#PMMA injection molding

Explore tagged Tumblr posts

Text

The most comprehensive injection molding technical parameters in history

PMMA injection molding technical parameters Drying temperature (℃)80Drying time (hr)2~3Mold temperature (℃)40~70Residual material (mm)2~6Melt temperature (℃)215~240Back pressure (MPa)13~28 (higher)Injection pressure (MPa)100~170Clamping force (ton/in2)4Injection speedLow speedFeedback speed (rpm)60~80Screw typeStandard screw (if a larger injection pressure is required, a small screw can be…

View On WordPress

#ABS injection molding#AS injection molding#injection molding technical parameters#Mold temperature#P0M injection molding#PA66 injection molding#PBT injection molding#PC injection molding#PE injection molding#PE injection molding technical parameters#PET injection molding#PMMA injection molding#PMMA injection molding technical parameters#PP injection molding#PPS injection molding#PS injection molding#PVC injection molding

0 notes

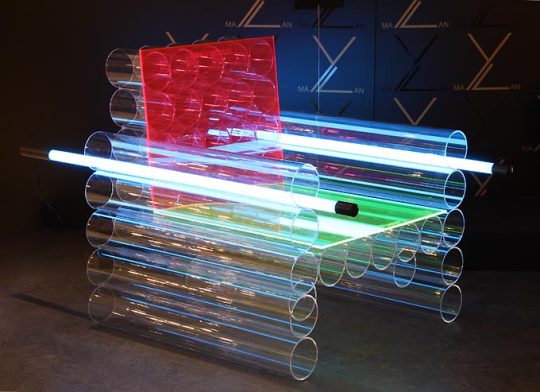

Photo

Glasses: Acrylic glass

Both a glass and a polymer, thanks to its amorphous structure, acrylic glass is just another name for poly(methyl methacrylate), or PMMA. A thermoplastic, acrylic glass is marketed under numerous brand names, including Plexiglas, Crylux, Lucite, and Perspex, among numerous others. Because of its transparency and strength, it is often used in places where non-organic glasses are also used.

First produced in the late 1920s, today acrylic glass is produced in a variety of forms and using a variety of methods. In addition to strength and transparency, this plastic has high impact resistance, excellent chemical resistance, and good dimensional stability - it is both lightweight and durable, all of which are properties that lend themselves to its popularity. Its strength is less than that of traditional glass, however, so it cannot replace the latter in all applications, at least not without design changes (i.e., increased thickness of acrylic glass, as compared to traditional glass).

Applications of acrylic glass are too numerous to list here. Nearly any common mold processing methods can be used to shape the polymer, including injection molding and extrusion. Higher quality sheets of the material are made with cell casting, in which the polymerization step and molding step are carried out simultaneously.

Sources/Further reading: ( 1 - all images ) ( 2 ) ( 3 )

34 notes

·

View notes

Text

Rapid Prototyping in Prototype

Rapid prototyping refers to one or several prototypes made first according to the product appearance drawings or structure drawings for checking the appearance or structure reasonableness without opening the mould. With the development of technology, the definition and use of the handpiece has expanded, and it is now more often used to test and validate products, optimize product design, and even used directly as a finished product.

Historical Background and Definition Rapid prototyping technology originated in the 1980s, initially to solve the problems in traditional manufacturing methods, such as high cost and long cycle time. With the development of technology, rapid prototyping has gradually matured and has been widely used in various fields. It is not only suitable for product development, but also has a wide range of applications in software applications, architectural design and other fields.

Process Rapid prototyping processes include a variety of technologies such as Stereolithography (SLA), Fusion Deposition Modeling (FDM) and others. SLA technology initiates the polymerisation of photosensitive resins by means of a light source of a specific wavelength to form polymers, while FDM technology involves the extrusion of melted material in layers. In addition, traditional moulding methods such as vacuum infusion, low pressure casting and CNC machining are also widely used in the production of handmade boards. 1.3D printing: Prototypes are created using a 3D printer by adding material layer by layer. This method allows for fast, low-cost prototyping of products with complex structures. 2.CNC machining: Cutting and engraving of materials by means of computer numerically controlled machines, suitable for prototypes requiring high precision and complex shapes. 3.Vacuum casting: Liquid material is injected into the mould using a mould and then cured into shape, suitable for validation prior to mass production. 4.Rapid tooling: Creation of moulds by means of rapid tooling technology, followed by series production. 5.Injection molding: Mass reproduction using injection moulding machines for situations where mass production is required.

Material There is also a wide selection of materials for rapid prototyping, with common ones such as photosensitive resin and nylon. For small batch production, vacuum casting process can be used, using materials such as ABS and PMMA for replication, followed by subsequent processing such as sanding and spraying with oil. For metal parts, the machining services are mostly used.

Advantages 1.Rapid outputs: Compared to traditional manufacturing methods, rapid prototyping can complete prototyping in a short period of time, greatly reducing product development cycles which suitable for low volume manufacturing. 2.Low cost: 3D printing technology, in particular, allows for the low-cost production of complex structural prototypes and small batches. 3.High flexibility: Can be prototyped using a wide range of materials and techniques, adapting to different design needs. 4.High precision: The ability to accurately replicate the structure, detail and texture of a prototype provides a surface quality. 5.Variety of materials: Polyurethane materials with different properties such as rigid, elastic, transparent or various coloured materials can be selected according to requirements.

Applications 1.Manufacturing and Industrial Applications Rapid prototyping technology enables the rapid production of complex and accurate prototypes, helping designers and engineers to validate design concepts, perform functional testing and evaluate appearance. For parts that need to be produced in small quantities, it offers a cost-effective and flexible solution. 2.Automobile industry Automakers use rapid prototyping technology to rapidly develop prototype automotive parts for performance testing and validation.In addition, it enables the manufacture of personalised automotive parts, such as dashboard panels and door handles, and is used for production tooling. 3.Medical field Rapid prototyping technology enables personalized medical devices, implants and prosthetics to be tailored to a patient's body structure, providing better fit and comfort.In the field of bioprinting, it is used for research in tissue engineering and organ transplantation. 4.Others Rapid prototyping also plays an important role in a number of industries, including aerospace, consumer electronics, and artwork creation, and its applications will become more widespread as technology advances and costs are reduced.

