#Power BusBar Terminal

Explore tagged Tumblr posts

Text

Enhance Efficiency and Flexibility with DIN Rail Mounted Terminal Blocks in India

Introduction:

In today's rapidly evolving industrial landscape, efficient and reliable electrical connections are crucial for ensuring smooth operations. DIN rail mounted terminal blocks have emerged as a preferred solution for creating secure and organized electrical connections in a wide range of applications. With their versatility, durability, and ease of installation, these terminal blocks have gained immense popularity among professionals in India. In this blog post, we will explore the benefits and applications of rail mounted terminal blocks and highlight their importance in the Indian industrial sector.

What are DIN Rail Mounted Terminal Blocks?

DIN rail mounted terminal blocks are electrical connectors that provide a convenient and standardized method for connecting and distributing power or signals in industrial control systems. These blocks are specifically designed to be mounted on DIN rails, which are widely used for organizing and securing electrical components in control panels, switchgear cabinets, and equipment enclosures.

Benefits of DIN Rail Mounted Terminal Blocks:

Space-saving and Modular Design: DIN rail mounted terminal blocks feature a compact design that allows for optimal use of available space. Their modular construction enables easy customization and expansion as per the specific requirements of an application, making them highly adaptable.

Secure and Reliable Connections: These terminal blocks ensure secure and reliable connections, thanks to their robust construction and advanced connection technologies. They provide a sturdy grip on wires and facilitate excellent contact, minimizing the risk of loose connections and electrical failures.

Easy Installation and Maintenance: With their tool-less and user-friendly design, DIN rail mounted terminal blocks simplify installation and maintenance procedures. The snap-on mounting feature of these blocks allows for quick and hassle-free assembly, reducing overall downtime during system installation or upgrades.

Enhanced Safety: Rail mounted terminal blocks adhere to stringent safety standards and offer features like finger-safe design, which prevents accidental contact with live components. This ensures the safety of both the equipment and the personnel working with them.

Applications of DIN Rail Mounted Terminal Blocks:

Industrial Automation: Rail mounted terminal blocks are extensively used in industrial automation systems, where they serve as a vital component for connecting sensors, actuators, motors, and other devices. These blocks provide a reliable interface for transmitting power and signals between various control elements.

Power Distribution: DIN rail mounted terminal blocks play a crucial role in power distribution systems, allowing for easy and organized connection of power supply lines to different equipment. They enable efficient energy management and facilitate the distribution of power to multiple devices within a control panel.

Building Automation: In building automation systems, DIN rail mounted terminal blocks provide a convenient solution for connecting various electrical components, such as lighting controls, HVAC systems, security systems, and more. Their modular design allows for easy integration and maintenance of these systems.

Rail Mounted Terminal Blocks in India:

The Indian industrial sector is witnessing significant growth, and the demand for reliable electrical connectivity solutions is higher than ever. Rail mounted terminal blocks have gained traction in India due to their versatility and ability to meet the diverse requirements of industries ranging from manufacturing to infrastructure development. Manufacturers and suppliers in India offer a wide range of DIN rail mounted terminal blocks, catering to different voltage and current ratings, wire sizes, and connection types.

Conclusion:

Rail mounted terminal blocks have revolutionized the electrical connectivity landscape in India, providing efficient, secure, and organized solutions for various industrial applications. Their space-saving design, ease of installation, and robust construction make them indispensable for creating reliable connections in control systems and power distribution networks. As the industrial sector continues to thrive in India, the importance of DIN rail mounted terminal blocks as a key component in electrical installations cannot be overstated. By embracing these advanced terminal blocks, Indian industries can enhance efficiency, reduce downtime, and ensure safe and reliable operations.

#Rail Mounted Terminal Blocks India#DIN Rail Mounted Terminal Blocks India#Power BusBar Terminal#Finger Safe Power Terminal blocks#Barrier Terminal Block Manufacturer in India#electrical wire termination technology#manufacturer#terminal block#DIN Rail Mounted Connectors#switchgear industry#solar product#PCB connectors#DIN rails channels#digital voltmeter#digital ammeter#power and signal#current transformer#railway#renewable energy#elmex#electrical company#electrical industry

2 notes

·

View notes

Text

BI METAL LUGS

Pioneer Power is a leader in the energy sector, known for its innovative solutions and commitment to quality. One of the key components that underline the reliability and efficiency of their electrical systems is the use of bi-metal lugs. Bi-metal lugs are critical in ensuring optimal performance and safety in electrical connections, particularly where different metals are involved. The core functionality of bi-metal lugs lies in their ability to connect dissimilar metals, typically aluminum and copper, which are commonly used in power distribution networks. The connection between these two metals can pose significant challenges due to their differing electrical properties and thermal expansion rates. Without proper handling, this disparity can lead to galvanic corrosion, increased resistance, and eventual failure of the connection, posing risks to both the system and safety.

Pioneer Power's bi-metal lugs are engineered to address these challenges effectively. They are designed with an aluminum barrel and a copper palm, seamlessly bonded through friction welding. This method ensures a robust and reliable connection, minimizing the risk of galvanic corrosion and ensuring efficient conductivity. The aluminum barrel is designed to accommodate aluminum conductors, while the copper palm connects to copper busbars or terminals, providing a stable and secure link between the two different metals. This meticulous engineering helps in maintaining low electrical resistance and high conductivity, crucial for the efficient functioning of power systems.

In addition to their functional benefits, bi-metal lugs from Pioneer Power are also highly durable and resistant to environmental factors. They are often coated with tin to further enhance their resistance to corrosion, which is particularly important in harsh environments where moisture and other corrosive elements are present. The tin coating also facilitates easier soldering, if required, making installation and maintenance simpler and more efficient. This attention to detail in the design and construction of bi-metal lugs underscores Pioneer Power's commitment to providing high-quality, reliable components for their customers.

Another significant advantage of using bi-metal lugs is their ability to accommodate thermal expansion. When electrical current flows through conductors, it generates heat, causing the metals to expand. Aluminum and copper expand at different rates, which can lead to loosening of connections over time if not properly managed. Bi-metal lugs are designed to absorb these differences in thermal expansion, maintaining a secure and stable connection even under varying thermal conditions. This ensures the longevity and reliability of the electrical system, reducing the need for frequent maintenance and preventing potential failures.

Pioneer Power’s bi-metal lugs are also designed with ease of installation in mind. They come with features such as inspection holes to verify the proper insertion of conductors and pre-filled with oxide-inhibiting compounds to ensure clean and secure connections. These features simplify the installation process, reduce the time required for installation, and ensure a reliable connection from the outset. This user-friendly design is particularly beneficial in large-scale power distribution projects where efficiency and reliability are paramount.

The use of bi-metal lugs is not limited to new installations; they are also ideal for retrofit applications. As power distribution networks evolve and upgrade, the ability to seamlessly connect new components with existing infrastructure is crucial. Bi-metal lugs provide the flexibility needed to integrate new systems with old, ensuring continuity and reliability without the need for extensive modifications. This adaptability is a significant benefit for utilities and other entities involved in maintaining and upgrading power distribution networks.

