#Vane pumps

Explore tagged Tumblr posts

Text

Vane Pumps: A Guide to Rotary Positive Displacement Pumps for Efficient Fluid Transfer

Introduction: Vane pumps are a type of positive displacement pump that play a crucial role in various industrial and automotive applications. They are known for their efficiency in transferring clean, low to medium viscosity fluids at varying pressures and temperatures. This guide delves into the world of vane pumps, exploring their working principles, key components, and applications. We’ll also…

View On WordPress

#Hydraulic Pump#Positive Displacement Pump#Rotary Vane Pump#Sliding Vane Pump#Vane Pump Applications#Vane Pump Efficiency#vane pumps

0 notes

Text

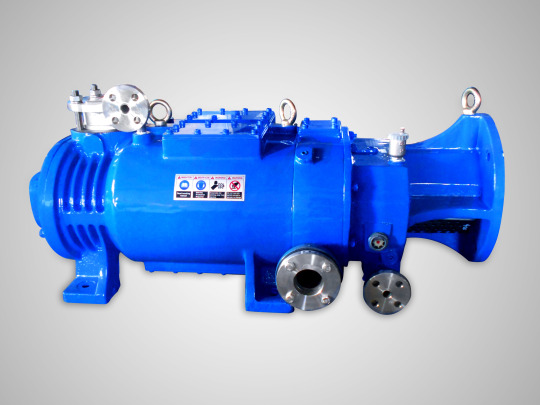

Vacuum System And Package at Best Price in Noida

Swam dry screw vacuum pumps are designed under SWAM’s unique screw profile engineering to fulfill wide range of chemical and industrial processes. It is operating by rotating a paired screws that efficiently admit gases from inlet into the pump inside and compress through the screw’s swept volume toward the discharge.

For more information Visit Now :https://swamatics.com/ProductDetails.aspx?prod=Vacuum%20Systems%20and%20Packages

#air blower exporter#best process gas blowers#bio gas compressors#Twin lobe blowers#bio gas blowers#Turbo Blower#Mechanical vacuum re compressor#Aeration blowers#Combustion air blowers#Oxidation blowers#Dry screw vacuum pumps#Vane pumps#tri lobe rotary piston#Vacuum system and packages#Tri lobe blowers#Mechanical vacuum boosters

0 notes

Text

Buy Hydraulic Products

Buy high quality hydraulic products from Cascade Industrial Services. Professional and experienced technicians are ready to help you find what you need quickly!

0 notes

Note

So if Siegfried's VA is coming on Granblue TV next week, pretty much everyone assumes we're getting a new Sieg unit. What are we hoping for, here? Fanservice and sexy? Strong and intimidating? Maybe showing off some fierce draconian power? I guess it's all sexy

Grand Sieg Real!!! Grand Sieg Real!!!

i don't know if it's what you really want to know since your ask is more lighthearted but here's what have been my thought process about it all and i've thought about it a lot for the past two years:

ever since Grand!Lancelot dropped in December 2021, we've known that they were going to release a set of Grand for each of the Dragon Knights.

Grands are given to some of the most important characters of the lore and of the game in general.

The Dragon Knights also are in a situation where they're popular and powerful, but their very first units (except for Vane) have been relegated to the Classic Draw, making them difficult to access for new players. It also means that their original kit has been outdated (though they still have their use)

So the idea of those Grands will be to be an upgrade on the Base Units, while taking into account their development so far, and also recapping the important parts of their lore.

It's why Grand!Lancelot recapped from the ground up everything we knew from Siegfried being framed to the crimes of Feendrache and the way Lancelot has grown from his blindly patriotic days.

Since the announcement of the Grand series for the Knights, only Lancelot and Percival have been released. it's also noteworthy that before the current rotation of knights, the last released unit was Halloween Vane, meaning that in the rotation, next one has to be Siegfried.

If they continue on the logic of replacing the base units, it will be an Earth Grand Unit for Siegfried.

What to expect from it? well, it just needs a look at the previous grands to have an idea.

Grand!Lancelot gave him an upgrade by connecting him to the Fairies of Feendrache, finally coming out from their slumbers and blessing their new champion.

Grand!Percival meanwhile got an upgrade thanks to Cath Palug, the guardian creature of the rulers of Wales, who has been set since BFAF with looking over the possible rulers of the nation and eventually give them the power to do so if they're considered worthy.

Their new arts came with an overhaul on their armors and also something that strengthen their current affiliation. Lancelot leaves behind the blue armor to embrace a white one as the leader of the White Dragons. Percival's armor meanwhile ends up upgraded with regal designs reminding of the coat of kings, strengthening as well his goal to become a worthy protective king. His uncap also strengthen this imagery by showing him as a leader of the people, while Lancelot is a little more "battle generic".