Rapid Prototyping is the process of creating a simple model of a product or project in the early stages of development so that it can be used to validate and test design concepts, features and interfaces. It is a method of rapidly building physical prototypes and iterating on a design with few changes to improve the design.

#design#business#prototyping#autos#prototype#prototype machining#rapid prototyping#cnc machining#precision machining#machining parts#3d printing services#3d printing#metal 3d printing#3d printed#cnc machining service#vacuum casting#rapid tooling#rapid prototype

1 note

·

View note

Text

Key Trends Shaping the Medical Plastics Market in 2024 and Beyond

Medical Plastics Industry Overview

The global medical plastics market size is expected to reach USD 87.58 billion by 2030, registering a CAGR of 7.4% from 2024 to 2030, according to a new report by Grand View Research, Inc. The demand for medical device packaging is likely due to the increased need for in-house and advanced medical devices. Plastics including polyethylene, polypropylene, and polycarbonate are increasingly being utilized in the medical device manufacturing The growth of the home healthcare sector on account of the low costs involved as compared to hospital care and intensive care contributes to a rise in the demand for medical devices and multiple hospital associated tests as well.

The growth of the home healthcare sector on account of the low costs involved as compared to hospital care and intensive care has resulted in a rise in the demand for medical devices. The increasing demand for medical devices can also be attributed to the various types of medical tests conducted by hospitals for diagnostic purposes.

Gather more insights about the market drivers, restrains and growth of the Medical Plastics Market

Healthcare spending in the country is likely to accelerate in the near future owing to the growing awareness about healthcare. The rise in demand is driven by the aging population (65 years of age or above), growing prevalence of chronic diseases, infrastructure enhancements and technological advancements in medical plastics market.

The strengthening of the Western European economies is expected to result in an increased provision of healthcare expenditure in the annual budgetary proposals. Moreover, Northern European economies such as Germany, the UK, and Sweden are projected to exhibit an increase in healthcare expenditure, thereby leading to a growth in the production of medical devices. However, the growth is expected to be supported by political unrest in Europe’s transition economies such as Russia and Ukraine.

Browse through Grand View Research's Plastics, Polymers & Resins Industry Research Reports.

The global poly alpha olefin market size was valued at USD 1.48 billion in 2023 and is projected to grow at a CAGR of 2.8% from 2024 to 2030.

The global cross-linked polyethylene market size was valued at USD 8.0 billion in 2023 and is projected to grow at a CAGR of 6.9% from 2024 to 2030.

Medical Plastic Market Segmentation

Grand View Research has segmented the global medical plastic market based on product, application, and region:

Medical Plastics Product Outlook (Volume, Kilotons & Revenue, USD Million, 2018 - 2030)

Polyethylene (PE)

Polypropylene (PP)

Polycarbonate (PC)

Liquid Crystal Polymer (LCP)

Polyphenylsulfone (PPSU)

Polyethersulfone (PES)

Polyethylenimine (PEI)

Polymethyl Methacrylate (PMMA)

Others

Medical Plastics Process Technology Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Extrusion

Injection Molding

Blow Molding

Other

Medical Plastics Application Outlook (Volume, Kilotons & Revenue, USD Million, 2018 - 2030)

Medical Device Packaging

Medical Components

Orthopedic Implant Packaging

Orthopedic Soft Goods

Wound Care

Cleanroom Supplies

BioPharm Devices

Mobility Aids

Sterilization and Infection Prevention

Tooth Implants

Denture Base Material

Other Implants

Others

Medical Plastics Region Outlook (Volume, Kilotons & Revenue, USD Million, 2018 - 2030)

North America

US

Canada

Mexico

Europe

Germany

UK

France

Italy

Netherland

Asia Pacific

China

India

Japan

Central & South America

Brazil

Argentina

Middle East & Africa

Saudi Arabia

UAE

Key Companies profiled:

Röchling SE & Co. KG

Nolato AB

Saint-Gobain S.A.

SABIC

Orthoplastics Ltd

Eastman Chemical Company

Celanese Corporation

Dow, Inc.

Tekni-Plex, Inc.

Solvay S.A.

HMC Polymers Company Limited

ARAN BIOMEDICAL TEORANTA

Trelleborg Group

Avantor, Inc.

Trinseo

Evonik Industries AG

Key Medical Plastics Company Insights

Some key market players include BASF SE; Celanese Corporation; Evonik Industries AG; SABIC; Dow, Inc.; Solvay S.A.; Trinseo S.A.; and Eastman Chemical Company.

In November 2022, Celanese Corporation announced the acquisition of DuPont's Mobility & Material (M&M) business for USD 11 billion. This strategic move enables Celanese to expand its global reach and enhance its offerings in the environmental sector, particularly in sustainable transportation.

Recent Developments

Some key players operating in market include BASF SE; Celanese Corporation; Evonik Industries AG; SABIC; Dow, Inc.; Solvay S.A.; Trinseo S.A.; Eastman Chemical Company among others.

In February 2023, Cleanse Corporation announced the acquisition of DUPONT's mobility and mobility business for USD 11.00 billion. This strategic move enables Cleanse to expand its global reach and enhance its offerings in the environmental sector, particularly in sustainable transportation.

In June 2023, SABIC acquired Clariant's 50% stake in Scientific Design, a renowned catalysis leader. This acquisition bolstered the non-cyclical, technology-driven business and brought it closer to becoming a leading global specialist.

Order a free sample PDF of the Medical Plastics Market Intelligence Study, published by Grand View Research.

0 notes

Text

Medical Plastics Market Business Growth, Opportunities and Forecast 2024 - 2030

The global medical plastics market size was estimated at USD 52.9 billion in 2023 and is expected to grow at a compound annual growth rate (CAGR) of 7.4% from 2024 to 2030.

This growth can be attributed to the development of advanced plastics and plastic composites used in medical components such as catheters, surgical instrument handles, and syringes. The demand for medical device packaging is likely to be driven by a rise in demand for in-house and advanced medical devices. Plastics including polyethylene, polypropylene, and polycarbonate are increasingly being utilized for the manufacturing of medical devices. The growth of home healthcare due to its low costs compared to hospital care and intensive care has resulted in a rise in demand for medical devices.