Pioneer Power’s commitment to quality and innovation extends beyond the product itself to encompass comprehensive support and service. They provide detailed installation guides and technical support to ensure that their bi-metal lugs are installed correctly and perform optimally. This holistic approach ensures that customers can rely on the performance and durability of Pioneer Power’s products, backed by the assurance of expert support and guidance.

In summary, bi-metal lugs are an essential component in modern power distribution systems, and Pioneer Power’s offerings in this domain are exemplary. By addressing the challenges of connecting dissimilar metals, these lugs ensure reliable and efficient electrical connections, contributing to the overall performance and safety of power systems. Their robust design, resistance to environmental factors, and ease of installation make them an ideal choice for both new installations and retrofit projects. Pioneer Power’s bi-metal lugs embody the company’s dedication to quality, innovation, and customer satisfaction, making them a trusted choice in the energy sector. Whether for large-scale utilities or smaller-scale applications, the use of bi-metal lugs represents a smart, forward-thinking approach to electrical connectivity, ensuring that power systems are robust, reliable, and efficient.

2 notes

·

View notes

Text

Exothermic welding powder supplier

# **Exothermic Welding Powder Supplier: Ensuring Strong and Reliable Connections**

When it comes to creating permanent, high-conductivity electrical connections, **exothermic welding** is one of the most trusted methods in industries like power distribution, telecommunications, railways, and lightning protection. At the heart of this process is **exothermic welding powder**, a specialized compound that facilitates a robust molecular bond between conductors.

As a leading **exothermic welding powder supplier**, we understand the critical role this material plays in ensuring safety, efficiency, and longevity in electrical grounding and bonding systems.

## **What is Exothermic Welding Powder?**

Exothermic welding powder is a mixture of **copper oxide and aluminum powder**, which, when ignited, produces an extremely high-temperature reaction (up to 2500°C). This reaction melts the copper, allowing it to flow into a mold and create a permanent, corrosion-resistant weld between conductors.

### **Key Benefits of Exothermic Welding:**

✔ **Superior Conductivity** – Better than mechanical or compression connectors.

✔ **Permanent Bond** – No loosening over time due to thermal cycling or corrosion.

✔ **Corrosion-Resistant** – Lasts decades, even in harsh environments.

✔ **High Current Capacity** – No risk of overheating under high loads.

## **Choosing the Right Exothermic Welding Powder Supplier**

Not all welding powders are created equal. A reliable supplier should offer:

✅ **High-Quality Materials** – Consistent chemical composition for reliable welds.

✅ **Multiple Sizes & Types** – Powders for different conductor sizes (from small cables to large busbars).

✅ **Safety Compliance** – Properly tested and certified powders for industrial use.

✅ **Technical Support** – Expert guidance on mold selection and welding procedures.

## **Applications of Exothermic Welding Powder**

- **Electrical Grounding Systems** (substations, power plants)

- **Lightning Protection** (air terminals, down conductors)

- **Railway & Transportation** (track bonding, signaling systems)

- **Telecommunications & Data Centers** (earthing and bonding)

## **Why Trust Us as Your Exothermic Welding Powder Supplier?**

We supply **premium-grade exothermic welding powders** that meet international standards (IEEE 837, UL 467, IEC 62561). Our products ensure:

✔ **Strong, bubble-free welds**

✔ **Minimal slag formation**

✔ **Consistent ignition and reaction**

Whether you need **CADWELD, ERICO, or generic exothermic welding powder**, we provide cost-effective solutions without compromising quality.

### **Get in Touch Today!**

Looking for a **trusted exothermic welding powder supplier**? Contact us for bulk orders, technical advice, and competitive pricing. Ensure your electrical connections are **safe, durable, and high-performance** with our top-quality welding powders.

0 notes

Text

Power, Protection, and Precision: A Guide to Panel Board Accessories

When it comes to electrical systems, most of us focus on the big stuff — the main panel, the wiring, the breakers. But what really keeps everything running smoothly behind the scenes? It’s the Panel Board Accessories.

They may be small, but these components play a huge role in making sure your panel board works safely, efficiently, and without any hiccups. So, let’s break it all down — no jargon, no over-complication.

⚡ What Are Panel Board Accessories, Really?

Simply put, Panel Board Accessories are the essential parts and fittings that support the operation of your electrical panel. They make sure everything stays connected, protected, and well-organized inside the distribution system.

Think of them as the behind-the-scenes crew. Not always visible, but absolutely necessary to keep the show going.

🛠️ Key Panel Board Accessories You Should Know

Here are some of the most commonly used (and essential) accessories found inside panel boards:

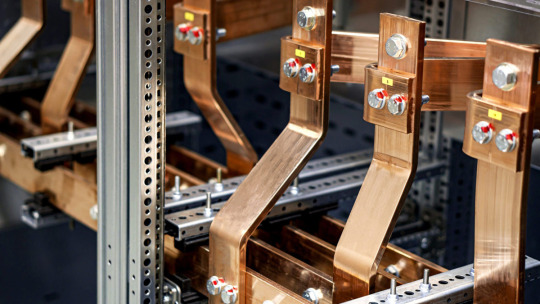

Busbars: These metal strips distribute electricity to different circuits — clean and efficient power flow.

DIN Rails: A mounting system that keeps breakers and components securely in place.

Cable Lugs & Terminal Blocks: Help connect wires to the panel safely and tightly.

Neutral & Earth Bars: Vital for safe earthing and proper grounding.

Blanking Plates & Covers: For closing unused breaker slots and protecting the internals.

Gland Plates & Cable Entry Kits: Manage how cables enter and exit your panel, keeping it neat and secure.

Each of these parts plays a role in keeping your power flow organized, safe, and easy to maintain.

🔒 Why Panel Board Accessories Matter

Without the right accessories, even the best electrical panels can fall short. Here's what these accessories really do for you:

✅ Boost Safety: They help prevent loose connections, short circuits, and other common risks.

✅ Improve Efficiency: Everything stays organized, which means quicker installations and easier maintenance.

✅ Extend Panel Life: Accessories reduce stress on main components, helping them last longer.

✅ Simplify Upgrades: Need to add new circuits? Good accessories make expansion easy.

In short, the right accessories turn a basic panel into a smart, safe, and future-ready power hub.

🔧 Why Choose Translight?

When you’re dealing with electrical safety, there’s no room for compromise. That’s why professionals trust Translight for high-performance Panel Board Accessories. Whether you're setting up a simple distribution panel or managing a large commercial installation, Translight offers durable, well-designed accessories that keep everything running smoothly.

Their components are made to fit perfectly, last longer, and handle the demands of modern electrical setups — with both safety and performance in mind.

💡 Final Thoughts

In the world of electricity, it’s often the small things that make the biggest difference. Panel Board Accessories might not get the spotlight, but they’re essential to how well your entire system performs.

And with Translight, you can be sure those small components are doing a big job — reliably, safely, and efficiently.

So next time you open a panel board, remember: it’s not just what’s powering it — it’s how well everything inside is working together.

0 notes

Text

Common Challenges in PCC Panel Maintenance and How to Overcome Them

Introduction

A pcc electrical panel is the backbone of power distribution in industrial and commercial setups. While it ensures smooth operations, maintaining it can be a challenge. Poor maintenance can lead to unexpected failures, increased downtime, and even safety hazards. Identifying common challenges and knowing how to address them is key to ensuring the longevity and efficiency of your pcc electrical panel

Why PCC Panel Maintenance is Crucial

A well-maintained pcc electrical panel reduces the risk of electrical failures, protects equipment from damage, and ensures compliance with safety standards. Ignoring maintenance can result in breakdowns, production losses, and expensive repairs.

