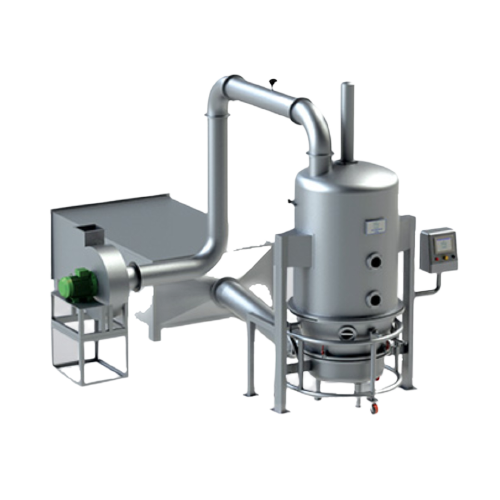

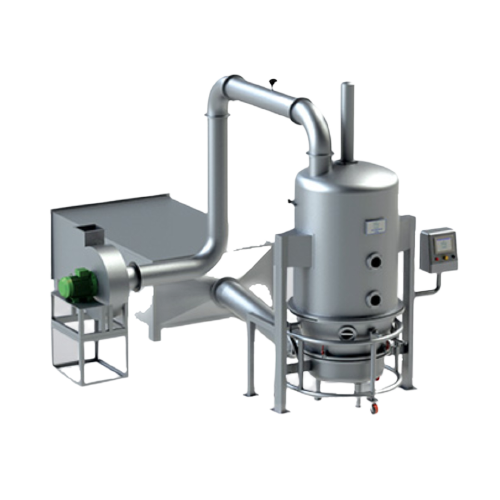

#Small Fluid Bed Dryer

Explore tagged Tumblr posts

Text

Fluid Bed Dryer

youtube

Fluid Bed Dryer (fluidized bed dryer) including fluid bed granulation machine is ideal for production scale, pilot scale & R&D lab with latest Improvement in design makes this unit a truly versatile for Pharmaceuticals, Food, Dyestuff, Chemical, API, Bulk Drugs and Polymer Industries. Fluid Bed Dryers are designed to Uniform drying of the material at low temperature. All contact parts are made of SS 304 / 316 / 316L. The complete unit is supplied with Suitable motor, blower, filters, filter bag, control panel. Heating system provided as per specific customer requirements.

We manufacture Fluid Bed Dryer in production capacity ranging from 10 Liters Small Fluid Bed Dryer to 2000 Liters Industrial Fluid Bed Dryer. We also manufacture Fluid Bed Processor and Fluid Bed Coater with spray purging arrangements.

#fluidized bed dryer#fluid bed granulation machine#Small Fluid Bed Dryer#Fluid Bed Processor#Youtube

0 notes

Text

Anyone interested in a cheap old brothel in Fallon, NV? The living quarters is a manufactured building w/3bds, 3ba, (the whole building is 4,400 sq ft), reduced $34k to $275k. Man, is it yucky inside- bring your UV light to detect all the body fluids and several cases of bleach.

It's the old Pink Cadillac brothel and all of the furnishings are also for sale. It looks so unappealing. Why isn't it painted pink and black?

This must be the common area where the girls hung out.

Open mezzanine above with a nice gold railing. Is that a bar or a reception desk?

What in the world is this setup? Is this a drive-in movie simulation? It's upstairs, and it's a 1955 T-Bird that will convey, but it's just a shell.

Grungy old hot tub room.

Oh, lockers. Maybe for the girls' or clients' belongings?

Depressing looking powder room. Why would they install that style sink w/those old exposed pipes?

I don't know if all these things are included or not. Look at the big cage. I wonder if that was for go-go dancing. There's a stripper pole in the opposite corner.

Ugly kitchen with the flooring taped down.

Small, dingey lounge off the kitchen.

Old washer and dryer right off one of the rooms.

This is depressing.

1/2 bath ensuite. So dreary.

Just burn the mattresses and bedding.

This room has a full ensuite. It will take more than that spray cleaner to sanitize this.

5 acres of desolate dessert.

https://www.zillow.com/homedetails/2700-King-Dr-Fallon-NV-89406/71185528_zpid/?

80 notes

·

View notes

Text

Fluid Bed Dryer Granulator Processor: A True All-in-One Solution?

