#Stone crusher

Explore tagged Tumblr posts

Text

stone crusher

A comprehensive guide to choosing and buying a stone crusher As one of the most important and vital tools in various industries such as mining, construction, and processing industries, the stone crusher has a very fundamental and influential role. These machines are used in various aspects to crush hard and large materials into suitable dimensions for various uses, including processing and manufacturing. In the mining industry, the mining crusher is very vital as one of the basic tools for preparing minerals for subsequent processing steps such as grinding or separating materials.

0 notes

Text

Sand Making Plant For Sale in the USA

In recent years, the demand for high-quality sand, particularly for construction and industrial applications, has surged in the United States. As a result, the market for sand making plants—facilities designed to produce manufactured sand or crushed sand—has grown significantly. These plants are critical in meeting the demand for construction-grade sand, which is used in concrete production, asphalt mixing, and other key building materials. If you’re looking for a sand making plant for sale in the USA, this article will guide you through what to consider, the types of plants available, and the benefits of investing in such equipment.

Understanding Sand Making Plants

A sand making plant, also known as a sand production plant or artificial sand plant, is a facility that processes various raw materials, such as granite, basalt, limestone, and other stones, to produce high-quality sand. The primary function of these plants is to produce crushed or manufactured sand that mimics the properties of natural sand. These plants typically consist of multiple stages of processing, including crushing, screening, washing, and sometimes, drying.

The key equipment involved in a sand making plant includes:

Jaw Crusher: Used for the primary crushing of large rocks.

Impact Crusher or Cone Crusher: Secondary crusher that further break down materials.

Vibrating Screens: Used for sieving sand and separating different sizes.

Sand Washing Machines: To remove impurities like clay, dust, and silt.

Belt Conveyors: For material handling between different stages of the process.

Sand Making Machines (Vertical Shaft Impactors): These machines are specifically designed to create the final manufactured sand by crushing rocks into finer particles.

Types of Sand Making Plants Available in the USA

In the USA, there are various types of sand making plants available for sale, ranging from small-scale operations to large, industrial plants. The right choice depends on the specific needs of the buyer, including production capacity, the type of raw materials available, and the intended application of the sand.

1. Small-Scale Sand Making Plants

These plants are typically designed for smaller operations, often with a production capacity of less than 100 tons per hour. They are ideal for smaller construction companies or operations located in areas where natural sand deposits are scarce. The key advantage of small-scale plants is their lower initial investment and operational costs.

2. Medium-Scale Sand Making Plants

These are mid-sized operations with a production capacity ranging from 100 to 500 tons per hour. They are suited for medium-sized construction projects, such as road building, and can handle a broader range of raw materials. These plants often feature more sophisticated processing equipment for higher efficiency and finer sand output.

3. Large-Scale Sand Making Plants

These industrial-grade plants are capable of processing 500 tons or more per hour. Large-scale sand production plants are often used by major construction firms or mining operations. They include high-end machinery and are designed for continuous, high-volume production. These plants are typically automated and optimized for maximum efficiency and output.

Factors to Consider When Purchasing a Sand Making Plant in the USA

When looking for a sand making plant for sale, there are several factors to consider to ensure you get the best equipment for your needs:

1. Production Capacity

Determine how much sand you need to produce on a daily or monthly basis. Larger plants typically have higher upfront costs but can process more material over time. Smaller plants are more affordable but might not be able to meet the demand of large-scale projects.

2. Raw Material Availability

Ensure that the plant you purchase is capable of handling the type of raw materials available in your area. Some plants are better suited for hard rocks like granite or basalt, while others are designed for softer materials like limestone or sandstone.

3. Energy Efficiency

Energy consumption is a key factor in the operational costs of a sand making plant. Look for plants with energy-efficient equipment to reduce long-term operating costs. Modern machines often have improved technology that reduces power consumption while maintaining high performance.

4. Automation and Control Systems

Advanced plants come with automated systems for monitoring and controlling production processes. These systems improve efficiency, reduce the need for manual labor, and enhance the overall quality of the manufactured sand.

5. Maintenance and Support

Ensure that the supplier offers strong after-sales support, including maintenance services, spare parts availability, and operator training. A good maintenance plan is essential for reducing downtime and ensuring the plant runs smoothly.

6. Compliance and Regulations

Check local regulations regarding environmental and operational standards. Some sand making plants incorporate dust control systems and water recycling features to comply with environmental regulations.