Common Maintenance Challenges and Their Solutions

Loose Connections and Overheating

Challenge: Over time, electrical connections in the pcc electrical panel can loosen due to vibrations and thermal expansion, leading to overheating.

Solution: Regularly inspect and tighten all terminals and busbar joints to prevent excessive heat buildup.

Dust and Moisture Accumulation

Challenge: Dust and moisture can cause insulation failures, short circuits, and corrosion.

Solution: Keep the pcc electrical panel in a clean, dry environment and use enclosures with appropriate IP ratings to prevent contamination.

Aging Components and Wear & Tear

Challenge: Circuit breakers, relays, and contactors degrade over time, affecting performance.

Solution: Follow a scheduled replacement plan for aging components to avoid sudden failures.

Unbalanced Load Distribution

Challenge: An uneven load distribution across phases can cause power inefficiencies and overheating.

Solution: Regularly monitor load balancing and make necessary adjustments to optimize performance.

Faulty Protection Devices

Challenge: If circuit breakers or relays fail to operate correctly, they may not provide proper protection.

Solution: Conduct routine testing of all protective devices to ensure they function as required.

Insulation Degradation

Challenge: Over time, cable and busbar insulation can weaken, increasing the risk of short circuits.

Solution: Perform insulation resistance tests periodically to detect any deterioration early.

Ensure uninterrupted power distribution by partnering with a trusted PCC Panel Manufacturer for reliable maintenance solutions!

Best Practices for Overcoming Maintenance Challenges

Implement a structured maintenance schedule for regular inspections

Use thermal imaging technology to detect overheating issues before they escalate

Train personnel on proper handling and troubleshooting techniques

Keep spare critical components on hand to minimize downtime

Work with an experienced PCC Panel Manufacturer for expert servicing and upgrades.

Conclusion

Proper maintenance of your pcc electrical panel ensures operational efficiency, safety, and long-term cost savings. By addressing common maintenance challenges proactively, industries can avoid costly failures and maintain smooth operations.

Looking for expert support? Connect with a reliable PCC Panel Manufacturer today to keep your power system in top condition!

0 notes

Text

How Does A Feeder Pillar Function?

Introduction

Electrical systems are everywhere, but what ensures they run smoothly and safely? One crucial component that supports this is the Feeder Pillar Panel. This article answers a common question: How Does A Feeder Pillar Function? It walks through its structure, role, types, and benefits with clear examples, focusing on practical knowledge.

Whether you are involved in power systems or simply want to understand how electricity flows securely, this guide provides clarity on What is a Feeder Pillar? and why it matters.

What Is a Feeder Pillar?

A Feeder Pillar is a robust outdoor electrical cabinet that houses protective devices such as fuses, switches, and circuit breakers. It acts as a central hub where power enters and then branches off to different circuits. You often see them installed along streets, in residential complexes, industrial sites, or public spaces.

In simple terms, think of it as the control station that manages the flow of electricity safely and efficiently to various points from one central unit. It serves as a barrier against overloads, short circuits, and other risks while ensuring the smooth distribution of electrical power.

What Does a Feeder Pillar Do?

The key role of a Feeder Pillar Panel is to control and protect electrical circuits. It connects the main power source to multiple outgoing cables. By doing this, it ensures that electricity is evenly distributed and each circuit receives the power it needs.

Here’s a real-world example. Imagine street lights across a city block. Rather than having each light connected separately to the main grid, they are all connected to a Feeder Pillar. This setup allows centralized control, easy maintenance, and better safety management.

In technical terms, What does a feeder pillar do? It isolates faults in the system, prevents complete blackouts, and ensures minimal downtime by directing the flow of electricity in a structured way.

Understanding the Functionality of Feeder Pillar Panels

To understand How Does A Feeder Pillar Function, it's essential to look at how current moves through it and how it responds during faults or heavy loads.

When electricity enters the Feeder Pillar Panel, it passes through protective devices. These devices are designed to detect abnormalities such as voltage spikes or short circuits. When such events occur, they immediately cut off the affected circuit without interrupting the entire system.

This process is automatic and quick. It protects not only the electrical appliances connected downstream but also safeguards users from electrical hazards. The Feeder Pillar Panel thus acts like a gatekeeper monitoring and managing how electricity is delivered.

Components of a Feeder Pillar Panel

Each Feeder Pillar Panel consists of specific components that work together for reliable power control. Here’s a breakdown of the essential parts:

Main Switch: Controls the entire flow of electricity into the feeder pillar.

Circuit Breakers or Fuses: These safety devices stop the power flow when problems are detected.

Busbars: Metal strips that distribute current to various circuits.

Terminal Blocks: Secure connection points for incoming and outgoing wires.

Earth Terminals: Safely discharge excess electricity to the ground to prevent shock or equipment damage.

Enclosure Box: Protects the internal parts from environmental factors like rain, dust, and heat.

These parts are arranged logically inside the Feeder Pillar Panel to allow safe handling, easy access during maintenance, and proper ventilation.

Types of Feeder Pillars

Several types of feeder pillars are available, each designed for specific needs. Choosing the right one depends on where and how it will be used.

Outdoor Feeder Pillars: Built to handle weather exposure with robust enclosures. Used in streets, parks, and outdoor facilities.

Indoor Feeder Pillars: Found inside factories, warehouses, or commercial buildings where weather is not a concern.

Single-Phase Feeder Pillars: Suitable for light-duty applications such as small shops or residential areas.

Three-Phase Feeder Pillars: Used in heavy-duty environments like industries or large commercial complexes.

Street Lighting Pillars: Special feeder pillars designed only for lighting control across roads or public spaces.

By understanding these types, users can match their electrical needs to the right solution, avoiding overuse or underuse of equipment.

Features of Feeder Pillars

Good feeder pillars are built to last and function under varying conditions. The Features of Feeder Pillars include:

Weatherproof Construction: Resists rain, dust, and temperature changes.

Modular Design: Allows easy expansion or upgrading.

Safety Locks: Prevent unauthorized access.

Efficient Cooling: Ensures components don’t overheat.

Durable Materials: Made of stainless steel or treated metal to avoid corrosion.

These features not only extend the life of the Feeder Pillar Panel but also reduce the need for frequent maintenance.

Top Features of High-Quality Feeder Pillar Boxes

High-quality feeder pillars stand out due to precision design and reliable performance. The Top Features of High-Quality Feeder Pillar Boxes include:

Seamless Installation: Mounting holes, grounding provisions, and cable entries are pre-arranged.

Robust Hinges and Latches: Support frequent opening and secure closing.

Easy Identification: Clear labels and indicators for every circuit.

Compliance: Meets national and international safety standards.

These features ensure that the product performs under pressure, making it ideal for installations in challenging environments. Trustworthy electrical panel manufacturers ensure these aspects are never compromised.

Benefits of Feeder Pillars

Feeder pillars bring several benefits that improve how electricity is handled:

Enhanced Safety: Prevents overload and protects both equipment and people.

