#U Bolts Manufacturer

Explore tagged Tumblr posts

Text

Bolt protection caps prevent moisture, dust, and debris from causing corrosion or short circuits, ensuring the longevity and reliability of electronic components.

0 notes

Text

Best U Bolt Manufacturing Company in India – IntelloTech

IntelloTech is the Leading U Bolt Manufacturing Company in India, offering high-quality, durable U bolts for various applications. Contact us today!

#U Bolt Manufacturers Delhi#U Bolt Manufacturing Company in India#U Bolt Manufacturing Company near Me#U Bolt Company in India

2 notes

·

View notes

Text

The Top Reasons to Choose Ananka Group for High-Quality U Bolts

If you're looking for high-quality and reliable U Bolts, Ananka Group is one of the top U Bolts manufacturers in India. With decades of experience as well as cutting-edge technology and a dedication to excellence, Ananka Group ensures that its U Bolts meet the highest industry standards, providing robust and well-engineered solutions for a variety of uses.

What Are U Bolts?

U Bolts are fasteners with a specialization designed to look like letters like "U." Their unique design makes them able to fix poles, pipes as well as any other cylindrical items to a variety of frames or surfaces. They are used extensively in plumbing, construction automotive, marine, and construction applications because of their flexibility and long-lasting nature.

It is the U Bolt is a key component in a wide range of industries where a strong, durable fastening is needed. The curved design provides great strength and support, which makes them a crucial tool for many industries.

An Overview of U Bolts Specifications

In the Ananka Group, U Bolts are manufactured in many dimensions and specifications that satisfy the needs of various industries. Here are a few most commonly used specifications:

Size Variation The U Bolts made by Ananka Group are available in various sizes, from large to small diameters. This means that customers will get the best fit to their specific needs.

Thread types U Bolts are available in a variety of thread types, such as metric and imperial to satisfy the particular requirements of different industries and markets.

Optional Coatings: Ananka Group offers U Bolts with different types of coatings like zinc-plated, galvanized, or stainless steel for enhancing the durability and resistance to corrosion particularly in extreme environments.

Materials & Grades of U Bolts

The strength and endurance that comes from U Bolts are heavily dependent on the type of material employed. Ananka Group manufactures U Bolts with high-quality components, making sure U Bolts that are durable robust, durable, and immune to wear and corrosion. Here are the most frequently utilized materials used for U Bolts:

Carbon Steel: U Bolts made of carbon steel is well known for its strength and durability. They are ideal for use for applications that require high tension force.

The Stainless Steel U Bolts provide excellent resistance to corrosion and are ideal for outdoor and marine applications in which exposure to moisture and chemicals is very high.

Alloy Steel: Alloy steel U Bolts are superior for high-temperature applications. They provide strength and durability in extreme conditions.

Galvanized Steel Galvanized U Bolts are coated with a coating of zinc to stop rust from forming and make them ideal to be used in damp or harsh environments.

Ananka Group offers U Bolts in various grades to satisfy the particular demands for strength and durability of different industries. The grades are:

Grade 4.6

Grade 8.8

Grade A2-70 (stainless steel)

Grade A4-80 (stainless steel)

Applications of U Bolts

U Bolts are commonly employed in industries where high-end fastening is needed. Here are a few typical applications:

Piping Systems: U Bolts are used to keep pipes in place securely to stop them from bouncing or vibrating.

Automotive Industry: U Bolts are used in automobiles for securing leaf springs onto the axles. They provide stability and security.

Construction U Bolts are used in construction structures to hold poles, beams and other building substances.

Marine Industry: Due to their resistance against corrosion stainless steel U Bolts are utilized in vessels, boats and various marine structures.

Why Choose Ananka Group as Your U Bolt Manufacturer?

Finding the top U Bolt manufacturer is crucial to ensure the quality and durability of the bolts used to complete your job. Here are some reasons to consider why Ananka Group is the most suitable choice

Highest Quality: Ananka Group uses only the finest raw materials and imposes strict quality control procedures throughout the manufacturing process to ensure that every U Bolt meets international standards.

custom manufacturing If you require traditional U Bolts or customized solutions, Ananka Group offers flexible manufacturing options to meet your needs.

Price Competitive By using the latest manufacturing techniques, Ananka Group offers high-quality U Bolts at competitive prices without compromising quality.

