#Solar Module Recycling

Explore tagged Tumblr posts

Text

How Are Solar Panels Recycled? A Step-by-Step Breakdown

As the solar industry grows, so does the challenge of managing old and damaged panels. But what happens to solar modules at the end of their lifespan? This guide breaks down the solar panel recycling process step by step, from collection and material separation to reclaiming valuable components like silicon, glass, and metals. Learn how innovative recycling technologies are making solar energy even more sustainable and what the future holds for end-of-life solar panels.

#Solar Panel Recycling#Solar Panel Disposal#Solar Module Recycling#Solar Panel Recycling near me#Solar Panel Recycling companies#ESG report#environmental social and governance report#Commercial Solar Site#Solar Recycling#ESG report consulting#We recyle solar#Recycle solar panel near me#ESG Reporting Companies#ESG sustainbility report#end of life solar panels#Decommission#Decommissioning Solar Panels#Decommission Solar Systems#Solar Panel Decommissioning#Decommissioning Solar Power Plants#Solar Farm Decommissioning#Utility Scale Solar Projects#Utility Scale Projects#Solar waste management companies#Solar Waste Management Consulting Services#Solar Panel Disposal near me#Solar Panel Removal near me#Waste from solar panels#Solar Panel Removal & reinstall near me#Solar panel waste

2 notes

·

View notes

Text

Factorio: Space Age introduces the "quality" system, which you can technically play without, though I'm not sure it's balanced around that. I've now played with it enough that I have some thoughts on it.

First, I think it's kind of stupid that machines cannot naively use mixed-quality materials. It means that if you put a quality module in a single furnace, the lines will get "polluted" by the plates that are produced, and the whole factory will eventually gum up. Ask me how I know. I would vastly have preferred that it not matter: use a rare gear in a belt, and either it has no special benefit, or gives a chance to grant quality or something. But if it did that, I suppose it wouldn't be much of a gameplay challenge.

There are a few other pain points. One of them is that bots and the interface in general do not handle quality very well. Quality is almost always a strict upgrade, so it would be nice if there was a setting I could tick that said "hey, go upgrade things if possible". But instead, the UI and mechanics are such that you need to specify it, and this is super annoying, because it means that I have to manually go do the replacement myself, or have an upgrade planner to upgrade quality, then cancel the job once everything that can be replaced is so that the game will stop giving me an alert. I have accumulators and solar panels set up for quality right now, and I can't immediately think of a way to automate the process of upgrading the solar fields. I'm guessing that mods will help with that eventually. I also definitely want a keybind for "increase quality" and "decrease quality" on a machine, though I guess I never went looking to see whether that was a thing, so maybe it exists and I'm ignorant.

So as I see it, there are three main ways to engage with the mechanics:

Put quality modules in a machine that you're going to craft once and hope to roll high. The advantage is that hey, maybe you'll get lucky, and for stuff that goes in the equipment grid, I think this is sensible to do. Probably also wise for infrastructure, so long as you're fine doing some manual finagling that really should be done with bots.

Put quality modules in (some) machines that make intermediates, then use whatever you skim off the top there to make quality things. This does work, but you have to skim off essentially every single production line, and I think over time you end up with too much of certain things, which kind of sucks. It's one of the things that I've been doing, since it can guarantee the higher quality stuff, and ideally all the stuff in a spaceship and your equipment grid is at highest quality available. (You can also "skim" off anything you're making a shit-ton of for science: electric furnaces and yellow inserters are the two most obvious ones. I do wish this were easier to automate so that at some point you could say "actually, don't do the quality thing anymore". Probably some circuit logic could get you there, but you can't replace modules automatically that I know of.)

Use the recycler to "reroll" quality, making a gear over and over and over until it rolls high and can be separated out. The only issue with this is that it requires the recycler, and also is very expensive, but it does mitigate the randomness in its own way.

There's a secret fourth way that I've been noodling, which is that you could essentially build five separate copies of your base, put quality modules in everything, then if you roll high, send the better materials to the other base. This is insane, which is why I like it. So you would have miners mining with quality, which then gets separated onto five different trains and brought to the smelters, which then turn some fraction into higher quality plates that get sent to the "higher" factories. Those plates go into assemblers, which have a chance of upgrade, and so on, until there are five sets of labs, each of which is working with a different set of quality flasks. But I'm pretty sure that this would have a lot of technical problems, and really risk gumming up, as well as being very space inefficient and resource intensive. Still, might be workable end game, if you could deal with the inevitable overflows and imbalances.

Overall, I like it as a problem to chew on, but I think in practice they made a few decisions that I find annoying. Mods seem like they're fix some of it, like having to manually select upgrades, but the "clogging up the inventory" issue isn't going to go away, and in fact seems like one of the basic things that the mechanic is balanced around. I really appreciate that there are many ways to approach it, and that it creates this tradeoff of "go tall" or "go wide".

I'm very curious to see what people do with it, though I think the "throw vast resources into recycling" approach is probably going to be the dominant one unless there's a great blueprint for handling the overhead. And I'm also curious where public opinion is going to land on it, since it seems like the kind of thing that might end up divisive.

17 notes

·

View notes

Text

The use of femtosecond lasers to form glass-to-glass welds for solar modules would make the panels easier to recycle, according to a proof-of-concept study conducted by researchers at the U.S. Department of Energy's National Renewable Energy Laboratory (NREL). The welds would eliminate the need for plastic polymer sheets that are now laminated into solar modules but make recycling more difficult. At the end of their useful lifespan, the modules made with the laser welds can be shattered. The glass and metal wires running through the solar cells can be easily recycled and the silicon can be reused. "Most recyclers will confirm that the polymers are the main issue in terms of inhibiting the process of recycling," said David Young, senior scientist and group manager for the High-Efficiency Crystalline Photovoltaics group in the Chemistry and Nanoscience department at NREL. Young is lead author of a new paper outlining the use of laser welds for solar modules. The paper, "Towards Polymer-Free, Femto-Second Laser-Welded Glass/Glass Solar Modules," appears in the IEEE Journal of Photovoltaics.

Read more.