Reduced Downtime: Isolates faulty circuits without shutting down the entire system.

Cost-Effective: Minimizes repair costs due to early fault detection.

Central Control: Easy management of multiple circuits from one point.

Flexible Usage: Suitable for various environments from residential to industrial.

These Benefits of Feeder Pillars prove their importance in maintaining a consistent and safe power supply across multiple sectors.

Step-by-Step Process for Installing Feeder Pillars

Installing a Feeder Pillar Panel is a detailed process that requires planning and accuracy. Below is a simple step-by-step guide:

Site Selection: Choose a level, accessible area with proper drainage.

Foundation Preparation: Construct a concrete base or plinth for mounting.

Mounting the Pillar: Secure the feeder pillar using bolts and align it properly.

Connecting Wires: Attach incoming and outgoing cables to the correct terminals.

Earthing Setup: Connect the earth wire for safety.

Testing: Run electrical checks to confirm everything works as intended.

Engaging a reputable feeder pillar supplier in India ensures quality components and proper guidance during installation.

Why Choose DJ Electro Controls?

When looking for reliable electrical panel manufacturers, product quality and expertise matter. DJ Electro Controls is recognized for building efficient, durable, and safe Feeder Pillar Panels that meet diverse requirements.

Reasons to consider DJ Electro Controls include:

In-depth knowledge of power systems.

Extensive range of feeder pillars for various uses.

Strong presence as a feeder pillar supplier in India.

Focus on long-term performance and safety standards.

FAQs

Q1: What is the purpose of a feeder pillar in an electrical system?

Answer: It manages and distributes electrical power safely from one point to multiple circuits, ensuring protection against faults.

Q2: How does a feeder pillar ensure electrical safety in public areas?

Answer: By using fuses, circuit breakers, and secure enclosures, it limits electrical hazards and controls access.

Q3: What is the difference between a feeder pillar and an electrical distribution board?

Answer: A feeder pillar is used for outdoor, large-scale distribution, while a distribution board is typically used indoors for limited circuits.

Q4: Can a feeder pillar be used for both residential and industrial applications?

Answer: Yes, depending on its type and design, it can serve both environments effectively.

Q5: How do I choose the right feeder pillar for my project?

Answer: Consider load requirements, installation site, number of circuits, and consult with experienced electrical panel manufacturers for the best match.

Q6: Who are the best electrical panel manufacturers for feeder pillars in India?

Answer: Companies like DJ Electro Controls are known for reliable products and service as a top feeder pillar supplier in India.

Q7: How often should feeder pillar panels be inspected or maintained?

Answer: Routine inspections every 6 to 12 months are recommended, with immediate checks after major weather events or electrical faults.

Conclusion

A feeder pillar is not just a metal box with switches. It’s a structured system that ensures power is distributed safely and efficiently. By understanding How Does A Feeder Pillar Function, users can appreciate its importance in daily electrical setups.

With durable construction, intelligent design, and practical usage, Feeder Pillar Panels are essential for modern electrical networks. Trusted names like DJ Electro Controls support this need by delivering solutions that balance safety, performance, and reliability.

A clear understanding of What Does a Feeder Pillar Do helps professionals, technicians, and users manage electrical systems with confidence and precision.

#djelectrocontrol#feeder pillar#Feeder Pillar Panel#Feeder Pillar Panel supplier in india#Feeder Pillar Panel Near me#Functionality of Feeder Pillar Panels#Types of Feeder Pillars

0 notes

Text

The Combined Strength of Overhead Line Covers, Busbar Heat Shrink Sleeves, and Euromold Connectors in High-Voltage Systems

In the intricate and demanding landscape of high-voltage electrical infrastructure, reliability and safety are paramount. From the vast expanse of overhead power lines to the complex configurations within substations, the seamless flow of electricity hinges on robust and dependable components. Overhead Line Covers, Busbar Heat Shrink Sleeves, and Euromold connectors are essential technologies that contribute significantly to the safety, reliability, and longevity of high-voltage systems. Each serves a distinct purpose, yet they work in synergy to fortify electrical infrastructure against environmental stresses, mechanical forces, and electrical hazards.

Overhead Line Covers: Defending Against the Elements and Wildlife

Overhead power lines, exposed to the relentless forces of nature and the potential disruptions caused by wildlife, require robust protection. Overhead Line Cover provide a critical shield against environmental hazards and animal interference.

These protective devices, typically made from durable polymers, are designed to:

Weather Protection: Shield conductors and insulators from rain, snow, ice, and UV radiation, preventing corrosion and insulation degradation.

Wildlife Mitigation: Prevent animals, such as birds and squirrels, from causing short circuits and outages by coming into contact with energized conductors.

Vegetation Management: Reduce the risk of flashovers and outages caused by vegetation encroachment.

Mechanical Protection: Provide a degree of protection against abrasion and impact damage.

Enhance Reliability: Minimize the risk of outages, ensuring continuous power delivery.

By mitigating these risks, Overhead Line Covers contribute to the overall reliability and resilience of power transmission and distribution networks.

Busbar Heat Shrink Sleeves: Insulating and Protecting Critical Connections

Within substations and switchgear, busbars play a crucial role in distributing high-voltage electricity. These critical connections require effective insulation and protection to prevent short circuits and ensure safe operation. Busbar Heat Shrink Sleeve provide a reliable solution for this purpose.

These sleeves, made from cross-linked polyolefin or other suitable materials, offer:

Electrical Insulation: High dielectric strength to prevent electrical breakdown.

Environmental Protection: A barrier against moisture, dust, and chemicals, preventing corrosion.

Mechanical Protection: Resistance to abrasion, impact, and mechanical stresses.

Enhanced Safety: Reduced risk of accidental contact with energized busbars.

Improved Reliability: Prevention of insulation breakdown and short circuits.

Ease of Installation: Simple installation with minimal specialized tools.

The heat-shrink process creates a tight-fitting sleeve that conforms to the shape of the busbar, providing a uniform insulation layer and long-lasting protection.

Euromold Connectors: Reliable and Versatile Cable Connections

For reliable and versatile cable terminations and connections in medium-voltage and high-voltage systems, Euromold connectors are a preferred choice. Their modular design and high-quality materials ensure dependable performance.

Euromold connectors offer:

Modular Design: Flexibility in configuring connections to meet specific requirements.

High-Quality Materials: Excellent electrical insulation and environmental resistance.

Reliable Performance: Dependable operation under demanding conditions.

Ease of Installation: Simplified installation process.

Wide Range of Applications: Versatility in substations, switchgear, and transformers.

These connectors are available in various types, including cable plugs, elbow connectors, and tee connectors, enabling versatile connection configurations. They provide a reliable and long-lasting interface between cables and electrical equipment.

The Integrated System: Ensuring High-Voltage Reliability and Safety

Overhead Line Covers, Busbar Heat Shrink Sleeves, and Euromold connectors work in conjunction to provide a comprehensive approach to ensuring the reliability and safety of high-voltage electrical systems. Overhead Line Covers protect against external hazards, Busbar Heat Shrink Sleeves insulate and protect critical connections within substations, and Euromold connectors provide reliable cable interfaces.

By implementing these technologies, electrical engineers and technicians can:

Minimize the risk of outages and equipment failures.

