#Steel Tube Manufacturers in USA

Explore tagged Tumblr posts

Text

Steel Tube Manufacturers: Pioneering Sustainability in the Age of Industrial Progress

Piping Projects is one of the leading Steel Tube Manufacturers in USA. We manufacture and supply a wide range of steel tubes, including carbon, seamless and welded, with wall thicknesses up to 40 mm and OD ranges of 12.7 mm to 906 mm. We use different materials to manufacture steel tubes. Pipingprojects.us is a top Steel Tube Supplier in USA. We use premium quality raw materials which enhance the durability and performance of Steel Tube.

Various materials and grades such as Brass, copper, stainless steel 304/304L, 316L, duplex, titanium, alloy 600, alloy 400, alloy 625, alloy 825, and alloy C276 to manufacture Steel Tubes.

In a world where environmental concerns are at the forefront of global discussions, industries are under increasing pressure to innovate and embrace sustainable practices.

Steel Tube Manufacturers have stepped up to the challenge, playing a vital role in pioneering sustainability in the age of industrial progress. Let's explore how these manufacturers lead the way towards a greener future.

The Evolution of Steel Tube Manufacturing:

Steel tube manufacturing has come a long way from its traditional roots, with modern techniques and technologies revolutionizing the industry. Here's how steel tube manufacturers are embracing sustainability:

1. Use of Recycled Materials:

Steel Tube Manufacturer are increasingly turning to recycled materials to reduce their environmental impact.

Manufacturers are reducing waste and conserving natural resources by incorporating recycled steel into their production processes.

2. Energy-Efficient Practices:

Energy consumption plays a significant role in the manufacturing process. Steel Tube Supplier are investing in energy-efficient technologies to minimize their carbon footprint.

Manufacturers are making significant strides towards sustainability by optimizing their operations and utilizing renewable energy sources.

3. Waste Management and Recycling:

Waste management is a critical aspect of sustainability in manufacturing. Steel tube manufacturers are implementing robust recycling programs to minimize waste generation.

By reusing scrap materials and adopting circular economy principles, manufacturers are reducing landfill waste and promoting a more sustainable approach to production.

Innovations in Sustainable Steel Tube Production:

In addition to adopting eco-friendly practices, steel tube manufacturers drive innovation in sustainable production methods. Here are some notable advancements:

1. Green Coating Technologies:

Manufacturers are developing environmentally friendly coating technologies that reduce the use of harmful chemicals and emissions.

These green coatings enhance the longevity of steel tubes and contribute to a cleaner, more sustainable manufacturing process.

2. Lightweighting and Material Optimization:

Steel tube manufacturers focus on lightweight solutions and material optimization to reduce energy consumption during transportation.

Manufacturers contribute to lower fuel consumption and emissions in the transportation sector by designing lighter tubes without compromising strength.

Conclusion:

Steel tube manufacturers are at the forefront of sustainability in the industrial landscape, spearheading innovation and embracing eco-friendly practices. By prioritizing using recycled materials, implementing energy-efficient measures, and driving advancements in sustainable production methods, these manufacturers are setting a new standard for environmentally conscious manufacturing. As we look to the future, it's clear that steel tube manufacturers will continue to play a pivotal role in shaping a more sustainable and resilient industrial sector. We are also USA top Welding Electrode Manufacturers.

Website: pipingprojects.us

#Steel Tube Manufacturers in USA#Steel Tube Supplier in USA#Steel Tube Manufacturers#Steel Tube Manufacturer#Steel Tube Supplier#Steel Tube Suppliers#Welding Electrode Manufacturers

0 notes

Text

KRYSTAL GLOBAL ENGINEERING LIMITED AT HEAT EXCHANGER WORLD AMERICAS - 2024

16 - 17 October 2024, Houston, Texas USA

HEAT EXCHANGER WORLD AMERICAS - 2024

Krystal Global Engineering Limited at HEAT EXCHANGER WORLD AMERICAS - 2024

Welcome to Krystal Global Engineering Limited’s official event page for Heat Exchanger World Americas 2024! Discover our leading solutions in high-performance Stainless Steel, Duplex, Super Duplex, Nickel Alloy, and Exotic-Grade Material Tubes, Pipes, and U-Tubes.

Event Details:

Date: 16 – 17 October 2024

Venue: Houston, Texas, USA

Booth Number: Stand 2110

Event Hours: 10:00 AM – 5:00 PM

Event Link: https://heat-exchanger-world-americas.com

KRYSTAL X HEAT EXCHANGER

2024

Manufacturer and Exporter of Seamless Stainless Steel, Duplex, Super Duplex, Nickel Alloy Tubes, Pipes & U Tubes.

At the trendsetting, ultimate networking event for the process industry, you will have an opportunity to connect with Krystal experts, tune into our thought-provoking presentations on an hourly basis and experience our virtual reality training demo live. Highlight topics include the path beyond blue to green hydrogen, the latest decarbonization innovations, advances in electrolyser technologies with ITM Power and the role of services in future-proofing your plant.

About Krystal Global Engineering Limited:

Krystal Global Engineering Limited is your premier destination for top-quality tubes and pipes, serving industries worldwide including petrochemical, oil and gas, chemical processing, and power generation. We prioritize excellence and innovation, delivering superior products tailored to global standards.

What to Expect:

Extensive Product Showcase: Explore our comprehensive range of high-performance tubes, pipes, and U-tubes designed to endure extreme temperatures, corrosive environments, and high-pressure conditions.

Expert Consultation: Meet our team of industry specialists available to discuss your specific needs and provide tailored solutions.

Networking Opportunities: Connect with professionals, engineers, and industry leaders to exchange ideas, insights, and business opportunities.

Live Demonstrations: Witness live demonstrations highlighting the durability, reliability, and performance of our products in real-world applications.

Why Visit Us?

Quality Assurance: Our products undergo stringent quality control measures, ensuring compliance with international standards and specifications.

Customization: Benefit from our flexible manufacturing capabilities, allowing for customized solutions to meet your unique project requirements.

Global Reach: With a vast network of distributors and partners, we offer prompt delivery and comprehensive support worldwide.

Innovation: Stay ahead with our continuous investment in research and development, delivering cutting-edge solutions to address evolving industry challenges.

#16 - 17 October 2024#Houston#Texas#USA#HEAT EXCHANGER WORLD AMERICAS - 2024#Krystal Global Engineering Limited at HEAT EXCHANGER WORLD AMERICAS - 2024#Welcome to Krystal Global Engineering Limited’s official event page for Heat Exchanger World Americas 2024! Discover our leading solutions#Duplex#Super Duplex#Nickel Alloy#and Exotic-Grade Material Tubes#Pipes#and U-Tubes.#Event Details:#•#Date: 16 – 17 October 2024#Venue: Houston#Booth Number: Stand 2110#Event Hours: 10:00 AM – 5:00 PM#Event Link: https://heat-exchanger-world-americas.com#KRYSTAL X HEAT EXCHANGER#2024#Manufacturer and Exporter of Seamless Stainless Steel#Nickel Alloy Tubes#Pipes & U Tubes.#At the trendsetting#ultimate networking event for the process industry#you will have an opportunity to connect with Krystal experts#tune into our thought-provoking presentations on an hourly basis and experience our virtual reality training demo live. Highlight topics in#the latest decarbonization innovations

0 notes

Text

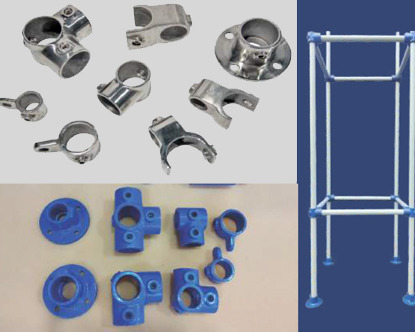

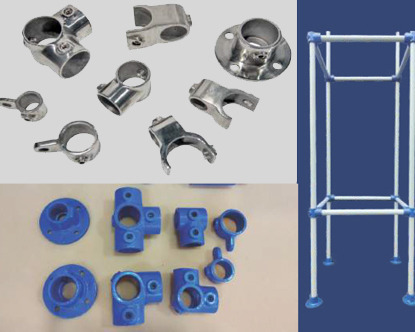

Structure and Support | Goel Scientific | Canada

We supply Glass plants that are supported in a tubular structure formed of galvanized steel tubes Manufacturers, in Canada, the USA Goel Scientific Glass

#Best#Top#supply Glass plants that are supported in a tubular structure formed of galvanized steel tubes Manufacturers#in Canada#the USA Goel Scientific Glass

0 notes

Photo

New Post has been published on https://www.vividracing.com/blog/top-8-best-mods-for-a-800-hp-c7-z06-corvette/

Top 8 Best Mods for a 800+ HP C7 Z06 Corvette

If you’re looking to take your Corvette’s power and presence to the next level, you’ve come to the right place. In this guide, we’ll explore the top 8 best mods that can transform your Z06 into an 800+ horsepower beast, unleashing its full potential on the track or the street.

