#aluminium busbar manufacturer

Explore tagged Tumblr posts

Text

#aluminium ips tube manufacturer#aluminium busbar manufacturer#heatsink extrusion manufacturers#aluminium heat sink manufacturers#aluminum led manufacturers#aluminium construction profiles#Aluminium Extrusion Profiles

0 notes

Text

Integrating Sustainability and Efficiency – WintechSolar's Expertise in Solar Street Lights and Aluminium Busbars

In today's energy-conscious world, pioneering solutions such as integrated solar street lights and high-quality aluminium busbars are essential. WintechSolar stands at the forefront of this innovation, specializing in manufacturing top-notch integrated solar street light and serving as a leading aluminium busbar manufacturer. Discover how our products are lighting the path towards a sustainable future!

Body:

Advanced Integrated Solar Street Lights: WintechSolar’s integrated solar street lights are designed to provide powerful illumination while promoting energy efficiency. These lights harness solar energy during the day and provide consistent and reliable lighting throughout the night, reducing dependence on traditional power sources and lowering energy costs.

High-Quality Aluminium Busbars: As a prominent aluminium busbar manufacturer, we produce busbars that are renowned for their excellent conductivity, lightweight nature, and resistance to corrosion. Our aluminium busbars are integral components in various electrical applications, ensuring the efficient distribution of electrical power with minimal energy loss.

Customized Solar Solutions: Understanding the diverse needs of our clients, we offer customized solutions for integrated solar street lights. Whether you require lighting for urban streets, parks, or industrial areas, our tailored solutions ensure optimal illumination and energy efficiency tailored to your specific needs.

Durable and Sustainable: Sustainability is at the heart of WintechSolar’s operations. Our integrated solar street lights and aluminium busbars are crafted with durability and environmental friendliness in mind. By choosing our products, you contribute to reducing carbon emissions and promoting a greener planet.

Client-Centric Approach: Your satisfaction is our priority. From initial consultation to installation and after-sales support, we are committed to delivering an exceptional customer experience. Our team of experts is always available to address any queries and provide the necessary assistance.

Affordability Meets Quality: At WintechSolar, we believe that quality and affordability can coexist. Our competitive pricing ensures that you receive value for your investment without compromising on the quality and performance of our solar street lights and aluminium busbars.

Industry Expertise: With years of industry experience and a team of dedicated professionals, WintechSolar has earned a reputation for reliability and excellence. Our expertise in manufacturing and supplying integrated solar street lights and aluminium busbars positions us as a trusted partner in the renewable energy sector.

Conclusion:

WintechSolar is committed to advancing the future of renewable energy with our state-of-the-art integrated solar street lights and high-quality aluminium busbars. As we continue to innovate and push the boundaries of what's possible, we invite you to join us on this journey towards a more sustainable and energy-efficient world. Contact us today to learn more about our products and how we can light up your path with our innovative solutions!

0 notes

Text

Wintech Solar: Illuminating Street Light Manufacturer in Delhi with Sustainable Brilliance

In the bustling city of Delhi, where life never truly sleeps, the importance of efficient and reliable street lighting cannot be overstated. A well-lit street not only ensures the safety and security of its inhabitants but also adds to the Street Light Manufacturer in Delhi vibrant and dynamic essence of the metropolis. Among the pioneers of this crucial urban transformation is Wintech Solar, a leading street light manufacturer that has been at the forefront of revolutionizing Delhi's lighting landscape. Wintech Solar has earned a stellar reputation for its commitment to sustainability and cutting-edge technology. As a key player in the solar energy industry, they have seamlessly integrated renewable energy solutions with contemporary design to create highly efficient and eco-friendly street lighting systems. With a wide range of products catering to various urban needs, the company has become the go-to choice for municipal corporations and private entities alike.

#Street Light Manufacturer in Delhi#Solar Photovoltaic Module#Street light manufacturer in india#Aluminium busbar manufacturer#MS Pole Manufacturer

0 notes

Text

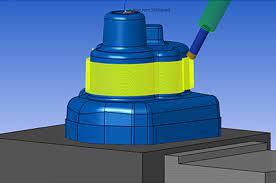

From Concept to Creation: Mastering Busbar Processing with SS-80-3NC

When it comes to manufacturing, precision and efficiency are the names of the game. The SS-80-3NC aluminium busbar bending machine epitomizes these qualities, transforming raw aluminium into precise components used across various industries. But why should you care about a machine that bends metal? Because this isn't just any metal—it's a crucial part of the electrical systems that power everything from your kitchen appliances to the entire subway systems. Let’s explore this fascinating machine and its impact.

