paving the way for successful and reliable electronic products.Pcb Assembly Cable

#Pcb Assembly Cable#4 Cores Power Cable#4pin Connector Cable#5pin Connector Cable#MT PCB Assembly#printed circuit assembly#pcba circuit board

0 notes

Text

What Is Polyimide PCB?

To understand the real meaning of polyimide PCB, at first, you will have to know about the ‘polyimide’ properly.

The word polyimide consists of two sub-phrases that includes, ‘poly’ which typically refers to polymers and ‘imide’ which refers to the advanced imide monomers. Together they create a diverse polymer group.

Moreover, the polymer group is manufactured using either natural or synthetic process. However, for now, forget about the natural polymers and focus on the synthetically manufactured polyimides. These polyimides are used to build the PCBs, hence the name polyimide PCB.

The synthetic polyimide used in manufacturing PCBs is resourced from different chemicals with imide structures. This manufacturing process is known as polymerizing to us. These polyimides are then used in making PCBs.

Different Types of Polyimide PCBs

Likewise, metal PCB and ceramic PCB, the polyimide made printed circuit boards also have multiple types. These classification has been made by determining the material used in synthesizing the amide polymer or polyimide.

The most common polyimide PCBs are:

Pure Polyimide or 2nd Generation Polyimide:

This is the simplest PCBs and lacks additional features such as brominated flame retardants. While the word ‘lacking’ is used negatively for most materials, pure polyimide has used it positively. The lack of flame retardants makes it extremely stable while still being flexible enough to use in different electrical and communicating devices. The polyimide is also occasionally called as polyimide flex PCB, mainly because of its useful flexibility.

Although it is the oldest of all polyimide PCB types, pure polyimides have widespread use. It is made possible thanks to the extreme endurance against temperature change and thermal stability during challenging situations.

3rd Generation Polyimide:

It is an updated version of pure polyimides. Also, it has additional additives which effectively make it more flammability resistance. The flammability resistance is crucial because it comes forward in stopping accidental electric fires.

However, the 3rd generation polyimide lacks the thermal stability of pure polyamides which can be a disadvantage for it. On the contrary, it is easy to manufacture, which propels the production line faster than any other polyimide flexible PCB.

So, you can manufacture the 3rd generation polyimide in bulk which lies in its vast favour.

Filled Polyimide:

This type of polyimide is similar to multilayer PCBs since it comes with more than one filler materials. The additional filler lowers the resin shrinkage.

The resin shrinkage resistance is vital since due to the shrinkage, many printed circuit boards become frail and cracks down during the drilling and curing proceedings. Also, the shrinkage resistance helps the filled polyimide maximize its long-term usage.

Low-Flow Polyimides:

The low-flow polyimides are made without the flexibility of the standard PCBs. So, sometimes people also refer to it as the rigid polyimide PCB.

The rigidity of the low-flow PCB comes useful when PCBs require stiffness to stay strong during the challenging conditions. So, when the traditional flexible PCBs fail, the low-flow polyimides come forward to solve the tough situations.

Benefits of Polyimide PCB

Since the polyimide PCB is a particular type of printed circuit boards, it is mainly used on special occasions. So, it would help if you understood when to use the polyimide PCB and when not to. Use the polyimide made PCBs when you need either one or all of the following characteristics:

Stable flexibility: The greatest benefit of the polyimide PCBs is its extreme stability and flexibility at the same time. It is a perfect combination of rigidity and flexibility which regular PCBs lack.

Tensile strength: Polyimide PCBs have excellent resistance against warping. It is made possible thanks to the flexibility of the polyimide materials. So, if you want durability for the PCB applications, the superior tensile strength and durability will be beneficial for you.

Thermal stability: Polyimide materials are known for having superior thermal endurance and resilience. So, the polyimide made PCBs are capable of working even at 260° temperature. Furthermore, thermal conduciveness prevents thermal damage during manufacturing and repairing jobs.

Extreme durability: Polyimide has resistance against various chemicals and temperature. So, it enjoys enhanced durability. The durability is essential to endure extreme physical stress which is a necessary benefit for PCBs.