The conclusion to drive from it with Siegfried, which i had at the time and have been strengthened by the preview, is that Siegfried is also going to get a power up from a specific creature that will lead him to reevaluate himself.

So obviously, for his Grand to actually have the impact it needs, Siegfried's storyline must continue on the Draconian front.

in Siegfried's Fire unit, following the event of SIEGFRIED, the dragon blood has basically been consumming him and he's losing himself more and more and is currently in a situation of near death or losing his mind if he doesn't find a way to ease up Fafnir's blood. One of the theory mentioned in the FE as to how to save Siegfried's life, is that he has to connect with Fafnir in some way again. (we also know now, from Naoise's storyline, another draconian, than a positive relationship with the dragon you have the blood of in your vein can help you control this power).

So it's basically been set up for years that the next logical step in Siegfried's journey would be related to Fafnir and to his condition as a Draconian, and with the current Grand trend, it seems likely that this will be the core componant to his upgrade.

The newest event is called "The Dragon weep before Daybreak" and will feature discussion of the Sins of Feendrache. The sins of Feendrache are many, and one that is important is the way Fafnir has basically been used to poison the people of Feendrache for years due to Isabela's influence, after all. Moreover, any sins of Feendrache would imply unveiling Josef's past.

So i believe Siegfried will get his upgrade because he will be forced to confront Fafnir, in one way or another, and will come out of it with more power. I also believe that the past we'll unveil, probably even more regarding Josef, are going to break Siegfried to some level.

So what it means for Siegfried's Grand Unit:

-I think it's going to double down on the draconian angle. Since Fire!Siegfried we expect so, Fire!Naoise showed us how a proper feral draconian can evolve, and we know from gbvs that Granblue is leaning harder in harder on Siegfried being fully a draconian now. (besides, in Summer!Siegfried, a huge plot point is that the dragon blood almost drives him to insanity again and he still has to fight it and he wants to enjoy the last few moments he has with his friends for now)

-Which will probably mean that the uncap at least might be Feral and unhinged

-There's the possibility that the uncap also actually reflect his dynamic with Josef.

-I don't really think it'd be sexy for the sake of it being sexy, i think for such a big unit moment, they'll focus on the lore itself. I just hope that they remove his helmet for it bc looking at the concept art for Fire!Sieg, where he wasn't wearing the helmet while in the final art he does, is painful.

-Siegfried's theme colors are already Black and blue, so i think if change to his design, rather than color palette, it will be a design change like Percival had.

tldr So personally i believe it'll be strong and powerful, with a high chance of feral depending on how in control he will be, but nevertheless i do think the focus will be on the draconian aspect of his characterization, or eventually on his relationship with Josef.

and yeah i've been thinking about all of this since 2021 so i have many thoughts alright

#i kno we discuss sexy men all the time on here but nothing gets my blood pumping as much as character dives#granblue could still be going completely in a different direction but at least that's how it would work on their current patern#for the record when it comes to Vane: i'm still wondering if they might change his element#since his unit is still pretty useable and in the common pool#they wouldn't make him wind or fire bc of his alts though which makes it complicated#Light Vane real in my heart and in OnoYuu's and it's all that matters#coughs but actually the point i wanted to make about Vane#is that i believe in his case depending on what he ends up facing in his subsequant stories#i think ghosts or wyverns might be the cataclyst to his evolutions#as those are the two creatures that usually accompany his stand alone stories#i have many thoughts about the dragon knights#ichareply#ichafantalks gbf#anonymous#ichablogging 4kishi

3 notes

·

View notes

Text

The Ultimate Guide to Understanding Vacuum Pumps: Types, Applications, and Benefits

Vacuum pumps play a vital role in many industrial and laboratory applications, providing an essential means of removing air and gases from sealed environments. With different types of pumps available, each designed for specific purposes, understanding the mechanics and uses of these pumps can help you make informed decisions about which is best suited for your needs. This guide covers the basics of Dry Vacuum Pump, Rotary Vane Vacuum Pump, Rotary Vane Pump, Single Stage Oil Sealed Vane Pump, and Oil Sealed Vacuum Pump, highlighting their differences, uses, and advantages.

What Is a Vacuum Pump?

At its core, a vacuum pump is a device that removes gas molecules from a sealed volume to create a vacuum. The specific type of vacuum pump chosen depends on the application and the level of vacuum required. Different pumps offer varying capabilities in terms of pressure levels, operational efficiency, and the type of gas or fluid being handled.