The SS-80-3NC

Ever watched a skilled chef effortlessly chop vegetables? The SS-80-3NC works similarly, but instead of veggies, it crafts aluminium with precision that chefs would envy. This machine is a stalwart in the world of electrical component fabrication, known for its robustness and precision.

What is Busbar?

A busbar is essentially an electrical junction where multiple branches come together. Think of it as a major transportation hub in a large city, directing buses (or in this case, electrical currents) in various directions efficiently.

Importance of Aluminium in Busbars

Aluminium is to busbars what carbon fiber is to sports cars—light, strong, and efficient. Its excellent conductivity and adaptability make it ideal for use in electrical systems.

Core Features of the SS-80-3NC Machine

The SS-80-3NC is not just a tool; it's a craftsman. With capabilities to bend, cut, and shape aluminium with astonishing accuracy, it’s a pivotal asset in any manufacturing setup.

How Does the SS-80-3NC Enhance Busbar Fabrication?

This machine automates the shaping of aluminium, ensuring each piece is exactly right. It’s like having a set of high-precision hands sculpting metal all day long—without a coffee break.

Applications of Aluminium Busbars

From the smallest gadgets to the largest power stations, aluminium busbars are everywhere. They’re crucial in distributing power safely and effectively.

The Advantages of Using an Aluminium Busbar Machine

Why manual when you can automate? The SS-80-3NC reduces errors, speeds up production, and doesn’t call in sick.

Maintenance Tips for Your SS-80-3NC Machine

Like any high-performance machine, the SS-80-3NC needs regular check-ups. Keeping it clean and well-lubricated ensures longevity and reliability.

Cost-Benefit Analysis of Aluminium Busbar Machines

Yes, the upfront cost is significant. But the efficiency and precision it brings to your operations can lead to savings and increased production capacity.

Environmental Benefits of Aluminium in Manufacturing

Aluminium is not only efficient but also recyclable. Using this metal helps keep the manufacturing process greener.

Future Trends in Busbar Fabrication

As technology advances, expect to see smarter, faster, and even more efficient busbar machines on the horizon.

User Experiences with the SS-80-3NC

Users rave about its reliability and the precision of its output. It’s the unsung hero in many production lines.

How to Choose the Right Busbar Machine

Not every project needs a powerhouse like the SS-80-3NC. Assessing your needs can help you pick the right machine that matches your requirements.

Innovations in Busbar Machine Technology

With ongoing advancements, machines like the SS-80-3NC are getting smarter. Integration with IoT and AI is on the rise, making these machines not just tools, but partners in production.

Conclusion: The Role of the SS-80-3NC in Modern Technology

The SS-80-3NC aluminium busbar bending machine is more than just a component of the manufacturing process; it's a bridge to the future of technological innovation. Whether you’re a seasoned engineer or just a curious bystander, the capabilities of this machine are a testament to how far we’ve come in the journey from concept to creation. It’s not just about bending metal; it’s about shaping the future.

0 notes

Text

Understanding the Different Types of Electrical Lugs and Their Uses

A cable lug is essential in electrical systems, providing a secure connection between cables and device terminals. It simplifies the assembly, maintenance, and repair processes, especially when a permanent connection is required, but a direct one is inconvenient or impossible. Whether you are looking for solutions from a lightning arrester manufacturer or a cable gland manufacturer in India, choosing the proper lugs is crucial for the success and safety of your electrical installations.

Here's a look at the different types of lugs and their applications. Let’s explore!

Types of Electrical Lugs

Copper Lugs

Copper lugs are ideal for large gauge applications such as power draw or grounding. These lugs can be crimped, soldered, or welded onto cables, offering installation flexibility. They are made from high-grade electrolytic copper (ETP grade) and are available in various diameters and mounting holes, accommodating wire sizes from #8AWG to 1000MCM. Copper lugs are known for their excellent conductivity and durability, making them suitable for indoor and outdoor applications, including marine environments.

