#lithium battery waste recycling

Explore tagged Tumblr posts

Text

Closing the Loop: LOHUM’s Vision for a Sustainable Battery Future Through Reverse Logistics and Lithium-Ion Battery Waste Management

From scooters to trucks, laptops to aircraft, lithium-ion batteries are powering a global transformation in mobility and energy. This transition to electrification is not just a trend—it is a systemic shift reshaping industries, economies, and climate strategies. But as battery adoption accelerates, so does the urgency to address a parallel challenge: what happens when these batteries reach the end of their life?

According to market analysts, by 2030, over 2 million metric tonnes of lithium-ion batteries could be retired each year, with more than half a million EV battery retirements annually. These staggering numbers underscore the need for robust systems not only to manage battery disposal but also to extract value from what might otherwise become environmental burden.

At LOHUM, we’re not just innovating for the future—we’re building a circular economy where sustainability, profitability, and technology go hand in hand. Our mission is to "Power Sustainability" through solutions that redefine how the world looks at used lithium-ion batteries: not as waste, but as a resource.

The Growing Opportunity and Challenge of Battery End-of-Life

As the lithium-ion battery market continues to grow at breakneck speed—projected to grow 10-fold over the next decade—new challenges are emerging. The global mining system is already strained, unable to keep up with the demand for key minerals like lithium, cobalt, and nickel. Establishing new mines is expensive, time-consuming, and often environmentally contentious.

This is where battery recycling and reuse become not just a viable alternative, but a necessary solution for building a sustainable supply chain. More specifically, reverse logistics for lithium-ion batteries is fast becoming a critical enabler in this ecosystem—ensuring that batteries are tracked, collected, transported, and processed efficiently after their first life.

Reuse, Recycling, and Second Life: A New Battery Journey

While many retired EV batteries are not yet ready for disposal, they are certainly ripe for reuse. A modern EV battery, once it degrades below 80% of its original capacity, is often no longer optimal for automotive use—but it still holds immense potential in stationary energy storage.

At LOHUM, our solutions extend the battery lifecycle through second-life applications, allowing used EV batteries to serve for another 6 to 10 years in grid-scale or decentralized energy systems. This not only maximizes resource efficiency but also reduces the demand for new batteries in non-automotive applications.

When reuse is no longer feasible, the path turns to recycling. Traditional pyrometallurgical methods recover only select metals, such as cobalt and nickel, and often lose lithium in the slag. These methods are energy-intensive, emitting harmful pollutants and creating secondary waste.

LOHUM’s approach is different. We invest in low-impact, high-recovery hydrometallurgical and direct recycling technologies that recover more value, consume less energy, and are built to scale with environmental priorities in mind. In fact, new research suggests that direct recycling of cathodes not only retains structural integrity but also enhances battery performance—with faster charging and longer life compared to batteries made from freshly mined materials.

Building a Domestic and Circular Battery Supply Chain

Geopolitical dependencies on mineral imports, especially for cobalt (over 60% of which is mined in the DRC under questionable conditions), expose both ethical and economic vulnerabilities. Recycling and reusing domestically sourced battery materials help nations secure their energy future while upholding higher standards of environmental and labor responsibility.

For India, a country rapidly advancing towards EV adoption, lithium-ion battery waste management rules have become a policy imperative. The government’s emphasis on Extended Producer Responsibility (EPR), battery passporting, and recycling targets signal a growing alignment with global best practices. However, true compliance and impact require scalable infrastructure, standardized data protocols, and investment in innovation.

LOHUM is at the forefront of this transformation. We collaborate with OEMs, energy providers, and government bodies to implement compliant, scalable, and traceable recycling systems. Our proprietary processes are built to support the lithium-ion battery waste management rules, delivering both regulatory compliance and long-term sustainability.

The Future Is Circular—and LOHUM Is Leading the Way

The battery ecosystem of tomorrow will be judged not only by its energy output but by its environmental input. Reverse logistics for lithium-ion batteries must evolve into an intelligent, automated, and accountable network that drives recovery, reuse, and recycling at scale.

Automation in battery disassembly and material separation is already showing promise—reducing labor risk and improving material purity. Integration of AI in logistics, blockchain in tracking, and robotics in dismantling could soon become industry standards.

At LOHUM, we envision a world where every lithium-ion battery completes a full circle—from manufacturing to use, to reuse, to recovery, and back again. Our vertically integrated operations are designed to optimize value extraction at every point in the battery lifecycle.

And the market is responding. The global battery recycling industry, currently valued in the billions, is projected to exceed $30 billion by 2030. But this is not just about market opportunity—it’s about environmental necessity and social responsibility.

Final Thoughts

The future of electrification is bright, but only if we manage its dark side responsibly. Retired batteries cannot become tomorrow’s landfill problem—they must become tomorrow’s solution.

At LOHUM, we are powering this transition with purpose. By combining cutting-edge science, circular business models, and scalable partnerships, we are building an ecosystem where waste becomes wealth, and sustainability becomes standard.

It’s time to reimagine lithium-ion batteries not just as power sources—but as perpetual value carriers. Because at LOHUM, we don’t just make energy sustainable. We make sustainability powerful.

Visit us at: Critical Minerals

#lohum#li-ion battery waste management#battery waste management#lithium battery reusing and recycling#critical minerals#3 wheeler ev battery#lithium battery waste recycling#reverse logistics for lithium-ion batteries

0 notes

Note

I'm worried about electronic waste, e-waste recycling, and such loss of resources.

That's real. For what it's worth, I think it's something we're going to get a LOT better at. The raw materials - and even partially depleted materials that can be downcycled - are too valuable to be left forever.