Versatile Usage of Polyimide PCB

Both the rigid polyimide PCB and polyimide flexible PCBs are widely used in different industries. The most common applications of the polyimide PCBs are:

Computer and Laptops:

Modern-day laptops and computers suffer from heavy-duty usage and go through the extreme thermal rise of the components. Thus, the thermal conduciveness of the polyimide PCBs is beneficial for laptops and PCs.

Also, the flexibility and rigidity of these circuit boards come forward to enhance the overall durability of the computers.

Automotive Electronics:

Out of all electronic components, automotive electronics face the most challenging conditions. They need to function both in extreme cold and summer along with continuous jostling f multiple components.

Naturally, these automotive components ask for a durable PCB, which only the polyimide can supply.

Military and Aerospace:

Both the aerospace and military industry uses the most advanced electronics for their superior performance and safety requirements. Also, in both industry electronics component operates in the most hostile environment.

So, the durability and thermal stability of polyimide made PCB is essential to safeguard these components, which can be the ardent difference between life and death of millions.

Medical Industry:

Various medical treatments and diagnosis such as advanced imaging, implants and prosthetics require high-efficiency applications. This useful and high-performing efficiency will only come from the polyimide PCBs.

Differences Between FR4 and Polyimide PCB

When you know the factual distinctions between polyimide PCB and FR4, you will be able to pick the perfect printed circuit board for your desired jobs.

FR4 circuit boards are made of epoxy glass resin and laminated copper. So, it is rigid and not as flexible as the polyimide material. Also, polyimide is lightweight and more durable. Besides, polyimide also has better chemical and heat resistance compared to the FR4.

Last but not least, polyimide boards are more expensive the FR4. But its durability and widespread usage balance the overpricing to a greater extent.

The following table will help you understand the differences better between the FR4 PCB and polyimide PCBs-

Polyimide PCB with its great flexibility and extreme resistance to heat and chemicals is preferred in the aerospace industry. In fact, it has changed the aerospace industry quite brilliantly.

Who makes the best Polyimide PCB?

Many companies build polyimide PCBs and serve them in the market. But, not all of them are reliable. Hence, you must pick the right polyimide circuit board manufacturer for your works.

An ideal polyimide manufacturer will work with the highest-quality polymer plastics for the best flexibility and thermal resistance of the boards. Also, it should be able to offer you different types of polyimide circuit boards so you can easily get the right circuit boards.

Hitech Circuits can be a reliable source in this regard. Hitech Circuits with 15+ years of experience in manufacturing different types of PCBs will offer you tailored offers and the highest-quality PCBs. We manufacture both polyimide and FR4 circuit boards.

#pcb#pcb design#pcb assembly#pcb manufacturer#pcb factory#flex circuit pcb#PCBA#pcba circuit board#pcba manufacturing

0 notes

Text

PCBA Supplier

XDPCBA.cn is your premier PCBA supplier, offering top-quality solutions designed for precision and reliability. As a trusted supplier, we specialize in delivering high-performance PCBA services tailored to diverse applications. Our expert team ensures seamless integration, superior quality, and innovation in every project. Partner with XDPCBA.cn for efficient, reliable, and cutting-edge PCBA solutions. Experience the assurance of working with a dedicated supplier committed to delivering excellence in every product.

Visit : https://www.xdPCBA.cn/PCBA.html

0 notes

Text

hi,I'm zoe,a sales engineer in the Shenzhen STHL Electronics Co.,Ltd.we are a professional PCB & PCBA manufacturing servicer with more than 18 years of experience located in Shenzhen, China. Mainly provide services of electronic components sourcing + PCB fabrication + PCB Assembly + Housing assembly + Function testing services.

Our factory covers 7000+ square meters, has 5 (Panasonic) high-speed SMT production lines, 2 DIP lines, 2 testing lines, and 180+ workers, passed ISO9001, ISO14001, ISO13485 and IATF 16949 certifications, win recognization by Littelfuse, Hisense,Surfilter, etc.