Speedy Delivery With a solid distribution channel, Ananka Group ensures timely delivery of U Bolts across India and internationally.

expert support with a team of highly skilled professionals, Ananka Group offers excellent customer service, assisting customers to choose the appropriate U Bolts for their applications.

Conclusion

If you are in need of sturdy and reliable U Bolts to suit any purpose you can count on Ananka Group to supply. Being one of the most renowned U Bolts producers in India They offer the widest selection of high-quality U Bolts with different dimensions and materials to meet the various requirements of different industries. No matter if you're in construction or marine or automotive, Ananka Group has the experience and capability to supply you with the highest quality U Bolts in the market.

For more details about Our U Bolts and to place your order, please visit our Ananka Group website today!

When it comes to protecting your projects with stability and strength, selecting the best hardware is essential. Join Ananka Group, where quality meets technology within the realm of U bolts! No matter if you're in construction or manufacturing, or automotive choosing durable and reliable fasteners can make a huge difference. FAQ

What industries benefit from using U Bolts from Ananka Group?

Ananka Group’s U bolts are used in a variety of industries, including construction, automotive, agriculture, and manufacturing. Their high-quality U bolts provide the strength and durability needed for critical applications across these sectors.

What customization options are available for U Bolts?

Ananka Group offers a range of customization options, including different sizes, materials (like stainless steel, carbon steel, galvanized steel), and coatings. They also provide tailored solutions for specific project needs, ensuring that the U bolts meet your exact requirements.

How does Ananka Group ensure the quality of their U Bolts?

Ananka Group follows strict adherence to international quality standards throughout their production process. They use advanced technology for precision manufacturing and conduct thorough testing to ensure every U bolt meets rigorous specifications.

Are Ananka Group’s U Bolts suitable for outdoor or marine applications?

Yes, Ananka Group offers stainless steel and galvanized U bolts that provide excellent corrosion resistance, making them ideal for outdoor and marine environments where exposure to moisture and harsh conditions is common.

How competitive are the prices for U Bolts at Ananka Group?

Ananka Group offers competitive pricing for their high-quality U bolts. Despite their commitment to superior manufacturing and customization, they ensure affordability, making them an excellent choice for businesses operating within tight budgets.

How quickly can I expect my order of U Bolts to be delivered?

Ananka Group prioritizes timely delivery. Thanks to their efficient production processes and dedicated logistics team, they ensure that your U bolts are delivered as per schedule, helping you meet your project timelines without delays.

0 notes

Text

Leading U Bolts Manufacturer in Saudi Arabia - AOBSCO's Quality Solutions

AOBSCO is a renowned U Bolts Manufacturer in Saudi Arabia, recognized for delivering high-quality fastening solutions to meet the diverse needs of various industries. With years of expertise in manufacturing and a commitment to excellence, AOBSCO has become a trusted name in the market, ensuring that every product meets the highest standards of durability and performance.

Why Choose AOBSCO as Your U Bolts Manufacturer in Saudi Arabia?

When it comes to industrial applications, choosing the right U Bolts Manufacturer in Saudi Arabia is crucial. AOBSCO stands out for several reasons:

Quality Materials: At AOBSCO, we use only the best materials in our manufacturing process, ensuring that our U Bolts are not only strong but also resistant to corrosion and wear. This makes them ideal for use in harsh environments, where reliability is a must.

Custom Manufacturing: We understand that each project has unique requirements. That’s why AOBSCO offers custom manufacturing solutions. Whether you need specific dimensions or special coatings, our team can deliver U Bolts tailored to your exact specifications.

Advanced Technology: As a leading U Bolts Manufacturer in Saudi Arabia, AOBSCO employs state-of-the-art technology in our production processes. This ensures precision and consistency across all our products, guaranteeing that you receive U Bolts that fit perfectly and perform reliably.

Experienced Team: Our team of experts brings decades of experience to the table, providing not only top-notch manufacturing but also valuable insights and advice. Whether you’re working on a large-scale construction project or a small repair, our team can guide you in selecting the right U Bolts for the job.

Applications of U Bolts Manufactured by AOBSCO

AOBSCO’s U Bolts are used across a wide range of industries, including:

Construction: From securing pipes and tubes to holding heavy structures in place, our U Bolts provide the strength and durability needed for construction applications.

Automotive: Our U Bolts are essential in the automotive industry for securing exhaust systems, suspensions, and other critical components.

Marine: In the marine industry, corrosion resistance is key. AOBSCO’s U Bolts are designed to withstand the harsh conditions of saltwater environments, making them ideal for use in ships and offshore structures.