Uses: Connecting heavy gauge power cables to bus bars, relays, batteries, solar power inverters, and grounding devices. They provide efficient and reliable connections in power distribution and industrial machinery.

Aluminium Lugs

Aluminium lugs are manufactured from high-purity (99.6%) aluminum rods and are suitable for outdoor use due to their sealed palm ends. They are typically less expensive than copper lugs, making them a cost-effective solution for many wiring systems. These lugs come with jointing compounds and are sealed with end caps to prevent oxidation.

Uses: This lug is used in overhead transmission lines, substations, switchgear, and other applications where cost is a critical factor. Innovations in aluminum lugs have improved their safety and convenience, making them increasingly comparable to copper lugs.

Bimetallic Lugs

Bimetallic lugs are designed to connect aluminum conductors to copper busbars. They feature an aluminum barrel friction-welded to a copper palm, ensuring a high-quality connection. This design prevents galvanic corrosion, which can occur when different metals come into contact.

Uses: Solar plants, control panels, switchgear, and combiner boxes. Bimetallic lugs are essential in applications that transition between aluminum and copper components.

Specialized Lugs and Connectors

Crimping Lugs

Crimping lugs are used to connect cables securely by deforming the metal parts to hold each other in place. These lugs are commonly seen in automotive wire systems, electrical boxes, machinery, household appliances, and electronics. Insulated crimping lugs prevent accidental energy transfers and enhance safety.

Uses: Automotive battery connections, battery jumper cables, and various durable goods requiring secure electrical connections.

Mechanical Lugs

Mechanical lugs, or shear-off bolted connectors, use advanced technology to attach cable conductors. These lugs are suitable for underground and above-ground applications and are available in low-, medium-, and high-voltage versions.

Uses: Large-scale electrical installations in buildings, commercial facilities, and infrastructure projects. They are instrumental in applications requiring robust and reliable connections.

In a Nutshell

Electrical lugs are indispensable in ensuring secure and efficient connections in various applications. From power distribution to industrial machinery, the correct type of lug ensures reliable performance and safety. By understanding the different kinds of lugs and their specific uses, businesses can make informed decisions to optimize their electrical systems. As leading lugs manufacturers in India, we offer a comprehensive range of high-quality lugs to meet diverse needs, ensuring robust and efficient electrical connections.

Discover the perfect electrical connection solution with Axis India. Explore our wide range of high-quality lugs today.

About The Author:

Axis India stands at the forefront as a premier cable gland manufacturer in India and supplier of lightning arrestors and a wide array of Electrical Components, serving clients across 80+ countries worldwide. Whether you're seeking a quote or expert consultation, our dedicated team is ready to assist you.

0 notes

Text

Bus Ducts

Electricians are undoubtedly aware of bus duct and their applications. The normal non-specialist, on the other hand, may come across phrases like busbar or busway and need an introduction. Continue reading to discover more about this vital aspect of electricity distribution. The bus duct is an important component in electrical power distribution. A bus duct, sometimes known as a busway, is an alternate transmission method. A bus duct transfers energy to power cables or cable buses in commercial and industrial contexts. A bus duct is a grounded sheet metal duct that contains either aluminium or copper busbars (metallic strips or bars that carry a significant electrical current). Bus duct is simple to maintain and adaptable, making it ideal for accommodating changing load needs.It is critical to prepare ahead of time when acquiring a bus duct for a particular purpose. Milestones Switchgears Pvt Ltd. advises paying close attention to measurements. Take note of any bends, columns, changes in floor height, or other route details. Create drawings of the path the bus duct must go. The manufacturer may use this information to create final layout drawings. Standard bus ducts may obtain from the inventory supply for any simple installations. High-quality electrical equipment is critical for the safety of the electricians who instal it and those who work in the building where it is utilised. Current Midwest maintained a wide stock of bus ducts and plugs, including contemporary and vintage varieties and reconditioned used supplies. Our highly qualified personnel has professionally refurbished any secondhand bus duct or plug we sell, and it comes with a three-year guarantee.

0 notes

Text

Top Aluminium Flexibles Manufacturers in the Industry

AMA Metal Link, a reputable Indian aluminum flexibles manufacturers, excels in providing durable and superior aluminum flexible products across various industrial sectors. Our utilization of modern production techniques, coupled with extensive experience, guarantees exceptional performance and dependability. AMA Metal Link is your trusted choice for top-quality flexible aluminum solutions, ensuring unparalleled quality and client satisfaction.