2 notes

·

View notes

Text

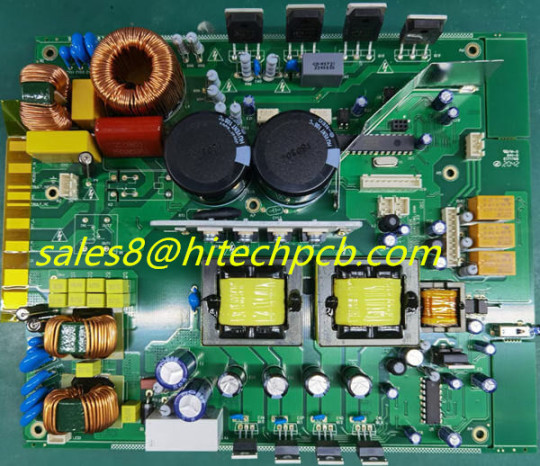

PCBA assembly manufacturing services provides by Hitech provides, from PCBA sample to medium or mass production volume. Our professional SMT factory has advanced equipments help us to offer rich experience in various PCBA manufacturing. Contact susie [email protected]

3 notes

·

View notes

Text

Multilayer PCBs (Printed Circuit Boards) offer numerous advantages over their single-layer or double-layer counterparts. These benefits arise from their enhanced design capabilities, improved performance, and greater flexibility. Here are some key advantages of multilayer PCBs:

#PCB#printed circuit board manufacturers#electronic cable assembly#pcb manufacturing#pcb assembly manufacturer#pcb assembly services#pcb board manufacturer#printed circuit board manufacturer in india#circuit board manufacturing#pcb exporters#pcba#pcb manufacturer#pcb design#pcbassembly#multilayer pcb

2 notes

·

View notes

Text

PCBA (Printed Circuit Board Assembly)

PCBA (Printed Circuit Board Assembly) combines precision manufacturing, component placement, and advanced soldering techniques to create high-quality, reliable electronic assemblies. Ideal for industries like telecom, medical, and automotive, PCBA ensures optimal performance for complex electronic devices.

Call: 408 205-6789

Email: [email protected]

Website: https://www.absolute-ems.com/our-services/pcb-assembly/

0 notes

Text

Choosing the Right China PCB Supplier: Key Factors to Consider

In this dynamic world of electronics, Printed circuit boards (PCBs) are the skeleton of every device, from digital clocks to laptops and smartphones. China has become one of the largest hubs of producing PCBs worldwide.

Choosing the right China PCB supplier can be challenging, so make sure to read the factors we will discuss in this article. Let’s get started!

Key Factors to Consider When Choosing a China PCB Supplier

youtube

1. Understanding your PCB Requirments

The first step is to understand what kind of PCBs you need. Do you want single-layer, multilayer PCBs or a specific type? Knowing whether you want standard or customized PCBs will help you shortlist China PCB suppliers. Discuss your project specifications in detail with the supplier for better understanding.

2. Manufacturing Capabilities

While selecting a PCB supplier, check their manufacturing capabilities to ensure they have the right machines and sound technology to meet your specific requirements.

3. Pricing

Every buyer wants to purchase from a supplier that provides the best quality at affordable prices. So, just list suppliers you want to buy from and compare their quality and price. Remember that there may be additional costs like assembly or testing. Buying in bulk can be cost-effective.

4. Quality Control Standards

Ask suppliers for samples and check if they have an in-house inspection team to certify high-quality PCBs. PCBs must pass visual and functional tests to ensure they are durable and reliable. Research if the PCB supplier has globally recognized certifications like ISO 9001 and IPC-A-600.

5. Customization Options

You may have unique requirements for PCBs, so look for a supplier who can customize the boards for you. Whether you are looking for single-layer or multilayer PCBs, make sure the supplier has your desired materials and production techniques for customization.

6. Deadlines & Production Capacity

When working on an urgent project, you may want a supplier with high production capacity to meet your deadlines without compromising quality. Therefore, you should evaluate the supplier’s previous track record to assess their delivery timelines.

7. Communication & Support

Smooth communication and customer support are important to build a relationship between the two parties. Therefore, choose a supplier who gives you updates during the manufacturing process and is pleased to answer your queries in detail.

8. Industry Reputation

A supplier’s reputation is a powerful symbol of their performance and reliability. To check a supplier’s reputation in the industry, read their testimonials, case studies, and customer reviews. This will help you to be confident while selecting a supplier.

Why Choose a China PCB Supplier?

Here are some reasons you should choose a China PCB supplier.

China offers competitive manufacturing costs, making it a perfect choice for buyers seeking quality on a budget. Plus, it is more cost-effective compared to other countries.

China suppliers provide high-quality PCBs using innovative technologies and modern machines.