Enhance safety for personnel and equipment.

Extend the lifespan of electrical infrastructure.

Ensure the continuous and efficient delivery of power.

The integration of these products provides a robust and dependable high voltage electrical system.

0 notes

Text

The Versatility of Round Copper Plates: Applications Across Industries

Copper has long been a preferred material in various industries due to its superior conductivity, durability, and corrosion resistance. Round copper plates play a crucial role in sectors like electrical, marine, and construction, offering unmatched efficiency and longevity. In this article, we explore the diverse applications of copper discs for industrial use and how businesses can benefit from their unique properties.

1. Electrical Industry: The Backbone of Conductivity

Power Distribution and Conductors

One of the most common uses of round copper plates is in electrical applications. Their high conductivity makes them ideal for:

Busbars and electrical terminals in power plants and substations.

Transformer components for efficient energy transfer.

Circuit breakers and switchgear to enhance electrical safety.

Case Study: A power distribution company replaced aluminum conductors with high-purity round copper plates, reducing energy loss by 20% and improving efficiency.

2. Marine Industry: Resisting Corrosion in Harsh Environments

Shipbuilding and Anti-Fouling Solutions

In marine environments, metals must withstand extreme moisture and salt exposure. Copper plates are widely used for:

Hull protection and anti-fouling coatings to prevent algae and barnacle buildup.

Seawater piping and heat exchangers for long-term durability.

Electrical grounding plates in ships and submarines to prevent galvanic corrosion.

Case Study: A shipbuilding firm adopted copper discs for industrial use in its grounding systems, enhancing vessel lifespan and reducing maintenance costs.

3. Construction Industry: Strength, Aesthetics, and Longevity

Architectural Elements and Roofing Solutions

The construction industry utilizes round copper sheet applications for both functional and aesthetic purposes:

Decorative wall panels and sculptures that develop a beautiful patina over time.

Roofing and flashing materials, offering unmatched durability and weather resistance.

Plumbing fittings and water filtration systems due to copper’s antimicrobial properties.

Case Study: A commercial building integrated copper roofing plates, cutting long-term repair costs by 30% while enhancing aesthetic appeal.

FAQs About Round Copper Plates

Q1: What sizes and thicknesses are available for round copper plates?

A: Accromet offers a wide range of copper plate dimensions, with customizable options to meet industrial specifications.

Q2: Are copper plates recyclable?

A: Yes! Copper is 100% recyclable, making it a sustainable choice for various industries.

Q3: How does copper compare to aluminum in conductivity?

A: Copper is nearly twice as conductive as aluminum, making it the superior choice for electrical applications.

Q4: Can copper plates be used in high-temperature applications?

A: Absolutely! Copper retains its strength and conductivity even at high temperatures, making it ideal for furnaces and heat exchangers.

Get High-Quality Round Copper Plates from Accromet

Looking for top-grade copper plates for your next project? Accromet offers premium round copper discs tailored for industrial and commercial applications. Whether you need custom sizes or bulk orders, we have the right solution for you!

👉 Contact us today to discuss your requirements and get a free quote!

0 notes

Text

A9N16256

Introducing the Schneider RCCB A9N16256, a powerful and reliable solution for your electrical protection needs. This Acti9 xID biconnect residual current circuit breaker is designed to keep you safe from electrical shock and fire hazards. With a sensitivity of 300mA and a 40A In rated current, you can trust that your circuits are well-protected.

Installation is a breeze with the biconnect comb busbar or tunnel terminals, allowing for easy connection downstream or upstream. With a rated breaking and making short circuit capacity of up to 500A, this RCCB is compliant with the IEC/EN 61008-1 standard, giving you peace of mind that you are using a quality product.

Don't compromise when it comes to electrical safety - choose the Schneider RCCB A9N16256 for reliable protection that you can trust.

0 notes

Text

Sodium (18Ah Cells) 4S 5P Busbars and Hardware

Sodium-ion batteries, using 18Ah cells in a 4S 5P configuration, are gaining attention as an alternative to traditional lithium-ion technology due to their lower cost and environmental benefits. In a 4S 5P setup, four cells are connected in series (4S) to provide the required voltage, while five cells are connected in parallel (5P) to achieve a total capacity of 90Ah. This configuration is ideal for applications requiring significant energy storage, such as large-scale energy systems and electric vehicles.

The busbars used in this configuration are essential for ensuring efficient power distribution between the cells. Made from high-conductivity materials like copper or aluminum, these busbars are designed to handle the high currents generated by the 90Ah battery pack while minimizing energy losses and heat generation. Proper design is crucial for maintaining system stability and preventing potential failures.

In addition to the busbars, hardware components such as connectors, terminals, and insulation materials play an integral role in the battery's performance. These components ensure secure connections between cells and help prevent issues like short circuits, overheating, or voltage imbalances.

As the demand for sustainable energy storage solutions grows, the 4S 5P sodium-ion battery configuration, along with robust busbars and hardware, offers a reliable and cost-effective solution for powering everything from renewable energy storage to electric vehicles.

Contact

+𝟭 𝟳𝟳𝟵-𝟳𝟳𝟬-𝟯𝟭𝟬𝟵

1585 Beverly CT, Unit 121, Auror

0 notes

Text

Discover EC grade copper and aluminum bare wires and strips, ideal for busbars, earthing, terminal connections, and power control panels. High-quality solutions for electrical applications.

0 notes

Text

Benefits of Using Cells Contact System Integrated Busbars

Energy storage devices are crucial components contributing to the energy needs of the modern world. They are used to power portable electronics and establish a smooth balance between energy source and grid. As the world is looking towards options for sustainable energy, efficient and cost-effective energy storage solutions have become the need of the hour. Several innovations are done in the energy storage sector to ensure the least wastage and increased efficiency.

One such solution is the Cells Contact System integrated busbar, which offers a range of advantages for energy storage applications. This article will explore the key benefits of using Cells Contact System integrated busbars for energy storage. Before that, let us understand what are Cell Contact System Integrated Busbars and why are they needed.

What are Cells Contact System Integrated Busbars?

Cells Contact System Integrated Busbars are a type of electrical interconnect system used in different types of lithium-ion battery cells, including prismatic, cylindrical, and pouch cells. CCSIBs are designed to provide a compact and efficient method of connecting the positive and negative terminals of the battery cells. They consist of conductive busbars that are integrated directly into the cell design, eliminating the need for external connectors or wiring.

Innovative solutions like Cells Contact System Integrated Busbars (CCSIB) can address these challenges and provide more accurate and efficient testing. CCSIB is a non-destructive testing method that uses a specially designed busbar to measure the voltage of each cell in a battery pack. This approach eliminates the need for disassembly, reducing the risk of damage and improving testing efficiency.

Why are CCSIBs Needed?

CCSIBs are needed as they hold the ability to minimize the resistance and impedance in the electrical path, resulting in improved power delivery and reduced energy losses. They lead to better overall battery performance, including higher energy density, faster charging, and increased cycle life. Also, in a battery, space plays a major role and it is not a wise thing to use thick wires for cell contact that may result in short circuits and safety issues.