According to the latest U.S. census, 16.8% of the U.S. population is over the age of 65 years and this number is anticipated to reach 74 million by 2030. People aged over 85 need the most care and their population is growing rapidly. In March 2021, the U.S. President, Joe Biden, proposed spending USD 400 billion on Medicaid over eight years to fund at-home care for elderly and disabled people as well as increase the wages of caregivers.

Gather more insights about the market drivers, restrains and growth of the Medical Plastics Market

Medical Plastic Market Report Highlights

• Based on product, the Polyphenylsulfone (PPSU) resin dominated product segmentation for 2023 in terms of revenue share above 51.0%, due to the heat and chemical resistance of PPSU. These plastics possess high strength and durability, making essential surgical tools.

• Asia Pacific possessed a high market share in 2023, due to increasing healthcare expenditure. However, Governments in China, India and Japan are investing heavily, to prevent rising chronic diseases and upgrading healthcare infrastructures. Per capita healthcare spending is elevating, setting the stage for healthcare revolution in the region.

• Regulations are the key factor influencing the medical device industry, thereby influencing the medical plastics market in Europe and North America. Rising government concerns regarding the offering of high-quality, safe, and effective medical devices are expected to have a negative impact on the market growth over the forecast period.

Browse through Grand View Research's Plastics, Polymers & Resins Industry Research Reports.

• The global polybutadiene market size was valued at USD 1.88 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 4.9% from 2024 to 2030.

• The global polycarbonate sheet market size was valued at USD 4.64 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 5.7% from 2024 to 2030.

Medical Plastic Market Segmentation

Grand View Research has segmented the global medical plastic market based on product, application, and region:

Medical Plastics Product Outlook (Volume, Kilotons & Revenue, USD Million, 2018 - 2030)

• Polyethylene (PE)

• Polypropylene (PP)

• Polycarbonate (PC)

• Liquid Crystal Polymer (LCP)

• Polyphenylsulfone (PPSU)

• Polyethersulfone (PES)

• Polyethylenimine (PEI)

• Polymethyl Methacrylate (PMMA)

• Others

Medical Plastics Process Technology Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

• Extrusion

• Injection Molding

• Blow Molding

• Other

Medical Plastics Application Outlook (Volume, Kilotons & Revenue, USD Million, 2018 - 2030)

• Medical Device Packaging

• Medical Components

• Orthopedic Implant Packaging

• Orthopedic Soft Goods

• Wound Care

• Cleanroom Supplies

• BioPharm Devices

• Mobility Aids

• Sterilization and Infection Prevention

• Tooth Implants

• Denture Base Material

• Other Implants

• Others

Medical Plastics Region Outlook (Volume, Kilotons & Revenue, USD Million, 2018 - 2030)

• North America

o U.S.

o Canada

o Mexico

• Europe

o Germany

o U.K.

o France

o Italy

o Netherland

• Asia Pacific

o China

o India

o Japan

• Central & South America

o Brazil

o Argentina

• Middle East & Africa

o Saudi Arabia

o UAE

Order a free sample PDF of the Medical Plastics Market Intelligence Study, published by Grand View Research.

0 notes

Text

Medical Plastics: Industry Dynamics, Major Companies Analysis and Forecast- 2030

Medical Plastics Industry Overview

The global medical plastics market size was estimated at USD 52.9 billion in 2023 and is expected to grow at a compound annual growth rate (CAGR) of 7.4% from 2024 to 2030.

This growth can be attributed to the development of advanced plastics and plastic composites used in medical components such as catheters, surgical instrument handles, and syringes. The demand for medical device packaging is likely to be driven by a rise in demand for in-house and advanced medical devices. Plastics including polyethylene, polypropylene, and polycarbonate are increasingly being utilized for the manufacturing of medical devices. The growth of home healthcare due to its low costs compared to hospital care and intensive care has resulted in a rise in demand for medical devices.

Gather more insights about the market drivers, restrains and growth of the Medical Plastics Market

According to the latest U.S. census, 16.8% of the U.S. population is over the age of 65 years and this number is anticipated to reach 74 million by 2030. People aged over 85 need the most care and their population is growing rapidly. In March 2021, the U.S. President, Joe Biden, proposed spending USD 400 billion on Medicaid over eight years to fund at-home care for elderly and disabled people as well as increase the wages of caregivers.

In the U.S., the frequent increment in costs and reduced margins have severely impacted healthcare providers and health plans. This compelled the government to ensure a significant transformation of healthcare funding and insurance coverage segments in the country through the introduction of ACA and Medicaid.

The COVID-19 pandemic has made in-home care more appealing than nursing home facilities as home care reduces healthcare costs and is more convenient for patients. According to Medicaid and CHIP Payment and Access Commission (MACPAC), it costs about USD 26,000 a year for home care compared to USD 90,000 a year for a nursing home. Increasing investment in healthcare by the government and rising preference for home care are expected to drive the medical plastics market in the U.S. over the forecast period.

The presence of key manufacturers such as Dow, Inc., Eastman Chemical Co., and DuPont can be regarded as one of the major factors driving the market for medical plastics in the country.

Browse through Grand View Research's Plastics, Polymers & Resins Industry Research Reports.

• The global wood pallets market size was estimated to be USD 13.12 billion in 2023, growing at a CAGR of 4.5% from 2024 to 2030.

• The global food wrap market size was estimated at USD 5.15 billion in 2023 and is projected to grow at a CAGR of 7.5% from 2024 to 2030.

Global Medical Plastic Market Report Segmentation

This report forecasts volume & revenue growth at global, regional, and country levels and provides an analysis of latest industry trends in each of sub-segments from 2018 to 2030. For this study, Grand View Research has segmented the global medical plastic market report based on product, application, and region.

Product Outlook (Volume, Kilotons & Revenue, USD Million, 2018 - 2030)

Polyethylene (PE)

Polypropylene (PP)

Polycarbonate (PC)

Liquid Crystal Polymer (LCP)

Polyphenylsulfone (PPSU)

Polyethersulfone (PES)

Polyethylenimine (PEI)

Polymethyl Methacrylate (PMMA)

Others

Process Technology Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Extrusion

Injection Molding

Blow Molding

Other

Application Outlook (Volume, Kilotons & Revenue, USD Million, 2018 - 2030)

Medical Device Packaging

Medical Components

Orthopedic Implant Packaging

Orthopedic Soft Goods

Wound Care

Cleanroom Supplies

BioPharm Devices

Mobility Aids

Sterilization and Infection Prevention

Tooth Implants

Denture Base Material

Other Implants

Others

Region Outlook (Volume, Kilotons & Revenue, USD Million, 2018 - 2030)

North America

U.S.

