#abs injection molding

Explore tagged Tumblr posts

Text

The most comprehensive injection molding technical parameters in history

PMMA injection molding technical parameters Drying temperature (℃)80Drying time (hr)2~3Mold temperature (℃)40~70Residual material (mm)2~6Melt temperature (℃)215~240Back pressure (MPa)13~28 (higher)Injection pressure (MPa)100~170Clamping force (ton/in2)4Injection speedLow speedFeedback speed (rpm)60~80Screw typeStandard screw (if a larger injection pressure is required, a small screw can be…

View On WordPress

#ABS injection molding#AS injection molding#injection molding technical parameters#Mold temperature#P0M injection molding#PA66 injection molding#PBT injection molding#PC injection molding#PE injection molding#PE injection molding technical parameters#PET injection molding#PMMA injection molding#PMMA injection molding technical parameters#PP injection molding#PPS injection molding#PS injection molding#PVC injection molding

0 notes

Text

Unleashing Excellence: Dong Guan Sincere Tech - Your Trusted Mould Supplier in China

Are you seeking top class plastic injection molds for your business? Look no further than Dong Guan Sincere Tech, a renowned name in the industry. As one of the leading Injection mold China suppliers, Sincere Tech is dedicated to delivering exceptional solutions tailored to meet your specific requirements.

With a wealth of experience and expertise, Sincere Tech excels in providing high-quality plastic injection molds. From concept to completion, their skilled team utilizes state-of-the-art technology and cutting-edge techniques to produce superior results. Whether you need ABS Injection Molding, Machining Service, Die Casting Mold, Precision Insert Molding, Silicone Molding Parts or anything else, Sincere Tech has you covered.

So Why Dong Guan Sincere Tech?

What sets Sincere Tech apart from other injection mould suppliers is their unwavering commitment to customer satisfaction. They prioritize open communication and collaboration, ensuring that your unique needs are understood and met throughout the entire process. Their attention to detail and meticulous craftsmanship guarantee outstanding results, every time for both small-scale manufacturers and global enterprises.

Sincere Tech understands the importance of meeting deadlines and maintaining cost-efficiency. With their streamlined production process, they deliver exceptional quality molds within agreed-upon timelines, helping you stay ahead of the competition. Furthermore, their competitive pricing ensures excellent value for your investment.

Don't settle for anything less than excellence. Choose Dong Guan Sincere Tech as your trusted mould supplier in China and experience the difference they can make for your business. Contact them today to unleash the full potential of your injection molding projects.

0 notes

Text

knowing what i know now about injection molding, i have a lotta respect for whoever lego's mold techs and machine operators are because the tolerances of these bricks must be crazy. ik for most pieces they can just avoid a parting line altogether by putting it at the edge of the brick but you cant do that for a lot of them and a majority of the time the parting line is virtually invisible. most of the time you can still feel and identify the parting line pretty easily but with lego there's so much less flash than usual and i have a lot of respect for that. also theyre usually pretty good about finding inconspicuous spots for the gates (or at least ones that dont downgrade the appearance of the part) while not having any short shots or burns, which for some of these gate locations is really impressive to me

#injection molding is actually rly cool and whoever legos plastics ppl are theyre GOOD#which makes sense obvs but it's still really cool to feel like i know why it's good now#i feel like the dream for me would be tooling for lego. that would be amazing#not even necessarily mold making just tooling for them in general. but alas i dont know danish#also other things i didnt mention#for how many pieces are made of abs there's surprisingly little warping which is impressive for abs#and in the same vein abs is more prone to flash and as i said above there's also very little of that which is again. really cool#alright enough of me talking abt plastics for now but it does excite me haha#ALSO ALSO FEEL FREE TO ASK ME MORE ABOUT INJECTION MOLDING IF YOU WANT ANY EXPLANATIONS OR ELABORATIONS ON WHAT I SAID HERE I LVOE TALKING#BT INJECTION MOLDING I LOVE IT.#haha no pressure 2 tho ofc

5 notes

·

View notes

Text

Secondary processing technology of ABS plastics: a new way to expand the application field

In the plastic processing industry, ABS plastics (acrylonitrile-butadiene-styrene copolymer) are highly favored for their excellent mechanical properties, processing performance and surface gloss. However, with the advancement of science and technology and changes in market demand, the single performance of ABS plastics has been difficult to meet the increasingly diverse application scenarios.…

#ABS plastic#extrusion molding#injection molding#modification technology#mold design#secondary processing technology#surface treatment technology#thermoforming

0 notes

Note

My Dad has been really on my case lately. He’s always wanted me to be more manly like him, and he’s never been good at hiding how disappointed he is that I’m so feminine. He says he’s sending me to a special camp to ‘Man Up’. I’m really nervous. What should I do?