18 notes

·

View notes

Text

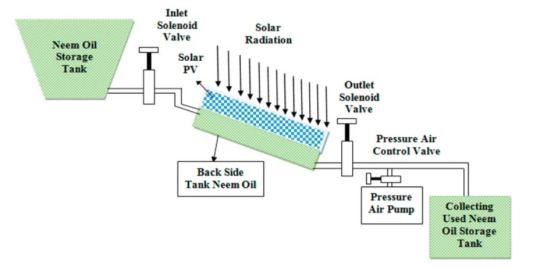

A group of scientists led by Kongu Engineering College in India investigated the use of waste neem oil as a cooling solution for PV modules. Neem oil is extracted from the seeds of the neem tree and is commonly used as a medicine for some skin diseases.

The researchers explained that this oil acts like phase-changing materials (PCMs), which can absorb, store, and release large amounts of latent heat over defined temperature ranges. PCMs have often been used at the research level for PV module cooling and the storage of heat.

“The neem oil has a good thermal range, is physically high in density, is chemically stable and noncorrosive, is environmentally pollution-free, reusable, and recyclable, and is economically low-cost and easy to dispose of,” they added. “Commonly, any PCM used for cooling purposes should have low thermal conductivity, stability, and cycling. The neem oil has fulfilled all the limitations.”

9 notes

·

View notes

Text

Mercedes-Benz is developing a new type of solar paint that could transform electric vehicle power. This photovoltaic coating, just 5 micrometers thick, covers 11 square meters. It can generate enough energy to power a car for up to 7,456 miles (12,000 kilometers) annually under ideal conditions.

The nanoparticle-based paint allows 94% of solar energy to pass through and is easy to recycle. It’s designed to be lightweight (50 grams per square meter) and can cover all exterior vehicle surfaces.

This solar paint, which contains no rare earth elements or silicon, is also cheaper to produce than conventional solar modules. The energy generated can be used to drive the vehicle or feed into the high-voltage battery even when the car is off.

This could mean no need to plug in for charging. The paint can be applied directly to the car’s body, with the color paint job sprayed over it to protect against scratches and other damage.

5 notes

·

View notes

Text

(The following article is a bit spoilery, but I've been working on this stupid concept for years and I just want to post it already. Still not happy with the design, but I can tweak it some more in the future. Since Ojio is a sci-fi geek, I wanted to give his invention a hokey retro futurist/anime flair.)

CHROMIGHT MECHASKEMA

OVERVIEW

The ChroMight Mechaskema(™) is a device invented by Ojio Paramonimos, founder of Chromight Technologies. It is a robotic body-augmentation that is custom tailored to its user. The mechanical framework permanently interfaces with the user’s nerves and organs, enhancing all bodily functions. Mr. Paramonimos himself describes it as “a mechanical shell”.

Once connected with the Mechaskema(™), users experience increased strength and speed, enhanced senses, and various other abilities which can be customized with modules, such as flight and water-breathing.

The Mechaskema(™) draws power from the user’s own energy reserves, meaning the user must eat more calories to accommodate extra power draw. Additional modules will draw even more power, and at a certain point it becomes impossible for the user to keep the device powered on calories alone. In these cases, additional power sources such as petrol, arcane crystals, or batteries must be used.

BENEFITS

Mechaskema(™) users (also known as “chromen” or “chromies”) enjoy a wide range of benefits from their mechanical parts. The device efficiently recycles calories into energy, eliminating the need to defecate altogether. Its blood purification system can filter disease and improve healing speeds, and may even allow the user to eat toxic materials with little to no harm.

The device can also slow the body’s aging process, but how much depends on which modules are used. This enables short-lived species such as trolls and minotaurs to enjoy longer lifespans. The device can also compensate for missing limbs and failing organs, effectively acting as a life-support system for sick users and allowing them to function normally.

In addition, the devices allow users to bypass the need for sleep using supplemental energy sources, giving them more waking hours for productivity or recreation.

Mechaskemas(™) are available in 2 models: basic and ultra.

The basic model offers many benefits and customization options, but is less powerful than the ultra model and cannot support as many modules. Its design is less invasive, leaving more of the user's flesh exposed and bodily functions unaltered. It may interact with some organs and other body parts, but not all of them.

The ultra model offers maximum benefits to the user and many slots for modules, but its heavy power draw can prove burdensome and even dangerous to the user if not managed properly. This model requires a supplemental power source to function, such as a battery. It is highly invasive, as it interacts with every part of the user's body.

SIDE EFFECTS

Mechaskemas(™) are a permanent body augmentation. Because they interface so heavily with the user’s biology, removing them is a fatal process. This also means that the user is at the mercy of the device’s core mechanisms, and should any of these mechanisms fail, the user may die or suffer severe biological damage. Broken mechanisms must be fixed or replaced promptly, but they are expensive, and this can only be done by skilled technicians.

Not everyone is a good candidate for a Mechaskema(™). The ideal user is a biologically mature adult, financially upper class, and technologically savvy. They should never plan to travel far from a ChroMight Technologies repair center, in case of a critical mechanism failure. The devices utilize several materials that are forbidden by the Nymph Pact, meaning chromen will struggle to survive in Great Kingdoms where the pact is in effect, and may be banned from those territories altogether.

Mechaskemas(™) depend entirely on a power source. Calories, arcane energy, solar, petrol, or electricity are all options depending on the user’s model, but when these sources are not available, the device will begin consuming the user’s body. Allowing the device to run out of power leads to serious consequences, such as permanent bodily damage and even death.

In addition to food, the devices also require water to function properly. More advanced models require more water, which they utilize for cooling and other systems. Becoming dehydrated causes the device to malfunction and will lead to the user’s death if it is not corrected promptly.

Chromen experience increased hunger and thirst as a result of their mechanically-augmented bodies. Using supplemental power sources and water-management modules can mitigate these side effects.

The Mechaskemas(™) are mechanical devices, and as such they require maintenance. Regular oiling, polishing, and tune-ups will keep them functioning optimally, but failing to take care of these machines will lead to poor performance and possibly death to the user.

Over time, users will become more and more dependent on their devices to survive as their bodies begin to atrophy. Older users experience a phenomenon known as “module creep”, where they require more modules to keep themselves alive as time goes on.

Mechaskemas(™) are not free, nor are their power sources, replacement parts, modules, or maintenance. In fact these things are all quite expensive, so choosing to become a chroman is not a decision to be taken lightly. At a certain point, a chroman’s survival becomes entirely dependant on how much money they have for repairs.

MODULES

Each new Mechaskema(™) comes equipped with a set of standard features, depending on whether it’s a basic or ultra model. If users want more features, they must purchase modules. Modules are extra parts that attach to the device and enable more features. Each module draws additional power, and more sophisticated modules draw even more.