Advantages of Investing in a Sand Making Plant

Investing in a sand making plant comes with several advantages, especially for companies involved in the construction and mining industries:

Sustainability: Manufactured sand is increasingly seen as a more sustainable alternative to natural sand. The production of artificial sand helps conserve natural resources, reduces environmental degradation, and mitigates the negative effects of sand mining on local ecosystems.

Customization: Sand making plants can be tailored to produce sand with specific properties, such as different grain sizes or grades, which can be important for particular applications (e.g., fine sand for concrete production).

Profitability: With the increasing demand for construction materials, a sand making plant offers significant profitability potential, especially in areas where natural sand is scarce or expensive.

Reduced Transportation Costs: By establishing a sand production facility closer to construction sites or urban areas, companies can reduce transportation costs associated with sourcing and delivering natural sand.

Conclusion

A sand making plant is an essential piece of equipment for companies involved in construction, concrete production, and other industries that rely on high-quality sand. If you’re considering purchasing a sand making plant for sale in the USA, it’s crucial to assess your needs carefully, from production capacity to raw material availability. With the right plant, you’ll be able to meet growing demand for manufactured sand, improve efficiency, and ensure long-term profitability. Whether you’re looking for a small-scale operation or a large industrial plant, investing in a sand making plant can give your business a competitive edge in the thriving construction market.

0 notes

Text

How Much Does It Cost to Invest? Situation Analysis

Investing in stone crushing equipment is a pivotal decision for businesses in construction, mining, and aggregate production. The costs involved can vary significantly depending on various factors, from the type of crusher to the size of the plant. This article will provide a detailed breakdown of the factors influencing the stone crusher price and the overall cost of establishing a crusher plant.

Understanding the Stone Crusher Price

1. Types of Stone Crushers

The type of stone crusher you choose plays a critical role in determining the price(chancadora de piedra precio). Different crushers are designed for specific applications:

Jaw Crushers: Known for their ability to handle large stones, jaw crushers are cost-effective for primary crushing but may not provide the fine output needed for some projects.

Cone Crushers: These are more expensive but offer precision in secondary and tertiary crushing stages.

Impact Crushers: While moderately priced, they are ideal for shaping materials and creating uniform output.

Mobile Crushers: Offering convenience and flexibility, these units are typically more expensive than their stationary counterparts.

2. Capacity and Output

The production capacity of the stone crusher significantly impacts its price. Crushers designed to process larger volumes of material or produce finer outputs are generally more expensive. For example, a crusher with a capacity of 200 tons per hour will cost more than one designed for 50 tons per hour.

3. Material and Build Quality

High-quality materials, such as wear-resistant steel and advanced engineering, contribute to the durability and efficiency of the crusher. While these features may increase the upfront cost, they reduce long-term maintenance expenses.

4. Brand Reputation

Well-established brands often charge higher prices due to their reliability, innovation, and strong after-sales support. AIMIX, for example, is renowned for its high-performance crushers that balance quality and affordability.

youtube

Cost Breakdown for Setting Up a Crusher Plant

1. Initial Investment

Setting up a crusher plant(planta chancadora) involves multiple components, each contributing to the overall cost:

Primary Equipment: Crushers, screens, feeders, and conveyors form the core of the plant. Depending on the scale of the operation, these can range from $100,000 to over $1 million.

Land Acquisition: The cost of land varies based on location and size, with rural areas generally being more affordable.

Construction and Installation: Building the necessary infrastructure and installing the equipment requires significant investment.

2. Operational Costs

Once operational, the crusher plant incurs ongoing expenses, including:

Energy Costs: Crushers are energy-intensive, making electricity or fuel a major recurring expense.

Labor Costs: Skilled operators and maintenance personnel are essential for smooth operations.

Spare Parts and Maintenance: Regular servicing and replacement of wear parts are necessary to maintain efficiency.

3. Compliance and Legal Costs

Operating a crusher plant requires permits and adherence to local environmental and safety regulations. Obtaining these can add to the initial investment.

4. Transportation and Logistics

The cost of transporting heavy equipment to the site and moving raw materials and finished products also contributes to the overall investment.

Analyzing the Market Situation

1. Growing Demand for Crushed Stone

The rising demand for crushed stone in construction, road building, and infrastructure projects is driving the market. This makes investing in a crusher plant a potentially lucrative opportunity.