Electrical: For securing conduits and cables, AOBSCO’s U Bolts provide a reliable solution that ensures safety and longevity.

Commitment to Customer Satisfaction

At AOBSCO, we are more than just a U Bolts Manufacturer in Saudi Arabia. We are your partner in ensuring the success of your projects. Our commitment to customer satisfaction is evident in every aspect of our business, from the quality of our products to the responsiveness of our customer service. We work closely with our clients to understand their needs and deliver solutions that exceed their expectations.

Contact AOBSCO Today

If you’re looking for a reliable U Bolts Manufacturer in Saudi Arabia, look no further than AOBSCO. With our extensive experience, high-quality products, and dedication to customer service, we are confident that we can meet all your fastening needs. Contact us today to learn more about our products and services or to request a quote for your next project.

1 note

·

View note

Text

#Duplex Stainless Steel Stud Bolts#2205 duplex stainless fasteners and U Bolts Exporter#Duplex Steel UNS S31803 & UNS S32205 Nuts Manufacturers#Duplex Steel UNS S31803 & UNS S32205 Nuts Suppliers.

0 notes

Text

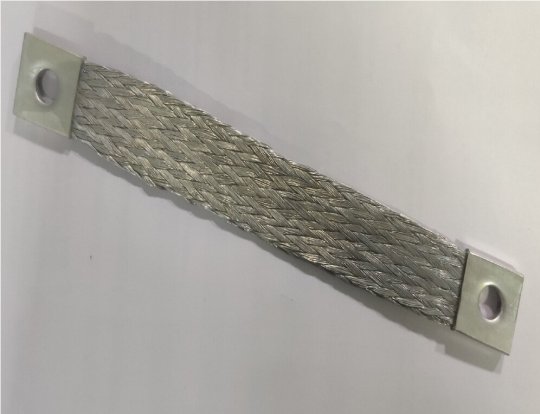

Tinned Copper Flexible Braided Connectors & Manufacturer

Terowell manufactures, exports and supplies Flexible Flat Copper Braid Bond made of numerous copper wires are likewise now and again utilized for adaptable electrical associations between large components. The various littler wires involving the twist are a great deal more impervious to breaking under repeated motion and vibration than is a cable of larger wires.

#Gunmetal Clamps manufacturer#solid copper earth rod manufacturer#Copper Bonded Earth Rod manufacturer in mumbai#u bolt clamp suppliers in mumbai#PVC Covered Copper Tape

1 note

·

View note

Text

DC Engineering is leading Manufacture and Exporter of High quality of Nickel 200 Fasteners, UNS N02200 Fasteners, Alloy 200 Fasteners

#Nickel 200 Fasteners#High Nickel Alloy 200 Fastener Manufacturer#Nickel Alloy 200 Heavy Hex Nuts#Nickel 200 Hex Head Bolt#UNS N02200 Fastener#DIN 2.4066 Fasteners Supplier#Nickel 200 Spring Washer#Alloy 200 Socket Cap Screws#Nickel Alloy 200 U-bolts#Nickel Alloy 200 Hex Cap Screws#200 Nickel Alloy Hex Bolts

0 notes

Text

U Bolt Manufacturers in India | KGRK Enterprises

KGRK Enterprises is a prominent U Bolt manufacturer in India. They specialize in producing high-quality U Bolts that are widely used in various industries for fastening applications. With a strong commitment to excellence, KGRK Enterprises ensures their U Bolts meet stringent quality standards and provide reliable performance and durability.

#U Bolt Manufacturers in India#Concrete Grinding Machine Manufacturer in India#Vibratory Roller Compactor Manufacturer in India

0 notes

Text

Automotive U Bolts - KGRK Enterprises

KGRK Enterprises provides supreme quality automotive products at wholesale prices. Our automotive u bolts are made from high-grade Aluminum, Bronzes, and Iron materials and are widely demanded in the automobile industry.