Visit: https://www.amametallink.com/aluminium-flexibles.html

#Aluminium Flexibles Manufacturers#Flat Flexible Braided Links Manufacturers#Copper Jumper Manufacturers in India

0 notes

Text

Aluminium Busbar Manufacturer

Looking for dependable aluminium busbar solutions? Our high-quality aluminium busbars are designed for optimal conductivity and durability, catering to a variety of industrial applications. Trust our manufacturing excellence for your electrical distribution needs.

0 notes

Text

Furnace Cable | Bajeria Industries

Bajeria Industries specializes in manufacturing high-quality busbar connectors and copper-aluminium bimetallic strips. Our products are designed to provide efficient and reliable performance in various electrical applications. We use top-grade materials and state-of-the-art manufacturing techniques to ensure the highest level of quality and customer satisfaction.

0 notes

Text

Aluminum heat sink manufacturers produce high-quality heat sinks that efficiently dissipate heat from electronic components. Utilizing advanced techniques and durable aluminum materials, they create lightweight and custom designs for various industries, including electronics and automotive. Their focus on superior thermal conductivity ensures the reliability and longevity of electronic devices. For More Details Visit Us.

#aluminium heat sink manufacturers#extruded aluminium manufacturers#aluminum led manufacturers#heatsink extrusion manufacturers#aluminium busbar manufacturer

0 notes

Text

The Power Duo: Aluminium Busbars and Solar Panel Installation by Wintechsolar

In the world of renewable energy, two key players have joined forces to create a more efficient and sustainable future: Aluminium busbar manufacturer and solar panel installation companies. At the forefront of this partnership is Wintechsolar, a leading name in the industry. In this blog post, we will explore the significance of aluminium busbars, the importance of professional solar panel installation, and how Wintechsolar seamlessly integrates these elements for an eco-friendly energy solution.

Aluminium Busbars: The Backbone of Solar Power Systems

Aluminium busbars are the hidden heroes of solar power systems. These electrical conductors play a vital role in efficiently transmitting electricity generated by solar panels to various components of the system, including inverters and batteries. Here's why aluminium busbars are crucial:

Conductivity: Aluminium is an excellent conductor of electricity, ensuring minimal energy loss during transmission, which is crucial for optimizing the efficiency of solar power systems.

Durability: Aluminium busbars are known for their durability and resistance to corrosion, making them an ideal choice for outdoor solar installations.

Space Efficiency: They are compact and take up less space in solar panels, allowing for more efficient panel designs and increased energy output.

Solar Panel Installation Company : Wintechsolar

While quality solar panels are essential, their proper installation is equally critical for maximizing energy generation and system longevity. Professional solar panel installation companies bring expertise and experience to the table. Here's why their role is indispensable:

Precision Matters: Proper placement and orientation of solar panels are essential for capturing the maximum amount of sunlight throughout the day. Professional installers ensure precise alignment.

Safety First: Installation companies adhere to strict safety standards, reducing the risk of accidents during and after installation. This guarantees the well-being of both installers and homeowners.

Efficiency and Reliability: Professional installation minimizes the chance of errors and system malfunctions, ensuring that your solar power system operates optimally for years to come.

Wintechsolar: A Sustainable Energy Pioneer

Wintechsolar stands out as a pioneer in the renewable energy sector, offering a comprehensive solution that combines high-quality aluminium busbars and professional solar panel installation services. Here's what makes Wintechsolar a standout choice:

Top-Notch Aluminium Busbars: Wintechsolar partners with leading aluminium busbar manufacturers to provide the most efficient and reliable electrical connections within solar panels, optimizing energy production.

Expert Installation Services: With a team of experienced professionals, Wintechsolar ensures that your solar panels are installed correctly and efficiently, maximizing your return on investment.

Commitment to Sustainability: Wintechsolar's solutions are designed with sustainability in mind, contributing to a greener and more eco-friendly future.

Customer-Centric Approach: Wintechsolar is dedicated to providing personalized solutions that cater to the unique needs of each customer, ensuring satisfaction and peace of mind.