They have built a solid global reputation, with customers worldwide acknowledging their expertise in shipping PCBs efficiently.

Conclusion

Choosing a China PCB supplier can impact the progress and reliability of your electronic devices. By understanding your requirements and the factors mentioned, you can select a supplier that meets your specific material and production techniques requirements.

#pcb assembly#pcb#pcb manufacturer#pcba manufacturing#flex pcb#pcb fabrication#flexible pcb board#flex circuit pcb#flexible circuit board#Youtube

0 notes

Text

The Extreme Direct to Circuit Card Assembly and PCB Board Assembly

Circuit Card Assembly (CCA) and PCB Board Assembly (PCBA) are vital components in the world of hardware. Whether you are fabricating buyer gadgets, car parts, or aviation gadgets, the Assembly of these boards plays a basic part in guaranteeing that items work accurately. In this article, we shall determine the forms, advantages, and importance of Circuit Card Assembly as well as PCB Board Assembly.

What is Circuit Card Assembly (CCA)?

Circuit Card Assembly alludes to the prepare of interfacing electronic components to a PCBA Circuit Board. This handle can be either computerized or physically performed. The reason of CCA is to make a working circuit by fastening components like resistors, capacitors, and transistors onto the PCB.

Steps Included in Circuit Card Assembly

1. Design and Format: The plan stage includes making a schematic of the circuit and laying out the PCB. Engineers plan the circuitry to guarantee legitimate functionality.

2. Component Arrangement: In the Assembly handle, components are put accurately on the board. CCA step can be performed using Surface Mount Technology (SMT) or Through-Hole Technology (THT).

3. Soldering: The components are soldered to the board once they are mounted. Patching can be performed utilizing wave patching, reflow patching, or hand fastening techniques.

4. Inspection and Testing: After Assembly, the board experiences thorough review and testing to guarantee it capacities accurately. AOI as well as X-ray inspection are widely used to detect any failure.

PCB Board Assembly (PCBA)

PCB Board Assembly (PCBA) is the handle of collecting a printed circuit board (PCB) with all the essential electronic components to make a utilitarian circuit board. It is comparative to Circuit Card Assembly but centres on the total Assembly of all components on the PCB.

Types of PCB Assembly

1. Single-Sided PCB Assembly: In this sort, components are collected as it were on one side of the board. It is commonly utilized in basic electronic devices.

2. Double-Sided PCB Assembly: The two sides of the PCB are used in setting up the components. With this, much more complex circuitry is possible, and it is one of the wide applications for advanced electronic devices.

3. Multi-Layer PCB Assembly: Multi-layer PCB Assembly implies using more than one layer of PCBs held together. This sort is perfect for progressed gadgets requiring higher complexity and more compact designs.

Key Benefits of Circuit Card and PCB Assembly

• High Unwavering quality: Well-assembled PCBs give tall unwavering quality, guaranteeing the gadget capacities without blunders over an amplified period.

• Cost-Effective Generation: The robotized Assembly of PCBs decreases labor costs, making it more cost-effective for large-scale production.

• Compact Plans: With the advancement of multi-layer PCBs, electronic gadgets can be outlined more compactly whereas keeping up functionality.

• Enhanced Execution: Appropriate Assembly and component situation make strides the in general execution of the gadget, guaranteeing productive control administration and flag transmission.

Applications of PCBA and CCA

• Consumer Electronics: Gadgets like smart phones, portable workstations, and tablets depend on exact PCB Assembly to work effectively.

• Automotive: Circuit boards are fundamental in car hardware for frameworks like route, infotainment, and security features.

• Medical Gadgets: Life-saving therapeutic gear, counting observing frameworks and symptomatic machines, depends on precise PCB assembly.

• Aerospace: Circuit boards utilized in aviation applications must meet exacting quality guidelines to guarantee tall unwavering quality beneath extraordinary conditions.

ConclusionCircuit Card Assembly and PCB Board Assembly are at the heart of advanced gadgets. They give a establishment for building utilitarian and proficient gadgets over different businesses. Whether you're in buyer gadgets, car, or aviation, understanding the significance of legitimate PCB Assembly will offer assistance you create dependable and high-performing items.