0 notes

Text

His first thought, on laying eyes on his new assistant, was God, but he’s young. He quickly revised his judgement; after all, people could and did look younger than their years. But still. In his line of work, it was rare to encounter someone quite so – fresh-faced. “Marty, this is Doctor B,” said Strickland, motioning at him. “He’s the head of your department. Doctor, this is your new assistant, Marty M.” They were standing in the hallway outside Manufacturing and Development. It was a little after ten thirty in the morning. Marty M was flanked by Strickland on one side and a security guard on the other; he had on a wide-eyed, dumbstruck look that Emmett recognised vaguely from his previous, rare encounters with new hires. Clearing his throat, he stepped forward and offered up a friendly handshake. “Good morning,” he said. “I’m Doctor B. It’s a pleasure to meet you.” The kid – it was difficult not to think of him as a kid – had his arms folded across his chest. He made no move to return the handshake. He looked at Emmett’s outstretched hand. His eyes went to his face; they tracked, slowly, up and down his body, taking all of him in. Then he turned and bolted like a frightened animal. “Oh, my,” said Emmett, as he vanished around the corner with a squeak of shoes on hard floor. The security guard was laughing. “Mr Murphy!” barked Strickland. “On it,” said the security guard. “I’ll get him – don’t worry.” He jogged away in pursuit. For a long and uncomfortable moment Emmett stood in the doorway of M&D, trying not to meet Mr Strickland’s unfalteringly stern gaze. “Uh,” he said, looking somewhere in the direction of his left ear. “How’s the orientation going?” “He’s been trying to give us the slip all morning,” said Strickland. “Ah,” said Emmett. “I’ve had worse,” Strickland added. He did not elaborate. There was a yell, nearby; and the security guard rounded the corner, half-carrying, half-dragging Marty M, arms firmly around his waist. “Let me go!” the kid was yelling. “Let go – let go of me –” His feet fully left the ground, kicking out at the air, his hands grasping at nothing, and at the look on his face Emmett’s guts twisted. “Feistiest new hire we’ve had in a while, huh?” said the security guard.

hey guys!! big news!! after stalling at like 99% completion for many weeks, i finished this monster of a Back to the Future/Severance AU tonight!! i have titled it 'Welcome to the Panopticon'.

When will it be published?

as soon as i finish editing chapter 1

What if I like Back to the Future but haven't seen Severance?

i would recommend you watch Severance bcos it does slap, however, the majority of the relevant worldbuilding is recapped in the fic so u should be fine

What if I like Severance but haven't seen Back to the Future?

you will have 0 problems with this fic as it has fuck all to do with Back to the Future

What if I haven't seen either?

you can do whatever you want

Why would you combine those 2 things?

listen sometimes you're hyperfixated on a thing and then you watch a really good TV show and you are compelled to plug tab A into slot B even if it makes no sense. idk something something time travel?? alternate selves? idk Severance is just a really fun way to explore character dynamics

How long is it?

it will be my longest published fanfic to date at seven chapters & just shy of 90,000 words!!

Jesus fuck

yeah I know :( read my fic anyway it took me 8 months to write and im very proud

44 notes

·

View notes

Note

hi! i was wondering, why are some cars faster than others? what makes red bull different from other teams when they're all subject to the same reg changes? is it just due to their resources or a lack thereof?

hello! i will try to answer this the best that i can with my limited tech knowledge and vocabulary <3

tldr; basically, yes, there is a difference between the teams' performance cause by the variation in the amounts of money, sponsors and overall resources. but as certain teams have showed time n time again (eh-em scuderia ferrari), it's not just about having money but what you do with it; largely when it comes to aero development and the wiggle room the regs give

first things first, while the regs are same for all teams, the way the regs are interpreted by the teams differ largely. everything from the floor to the wings to the nuts and bolts can be customised by the teams. Some choices work in their favour, others not so much.

something to remember is that, while building a f1 car, you're always choosing to sacrifice one thing or another. for example, during the merc domination era, their cars were rarely ever following another due to always qualifying in the top 2. that's how they designed their car then; to lead, not to follow. which means that when they did have to follow another their car, their aerodynamics struggled and the car got much harder to drive. but that's a risk they chose to take because they knew that their car had good qualifying pace.

the teams try to build a car that suits to all tracks; ones with mostly slow speed corners or fast speed corners or mid. long straights or not. all that jazz. the ideal car is one that can do well or at least relatively well in all of these tracks. but as last year showed, even the best developed cars (rip rb19 u will always be famous) will struggle on some tracks (singapore; marina bay circuit; heartbreaker). it is extremely hard to be able to build a car that's always in the top 2, and often, it requires other teams massively fucking up their interpretation of the regs and the parts and features they believe makes for a fast f1 car.