Tip for anyone worried about e-waste or looking to be more environmentally conscious: Whenever I have something electronic that dies (this includes batteries, power cords, string lights, and vapes), I stick it in an out-of-the-way drawer, and then once every year or two, I bring it all to either an e-waste recycling place or an e-waste disposal place (which, my understanding is most e-waste disposal places do a lot of materials reclamation as well, though if I'm wrong someone please correct me). I just look online to find a place.

Sometimes it's a bit of a drive, but it's so worth it. I encourage others to do the same!

Anyway, here's some headlines about e-waste to hopefully lift your spirits:

^That's Western Australia, not Washington state.

#dyingpleasehelp#ewaste#e waste#waste disposal#electronics#recycling#batteries#lithium#rare earth metals#good news#hope#united states#australia#rwanda

209 notes

·

View notes

Text

Recycling lithium-ion batteries to recover their critical metals has significantly lower environmental impacts than mining virgin metals, according to a new Stanford University lifecycle analysis published in Nature Communications. On a large scale, recycling could also help relieve the long-term supply insecurity -- physically and geopolitically -- of critical battery minerals. Lithium-ion battery recyclers source materials from two main streams: defective scrap material from battery manufacturers, and so-called "dead" batteries, mostly collected from workplaces. The recycling process extracts lithium, nickel, cobalt, copper, manganese, and aluminum from these sources.

Read more.

#Materials Science#Science#Lithium ion batteries#Batteries#Recycling#Lithium#Waste#Mining#Environment#Stanford University

65 notes

·

View notes

Text

Black Mass Recycling: The $51.7B Future of Green Tech by 2032

The world is buzzing with sustainable innovation, and black mass recycling is stealing the spotlight. The black mass recycling market is set to skyrocket from $14.41 billion in 2024 to an impressive $51.70 billion by 2032, growing at a jaw-dropping CAGR of 17.3%. This isn’t just a trend—it’s a revolution in how we handle battery waste and secure critical metals. So, what’s driving this boom, and why should you care? Let’s break it down.

What Is Black Mass Recycling, Anyway?

Black mass recycling is the process of reclaiming valuable metals—like lithium, cobalt, and nickel—from used batteries, especially lithium-ion ones. Picture this: old electric vehicle (EV) batteries, discarded laptops, and even marine power packs get crushed into a powdery “black mass.” From there, advanced recycling techniques (think pyrometallurgy and hydrometallurgy) extract the good stuff, turning waste into treasure. It’s a win for the planet and a lifeline for industries hungry for sustainable raw materials.

Why the Market’s Exploding

The black mass recycling market is riding a wave of urgent demand. With EV sales soaring and renewable energy storage on the rise, lithium-ion batteries are everywhere—and so is their waste. The MarketsandMarkets report highlights that automotive batteries, fueled by the EV boom, will dominate this space. By 2032, this segment alone is expected to claim the largest market share by value. Why? Electric and hybrid vehicles are multiplying fast, and their batteries don’t last forever.

Add stricter environmental regulations and a global push for circular economies into the mix, and you’ve got a perfect storm. Governments and consumers alike are demanding greener practices, and recycling high-value metals reduces the need to mine virgin resources. It’s a no-brainer: less environmental damage, more sustainability, and a steady supply of materials for tech-driven industries.

Asia Pacific Leads the Charge

If you’re wondering where this growth is happening, look to Asia Pacific. The report pegs this region as the leader, and it’s easy to see why. Countries like China, Japan, and South Korea are churning out EVs, consumer electronics, and renewable energy solutions at breakneck speed. That means more end-of-life batteries—and a bigger need for recycling. Toss in tough environmental rules and heavy investments in cutting-edge tech, and Asia Pacific is poised to rule the black mass recycling game through 2032.

Pyro vs. Hydro: The Recycling Showdown

How do we get those precious metals out of black mass? Two heavy hitters dominate: pyrometallurgy and hydrometallurgy. Pyro uses intense heat to melt down batteries and separate metals—think of it as a fiery forge for the modern age. Hydro, on the other hand, leans on chemical solutions to leach out materials, offering a cleaner, more precise approach. The MarketsandMarkets report dives into both, noting their roles in recovering nickel, cobalt, lithium, and copper. Each method has its fans, but together, they’re powering this market’s explosive growth.

The Big Players and What’s at Stake

Who’s making waves in this space? Giants like Glencore (Switzerland), Umicore (Belgium), and Cirba Solutions (US) are leading the pack, alongside China’s Contemporary Amperex Technology Co., Ltd. These companies aren’t just recycling—they’re shaping a future where battery waste fuels innovation. The stakes are high: securing a steady supply of metals like lithium and cobalt is critical as demand for EVs and renewables surges. Plus, with mining facing environmental backlash, recycling is the smarter, greener bet.

Stay ahead with the latest trends – Download the PDF brochure.

This isn’t just industry jargon—it’s a shift that touches everyone. Black mass recycling means fewer landfills clogged with toxic batteries, cleaner air from reduced mining, and a tech world that keeps humming without depleting the planet. By 2032, this $51.7 billion market will be a cornerstone of sustainability, proving that green tech isn’t a pipe dream—it’s a reality we’re building today.

The Road Ahead

The black mass recycling market is more than a niche—it’s a game-changer. With a projected CAGR of 17.3%, it’s clear this industry is on fire. Whether you’re an EV enthusiast, a sustainability advocate, or just curious about the future, keep your eyes on this space. It’s where waste meets wealth, and the planet wins big.

#black mass recycling#sustainability#lithium-ion batteries#EV market#green tech#recycling process#Asia Pacific#pyrometallurgy#hydrometallurgy#circular economy#critical metals#battery waste#market growth#environmental regulations

0 notes

Text

Recycling Gaming Consoles

In the past three decades we have seen the release of over two dozen gaming consoles. During the noughties and the 2010s, plenty of game enjoyers had more than one, with the most popular three being the Playstation series from Sony, the Xbox from Microsoft, and the Wii from Nintendo, though the Nintendo DS and Switch are also very popular hybrid consoles.