Dry Vacuum Pump: A Clean Solution

A dry Vacuum Pump is a type of vacuum pump that operates without the need for any lubricants or oil. These pumps are preferred for applications that require a clean and dry environment, as they avoid contamination issues that can arise from oil mist or liquid leaks. Dry vacuum pumps are commonly used in food processing, pharmaceuticals, and semiconductor industries, where hygiene is crucial.

One of the key advantages of a dry vacuum pump is its reduced maintenance needs. Without the need for oil changes, these pumps offer a longer operational life and greater efficiency. Additionally, dry vacuum pumps are environmentally friendly as they eliminate the need for oil disposal and reduce the risks of oil contamination in sensitive applications.

Rotary Vane Vacuum Pump: Versatile and Reliable

The rotary vane vacuum pump is a widely used positive displacement pump that employs rotating vanes inside a cylinder to create a vacuum. It is known for its versatility and reliability in various industrial settings. The pump's rotating vanes move in and out of contact with the pump casing, compressing and expelling gas with each rotation.

These pumps are often used in applications such as air conditioning, refrigeration, and industrial processing, where moderate vacuum levels are required. They are efficient, capable of reaching relatively deep vacuums, and can handle a variety of gases, making them an essential tool in many industries.

Rotary Vane Pump: How It Works

The rotary vane pump operates through a similar mechanism as the rotary vane vacuum pump but may differ in its design and application. The core principle remains the same, with rotating vanes creating alternating high and low-pressure zones to move gases out of the pump.

This pump is ideal for environments requiring a robust, reliable vacuum source with moderate pressure levels. Its compact size and ability to handle a wide range of gases make it a popular choice for scientific research, laboratory work, and small-scale industrial operations.

Single Stage Oil Sealed Vane Pump: Ideal for High Performance

The single stage oil sealed vane pump is a specific type of rotary vane pump that uses oil for lubrication and sealing purposes. The oil acts as a lubricant for the vanes and creates an additional seal to improve the pump's performance. This pump is designed to reach deeper vacuum levels compared to dry pumps and offers better efficiency in high-demand applications.

Single Stage Oil Sealed Vane Pumps are typically used in industries that require higher vacuum levels, such as in the chemical and pharmaceutical sectors. The oil helps prevent wear on the moving parts, ensuring a longer lifespan for the pump. However, regular maintenance and oil changes are necessary to maintain optimal performance.

Oil Sealed Vacuum Pump: Enhanced Sealing Efficiency

An oil sealed vacuum pump uses oil to create an airtight seal, which enhances the efficiency of the vacuum process. The oil serves a dual purpose: it seals the gaps between the rotating vanes and the pump casing while also lubricating the components to reduce friction and wear. This makes the oil sealed vacuum pump a highly efficient option for demanding applications where deep vacuums are needed.

One of the main advantages of oil-sealed pumps is their ability to achieve high levels of vacuum, often reaching pressures that are difficult to achieve with other types of pumps. The oil also helps dampen noise and vibration, making these pumps quieter than other vacuum pump types.

Key Differences Between Dry and Oil Sealed Vacuum Pumps

When comparing Dry Vacuum Pumps and Oil Sealed Vacuum Pumps, the most obvious difference lies in the presence of oil. Oil Sealed Vacuum Pumps rely on oil to lubricate, seal, and cool the pump, providing enhanced performance and a greater ability to handle high vacuum pressures. However, the use of oil can also lead to contamination risks in certain applications.

In contrast, Dry Vacuum Pumps do not require oil, offering a cleaner solution with fewer maintenance requirements. They are typically more environmentally friendly, making them ideal for industries where contamination must be avoided, such as in food processing, pharmaceuticals, and electronics manufacturing.

Applications of Vacuum Pumps Across Industries

Vacuum pumps, whether Dry Vacuum Pumps or Oil Sealed Vacuum Pumps, are utilized across a broad spectrum of industries. Some of the most common applications include:

Chemical and Pharmaceutical Industry: Vacuum pumps are used for solvent recovery, drying processes, and distillation procedures.

Food and Beverage Industry: Used in vacuum packaging and freeze-drying to preserve food quality.

Semiconductor Industry: For creating ultra-clean conditions during the manufacturing of microchips and electronics.

Medical and Laboratory Applications: Providing controlled environments for equipment and experiments.

Manufacturing and Processing: For vacuum forming, degassing, and other processes requiring low-pressure conditions.

Benefits of Vacuum Pumps

The use of vacuum pumps offers several benefits, such as:

Increased Efficiency: Vacuum pumps allow processes to be completed more efficiently by removing gases or liquids, optimizing workflow.