Canada

Mexico

Europe

Germany

U.K.

France

Italy

Netherland

Asia Pacific

China

India

Japan

Central & South America

Brazil

Argentina

Middle East & Africa

Saudi Arabia

UAE

Key Medical Plastics Company Insights

Some key market players include BASF SE; Celanese Corporation; Evonik Industries AG; SABIC; Dow, Inc.; Solvay S.A.; Trinseo S.A.; and Eastman Chemical Company.

Key Medical Plastics Companies:

The following are the leading companies in the medical plastics market. These companies collectively hold the largest market share and dictate industry trends. Financials, strategy maps & products of these medical plastics companies are analyzed to map the supply network.

Röchling SE & Co. KG

Nolato AB

Saint-Gobain

SABIC

Orthoplastics Ltd

Eastman Chemical Company

Celanese Corporation

Dow, Inc.

Tekni-Plex, Inc.

Solvay S.A.

HMC Polymers Company Limited

ARAN BIOMEDICAL TEORANTA

Trelleborg Group

Avantor, Inc.

Trinseo

Evonik Industries AG

Recent Developments

Some key players operating in market include BASF SE; Celanese Corporation; Evonik Industries AG; SABIC; Dow, Inc.; Solvay S.A.; Trinseo S.A.; Eastman Chemical Company among others.

In February 2023, Cleanse Corporation announced the acquisition of DUPONT's mobility and mobility business for USD 11.00 billion. This strategic move enables Cleanse to expand its global reach and enhance its offerings in the environmental sector, particularly in sustainable transportation.

In June 2023, SABIC acquired Clariant's 50% stake in Scientific Design, a renowned catalysis leader. This acquisition bolstered the non-cyclical, technology-driven business and brought it closer to becoming a leading global specialist

Order a free sample PDF of the Medical Plastics Market Intelligence Study, published by Grand View Research.

0 notes

Text

Everything You Need to Know about Heavy Gauge Thermoforming

Thermoforming is a plastic processing technology. Different from other plastic processes, the main principle is to heat a hard plastic flat sheet to soften it, then use vacuum adsorption to adsorb the softened sheet to the surface of the mold, and then form it after cooling. Thermoforming is widely used in plastic packaging, lighting, advertising, decoration and other industries.

With the continuous development of science and technology, the manufacturing industry is also constantly innovating and progressing. Among them, thermoforming process, as an emerging manufacturing technology, is gradually becoming a new trend in future manufacturing industry.

There are several thermoforming methods used in actual production, and the most basic ones are six: differential pressure forming, overmolding, plunger-assisted molding, suction molding, countermolding, and twin sheet forming.

Thermoforming is divided into heavy gauge thermoforming and thin gauge thermoforming according to the thickness of the sheet. In this article, we will focus on heavy gauge thermoforming.

What is Heavy Gauge Thermoforming

Heavy gauge thermoforming, also known as thick sheet vacuum forming, refers to a technology where the thickness of the raw materials used exceeds 2mm and cannot be formed on a fully automatic machine. Semi-automatic machining and production technology dedicated to thick sheets must be used.

Heavy gauge thermoforming machine is a key process equipment for producing thermoformed plastic parts through vacuum forming manufacturing process using plastic sheets as raw materials. It uses thermoplastic material sheets as raw materials, is heated to the softening temperature in an oven, and then uses the vacuum negative pressure between the plastic sheet and the thermoforming mold to adsorb the plastic sheet in the thermoplastic state to the surface of the thermoforming mold and then cool it for molding.

Heavy Gauge Thermoforming Materials

The main materials for thick gauge thermoforming include: various colors of ABS, acrylic, PETG, PVC, PC, PP, PE, PS, etc. and various modified plastic plain sheets, textured sheets, and transparent sheets.

Application of Heavu Gauge Thermoforming

Heavy gauge thermoforming can be used for product design and manufacturing of rear projection TV back covers, displays, medical equipment, textile machinery, automotive accessories, and product design and manufacturing in precision electronics, medical equipment, and cosmetics industries.

Heavy gauge thermoforming products mainly include refrigerator liner thermoforming, PS thermoforming, ABS thermoforming, thick sheet thermoforming, thick sheet thermoforming, PMMA thermoforming, etc., which are widely used in medical equipment, food equipment, instrument casings, and electrical appliances. Shells, car body sheaths, pet trays, advertising light boxes, lighting, refrigerator industry, air conditioning industry and home appliance accessories, etc.

Heavy gauge thermoforming products can not only replace injection molding, saving expensive injection mold costs, but also replace traditional manual production. They have the advantages of advanced production technology, fast speed, and reliable quality.

Advantages of Heavy Gauge Thermoforming

It saves raw and auxiliary materials, is light in weight, easy to transport, has good sealing performance, and meets the requirements of environmentally friendly green packaging.

It can pack any special-shaped products, and no additional buffering materials are needed for packaging.

The packaged products are transparent and visible, beautiful in appearance, easy to sell, and suitable for mechanized and automated packaging, which facilitates modern management, saves manpower, and improves efficiency.

Heavy Gauge Thermoforming Machine Components

Heavy gauge thermoforming machines generally consist of sheets positioning system, thermoforming mold positioning system, frame system, heating system, cooling system and electrical control system.

1. The sheets positioning system generally consists of material pressing frame, power cylinder or an oil cylinder, and balance synchronization mechanism. Its function is to tighten the positioning of plastic sheets. The press frame of the walking frame heating method has an upper and lower structure, and is equipped with a transverse locking mechanism to ensure that the press frame can be tightly sealed with the plate backing plate. The frame can be adjusted according to the size of the mold, either manually or automatically.

2. The thermoforming mold positioning system generally consists of upper and lower mold tables, upper and lower mold cylinders or oil cylinders, and synchronization mechanisms. Its function is to tighten the positioning of the thermoforming mold and connect the mold to the vacuum pipeline. There are two positioning methods: manual screw locking or pneumatic automatic locking. The synchronization mechanism can ensure that the upper and lower molds rise and fall simultaneously to ensure vacuum forming accuracy.