The Playstation series currently has five released consoles, while the Xbox has four generations, and the Wii has three.

As new console generations are created, with new benefits and new capabilities, previous models are likely to end up in the trash. Therefore, it is important to know that gaming consoles are largely recyclable.

Electronic waste often contains lead, mercury, or cadmium - hazardous metals that can contaminate soil and water when tossed away with regular waste. When properly recycled, electronic waste can instead be refurbished or separated into materials that can be reused in manufacturing1. This has the additional benefit of reducing the demand on raw materials.

Most consoles consist of plastic casings, usually polycarbonates, with metal internal components, often aluminum or steel. They also have semiconductors, small components that can involve silicon, germanium, tin, copper, sometimes gold, and many more elements that, in small parts, make up the internal bits of electronic functions.

The Playstation 5 also uses liquid metal to advance its cooling system, as it is more conductive than alternatives like thermal paste3. This liquid metal, called Galinstan, is made of gallium, indium, and tin3.

Metals are highly recyclable, and our ability to separate mixed metals is continually improving. Aluminum is especially common in computing devices and commonly collected for reuse. In fact, it can be recycled continually without losing any quality4. Galinstan is less documented regarding its ability to be recycled, but each of its components -gallium, indium, and tin- can be recycled5.

Likewise, polycarbonates are completely recyclable. They can be shredded and used for other electronics, covers, and bottles, and more6.

Silicone is more complicated to recycle. It’s primarily made from sand or the metamorphic rock, quartzite. Fortunately, ore containing high levels of silica are plentiful and the main ingredient of silicone7. Because of the intensity of the silicone recycling process -breaking it down into tiny pieces and melting it with new silicone- it requires specialized facilities and experts8. Simply, silicone can be recycled but it cannot be casually thrown in with other random recyclable materials, or it will just end up in a landfill.

Recycling is a complex process, especially for products that use a mix of materials. Gaming consoles use many different types of metals, plastics, and silicone that need to be picked apart to properly recycle. With the advancement of technology, more ways to recycle difficult materials have been developed, so we can expect that these processes will become more efficient with time. As you look to dispose of items like your gaming consoles, be sure to investigate the best recycling sources in your area.

Lithium-Ion Batteries

While we’ve focused on standing consoles in this article, I do want to address the lithium-ion batteries in handheld devices such as the Nintendo Switch.

Lithium mining is a water-intensive process that, along with the manufacturing of these batteries, produces a lot of carbon dioxide and can contaminate water supplies with toxic materials like sulfur10. A majority of lithium-ion batteries also end up in landfills, where they continue to leach toxins and increase the risk of landfill fires10.

Fortunately, the industry of recycling these batteries is growing. This process usually involves the electronic device being taken back by the retailer or by specific e-waste storefronts, and, if sorted properly, eventually make their way to the specialized facilities that can process them11. Similarly to other consoles, it is a complicated process that has yet to be optimized, but should be doable if the consumer returns their device to the retailer at the end-of-life point.

Additional Resources

1.https://www.epa.gov/smm-electronics/basic-information-about-electronics-stewardship

2. https://droidmeg.com/what-materials-are-used-to-make-video-game-consoles/

3. https://tronicsfix.com/blogs/news/all-about-ps5-liquid-metal

4. https://international-aluminium.org/work_areas/recycling/

5. https://pubs.acs.org/doi/10.1021/acssuschemeng.7b03689#

6. https://www.vandenrecycling.com/en/what-we-do/buy-and-sell-plastic/pc/#

7. https://mineralseducationcoalition.org/minerals-database/silica/#

8. https://www.trvst.world/waste-recycling/is-silicone-recyclable/

9. https://www.cohenusa.com/recyclable-items/game-consoles/

10.https://www.instituteforenergyresearch.org/renewable/environmental-impacts-of-lithium-ion-batteries/

11. https://www.epa.gov/hw/lithium-ion-battery-recycling

#environment#climate change#article#research#recycling#sustainability#gaming consoles#wii#xbox#nintendo switch#plastic#lithium ion batteries#e waste recycling#playstation#aluminum

1 note

·

View note

Note

I feel like if you're using a lot of disposable plastic bags in your day to day life, you've gotta do something sustainable to make up for it. Like using bamboo toilet paper or eco friendly cat litter or something, yknow

Honestly I exaggerate for comedic effect, while I DO routinely use ziplock bags to hold spaghetti I cook maybe once a month and the bag itself is usually for freezer storage. I actually throw out maybe one bag a week? I DO hate washing plates and tupperware and junk but that usually just means I eat sandwiches without a plate.

I agree though that needless waste should be avoided, and I do avoid it- biodegradable bags and recyclables, empty butter tubs used to store leftovers, etc.

This said, though, not applicable necessarily for myself but for a lot of others- I feel that it's importat to remember that there are many people who legitimately NEED things like plastic straws, or catheters, or pre-packaged foods

And the idea that that's a moral failing that individuals need to personally make up for when a single billionaire blows out more CO2 in a long weekend than I will in my whole life on a superjet meet-cute in the Bolivian rainforest between humvee drag races funded by the river-polluting textiles plants they planted in a third world country to avoid EPA laws and give an entire village stillbirths and stomach cancer is an idea that those very same bigwigs have spent a LOT of time and money investing in planting in the public psyche.

Like- Glass bottles are infinitely recyclable, so why are so many drinks in plastic now? Loads of drinks manufacturers used to buy them back and clean them for re-use, so why did they stop? If they chose to make something out of a limited and environmentally irresponsible material, why is it my failing to track down a correct process of disposal for them? What if there are none in my area? Do I lobby for more recycling plants in my area? Do I set aside some of my limited time outside the pain factory of my job- which I have more than one of, thanks to rising costs of things just like that drink I just emptied- to properly dispose of this company's waste FOR them?