2. Regional Market Variations

The cost of stone crushers and the demand for their output vary significantly across regions. Conducting a regional market analysis helps identify the most profitable locations for investment.

3. Advancements in Technology

Modern crusher plants are equipped with advanced features such as automation, energy efficiency, and real-time monitoring. These innovations can reduce operational costs and improve productivity, offsetting the higher initial investment.

Tips for a Successful Investment

1. Conduct Thorough Research

Compare the prices and features of stone crushers from various manufacturers. Look for models that meet your specific needs without overextending your budget.

2. Choose Reliable Manufacturers

Opt for manufacturers with a strong reputation for quality and service. AIMIX, for example, offers robust and efficient stone crushers, along with excellent after-sales support.

3. Plan for Future Growth

Select equipment that can handle increased production demands. This ensures that your investment remains viable as your business scales.

4. Consider Total Cost of Ownership

While the upfront cost is important, consider the long-term costs of energy, maintenance, and spare parts. A slightly higher initial investment in a durable, energy-efficient crusher can save money over time.

Conclusion

Investing in a stone crusher or crusher plant requires careful planning and analysis. Factors such as equipment type, capacity, material quality, and market conditions play a vital role in determining the overall cost. By understanding these elements and working with reliable manufacturers like AIMIX, businesses can maximize their return on investment.

Whether you are looking to expand your operations or enter the market, the growing demand for crushed stone offers promising opportunities. Take the time to research, plan, and choose wisely for a successful and profitable investment.

For expert advice and high-quality stone crushing equipment, contact AIMIX today!

#aimix#aimixgroup#construction#equipments#machinelearning#machinery#mining#crusher#stone crusher#Youtube

0 notes

Text

Picson, a renowned stone crusher manufacturer, has established its position as a major participant construction equipment industry. With an emphasis on quality and innovation, Picson provides a wide range of crushing solutions made to satisfy the various demands of its customers. Visit our website https://www.picsinternational.com/crusher for additional information.

0 notes

Text

25 stone crushers closed in Kathua over illegal mining

JAMMU — Authorities in Jammu and Kashmir’s Kathua district closed down 25 stone crushers, in a major crackdown against illegal mining activities and unauthorised processing of mined material, an official said on Sunday. The action against the stone crushers was initiated by Kathua Deputy Commissioner Rakesh Minhas after conducting physical verification and assessing the working of such units…

0 notes

Text

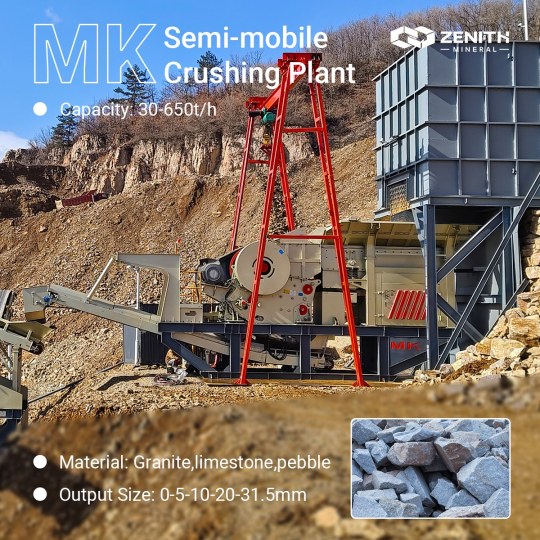

MK Semi-mobile Crusher and Screen

Material: Granite,limestone,pebble

Output Size: 0-5-10-20-31.5mm

Capacity:30-650 t/h

0 notes

Text

Artificial Sand Making Machines, VSI Crushers, Jaw And Cone Crushers

We are Manufacturer, Supplier, Exporter of Artificial Sand Making Machines, Jaw And Cone Crushers, Finopactor, Special VSI Crushers from India.