3. The frame system generally consists of profile frame, sealed box, and protective door. Protective doors are divided into automatic and manual.

4. The heating system generally consists of heating bricks or heating tubes, oven frames, and power cylinders or motors.

5. The cooling system generally consists of air and water pipes and spray heads.

6. Electrical system: The electrical control system cooperates with the pneumatic or hydraulic system to realize the process requirements (temperature, speed, time) and various program actions of the thermoforming machine. It is mainly composed of PLC and touch screen, contactors, electronic components, temperature regulating instruments, solenoid valves, sensors, etc. There are generally three control methods, manual, automatic and adjustment.

Heavy Gauge Thermoforming Production Process

The principle of heavy gauge thermoforming is similar to that of light gauge thermoforming. The positioned sheet is heated to a softened state in an oven, and the vacuum forming mold forms a closed space around it to instantly remove the air from the mold cavity and tightly cover the sheet. The process of cooling and shaping the mold surface to obtain the finished product.

Thermoforming is a cyclic process, and each cycle mainly includes: loading - heating and softening - backflushing and pre-drawing - pressure forming - cooling and shaping - demoulding and picking. After taking out the plastic parts, place the plate again (can be received or automatically) and proceed to the next cycle.

1. Mold making and processing: Different customers have corresponding specifications for the product, so plastic molds must be made before production. In this case, the mold is made from plaster of a plastic mold, and the mold is produced using plastic. The lower cost is the plaster mold, followed by the electroplated copper mold, while the aluminum mold is more expensive. When the mold is made, let it dry naturally or dry it, and then treat it according to the specific conditions of the product surface. to

2. When the mold is completely dry, the mold should be placed on the upper iron plate of the vacuum chamber, and then according to the size of the mold, load the mold into the applicable size and then put the paper into the hot wood cabinet to fix it and process it.

3. Fix the plastic sheet on the mold with fixing clips, heat both ends of the plastic sheet until it becomes soft, and then use a vacuum pump to remove the air between the material and the mold, allowing the softened plastic sheet to be adsorbed on the mold and cool. Then blow air in the opposite direction to release the product from the mold.

4. Finishing: The finished product is trimmed and integrated into a product that can be packaged for sale. Thin gauge plastic thermoforming is generally used in food packaging, pharmaceutical packaging, cosmetic packaging and other industries. Product thickness 10-100 silk. Heavy gauge vacuum forming is mainly used in automobile, hardware, electric vehicle and other industries, and the product thickness is 1-10mm or even thicker.

Thermoforming & Injection Molding & Blow Molding

Injection molding

Injection molding is to melt the plastic raw materials, then put them into the mold under high pressure through an injection molding machine, and then cool them into shape.

Blow Molding

Blow molding is a rapidly growing plastic processing method. The tubular plastic parison obtained by extrusion or injection molding of thermoplastic resin is placed in a split mold while it is hot (or heated to a softened state). After the mold is closed, compressed air is immediately introduced into the parison to blow the plastic parison. It expands and adheres closely to the inner wall of the mold. After cooling and demoulding, various hollow products are obtained.

Main Difference

1. Thermoforming: It is suitable for products with relatively simple structure, single-sided molding and small quantity. Molds are very cheap. The mold cost is only 1/20 of that of injection molds. The mold opening time of products of similar complexity is only 1/4 of that of injection molds. However, complex structures cannot be designed and are generally bonded through adapters. It is also similar to the carbon fiber hot pressing process.

2. Injection molding: suitable for large-volume, high-precision products, the mold cost is very high, and complex structures can be designed.

3. Blow molding: mainly used to produce hollow products, such as bottles, cans and other products. The price of the mold is not much different from that of thermoforming molds.

Case

Medical industry

Why heavy gauge thermoforming?

1. The order quantity of medical products is small. Compared with other consumer products, the steel materials with slightly better mold life of general injection molding can be molded one million times. However, it is difficult for general large-scale medical products to reach this level. The plastic mold The price is transferred to a single product, resulting in a very high unit price (applicable to products with a batch size of less than 5,000 and whose appearance level requirements are not particularly high, especially suitable for the casing of robot products).

2. Compared with injection molding, heavy gauge thermoforming has a simple structure and can still meet most of the needs. It has stable performance, satisfactory surface treatment, and can be adapted to silk screen printing (ABS) of various colors.

Conclusion

Heavy gauge thermoforming can mold plastic products of large size, simple appearance, and imprecise size requirements at one time. In some aspects, it can replace injection molding, fiberglass, metal shells, etc. The blister mold has the advantages of low manufacturing cost and short development cycle. advantage. Its cost is 1/10 to 1/20 of that of an injection mold, and its production cycle is fast. It is gradually widely used in various fields of people's daily life, such as automobile interior and exterior decoration, transportation, building materials, packaging, medical equipment, household appliances, cultural, educational and sanitary ware, sporting goods and so on. Today, with the rapid development of the plastics industry, the use of heavy gauge thermoforming is also expanding.

0 notes

Text

Ultra Purge C6090: Safe, FDA-Compliant Cleaning for Thermoplastic Resins

Ultra Purge C6090 offers a safe and FDA-compliant solution for cleaning thermoplastic resins during material transitions. Specifically designed for polycarbonate (PC) and poly methyl methacrylate (PMMA), this purging compound ensures that transitions are smooth and free from contaminants, maintaining the integrity and quality of the final products.

Operating at temperatures between 190°C (374°F) and 320°C (608°F), Ultra Purge C6090 is versatile and effective for various applications, including injection molding and extrusion. The compound requires no additional mixing or preparation, making it easy to use and handle. Its non-abrasive formulation protects sensitive equipment components, ensuring long-term operational efficiency and safety.

Compliance with FDA regulations (21 CFR) is a significant advantage of Ultra Purge C6090. All components of the compound are either Generally Recognized As Safe (GRAS) or permitted for direct or indirect food contact. This makes Ultra Purge C6090 an ideal choice for food-related industries, providing assurance that the purging process is safe and compliant. By incorporating Ultra Purge C6090 into your cleaning routine, you can maintain high safety standards and enhance production quality.