Say coca-cola just rolled up to your town and started dumping millions of empty plastic bottles in the street, going, "wow, you should really think about building and staffing a recycling depot, it would be really shameful of you to just put these in the trash." When companies purposefully use materials with limited lifespans- because yes, even plastic can only be reused so many times- and tell you it's your own fault if it harms the environment- that's essentially what they're doing, just with more steps.

Yes, its important to be as environmentally concious as we can in our day to day life, but responsible sustainability is not catholicism. We don't get good boy points from our lord and savior Captain Planet every time the average low-income household gathers together to hold hands and repent for a single-use plastic that allows them to access something they need.

Entire families could eat trees and shit dead lithium batteries for years and still not do as much damage to the planet as an average dye plant or braindead celebrity does in a week just for fun, and I'm mad about it

...this went on longer than intended.

TL/DR: DO recycle and minimize waste, but don't beat yourself up over the little waste you can't avoid, and follow the money.

EDIT: Part 2

#I swear to god if any one of you in the notes calls me terminally online or pretends I'm saying you can just dump bags in the ocean#Yes definitely do your best to live sustainably#But also#You personally are not killing pandas#Unless you are in which case please stop#We put too much money into pandas but let them go in peace#Go do some yoga#Sorry if this is a lot but I have a friend with OCD who has legit panic attacks over stuff like this#Like they have to throw out a ripped plastic grocery bag they've had for six years instead of using it to weave yard furniture or smthn#And they'd go into a spiral about killing the planet#So like#I have strong feelings now

1K notes

·

View notes

Text

When Nihal Tammana was just 10 years old, he heard a news report about a lithium-ion battery exploding at a waste disposal plant—and when he learned about the environmental risks of batteries being left in landfills, he decided to do something.

Tammana started the nonprofit, Recycle My Battery, and now, at 15 years old, he has already recycled over 625,000 batteries—and placed over 1,000 battery bins in schools, libraries, and businesses to make recycling easier.

Anyone can now visit RecycleMyBattery.org for instructions on how to make their schools and businesses battery recycling heroes.

The teen from Monroe, New Jersey, has expanded his impact beyond the United States, too. Tammana’s story and mission were recently featured in a German educational textbook, integrating battery recycling advocacy into school curriculums.

He is also teaming up with B-cycle, Australia’s largest battery recycling company, so the country can adopt his initiative to place battery bins in schools nationwide.

Lately, Nihal is working on a Residual Charge Project, developing a prototype (that was confirmed by a University of Waterloo expert) to extract leftover energy from used batteries that could power the battery recycling plants.

Engaging its 1,000 youth volunteers globally, Recycle My Battery is educating the public about the destructive effects of throwing batteries in with your trash. The nonprofit researched the effects of a normal alkaline battery, such as Duracell, on soil quality. The degrading battery dramatically increased salt levels, rendering the soil toxic, with an alarming pH of 13.01—far beyond the range suitable for any vegetation.

With its goal of recycling 1 million batteries by the end of the year through initiatives like The Battery Challenge, which gamifies school participation, Tammana invites communities and organizations to join the effort. From setting up battery bins to spreading awareness, every action contributes to a cleaner, healthier planet.

“If I can make the Earth a better place to live, you can…. If you can, we all can,” said Tammana.

#batteries#battery recycling#lithium#lithium battery#recycling#sustainability#good news#innovation#nonprofits#usa#soil health#science#environmentalism#environment

26 notes

·

View notes

Text

Scientists achieve near-total recovery of rare metals in just 15 minutes: 'Opens a new pathway'

24 notes

·

View notes

Text

How come almost every rechargeable device in the world has a lithium battery which will one day, at the end of its life, swell up into a ticking time-bomb full of fire and toxic gas, and yet whenever this happens and I phone up my local council waste management department/recycling center/fire safety advice hotline like "Hi, i have a bomb, who do i give it to" they're all like

#'Put it in a metal bucket outside with some sand' AND THEN WHAT?#IT STAYS THERE? FOREVER??#The fire dept was like 'IDK take it to the tip or to a mobile phone shop'#and the tip and all the mobile phone shops were like 'I don't want this'#'We take regular LI batteries but this is now a Hazardous Material. Ask the council'#And the council was like 'IDK. Ask the fire department'#British government efficiency at its finest

76 notes

·

View notes

Text

there's this cruel irony of imperialism -- obviously many of them -- and there's a good chance somebody is going to call me either shortsighted, highfalutin, ungrounded, or reaching for saying this, but i've been thinking about the networked effects of extracted resources. first it was spice colonialism, then the spices all turned out to be too aphrodisiac and this eventually led to the industrialization of cornflakes

they used to construct elaborate fictions for conflict minerals, this item is unbelievably valuable and the only appropriate use for it is to commemorate a lifelong, monogamous and reproductive relationship (diamonds). now the conflict mineral (lithium) is an unnecessary substitute for an herb (tobacco) and it has become disposable

the nature and progression of imperialism requires continual growth and this means the conflict minerals can't maintain their value, they turn from precious heirloom jewelry to litter, simply because litter is less rare and so more profitable. first they had to mine the raw metals to build out an electrical grid, and then the materials to build roads and cars, and now that the grid requires baseload batteries parked in your garage we're throwing lithium on the ground. plastics have an irrevocable hold on the market simply because they're petroleum byproducts

cities could never have become as large as they did without the development of firefighting and now the baseload batteries are inextinguishable. progress of ever-smaller fragmentation for profit leads to contradiction. the city cannot move forward without the conflict mineral battery, but it can't put the fire out and it can't stop throwing them away, ostensibly to suppress use of an herb, once medicinal, now an adulterated vice. because adulterating it not only increases the rate of cancer but attributes it to personal choice, which is necessary, because otherwise it would be more attributable to the materials that keep the system running (uranium). it's incredible