a BIG part of setting up and building a car is having drivers that can give you feedback on how the cars act and react on the track. the simulators are great and helpful but they cannot be compared to the feeling of being in the actual car, going 300 miles an hour and feeling it in your bones. time and time again, it's been seen that teams who have ignored their drivers' suggestions on what to change about the car (lewis @ merc since the last two years) have suffered a decline in the quality of their machines.

all of this comes down to the development of the car and the people involved in developing said car. of course the resources matter but the development philosophy (especially when it comes to what they do with their aero package) often plays the biggest part.

but to come to the resources part,

sponsorships, the finishing position in the wcc; the price money that comes along with it, and whether the team is backed by an engine manufacturer/major brand does give that monetary boost that leads to massive differences in lap time on track. for one, it influences the people you can hire; right from the drivers to the strategists and aerodynamicists. talent comes with a massive price tag in f1.

with teams with lesser sponsors (for eg, haas), there also comes the limitation of not being able to afford extra, spare engines or front/rear wings which can then limit and lead to a drop in the car's performance. while rbr can afford to switch out their PU if it's not giving them peek performance, williams or haas cannot do that simply because of not having enough money to be able to buy another engine from the manufacturer.

f1 is trying to decrease the difference between the teams' performance based on access to resources with adding a cost cap and giving more aero development time to the teams that finish lower in the constructors championship. but so far, it doesn't seem to have made too much of a difference to the finishing order. although, the gaps between the teams in terms of lap times has come down significantly.

i have to mention (thank u @epylonia for reminding me of this) that merc has definitely struggled since the cost cap was put in place. do with that what u will <3

also, i cannot write an essay without bringing up adrian newey. there have been talks of him retiring since 2016 but rbr has kept a deathgrip on him and paid a good amount (10 milli dollars/year) to do so. that man is a genius and rbr is fucking lucky to be able to have him/afford him.

#on f1 regs#ask#i hope this made sense??#thank u for trusting me to be able to answer this for u anon#im sorry it took so long#i was worried i would say something wrong and/or not explain it properly#and ppl would come for my throat#that being said#if i have missed out on anything#or misunderstood something#pls tell me#i am always open to learning#just be nice about it so we can make out after#jk#or am i#im going insane goodbye

23 notes

·

View notes

Text

What are the key functions of U bolts in fastening solutions?

U bolts secure pipes, tubes, and cables, ensuring structure stability. They also hold components together in automotive, construction, and machinery applications. Read More @ https://bit.ly/4bOO5xe

0 notes

Text

U Bolt Manufacturing Company in India – IntelloTech

IntelloTech is the best U Bolt Manufacturing Company in India. We specialize in producing durable U bolts for various industries. Contact us today!

#U bolt manufacturing company in India#U bolt manufacturers Delhi#U bolt manufacturing company near me

1 note

·

View note

Text

Promoda Verse

■Inquiries/Desmond Co., Ltd. 082-927-3811

Shiny face with fin design

The sedan monowheel that is becoming popular all over the country

Make it yours as soon as possible

The current big sedan boom is thought to have started in Daikoku, Yokohama, and Nanko, Osaka. Of course, there were many other users working hard, but Daikoku and Nanko, where sedans spontaneously gathered, are considered to be the epicenter of the sedan boom.

As more and more sedans gather together, it's natural that a poorly dressed car won't stand out. Therefore, they tried to make the car stand out by making the aerodynamics bigger and bigger and lowering the vehicle height, but there are limits to that. Therefore, American dress-up, and modern shiny wheels, such as plating, sputtering, and super metal coating, which were used in low-rider cars, were set on sedans in an attempt to attract the attention of the gallery. This was the beginning of wheel popularity.

However, no matter how hard you try, it is impossible to match high-tech American wheels like the wing design. Wheel manufacturers were also well aware of this and were trying to secure users by making the sedan wheels they had released so far shine. However, this wheel The “Verse” is one step further than that. It is a wheel dedicated to shining objects, assuming that it will be a shining thing from the beginning of development.

The base design is a classical American wire spoke wheel. Of course, even if we bring that into the present age, we will end up wondering what the heck is going on. For this reason, this Verse has fine fin spokes and a part of the center connected to them folded back in a U shape, giving it a wire-like atmosphere despite the fin design. The full-moon design of the center cap reflects the light evenly, creating a good contrast with the sharp reflections of the fine fins. There are two types of coloring: white polish and champagne gold, as shown in the photo. The polished finish that shines by polishing the aluminum shines more white than ordinary plating, so even if you put it on a voluminous sedan, you can feel a strong presence. If you set the optional gold piercing bolt, you can create an even more gorgeous American sedan-like look.

is the sense of everyone who wears it

It's number one.