Your dad stood at the entrance to Mu Alpha Nu Camp, a stern look on his face. Trying to do his best to contain his excitement. It had been a few days since he dropped you off here. Initially, when your dad told you he was sending you to one of these “Man Up” camps, you thought he was joking. But your old man had tricked you- promising to take you to a concert to celebrate the end of your first year in college. Foolishly, you believed him- thinking he was trying to start anew. But he had no feelings of guilt.

Truth be told, you two never really got along. His interests and yours were polar opposite, even antagonistic. He couldn’t understand where your feminine hobbies came from and instead of trying to understand, he resisted them. Time at college- sissy liberal university as your father would say- only cemented these interests. No matter what he did, he was never able to mold you into the rugged, masculine specimen that he wanted in a son. And while his disappointment initially hurt, you came to realize he was the epitome of toxic masculinity- a true narcissist.

“Hey bro,” A jock greeted him, “Your son is done.” He chuckled dumbly.

Your father nodded, a smirk forming on his face. He would never really know what you went through over the past few days. He would only see the end result. But when he dropped you off, he did give the facility specifications. He checked off boxes, indicating what qualities he wanted in his son. He would never know how they would initially start easy. Daily gym sessions and lectures about masculinity. How you ignored them at first and resisted their brainwashing. But then it became more intense. They threw you in a chamber. Metallic hands gripping your weak arms. Others massaging your lean chest.

“Wait! Let me go!” You had cried out.

But they continued to manhandle you. Continued to massage your muscles with their ‘special lotion’. You had cried out as your muscles expanded rapidly, at first with firm muscle, and then followed closely by fat. Your new abs and pecs quickly covered by a layer of soft fat. You tried to use your new strength to break free, but even with your massive bis and tris, you were powerless. Only able to watch your metamorphosis in a mirror on the wall adjacent to you.

“No! What is that?” You groaned as you were injected with a serum.

Tears filled your eyes as your skin lost its youthful glow. Wrinkles formed and your skin weathered with age. The firm fat sagging ever so slightly. You looked to be in your late 40s, just like your dad. And before you could fully process this horrific realization, you were sprayed from head to toe with a foul smelling liquid. The burning, prickling sensation that followed caused you to squirm. And as you watched closely in the mirror, you could see your hair follicles come alive. Tufts of manly hair erupted from your chest and abdomen, coating you in manly fur. Even your clean-shaven face became blanketed in a manly beard. And your hair darkens considerably, interlaced with a few grays.

“Please... please stop...” You groan.

But you’d find no mercy. You were being molded exactly to your dad’s specifications. Before you could resist any further, the screen in front of you comes alive. Spirals interlaced by manly images fill your vision. Images of beer, trucks, guns, and working-out are forced into your brain. And as they enter, your prior interests start to fade. You envision a life working construction, just like your dad. Drinking beers at the bar. Picking up chicks. And this continues. For hours, days even. Your cock rock hard.

Your dad’s eyes widen when you approach him. Naturally, you were shirtless. Showing off your manly chest. A smirk plastered on your face. And your dad can’t help but feel as if he’s looking in a mirror. The stupid jock smiles.

“We’ve followed your specifications to a tee.” He says with a dopey grin.

And then it dawns on your dad. He wanted you to be more manly, just like him. Just like him. In his self-absorbed narcissism, he didn’t realize that his specifications led them to create a twin. Gone was his son. Instead, he had a twin brother. One that matched him in all ways- stench, masculinity, and size.

“What’s up, bro?” Your baritone voice matches your father’s brother’s, “You wanna grab some beers?”

Your twin brother nods, slowly accepting his new reality. And the two of you head out. Perhaps not what your father initially intended. But as you throw back beers down at the local bar and cheer for your favorite football team, he can’t help but appreciate the newfound camaraderie.