From enhancing exhaust notes to optimizing engine performance and improving traction, each of these mods plays a crucial role in elevating your driving experience. Whether you’re a seasoned enthusiast or just diving into the world of automotive upgrades, these carefully selected parts and accessories are sure to make a significant impact on your Corvette’s performance and aesthetics.

So buckle up, rev your engines, and let’s dive into the details of the Kooks Headers, Kooks X-Pipe, Borla ATAK Axleback exhaust, Cordes Performance upgrades including the 2.30″ LT4 Upper Pulley Kit and Engine Bay Ice Tank, the Low Side Fuel System for optimal fuel delivery, the traction-boosting Mickey Thompson Et Street SS Tires, and the stylish yet functional Forgestar D5 Drag Wheels. Get ready to experience the thrill of pushing your C7 Z06 Corvette to new heights!

youtube

https://www.vividracing.com/blog/wp-content/uploads/img-c7z06_forgestard5_mickeythompsonetstreet-3-scaled.jpg

1.) Kooks 1-7/8″ x 2″ x 3″ Stainless Steel Headers Chevrolet Corvette C7 2014-2019

When it comes to elevating your Corvette’s performance, few names carry as much weight as Kooks Headers and Exhaust. With a legacy spanning over 50 years, Kooks has solidified its position as a leader in the High Performance Exhaust Industry since 1962. What sets Kooks apart is not just their reputation but their unwavering commitment to delivering top-notch headers and exhaust systems for street, race, and off-road applications.

The accolades speak for themselves – Kooks has secured hundreds of championships and set numerous records across renowned racing organizations like NHRA, IHRA, NMCA, NMRA, NASCAR, NASA, SCCA, and many others. This level of success is a testament to the quality and performance of Kooks products.

What makes Kooks truly special is their dedication to craftsmanship and American manufacturing. With three generations of family leadership at the helm, every Kooks product is handcrafted right here in the USA. This commitment to quality control and precision ensures that every header and exhaust system that bears the Kooks name meets the highest standards of excellence.

The Kooks Headers and Exhaust kit for the C7 Corvette includes a 1-7/8″ x 2″ x 3″ Stainless Steel Long Tube Header, Cometic Multi-Layer Gaskets, Stage 8 Header Bolts, O2 Extensions, and Torca Clamps. Crafted from premium 304 Stainless Steel, these components not only offer exceptional durability but also add a touch of aesthetic appeal with their stainless steel finish.

Fitment is seamless for various Corvette models, including the Chevrolet Corvette C7 LT1 6.2L (2014-2019), Chevrolet Corvette C7 Z06/Z07 LT4 6.2L (2015-2019), and Chevrolet Corvette C7 ZR1 LT5 6.2L (2019).

So, if you’re ready to “Get Kookin with KOOKS!” and experience a performance boost like never before, the Kooks Headers and Exhaust system is a must-have addition to your C7 Corvette.

2.) Kooks OEM X 3 X 2 3/4 (OEM) C7 X Pipe Chevrolet Corvette C7 6.2L -All models 2014-2019

Upgrade your Chevrolet Corvette C7’s exhaust system with the high-performance Kooks X-Pipe. Crafted from T-304 Aircraft Quality Steel, this 3″ x 3″ X-Pipe optimizes exhaust gas flow for maximum power and a thrilling exhaust note.

Features:

OEM x 3″ Front connections to factory catalytic converter

3″ x 3″ X-Pipe

3″ x 2 3/4″ Mid-Pipes. Connects to 2 3/4″ OEM Style Exhaust.

Benefits:

Enhanced engine efficiency with reduced back pressure

Dyno and race-tested for optimal performance

Direct fitment for Chevrolet Corvette C7 6.2L models 2014-2019

Limited lifetime warranty to the original purchaser

Note: Designed for off-road use only and not CARB compliant for California.

Experience over fifty years of exhaust system craftsmanship with the Kooks X-Pipe, delivering power and performance for your Corvette C7.

3.) Borla ATAK Axleback Exhaust System Chevrolet 6.2L V8

The Borla ATAK Axleback exhaust system is the ideal companion to your Kooks X-Pipe and Headers upgrade for the Chevrolet Corvette C7, offering a seamless integration that results in a host of performance benefits. Together, these high-performance exhaust components optimize exhaust flow, reduce back pressure, and improve engine efficiency, translating into a noticeable increase in horsepower and torque for exhilarating acceleration. What truly sets this combination apart is the distinctive Borla Sound of Power, delivering an aggressive yet refined exhaust note that not only enhances driving excitement but also sets your Corvette apart from the crowd. Crafted from polished T-304 stainless steel, the Borla exhaust system not only ensures premium quality and durability but also adds a touch of visual appeal to your Corvette’s rear end. With precision CNC manufacturing and Borla’s Million-Mile Warranty backing, you can trust that your exhaust system will fit perfectly and be covered for the long haul. Together, the Kooks X-Pipe and Headers with the Borla ATAK Axleback exhaust unleash the full potential of your Corvette C7, offering an unmatched driving experience that’s as thrilling as it is refined.

4.) Cordes Performance 2.30″ LT4 Upper Pulley Kit Chevrolet Corvette 2014-2021

Upgrade your Chevrolet Corvette’s performance with the Cordes Performance 2.30″ LT4 Upper Pulley Kit, designed specifically for models from 2014 to 2021. This kit offers a significant improvement by reducing the pulley size from the OEM 2.5 inches to a 2.3-inch diameter, resulting in a boost of 2-3 psi over stock levels. Included in the kit are essential components such as a press-on hub, 10 titanium torx bolts for secure installation, and the pulley itself featuring the newest griptec finish for enhanced traction and durability. Notably, the OEM belt can be reused if you have a stock-size lower, ensuring compatibility and ease of installation. This kit is compatible with all LT4 superchargers, making it a versatile and effective upgrade for unlocking additional power and performance from your Corvette’s engine. Experience improved boost levels and overall driving excitement with the Cordes Performance 2.30″ LT4 Upper Pulley Kit, tailored to elevate your Corvette’s performance to new heights.

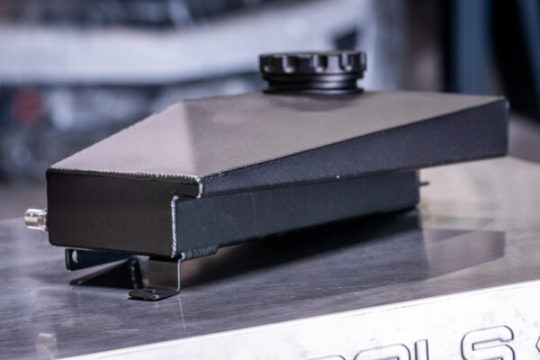

5.) Cordes Performance Engine Bay Ice Tank Chevrolet Corvette 2014-2021

Elevate your Chevrolet Corvette’s cooling capabilities with the Cordes Performance Engine Bay Ice Tank designed for models from 2014 to 2021. Cordes Performance Racing, renowned as the premier GM LTX/LTX motorsports company in Arizona, brings a wealth of expertise and passion to every product they offer. As a family-run business deeply committed to performance excellence, Cordes Performance Racing not only focuses on building high-level performing vehicles but also prioritizes the overall presentation, ensuring that you’re proud to showcase your Corvette. The Engine Bay Ice Tank is no exception, crafted using the highest-quality components to deliver optimal cooling efficiency and performance reliability. By maintaining lower engine temperatures, especially during high-performance driving or track sessions, this ice tank ensures that your Corvette operates at the peak of its performance, providing consistent power delivery and reliability. Trust Cordes Performance Racing to go above and beyond in enhancing your Corvette’s cooling system, enabling you to push the limits with confidence and enjoy an exhilarating driving experience every time you hit the road or track.