A message from the manufacturer

It is a wheel that can be used as a complement to dress up.

The basic design itself is intended to be ordinary, not eccentric. From the very beginning of the development process, we wanted to emphasize brilliance, so we focused on the balance with brilliance rather than the uniqueness of the design itself. Basically, we thought that shiny wheels would match not only American tailoring, but also European dress-up, so rather than setting them on an overly elaborate aero car, we set them on a well-balanced car. Wouldn't it be cool to receive one? Of course, even if you set it on a full normal Y32/33 car, the design is simple, so I think it will work perfectly.

14 notes

·

View notes

Text

Alright, kids, my unhinged data gathering about EVs has culminated in a google sheet that is now, to the best of my knowledge, complete. I have looked at every active car manufacturer in the US, their EVs (if they have any), their plug-in hybrids (if they have any) (also, referred to as PHEVs), their base price, their max price (meaning, I went in to their build function and added all the shit to it I possibly could), their minimum range, maximum available range, and the type of vehicle. For PHEVs, this included electric-only range, total range, and MPGe (miles per gallon equivalent).

You can visit the Google sheet where this information lives here. Edit from June of 2024: the Google sheet is currently unavailable, sorry!

First of all: Why the hell did I do this?

Great question. I got passed on the road about a month ago by a pack of Lucid Air test drive vehicles. It was a rare instance of me not recognizing a vehicle--I literally work with them every day to make a living, and I consider myself to be pretty acquainted with the available auto manufacturers in the US. So, I looked them up, and it's a new EV brand, which might be a good thing vis a vis bringing more players to the market and all that jazz... but their base MSRP is fucking $87,000. I got so mad about the fact that manufacturers just keep bringing luxury EVs to the market and not like, consumer-level, reasonably priced EVs that I decided to compile this list of information to... well. To be fair I don't know what I was hoping to accomplish with this. At most, prove a point, I guess?

With that out of the way... what did we learn from this?

No more electric SUV options. Society has progressed past the need for more electric SUV options.

I compiled information on a grand total of 40 current EV models, 43 future EV models, 35 current PHEV models, and uh... 2 future PHEV models. Of those, 34 current EVs, 26 future EVs, 23 current PHEVs, and 1 of the future PHEVs were SUVs. That's 70%. Meanwhile, we have (in all four categories) 1 lone cargo van/work vehicle, 10 coupes, 8 pickup trucks, 1 hatchback, 1 minivan, 29 sedans, 3 wagons, and 1 microbus (VW ID. Buzz my beloved). And listen, don't get me wrong: SUVs are great. They're versatile (the U in SUV is for 'utility' after all!) and they're filling the niche that minivans once did, but damn, 70% of the market? Come ON guys. We're more interesting than that, I hope.

Are you not rich? Want an EV? Too bad.

The average base MSRP for an EV in the US right now is $65,556. Are you kidding me? The average base MSRP for the future EVs I found information on is $86,377. The PHEVs include some performance/ultra-luxury brands because of the fact electric motors provide a lot of torque and are desirable in some performance vehicles, so even taking those out, the average base MSRP of a PHEV is $63,442.

The superlatives

Current EVs

First, the good superlatives:

Lowest base MSRP & max price both go to the Chevy Bolt EV, ranging from $26,500 to $34,000. (sedan, range around 259 miles)

Highest range (unfortunately) goes to the Lucid Air, the vehicle that started me on this whole thing. The minimum range is 410 miles, which is the highest minimum range available. The maximum range is 516 miles, blowing the Tesla Model S extended range out of the water by 111 miles. (sedan, price ranges from $87,400 to $249,000).

Now, the bad superlatives

Highest base MSRP goes to the Audi RS e-tron GT, at a whopping $143,900. This beats our highest maximum price model's base MSRP by $2,700. (sedan, range around 232)

Highest maximum price goes to the Porsche Taycan Sport Turismo and Cross Turismo at $304,000. Fun fact: $30,000 of that maximum price is for custom paint. (wagon, range from 222-235 miles)

Lowest range goes to the Mazda MX-30 with a measly 100 miles of range. The next lowest range, the Ford E-Transit, a cargo van, gets 108! This vehicle is currently only available in California. (SUV, price ranges from $34,110 to $43,000)

Current PHEVs

Good superlatives

Highest electric only range goes to Land Rover, both the Range Rover and the Range Rover Sport, with 51 miles. (SUV, MPGe for both is 42, total range for both is 480, price for the Range Rover Sport ranges from $118,200 to $159,000, and price for the Range Rover Sport ranges from $142,575 tp $170,000).