#SafeCleaning#FDACompliant#UltraPurgeC6090#ThermoplasticResins#InjectionMolding#ExtrusionCleaning#NonAbrasive#IndustrialCleaning#OperationalSafety#ProductionQuality

0 notes

Text

Evolution and Projections in the Global Polymethyl Methacrylate (PMMA) Market

Polymethyl Methacrylate (PMMA) has established itself as a versatile and highly sought-after polymer in various industries due to its exceptional optical clarity, impact resistance, weatherability, and ease of processing. This article dives into the current trends, applications, challenges, and future projections for the global PMMA market.

Current Market Landscape:

Diverse Applications Across Industries:

PMMA finds extensive use in automotive, construction, electronics, healthcare, signage, lighting, and consumer goods sectors. Its optical properties make it an ideal alternative to glass in many applications Polymethyl Methacrylate (PMMA) Market.

Growth in Construction and Architecture:

PMMA's use in architectural glazing, skylights, and façade panels has seen a steady rise due to its lightweight nature, UV resistance, and design flexibility, contributing to energy-efficient building designs.

Automotive Sector Demand:

The automotive industry utilizes PMMA for headlight lenses, interior trim components, and displays due to its impact resistance, optical clarity, and ease of molding, meeting stringent safety and design requirements.

Consumer Goods and Electronics:

PMMA is prominent in consumer electronics (smartphone screens, displays) and household goods (furniture, kitchenware) for its scratch resistance, transparency, and ability to be molded into intricate shapes.

Key Market Trends:

Focus on Sustainability and Recycling:

The PMMA industry is shifting towards sustainable practices, including recycling initiatives and the development of bio-based PMMA to reduce environmental impact and meet regulatory standards.

Technological Advancements in Processing:

Innovations in PMMA processing technologies, such as extrusion, injection molding, and nanostructured materials, are enhancing product performance, aesthetics, and cost-effectiveness.

Demand for High-Performance Plastics:

As industries demand lightweight, durable, and aesthetically pleasing materials, PMMA's properties align with these requirements, especially in sectors like aerospace, marine, and renewable energy.

Challenges and Opportunities:

Price Volatility and Raw Material Sourcing:

Fluctuations in raw material prices, particularly methyl methacrylate (MMA), can impact PMMA production costs. Diversification of sourcing and strategic partnerships mitigate such risks.

Competition from Alternative Materials:

PMMA faces competition from other transparent polymers and glass substitutes. Continued innovation, differentiation through properties like chemical resistance and recyclability, and market education are essential.

Future Projections:

Expansion in Emerging Economies:

Rapid urbanization, infrastructure development, and automotive industry growth in regions like Asia-Pacific and Latin America will fuel PMMA demand for construction, automotive, and consumer applications.

Advancements in Performance Grades:

Development of high-performance PMMA grades with enhanced UV stability, impact resistance, fire retardancy, and self-cleaning properties will open new opportunities in demanding applications.

Customization and Additive Manufacturing:

Tailored PMMA formulations, additive manufacturing (3D printing), and smart material integration (embedded sensors, light diffusion technologies) will drive innovation and market penetration in niche sectors.

Conclusion: The global PMMA market is poised for sustained growth driven by its diverse applications, technological advancements, and increasing emphasis on sustainability and performance. Collaboration across the value chain, innovation in material properties, and strategic market positioning will be pivotal for stakeholders to capitalize on emerging opportunities and navigate market challenges effectively.

0 notes

Text

Automotive Plastics Market Trends Analysis Report By Product, Function, Application, Region And Forecast 2030: Grand View Research Inc.

San Francisco, 20 March 2024: The Report Automotive Plastics Market Size, Share & Trends Analysis Report By Product (ABS, PP, PU, PVC, PE, PC, PMMA, PA), By Process (Injection Molding, Blow Molding, Thermoforming), By Application, By Regions, And Segment Forecasts, 2024 – 2030 The global automotive plastics market size is anticipated to reach USD 43.77 billion by 2030 is projected to grow at a…

View On WordPress

0 notes

Text

Thermoformed Plastics Market Size 2024, Share, Growth Forecast Report By 2032

IMARC Group's report titled " Thermoformed Plastics Market Report by Product (Polymethyl Methacrylate (PMMA), Bio-degradable Polymers, Polyethylene (PE), Acrylonitrile Butadiene Styrene (ABS), Poly Vinyl Chloride (PVC), High Impact Polystyrene (HIPS), Polystyrene (PS), Polypropylene (PP)), Process (Plug Assist Forming, Thick Gauge Thermoforming, Thin Gauge Thermoforming, Vacuum Snapback), Application (Healthcare and Medical, Food Packaging, Electrical and Electronics, Automotive Packaging, Construction, Consumer Goods and Appliances, and Others), and Region 2024-2032",The global thermoformed plastics market size reached US$ 44.3 Billion in 2023. Looking forward, IMARC Group expects the market to reach US$ 67.1 Billion by 2032, exhibiting a growth rate (CAGR) of 4.6% during 2024-2032.

For an in-depth analysis, you can refer sample copy of the report: https://www.imarcgroup.com/thermoformed-plastics-market/requestsample

Factors Affecting the Growth of the Thermoformed Plastics Industry:

Growing Demand in Packaging Industry:

Thermoformed plastics offer a cost-effective solution for packaging compared to traditional materials like glass, metal, or injection-molded plastics. This cost advantage makes them highly attractive to manufacturers seeking to optimize their packaging expenses. Thermoformed plastics are lightweight, which reduces transportation costs and energy consumption during shipping. This aspect is particularly beneficial for industries with large-scale distribution networks, such as the food and beverage (F&B) industry.

Technological Advancements:

Continuous improvements in thermoforming technology, such as advancements in machinery, automation, and software, are leading to enhanced process efficiency. This results in higher production rates, reduced cycle times, and improved overall manufacturing productivity. Technological innovations in materials science are leading to the development of new polymer formulations and composite materials with superior properties. These advanced materials offer enhanced strength, durability, flexibility, and heat resistance, expanding the range of applications for thermoformed plastics in various industries.

Cost-Effectiveness and Versatility:

Thermoforming processes require less material compared to alternative manufacturing methods, such as injection molding or blow molding. This reduction in material usage contributes to cost savings and helps minimize waste, making thermoformed plastics a sustainable and economical choice. In addition, thermoformed plastics can be easily customized to meet specific design requirements, allowing manufacturers to create packaging and products tailored to their unique needs. This versatility in design and functionality enables businesses to differentiate their offerings in the market and cater to diverse consumer preferences.