The Multitasking Marvel of Pharmaceutical Production

Efficiency and quality are paramount in pharmaceutical manufacturing. Drug production demands precision, consistency, and streamlined processes. This is where the fluid bed dryer granulator processor shines. This versatile system has revolutionized how pharmaceuticals and other products are made, offering a compelling solution for companies seeking to optimize production and enhance product quality. But does it truly live up to its all-in-one claim? Let's explore this multifaceted technology.

What is a Fluid Bed Dryer?

A stream of hot air is used by a fluid bed drier to dry solids. The material is suspended and agitated by the upward airflow, creating a "fluidized bed" where each particle is enveloped in drying gas. This ensures efficient heat and mass transfer, resulting in rapid and uniform drying. While widely used in pharmaceuticals, fluid bed dryer are also employed in food processing, chemical production, and agriculture for drying powders, granules, and crystals.

What is a Fluid Bed Granulator?

Granulation combines small particles into larger granules, improving flow properties, reducing dust, and enhancing compressibility for tablet formation. A fluid bed granulator achieves this by spraying a binding solution onto the fluidized bed, causing particles to agglomerate into granules. This method offers precise control over granule size and density, ensuring consistent product quality.

What is a Fluid Bed Processor?

A fluid bed processor expands on the dryer and granulator, enabling coating, agglomeration, and spheronization. This versatility makes it invaluable for developing and manufacturing a wide range of products with specific characteristics. Fluid bed processing allows for modifying particle size, shape, and surface properties, improving drug dissolution, bioavailability, and stability.

Fluid Bed Dryer Granulator Processor: The All-in-One Wonder

The beauty of this system lies in its ability to perform multiple operations in a single unit. This eliminates transferring materials between different pieces of equipment, reducing contamination risk, minimizing material losses, and streamlining production. By combining drying, granulation, and other processing steps, it significantly reduces production time and labor costs while minimizing equipment footprint.

Advantages of Using a Fluid Bed Dryer Granulator Processor

Consistent processing conditions are guaranteed by fluid bed technology, which produces consistently high-quality products. The all-in-one nature minimizes downtime associated with equipment changeovers and cleaning.Additionally, it lessens the need for manual intervention, which lowers labor expenses. Fluid bed dryer granulator processors can be customized to meet specific product requirements and production volumes, allowing manufacturers to adapt to changing market demands.

Industries that Benefit

Pharmaceutical Industry: Ensures drug quality and efficacy in producing tablets, capsules, powders, and granules.

Food Industry: Preserves flavor, aroma, and nutritional value while extending the shelf life of products like fruits, vegetables, and spices.

Chemical Industry: Enables precise processing for consistent results in drying, granulation, coating, and agglomeration.

Choosing the Right System

Selecting the appropriate system requires considering factors like production capacity, desired features, and customization options. Researching reputable manufacturers specializing in fluid bed technology is crucial.

Maintenance and Troubleshooting

It is essential to do routine maintenance, which includes cleaning, inspecting, and replacing worn parts. Reducing downtime can be achieved by being aware of typical issues and how to resolve them. Consulting the manufacturer's troubleshooting guide or seeking expert assistance can be beneficial.

The Future of Fluid Bed Dryer Granulator Processors

Ongoing research and development focus on improving efficiency, sustainability, and automation. Advancements in process analytical technology (PAT) and control systems enable real-time monitoring and optimization of fluid bed processes. Fluid bed technology is inherently energy-efficient, and further advancements aim to reduce energy consumption, minimize waste, and utilize eco-friendly materials.

Conclusion: Investing in Efficiency and Quality

Fluid bed dryer granulator processors offer a compelling solution for industries seeking to optimize production and enhance product quality. Their versatility, efficiency, and ability to streamline operations make them a valuable investment. By carefully considering their needs and selecting the right equipment, companies can reap the numerous benefits of this all-in-one technology, ensuring consistent product quality, improved process efficiency, and a competitive edge.

0 notes

Text

Top Manufacturing Solutions for Pharma & Cosmetic Industries

In the dynamic world of pharmaceutical and cosmetic manufacturing, quality, efficiency, and precision are paramount. At Pharmachem Cosmetics, we understand the importance of using state-of-the-art equipment to ensure top-tier products. Whether you're producing ointments, oral liquids, or other cosmetic formulations, having the right machinery is crucial for success. In this blog, we'll highlight essential equipment and machinery that every manufacturer in the pharmaceutical and cosmetic industries should consider.