Artificial Sand, Artificial Sand Making, Artificial Sand Making Machine, Artificial Sand Making Machines, Sand Making, Sand Making Machine, Sand Making Machines, Crush Sand, Crushed Sand, Sand Crusher, Sand Crushers, Stone Crusher, Stone Crushers, Jaw Crusher, Jaw Crushers, Cone Crusher, Cone Crushers, Hammer Crusher, Hammer Crushers, Finopactor, Plaster Sand Making Machine, Plaster Sand Making Machines, Sand Washing Plant, Sand Washing Plants, Benefication Plant, Benefication Plants, Conveyors Silo, Conveyors Silos, Hoppers, Constructional Machine, Constructional Machines, Constructional Machine Accessories, Concrete Mixer, Concrete Mixers, Hand Driven Concrete Mixer, Hand Driven Concrete Mixers, Semi Automatic Concrete Mixer, Semi Automatic Concrete Mixers, Semi-Automatic Concrete Mixer, Semi-Automatic Concrete Mixers, Concrete Block Machine, Concrete Block Machines, Vibratory Screen, Vibrating Compactor, Vibrating Compactors, Autoramming Block Machine, Autoramming Block Machines, Auto Ramming Block Machine, Auto Ramming Block Machines, Hydraulic Block Laying Machine, Hydraulic Block Laying Machines, Block Machines For Different Profiles, Dust Separator, Dust Separators, Dust Seperating Unit, Dust Seperating Units, Dust Free Product, Dust Free Products, Road Roller, Road Rollers, Oil Cooling System, Oil Cooling Systems, Drier Drum, Host Winch, Builders Hoist, Builders Hoists, Tower Hoist, Tower Hoists, VSI Crusher, Special VSI Crusher, VS Rotopactor, Bajree Sand, Bajaree Sand, Bajari Sand, Bajri Sand, Mining Sand, Construction Machinery, Stone Processing Machinery, Stone Cutting Machinery, Stone Crushing Machinery, Road Building Machinery, Granite Sand, Manufacturer, Supplier, Exporter, Karnataka, Mysore, Gulbarga, Chitradurga, Kolar, Bijapur, Dakshina Kannada, Raichur, Bellary, Belgaum, Hassan, Dharwad, Bangalore Rural, Shimoga, Mandya, Chickmagalur, Bangalore Urban, Madikeri, Tumkur, Bidar, Karwar, Udupi, Davanagare, Chamrajnagar, Koppal, Haveri, Gadak, Yadgir, Andhra Pradesh, Nellore, Cuddapah, Karim Nagar, Kurnool, West Godavari, Srikakulam, Anantpur, Adilabad, Chittor, East Godavari, Guntur, Hyderabad Urban, Khammam, Krishna, Mehboobnagar, Medak, Nalgonda, Nizamabad, Prakasam, Ranga Reddy, Vishakapatnam, Vizianagaram, Warangal, Madhya Pradesh, Sindi, Vidisha, Jabalpur, Bhopal, Hoshangabad, Indore, Rewa, Satna, Shahdol, Chhindwara, Ratlam, Balaghat, Betul, Bhind, Mandla, Chhattarpur, Damoh, Datia, Dewas, Dhar, Guna, Gwalior, Jhabua, Sehore, Mandsaur, Narsinghpur, Panna, Raisen, Rajgarh, Sagar, Seoni, Morena, Shivpuri, Shajapur, Tikamgarh, Ujjain, Khandwa, Khargone, Dindori, Umaria, Badwani, Sheopur, Katni, Neemuch, Harda, Anooppur, Burhanpur, Ashoknagar, asia, asian, india, indian, mumbai, maharashtra, industrial, industries, thane, pune, nashik, aurangabad, ratnagiri, nagpur, ahmednagar, akola, amravati, chandrapur, dhule, jalgaon, raigad, sangli, satara, belgaum, kolhapur, belgaon.

#Artificial Sand#Artificial Sand Making#Artificial Sand Making Machine#Artificial Sand Making Machines#Sand Making#Sand Making Machine#Sand Making Machines#Crush Sand#Crushed Sand#Sand Crusher#Sand Crushers#Stone Crusher#Stone Crushers#Jaw Crusher#Jaw Crushers#Cone Crusher#Cone Crushers#Hammer Crusher#Hammer Crushers#Finopactor#Plaster Sand Making Machine#Plaster Sand Making Machines#Sand Washing Plant#Sand Washing Plants#Benefication Plant#Benefication Plants#Conveyors Silo#Conveyors Silos#Hoppers#Constructional Machine