0 notes

Text

Efficient PCB and Assembly Techniques: Exploring Printed Circuit Board PCBA and Methods to Assemble PCBs

In the techno-speedy world of today, printed circuit boards form the crux of modern electronics. It is mainly the method of PCB and assembly which decides not only the efficiency but also the reliability and performance of products. To read more click on the link.

0 notes

Text

Además, hay una tecnología de separación termoeléctrica de PCB a base de cobre (también conocida como tecnología de tacto directo). Esto significa aumentar el espesor del cobre en la posición requerida a través de la apertura de la máscara de soldadura y la galvanoplastia de cobre, y el calor se conduce directamente desde el led u otros componentes a la base de cobre, mientras que la red eléctrica es independiente de la red térmica.

Como fabricante de mcpcb, Hitech Circuits produce una variedad de PCB a base de cobre para sus clientes.

Para lámparas LED de alta potencia (1000w +) y fuentes de alimentación.

En el campo de los led, hay cuatro tipos de placas de circuito a base de cobre.

#pcb assembly#aluminium pcb#flex pcb#flex circuit pcb#pcb#pcba manufacturing#pcb manufacturer#pcb fabrication#pcb design#LEDPCB#Circuit board

0 notes

Text

Medical PCB Assembly

Medical PCB Assembly Manufacturer – One-stop service

Medical PCB Assembly Manufacturer – One-stop service

Medical devices (medical PCB assembly) refer to instruments, devices, instruments; in vitro diagnostic reagents and calibrators, materials, and other similar or related items. There are used directly or indirectly in the human body, including the required computer software.

Hitech Circuits has extensive experience in providing medical PCB assembly services to our medical industry customers, and we deeply understand that our medical PCBA will be used in life-critical medical devices, which have extremely high requirements for precision and reliability.

We are committed to offering the world-class PCBA by strictly controlling the quality of every piece, our medical PCB assembly, box build assembly, and prototypes assembly capacities allow us to assemble kinds of medical devices such as diagnostic imaging equipment, lasers, and handheld dental tools.

At Hitech Circuits, we take care of the medical PCB assembly of your product so you can spend more time running your business and marketing your medical devices.

Hitechpcba medical PCB assembly technique:

Whether in a controlled environment such as a hospital or in an uncontrolled environment such as a home health care center, medical equipment must protect the lives of patients and surgeons. Medical PCBA refers to instrumented circuit boards that are used directly or indirectly in the human body. Such as instruments, equipment, instruments, in vitro diagnostic reagents, and calibrators, materials, and other similar or related instruments.

Therefore, the requirements for component procurement and processing are very strict, and a more precise technique is required, which is produced by IPC Class 3 standard. Hitechpcba is fully certificated, apart from certifications of ISO9001:2015, ISO14001, REACH and IATF16949, we have also obtained the ISO13485 certification, which means that our PCBs can meet the high standards required by medical devices, and all of our finished medical devices are of FDA Class II. Working with us can avoid you from worrying about the quality problem.

This standard provides you with the ability to produce and manufacture to meet higher customer needs. In the medical device industry, safety and quality are not negotiable. At every step of the product life cycle, including service and delivery, regulatory requirements are becoming more stringent.

More and more industry organizations want to showcase their quality management processes and make sure that everything they do is best practice. PCBA is used in the medical industry to bring good news to patients. Hitechpcba is a certified manufacturer offering a one-stop PCB and PCBA turnkey service with 15 years experience and we have the confidence to become your preferred supplier.

Hitechpcba advantages:

We offer unprecedented service and flexibility for any medical device PCB. Without a small batch test, you can’t start your concept prototype so that it doesn’t help you get it to market. We offer comprehensive engineering support to make your medical device printed circuit board manufacturing process reality in the most cost-effective way.

We provide high-end customized processing services for PCBA in medical machinery customers. It is manufactured by PCB circuit board, component procurement, SMT chip processing, patch plug-in soldering, assembly testing and other one-stop services.

QC was set up in front of the furnace for poor screening, PCBA 100% visual inspection after furnace, PCBA 100% optical inspection, and 13 temperature zone reflow soldering each product independently set temperature. Must undergo rigorous tests, such as ICT, FCT, Burn-in test. The products produced include monitors, pacemakers, sphygmomanometers, etc.

We ensure the quality, reliability, and traceability of our medical PCB manufacturing assembly.