The integration of CCSIBs into these cell designs helps optimize the electrical connections and enhance the overall performance and reliability of the battery systems. Here are some of the other reasons why it is very important to use

CCSIBs in place of other wire connectors or power strips. CCSIB also provides more accurate test results by measuring the voltage of each cell individually, allowing for a more precise analysis of battery performance. This method can detect issues like cell imbalance, which can affect overall battery performance and lifespan.

Furthermore, CCSIB can be used to test batteries under different conditions, including extreme temperatures and high currents, to simulate real-world usage scenarios. This approach can help identify potential issues early on and improve the safety and reliability of batteries. Cells Contact System Integrated Busbars (CCSIB) are a type of electrical interconnect system used in different types of lithium-ion battery cells, including prismatic, cylindrical, and pouch cells.

CCSIBs For Different Cell Types

Prismatic Cells – The contact system integrated busbars are an essential component of prismatic cells used in energy storage systems. These cells are commonly used in electric vehicles, renewable energy systems, and other applications where high power density is required. The contact system integrated busbars serve as the backbone of the cell, connecting the positive and negative terminals to the external circuit. This ensures efficient power transfer and minimizes losses due to resistance.

The busbars are designed to withstand high currents and temperatures, ensuring reliable operation over the life of the cell. They are typically made of Copper or Aluminium and are coated with a protective layer to prevent corrosion. Overall, the contact system integrated busbars play a crucial role in the performance and longevity of prismatic cells, making them a key consideration in the design and manufacture of energy storage systems.

Cylindrical Cells – Cells Contact System Integrated Busbars in cylindrical shape are an innovative solution for efficient power distribution. These busbars are designed to seamlessly integrate with the Cell Contact System, providing a reliable and compact solution for power transmission. The cylindrical shape of these busbars allows for easy installation and space-saving design.

They can be easily mounted on various surfaces, making them versatile for different applications. The integration with the Cell Contact System ensures a secure and stable connection, minimizing the risk of power loss or interruptions.

These integrated busbars are designed to handle high currents and voltages, making them suitable for a wide range of power distribution needs. They are made from high-quality materials that ensure durability and long-lasting performance.

In addition to their technical advantages, these integrated busbars also offer cost savings. Their compact design and easy installation reduce the need for additional wiring and components, resulting in lower installation and maintenance costs.

Pouch Cells – In pouch cells, the Cell Contact System is integrated with busbars. This allows for efficient and reliable transfer of energy between the cells and the external circuit. The busbars provide a secure connection between the cells, ensuring that the energy flow is uninterrupted. This integration also helps to reduce the overall size of the battery, making it more compact and easier to handle. With this technology, pouch cells can deliver high-performance and long-lasting power for a variety of applications.

Enhanced Accuracy and Efficiency

One of the primary advantages of using Cells Contact System Integrated Busbars for energy storage is their ability to enhance energy efficiency. By minimizing energy wastage, CCSIBs help ensure that the stored energy is efficiently delivered to its intended destination, whether it’s a residential home, a portable device, or an industrial facility.

Power density is a critical factor in energy storage systems, especially for applications that require high power output in a compact space. CCSIBs are engineered to maximize power density, allowing for more energy to be stored and delivered in a smaller footprint. This is particularly advantageous in applications where space is limited, such as in urban environments or onboard electric vehicles.

Increased Design Possibilities

The modular design of Cells Contact System integrated busbars allows for flexibility in energy storage system configuration. Users can easily scale their energy storage capacity by adding or removing modules as needed. This modular approach simplifies the installation and maintenance of energy storage systems, making it an attractive option for a wide range of applications. CCSIBs are flexible in design and can adapt to different sizes and types of energy storage equipment, which is convenient for the expansion and upgrading of the system.

Safety Assurance

Safety is a paramount concern in energy storage applications. Cells Contact System integrated busbars are equipped with a range of safety features, including overcurrent protection, short-circuit prevention, and fault detection. These safety mechanisms ensure that the energy storage system operates without risks of electrical accidents or damage, providing peace of mind for both operators and end-users. CCS provides multiple protection mechanisms, such as voltage and current monitoring, fault isolation, etc., to ensure the stable operation and safety of the energy storage system.

Compatibility with Various Chemistries

Energy storage systems use various battery chemistries, such as lithium-ion, lead-acid, or flow batteries. Cells Contact System integrated busbars are designed to be compatible with a wide range of battery chemistries, offering versatility to energy storage system designers and operators. This compatibility ensures that users can choose the most suitable battery technology for their specific application.

Conclusion

In conclusion, Cells Contact System integrated busbars offer a host of advantages for energy storage applications. Their high efficiency, power density, reliability, and safety features make them an attractive choice for a wide range of uses, from residential and commercial energy storage to grid-scale applications.

As the world continues to transition towards cleaner and more sustainable energy solutions, innovative technologies like Cells Contact System integrated busbars play a crucial role in shaping the future of energy storage. CCS can quickly detect and locate faults and reduce maintenance time and cost. In short, the use of integrated busbar (CCS) for energy storage plays a key role in the energy storage system, improves the efficiency and reliability of energy management, and promotes the development and application of energy storage technology.

#cylindrical cells#electric vehicles#energy storage system#ev's#lithium-ion batteries#pouch cells#prismatic cells

0 notes

Text

Exothermic welding powder supplier

# **Exothermic Welding Powder Supplier: Ensuring Strong and Reliable Connections**

When it comes to creating permanent, high-conductivity electrical connections, **exothermic welding** is one of the most trusted methods in industries like power distribution, telecommunications, railways, and lightning protection. At the heart of this process is **exothermic welding powder**, a specialized compound that facilitates a robust molecular bond between conductors.

As a leading **exothermic welding powder supplier**, we understand the critical role this material plays in ensuring safety, efficiency, and longevity in electrical grounding and bonding systems.

## **What is Exothermic Welding Powder?**

Exothermic welding powder is a mixture of **copper oxide and aluminum powder**, which, when ignited, produces an extremely high-temperature reaction (up to 2500°C). This reaction melts the copper, allowing it to flow into a mold and create a permanent, corrosion-resistant weld between conductors.

### **Key Benefits of Exothermic Welding:**

✔ **Superior Conductivity** – Better than mechanical or compression connectors.

✔ **Permanent Bond** – No loosening over time due to thermal cycling or corrosion.

✔ **Corrosion-Resistant** – Lasts decades, even in harsh environments.

✔ **High Current Capacity** – No risk of overheating under high loads.

## **Choosing the Right Exothermic Welding Powder Supplier**

Not all welding powders are created equal. A reliable supplier should offer:

✅ **High-Quality Materials** – Consistent chemical composition for reliable welds.

✅ **Multiple Sizes & Types** – Powders for different conductor sizes (from small cables to large busbars).

✅ **Safety Compliance** – Properly tested and certified powders for industrial use.

✅ **Technical Support** – Expert guidance on mold selection and welding procedures.

## **Applications of Exothermic Welding Powder**

- **Electrical Grounding Systems** (substations, power plants)

- **Lightning Protection** (air terminals, down conductors)

- **Railway & Transportation** (track bonding, signaling systems)

- **Telecommunications & Data Centers** (earthing and bonding)

## **Why Trust Us as Your Exothermic Welding Powder Supplier?**

We supply **premium-grade exothermic welding powders** that meet international standards (IEEE 837, UL 467, IEC 62561). Our products ensure:

✔ **Strong, bubble-free welds**

✔ **Minimal slag formation**

✔ **Consistent ignition and reaction**

Whether you need **CADWELD, ERICO, or generic exothermic welding powder**, we provide cost-effective solutions without compromising quality.