0 notes

Text

Stone crusher

CraftsmenCrusher, a leading name in industrial machinery, proudly introduces its groundbreaking Stone Crusher, a pinnacle of innovation in the stone crushing sector. CraftsmenCrusher's Stone Crusher is meticulously engineered to meet the rigorous demands of the construction and mining industries. With its robust construction and cutting-edge technology, this crusher effortlessly pulverizes large stones into smaller, more manageable sizes, streamlining the production process and maximizing efficiency. CraftsmenCrusher's Stone Crusher is equipped with state-of-the-art features, including a powerful motor and precision-designed crushing chambers, ensuring consistent performance and reliable operation. Its user-friendly interface and durable components make maintenance hassle-free, reducing downtime and enhancing productivity. CraftsmenCrusher's dedication to excellence is evident in every aspect of the Stone Crusher's design and functionality, from its superior crushing capabilities to its energy-efficient operation. By offering this innovative solution, CraftsmenCrusher continues to redefine industry standards, providing customers with unparalleled quality, performance, and value in stone crushing equipment. With CraftsmenCrusher's Stone Crusher, customers can trust in a solution that not only meets but exceeds their expectations, driving success and profitability in their operations.

0 notes

Text

Stone Crushers: Where Innovation Meets Unyielding Strength

In the realm of construction, mining, and quarrying, the enduring roar of stone crushers reverberates, symbolizing a perfect fusion of innovation and unyielding strength. These mechanical marvels stand as testament to the evolution of crushing technology, transcending traditional boundaries and reshaping industries. In this article, we delve into the world of stone crushers, exploring the marriage of innovation and strength that defines these powerful machines.

The Symphony of Innovation

Stone crushers, once humble machines, have undergone a transformative journey propelled by innovation. The relentless pursuit of efficiency, safety, and environmental sustainability has driven engineers and manufacturers to infuse cutting-edge technology into these formidable crushers. Advanced control systems, automation, and material science have converged to create a symphony of innovation that enhances performance and reliability.

Unyielding Strength in Design

At the core of every type of stone crusher lies an unyielding strength, engineered to withstand the harshest conditions. From the robust frames to the durable components, these crushers are meticulously crafted to endure the rigors of heavy-duty crushing operations. The application of high-strength materials and precision engineering ensures that stone crushers stand tall in the face of challenging tasks, demonstrating a resilience that defines their character.

Breaking Boundaries with Efficiency

Innovation in stone crushers is not merely about incorporating new features but about achieving unprecedented levels of efficiency. Modern stone crushers boast impressive throughput capacities, reducing downtime and increasing productivity. Enhanced crushing chambers, adjustable settings, and intelligent monitoring systems contribute to a level of efficiency that was once considered unattainable.

Sustainability at the Core

As industries globally embrace sustainable practices, stone crushers have evolved to align with environmental consciousness. Innovative designs allow for greater energy efficiency, and some models even incorporate electric or hybrid technologies, minimizing the environmental impact. Stone crushers are not only crushers of rocks but also of environmental barriers, demonstrating that progress in crushing technology can be synonymous with responsible practices.

Versatility in Application

Stone crushers have expanded beyond their traditional roles, adapting to a multitude of applications. From primary crushing in quarries to secondary and tertiary crushing in various industries, these machines have become versatile workhorses. Their adaptability extends to crushing a diverse range of materials, from hard granite to soft limestone, showcasing the flexibility that modern stone crushers offer.

Meeting Challenges Head-On

The unyielding strength of stone crushers is most evident when faced with formidable challenges. Whether tasked with breaking colossal rocks or processing large volumes of materials, these machines tackle challenges head-on. Their ability to handle diverse materials and applications makes them indispensable in construction and mining operations, contributing to the realization of ambitious projects.

The Future Unveiled

As we gaze into the future, the marriage of innovation and unyielding strength in stone crushers promises even greater accomplishments. Emerging technologies such as artificial intelligence, machine learning, and advanced sensor systems are likely to further enhance efficiency and performance. The stone crusher industry is poised to play a pivotal role in the evolving landscape of construction, mining, and quarrying.

Conclusion

"Stone Crushers: Where Innovation Meets Unyielding Strength" is a narrative of progress, resilience, and the relentless pursuit of excellence. These machines, born of innovation and forged in unyielding strength, have become indispensable in shaping the modern world. As technology continues to advance, the symphony of innovation and strength in stone crushers will resonate even more powerfully, defining new standards and possibilities for the industries they serve. In the dynamic interplay between innovation and strength, stone crushers stand tall, breaking barriers and shaping the future of crushing.

0 notes

Text

Can the Stone Crushing Plant Promote Road Construction?