6.) Cordes Performance Low Side Fuel System Chevrolet Corvette 2014-2021

(Image may differ from actual product)

Enhance the fuel delivery and performance of your Chevrolet Corvette from 2014 to 2021 with the Cordes Performance Low Side Fuel System. Cordes Performance Racing stands as the premier GM LTX/LTX motorsports company in Arizona, driven by a deep passion for excellence in automotive performance. As a family-run business, Cordes Performance Racing not only focuses on building high-level performing vehicles but also emphasizes an overall presentation that you’ll be proud to showcase. The Low Side Fuel System exemplifies this commitment, utilizing only the highest-quality components to ensure optimal fuel delivery and engine performance. Compatible with Chevrolet Corvette C7 models from 2014 to 2021, including the C7ZO6 and C7ZR1 variants, this fuel system upgrade is designed to keep your vehicle at the peak of its performance, providing consistent fuel delivery and power output. Trust Cordes Performance Racing to go the extra mile in upgrading your Corvette’s fuel system, delivering reliability and performance that you can count on for every drive.

7.) Forgestar D5 Drag Wheel 18×12 5×120.65 50mm Gloss Black w/ Machined Lip

The Forgestar D5 Drag Wheel in 18×12 size with a 5×120.65 bolt pattern and 50mm offset is a game-changer for high-performance builds like the 800hp C7 Z06 Corvette. Forgestar performance wheels are renowned for bridging the gap between forged and cast wheels, delivering exceptional strength and lightweight characteristics crucial for demanding applications. Using an innovative rotary formed production process, Forgestar creates a lightweight cast wheel with strength and impact values comparable to forged wheels, making them ideal for street, racing, and drag racing applications. The Drag Wheel variant is drag strip approved with SFI 15.1 and 15.2 ratings, ensuring top-notch safety and performance standards. The wheel features a rotary forged flow-formed barrel, monoblock construction, and a Gloss Black finish with a machined lip, combining aesthetics with functionality. Its lightweight design not only enhances acceleration and handling but also clears big brake kits for improved stopping power. The raised center cap adds axle clearance convenience, while bead knurling ensures secure tire fitment. With a load rating of 1600 lbs and meticulous attention to detail in construction, the Forgestar D5 Drag Wheel is a must-have for high-performance enthusiasts looking to maximize their C7 Z06 Corvette’s potential on the drag strip and beyond.

Mickey Thompson ET Street S/S Tire – P345/35R18

The Mickey Thompson ET Street S/S Tire in P345/35R18 size is a high-performance street-to-strip tire designed for enthusiasts seeking exceptional traction on both the street and the drag strip. Featuring radial construction and the renowned R2 compound, this tire delivers superior performance in 15- to 20-inch fitments. It is D.O.T. approved for street use, making it a versatile choice for daily driving and track days alike. The ET Street S/S tire boasts an equivalent tread void as the ET Street Radial II but with improved hydroplane resistance, ensuring excellent dry traction while maintaining safety in wet conditions. The proven R2 compound, also used in top “drag radials,” provides superior traction at the strip, often requiring minimal or no burnout for optimal performance. Tubeless construction adds convenience with a leak-free seal, eliminating the need for tubes. With specifications like a centerline tread depth of 6.0/32″, an inflated overall diameter of 27.8 inches, and a maximum rim width of 13.5 inches, this tire offers a perfect balance of performance and durability. Whether you’re hitting the drag strip or cruising the streets, the Mickey Thompson ET Street S/S Tire is the ideal choice for enthusiasts seeking exceptional traction and performance in a street-legal package.

By combining top-notch performance upgrades from industry leaders, the Chevrolet Corvette C7 Z06 transforms into an 800hp powerhouse ready to dominate the streets and the track. The Kooks Headers and Exhaust system, along with the Borla ATAK Axleback exhaust, not only optimize exhaust flow but also enhance the aggressive exhaust note, while the Cordes Performance 2.30″ LT4 Upper Pulley Kit and Engine Bay Ice Tank ensure optimal engine cooling and power delivery. The Cordes Performance Low Side Fuel System keeps fuel delivery consistent, while the Forgestar D5 Drag Wheels and Mickey Thompson ET Street S/S Tires provide traction and stability necessary for harnessing the massive power output. Together, these meticulously selected upgrades create a harmonious synergy, elevating the Corvette C7 Z06 to 800hp and delivering an exhilarating driving experience that’s as thrilling as it is refined.

As always, if you need any assistance with selecting the right parts for your car, feel free to shoot us an email at [email protected] or give us a call at (480) 966-3040. Whether it’s helping you pick the best parts, or being a shoulder to cry on, we’ll be here!

#800hp C7 Z06 Corvette#Borla ATAK#c7 z06#Chevrolet#Cordes Performance#Corvette#Engine Bay Ice Tank#exhaust#Forgestar Drag Wheels#Headers#kooks#Low Side Fuel System#Mickey Thompson

7 notes

·

View notes

Text

Pes Membrane

Email Us : [email protected]

Applications of PES Membrane Use Systems

PES membrane filters are integral to various industries and scientific applications. Some key use cases include:

1. Pharmaceutical & Biotech Filtration

Used in sterile filtration of biological fluids

Ideal for buffer and media filtration

Suitable for serum and vaccine production

2. Laboratory & Research Filtration

Commonly used in microbiological studies

Essential for cell culture filtration

Helps in removing contaminants from aqueous solutions

3. Food & Beverage Industry

Ensures sterility of beverages like wine, beer, and dairy

Used in bottled water filtration

4. Environmental & Water Filtration

Effective in removing bacteria and particulates from water

Ideal for wastewater treatment systems

5. Medical Device & Diagnostic Applications

Used in IV filtration and infusion therapy

Essential for diagnostic test kits

Why Choose Foxx Life Sciences PES Membrane Filters?

Foxx Life Sciences is a trusted leader in advanced filtration solutions, offering high-performance EZFlow PES Membrane Disc Filters that ensure reliable, sterile, and efficient filtration.

Key Features of Foxx Life Sciences PES Membrane Filters:

✔ High Flow Rate — Rapid filtration without compromising efficiency ✔ Low Protein Binding — Ideal for biological samples and cell cultures ✔ Hydrophilic Surface — Ensures smooth liquid passage ✔ Sterile & Non-Sterile Options — Suitable for various lab and industrial needs ✔ Chemical Compatibility — Resistant to acids, bases, and alcohols

Explore Foxx Life Sciences’ PES Membrane Filters

Looking for premium PES membrane disc filters? Foxx Life Sciences offers top-quality EZFlow PES membrane filters designed for precision and performance.

🔗 Visit our website to browse our full range of PES membrane filtration solutions and enhance your filtration efficiency today!

Contact Us : [email protected]

https://www.linkedin.com/company/foxxlifesciences

0 notes

Photo

Vintage 1940,s Handlan Caboose St. Louis 4 Way Railroad Switch & Stand Light

Vintage 1940's Handlan Caboose Oil Lantern that lights up4 way lantern: 2 red glass lenses and 2 glass green lenses / The lantern will still come with all its original contents including the glass round tube inside the lantern. This item will look used.Large railroad lantern measures 18" H x 10" W x 10" D / This is a very heavy duty railroad lantern and weighs over 12 pounds.This lantern was converted with power cord, switch and light and now it will light up. 120 volt operation.Original glass tube still inside lantern were the flame comes out. You can remove the power cord, switch and light and put it back to its original condition.HISTORY/ ABOUT:This railroad hand-signal kerosene lantern was manufactured by the Handlan Manufacturing Company of St. Louis, Missouri around 1930–1940. The lamp was used on the New York, New Haven, and Hartford Railroad. The lamp has a metal body, a red and green glass globe encircled by a metal handle and base. The top of the lamp is inscribed with the Handlan logo and the text “HANDLAN/ST. LOUIS USA.Before the advent of portable two way radios, train crews communicated via hand signals during the day, and lantern signals during periods of low visibility or at night. This lantern with the red globe was used by station agents to signal a train to stop, sometimes to pick up Form 31 train orders. They also used various globe colors such as amber, blue, red, etc., and these colors do correspond to the same signal meanings that the railroad used. For example, red meant to stop, and blue meant that men were working or equipment was not to be moved. Green lens was for to signal the wrecker operator.ITEM TYPE Vintage COLOR Black MATERIAL Metal, Steel, Glass ORIGIN United States • AmericanHEIGHT18" (46 cm) WIDTH10" (25 cm) DEPTH10" (25 cm)

Have any questions please ask ?