Some smaller modules can be added and removed without consequence. Others are more invasive and cannot be removed without killing the user.

Modules can perform a virtually endless number of functions. Each one falls under a broad category, and these categories include: Health, Utility, Defense, Energy, and Miscellaneous.

The following is a list of popular modules from each category:

HEALTH: Blood detoxifier, pacemaker, aging deceleration, synthetic womb, pain blocker

UTILITY: Enhanced strength, optical zoom lens, speed boosters, lights, artificial gills, wings, jetpack

DEFENSE: Armor plates, blades, guns, spikes, spell magnifier

ENERGY: Water tanks, fuel tanks, water vaporizer, fuel burner, solar panels, battery slots

MISCELLANEOUS: Radio, calculator, voice modulator, sexual enhancers, cosmetic modifications

CULTURE

Mechaskemas(™) are a novel technology in the world of Looming Gaia, and public opinion on them varies wildly. Some staunchly disapprove, viewing them as an insult to nature, and believe they will lead to allkind’s demise. Others support the technology, believing it can change many lives for the better.

Currently the devices are only available in Zareen Empire, but ChroMight CEO Ojio Paramonimos wishes to expand this technology to foreign lands in the future. Critics argue that chromen become entirely dependant on the company’s technology, and must keep surrendering more and more money to ChroMight Technologies as they become more dependent on their devices. Because of this, the company faces frequent protests and media scrutiny.

However, many corporations and even world militaries are very interested in Paramonimos’ creation, and have invested in his research in hopes that they can benefit from this novel tech in the future.

Mr. Paramonimos is under immense political, ethical, and financial pressure from all sides, and while his invention could possibly lead to disaster, he claims his only intention is to create a better future for allkind. He believes the marriage of flesh and machine will open the door to a safer, cleaner, and smarter tomorrow.

*

Questions/Comments?

Lore Masterpost

Read the Series

12 notes

·

View notes

Text

Drifting

A chemically propelled rock hopper in orbit. The ship is roughly 160 meters in length, with the mast in front holding a small reactor at the far end where it's radiation will not harm the crew. The two centrifuge arms are 30 meters long each, simulating 1.3 m/s^2 or .13g at 2rpm. This ship is still a work in progress, and some design elements have changed but not yet been rendered. The ship is intended to be a cheap but slow way to travel through this fictional solar system, accessible to well off individuals or small groups of civilians willing to pool resources to run a ship. One arm holds a vertical refinery and fabrication facility to produce air, fuel, and some replacements for equipment on the ship, along with a workshop for crew members to perform maintenance in a spin gravity environment. The other arm holds sleeping quarters for crew, and a gym/cramped recreational area. The central non spinning module contains ECLSS, storage, additional crew quarters, consumables recycling, and other facilites necessary for running a ship for several months without resupply. Chemical fuel is relatively easy to find via water in comets, which is split with power from the reactor and stored in the tanks. Autogeneous pressurization removes the need for the ship to rely on stations to acquire new stores of helium to keep the fuel tanks properly pressurized. With sufficient planning and use of recycling systems these ships can operate for several months or even a few years without need for any resupply.

2 notes

·

View notes

Text

Alltick API: Where Market Data Becomes a Sixth Sense

When trading algorithms dream, they dream in Alltick’s data streams.

The Invisible Edge

Imagine knowing the market’s next breath before it exhales. While others trade on yesterday’s shadows, Alltick’s data interface illuminates the present tense of global markets:

0ms latency across 58 exchanges

Atomic-clock synchronization for cross-border arbitrage

Self-healing protocols that outsmart even solar flare disruptions

The API That Thinks in Light-Years

🌠 Photon Data Pipes Our fiber-optic neural network routes market pulses at 99.7% light speed—faster than Wall Street’s CME backbone.

🧬 Evolutionary Endpoints Machine learning interfaces that mutate with market conditions, automatically optimizing data compression ratios during volatility storms.

🛸 Dark Pool Sonar Proprietary liquidity radar penetrates 93% of hidden markets, mapping iceberg orders like submarine topography.

⚡ Energy-Aware Architecture Green algorithms that recycle computational heat to power real-time analytics—turning every trade into an eco-positive event.

Secret Weapons of the Algorithmic Elite

Fed Whisperer Module: Decode central bank speech patterns 14ms before news wires explode

Meme Market Cortex: Track Reddit/Github/TikTok sentiment shifts through self-training NLP interfaces

Quantum Dust Explorer: Mine microsecond-level anomalies in options chains for statistical arbitrage gold

Build the Unthinkable

Your dev playground includes:

🧪 CRISPR Data Editor: Splice real-time ticks with alternative data genomes

🕹️ HFT Stress Simulator: Test strategies against synthetic black swan events

📡 Satellite Direct Feed: Bypass terrestrial bottlenecks with LEO satellite clusters

The Silent Revolution

Last month, three Alltick-powered systems achieved the impossible:

A crypto bot front-ran Elon’s tweet storm by analyzing Starlink latency fluctuations

A London hedge fund predicted a metals squeeze by tracking Shanghai warehouse RFID signals

An AI trader passed the Turing Test by negotiating OTC derivatives via synthetic voice interface

72-Hour Quantum Leap Offer

Deploy Alltick before midnight UTC and unlock:

🔥 Dark Fiber Priority Lane (50% faster than standard feeds)

💡 Neural Compiler (Auto-convert strategies between Python/Rust/HDL)

🔐 Black Box Vault (Military-grade encrypted data bunker)

Warning: May cause side effects including disgust toward legacy APIs, uncontrollable urge to optimize everything, and permanent loss of "downtime"概念.

Alltick doesn’t predict the future—we deliver it 42 microseconds early.(Data streams may contain traces of singularity. Not suitable for analog traders.)

2 notes

·

View notes

Text

Creating a Space Station

Name and Location:

Name of the space station

Orbital location (e.g., around a planet, moon, or in deep space)

Any unique features or characteristics of the location

Background and Purpose:

Brief history and reasons for the station's construction

Primary purpose or mission of the station (e.g., research, colonization, defense, trade, mining, etc.)

Key organizations or entities involved in its establishment

Design and Structure:

Overview of the station's architectural design and layout

Different modules or sections of the station (e.g., living quarters, research labs, docking bays, etc.)

Key engineering feats or technological advancements used in its construction

Size and Population:

Dimensions of the space station (length, width, height)

Estimated population and demographics (humans, aliens, robots, etc.)