Conclusion

Aluminium busbars and professional solar panel installation are two critical components of a successful solar power system. Wintechsolar's commitment to excellence and sustainability brings these elements together seamlessly, offering customers a reliable and efficient solution for harnessing the power of the sun. As we continue to strive for a more sustainable future, Wintechsolar's innovative approach paves the way for a brighter, cleaner, and more energy-efficient world.

0 notes

Text

Aluminium Busbar Manufacturer in Delhi

Wintech Enterprises has established itself as a leading aluminium busbar manufacturer in Delhi, catering to the growing demand for high-quality electrical conductors. With a strong commitment to excellence and a track record of delivering superior products, Wintech Enterprises has become a trusted name in the industry. As a manufacturer, Wintech Enterprises understands the importance of reliable and efficient electrical systems. Aluminium busbars are an essential component of such systems, Aluminium Busbar Manufacturer in Delhi offering numerous advantages over traditional copper conductors. With their lightweight yet durable construction, aluminium busbars provide excellent electrical conductivity while reducing the overall weight and cost of the system. Wintech Enterprises specializes in producing aluminium busbars that meet stringent industry standards and customer specifications. Wintech Enterprises prides itself on its state-of-the-art manufacturing facility, equipped with advanced machinery and technology. The company employs a team of skilled professionals who are well-versed in the intricacies of aluminium busbar production.

2 notes

·

View notes

Text

The Role of Power Busbar Terminals in Electrical Distribution Systems

In electrical distribution systems, power busbar terminals play a crucial role in ensuring the efficient and safe transfer of electricity. These terminals serve as the interface between the power source and the various electrical components and equipment within a system. They are designed to provide a reliable and low-resistance connection, allowing for the distribution of power to multiple devices.

What are Power Busbar Terminals?

Power busbar terminals, also known as busbar connectors or busbar joints, are conductive devices used to connect power sources, such as transformers or generators, to distribution boards, switchgear, and other electrical devices. They are typically made of high-quality copper or aluminium, chosen for their excellent electrical conductivity and mechanical strength.

Benefits of Power Busbar Terminals:

● Efficient Power Distribution: Power busbar terminals offer a low-resistance connection, ensuring minimal energy loss during power transmission. This efficiency is crucial in electrical distribution systems, where the goal is to deliver electricity to various components without significant voltage drops or power wastage.

● Flexibility and Expandability: Busbar terminals provide a flexible solution for electrical installations. They can accommodate a wide range of current ratings, allowing for the expansion and modification of the distribution system as needed. This flexibility makes them ideal for industrial and commercial applications, where power demands may vary over time.

● Space Saving: Compared to traditional cable connections, power busbar terminals require less space. By consolidating multiple cables into a compact busbar system, valuable space in electrical panels or switchgear is saved. This compact design also enhances accessibility and simplifies maintenance and troubleshooting activities.

● Enhanced Safety: Power busbar terminals are designed to ensure safe and reliable power distribution. Their sturdy construction and secure connections minimize the risk of loose connections, which can lead to electrical faults, overheating, or even fires. Additionally, busbar systems often incorporate insulation materials and protective enclosures to further enhance safety.

Types of Power Busbar Terminals:

Bolted Busbar Terminals: These terminals use bolts or screws to secure the busbars in place. They provide a robust and reliable connection, making them suitable for high-current applications. Bolted busbar terminals require precise tightening to achieve proper electrical contact and often incorporate washers or insulating materials to prevent corrosion and improve insulation.

Clamp-on Busbar Terminals: Also known as compression terminals, clamp-on busbar terminals utilize a clamping mechanism to establish a connection. They offer quick and easy installation, making them suitable for applications that require frequent modifications or additions to the distribution system. Clamp-on terminals provide a strong mechanical grip and excellent electrical contact.

Stud Busbar Terminals: Stud terminals feature a threaded stud or bolt that allows for secure connections. They are commonly used in applications that require high mechanical strength and electrical conductivity, such as large-scale power distribution systems and heavy machinery installations.

Applications of Power Busbar Terminals in various industries:

Power busbar terminals manufactured and supplied by Elmex Controls–find applications in various industries due to their numerous benefits and capabilities, such as;

● Manufacturing Industry: Power busbar terminals are extensively used in manufacturing facilities to distribute power to machinery, production lines, control panels, and other equipment. The ability to handle high currents and provide efficient power distribution makes them suitable for powering heavy machinery and industrial processes.