Listing and template services provided by inkFrog

0 notes

Text

Guide to Alloy Steel Pipes and Tubes: Applications, Grades, and Maintenance

Are you searching for pipes that excel in high temperatures and pressures? Alloy steel pipes are the superior choice for demanding environments. Made from steel combined with crucial alloying elements such as Chromium (Cr), Manganese (Mn), and Nickel (Ni), these pipes offer unmatched strength, durability, and corrosion resistance. Typically, alloy steel might contain about 1-5% Chromium, 0.3-1.5% Manganese, and 0.2-2% Nickel, though these percentages can vary based on the specific grade and desired properties.

This guide will delve deep into everything you need to know about alloy steel pipes, from their types and applications to the specific grades suitable for various industries. At the forefront of providing these robust solutions is Amardeep Steel, recognized as the premier manufacturer and supplier of alloy steel pipes. Amardeep Steel boasts extensive operations in major markets such as India, the USA, Germany, Poland, Saudi Arabia, the United Arab Emirates, Italy, and the Netherlands. Each of these countries represents a significant consumer of high-quality alloy steel pipes, underscoring Amardeep Steel’s capacity to meet diverse global industrial requirements with precision and reliability.

What are Alloy Steel Pipes?

Alloy steel pipes are made from steel enhanced with alloying elements such as Chromium (Cr), Manganese (Mn), Nickel (Ni), and Silicon (Si). These elements are added to steel to improve its mechanical properties, including strength and corrosion resistance, making the alloy steel exceptionally versatile and suitable for various industrial applications. These pipes come in multiple grades, each tailored to meet specific environmental and mechanical demands.

Types of Alloy Steel Pipes

Seamless Alloy Steel Pipes: These are manufactured by extruding steel to create a seamless tube, making them ideal for high-pressure applications where uniform strength is crucial across the pipe's entire circumference.

Welded Alloy Steel Pipes: Made by welding together pieces of steel, these pipes are more economical and typically used in environments where pressures are lower.

Amardeep Steel, a leader in steel manufacturing, excels in producing both types of alloy steel pipes, ensuring high quality that meets global industrial standards. Whether for critical applications in the oil and gas industry or for transportation of liquids in the chemical sector, Amardeep Steel's alloy pipes offer reliability and durability, making them a top choice for industries around the world. With a robust supply chain and advanced manufacturing capabilities, Amardeep Steel stands out as a premier supplier, continually adapting to meet the needs of an evolving market.

Applications of Alloy Steel Pipes

Alloy steel pipes play a crucial role in industries that demand high strength and resistance to harsh conditions. Key applications include:

Oil and Gas Industry: In the demanding oil and gas sector, alloy steel pipes are essential for drilling and transporting oil and gas. Their high strength and corrosion resistance make them ideal for the deep-earth conditions and corrosive substances they encounter. These pipes can handle the high pressures and temperatures found in oil wells, ensuring safe and efficient fluid transport.

Chemical Processing Plants: Alloy steel pipes are vital in chemical processing where they transport corrosive fluids and gases. Their enhanced resistance to chemical attack prevents premature wear and leaks, which could be catastrophic in this environment.

Power Generation: In power plants, alloy steel pipes play a critical role in moving steam and hot fluids. Their ability to handle high temperatures and pressures without deforming makes them crucial for the efficiency and safety of power generation systems.

Aerospace Applications: The aerospace industry relies on alloy steel pipes for systems that require robust performance under extreme conditions. Their high tensile strength and toughness protect against the mechanical stresses and environmental challenges of aerospace applications.

Heat Exchangers and Boilers: These applications benefit significantly from the thermal resistance of alloy steel pipes. They are used in settings where high temperature and pressure resistance is essential, such as in boilers and heat exchangers, helping to maintain system integrity and operational reliability.

Grades of Alloy Steel Pipes

Alloy steel pipes come in various grades, each suited to specific applications based on their mechanical properties and resistance levels. Understanding these grades is essential for procurement managers to select the most appropriate materials for their projects. Below is a detailed table summarizing key grades of alloy steel pipes and their typical uses

Maintaining Alloy Steel Pipes for Optimal Performance

The longevity and performance of alloy steel pipes can be significantly enhanced through proper maintenance practices. Ensuring the durability of these pipes involves several critical steps:

Regular Inspections: It's essential to conduct regular inspections to detect early signs of corrosion or damage. This proactive approach helps in addressing potential issues before they escalate, thereby extending the lifespan of the pipes.

Routine Cleaning: Regular cleaning is crucial to prevent build-ups of deposits and residues that can lead to corrosion. This step is particularly important in industries like oil and gas, where the pipes are exposed to various corrosive substances.

Protective Coatings and Cathodic Protection: Applying protective coatings and implementing cathodic protection are effective methods to shield alloy steel pipes from environmental damage. These treatments provide a barrier against corrosive elements, thus enhancing the pipes’ resistance to degradation.

Installation Tips for Alloy Steel Pipes

Proper installation is paramount for the optimal performance of alloy steel pipes. Key considerations include:

Selecting Appropriate Fittings and Flanges: It's vital to ensure compatibility with the type of alloy pipe used. Using the right fittings enhances the integrity of the pipe system, ensuring efficient and safe operations.

Employing Correct Welding Techniques: Utilizing industry-standard welding methods ensures durable joints and maintains the structural integrity of the pipeline. This step is crucial for applications involving high pressures and temperatures.

Hiring Skilled Professionals: Installation should always be performed by certified technicians who adhere to strict safety and reliability standards. Their expertise guarantees that the installation complies with industry regulations and performance expectations.

Price of Alloy Steel Pipes - Market Insights

The price of alloy steel pipes in India varies, reflecting the global steel market dynamics. As of the latest reports, the average price can range significantly based on the grade and specific requirements of the project. Furthermore, India's role as a leading exporter in the alloy steel pipe market continues to expand, with significant shipments to countries in Europe, the Middle East, and North America.

According to recent export data, there's a rising demand for high-grade alloy steel pipes in sectors such as automotive and energy, which has led to an increase in their market value. This trend underscores the importance of choosing high-quality suppliers like Amardeep Steel, who can provide certified alloy steel pipes at competitive prices.

Alloy steel pipes offer a robust solution for industries operating under tough conditions. By selecting the right type and grade, and ensuring diligent maintenance and expert installation, these pipes provide a reliable and long-lasting system. For more detailed information or to choose the ideal alloy steel pipe for your needs, please contact Amardeep Steel or fill out our inquiry form to receive tailored expert advice for your project.

0 notes

Text

Compression Tube Fittings Manufacturer in Thailand

We are providing superior quality manufacturer of compression tube fittings in Thailand. A Stainless Steel Compression Fittings is a kind of versatile coupling that can be used to connect two pipes or a pipe to either a fixture or a valve. Get in Touch With Us Now!

0 notes

Text

Top Flare End Fittings Manufacturers Suppliers Exporters in USA - Mcneil Instruments

Mcneil Instruments is one of the leading Instrumentation Flare End Fittings manufacturers, suppliers, and exporters. Flare End Fittings are compression fittings that are usually made of soft steel, ductile copper, etc. We make the best and most useful flare end fittings with extreme dimensional precision made for convenience and perfection. Getting your flare end fittings from Flare Fittings Manufacturers that provide nothing but quality products will help you make the best out of your investment in these instruments. Hence you can trust our efficient workforce to deliver the best in class instruments to your doorstep. Contact us today to place an order and get your flare tube fittings customized as per your requirements!

0 notes

Text

Unveiling the Genius of Steel Tube Manufacturers in USA - Piping Projects US

Piping Projects is one of the leading Steel Tube Manufacturers in USA. We are a manufacturer and supplier of seamless and welded steel tubes with wall thicknesses up to 40 mm and OD ranges of 12.7 mm to 906 mm. Different materials are used to make welded and seamless steel tubes. Brass, copper, stainless steel 304/304L, 316L, duplex, titanium, alloy 600, alloy 400, alloy 625, alloy 825, and alloy C276 are among the metal tubes we manufacture. PipingProjects.us is a top Steel Tube Supplier in USA.