Road construction is essential for enhancing transportation effectiveness and promoting economic growth. To achieve this, it is imperative to use high-quality materials. Crushed stone is a fundamental material that serves as a foundation for robust and long-lasting roads. In this article, we will examine the advantages of stone crushing plants and their contribution to efficient road construction.

The Power of Stone Crusher Plants

A stone crushing facility, commonly referred to as a stone crushing plant, processes a variety of rocks into aggregates of varying sizes for road construction. These plants implement cutting-edge technology and advanced equipment to guarantee the production of top-quality materials.

One significant benefit of stone crushing plants is their proficiency in handling a diverse range of materials. Be it limestone, granite, or basalt, these plants can grind and convert rocks into accurately graded aggregates essential for constructing roads.

Furthermore, the stone crushing machines utilised in these facilities are engineered to function with minimal interruptions, guaranteeing non-stop production and uninterrupted supply of crushed stones. This dependability is crucial for fulfilling the arduous schedules of road construction projects.

The Role of Stone Crusher Plants in Road Construction

When it comes to road construction, stone crusher plants play an essential role. These plants contribute significantly to the success of road development projects in several ways.

1. Quality Aggregates:

Stone crushing plants manufacture top-quality aggregates that act as the foundation of robust and long-lasting roads. These aggregates deliver outstanding load-bearing capability, guaranteeing the longevity of the constructed thoroughfares.

2. Cost Efficiency:

Utilizing stone crusher plants for road construction offers cost advantages. By producing aggregates on-site, transportation costs are significantly reduced. Additionally, the availability of locally sourced materials lowers expenses associated with long-distance material procurement.

3. Environmental Sustainability:

Stone crushing plants make a valuable contribution to environmental sustainability by recycling and reusing construction waste. Breaking down demolished concrete, asphalt and other materials, these plants diminish landfill waste, championing a more eco-friendly approach to road construction.

The Installation Process: Simplified

The installation of stone crushing plants is an efficient process that minimizes disturbance to road building projects. These plants are designed for swift assembly and can be promptly installed in the designated area.

Typically, the installation process comprises site preparation, foundation construction, equipment assembly, and electrical connections. Manufacturers of stone crushing plants offer comprehensive guidance and support throughout the installation process, guaranteeing a seamless transition from construction to operation.

youtube

Conclusion

Stone crushing plants play a crucial role in driving efficient road construction. By generating top-notch aggregates, ensuring cost-effective operations and promoting environmental sustainability, these plants bring a plethora of advantages to road-building endeavors. The simplified installation process further adds to their attractiveness.

Whether your construction company is searching for dependable suppliers or your government entity is planning road infrastructure, evaluating a stone crusher plant for sale is a wise choice. Witness the benefits firsthand and observe the favourable impact these plants have on your road construction projects.

1 note

·

View note

Text

The First Stone Crushers Andrew Cram

The Lanark Era Lanark, Ontario, Canada • Wed, Jun 22, 1898Page 3 Lorne McNeely crushing rock in the Beckwith quarryOne of the largest crushers was a model produced by Taylor Engineering in 1919. It had a 60-inch (152-cm) receiving opening and remained in first place until Taylor produced the 72-inch (183-cm) gyratory crusher in 1969. It served as the world’s biggest and only machine at that…

View On WordPress

#andrew cram#andrew wilson cram#Carleton-Place#cram#genealogy#History#Lanark-County#ontario#quarry#roads#stone crusher

0 notes

Text

same picture

#catching up on the reaction posts I wanted to make#star trek#star trek tng#the next generation#jean luc picard#wesley crusher#the sword in the stone

194 notes

·

View notes

Note

💕

💕: What is an unpopular ship that you like?

As I mentioned last time when I did this ask meme, the only liked ship I can think of in the Sonic fandom that's actually popular is Sonaze, because I like their dynamic together in the Rush duology. There's also one-sided Staregg and Eggstone, but the way I see those is probably different from how most fans see them... y'know, like usual.

The rest though? Not the ones you normally see.

Tails/Amy? Always thought they could pick each other up.

Tails/Marine? A young pair of adventurers.

Knuckles/Amy? Despite both of them exhibiting a hotheaded side, I think they could really grow to understand each other (also Beevean indoctrinated me, so I guess that makes us even after I indoctrinated her with Sonic and Trudy lol).