Highest total range, best MPGe, AND lowest base MSRP goes to the Toyota Prius Prime, with 640 miles of total range and a whopping 133 MPGe. Its base MSRP is $32,350. (sedan, electric only range is 44 miles, maximum price is $50,000)

Lowest maximum price goes to the Kia Niro, which will only let you spend $44,000 on it. (SUV, base MSRP $33,840, electric only range 33 miles, total range 560, MPGe 108)

Bad superlatives (a lot of ties for this one, folks)

Worst total range: a tie between the BMW XM and the MINI Countryman, both at 300 miles. (BMW XM: SUV, 30 miles electric only range, 46 MPGe, costs between $159,00 and $186,000. MINI Countryman: Sedan, 17 miles electric only range, 73 MPGe, costs around $41,000)

Worst electric only range is a tie between the Ferrari 296 and Ferrari SF90, both at 15 miles. I have thoughts (derogatory) about these models, but I'll save them. (both coupes; both 330 miles total range; 296 gets 47 MPGe, SF90 gets 51 MPGe. Base MSRP for the 296 is $237,500. I'll get to the SF90 in a moment,)

Worst MPGe goes to the McLaren Artura at 39 MPGe. (Coupe, 330 total range, 19 miles electric only range, base MSRP $237,500)

The highest listed maximum price goes to the Porsche Panamera E-Hybrid, at $295,815. (Sedan, 19 miles electric-only range, 480 miles total range, 52 MPGe, base MSRP is $109,000.)

The highest base MSRP goes, once again, to the Ferrari SF90 at $524,815. Just reading that number hurts me.

Finally, a five-way tie for the most likely to have the highest actual maximum price, because they're cowards and don't put their pricing on their websites. These are the Ferrari SF90, the Ferrari 296, the Bentley Flying Spur, the Bentley Bentayga, and the McLaren Artura. (Bentley Flying Spur: Sedan, 26 miles electric-only range, 500 miles total range, 46 MPGe, base MSRP $217,525. Bentayga: SUV, 29 miles electric only range, 448 total range, 45 MPGe, base MSRP $200,025).

I'm not going to do any superlatives for future vehicles because I don't want to jump the gun on any judgements. Plus, with some of them the MSRPs are just like... educated guesses. Anyway, I have the whole google sheet here if you wanna poke around.

What conclusions can we draw from this?

I appreciate that the US wants to regulate new car sales sooner rather than later to encourage new EV sales in an attempt to be more environmentally friendly. However, until the average price for a new EV comes down significantly, more and more people are going to be in the used car market whether they want to be or not. Beyond that, we simply do not have the infrastructure for this. There are gas stations on damn near every corner, but the closest charging station to me is 2 miles away, and even that's a Tesla Supercharger, so it's only useful if you have a Tesla. The closest non-Tesla charger is 4 miles away. Sure, you can plug it in at home, but in order for that to be done at more than a snail's pace, you need to have it specially installed which is an additional cost that people may not be able to afford.

Additionally, it's interesting to me that being environmentally friendly is still such a huge privilege that's seemingly marketed towards wealthy people, yet huge corporations and the ultrawealthy people actually polluting our planet continue to offload the blame onto poor people for using single use plastics. It's a bizarre paradox.

In conclusion, car manufacturers need to get their shit together so more people can buy EVs at a price that isn't insane. Thank you goodbye

7 notes

·

View notes

Text

Inconel Alloy 718 Fasteners: Manufacturer, Supplier & Exporter

Introduction

Inconel Alloy 718 is a high-strength, corrosion-resistant nickel-chromium alloy that is well-suited for extreme environments, including high-temperature and high-pressure applications. Due to its superior properties, Inconel 718 is widely used in the aerospace, marine, and chemical processing industries. Fasteners made from this alloy exhibit excellent mechanical strength, outstanding oxidation resistance, and superior weldability.

Properties of Inconel 718 Fasteners

High Strength: Inconel 718 fasteners maintain their structural integrity at high temperatures.

Corrosion Resistance: Exceptional resistance to oxidation and corrosion in various harsh environments.