Leading Companies Operating in the Global Thermoformed Plastics Industry:

Amcor plc

Anchor Packaging LLC

Berry Global Inc

Brentwood Industries Inc.

D&W Fine Pack

Dart Container Corporation

Fabri-Kal Corp. (Two Mitts Inc.)

Genpak LLC (C-P Flexible Packaging)

Greiner Packaging GmbH

Pactiv LLC

Placon Corporation

Sabert Corporation

Sonoco Products Company.

Thermoformed Plastics Market Report Segmentation:

By Product:

Polymethyl Methacrylate (PMMA)

Bio-degradable Polymers

Polyethylene (PE)

Acrylonitrile Butadiene Styrene (ABS)

Poly Vinyl Chloride (PVC)

High Impact Polystyrene (HIPS)

Polystyrene (PS)

Polypropylene (PP)

Polypropylene (PP) represents the largest segment due to its favorable properties, such as durability, chemical resistance, and versatility, making it widely used in various packaging and manufacturing applications.

By Process:

Plug Assist Forming

Thick Gauge Thermoforming

Thin Gauge Thermoforming

Vacuum Snapback

Thin gauge thermoforming accounts for the majority of the market share as it offers cost-effective production of lightweight and flexible packaging solutions, meeting the demand for disposable packaging in industries, such as pharmaceuticals and consumer goods.

By Application:

Healthcare and Medical

Food Packaging

Electrical and Electronics

Automotive Packaging

Construction

Consumer Goods and Appliances

Others

Food packaging exhibits a clear dominance in the market owing to stringent hygiene standards, the increasing demand for convenient and sustainable packaging solutions, and the versatility of thermoformed plastics in preserving and protecting food products.

Regional Insights:

North America (United States, Canada)

Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

Latin America (Brazil, Mexico, Others)

Middle East and Africa

North America enjoys the leading position in the thermoformed plastics market on account of the robust manufacturing infrastructure, technological advancements, and strong presence of key industry players.

Global Thermoformed Plastics Market Trends:

Increasing consumer and regulatory pressure is driving the adoption of sustainable thermoformed plastics made from recycled materials or bio-based polymers to reduce environmental impact and meet sustainability goals. Apart from this, the growing preferences for lightweight and portable packaging solutions, particularly in the food and beverage (F&B) and e-commerce sectors, is increasing the use of thermoformed plastics due to their cost-effectiveness and durability.

Moreover, the rising demand for single-use and on-the-go packaging solutions, driven by changing consumer lifestyles and convenience preferences, is fueling the adoption of thermoformed plastics in industries, such as foodservice and healthcare.

Note: If you need specific information that is not currently within the scope of the report, we will provide it to you as a part of the customization.

About Us:

IMARC Group is a leading market research company that offers management strategy and market research worldwide. We partner with clients in all sectors and regions to identify their highest-value opportunities, address their most critical challenges, and transform their businesses.

IMARCs information products include major market, scientific, economic and technological developments for business leaders in pharmaceutical, industrial, and high technology organizations. Market forecasts and industry analysis for biotechnology, advanced materials, pharmaceuticals, food and beverage, travel and tourism, nanotechnology and novel processing methods are at the top of the companys expertise.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact US

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: [email protected]

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145 | United Kingdom: +44-753-713-2163

0 notes

Text

FRONT FOG LIGHTS PMMA

Zhejiang Yongfeng Plastic Co., Ltd. was established in 1985, is a Front Fog Lights PMMA Suppliers and Front Fog Lights PMMA manufacturers. We have a completed system starts from design, DFM analysis, mold manufacture, to product processing, assembly, examination. The company takes over 50,000 square meters. It is professional in design, tooling and moulding automotive interior and exterior plastic parts. The company is fully equipped with design programs (UG, Catia etc.) and injection machines(mainly Haitian injection machine, from 160T to 21000T). Yongfeng cooperates with customers from design, mould tooling, and plastic parts moulding, assembling and quality checking. Company capacity is over 1 million sets plastic parts per year. Yongfeng’s high-standard quality products and professional service helps the company cooperate with customers like Beiqi, Guangqi and Huanghai.

0 notes

Text

BROWN FLOWER POT MOULD

Product:Plastic Mold

MoldNO:Customized

Brand:SHINE

Color:Customized

Placeof Orngin:Huangyan,China

Size:Customized

Material:Plastic

Packing:Poly Wood Box

Advantage:OEM Is AvailableS

haping Mold:Plastic Injection Mold

Supply Ability:About 100 Sets Per Month

Use:Household Product

Mold Material:NAK80,S136,H13,718H,P20, etc.

Plastic Material:PP, PC, PS, POM, PE, PU, PVC, ABS, PMMA, etc.

0 notes

Text

Some people have difficulty to choose a right process for his plastic part project. Injection molding or 3D printing?

Here are some advantages and disadvantages of molding and 3D printing:

Advantages of molding: High production volumes: Once a mold is created, it can be used to produce a large number of identical objects quickly and efficiently. Consistency and accuracy: Molds can produce objects with high accuracy and consistency, ensuring that each object is virtually identical to the others. Surface quanity: Molding process can turn out very smooth surface, even mirror polished surface.

Materail: There is wide range of material available for molding -- ABS, PP, PE, PC, PS, PA, PMMA,PET, TPE/TPU, engineering resins......

Large object sizes: Molding is better suited for producing large objects, whereas 3D printing has limitations on the size of the object that can be produced.

Cost-effective for large volumes: Molding can be a more cost-effective method for producing large volumes of objects, as the cost per unit decreases as the volume increases.

Disadvantages of molding:

High setup cost: The initial cost of creating a mold can be expensive, particularly if a custom mold is required.

Limited design flexibility: Molding is less flexible when it comes to design changes, as any changes to the mold may require significant time and expense.

Lead time: Molds can take time to create, which can delay production.

Advantages of 3D printing:

Design flexibility: 3D printing allows for a high level of design flexibility, making it ideal for producing customized objects.

Rapid prototyping: 3D printing allows for the quick and inexpensive production of prototypes, which can help speed up the product development process.

Low setup cost: 3D printing does not require expensive molds or tooling, making it a more cost-effective method for producing small volumes or one-off objects.