Capacity for expansion and accommodating future growth

Systems and Resources:

Life support and Resource systems: Air generation and filtration, Water purification and recycling, Waste management, Artificial gravity, Temperature and air pressure control, Radiation protection, Fire suppression systems, Medical supplies and tools, Food production, Maintenance and Repair tools and facilities

Energy source and storage: Solar power, Nuclear fusion, Advanced batteries, Fusion reactors, Harvesting solar flares

Living Quarters and Facilities

Description of residential areas (individual quarters, communal spaces, recreational facilities)

Water block

Medical facilities and healthcare services available

Education and training facilities for residents and their families

Scientific Research and Laboratories

Different types of laboratories and equipment available depending on the stations’s mission

Astronomical observatories, Biological Laboratory, Climate and Environmental Studies, Planet observation and Research, Rock Analysis Facility

Transportation and Docking:

Docking bays for spacecraft and shuttle services

Transportation systems within the station (elevators, maglev trains, etc.)

Maintenance and repair facilities for visiting spacecraft

Security and Defense:

Security measures and protocols

Defense systems against potential threats: Shielding technology, Defensive satellites & space drones, Cloaking Technology, Countermeasures (flares, countershots, etc), Intruder Detection Systems, Surveillance and AI protection, Protection by AI or Hacker from outside hacks, Self-Repair System

Security personnel and their roles and ranks

Communication and Information Systems:

Communication technology used for inter-station and interstellar communication

Data storage and retrieval systems

Access to networks anddatabases

Trade and Economy:

Types of goods and resources traded on the station

Cargo of the space station

Economic systems

Currency used

Marketplaces within the station

Social and Cultural Aspects:

Societal norms and cultural diversity among the station's residents

Recreational and entertainment facilities (cinemas, sports arenas, etc.)

Events or celebrations unique to the station's culture

Governance and Administration:

Station hierarchy and governing bodies (administrators, council, etc.)

Laws and regulations specific to the station

Interactions with external governing entities (planetary governments, interstellar alliances, etc.)

Exploration and Discovery:

Expeditions or missions launched from the station

Discoveries made during exploration and sample gathering efforts

Spacecrafts and vehicles associated with the station's exploration activities

Environmental Considerations:

Measures taken to mitigate the effects of microgravity or radiation on residents' health

Environmental controls and simulations for recreating gravity and natural environments

Preservation of ecosystems and biodiversity on the station (if applicable)

Emergency Response and Crisis Management:

Protocols for handling emergencies (fires, system failures, medical emergencies, etc.)

Emergency evacuation plans and escape pods

Training programs for emergency response teams

Relations with Other Space Stations or Entities:

Collaborative projects or joint initiatives with other space stations

Trade agreements or diplomatic relations with neighboring stations or colonies

Conflict resolution mechanisms for inter-station disputes

Notable Individuals or Figures:

Prominent leaders from the station

Accomplishments and contributions of notable residents

Astronauts, scientists, or pioneers who have called the station home

Challenges and Risks:

Environmental and technological risks faced by the station

Political and social tensions within the station's community

External threats and conflicts affecting the station's stability

Future Expansion and Development:

Plans for future expansion and upgrades (where are they gonna get the resources for this?)

Integration of new technologies, scientific advancements into the station's infrastructure