### **Get in Touch Today!**

Looking for a **trusted exothermic welding powder supplier**? Contact us for bulk orders, technical advice, and competitive pricing. Ensure your electrical connections are **safe, durable, and high-performance** with our top-quality welding powders.

0 notes

Text

Crimping vs. Soldering: What’s the Best Way to Install Cable Lugs?

When it comes to installing Cable Lugs, there are two main methods: Crimping and Soldering. Both are used to create secure electrical connections, but which one is better? If you're unsure about which method to choose, don't worry—I'll break it down in the simplest way possible.

At Raiden Electric, we know that using the right installation technique can make all the difference in ensuring a safe, strong, and long-lasting connection. So, let’s compare crimping vs. soldering and help you decide which method is best for your setup.

What Are Cable Lugs and Why Are They Important?

Before we dive into crimping and soldering, let’s quickly cover what Cable Lugs are.

✅ Cable Lugs are connectors used to attach electrical cables to terminals, busbars, or other equipment. ✅ They provide a secure and stable connection, ensuring smooth power transmission. ✅ They’re commonly used in industrial, commercial, and residential electrical setups.

Now, let’s look at the two main ways to install them.

Crimping: The Quick and Reliable Method

Crimping is the process of compressing a Cable Lug onto a cable using a crimping tool. This method mechanically locks the lug onto the cable, creating a strong electrical connection.

Why Choose Crimping?

✔ Faster and Easier – No need for additional materials like solder; just crimp and you’re done. ✔ Reliable in High-Vibration Areas – Crimped connections hold up better in environments with movement or shaking. ✔ Lower Electrical Resistance – A properly crimped lug ensures strong conductivity with minimal resistance. ✔ Safe and Consistent – Crimping is widely used in industrial and high-voltage applications because it provides a secure and uniform connection.

When to Use Crimping?

🔹 When working with thick or high-voltage cables. 🔹 In environments with vibration or movement (e.g., automotive, industrial machinery). 🔹 When you need a quick and efficient installation process.

Soldering: The Traditional Approach

Soldering involves melting a metal alloy (solder) to join the Cable Lug to the wire. Once cooled, the solder hardens, creating an electrical connection.

Why Choose Soldering?

✔ Stronger Bond – Solder creates a solid and permanent metal-to-metal connection. ✔ Better for Thin Wires – Works well when dealing with delicate or small-diameter wires. ✔ Good for Low-Vibration Environments – Works best in stable environments where movement is minimal.

The Downsides of Soldering

❌ Takes More Time – You need a soldering iron, solder, and proper technique. ❌ Weaker Under Stress – Soldered joints can become brittle over time, especially in areas with vibration or heat. ❌ Requires More Skill – Soldering requires precision, and mistakes can lead to weak or faulty connections.

When to Use Soldering?

🔹 When working with small, low-voltage connections. 🔹 In indoor environments where there’s no excessive movement. 🔹 When you need a permanent connection that won’t be disconnected often.

Crimping vs. Soldering: Which One Should You Choose?

FeatureCrimpingSolderingSpeed✅ Fast and efficient❌ Slower, requires heatingEase of Use✅ Simple with the right tool❌ Requires skill Strength✅ Strong under vibration and stress❌ Brittle under stress Electrical Conductivity✅ High with proper crimp✅ Good but depends on solder qualityBest ForThick cables, high voltage, industrial useSmall wires, low-voltage applications

The Verdict?

For most applications, crimping is the better choice—it’s faster, stronger, and more reliable, especially for industrial and high-power connections.

Soldering is best for delicate, low-voltage wiring but requires more time and skill.

Why Choose Raiden Electric for Cable Lugs?

No matter which method you choose, high-quality Cable Lugs are essential for a secure and long-lasting connection. That’s why Raiden Electric provides premium Cable Lugs designed for durability, conductivity, and ease of installation.

Why Raiden Electric?

✔ High-quality materials for maximum conductivity. ✔ Designed for both crimping and soldering applications. ✔ Reliable performance in industrial, commercial, and residential setups.

Final Thoughts

Both crimping and soldering have their uses, but if you want speed, strength, and reliability, crimping is usually the best choice—especially for industrial and heavy-duty applications.

For top-quality Cable Lugs that work perfectly with either method, trust Raiden Electric to deliver the best. Need reliable electrical connections? Check out Raiden Electric’s Cable Lugs today! ⚡

0 notes

Text

Why Busbars Are Essential for Large Plants

Large plants and industrial setups require a robust electrical distribution system to ensure seamless operations. Among the many components of electrical infrastructure, busbars stand out as indispensable. These conductors efficiently distribute power, handle high currents, and ensure safety. Let us explore why busbars are essential for large plants and how they contribute to smooth operations.

Enhanced Power Distribution

Busbars are crucial in distributing electrical power efficiently across various sections of a plant. Unlike traditional wiring systems, busbars can carry large currents with minimal energy loss. This is particularly important in large plants where power needs to travel long distances. With their compact design and ability to handle high loads, busbars simplify the process of managing power distribution, making them a preferred choice for industries. For businesses seeking advanced solutions, Manikaran Enterprises provides reliable Busbar Trunking System Installation Services in India to meet industrial needs.

Space-Saving Design

In large plants, space is always at a premium. Busbars offer a space-saving solution by replacing bulky cables with a streamlined design. They can be installed in confined areas without compromising their efficiency. This feature is especially beneficial for plants looking to optimize their layouts. As a Top Electrical Solutions Company in Rajasthan, India, Manikaran Enterprises ensures that its busbar systems are designed to maximize space utilization while maintaining performance.

High Safety Standards

Safety is a top priority in any industrial setup, and busbars significantly contribute to it. They are enclosed in protective casings that prevent accidental contact and reduce the risk of electrical hazards. This makes busbars safer than traditional wiring systems. Moreover, their design minimizes the chances of overheating, a common concern in high-load environments. For industries looking for secure and efficient electrical solutions, Manikaran Enterprises offers state-of-the-art Busbar Trunking System Installation Services in India tailored to ensure safety and reliability.

Easy Installation and Maintenance

One of the key advantages of busbars is their ease of installation and maintenance. Unlike cables, which require extensive routing and termination, busbars are straightforward to set up. They can be easily expanded or modified to accommodate changes in the plant’s power requirements. Regular maintenance is also simpler, as busbars provide clear access points for inspection. Partnering with a Top Electrical Solutions Company in Rajasthan, India, such as Manikaran Enterprises, ensures that the installation process is seamless and maintenance is hassle-free.

Cost-Effectiveness

Although the initial cost of busbars might be higher than traditional wiring, their long-term benefits make them a cost-effective solution. Their durability and efficiency reduce energy losses and maintenance costs, resulting in significant savings over time. Industries that invest in Busbar Trunking System Installation Services in India benefit from enhanced performance and lower operational costs. Manikaran Enterprises specializes in delivering solutions that balance quality and affordability.