the state with the lowest rate of cancer is downwind of the test site, because it's populated by yet another extremist christian wing of imperial progress, so extreme that they don't smoke or drink, because these personal choices have an outsized influence in comparison to the global contamination that the development of the bomb caused. a bit of the money made from the extraction of resources is put towards repayment for citizens of the imperial core, for exposure to the product that created their way of life, but the program expires and nobody cares because they seem to think it didn't affect them

anyway somebody threw a whole clock radio in my garden. i took the battery and now i can't do anything with it unless i want to figure out where to take it to be recycled. holding this blue plastic-wrapped cylinder of fire risk conflict mineral in my little hand and ruminating on it. do you think it traveled further than i have to get to me? i should never have left it sitting next to my keys i've been glancing at it in passing every day for weeks. of course you're not supposed to throw them on the ground, but i've already criticized the abdication of responsibility by corporations for the waste their products become. makes it into another issue of personal choice when they wouldn't have existed if they hadn't been industrialized

32 notes

·

View notes

Text

Excerpt from this story from Mother Jones:

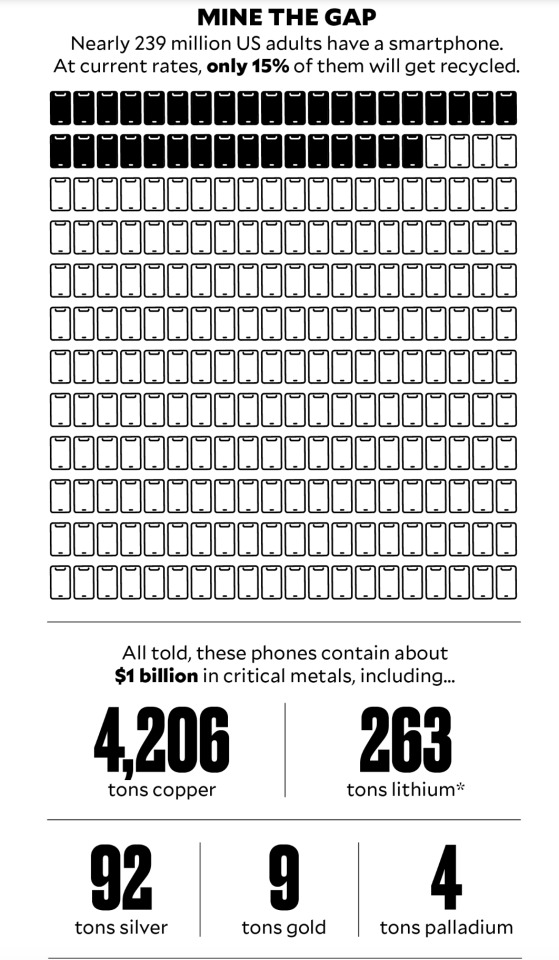

The world generates more than 68 million tons of e-waste every year, according to the UN, enough to fill a convoy of trucks stretching right around the equator. By 2030, the total is projected to reach 75 million tons.

Only 22 percent of that e-waste is collected and recycled, the UN estimates. The rest is dumped, burned, or forgotten—particularly in rich countries, where most people have no convenient way to get rid of their old Samsung Galaxy phones, Xbox controllers, and myriad other gadgets. Indeed, every year, humanity is wasting more than $60 billion worth of so-called critical metals—the ones we need not only for electronics, but also for the hardware of renewable energy, from electric vehicle (EV) batteries to wind turbines.

Millions of Americans, like me, spend their workdays on pursuits that lack any physical manifestation beyond the occasional hard-copy book or memo or report. It’s easy to forget that all these livelihoods rely on machines. And that those machines rely on metals torn from the Earth.

Consider your smartphone. Depending on the model, it can contain up to two-thirds of the elements in the periodic table, including dozens of metals. Some are familiar, like the gold and tin in its circuitry and the nickel in its microphone. Others less so: Tiny flecks of indium make the screen sensitive to the touch of a finger. Europium enhances the colors. Neodymium, dysprosium, and terbium are used to build the tiny mechanism that makes your phone vibrate.

Your phone’s battery contains cobalt, lithium, and nickel. Ditto the ones that power your rechargeable drill, Roomba, and electric toothbrush—not to mention our latest modes of transportation, ranging from plug-in scooters and e-bikes to EVs. A Tesla Model S has as much lithium as up to 10,000 smartphones.

The millions of electric cars and trucks hitting the planet’s roads every year don’t spew pollutants directly, but they’ve got a monstrous appetite for electricity, nearly two-thirds of which still comes from burning fossil fuels—about one-third from coal. Harvesting more of our energy from sunlight and wind, as crucial as that is, entails its own Faustian bargain. Capturing, transmitting, storing, and using that cleaner power requires vast numbers of new machines: wind turbines, solar panels, switching stations, power lines, and batteries large and small.

You see where this is going. Our clean energy future, this global drive to save humanity from the ever-worsening ravages of global warming, depends on critical metals. And we’ll be needing more.

In all of human history, we have extracted some 700 million tons of copper from the Earth. To meet our clean energy goals, we’ll have to mine as much again in 20-odd years. By 2050, the International Energy Agency estimates, global demand for cobalt for EVs alone will soar to five times what it was in 2022. Demand for nickel will be 10 times higher. Lithium, 15 times. “The prospect of a rapid increase in demand for critical minerals—well above anything seen previously in most cases—raises huge questions about the availability and reliability of supply,” the agency warns.