Over 15 Years of Medical PCBA Experience

With more than 10 years of experience in offering PCB assembly services, we have a good understanding of the medical industry, our experts have participated in a host of projects to provide medical PCBA solutions to leading medical companies and get trusted by them.

Types of Medical PCB Assemblies

As a PCB expert, Hitechpcba is capable of assembling types of medical PCBs such as multi-layer PCBs, rigid, rigid-flex PCB, and flexible PCBs, and there are various PCB materials available including copper, aluminum, and standard FR4, etc. So our medical PCB assembly solutions can be used for almost all medical devices.

High Efficiency

We utilize state-of-the-art equipment for medical PCB assembly that can reduce errors during the assembly process, meanwhile, we have proficient workers who know how to assemble PCBs correctly and efficiently.

The trend of PCB Medical Industry

The medical field is not like it used to be. Advances in technology have revolutionized the industry. This change is even more evident in electronic diagnostic, research, and treatment systems and tools. Every day, several complex electronic devices and instruments are introduced to simplify various medical procedures. This growth has largely benefited the PCBA technology industry because, without PCB in medical, new inventions would not be impossible. To meet the ever-changing needs of medical device and diagnostic machine manufacturers, today's PCB manufacturers are manufacturing extremely simple parts into highly complex PCB in medical industry. Using specialized high-speed laminates, copper and aluminum substrates, ceramics, and coatings, PCB manufacturers can make these boards best suited for medical industry applications.

Custom Medical PCB Assembly

Custom circuit board design in medical is the trend today. The medical industry has chosen the same approach when it comes to PCB. Customers can provide the correct specifications with the full form of PCB in medical for board size in X-direction, board size in Y-direction, total number of holes, minimum alignment and pitch size in inches, board material, number of layers, surface coating, etc. Therefore, the manufacturer will work according to the given specifications and deliver the right product for your application.

#pcb assembly#pcba#SMT & PCBA manufacturer#OEM assembly manufacturing#Printed Circuit Board Assembly

0 notes

Text

PCB boards after solder paste printing should enter reflow soldering oven after 30 minutes of solder paste printing to stop solder paste from being exposed to the air for long time with product quality reduced.

#FPCway #flexPCB#pcb#pcba#fpc# assembly#rigid-flex pcb #fpcway.com

#FPCway#flexPCB#pcb#pcba#fpc#assembly#rigid-flex pcb#fpcway.com#www.fpcway.com#flex pcb#flex circuit pcb#flexible pcb board#flexible circuit board#today on tumblr

0 notes

Text

Decoding PCBA Board Manufacture: A Roadmap to Efficient Production

PCBA (Printed Circuit Board Assembly) board manufacture stands as a pivotal stage in the journey from electronic concept to tangible product. This blog offers a detailed roadmap, guiding both novices and seasoned professionals through the multifaceted process of PCBA board manufacture.

The journey initiates with an elucidation of PCBA board components, ranging from basic resistors to intricate microprocessors. Understanding the role and compatibility of each component is paramount in crafting a functional and efficient board.

Subsequently, the blog navigates through the intricacies of PCB fabrication, encompassing design optimization, material selection, and fabrication techniques. Through insights into surface finishes, layer stackups, and trace routing, readers will grasp the fundamentals necessary for creating robust and reliable PCBs.

The narrative then transitions to the assembly phase, shedding light on component placement, soldering methodologies, and quality assurance protocols. From manual soldering to automated pick-and-place systems, readers will gain insight into the diverse assembly techniques and their respective advantages.

Moreover, the blog addresses the significance of thorough testing and inspection procedures to identify and rectify potential defects before the final product reaches the market. Topics such as in-circuit testing, functional testing, and quality control standards underscore the importance of delivering reliable and high-performance PCBAs.

In conclusion, "Decoding PCBA Board Manufacture" serves as a comprehensive guide for navigating the complexities of PCB assembly manufacturing. By leveraging the insights and best practices shared in this blog, electronics enthusiasts and industry professionals alike can streamline their manufacturing processes, ultimately fostering innovation and excellence in the realm of electronic design and production.

#pcb circuit#fr4 pcb#pcb factory#circuit board#led circuit board#flex pcb#pcb assembly#aluminum pcb#fpc#ems pcba

0 notes