Long-term goals for the station

35 notes

·

View notes

Text

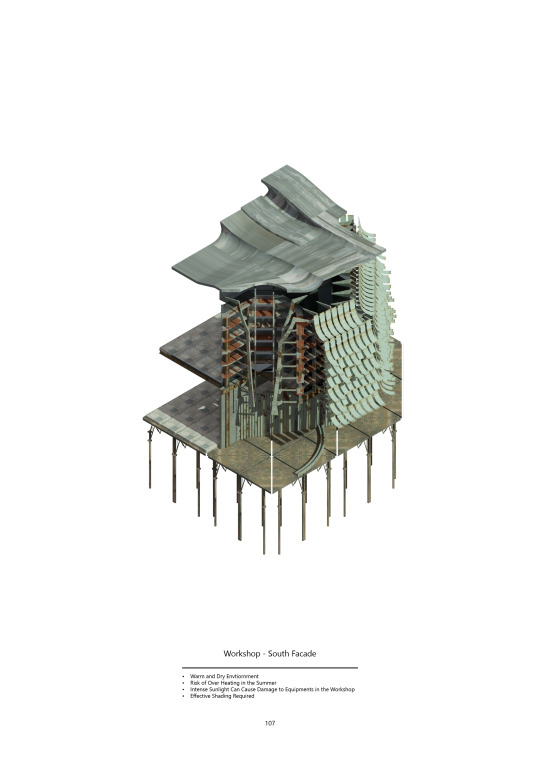

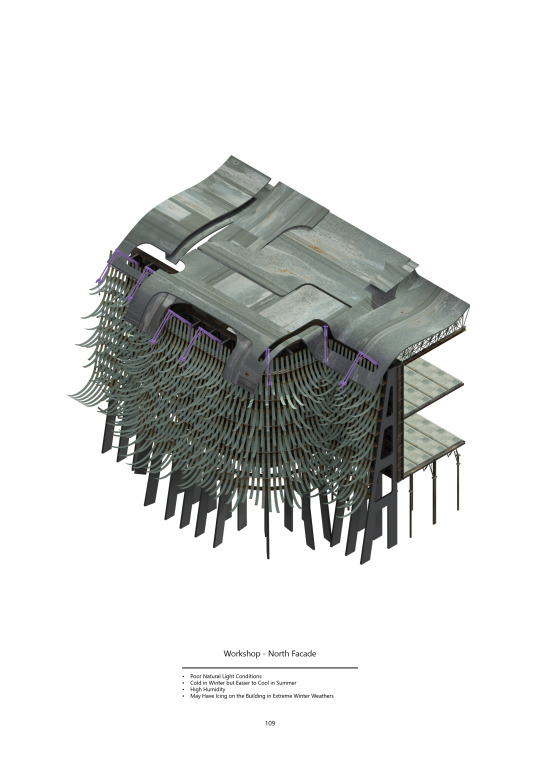

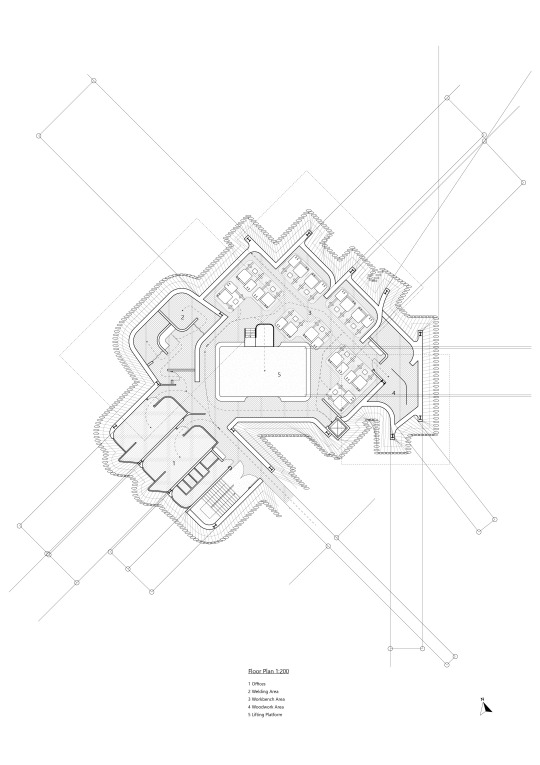

DP2 - Wandering Earth

Week 19:

This week I kept focusing on the workshop by first improving on the plan and then choosing three zones from the plan and designed the roof, facade and structural systems specifically to the environmental conditions required by each zone:

The south facing facade receives the highest level of solar radiation and activities including cutting and drilling take place in this zone, which can lead to overheating in the space, especially at summer. Therefore a layered strategy is implemented on the facade with dense and wide rain-fuel/solar panels acting also as shading devices which can result in effective cooling off the space.

The East Facing Facade provides excellent natural light in the morning and has a good view down the hill towards the city, therefore there are voids on the facades to provide opportunities for a balcony area. The facade panels are more curled up to further provide natural lighting and views as there are workbenches behind the east facade.

The North Facade in 2050 will encounter more severed environmental conditions as it receives poor natural light and is normally cold and damp. Therefore the facade panels are less dense to allow more light entering the space and more gaps on the roof to provide lighting. Deicing systems inspired by the aviation industry extends out from the roof to clean the icing that may form on the facade.

The Roof has different levels and grooves to direct the rainwater to drip down onto the facade elements and utilises its potential energy to regenerate energy; but also recycled into the bathroom to be reused. The roof has a curved shape that rises at certain points for lighting purposes.

I should keep working on these three design modules and use line drawings in combination with these renders to reveal the HVAC, structural and water systems of the space. Doing lighting and heating simulations on the interior space to prove the systems function properly

Key ideas mentioned:

Hollow tiles for heating and ventilation systems running through

shape the tiles so it guides the cool down streaming air around the furniture in the room

Pneumatically designed air exhaustion systems for manufacturing area (Reference to Zaha Science Museum)

Shelving systems on the facade to hang and dry the pieces manufactured in the workshop

Light pipes bringing light to the working area that is integrated with the furniture

furniture suspended from the ground with localized heating, water running through the furniture

Ramps connecting the buildings that extend out into the forest and foreshadowing the theme and emotions that the next building is going to bring to the visitors. Buildings get cut through similarly to canyons.

When presenting, show how spatial organization, facade systems and furniture systems are designed differently according to the hot and cold environment and lux levels.

8 notes

·

View notes

Text

Sustainable Solar Waste Management Solutions for a Greener Future

As solar energy adoption grows, so does the need for responsible disposal and recycling. Our solar waste management company specializes in the safe handling of decommissioned solar panels, batteries, and related equipment. We ensure eco-friendly recycling, reducing landfill waste and recovering valuable materials for reuse. Partner with us to meet regulatory standards and contribute to a circular economy. Whether you're a solar farm operator, installer, or homeowner, we offer tailored solutions for sustainable solar waste disposal. Protect the environment while embracing renewable energy—choose responsible solar waste management today!

#Solar Panel Recycling#Solar Panel Disposal#Solar Module Recycling#Solar Panel Recycling near me#Solar Panel Recycling companies#ESG report#environmental social and governance report#Commercial Solar Site#Solar Recycling#ESG report consulting#We recyle solar#Recycle solar panel near me#ESG Reporting Companies#ESG sustainbility report#end of life solar panels#Decommission#Decommissioning Solar Panels#Decommission Solar Systems#Solar Panel Decommissioning#Decommissioning Solar Power Plants#Solar Farm Decommissioning#Utility Scale Solar Projects#Utility Scale Projects#Solar waste management companies#Solar Waste Management Consulting Services#Solar Panel Disposal near me#Solar Panel Removal near me#Waste from solar panels#Solar Panel Removal & reinstall near me#Solar panel waste

0 notes

Text

Building a cargo spaceship capable of exploring our solar system based on current technology and the knowledge gleaned from our understanding of engineering, science, and chemistry requires us to work within practical and realistic constraints, given that we're not yet in an era of faster-than-light travel. This project would involve a modular design, reliable propulsion systems, life support, cargo handling, and advanced automation or AI. Here’s a conceptual breakdown:

1. Ship Structure

Hull and Frame: A spaceship designed for deep space exploration needs a durable, lightweight frame. Advanced materials like titanium alloys and carbon-fiber composites would be used to ensure structural integrity under the stress of space travel while keeping the mass low. The outer hull would be made with multi-layered insulation to protect against micrometeorites and space radiation.

Dimensions: A cargo space vessel could be roughly 80-100 meters long and 30 meters wide, giving it sufficient space for cargo holds, living quarters, and propulsion systems.

Cost: $500 million (materials, assembly, and insulation).

2. Propulsion Systems

Primary Propulsion: Nuclear Thermal Propulsion (NTP) or Nuclear Electric Propulsion (NEP):

NTP would involve heating hydrogen with a nuclear reactor to achieve high exhaust velocities, providing faster travel times across the solar system. NEP converts nuclear energy into electricity, driving highly efficient ion thrusters. Both systems offer relatively efficient interplanetary travel.

A hybrid solution between NTP and NEP could optimize fuel efficiency for longer trips and maneuverability near celestial bodies.

Cost: $1 billion (development of nuclear propulsion, reactors, and installation).

Fuel: For NTP, hydrogen would be used as a propellant; for NEP, xenon or argon would be the ionized fuel. It would be replenished through in-space refueling depots or by mining water on asteroids and moons (future prospect).