Metals are natural products, but the Earth does not relinquish them willingly. Mining conglomerates rip up forests and grasslands and deserts, blasting apart the underlying rock and soil and hauling out the remains. The ore is processed, smelted, and refined using gargantuan, energy-guzzling, pollution-spewing machines and oceans of chemicals. “Mining done wrong can leave centuries of harm,” says Aimee Boulanger, head of the Initiative for Responsible Mining Assurance, which works with companies to develop more sustainable extraction practices.

The harm is staggering. Metal mining is America’s leading toxic polluter. It has sullied the watersheds of almost half of the rivers in the American West. Chemical leaks and mining runoff foul air and water. The mines also generate mountains of hazardous waste, stored behind dams that have a terrifying tendency to fail. Torrents of poisonous sludge pouring through collapsed tailings dams have contaminated waterways in Brazil, Canada, and elsewhere and killed hundreds of people—in addition to the hundreds, possibly thousands, of miners who die in workplace accidents each year.

To get what they’re after, mining companies devour natural resources on an epic scale. They dig up some 250 tons of ore and waste rock to get just 1 ton of nickel. For copper, the ratio is double that. Just to obtain the metals inside your 4.5-ounce iPhone, 75 pounds of ore had to be pulled up, crushed, and smelted, releasing up to 100 pounds of carbon dioxide. Mining firms also suck up massive quantities of water and deploy fleets of drill rigs, trucks, diggers, and other heavy machinery that collectively belch out up to 7 percent of the world’s greenhouse gas emissions.

Metal recycling is a completely different proposition from recycling the paper and glass we toss into our home bins for pickup. It turns out that retrieving valuable raw materials sustainably from electronic products—toasters, iPhones, power cables—is a fiendishly complex endeavor, requiring many steps carried out in many places. Manufacturing those products required a multistep international supply chain. Recycling them requires a reverse supply chain almost as complicated.

Part of the problem is that our devices typically contain only a small amount of any given metal. In developing countries, though, there are lots of people willing to put in the time and effort required to recover that little bit of value—an estimated tens of thousands of e-waste scavengers in Nigeria alone. Some go door to door with pushcarts, offering to take or even buy unwanted electronics. Others, like Anwar, work the secondhand markets, buying bits of broken gear from small businesses or rescuing them from the trash. Many scavengers earn less than the international poverty wage of about $2.15 per day.

15 notes

·

View notes

Text

Powering the Future Sustainably: The Rise of Lithium-ion Battery Recycling and Second-Life Applications

As the world accelerates toward cleaner energy and electric mobility, lithium-ion batteries have become the backbone of this global transition. From electric scooters to high-performance EVs, from consumer electronics to large-scale grid storage—these energy-dense cells are transforming how we power our lives. Yet, as deployment surges, a parallel challenge has emerged: what happens when these batteries reach their end of life?

At LOHUM, we’re building sustainable solutions for tomorrow by closing the loop on battery materials today. Our mission is clear: to extend battery lifespans, reduce dependence on virgin resources, and make clean energy truly circular.

A Ticking Clock: The Coming Surge in Battery Retirements

The rapid adoption of electric vehicles (EVs) and battery-based energy storage is fueling exponential growth in lithium-ion battery usage. Analysts predict that by 2030, more than 2 million metric tonnes of lithium-ion batteries will retire annually—equivalent to batteries from over 500,000 vehicles each year.

Despite this looming influx, EV batteries currently constitute only a fraction of the vehicle market. Most batteries reaching end-of-life today come from consumer electronics or early-generation EVs. But that’s changing fast. Over 50% of all EV sales in the U.S. occurred in the past two years alone, suggesting a wave of battery retirements is on the horizon within the next 8–10 years.

Not the End, But a New Beginning: Battery Second-Life and Recycling

A lithium-ion battery is considered “retired” when its capacity drops below 80% of its original rating. But this doesn't mean it's useless. At LOHUM, we view every used battery not as waste—but as a resource. Through lithium-ion battery second-life applications, these cells can be repurposed into lower-power, stationary storage systems for solar, grid, or backup applications—adding 6 to 10 years of useful life.

Refurbished Li-ion Battery Application isn’t just a sustainability measure—it’s a smart economic decision. In several use cases, batteries can be refurbished for direct use in other vehicles or stationary systems. This practice not only extends the battery’s lifecycle but also reduces the environmental impact and material costs of producing new batteries.

The Technological Shift: From Pyrometallurgy to Direct Recycling

Current commercial recycling processes for lithium-ion batteries involve either pyrometallurgy (smelting at temperatures over 1500°C) or hydrometallurgy (chemical leaching). While these processes recover valuable metals like cobalt, nickel, and copper, they’re energy-intensive and often result in the loss of lithium and aluminum—either trapped in slag or needing additional treatment.

Emerging direct recycling technologies are promising game-changers. Instead of completely breaking down the battery, this method recovers the cathode compound intact and refunctionalizes it—adding lithium back into the structure without losing its engineered performance. This not only improves efficiency but also helps in retaining the highest-value component of the battery, the cathode, without costly reprocessing.

Recent breakthroughs have demonstrated that directly recycled cathodes can outperform virgin material. A study published in Joule found that recycled cathodes had better porosity, enabling faster charging and longer lifespans. These particles resist cracking better than conventional cathodes—solving one of the key issues behind battery degradation.

Materials Matter: The Critical Mineral Equation

Lithium-ion batteries are composed of highly valuable minerals—primarily lithium, nickel, and cobalt. These elements account for nearly 50% of battery costs. Yet, price volatility for these metals remains high, with fluctuations reaching up to 300% in a single year.

Moreover, over 60% of the global cobalt supply comes from the Democratic Republic of Congo—a region often associated with unethical mining practices, environmental degradation, and human rights concerns. By recovering materials through recycling, LOHUM contributes to reducing global reliance on such vulnerable supply chains and enhances energy security.