465 notes

·

View notes

Text

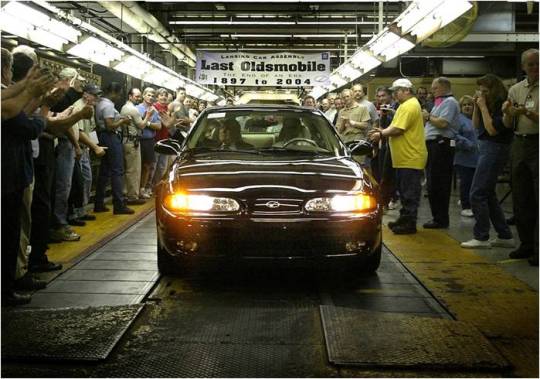

Oldsmobile

April 29'th 2004. The last Oldsmobile rolls off the line. You may be surprised to learn, that for a long time Oldsmobile meant innovation. Here are just a few of the Automotive technologies Olds pioneered in it's 100+ years in business:

1898: Olds Motor Vehicle Company exports the first American car, a steam-powered automobile, to Mumbai, India.

1901: The first speedometer offered on a production car was on an Oldsmobile Curved Dash.

1901: Oldsmobile was the first to procure parts from third-party suppliers.

1901: Olds produces 635 cars, becoming the first high-volume gasoline automobile producer.

1901: Oldsmobile becomes the first manufacturer to publicly promote their vehicles.

1902: The Oldsmobile Curved Dash is the first mass-produced vehicle in America.

1903: Oldsmobile builds the first purpose-built mail truck.

1908: Oldsmobile rebadges the Buick Model B as the Oldsmobile Model 20, possibly creating the first badge-engineered car.

1915: First standard windshield introduced by Oldsmobile.

1926: Oldsmobile is the first to use chrome plating on trim.

1929: Oldsmobile creates the first Monobloc V8 engine in its Viking Sister brand.

1932: Oldsmobile introduces the first automatic choke.

1935: Oldsmobile offers the first all-steel roof on an automobile.

1940: Oldsmobile introduces the Hydra-Matic, the first fully automatic transmission.

1948: Oldsmobile offers one-piece curved windshields, along with Buick and Cadillac.

1949: Oldsmobile introduces the Rocket, the first high-compression OHV V8 engine.

1952: Oldsmobile introduces the "Autronic Eye," the first automatic headlight dimming system.

1953: Oldsmobile switches its lineup to the 12v charging system.

1962: Oldsmobile creates the first production turbocharged car, the F-85 Jetfire.

1962: Oldsmobile also creates the first production car with water injection, the F-85 Jetfire.

1966: The Oldsmobile Toronado is the first mass-produced front-wheel-drive American car.

1969: First use of chromed ABS plastic exterior trim on the 1969 Oldsmobile Toronado.

1969: First electric grid window defogger on an American car, the 1969 Oldsmobile Toronado.

1971: The Oldsmobile Toronado is one of the first cars to feature a high-mounted brake light.

1974: The Toronado is the first American car to offer a driver-side airbag.

1977: The Toronado is the first American car with a microprocessor to run engine controls.

1982: First use of high-impact molded plastic body components on the 1982 Oldsmobile Omega.

1986: Oldsmobile introduces the Delco VIC touchscreen interface on the Toronado, shared with Buick Riviera.

1988: The first production heads-up display system is introduced on the 1988 Oldsmobile Cutlass Supreme Indy Pace Car.

1988: Oldsmobile breaks a world speed record with the Oldsmobile Aerotech at 267 mph, driven by A.J. Foyt.

1990: Oldsmobile updates the color touchscreen interface with a built-in cellular phone on the 1990 Toronado Trofeo.

1995: Oldsmobile introduces Guidestar, the first onboard navigation system on a U.S. production car.

1997: Oldsmobile becomes the first American car company to turn 100 years old.

2001: The redesigned 2002 Oldsmobile Bravada becomes the first truck to pace the Indianapolis 500.

90 notes

·

View notes

Text

Pullback, Transformers Throttlebot OC

Pullback grew out of a suggestion from my partner April that I should create my own self-insert OC or -sona as a Transformers character. Initially I considered modding a Bumblebee figure, but all of that painting sounded like a lot of work, so I decided to make my own instead, and ended up with a pretty distinct design.

Pullback is a 1987 Throttlebot who was totally there the whole time. They're a machinist, and their alternate form is a microcar EV legally distinct from a Smart Fortwo.

With the exception of the hollows and slots required by injection molding, I tried to keep Pullback authentic to how modern Transformers toys are constructed. Articulation is a bit limited, with no up and down movement in the foot, no waist articulation, and only a 90° bend at the elbow. But the alt mode rolls pretty well!

I'm still working out the ball and socket joints. Even with ABS-like resin, they bite and grind and lose material. I've found that inserting a bit of plastic film in between seems to firm them up and protect the interfacing surfaces.