Scalability for Future Needs

Large plants often need to expand their operations, which means increased power requirements. Busbars offer excellent scalability, allowing plants to upgrade their electrical systems without major overhauls. Their modular design supports easy integration of additional components, making them a future-proof solution. Businesses looking for scalable options can rely on Manikaran Enterprises, a Top Electrical Solutions Company in Rajasthan, India, for expert guidance and implementation.

Improved Aesthetic and Organization

Busbars contribute to a cleaner and more organized electrical setup. Their neat arrangement eliminates the clutter associated with traditional wiring systems. This not only improves the plant’s aesthetics but also makes troubleshooting and repairs easier. By opting for Busbar Trunking System Installation Services in India, companies can achieve a professional and efficient electrical infrastructure. Manikaran Enterprises ensures that its installations are both functional and visually appealing.

Energy Efficiency

Energy efficiency is a critical consideration for large plants aiming to reduce operational costs and environmental impact. Busbars minimize energy losses by maintaining consistent conductivity and reducing resistance. This efficiency translates to lower energy consumption and improved performance. As a Top Electrical Solutions Company in Rajasthan, India, Manikaran Enterprises prioritizes energy-efficient solutions that benefit both businesses and the environment.

Versatility Across Applications

Busbars are versatile and can be used in various industrial applications, from manufacturing units to power plants. Their adaptability makes them suitable for diverse electrical needs, ensuring optimal performance regardless of the industry. For companies requiring tailored solutions, Manikaran Enterprises offers comprehensive Busbar Trunking System Installation Services in India to meet specific requirements.

Contribution to Sustainability

Sustainability is becoming increasingly important in industrial operations. Busbars support this goal by reducing material waste and energy losses. Their long lifespan and recyclable components further enhance their environmental friendliness. Industries aiming to adopt sustainable practices can benefit from partnering with a Top Electrical Solutions Company in Rajasthan, India, like Manikaran Enterprises, for eco-friendly electrical solutions.

Conclusion

Busbars are an integral part of the electrical infrastructure in large plants. Their efficiency, safety, and scalability make them essential for managing complex power distribution needs. By investing in Busbar Trunking System Installation Services in India, industries can achieve reliable and cost-effective electrical systems. Manikaran Enterprises, a Top Electrical Solutions Company in Rajasthan, India, is committed to delivering high-quality busbar solutions that meet the demands of modern industries. Whether it’s optimizing space, enhancing safety, or ensuring energy efficiency, busbars are a vital component that no large plant can overlook.

0 notes

Text

What is Battery Module Laser Welding?

What is Laser Welding?

Laser Welding is a manufacturing process that uses a focused laser beam as the heat source to melt and join materials together. It is widely used in industries such as automotive, aerospace, electronics, and medical device manufacturing because of its precision, speed, and ability to weld complex shapes with minimal distortion.

Features of Laser Welding?

High Precision and Accuracy: Laser welding allows for precise control of the heat input, resulting in highly accurate welds, even for very fine or intricate parts. This precision is crucial in industries where tight tolerances are required.

Minimal Heat Affected Zone (HAZ): The focused nature of the laser minimizes the area affected by heat, reducing thermal distortion and the risk of damaging surrounding areas. This is particularly beneficial for welding delicate or thin materials.

High Welding Speed: Laser welding is fast, which increases productivity and reduces manufacturing time. It is ideal for high-volume production runs where speed is essential.

Automation and Precision: The laser welding process can be easily integrated into automated systems, making it suitable for mass production. The process can be controlled by a computer, ensuring consistent quality and precision.

Versatility: Laser welding can be used on a wide range of materials, including metals, plastics, and ceramics. It is especially effective on materials that are difficult to weld with traditional methods (like high-strength alloys and dissimilar metals).

Deep Penetration Welding: Laser welding can achieve deep penetration with a narrow weld bead, which is beneficial when joining thick materials. It provides strong, durable welds in a single pass.

Minimal Post-Weld Processing: Since laser welding produces clean and precise joints, it often requires little to no post-weld cleanup or finishing, reducing the overall cost and time of production.

Ability to Weld Small or Complex Geometries: The concentrated nature of the laser allows it to weld very small or complex parts that might be difficult or impossible to weld with traditional methods.

Low Heat Input: Compared to other welding methods, laser welding requires less heat, reducing the potential for warping and other thermal issues that can arise with other techniques.

Applications of Laser Welding in Battery Module

Welding Battery Terminals and Tabs: Laser welding is used to join the battery tabs (which are usually made of thin metal) to the battery cells. The process ensures a reliable electrical connection with minimal contact resistance. Since battery tabs are thin and delicate, laser welding allows for precise, high-quality welds without damaging the cells or causing excessive heat build-up.

Welding Battery Packs: In battery packs, multiple cells need to be connected securely. Laser welding is ideal for joining battery cells to each other or to the battery pack housing. The process can create strong, compact, and reliable welds that provide consistent electrical performance and mechanical stability.

Welding of Current Collectors: Battery cells often have current collectors (e.g., aluminum or copper foils), which are responsible for conducting electricity between the electrodes. Laser welding is used to precisely attach these current collectors to the battery terminals, ensuring efficient power transmission.

Laser Soldering of Copper and Aluminum Components: Some battery module designs require soldering of copper or aluminum components, such as electrical connectors or busbars. Laser soldering is a common application for joining these metals, as it offers precise control over the amount of heat applied, reducing the risk of damaging sensitive components.

Welding the Battery Case or Housing: Laser welding is used to join the battery module casing or housing, typically made from materials such as steel or aluminum. The precision of the laser ensures that the housing is sealed securely, providing structural integrity while maintaining a compact design.

Thermal Management Components: Some battery modules include thermal management components like heat sinks or cooling plates. These components need to be securely welded to the battery cells or modules to ensure proper heat dissipation. Laser welding offers the precision needed to attach these components without introducing too much heat into the surrounding areas.

Welding of Safety Mechanisms (e.g., Pressure Relief Valves): Many modern battery modules are equipped with safety features like pressure relief valves or vents, which are welded into place using lasers. These safety mechanisms help to prevent dangerous over-pressurization or thermal runaway in the battery pack, making laser welding an ideal solution for joining these critical components.

Automated Battery Assembly Lines: In high-volume manufacturing, laser welding is often integrated into fully automated battery assembly lines. Robots equipped with laser welding heads perform precise, repeatable welds on the battery modules, ensuring consistency and reducing labor costs. The automation of the welding process also improves safety and throughput.

Price of Battery Module Laser Welding

Types of Laser System: Different types of lasers (e.g., fiber lasers, CO2 lasers, diode lasers) have different costs. Fiber lasers, which are commonly used for battery welding due to their high precision and efficiency` . The cost depending on the specific model, power rating, and features.

If the laser welding system is integrated into an automated production line, there are additional costs for robotics, vision systems, material handling equipment, and control systems. Automation is typically more expensive but improves throughput and reduces labor costs in high-volume production.

Material Type and Complexity:The type of materials being welded (such as copper, aluminum, or steel) and the complexity of the weld (e.g., welding battery tabs or welding large battery modules) will influence the welding process. More complex or challenging materials may require more specialized equipment or process adjustments, which can increase costs.

Supplier of Battery Module Laser Welding Equipment

0 notes