Steel Tube Manufacturers USA stand at the heart of numerous industries, offering a foundational element that often goes unnoticed but plays a pivotal role in our everyday lives. Delving into the intricacies of their craftsmanship and innovation reveals a world of precision engineering and multifaceted applications. In this blog, we'll embark on a journey to uncover the hidden brilliance behind steel tube manufacturing, exploring the depth and versatility these industries provide.

Understanding the Steel Tube Manufacturer Process

The production of steel tubes involves a complex and meticulous process, blending technology, expertise, and innovation. It's essential to grasp the steps involved in crafting these essential components.

Raw Material Selection

Steel tubes originate from carefully selected raw materials. The choice of steel grade impacts the final characteristics of the tubes, including strength, durability, and corrosion resistance.

Forming and Shaping

The transformation of raw materials into tubes involves shaping processes such as hot rolling, cold rolling, or welding. Each method influences the tube's properties and applications.

Innovations in Steel Tube Manufacturers

Advancements in technology have revolutionized the Steel Tube Manufacturers landscape. Let's explore the cutting-edge innovations shaping the industry's future.

Advanced Materials and Alloys

Incorporating new materials and alloys enhances the performance of steel tubes, catering to diverse industries with specific requirements like lightweight structures or extreme conditions.

Precision Engineering and Automation

The integration of precision engineering and automation streamlines production, ensuring consistency, higher quality, and meeting stringent tolerances.

Cities Where We Supply Steel Tube

Steel Tube Manufacturers in Texas

Steel Tube Manufacturers in California

Steel Tube Manufacturers in New York

Steel Tube Manufacturers in Chicago

Steel Tube Manufacturers in Houston

Steel Tube Manufacturers in Michigan

Applications Across Industries

Steel tubes serve as the backbone of various sectors, showcasing their adaptability and indispensability in modern-day applications.

Construction and Infrastructure

The construction industry heavily relies on steel tubes for structural support, pipelines, and architectural designs due to their strength and durability.

Automotive and Transportation

From vehicle chassis to exhaust systems, steel tubes contribute to the safety and efficiency of automobiles, providing structural integrity and longevity.

The Future of Steel Tube Manufacturing

Looking ahead, the evolution of steel tube manufacturing appears promising, driven by sustainability, innovation, and expanding applications.

Sustainability Initiatives

Manufacturers are increasingly adopting sustainable practices, reducing waste, optimizing energy consumption, and exploring eco-friendly materials.

Emerging Trends and Market Growth

The demand for Steel Tube Suppliers continues to surge, fueled by expanding industrialization and the evolution of renewable energy sectors.

Website:pipingprojects.us

#Steel Tube Manufacturers in USA#Steel Tube Supplier in USA#Steel Tube Manufacturers#Steel Tube Supplier#Steel Tube

0 notes

Text

Alloy Tubes Manufacturer Things to Know Before You Buy

WE'VE GOT THE CAPABILITY TO MAKE WELDED OR ALLOY TUBING IN SQ., RECTANGULAR, FLAT SIDED OVAL, ELLIPTICAL AND A NUMBER OF OTHER CUSTOM MADE STYLES IN A NUMBER OF MATERIALS. CORROSION RESISTANCE: MANUFACTURER OF STAINLESS STEEL TUBES AND PIPES IS NATURALLY RESISTANT TO SEVERAL SORTS OF CORROSION ON ACCOUNT OF ITS TRICKY, OXIDIZED OUTER LAYER. AS IT IS PRODUCED FROM VARIOUS UNIQUE ALLOYS, IT COULD POSSIBLY ARISE TO TOUGH AILMENTS. POWERFUL NEED FOR ALLOY TUBING SIGNIFIES THAT THESE MANUFACTURERS MAY WELL NEED TO HAVE TO INVEST IN NEW PRODUCTS AND SERVICES TO HELP KEEP UP WITH DESIRE AND TURN THIS TREND INTO A POSSIBILITY FOR EXPANSION. A BIG PRESENCE IN THE FACILITY GENERATION FIELD IN THE MANUFACTURING AND EXPORTER OF SEAMLESS TUBES SUPPLIES A TRUSTED AND DEPENDABLE MERCHANDISE THAT WILL FACE UP TO ESSENTIALLY THE MOST DEMANDING APPS. FOR QUALITY THREADS OF THE HIGHEST INTERCONTINENTAL STANDARDS, FOR EXAMPLE API OR GOST, WE FEATURE OUR TCG THREAD CUTTING DEVICE AND RMG COUPLING THREADING EQUIPMENT INSIDE OUR PRODUCTS ASSORTMENT. OUR MACHINES PROVIDE HIGH-HIGH-QUALITY FINISHED MERCHANDISE – HOWEVER, TYPICAL CHECKS ARE INDISPENSABLE TO GUARANTEE THE PROPER EXCELLENT OF CUT THREADS. THUS, WE OFFER AN AUTONOMOUS OPTICAL INLINE MEASUREMENT PROCEDURE FOR ANALYZING THREADS AND SEALING LIPS ON OCTG TUBES. OFFERED OUR EXTENSIVE INVENTORY OF MATERIALS, AND EACH DAY PROFITS QUANTITY OF IN EXCESS OF 100 TONES, WE WOULD GIVE YOU THE TOP COSTS, EVEN REDUCE THE DIRECT MANUFACTURING UNIT RATES. THE ROTARY EXPANDER CAN BE A EXCLUSIVE FORM OF CROSS-ROLLING MILL WITH CONICAL, AXIALLY ADJUSTABLE ROLLS. THE NICKEL ALLOY TUBES ARE EXPANDED MANUFACTURER OF STAINLESS STEEL TUBES AND PIPES BY ROLLING THEM IN EXCESS OF A PLUG. COLD DRAWN STAINLESS STEEL SEAMLESS TUBE ORDINARILY INCORPORATES A SHINIER GLIMPSE WITHOUT WELD LINES INCREASING THE AESTHETICS WITH THE SOLUTIONS DURING WHICH IT'S INCLUDED. THE CERAMIC COATING CHARACTERISTICS MINIMAL THERMAL CONDUCTIVITY PLUS INTENSE HARDNESS. IT FUNCTIONS LIKE A HEAT AND HAVE ON DEFENSE SHIELD AND FOR A PASSIVE SEPARATING LAYER THAT SUBSTANTIALLY EXTENDS THE PROVIDER LIFE OF THE PIERCER PLUGS, LEADING TO DECREASED TOOLING PRICES AND ENHANCED PRODUCTIVITY OF YOUR RESPECTIVE PLANT. THROUGH ITS PENNSYLVANIA PRODUCTION FACILITY, SALEM TUBE, KRYSTAL GLOBAL ENGINEERING LIMITED. MUMBAI, TUBACEX AMERICA IS A NUMBER ONE MANUFACTURER OF HIGHER PRECISION STAINLESS METAL AND NICKEL ALLOY MORE INFO TUBES. THE TRUTH IS, AS A LEADING TUBING MANUFACTURER, TUBACEX THE USA OFFERS THE MARKETPLACE’S BIGGEST PORTFOLIO OF SIGNIFICANT-EFFICIENCY TUBING AND CORROSION-RESISTANT NICKEL ALLOYS, IN ADDITION TO A DEDICATION TO QUICK DIRECT INSTANCES AND CRISIS TASKS. THEIR 500 PERSONNEL PROVIDE HIGHER-HIGH QUALITY GOODS FOR YOUR AUTOMOTIVE AND POWER SECTORS AS WELL AS CUSTOMIZED INDUSTRIAL OPTIONS FOR CONSTRUCTION AND HYDRAULIC TUBES MANUFACTURER UNITS. COUNTRYWIDE ALLOY TUBE PROCESSING (NTP) IS STARTED AROUND THE BASIC PRINCIPLE OF CONSTRUCTING ENTERPRISE SIMPLE FOR OUR SHOPPERS. FROM SHORT GUIDE MOMENTS TO HELP WITH PROTOTYPE STRUCTURE AND DRAWINGS, NTP IS YOUR ONE PARTICULAR-CEASE SOLUTION FOR YOUR MONEL ALLOY TUBE REDUCING AND SHEET METALLIC DEMANDS. OUR LATEST COST FOR SS 304 STAINLESS STEEL SEAMLESS PIPES IS RS. 250/KG, SS 316L STAINLESS STEEL SEAMLESS TUBES IS RS. 305/KG, SEAMLESS BRIGHT ANNEALED TUBES IS RS. 410/KG AND SEAMLES PIPES IS RS. SEVENTY THREE/KG. THE PRICE FOR STAINLESS METAL SEAMLESS TUBES AND CARBON METAL SEAMLESS TUBES HAS IMPROVED NOT LONG AGO BECAUSE OF SHORTAGE OF RESOURCES, GREATER UNCOOKED PRODUCT COSTS AND EXPORTER CONSTRAINTS FOR MANUFACTURER OF STAINLESS STEEL TUBES AND PIPES. THE IMPORT RESTRICTIONS ARE ON ACCOUNT OF STEEL TOP QUALITY REGULATE GET, UNDER WHICH NICKEL ALLOY TUBES IS OFTEN IMPORTED INTO INDIA ONLY FROM BIS (BUREAU OF INDIAN STANDARDS) AUTHORIZED FACTORIES. FIND OUT HOW OUR STYLE AND DESIGN TEAM STARTED OUT WITH A NORMAL MOULD FOUNDATION TO PRODUCE A SEMI-CUSTOM CLAMSHELL WITH SEVERAL FEATURES IN A FAST AND PRICE-EFFICIENT METHOD.