Enhanced Quality Control: In industries like food processing and pharmaceuticals, vacuum pumps help maintain quality by providing cleaner, controlled environments.

Reduced Contamination: In sensitive environments, Dry Vacuum Pumps provide a contamination-free solution that avoids the risks of oil and residue buildup.

Higher Production Rates: The consistent and reliable operation of vacuum pumps enables continuous production without interruptions, boosting overall productivity.

Maintenance and Care for Vacuum Pumps

While vacuum pumps are designed to be durable and reliable, regular maintenance is essential to ensure their longevity and optimal performance. Oil Sealed Vacuum Pumps require oil changes, checking for leaks, and cleaning to avoid clogs or other operational issues. Similarly, Dry Vacuum Pumps should be checked for wear and tear, and filters should be cleaned or replaced periodically.

Proper maintenance helps avoid downtime, reduces repair costs, and ensures the pump operates at its peak efficiency, benefiting the overall productivity of the process or operation.

Conclusion

In conclusion, understanding the various types of vacuum pumps—Dry Vacuum Pump, Rotary Vane Vacuum Pump, Rotary Vane Pump, Single Stage Oil Sealed Vane Pump, and Oil Sealed Vacuum Pump—is crucial for selecting the right equipment for your specific application. Whether you need a dry, oil-free solution or a more powerful, oil-sealed option, each pump type offers distinct advantages suited to different industrial needs.

By considering the level of vacuum required, maintenance needs, and the potential risks associated with each type of pump, you can ensure the best performance for your operation.

#Dry Vacuum Pump#Rotary Vane Vacuum pump#Rotary Vane Pump#Single Stage Oil Sealed Vane Pump#oil sealed vacuum pump

0 notes

Text

Looking for high-quality rotary vane vacuum pumps in Kansas and Missouri? Whether for industrial, medical, or manufacturing applications, reliable vacuum pump solutions are essential for efficiency and performance. EDCO USA® in Fenton, Missouri, is a leading manufacturer providing top-tier rotary vane vacuum pumps to businesses across the region. Additionally, Air Compressor Supply, Inc. serves Kansas with premium vacuum and air compression systems, ensuring high performance and durabilit

0 notes

Text

Flowell Technologies – Industry Leaders in Liquid Ring and Rotary Vane Vacuum Pumps

Flowell Technologies has built a reputation for delivering industry-leading vacuum pump solutions, catering to the diverse needs of businesses worldwide. With a focus on advanced technology and precision engineering, Flowell Technologies stands out as a trusted partner in vacuum pump manufacturing. Their dedication to innovation and the highest quality standards ensures every product meets rigorous performance benchmarks.

Whether for industrial applications, laboratory needs, or specialized usage, Flowell Technologies offers a comprehensive line up tailored to your requirements. Their vacuum pumps are designed for durability, efficiency, and reliability, making them an invaluable addition to any operation. When it comes to finding dependable vacuum pump manufacturers, Flowell Technologies provides the expertise and product range you can trust.

Simplify Operations with Flowell’s Proven Vacuum Pump Technology and Expertise

Their innovative approach extends to being one of the leading liquid ring vacuum pump manufacturers, offering solutions that efficiently handle wet or volatile gases with ease. Flowell Technologies ensures these pumps deliver optimal performance across various industries where robust functionality is essential.

Furthermore, Flowell Technologies excels as top-notch rotary vane pump manufacturers. These pumps offer consistent, oil-sealed vacuum performance, making them a critical choice for applications such as refrigeration, medical devices, and more. Their expertise also shines as single stage vacuum pump manufacturers, delivering simple yet effective solutions for consistent vacuum levels in industrial processes.

Choosing Flowell Technologies means partnering with a company that prioritizes customer satisfaction, offering not just products but also unparalleled support and expertise. With their innovative vacuum technology and wide-ranging solutions, you can ensure your business operates seamlessly and efficiently. Experience the Flowell advantage today and elevate your operations with their trusted vacuum pumps!

#single stage vacuum pump manufacturers#rotary vane pump manufacturers#liquid ring vacuum pump manufacturers#vacuum pump manufacturers

0 notes

Text

The Versatile Role of Double Vane Hydraulic Pumps

The V Series 7.5-45mL/r 14.8kg 20V Low Noise High Pressure Hydraulic Vane Pump is a product manufactured by our professional vane pump specialists. This pump has several advantages and applications that make it stand out from its competitors.