Excellent Weldability: Can be readily welded without cracking, which is rare for high-strength nickel alloys.

Creep and Stress Rupture Resistance: Ensures long service life in demanding conditions.

Cryogenic Suitability: Performs well even in extremely low temperatures.

Types of Inconel 718 Fasteners

Inconel 718 Bolts – Hex bolts, carriage bolts, eye bolts, U-bolts, etc.

Inconel 718 Nuts – Hex nuts, lock nuts, dome nuts, wing nuts, etc.

Inconel 718 Washers – Flat washers, spring washers, fender washers, etc.

Inconel 718 Screws – Machine screws, self-tapping screws, wood screws, etc.

Inconel 718 Studs – Full thread studs, double-ended studs, etc.

Applications of Inconel 718 Fasteners

Aerospace Industry: Used in jet engines, turbine blades, and exhaust ducts due to high-temperature resistance.

Marine Industry: Applied in naval vessels, offshore platforms, and seawater applications.

Power Generation: Utilized in nuclear reactors and gas turbines.

Chemical Processing: Resistant to corrosive chemicals, making it suitable for processing plants.

Automotive Industry: Used in turbochargers and exhaust systems.

Standard Specifications

ASTM B637 – Standard specification for Inconel 718 forged products.

AMS 5662, 5663, 5664 – Aerospace material specifications.

UNS N07718 – Unified numbering system designation.

Chemical Composition of Inconel 718

Nickel (Ni): 50-55%

Chromium (Cr): 17-21%

Iron (Fe): Balance

Niobium (Nb) + Tantalum (Ta): 4.75-5.5%

Molybdenum (Mo): 2.8-3.3%

Titanium (Ti): 0.65-1.15%

Cobalt (Co): ≤ 1.0%

Aluminum (Al): 0.2-0.8%

Carbon (C): ≤ 0.08%

Silicon (Si): ≤ 0.35%

Manganese (Mn): ≤ 0.35%

Sulfur (S): ≤ 0.015%

Mechanical Properties of Inconel 718

Tensile Strength: 135 ksi (931 MPa)

Yield Strength (0.2% offset): 70 ksi (482 MPa)

Elongation: 30%

Hardness: 30-40 HRC

Advantages of Inconel 718 Fasteners

Withstands high-pressure and high-temperature environments.

Excellent fatigue and creep resistance.

Resistant to pitting and crevice corrosion.

Long service life with minimal maintenance.

Why Choose Ananka Group for Inconel 718 Fasteners?

Ananka Group is a trusted manufacturer, supplier, and exporter of Inconel 718 Fasteners. We provide high-quality, precision-engineered fasteners that meet international standards. Our fasteners are available in various sizes, grades, and custom specifications to suit industry needs.

Key Benefits of Choosing Us:

High-Quality Materials: We use premium-grade raw materials for manufacturing.

Precision Engineering: Advanced machinery ensures accurate dimensions and performance.

Global Supply Network: We export to countries worldwide with timely delivery.

Competitive Pricing: Affordable rates without compromising on quality.

Conclusion

Inconel Alloy 718 Fasteners are ideal for applications requiring superior strength, corrosion resistance, and durability. Their ability to withstand extreme conditions makes them indispensable in aerospace, marine, and industrial applications. Choosing a reliable manufacturer like Ananka Group ensures you get the best quality fasteners that meet stringent industry standards.

FAQs

Q1: What makes Inconel 718 different from other Inconel grades?A1: Inconel 718 has excellent weldability and high strength, which sets it apart from other Inconel alloys like 625. It is precipitation-hardened, making it ideal for high-stress applications.

Q2: Can Inconel 718 fasteners be used in seawater applications?A2: Yes, they offer excellent resistance to seawater corrosion, making them suitable for marine and offshore environments.

Q3: Are Inconel 718 fasteners expensive?A3: While they are more costly than stainless steel fasteners, their durability, high performance, and corrosion resistance justify the investment.

Q4: Do you provide custom sizes for Inconel 718 fasteners?A4: Yes, Ananka Group offers customized fasteners in different sizes and specifications as per client requirements.

For premium-quality Inconel 718 Fasteners, contact Ananka Group today!

#Ananka#fasteners#Inconel#Inconelfasteners#Inconel718#fastenersmanufacturer#article#blog#Anankafasteners#manufacturer#supplier#mumbai#bolt#usa#tumblr#blog tumblr#articles

1 note

·

View note