To know more about:

#nickel alloy tubes#stainless steel nickel alloy tubes#seamless steel nickel alloy tubes#top nickel alloy tubes in Mumbai#best nickel alloy tubes in Mumbai#top manufacturer of nickel alloy tubes#best manufacturer of nickel alloy tubes in Mumbai#nickel alloy tubes manufacturer in Mumbai#nickel alloy tubes in india#nickel alloy tubes in Mumbai#nickel alloy tubes in Vadodara#nickel alloy 200 in Mumbai#nickel alloy in Mumbai#nickel 2200#nickel 2201

0 notes

Text

Structure and Support | Goel Scientific | Canada | USA

We supply Glass plants that are supported in a tubular structure formed of galvanized steel tubes Manufacturers, in Canada, the USA Goel Scientific Glass

#Best#Top#supply Glass plants that are supported in a tubular structure formed of galvanized steel tubes Manufacturers#in Canada#the USA Goel Scientific Glass

0 notes

Text

North America Titanium Market - Forecast(2024 - 2030)

North America Titanium Market Overview

North America Titanium Market size is forecast to reach US$2,783.5 million by 2026, after growing at a CAGR of 3.9% during 2021-2026. Numerous applications of titanium products fueled by low thermal expansion and high co-efficient fire resistance properties that have sparked a massive increase in the North American titanium market demand. Increasing government initiatives, and investments to enhance and promote lightweight and fuel-efficient vehicles will further raise the usage of titanium. Thus, this would act as a key factor influencing the market growth during the forecast period. Moreover, the rising production of new aircraft for commercial and military use in countries such as the USA, Canada, and Mexico are further estimated to boost the North American titanium market growth. Also, the rising demand for titanium in 3D printing technology is anticipated to create opportunities for the growth of the market in the upcoming years.

COVID-19 Impact

However, in the year 2020 COVID-19 has left a lasting impact on all the sectors, especially on the aerospace and automobile sectors. The aerospace sector has been the hardest hit due to lockdowns, travel restrictions and flight bans. While the demand for defense and space products and services has been relatively immune to the pandemic due to the nature of their respective missions, commercial aviation has had to navigate an unprecedented crisis. Manufacturing was brought to a complete standstill leading to cancellation of orders. For instance, during the second quarter of 2020, Boeing temporarily suspended operations in Puget Sound, South Carolina, and Philadelphia, as well as at several other key production sites due to COVID-19-related operating restrictions. While the demand for defense & space products and services has been relatively immune to the pandemic, commercial aviation has had been hard hit. Boeing, especially, was at the receiving end already battling the grounding of 737-8 and 737-9 over safety concerns, coupled with the deep impact of the pandemic on commercial air travel. This is evident from the revenue of Boeing in 2020 that dropped to US$58,158 million in 2020.

Report Coverage

The report: “North America Titanium Market – Forecast (2021-2026)”, by IndustryARC, covers an in-depth analysis of the following segments of the North America Titanium Industry.

By Form: Bar, Sheet, Pipe, Plate, Threaded Rod & Wire, Tubing, Elbows, Flanges, Stub Ends, Screwed Fittings and Pipe Plugs, and Others

By Grade: Ti 6Al-4V (Grade 5), Ti 6Al-4V ELI (Grade 23), Ti 3Al 2.5 (Grade 9), Ti 5Al-2.5Sn (Grade 6), and Others

By Application: Aerospace, Military, Industrial Process, Automotive, Building and Construction, Medical, Sporting Goods, Jewelry, Mobile Phones, and Others

By Country: USA, Canada, and Mexico

Request Sample

Key Takeaways

USA dominates the North America Titanium Market, owing to the increasing aerospace and automotive sector in the country. The increasing per capita income and evolving lifestyle of individuals coupled with the rising population are the major factors expanding the aerospace and automotive sector in Europe.

Titanium is one of the rapidly emerging markets. The industry has changed dramatically over time, mainly due to continued growth and integration in aerospace products.

During the forecast period, extensive growth of fuel-efficient and lightweight vehicles is expected to drive the North American titanium market demand.

North America Titanium Market Segment Analysis – By Form

The plate segment held the largest share in the North America Titanium Market in 2020 up to 28% by revenue and is estimated to grow at a CAGR of 3.7% during 2021-2026. Titanium Plate is about 40% lighter than steel but 60% heavier than aluminium. Titanium grade 2 plate combines flexibility and superior corrosion resistance with high tensile strength. Like Titanium sheets, the Titanium plates also have a wide range of use case applications, especially in medical or orthopaedic implant functions. Titanium plates are used in protective armor, tanks, vests, helmets, and personnel carriers. These protective applications are used by both the military and police departments across the world. As a biocompatible metal, titanium is handled in large doses but has minimal impact on the human body. Although it’s ingested daily, it’s not always absorbed. The medical industry uses the titanium plates for the human body because it presents a similar density to bone and used for joint replacements, hip replacements or knee replacement purposes. A titanium plate can also be used for sporting equipment. An example of how the titanium plate can be used for equipment includes golf club heads/drivers. The lightweight structure of the plate allows golfers (of all abilities) to hit the ball with ease, enhancing their overall performance.

Inquiry Before Buying

North America Titanium Market Segment Analysis – By Technology

The Ti 6Al-4V (Grade 5) segment held the largest share in the North America Titanium Market in 2020 and is forecasted to grow at a CAGR of 3.5% during 2021-2026. The most often used titanium material is Ti 6Al-4V (Grade 5). Ti-6AL-4V refers to its chemical make-up, which includes about 90% titanium, 6% aluminium, 4% vanadium, 0.25 percent (max) iron, and 0.2 percent (max) oxygen. It possesses a high modulus of elasticity and a low modulus of elasticity, as well as excellent corrosion resistance, weldability, and heat treatability. The addition of aluminium and vanadium to the alloy matrix raises the hardness of the material, improving its physical and mechanical properties. Boeing recently designed and deployed a modelling simulation solution for Ti-6Al-4V plate, bar, and forged stock for Ti-6Al-4V plate, bar, and forged stock in 2020. Ti 6AI-4V is most commonly used in the aerospace industry. Jet engine compressor blades, discs, and rings; aircraft components; pressure containers; and many more are all applications where Grade 5 titanium is suitable. Heat treatment allows Ti-6AI-4V round bar material to acquire even higher strengths. Medical implants can also benefit from this friendly material. Titanium has a high capacity for combining with bones and other tissue because to its mechanical and physical properties. Slow speeds, high feed rates, rigid tooling, and flooding the work piece with non-chlorinated cutting fluid can all be used to manufacture Ti 6AL-4v Grade 5 Titanium bar stock.

North America Titanium Market Segment Analysis – By Application

The aerospace segment held the largest share in the North America Titanium Market in 2020 and is forecasted to grow at a CAGR of 3.6% during 2021-2026. Commercially available pure titanium and titanium alloys such as Ti-6Al-4V are primarily used for airframe and engine parts, respectively. Because of the low fuel consumption of aircraft, titanium demand is likely to grow. To reduce aircraft fuel consumption, the use of CFRP (Carbon Fiber Reinforced Plastic) in airframes and engine parts has increased recently. Similarly, titanium is in high demand because of its good compatibility with CFRP in terms of corrosiveness and coefficient of thermal expansion. According to Boeing, North America will require a total of 9,160 commercial airplanes deliveries during the period 2021-2040. With a nearly 9% increase in sales over 2018, space systems lead the aerospace and defense industry's growth in the United States. Thus, titanium manufacturing in the North America has been continuously increasing to suit the growing demand for new aircraft and engines. The growth in the production of aircraft will augment the demand for aircraft parts which will lead to rise in consumption and demand for titanium.