Ability to produce complex geometries: 3D printing can produce objects with complex shapes and geometries that would be difficult or impossible to produce with molding.

Disadvantages of 3D printing:

Limited production volume: 3D printing is generally slower than molding, making it less efficient for producing large volumes of objects.

Limited material option: 3D printing is currently limited in the types of materials that can be used, although this is rapidly changing with advancements in technology.

Lower accuracy and surface finish: 3D printing may not be able to achieve the same level of accuracy and surface finish as molding, particularly for larger objects.

Higher cost per unit for larger volumes: 3D printing can be more expensive than molding for large volumes of objects due to the slower production speeds.

Overall, both molding and 3D printing have their advantages and disadvantages, and the choice of manufacturing method will depend on factors such as production volume, design complexity, and cost considerations.

0 notes

Text

Exploring the Possibilities of Vacuum Mold Casting

If you're looking to create high-quality prototypes in small quantities, vacuum mold casting (also known as cast urethanes or vacuum casting) might be the ideal solution. This method can produce parts rapidly and efficiently, making it an excellent substitute for production tooling.

Working with a competent manufacturer, you can create parts of any size using a variety of materials that have similar properties to thermoplastics. By partnering with a trusted service provider, you can fully explore and leverage the capabilities of vacuum casting for your project, yielding superior results in a cost-effective and time-efficient manner.

What can vacuum casting do?

Vacuum casting involves creating a master model of your design using stereolithography (SLA 3D printing) or CNC machining. Once the model is ready, liquid silicone will be poured around it and left to cure. After drying, the master will be removed from the mold, leaving only the cavity. Then, the casting process begins by pouring your choice of resin into the cavity. This should ultimately result in a production-like replica.

With vacuum mold casting, it is possible to produce identical plastic or rubber parts for low-volume prototyping or end-use production. It’s also beneficial for rapid iterations and market testing, as it can be done with a low, upfront investment, and it can generate self-colored parts.

Build production-grade parts

Do you want to save time building identical parts for low-volume production? Molding has scalable production capabilities that will allow you to produce anywhere from thousands to millions of similar components. Additionally, vacuum casting can build your parts from a massive selection of materials. Regardless of your choice, it will result in production-like components. Reputable manufacturers can use materials similar to ABS, PMMA, PA, PP, or PC, with additional features like transparency or flame retardant. They can also make parts from transparent soft rubber.

Create quality, detailed parts

Though you are building prototypes, vacuum mold casting can generate production-quality parts as good as injection-molded ones but with more details, thanks to silicone molds. That makes it suitable for highly detailed, small components. So, you can confidently test your parts in real-world settings before mass producing them.

We can support your prototyping needs.

Are you considering vacuum mold casting for your project? Contact us here at HLH Proto, and we will make it happen! We can also review your project and provide design tips to help you make the most of vacuum casting.

0 notes

Text

Introduction of transparent plastic injection molding process

Introduction:

Transparent plastic injection molding is a highly versatile manufacturing process that has revolutionized the production of transparent plastic parts. From everyday products to intricate technical components, this process allows for the creation of transparent parts with exceptional clarity, strength, and precision. In this blog post, we'll look at the principles of transparent plastic injection moulding, as well as its benefits, uses, and important factors.

Understanding Transparent Plastic Injection Moulding:

high pressure, molten plastic material is injected into a mould cavity in plastic injection moulding, a commonly used manufacturing technique. The molten plastic then cools and solidifies, taking the shape of the mold cavity. Transparent plastic injection molding follows the same principle, but with the added challenge of maintaining optical clarity in the final product.

Material Selection:

Transparency in injection moulding requires careful material selection. Due to their superior optical qualities, polycarbonate (PC), acrylic (PMMA), and various styrenic polymers are preferred options. These materials possess inherent transparency, allowing light to pass through with minimal distortion. Additionally, they exhibit good dimensional stability, chemical resistance, and durability.

We R D Mould & Industries are a renowned Plastic Toy mould manufacturer in Ahmedabad,Gujarat, India, provide various types of Plastic Toy Mould Including Plastic Toy Injection Mould, Plastic Toy Blow Mould & Etc.

Design Considerations:

To ensure successful transparent plastic injection molding, certain design considerations must be taken into account:

Wall Thickness:

Consistent wall thickness must be maintained to prevent optical distortions and part flaws. Thin areas can cause light scattering, while thick areas may lead to flow marks or sink marks. To obtain uniform thickness across the item, careful design optimization is required.

Gate Placement:

Proper gate placement is critical to minimize visible gate marks on the final part. Care should be taken to position the gate in inconspicuous areas or where the marks can be easily removed during secondary processes.

Surface polish:

The mold's surface polish significantly contributes to achieving optical clarity.In order to reduce surface flaws and produce a clean, transparent finish, a high-gloss polished mould surface is preferred.

Apart from Plastic Toy Mould Exporters We're also dealing in Plastic Toy Injection Mould And Plastic Toy Blow Mould & Etc.

Advantages of Transparent Plastic Injection Molding:

Transparent plastic injection molding offers several advantages over alternative manufacturing methods:

Enhanced Clarity:

This process enables the production of transparent parts with exceptional clarity, allowing for the transmission of light without significant distortion or haziness.

Complex Geometries:

The production of intricate shapes and complex geometries is made possible by injection moulding, which expands the design options for transparent parts.

Cost-effective:

Transparent plastic injection molding offers cost advantages, particularly for large-scale production runs. The ability to produce multiple parts simultaneously and the relatively low cost of raw materials make it an economical choice.

Applications of Transparent Plastic Injection Molding:

Transparent plastic injection molding finds application in various industries, including:

Automotive: Transparent parts like lenses, sunroofs, and interior lighting components.

Electronics: Display panels, touchscreens, optical lenses, and light guides.

Medical: Transparent medical devices, diagnostic equipment, and packaging.

Consumer Goods: Transparent packaging, cosmetic containers, and household products.

Conclusion:

Transparent plastic injection molding has transformed the manufacturing landscape by providing a reliable and efficient method for producing transparent parts with exceptional optical properties. Manufacturers may produce high-quality transparent components for a variety of sectors by carefully considering material selection, design optimisation, and surface polish. As technology continues to advance, the future holds even greater possibilities for transparent plastic injection molding, driving innovation and pushing the boundaries of what is possible in the world of transparent plastic products.

0 notes