Circular Economy & Policy Support: The Time Is Now

Creating a sustainable and circular system for lithium-ion batteries isn’t just about technology. Policy and infrastructure will play crucial roles. The State of California is now pushing for 100% recycling or reuse of all EV batteries sold within the state. Measures like extended producer responsibility, deposit schemes, and battery labeling standards are steps in the right direction.

LOHUM supports forward-thinking policy development and actively collaborates with industry leaders and policymakers to foster a regulatory framework that supports ethical recycling, domestic material recovery, and green job creation.

LOHUM’s Role: Bridging Innovation with Impact

At LOHUM, we believe in not just innovating for impact—but innovating responsibly. Through our proprietary refining, repurposing, and refurbishing technologies, we provide end-to-end solutions for battery reuse and material recovery. Our approach includes:

Battery testing and diagnostics for second-life qualification

Refurbishment and module recombination for energy storage and mobility

Cathode and anode material recovery with low-carbon processes

Reintegration into the battery supply chain through sustainable sourcing

Whether it's Refurbished Li-ion Battery Application for mobility or lithium-ion battery second-life applications in energy storage, our mission remains the same: To make energy cleaner, longer-lasting, and circular.

Looking Ahead

As the world electrifies at an unprecedented pace, the importance of battery reuse and recycling cannot be overstated. With demand for battery minerals projected to grow tenfold in the next decade, recycling isn’t just an environmental responsibility—it’s an economic necessity.

By innovating today, LOHUM is helping build a future where lithium-ion batteries don’t just power progress—they sustain it. Visit us at: Li-ion battery waste management

#lohum#critical minerals#li-ion battery waste management#lithium battery reusing and recycling#lithium battery waste recycling#battery waste management#3 wheeler ev battery#reverse logistics for lithium-ion batteries

0 notes

Text

[In February, 2023], a small warehouse in the English city of Nottingham received the crucial final components for a project that leverages the power of used EV batteries to create a new kind of circular economy.

Inside, city authorities have installed 40 two-way electric vehicle chargers that are connected to solar panels and a pioneering battery energy storage system, which will together power a number of on-site facilities and a fleet of 200 municipal vehicles while simultaneously helping to decarbonize the UK’s electrical grid.

Each day Nottingham will send a combination of solar-generated energy — and whatever is left in the vehicles after the day’s use — from its storage devices into the national grid. The so-called “vehicle to grid” chargers deliver this energy just when it’s needed most, during peak evening demand, when people are home cooking, using hot water or watching TV. Later, the same chargers pull energy from the grid to recharge the vehicles in the wee hours of the night, when folks are sleeping and electricity is cheaper and plentiful.

“We are trying to create a virtual power station,” says Steve Cornes, Nottingham City Council’s Technical Lead. “The solar power and battery storage will help us operate independently and outside of peak times, making our system more resilient and reducing stress on the national grid. We could even make a profit.” ...

After around a decade, an EV battery no longer provides sufficient performance for car journeys. However, they still can retain up to 80 percent of their original capacity, and with this great remaining power comes great reusability.

“As the batteries degrade, they lose their usefulness for vehicles,” says Matthew Lumsden, chairman of Connected Energy. “But batteries can be used for so many other things, and to not do so results in waste and more mining of natural resources.”

The E-STOR hubs come in the form of 20-foot modular containers, each one packed with 24 repurposed EV batteries from Renault cars. Each hub can provide up to 300kW of power, enough to provide energy to dozens of homes. One study by Lancaster University, commissioned by Connected Energy, calculated that a second life battery system saved 450 tons of CO2 per MWh over its lifetime...

Battery repurposing and recycling is set to play a massive role over the coming years as the automobile industry attempts to decarbonize and the world more broadly attempts to fight waste. The production of EVs, which use lithium-ion batteries, is accelerating. Tesla, for example, is aiming to sell 20 million EVs per year by 2030 — more than 13 times the current level. In turn, 12 million tons of EV batteries could become available for reuse by 2030, according to one estimate.

“Over the next decade we are going to see this gigantic wave,” says Jessica Dunn, a senior analyst at the Union of Concerned Scientists. “Companies are recognizing this is a necessary industry. They need to ramp up infrastructure for recycling and reuse.”

-via Reasons to Be Cheerful, March 13, 2023

#ev#ev charger#electric vehicle#electric cars#batteries#battery recycling#lithium ion battery#auto industry#sustainability#circular economy#recycling#reuse#uk#nottingham#england#good news#hope

217 notes

·

View notes

Text

Researchers develop polyurea membranes for lithium recovery from waste batteries

In a study published in the Journal of Membrane Science, a research group led by Prof. Wan Yinhua from the Institute of Process Engineering (IPE) of the Chinese Academy of Sciences propose a new zone-regulated interfacial polymerization strategy, aiming to fabricate acid- and alkali-resistant nanofiltration (NF) membranes with high separation selectivity for the lithium recovery from waste lithium batteries. The rapid expansion of the new energy industry has driven a surge in demand for lithium resources, highlighting the need for effective recycling of spent lithium batteries. Green and efficient nanofiltration (NF) technology is emerging as a key solution for sustainable lithium recovery. However, conventional polyamide NF membranes face challenges such as structural degradation under acidic and alkaline conditions, which compromises their separation performance.

Read more.

#Materials Science#Science#Batteries#Waste#Lithium#Lithium ion batteries#Polymers#Polymerization#Interfaces#Membranes#Materials processing

13 notes

·

View notes

Text

Powering a Sustainable Future: The Rise of Lithium-Ion Battery Recycling

As the world leans towards sustainability and environmental responsibility, lithium-ion battery recycling has emerged as a crucial industry. With increasing awareness of the environmental impact of battery disposal and stricter regulations on electronic waste management, recycling these batteries is becoming more essential than ever. The high concentration of valuable metals such as nickel, cobalt, and lithium in lithium-ion batteries makes them prime candidates for recycling, helping to reduce dependence on virgin raw materials and promoting a circular economy.