Most of the color on this figure is ink again, including the silver. Since silver alcohol ink is really just a suspension of comparatively large particles, it doesn't bind to the resin the way others do, so there's a layer of acrylic clearcoat over those surfaces.

April has modded and repurposed a Legacy figure into her OC Parcel, so here's a couple photo!

Since Pullback is another fanart piece, the files to print a copy are on my Cults page. Note though that they require some extra materials for hinge pins.

16 notes

·

View notes

Note

Also, I feel like you’d have strong opinions about legos. Discuss, if you wish.

Sure, I have some opinions. I had me a few sets as a boy, but I never did nothin' by the book. Which was kinda stupid. That's the whole appeal. But I liked it better to tinker with them n my own mechanics.

The only thing that I have to say that matters is that those things are a work of geniuses. Lookie:

LEGOs ain't been changed in the 40 sumn years they been around. All have been made with CA (Cellulose Acetate), and were recently changed to ABS (Acrylonitrile Butadiene Styrene) for the foreseeable future. They changed from something that was easy to deform to a damn near impenetrable little brick toy. I mean, don't set one under a hydraulic press or nun, but for a kid? That feller can pass that set down to his boy and the boy after him and it ain't gonna be changed.

So, not only have they found the ultimate material for strength, but also an excellent one for molding. They heat ABS up reaaal hot, then inject it into these into these precision-engineered molds under high pressure to get all them crevices. N when I say precision-engineered, I mean it to the extreme. The tolerance ain't more than 5 measly microns. For a toy? That's no error at all. They're identical! They're cooled all rapidly to maximize efficiency. Won't crack or nothin. I'm talkin' seconds!

They're also recycled to make more bricks when them or their smart 'bots detect an anomaly.

I don't know how they color em real well. But it's all precise n accurate n seamless.

Y'all know that click when y'all put em together? Intentional. It ain't no LEGO brick without it. Hooo. Them's are perfect little things. Only thing I'd wanna be a boy for again.

Maybe y'all already knew all that.

6 notes

·

View notes

Text

the way this is written you'd think they're trying to convince you that ABS isn't one of the most common injection molded plastics

3 notes

·

View notes

Text

Yeah they it all look like injection molded ABS (which is actually reasonably strong and sometimes used on 3d printing)

145K notes

·

View notes

Text

ABS Prices in India

Today, Ahmedabad ABS scrap (injection molding) prices saw an increase. Price of the material increased by Re 1/kg to reach Rs.46/kg from a previous quote of Rs 45/kg grade of Crushed Black.The price rise reflects ongoing market volatility as seasonal and economic factors shift the demand for recyclable ABS waste. The upward movement in prices also highlights changes in supply patterns, with increased availability contributing to the lowered rate. ABS scrap remains crucial for the recycling industry, and this price movement may benefit manufacturers looking to source affordable materials for producing recycled ABS products.ABS scrap is produced as a byproduct of manufacturing processes, especially in industries like automotive, electronics, and consumer goods where ABS plastic is widely used. In India, several companies and recycling firms specialise in collecting, processing, and supplying ABS scrap. Some of the key ABS scrap producers and suppliers include. Indian ABS Prices, ABS Prices In India, Indian Prices ABS, Indianpetrochem.

0 notes

Text

Coloring and processing of ABS plastics: the perfect combination of art and technology

In today’s era of pursuing individuality and innovation, ABS plastics (acrylonitrile-butadiene-styrene copolymer) has become a shining star in the plastic processing industry with its unique physical properties and wide processing adaptability. Especially in coloring and processing, ABS plastics show the perfect combination of art and technology, providing unlimited possibilities for all walks of…

#ABS plastic#blow molding#coloring performance#environmental protection#extrusion processing#injection molding#processing adaptability#sustainable development

0 notes

Text

Custom Automotive Components Made with Injection Molding: A Big Change in Manufacturing

The automotive industry focuses on innovation, accuracy, and efficiency. Injection molding plays a big role in driving this progress, especially for custom car parts. From detailed interior pieces to tough under-the-hood components, injection molding stands out for making high-quality, affordable parts designed to fit specific needs.

What is Injection Molding?

Injection molding is a manufacturing process where molten plastic or other materials are injected into a mold cavity, allowed to cool, and then ejected as a finished part. This method is especially popular in the automotive sector for producing components with high precision and repeatability.

Why Choose Injection Molding for Automotive Parts?