Cost (fuel): $50 million.

3. Power Systems

Nuclear Fission Reactor: A compact fission reactor would power the ship’s life support, propulsion, and onboard systems. Reactors designed by NASA’s Kilopower project would provide consistent energy for long missions.

Backup Solar Arrays: Solar panels, optimized for efficiency beyond Mars’ orbit, would serve as secondary power sources in case of reactor failure.

Cost: $300 million (including reactors, solar panels, and energy storage systems).

4. Cargo Modules

The cargo holds need to be pressurized and temperature-controlled for sensitive materials or scientific samples, while some holds could be left unpressurized for bulk materials like metals, water, or fuel.

Modular Design: The ship should have detachable cargo pods for easy unloading and resupply at different planetary bodies or space stations.

Cost: $200 million (modular design, pressurization systems, automation).

5. Life Support Systems

Water and Oxygen Recycling: Systems like NASA’s Environmental Control and Life Support System (ECLSS) would recycle water, oxygen, and even waste. These systems are key for long-duration missions where resupply may be limited.

CO2 Scrubbers: To remove carbon dioxide from the air, maintaining breathable conditions for the crew.

Artificial Gravity (optional): A rotating section of the ship could generate artificial gravity through centripetal force, improving the crew’s health on longer missions. However, this would increase complexity and cost.

Cost: $200 million (life support systems, with optional artificial gravity setup).

6. AI and Automation

AI-Controlled Systems: AI would manage navigation, propulsion optimization, cargo handling, and even medical diagnostics. Automated drones could be used for ship maintenance and repairs in space.

Navigation: Advanced AI would assist in calculating complex orbital maneuvers, interplanetary transfers, and landings.

Autonomous Cargo Handling: Robotics and AI would ensure that cargo can be efficiently moved between space stations, planets, and the ship.

Cost: $150 million (AI development, robotics, automation).

7. Communication and Sensors

Communication Arrays: High-gain antennas would allow for deep-space communication back to Earth, supplemented by laser communication systems for high-speed data transfers.

Radars and Sensors: For mapping asteroid belts, detecting anomalies, and navigating planets, advanced LIDAR, radar, and spectrometers would be necessary. These sensors would aid in planetary exploration and mining operations.

Cost: $100 million (communication systems, sensors, and diagnostics).

8. Radiation Protection

Water Shielding: Water, which is also used in life support, would double as a radiation shield around the living quarters.

Electromagnetic Shields: Experimental concepts involve creating a small electromagnetic field around the ship to deflect solar and cosmic radiation (early TRL, requires more development).

Cost: $50 million (radiation shielding).

9. Crew Quarters

Living Quarters: Designed for long-duration missions with the capability to house 4-6 crew members comfortably. The quarters would feature radiation protection, artificial lighting cycles to simulate day and night, and recreational facilities to maintain crew morale on multi-year missions.

Medical Bay: An AI-assisted medical bay equipped with robotic surgery and telemedicine would ensure the crew remains healthy.

Cost: $100 million (crew quarters, recreational facilities, medical systems).

10. Landing and Exploration Modules

Surface Exploration Vehicles: For landing on moons or planets like Mars or Europa, a modular lander or rover system would be required. These vehicles would use methane/oxygen engines or electric propulsion to take off and land on various celestial bodies.

Cost: $300 million (lander, rovers, exploration modules).

---

Total Estimated Cost: $2.95 Billion

Additional Considerations:

1. Launch Vehicles: To get the spacecraft into orbit, you would need a heavy-lift rocket like SpaceX’s Starship or NASA’s Space Launch System (SLS). Multiple launches may be required to assemble the ship in orbit.

Cost (launch): $500 million (several launches).

2. In-Space Assembly: The ship would likely be built and assembled in low-Earth orbit (LEO), with components brought up in stages by heavy-lift rockets.

Cost: $200 million (orbital assembly infrastructure and operations).

---

Grand Total: $3.65 Billion

This estimate provides a general cost breakdown for building a cargo spaceship that could explore and transport materials across the solar system. This concept ship is realistic based on near-future technologies, leveraging both nuclear propulsion and automation to ensure efficient exploration and cargo transportation across the solar system.

#canada#canadian politics#space#science#scifi#scifiart#sci fi and fantasy#nasa#nasa photos#elon musk#share#engineering#ideas#ai#scientificresearch#billionaire

6 notes

·

View notes

Text

Callsign: Archon

Chapter One, Part Six

Arriving in the mech bay had been impressive enough; it was practically large enough to house an entire work segment of one of the stations, with four slots to a side - six of them occupied by mechs suspended in shock cradles. Framed by Ashes and Knight, she hadn't seen Archon sweeping in from the side, no until the redhead had plucked her from between the two and spun her around to face the least colorful of the mechs.

"Well, Mirror? What do you think, station girl? Your very own Everest, freshly assembled from the printer and awaiting your decisions to name, decorate, and outfit it." A push at her back, sending her stumbling toward it. "Go on, meet your new best friend!" The three veterans had shown her how to operate the lift and board the nameless mech, and so she'd done as they told her.

And now she sat in the quiet of the cockpit, carefully going through the boot sequence for the systems, following every prompt with the diligent care of station life. The soft hum of fans turning on, the bone-deep vibration as the reactor core came to life, the slow spread of lights starting at red and slowly fading across the spectrum to a green more lovely than any plant from the aeroponics modules; all of it whispering to the little girl who still lived deep inside her.

A prompt on the main screen; "Option: download standard operation NHP or upload personal module?"

She hesitated just before the acceptance - and drew her hand back, digging in the pockets for her personal data slate, the one she was supposed to return to be recycled by the station and never would now. She connected it to the mech's systems and gave the prompt the address of a file on it.

"Caution: Nonstandard NHP profile. Confirm upload?"

She confirmed, and watched the file upload into the casket of the mech. It wasn't a NHP; it was barely even a smart program, but it was something she'd built herself, a software aid she'd planned to use while working on the neutrino telescopes.

"V.I.S.I.O.N. uploaded. Boot shackling systems?"

Another confirmation.

A strange vibration rippled through the mech as the casket came online, ready to bind a full-blown NHP to causal reality and finding only a small piece of software rattling around inside the massive cage. The systems, adaptive, adjusted to give it the processing capacity it required, and then some, folding causality in around it in ways that would have fit a proper NHP but leaked slightly around it.