0 notes

Text

Yuken Vane Pump PVR 1T

HYDRANK'S HVP 10 pump is the best choice when replacing YUKEN'S PVR 1T pump. HYDRANK HVP 10 pumps comes with 12 vanes and can give you a pressure of 210 BAR Yuken Vane Pump PVR 1T

Specifications:Yuken Vane Pump PVR 1T

Product Name: YUKEN REPLACEMENT VANE PUMP PVR 1T Maximum pressure: 210 BAR Maximum speed: 1800 RPM

0 notes

Text

Why Eject System is India’s Go-To Manufacturer for Vacuum Pumps and Chillers

Efficiency, reliability, and innovation are the hallmarks of high-quality industrial equipment. Eject System, a leading name in the industry, specializes in offering cutting-edge vacuum pumps and chillers that enhance operational performance across diverse industrial applications. With a commitment to quality and customer satisfaction, Eject System delivers robust, efficient, and tailor-made solutions to suit the exact needs of its clients.

What sets Eject System apart is their dedication to precision engineering and the use of advanced technology. Every product is crafted to ensure durability and high performance, catering to industries that demand consistent and reliable results. Their expertise and customer-focused approach allow businesses to maximize efficiency and minimize downtime, ensuring smooth operations.

Trusted Liquid Ring Vacuum Pumps by Eject System for Demanding Applications

Recognized as a trusted industrial vacuum pump manufacturer, Eject System provides unparalleled solutions built for demanding environments. Their focus on innovation and high standards has cemented their position as one of the reliable rotary vane vacuum pump manufacturers in India, paving the way for performance-driven systems.

Eject System further strengthens its portfolio as one of the reputed liquid ring vacuum pump suppliers, delivering durable and efficient pumps for various industrial requirements. Additionally, their reputation as premier water chiller manufacturers in India underscores their commitment to excellence, offering energy-efficient cooling systems designed to meet the needs of modern industries.

Choosing Eject System means aligning with a partner that prioritizes your success. With a wide range of high-quality products, superior customer support, and a legacy of excellence, Eject System is the logical choice for businesses seeking reliable and innovative industrial solutions. Trust Eject System to empower your industry with precision and efficiency.

#water chiller manufacturers in India#liquid ring vacuum pump suppliers#rotary vane vacuum pump manufacturers in India#industrial vacuum pump manufacturer

0 notes

Text

Rotary Vane Vacuum Pump

Falcon Vacuum Pumps & Systems offers high-performance rotary vane vacuum pumps designed for efficient and reliable operation across various industrial sectors. Our pumps are built with advanced technology to provide consistent vacuum levels, low maintenance, and long-lasting durability. Ideal for applications requiring precision, Falcon’s rotary vane pumps deliver unmatched reliability and performance.

0 notes

Text

The Best Corken Compressors for Your Needs

In industrial settings, compressors are vital components that drive various processes forward. They are essential for tasks like air compression, gas handling, and refrigeration, playing a role in improving efficiency and productivity. This article will discuss the kinds of compressors, their uses, and important factors to consider when choosing the right compressor for your specific requirements. We'll cover topics such as unloading compressors, ammonia compressors, LPG compressors, and CORKEN compressors to give you an understanding of how they work and where they can be applied.

#Ammonia Compressor#CORKEN Compressor#LPG Compressor#LPG Transfer#unloading compressor#Vane Pump#Pump and Valves#IDEX India

0 notes

Text

Best Vacuum system and packages Manufacturer & Supplier in Delhi

Swam offers complete turnkey vacuum system packages with very high vacuums.

The system consists of backup pump with vacuum boosters, condensers, gauges,switches, starter panels etc. Thus Swam ready to provide optional total package

solution and will deliver package solution and will deliver package performance as per client requirements.

#condencer exhausters#truck blowers#air blower exporter#vacuum pump manufacturer#bio gas blowers#Turbo Blower#bio gas compressors#Roots blower#best process gas blowers#Twin lobe blowers#Aeration blowers#Combustion air blowers#Vane pumps#tri lobe rotary piston#Vacuum system and packages

0 notes

Text

#Helium Leak Detector#Helium Leak Testing Machine#Helium Recovery System#Rotary Vane Vacuum pump#Vacuum Furnace

0 notes

Text

High-Performance Carbon Vanes for Industrial Applications | Advance Carbon

Explore high-quality carbon vanes from Advance Carbon, designed for industrial applications like pumps and compressors. Our carbon vanes are crafted from durable, high-performance materials, ensuring superior wear resistance, longer operational life, and efficiency in demanding environments. Learn more about how our carbon vanes can improve the performance of your equipment and machinery. Link to Product Page

1 note

·

View note

Text

Rotary Vane Pump – Efficient & Reliable Vacuum Solution | Tekman

Tekman’s Rotary Vane Pump delivers high efficiency, durability, and consistent performance. Ideal for various industrial vacuum applications.

0 notes