● Oil and Gas Industry: In the oil and gas sector, power busbar terminals are employed in refineries, petrochemical plants, and offshore platforms. They play a critical role in distributing power to pumps, compressors, motors, and other electrical equipment, ensuring smooth operations in harsh and demanding environments.

● Renewable Energy Sector: Power busbar terminals are essential in renewable energy installations such as solar power plants and wind farms. They connect the power generated from solar panels or wind turbines to inverters, transformers, and the main grid, enabling the efficient transfer of renewable energy to the electrical network.

● Data Centers: Data centres require robust and reliable power distribution systems to support their high-density computing and cooling requirements. Power busbar terminals by Elmex Controls are utilized in data centres to distribute power to server racks, networking equipment, UPS systems, and cooling infrastructure. The scalability and flexibility of busbar systems allow for easy expansion and modifications to accommodate the growing demands of data centres.

● Commercial Buildings: Power busbar terminals are commonly used in commercial buildings such as office complexes, shopping malls, and hotels. They are responsible for distributing power to lighting systems, HVAC units, elevators, security systems, and other electrical loads. Busbar systems help optimize space utilization and provide a reliable and efficient solution for power distribution in these environments.

● Transportation Industry: Power busbar terminals play a significant role in transportation systems, including railways, subways, and electric vehicles (EVs). In railways and subways, they are used to distribute power to traction systems, signalling equipment, and lighting systems. In the EV industry, busbar terminals enable the efficient transfer of power from the battery pack to the vehicle's electrical system, including the motor, charging system, and auxiliary devices.

● Telecommunications Industry: Power busbar terminals are utilized in telecommunications facilities and data centres that support telecommunications infrastructure. They help distribute power to network switches, routers, telecom cabinets, and backup power systems, ensuring reliable and uninterrupted communication services.

Final Thoughts:

Power busbar terminals by Elmex Controls Pvt. Ltd. play a vital role in electrical distribution systems. They provide efficient power transfer, flexibility, space savings, and enhanced safety. By connecting power sources to various electrical components, busbar terminals contribute to the reliable operation of industrial, commercial, and infrastructure installations. Understanding the different types and applications of busbar terminals allows for the design and implementation of efficient and effective electrical distribution systems.

#Barrier Terminal Block Manufacturer in India#Finger Safe Power Terminal blocks#Power BusBar Terminal#Rail Mounted Terminal Blocks India#DIN Rail Mounted Terminal Blocks India

1 note

·

View note

Text

COPPER CABLE LUGS-ALUMINIUM CABLE LUGS

Copper cable lugs and aluminum cable lugs are two types of electrical connectors used to terminate cables in various applications. Let's explore each of them in more detail:

Copper Cable Lugs: Copper cable lugs are electrical connectors made of copper material. They are designed to connect copper conductors to other components or devices, such as switches, circuit breakers, busbars, or terminal blocks. Copper lugs are widely used in electrical systems due to copper's excellent electrical conductivity, corrosion resistance, and malleability. These lugs are available in various sizes and configurations to accommodate different cable sizes and connection requirements.

Aluminum Cable Lugs: Aluminum cable lugs, as the name suggests, are electrical connectors made of aluminum material. They are specifically designed for connecting aluminum conductors to other electrical components or devices. Aluminum lugs are commonly used in applications where aluminum conductors are preferred due to their lighter weight and lower cost compared to copper conductors. However, aluminum is not as conductive as copper, so aluminum cable lugs may have slightly higher resistance and lower current-carrying capacity than their copper counterparts. It's important to ensure that aluminum lugs are properly sized and installed to handle the intended electrical load.

When selecting between copper cable lugs and aluminum cable lugs, it's crucial to consider the conductor material, electrical requirements, and environmental conditions of the application. Copper lugs are generally preferred for copper conductors, while aluminum lugs are used with aluminum conductors. However, in some cases, bi-metallic lugs that can accommodate both copper and aluminum conductors may be used to ensure compatibility.

It's essential to follow the manufacturer's guidelines and applicable electrical codes when selecting and installing cable lugs to ensure reliable and safe electrical connections. Additionally, consulting with a qualified electrician or engineer is advisable for specific applications or if you have any doubts regarding the appropriate choice of cable lugs.