Here are the key reasons why injection molding is ideal for creating custom automotive components:

1. Design Flexibility

Injection molding allows for the creation of highly complex and detailed designs that would be difficult or expensive with other manufacturing methods. This makes it perfect for producing custom parts like dashboards, air vents, and light covers.

2. Material Versatility

The process supports a wide range of materials, including:

Thermoplastics like ABS, polycarbonate, and polypropylene for lightweight, durable parts.

Elastomer for flexible components like seals and gaskets.

Composite materials for enhanced strength and thermal resistance.

3. Cost Efficiency for Large Volumes

While the initial tooling costs for injection molding can be expensive, the cost per part drops a lot as production numbers go up. This makes it a cheaper option for mass production.

4. Durability and Quality

Injection molding creates parts with reliable quality, precise measurements, and smooth surfaces, which are crucial for meeting the high standards of the automotive industry.

5.Speed and Scalability

Once the mold is made, the process is very quick, allowing manufacturers to meet deadlines and increase production to match demand.

Applications in Automotive Manufacturing

Injection molding is used extensively for a variety of automotive components, including:

Interior Components: Dashboards, door panels, cup holders, and glove boxes.

Exterior Parts: Bumpers, grilles, and side mirrors.

Engine Bay Parts: Air intake manifolds, battery housings, and fluid reservoirs.

Lighting: Headlight and taillight casings.

Customization Opportunities with Injection Molding

Customization is important in the automotive industry to meet different customer needs and stand out from competitors. Injection molding helps with this by:

Custom Designs: Unique shapes, textures, and finishes.

Branding: Logos and patterns built into the parts.

Special Materials: Heat resistance, UV protection, and strength suited for specific conditions.

Sustainability in Injection Molding

Modern injection molding techniques focus on reducing waste and improving energy efficiency. Many manufacturers are incorporating:

Recycled materials to minimize environmental impact.

Bioplastics for eco-friendly components.

Energy-efficient machinery to lower carbon footprints.

Choosing the Right Partner for Injection Molding

For businesses in the automotive sector, selecting an experienced injection molding partner is crucial. Look for a provider with:

Expertise in custom designs and tooling.

A track record of high-quality production.

Knowledge of automotive industry standards and certifications.

Injection molding is an essential part of today’s car manufacturing, providing high precision, efficiency, and customization. Whether you need light parts for better fuel economy or strong parts for tough conditions, this process produces results that meet and often exceed industry standards.

Manufacturers can stay competitive by using injection molding for custom car parts, making products that are innovative, functional, and eco-friendly.

Want to see how injection molding can improve your automotive parts? Contact us to get advice from the experts

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] The Better Fit Helmet is a safer helmet. As your child grows, use the adjustable fit dial on the helmet (tighten to the right, loosen to the left) to keep them comfortable while cruising and their head safe. XJD Helmet for added protection The XJD helmet is made of ABS and EPS for lightweight, comfortable wear and added safety. Fully adjustable. The crank adjustment dials on the back of the helmet and chinstrap are adjustable to fit users over 360 degrees. The chin strap and chin pads are soft, so no more worrying about the straps potentially scratching your child's sensitive skin. The belt buckle is easy to attach and detach. PADDING SYSTEM Removable foam pads inside the helmet provide effective shock absorption and sweat wicking to keep you cool while wearing the helmet. The pads are removable and easy to clean, keeping you free from odours and bacteria. Please use mild soap and water for cleaning. 11 Ventilation holes with integrated insect mesh in the front vents; Extended sun visor for maximum protection. IMPACT RESISTANCE: XJD toddler helmet combines a super strong injection molded outer shell and a protective EPS foam inner shell HEAD SIZE: X-Small: 18.11-20.08 inch(46-51 cm), suit for 1-5 years old toddler; Small: 20.47 - 22.05 inch (52–56 cm), suit for 5-8 years old kids. We offer two different sizes of toddler helmet in order to give a comfy fit for kids SAFE AND COMFORT: XJD kids bike helmet equipped with 14 air vents, integrated bug mesh in the front vents that will keep your little rider comfortable of exercise, reduce sweating. It's covered in soft velcro padding that's comfortable for little chins PERFECT CHOICE: Baby helmet perfect for bike, bicycling,roller, and inline skating, skateboarding, scooter. The flexibility of the strap makes it fit well for different requirements of boys and girls. It’s a good Birthday, Christmas, Thanksgiving ADJUSTABLE FIT: As your child grows, use the adjustable fit dial(turn right to tighten and left to loosen) on the helmet to keep the fit comfortable and safe while they cruise [ad_2]

0 notes