North America Titanium Market Segment Analysis – By Geography

USA held the largest share in the North America Titanium Market in 2020 up to 68% by revenue, owing to the flourishing aerospace industry in the region. The United States accounts for about 4% of the total world production of titanium minerals and is heavily dependent on imports of titanium mineral concentrates on meeting its domestic needs. According to the U.S. Geological Survey, in 2020 majority of titanium was used in aerospace applications. According to the International Trade Administration (ITA), the U.S. aerospace sector continues to produce the highest trade balance (US$77.6 billion in 2019) and the second highest level of exports (US$148 billion) among all manufacturing industries. This predominant position has remained unchanged for decades, with aerospace exports having grown at an average rate of 5.31 percent over the last 10 years and the aerospace trade balance increasing at an average rate of 4.64 percent since 2010. Thus, it is anticipated that with the increasing aerospace production in the region, the demand for titanium is also eventually rising, which is positively impacting the USA titanium market growth.

Schedule a Call

North America Titanium Market Drivers

Increasing Demand for Titanium over Other Metals in the Automotive Industry

Titanium is increasingly influencing the automotive industry, spurred by the need to find alternative sources of materials in production to standard steel and aluminium. Titanium connecting rods are already utilized in engines to improve fuel efficiency and minimize pollution. The same material is also used in automotive engine valves, which improves fuel efficiency and vehicle reliability. Engines with titanium valves have a 20% higher speed restriction than those with steel valves. Also, titanium is utilized in an automobile since it helps to extend the life of motor parts. Titanium springs, for instance, are more corrosion resistant when compared to steel springs, which prolong their service life. Because the young's modulus of titanium is about half that of steel, the number of turns can be lowered when used in the springs. Titanium is hence thought to be beneficial not just in terms of weight loss but also in terms of size reduction. Furthermore, in terms of specific toughness and fatigue strength, the two most important indexes for titanium application to automobiles, titanium is advantageous over steel and aluminium alloys. Titanium is also beneficial to turbochargers as it improves heat resistance and longevity. Because of their low melting point, light metals like aluminium are not suitable for turbochargers, which will enhance an engine's power output. On the other hand, titanium is an excellent material for turbochargers because of its strong heat resistance. Thus, the rising demand for titanium over other metals in automotive components is further projected to fuel the North American titanium market during the forecast period.

Surging Demand for Titanium in the Healthcare Sector

For the past years, the medical industry has employed titanium for surgical and dental equipment in the healthcare industry. Titanium is increasingly used in various biomedical implants, including pacemakers, eye implants, and hearing aids. Titanium's remarkable ability to connect with the bone and living tissue makes it an excellent material for orthopaedic implants like knee and hip replacements. It's also suitable for various other medical tools due to its strength and higher corrosion resistance. It is also the most biocompatible of all metals, and it permits human bone development to cling to prosthetic and joint-replacement devices, allowing them to endure longer. Titanium is used in pacemaker casings because it is resistant to body fluids, lightweight, flexible, and non-magnetic. Titanium is even used in artificial heart valves. Furthermore, titanium has several properties that make it an excellent choice for medical applications. Its benefits include durability, non-ferromagnetism, biocompatibility, bio interfacing, osseointegration, and others, which has raised its demand. With the launch of new titanium implant products in the healthcare sector, the North American titanium market is estimated to rise. For instance, In July 2020, CancelleX Bio-inspired spinal implants from Xenco Medical launched the first injection-molded titanium foam implants for spine surgery pre-attached to disposable instruments. In addition, The Titanium/PEEK Posterior LEIF (Lateral Expandable Interbody Fusion) cage, designed for use in the lumbar spine as a spinal fusion procedure, was launched by Zavation Medical Products company an innovative designer and manufacturer of high-quality spinal implants, instruments, MIS procedural kits, and biologics headquartered in Flowood, MS in August 2020. Furthermore, in October 2020, The Adaptix Interbody System, a guided titanium implant with Titan nanoLOCK surface technology, a blend of macro, micro, and nano surface textures, was launched in the United States by Medtronic. Thus, due to such alluring properties and rising product launches, the demand for titanium in the healthcare sector is further projected to fuel the North American titanium market during the forecast period.

North America Titanium Market Challenges

The High Cost of Titanium Can Hinder Market Growth

Titanium is generally more expensive than other metals since it is rare and the fact that it is typically only found linked to other elements, which makes processing more difficult. Titanium cannot be recovered by reducing the ore with carbon because titanium carbide forms, making the metal brittle. Instead, the extraction procedure is divided into many stages known as the Kroll Process. The high market price of titanium is due to the intricacy of the process and the amount of energy required in its manufacture. Aircraft manufacturing entails the fabrication of sophisticated components, resulting in large amounts of scrap. Scrap availability has been limited throughout the second half of 2020 and into 2021, forcing prices to surge to levels last seen in 2012. When aviation came to a halt in April 2020, however, titanium prices plummeted dramatically. As the aerospace industry returns to 'business as usual' following the lengthy COVID-19 lockdown, it is estimated that the titanium market is improving, resulting in higher prices and the end of titanium scrap shortages. Thus, the titanium market is expected to struggle to attain widespread adoption throughout the forecast period due to the concerns mentioned above.

Availability of Substitutes has Restricted Market Growth

Titanium's application in the broad consumer market may be ruled out in the following years due to its high extraction and production costs. As a result, many companies seek new ways to cut costs, reduce the weight of their products, and lessen their overall energy use. As a result, metals including aluminum, magnesium, and steel are increasingly being investigated as titanium substitutes. Because magnesium is incredibly light, it is 50 percent lighter than titanium and 33 percent lighter than aluminum, makes it a viable titanium substitute. In addition, when compared to other metals such as steel, stainless steel of the highest grade is thought to be more durable than titanium. Thus, the increasing use of aluminum, magnesium, and steel as a substitute owing to their advantageous property over titanium is estimated to restrain the market's growth.

Buy Now

North America Titanium Market Landscape

Technology launches, acquisitions, and R&D activities are key strategies adopted by players in the North America Titanium Market. Major players in the North America Titanium Market are:

Allegheny Technologies Inc.

Titanium Metals Corporation

U.S. Titanium Industry Inc.

Titanium Fabrication Corporation

Ulbrich Stainless Steels and Special Metals Inc.

AP&C Powder Metallurgy

United Titanium, Inc.

Sierra Alloys Co.

Corrosion Materials, Inc.

Acquisitions/Technology Launches

In December 2020, Ulbrich announced the unveiling of one of the world’s most advanced 20 High Rolling Mill at Wallingford, CT, where precision strip and foil is cold rolled for over 160 alloys of stainless steel, nickel, titanium, and other special metals. The new Rolling Mill can handle a wide range of thicknesses. This new mill has a technically advanced automatic gauge control and shape control system to closely monitor real-time variations of thickness and flatness throughout the length of each coil.

#North America Titanium Market#North America Titanium Market Share#North America Titanium Market Size#North America Titanium Market Forecast#North America Titanium Market Report#North America Titanium Market Growth

0 notes

Text

Single Use Systems

Email Us : [email protected]

What Are Single Use Systems?

Single Use Systems are disposable systems used in biopharmaceutical manufacturing. Unlike traditional stainless steel setups, these systems are designed for one-time use, significantly reducing the need for cleaning, sterilization, and validation. They include various components such as bags, tubing, filters, and connectors, all crafted to maintain a sterile environment.

At Foxx Life Sciences, these systems are engineered to provide optimal performance, ensuring that your processes run smoothly while adhering to regulatory standards.

Advantages of Single Use Systems

Reduced Risk of Contamination Disposable components minimize cross-contamination risks, making them ideal for sensitive processes.

Cost Efficiency By eliminating cleaning and sterilization needs, Single Use Systems lower operational costs and save time.

Scalability These systems can easily adapt to production needs, from small-scale research to large-scale manufacturing.