Lithium-ion Battery Recycling Market is projected to grow from USD 16.23 billion in 2024 to USD 56.87 billion by 2032, at a CAGR of 17.0% during the forecast period

Consumer Electronics: The Largest Contributor to Battery Recycling

The consumer electronics industry is projected to dominate the lithium-ion battery recycling market. The fast turnover of devices such as smartphones, laptops, tablets, and wearable technology results in a significant supply of batteries reaching the end of their lifecycle. As newer models push older gadgets out of use, the need for proper disposal and recycling becomes more pressing. With valuable materials like nickel, cobalt, and lithium recoverable from these batteries, consumer electronics remains the most lucrative segment in battery recycling. Additionally, stringent regulations surrounding e-waste disposal are further driving the need for sustainable recycling practices.

LFP Batteries Leading the Charge in Recycling

Among various lithium-ion battery chemistries, lithium iron phosphate (LFP) batteries are expected to hold the largest share in the recycling market. Widely used in electric vehicles (EVs) and large-scale energy storage systems, LFP batteries are gaining preference due to their longer lifespan, enhanced safety, and superior thermal stability. As these batteries reach the end of their useful life, the extraction of valuable materials such as iron, lithium, and phosphate makes them increasingly attractive for recycling. With growing adoption in renewable energy and transportation sectors, LFP battery recycling is set to play a pivotal role in the industry’s expansion.

Asia-Pacific: The Epicenter of Battery Recycling Growth

Geographically, the Asia-Pacific region is anticipated to lead the lithium-ion battery recycling market. Countries like China, Japan, and South Korea are at the forefront of lithium-ion battery production and consumption, resulting in a surge of end-of-life batteries. The rapid expansion of industries such as renewable energy storage, electric vehicles, and consumer electronics has driven investment in innovative recycling technologies. Additionally, stringent environmental regulations and government incentives are further bolstering the market’s growth in this region.

Key Players Shaping the Future of Battery Recycling

Several prominent companies are driving advancements in lithium-ion battery recycling. Some of the major players in the industry include:

Glencore (Switzerland)

Umicore (Belgium)

Cirba Solutions (US)

Contemporary Amperex Technology Co., Ltd. (China)

RecycLiCo Battery Materials Inc. (Canada)

These industry leaders are investing in cutting-edge recycling technologies to enhance efficiency and sustainability, ensuring that lithium-ion batteries remain a part of a circular economy.

Stay ahead with the latest trends – Download the PDF brochure

Final Thoughts

Lithium-ion battery recycling is no longer an option—it is a necessity. With the growing demand for electric vehicles, consumer electronics, and renewable energy storage, the need for sustainable battery disposal and material recovery is more urgent than ever. As regulations tighten and technological advancements improve recycling efficiency, the industry is poised for significant growth. By embracing recycling, we can power a cleaner, greener, and more sustainable future for generations to come.

#Lithium Ion Battery#Battery Recycling#Sustainability#Circular Economy#E-waste Management#Renewable Energy#Electric Vehicles#LFP Batteries#Consumer Electronics#Green Tech

0 notes

Text

Recycling Centre Site Visit ✨

Today I had the opportunity to visit the Hazardous Waste Recycling Centre in Gateshead (i): a tour organised by Suez, the site owner ♻️

I am pleased with how transparent Laura and Hannah, our guides, have been while explaining what happens to the local recycling and general waste. No question has been left unanswered, and topics have been discussed with the most environmentally friendly tone: everything led to the concept of Reduce, Reuse and Recycle 🙌🏻

The overall experience exceeded my expectations as the amount of knowledge I gained was HUGE ⛰️

This is how I would summarise today’s experience in few points:

1. Disposable vapes are a PROBLEM 💨

Strangely classified by UK Legislation as “toys, leisure and sport equipment”, they have been responsible for numerous fires at the recycling centre. E-cigarettes contain lithium batteries, which can easily ignite when segregated with the other waste streams. Furthermore, recycling one 200L barrel full of disposable vapes costs more than £2000 😰

2. Machines that sort general waste out DO NOT EXIST ⚙️

Due to complex composition of general waste, there is no machine or automated process able to effectively separate non-recyclables from recyclables that ended up in the general waste. At Suez, sorting is done BY HANDS 🤲🏻

3. Energy-from-Waste (EFW) requires A LOT of ENERGY ⚡️

Suez’s EFW facility has the potential to generate enough electricity to power 30.000 homes via waste incineration. However, the majority of energy goes back into the facility to keep the process going: fire is on 24/7 🔥

4. Separate food waste segregation at home is COMING SOON 🍔

Around 6.5 MILLION tonnes of food waste come from households every year. The shocking thing is: around 70% of that food waste IS STILL EDIBLE when people dispose of it (4.5 MILLION tonnes). Suez compared it to 90 Royal Albert Halls! 😱

5. Load contamination is a serious thing ☣️

Staff works hard every day to ensure skips contain the waste they have been designed for. When hazardous materials get in the same bin with recyclables, the WHOLE load becomes hazardous. This means that all the waste contained in that bin is very likely to lose its recycling potential. As it has been said today: “It is better losing some recycling in the general waste than contaminating an entire load of recycling and losing all of it” 😞 This is such a powerful sentence.

For those interested in knowing about waste disposal and recycling, I strongly recommend this experience. Event details can be found on Eventbrite and many waste sites are available for tour booking 🤩

Ah, forgot this: IT’S FREE 🤯

References:

i. (Photo) https://lnkd.in/eYyWCWmp

#zero waste#climate change#sustainability#climate crisis#waste management#environment#nature#environmental science#energy from waste#recycling#disposable vapes#hazardous waste

7 notes

·

View notes