Sonic/Rouge? I think Rouge's flirtatious nature bounces well off of Sonic's banter, and they're not all that different either when you look closer.

Knuckles/Ariem? I liked the connection they showed, and also it means I can keep calling Knuckles a sheep shagger.

Sonic/Tall Girls? As in, in general. Elise, Shahra, whoever, it's canon, we all know this.

Eggman/Being a Villain? Rarest one of the lot, you'll be hard-pressed to find this one.

As for non-Sonic ships, there aren't many that I'm too deep into the kool aid with. There are some that I do like, but the only one I can think of that I'm unwell over is, of course, Mario and Vivian, but that one thankfully is fairly popular, and is arguably moreso than ever since the TTYD remake came out. Ho ho ho.

#Crusher's Asks#Opinion#Sonic the Hedgehog#Miles Tails Prower#Amy Rose#Knuckles the Echidna#Rouge the Bat#Blaze the Cat#Princess Elise#Shahra the Ring Genie#Marine the Raccoon#Ariem the Sheep#Dr. Eggman#Agent Stone#Dr. Starline

10 notes

·

View notes

Text

Stone Crusher Manufacturer –Picson International

In the field of building and infrastructure development, Stone Crusher Manufacturer is important for the development of building foundations and environments. Leading this industry at the top is Picson International, a manufacturer dedicated to creating innovative designs that raise standards for stone crushing equipment.

A dedication to innovation and quality of Stone Crusher Manufacturer:-

Picson International is committed to provide its clients durable, high-performing equipment. Their constant dedication to excellence shows by their:

Use of premium materials: To guarantee that their crushers can handle even the most difficult jobs, they place a high priority on sturdy and dependable components.

Dedicated engineering: Their group of skilled engineers creates their crushers with maximum production and efficiency in mind.

Extensive testing: Every crusher is subjected to extensive testing to ensure it truly satisfies their exacting performance requirements.

Reliability and Quality of Stone Crusher Manufacturer in India:

Picson International is committed to providing excellent products. They make sure that their stone crushers are powerful, durable, and dependable by using premium-grade parts and advanced manufacturing methods. Even under the most critical conditions, the durable build and careful engineering of their devices provide durability.

Stone Crusher: - Technology and Innovation:

Picson International understands the need of being current of technical developments. They consistently allocate resources towards research and development in order improve their stone crushers and integrate modern facilities features. They make sure that their machines are effective, productive, and tailored to the specific needs of their clients by accepting technology.

Customer support:

Picson values client satisfaction, and they stand out for their commitment to provide outstanding client service. They have a group of skilled professionals on hand to help users with any questions or issues pertaining to their cone crushers. Picson places its clients' needs first, from installation assistance to after-sales support, promising an error-free and enjoyable experience every step of the way.

Why choose to Picson International?

Picson International divides out as a dependable and creative manufacturer of stone crusher equipment. Here are some strong arguments supporting the idea of choosing them:-

Unmatched experience: Having worked in the field for more than 30 years, they have a wealth of knowledge and experience.

Put reliability first: Their dedication to use high-quality components and thorough testing provides sustained performance.

Extensive product point: They provide a range of crushers to meet the needs of different applications.

Excellent customer service: Their commitment to follow-up support guarantees an easy client journey.

Look little more than Picson International if you're searching for a stone crusher manufacturer that puts a premium on quality, innovation, and client happiness. Visit their website at https://www.picsinternational.com/ for more about their equipment and how it can improve your crushing operations.

#Stone Crusher Manufacturer#Stone Crusher Manufacturer in India#Stone Crusher#Stone Crusher in India

0 notes

Text

Assets used for Skylanders Trap Team's Earth Skylanders Polaroids (skylanders.com, 2013/2014) (pt3)

#not art#skylanders#skylanders website#skylanders trap team#skylanders swap force#terrafin#crusher#doom stone#rubble rouser#head rush#wallop#terrabite#bop#polaroid icons

15 notes

·

View notes

Text

just had like the most peaceful run of my life in RA by destroying both mountain pass before day 6. no colossi no vein guardians i just need to prepare for the boss

#boss is 5 days away its day 10#maybe its time to peacefully mine stones and iron and wood#arknights#fire within the sand#i think i only fight like 3 raid. 2 dog raid 1 defense crusher raid#which is preferable than 48 vein guardians

3 notes

·

View notes