Enhanced Flexibility Single Use Systems support various bioprocessing applications, from cell culture to final fill-and-finish.

Sustainability Modern systems incorporate recyclable materials, aligning with eco-friendly practices.

Foxx Life Sciences: Your Partner in Innovation

When it comes to Single Use Systems, Foxx Life Sciences stands out as a trusted provider. Their comprehensive product range caters to diverse needs, ensuring that every bioprocessing challenge is met with a tailored solution.

Explore Key Products:

Single Use Bags: Ideal for liquid handling, media storage, and transportation.

Tubing Assemblies: High-quality connectors and tubing for seamless fluid transfer.

Sterile Filters: Designed for optimal filtration and sterility assurance.

Visit their dedicated Single Use Systems webpage to explore the full range of products that redefine efficiency in bioprocessing.

Applications of Single Use Systems

Pharmaceutical Manufacturing: Streamlined processes for drug development and production.

Biotechnology: Enhanced scalability for cell culture and fermentation.

Vaccine Production: Flexible systems to accommodate diverse vaccine manufacturing needs.

Why Choose Foxx Life Sciences for Single Use Systems?

Industry Expertise: Years of experience in delivering reliable bioprocessing solutions.

Quality Assurance: All products are manufactured to meet international regulatory standards.

Comprehensive Support: From consultation to implementation, Foxx Life Sciences ensures a seamless experience.

Conclusion

Single Use Systems are revolutionizing bioprocessing by offering unparalleled convenience, efficiency, and reliability. With Foxx Life Sciences as your partner, you gain access to top-tier solutions that empower your operations and ensure compliance with industry standards.

Explore the innovative range of Single Use Systems at Foxx Life Sciences and elevate your bioprocessing capabilities today!

Contact Us : [email protected]

https://www.linkedin.com/company/foxxlifesciences

0 notes

Text

Stainless Steel 316l Pipe Manufacturers in USA

Looking for top-notch Stainless Steel 316L Pipe Manufacturers in USA? Look no further than Siddhigiri Tubes. Renowned for their exceptional quality and durability, their stainless steel pipes meet the highest industry standards. Whether you need pipes for industrial, commercial, or residential applications, we provides unparalleled craftsmanship and reliable delivery times. Trust in their expertise to ensure your projects are equipped with the best materials available in the market. Choose them for your stainless steel 316L pipe needs and experience the difference in quality and service.

1 note

·

View note

Text

Threaded Equal Tee Exporters in India

INTRODUCTION:- Shasan Piping Solution was founded by a group of many years of experienced specialists in product developing, designing, producing management, and quality control. Our Organisation is ISO 9001:2015. We supply only good quality, traceable inspection, and reliable delivery with excellent customer service.

We are professionals and specialize in manufacturing, stockist, importing, and export of Pipe Fittings, Flanges, Fasteners, Instrumentation Fittings, Hammer Union, Valves, Gaskets, Pipes and Tubes, Sheet, Plates, Coils, Bars & Structural Steel Products as per customer’s projects, drawings, standards, and specifications. The most popular kind of pipe fitting that can be used to combine or divide liquid streams is a threaded tee fitting. The ASTM A182 SS Threaded Tees can be accessed via a female-threaded side outlet and female thread sockets, solvent-weld sockets, or solvent-weld sockets.

Threaded Equal Tees can be used to divert a pipe run, connect pipes of different diameters, or do both. A stock list of forged threaded tees made in various materials, sizes, and wraps is available at Shasan Piping Solution. Additionally, the screwed tee made of alloy steel can also be used to transfer two liquid combinations. Based on their three connections, tees can be classified as equal or unequal in size, with equal tees being the most often produced kind.

DESCRIPTION:- These threaded tee fittings have undergone additional treatments, one of which includes surface treatments, to improve their outer layer. The threaded tee ASME B16.11 is available in several completions. Typical finishes for the outer layer of the threaded tee include electroplating, nickel plating, white coating, dark cast, gold plating, excited finish, and so forth. While these treatments provide an external advantage to the ASME B16.11 threaded tee features, there should occasionally be an opportunity to further enhance its mechanical qualities, such as by boosting its resistance to and tensile strength of erosion.

Most commonly, cast metal or bronze, forged alloy and carbon steel, or cast dark or flexible iron could be used to make threaded screwed tee fittings. Alternatively, alternative materials such as stainless steel, aluminum, nickel, cast iron, bronze, plastic, elastic, copper, metal, polypropylene, etc. might also be used to make the ASTM A182 SS Threaded Tees. There are three tension ratings available for the ASME B16.11 threaded tee fitting aspects: Class 2000, Class 3000, and Class 6000.

Presumably, the earliest technique for connecting pipe systems is represented by the threaded tee fitting characteristics of ASME B16.11. The ASME B16.11 threaded tee fittings, often called little drag pipework, are mostly used for small pipe diameters, much as socket weld fittings. Little drag pipe is typically defined as piping with an apparent diameter of NPS 2 or less.

SPECIFICATIONS:- 1. Specifications- Forged Threaded equal tee 2. Dimension Specification- ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 3. Threaded equal tee Forged Fittings Thread- NPT, BSPT, BSPP 4. Threaded equal tee FittingsType- DN15-DN1200 5. End- Threaded, Welding, JIC 6. Threaded equal tee Fittings Pressure Rating- Threaded end-2000lb/ 3000lb/ 6000lbs Threaded equal tee, Connection, Welding 7. Bending Radius- R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom 8. Threaded equal tee 8. Size Range- 1/8" NB TO 4" NB 9. Manufacturing process- Push, Press, Forge, Cast, etc. 10. Threaded equal tee Test Certificates- EN 10204/3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report, etc 11. Origin & Mills - Japanese, Indian, USA, Korean, European, Ukraine, Russian 12. Key markets and industries for Threaded equal tee Fittings- Bitumen upgraders, Heavy oil refineries, Nuclear power (mostly seamless), Petrochemicals and acids. 13. Application - Threaded equal tee To Connect Pipe & Tubes in Petroleum, Power, Chemical, Construction, Gas, Metallurgy, Shipbuilding etc.

BENEFITS:- High-Quality Products: Threaded equal tee exporters provide products that meet international standards such as ASME 16.11, MSS SP-79, and BS 3799. This ensures that the tees are of superior quality and suitable for various industrial applications.

Wide Range of Options: Exporters offer a diverse range of threaded equal tees, including different sizes, pressure ratings, and materials. This variety allows customers to find the perfect fit for their specific requirements, enhancing flexibility and compatibility with existing systems.

Ease of Installation: Threaded connections offer ease of installation, allowing for quick and hassle-free assembly of piping systems. Threaded equal tees provide a secure and reliable connection without the need for specialized tools or welding, saving time and labor costs during installation.

Versatility: Threaded equal tees are versatile components that can be used in a wide range of industries and applications, including petroleum, chemical, construction, and shipbuilding. Their ability to connect three pipes of equal diameter at right angles makes them essential for branching and distributing fluid flow in piping systems.

Customization Options: Exporters often offer customization options for threaded equal tees, allowing customers to tailor the fittings to their specific needs. Whether it's a particular size, material, or threading requirement, exporters can accommodate various customization requests to meet customer specifications.

Reliable Supply Chain: Exporters ensure a reliable supply chain, ensuring timely delivery of threaded equal tees to customers worldwide. With a robust manufacturing infrastructure and efficient logistics network, exporters can fulfill orders promptly, minimizing downtime and maximizing operational efficiency for businesses.

CONCLUSION:- In conclusion, threaded equal tee exporters play a crucial role in providing high-quality fittings for industrial piping systems. By offering a wide range of options, ease of installation, versatility, customization capabilities, and a reliable supply chain, exporters empower businesses to optimize their piping systems for enhanced efficiency and performance. Threaded equal tees serve as integral components in various industries, facilitating the distribution and control of fluid flow in piping networks. With a commitment to quality, reliability, and customer satisfaction, threaded equal tee exporters contribute to the success and competitiveness of industries worldwide.

CONTACT US:- Phone :+91-88797-09191 Phone :+91-22-6651 8642 E-mail : [email protected]

#Threaded Equal Tee Manufacturers#Threaded Equal Tee Suppliers#Threaded Equal Tee Stockists#Threaded Equal Tee Exporters#Threaded Equal Tee Manufacturers in India#Threaded Equal Tee Suppliers in India#Threaded Equal Tee Stockists in India

0 notes