For more information, visit our website - https://www.pioneerpowers.com/cable-terminal-lugs-&-connectors.php

#CopperCableLugs #AluminumCableLugs.

1 note

·

View note

Text

Leading Aluminium Manufacturer, Supplier, and Exporter in Mumbai, India

In the dynamic world of aluminum manufacturing and export, Nileesh Impex stands out as a prominent player based in the bustling city of Mumbai, India. Nileesh Impex has established itself as a dependable manufacturer, supplier, and exporter of aluminium products due to its commitment to quality and global reach.

Manufacturing Excellence in Mumbai: Nileesh Impex takes pride in its state-of-the-art manufacturing facility located in the industrial heart of Mumbai. As a trusted supplier, Nileesh Impex caters to diverse industries, offering a wide range of aluminium products for various applications. We are also manufacturer, supplier, stockiest and exporters of aluminium products like aluminium plates, aluminium Sheets, aluminium flat bars, aluminium pipe/Tubes, Aluminium Square Bar, aluminium rod, aluminium busbars, aluminium hexagonal bars etc. Contact us Today at [email protected] OR +91 - 87796 47178

1 note

·

View note

Text

Cable lugs & their types: Which one is the right one?

Cable lugs are an essential component of any electrical system, used to connect cables to electrical equipment and other wires. They come in various types, each designed for specific applications and requirements. Copper cable lugs are one of the most common in electrical systems.

In this blog post, we'll take a closer look at cable lugs and their styles and help you choose the right one for your application.

What are Cable Lugs?

Cable lugs are metal connectors attached to the ends of cables to connect them to other wires or electrical equipment, typically made of copper, aluminum, or brass, which are good conductors of electricity and can handle high current levels.

Copper cable lugs are an ideal choice for electrical connections.

Types of Cable Lugs

1) Copper Lugs: Copper lugs are ideal in large gauge applications for power draw or grounding. The wire can be soldered or crimped to each copper lug. One end of the copper lug takes the cable by soldering, welding, or crimping, depending on the type of lug used. The other end of the copper lug is secured to a matching termination or connection point by a bolt, screw, or spring clip.

2) Aluminium Lugs: Aluminium lugs are manufactured from the solid aluminium rod using high conductivity (99.6% pure) aluminium. The lugs are forged from solid material and are suitable for outdoor use (as the palm ends are sealed). The Aluminium Lugs are supplied with jointing compounds in the barrels and sealed with an end cap. We have a list of standard sizes but can manufacture according to the requirement. Crimping takes place with hex dies and usual aluminium cable preparation.

3) Bimetallic Lugs: Axis bimetallic lugs made of Friction welding establish the highest quality connection between the copper palm and the Aluminum barrel.

Bimetallic Lugs are used in Solar Plants to connect aluminium conductors to copper busbars in a range of electrical applications such as control panels, switchgear, and combiner boxes.

Choosing the Right Cable Lug

Choosing the right cable lug depends on several factors, such as the cable size and type, the electrical equipment connected, and the environmental conditions of the application.

Here are a few key considerations to keep in mind when selecting the appropriate cable lug for your application:

Cable size and type: Make sure to choose a cable lug designed to fit the size and type of used cable. Using the correct cable lug size or kind can result in a good connection preventing electrical hazards.

Voltage and current rating: Choose a cable lug that is rated to handle the voltage and current of your electrical system. Using a cable lug with a lower rating can result in overheating and damage to the equipment, while using a cable lug with a higher rating may be unnecessary and increase the cost.

Material: The material of the cable lug should be selected based on the environmental conditions of the application. For example, if the application is corrosive, a copper cable lug may be the preferred choice.

Installation method: Consider the installation method of the cable lug, as this can impact the ease and reliability of the connection. Crimped cable lugs are generally quicker and easier to install than soldered ones but may be less reliable in specific applications.

Standards compliance: Ensure that the cable lug you choose complies with applicable industry standards. Axis Lugs are UL & cUl approved and have corrosion-resistant tin plating.

Conclusion

Cable lugs are essential to any electrical system, and choosing the right one for your application is crucial to ensuring a reliable and safe connection.

0 notes