Unaware of what she'd just catalyzed, Julie returned to the rest of the boot sequence, and eventually hit a final one-time prompt. "Enter pilot callsign and mech name."

Her callsign went in almost more readily than her actual name ever had. As for the mech… She nodded. VISION, she entered, figuring it was a nice tribute to her soon-to-be-overworked program, unaware that something already observed the name and felt a tiny spark of joy at being recognized.

The comm cracked as a line opened, and one of the sisters - Ashes, she suspected, from the less-formal speech - came across it. "Mirror! If you are done there, come have a say with us! We are arguing with Archon over colors for your mech, eh, Vision. She wishes to paint it solar yellow, we say that if you are to be our new specialist in obscuring sensors you deserve more fitting hues such as black or silver. Come, tell us your pick! Even Archon will not deny you the right to your own choice of colors."

Unaware of the small awareness evolving inside the casket, Julie laughed and keyed the comm open from her end. "Just a moment! Let me power down the mech and I'll come choose!" It was, in a sense, the final closure of the door on her planned life; choosing her colors and marking the mech as hers, a thing too big for any station to support and too dangerous to let exist by itself in the system.

Mirror let herself out, and rode the lift down as the Everest ran through its automated shutdown sequence.

Intro | Previous | Next

2 notes

·

View notes

Text

The Future Is Circular: How LOHUM Is Redefining Battery Sustainability in the Age of Electrification

In the accelerating shift towards electric mobility and renewable energy, lithium-ion batteries stand as the cornerstone of progress. From two-wheelers and passenger EVs to solar backup systems and data center energy storage, lithium-ion batteries are powering the present—and shaping the future.

But with this transformation comes a crucial challenge: how do we ensure the sustainability of this exponential battery boom?

The Inevitable Surge in Retired Batteries

As EV adoption scales across the globe, we are approaching a tipping point in lithium battery retirements. According to industry projections, by 2030, the world could see over 2 million metric tonnes of used lithium-ion batteries annually—that’s the equivalent of batteries from more than half a million EVs retiring every year.

While today’s recycling infrastructure is still ramping up, the future holds an unprecedented opportunity to transform these retired batteries into a sustainable, circular economy of critical minerals and battery materials.

LOHUM: Building the Sustainable Battery Value Chain

At LOHUM, we believe that the key to global battery sustainability lies not only in recycling but in reimagining the entire value chain—from second-life applications to advanced material recovery.

With our single integrated ecosystem for energy transition materials, LOHUM is India’s leading producer of battery raw materials through both primary and secondary sources. We specialize in battery recycling, battery repurposing, and the production of high-purity materials, creating circularity in a way that is scalable, cost-effective, and environmentally conscious.

Our mission is to reduce the world's dependence on virgin mining by enabling the reuse and recovery of valuable elements already in circulation.

The Second Life Opportunity

One of the lesser-known yet powerful tools in reducing battery waste is battery repurposing. When lithium-ion batteries reach the end of their vehicular life—typically when their capacity dips below 80%—they often still retain significant energy potential.

This is where LOHUM’s second-life solutions come in.

By intelligently testing, refurbishing, and recombining functioning modules, LOHUM enables used batteries to serve additional lifetimes in lower-power, stationary applications such as renewable energy storage, telecom backup, or rural electrification projects. These applications not only extract more value from the battery's initial life cycle but also delay the need for energy-intensive recycling.

Recycling Innovation: From Black Mass to Battery-Grade Materials

Eventually, however, all batteries must be recycled. The majority of current recycling methods involve pyrometallurgical or hydrometallurgical techniques—processes that recover core metals like cobalt, nickel, and copper, often with significant energy input and environmental impact.

LOHUM has made strides in developing proprietary, environmentally responsible recovery technologies that minimize waste, reduce emissions, and maximize yield. These innovations are not just about material recovery—they're about delivering battery-grade precursors with precision and purity.

Our approach includes direct recycling processes that retain the cathode compound’s integrity, potentially bypassing the need for complete resynthesis. This minimizes energy consumption and allows us to produce high-value, high-performance materials faster and more efficiently.

Recent studies have shown that cathodes recovered via such advanced recycling techniques charge faster and last longer than those built from newly mined minerals. These insights only reinforce LOHUM’s strategic focus on circular solutions for lithium-ion battery precursors.

Securing the Future of Critical Minerals

The lithium-ion battery is composed of several high-value critical minerals, including lithium, cobalt, and nickel. These materials not only dictate the performance and life cycle of a battery but also define its cost structure—accounting for nearly 50% of the battery’s total cost.

With volatile global markets, geopolitical dependencies, and ethical concerns (especially surrounding cobalt sourcing in the Democratic Republic of Congo), domestic recovery and processing of critical minerals is no longer a choice—it is a necessity.

LOHUM is committed to reducing reliance on virgin mining and global supply chains by recovering and refining these minerals right here in India. Our recycling systems ensure that valuable materials are not lost to landfills but are returned to the supply chain as high-purity resources, ready for integration into next-gen batteries.

Enabling Policy & Responsible Innovation

LOHUM aligns itself with forward-looking policy initiatives that aim to mandate recycling, traceability, and extended producer responsibility (EPR). In markets like California, mandates are already in motion to ensure that 100% of EV batteries are recycled or reused at end-of-life.

We believe that standardization, smart labeling, and open data sharing can accelerate the growth of sustainable battery ecosystems. Our operations are designed to not only meet but set the benchmark for global circularity standards.

A Trillion-Dollar Opportunity

The global market for battery materials is projected to approach one trillion dollars, and recycling is poised to play a critical role in meeting that demand sustainably. By closing the loop on battery production and end-of-life processes, we can build resilient, cost-effective supply chains and mitigate the climate and environmental risks associated with mining.

LOHUM stands at the intersection of innovation and responsibility—pioneering solutions that don’t just meet today’s demand, but future-proof the planet.

Final Thoughts

The global shift to clean mobility and energy storage depends on how we treat the resources we already have. At LOHUM, we are not just recycling batteries—we are reshaping the material future of the planet.

Through innovation, partnership, and purpose, LOHUM is unlocking the full potential of battery reuse and material recovery—because sustainability isn’t just a destination, it’s a system we’re proud to build.

Visit us at: lithium battery reusing and recycling

Originally published on: Blogger

#lohum#critical minerals#lithium battery reusing and recycling#3 wheeler ev battery#battery waste management#lithium battery waste recycling#reverse logistics for lithium-ion batteries

0 notes

Text

Embracing the Future: Modular Home Trends in Ontario for 2025

As we move into 2025, the housing landscape in Ontario is experiencing a transformative shift, with modular homes at the forefront of innovation.

These prefabricated structures, known for their efficiency and adaptability, are now incorporating advanced technologies and design philosophies that cater to modern homeowners' evolving needs.

Integration of Smart Home Technologies

Today's modular homes are increasingly equipped with smart systems that enhance convenience and energy efficiency. Homeowners can control lighting, climate, and security features through voice commands or mobile applications, leading to a more streamlined and responsive living environment. For instance, smart thermostats learn user habits to optimize temperature settings, reducing energy consumption and lowering utility bills. Automated lighting systems can be programmed to adjust based on occupancy or time of day, further contributing to energy savings. Additionally, advanced security systems offer remote monitoring capabilities, providing peace of mind whether residents are at home or away.

Sustainable and Eco-Friendly Materials

Sustainability remains a key focus in the modular home industry. Builders are increasingly utilizing recycled and reclaimed materials, such as reclaimed wood and recycled steel, to minimize environmental impact. Energy-efficient designs are becoming standard, featuring superior insulation, energy-efficient windows, and airtight construction to reduce heating and cooling demands. The incorporation of solar panels and water-saving fixtures further enhances the eco-friendliness of these homes, aligning with the growing desire for environmentally responsible living spaces.

Customization and Personalization

Gone are the days of one-size-fits-all modular homes. In 2025, homeowners have the opportunity to tailor their residences to reflect personal tastes and lifestyles. Flexible floor plans allow for the addition or removal of modules to accommodate changing family needs. Aesthetic versatility is also on the rise, with options ranging from modern minimalist designs to more traditional styles. Interior upgrades, such as open-concept layouts and luxury finishes, enable residents to create spaces that are both functional and reflective of their unique preferences.

As modular homes continue to evolve, they offer a compelling solution for those seeking modern, efficient, and customizable housing options in Ontario.

0 notes

Text

How GREW Solar Leads in Solar Panel Manufacturing?

The solar industry is undergoing a transformation, and at the forefront of this change is GREW Solar. As one of India’s largest and most technologically advanced solar manufacturers, GREW Solar is not just producing solar panels, it is redefining how they are made.

With a commitment to innovation, quality, and sustainability, GREW Solar is setting new benchmarks in solar manufacturing. Through its state-of-the-art facilities, the company is driving the future of renewable energy by delivering the best solar panels in the industry.

State-of-the-Art Manufacturing: Precision, Innovation, and Scale

The secret behind GREW Solar’s success lies in its advanced manufacturing processes. The company has invested heavily in smart automation and cutting-edge technology to ensure precision at every stage. Some key features of GREW Solar’s manufacturing excellence include:

Automated Production Lines – Reducing human error and ensuring consistency in panel performance.

In-house R&D Laboratory – Constantly working on improving efficiency and durability.

Real-time Monitoring Systems – Ensuring that every panel meets stringent quality standards.

Advanced Testing Equipment – Validating performance across different environmental conditions.

By leveraging these innovations, GREW Solar is able to produce the best solar panels that offer high efficiency, long lifespan, and superior reliability.

Backward Integration: The Secret to Superior Solar Panels

Unlike many other manufacturers, GREW Solar controls the entire production process through its 3-stage backward integration. This approach guarantees the highest level of quality from raw material to final product:

Ingot & Wafer Production – GREW Solar ensures the purity and quality of the silicon used in its panels, leading to better efficiency and longevity.

Solar Cell Manufacturing – By optimizing cell performance at a granular level, GREW Solar enhances the energy output of its panels.

Module Assembly – The final step brings together proprietary solar cells into robust and high-performing solar modules.

By maintaining control over these crucial steps, GREW Solar eliminates inconsistencies and ensures that customers receive the best solar panels for their business.

Sustainability at the Core of Manufacturing

Sustainability is at the heart of GREW Solar’s operations. The company believes that manufacturing solar panels should be as environmentally friendly as using them. To achieve this, GREW Solar has implemented:

Green Energy-Powered Facilities – Using renewable energy sources to power production lines.

Eco-conscious Supply Chain Management – Sourcing materials responsibly to minimize environmental impact.

Waste Reduction Programs – Implementing advanced recycling and repurposing initiatives.

Local Sourcing Initiatives – Supporting the Indian economy while reducing transportation emissions.

One of the company’s biggest innovations in sustainability is its work on floating solar panels are an emerging technology that maximizes solar energy generation while preserving valuable land resources.

Uncompromising Quality: Testing & Validation at Every Step

GREW Solar’s commitment to quality goes beyond just using the best materials. The company employs rigorous testing protocols to ensure that each panel performs optimally in real-world conditions. Some of the quality control measures include:

Triple-Stage EL (Electroluminescence) Testing – Detects micro-cracks and hidden defects before the panels leave the factory.

100% Individual String Level Testing – Ensuring every solar cell is functioning properly.

Comprehensive Mechanical Load Testing – Guaranteeing that panels can withstand extreme weather conditions.

Climate-Controlled Manufacturing Environment – Preventing defects caused by temperature fluctuations during production.

These meticulous quality checks ensure that GREW Solar produces the best solar panels with industry-leading durability and efficiency.

Floating Solar Panels: The Next Big Innovation

As the demand for solar energy grows, space constraints are becoming a challenge. GREW Solar is at the forefront of solving this issue with floating solar panels. These innovative panels are designed to be installed on water bodies, offering several benefits:

Higher Efficiency – Water cooling naturally increases the efficiency of solar cells.

Land Conservation – Ideal for areas with limited land availability.

Reduced Water Evaporation – Protecting reservoirs and lakes from excessive water loss.

GREW Solar’s expertise in manufacturing ensures that its floating solar panels are as reliable and high-performing as traditional ground-mounted modules.

Powering the Future with the Best Solar Panels

GREW Solar’s commitment to innovation, backward integration, and sustainability has positioned it as a leader in the solar industry. By controlling the entire production process and implementing cutting-edge technologies, the company ensures that its customers receive the best solar panels available. Whether on land or water, GREW Solar is lighting the way toward a greener, more energy-independent future.

For those looking to invest in reliable, high-performance solar panels, GREW Solar remains the ultimate choice. Explore the possibilities today and be a part of the clean energy revolution.

0 notes