1. Fluid Bed Dryer Manufacturers: Enhancing Product Drying Efficiency

When it comes to drying powders, granules, or other materials in the pharmaceutical and cosmetic industries, Fluid Bed Dryers are indispensable. These dryers operate on the principle of fluidization, where hot air flows through the material, reducing moisture content quickly and efficiently. Fluid Bed Dryer Manufacturers like Pharmachem Cosmetics offer equipment designed for consistency, high-quality results, and energy efficiency, making them ideal for drying sensitive products such as powders, granules, and even some ointments.

Choosing the right Fluid Bed Dryer can significantly impact production timelines and product quality. At Pharmachem Cosmetics, we offer advanced Fluid Bed Dryers that meet industry standards and are customizable for different batch sizes and material types. Our equipment ensures uniform drying, preventing clumping and enhancing the overall product stability.

2. Ribbon Blender Mixer in Maharashtra: Optimal Mixing for Uniform Results

Uniformity in mixing is crucial for the success of any pharmaceutical or cosmetic product. The Ribbon Blender Mixer, a common choice in manufacturing plants, provides an efficient solution for blending powders and granules. This versatile equipment ensures thorough mixing of dry ingredients, resulting in uniform consistency throughout the batch.

Pharmachem Cosmetics, based in Maharashtra, is a leading provider of Ribbon Blender Mixers known for their precision and reliability. Whether you are blending active pharmaceutical ingredients (APIs) or cosmetic powders, our Ribbon Blender Mixers are designed to handle a wide range of formulations with ease. By providing a homogeneous blend, these mixers help in achieving the desired product quality, reducing waste, and optimizing production time.

3. Liquid Oral Manufacturing Plant Suppliers: The Backbone of Liquid Formulations

The demand for liquid oral medications and cosmetic products is on the rise. Whether it’s syrups, tonics, or oral gels, the liquid formulation process requires specialized manufacturing plants equipped with the latest technology. Liquid Oral Manufacturing Plant Suppliers like Pharmachem Cosmetics provide cutting-edge equipment for the smooth production of liquid formulations.

From raw material mixing to bottling and packaging, our liquid oral manufacturing plants are designed to ensure safety, hygiene, and efficiency. With automated systems and robust machinery, we help streamline your liquid production process, reducing contamination risks and ensuring consistent product quality. As a trusted supplier in the industry, Pharmachem Cosmetics ensures that your plant meets regulatory standards and operates at peak performance.

4. Ointment Manufacturing Plant Dealers: Producing High-Quality Ointments

Ointments are among the most widely used formulations in both the pharmaceutical and cosmetic industries. From topical treatments to skincare products, the right manufacturing process is essential to ensure the effectiveness and safety of the ointment. Pharmachem Cosmetics offers high-quality Ointment Manufacturing Plants, designed to produce consistent and reliable ointments for a variety of applications.

Our ointment manufacturing plants are equipped with advanced machinery such as mixers, homogenizers, and filling machines, designed to handle both small and large batches. As leading Ointment Manufacturing Plant Dealers, we provide you with everything you need to produce high-quality ointments while adhering to strict regulatory guidelines.

5. Multi Mill Manufacturers: Versatile and Efficient Milling Solutions

The Multi Mill is one of the most versatile machines used in the pharmaceutical and cosmetic industries. Capable of performing a range of functions such as grinding, milling, shredding, and crushing, the Multi Mill is an essential tool for reducing the size of materials for further processing. Whether you are working with APIs, herbal ingredients, or cosmetic raw materials, the Multi Mill ensures uniform particle size reduction, improving product consistency and performance.

At Pharmachem Cosmetics, we are proud to be recognized as leading Multi Mill Manufacturers, offering equipment that guarantees high throughput, durability, and ease of maintenance. Our Multi Mills are designed with user-friendly controls and are highly adaptable to different production needs.

Conclusion: Quality Equipment for Exceptional Products

At Pharmachem Cosmetics, we are committed to providing the highest quality manufacturing equipment for the pharmaceutical and cosmetic industries. Whether you are in need of Fluid Bed Dryers, Ribbon Blender Mixers, Liquid Oral Manufacturing Plants, Ointment Manufacturing Plants, or Multi Mills, we offer cutting-edge solutions to meet your production requirements.

Partner with Pharmachem Cosmetics today and elevate your manufacturing process to new heights. Our equipment ensures precision, efficiency, and safety in every batch, helping you deliver exceptional products to your customers.

#Multi Mill Manufacturers#Ribbon Blender Mixer in Maharashtra#Fluid Bed Dryer Manufacturers#Liquid Oral Manufacturing Plant Suppliers#Ointment Manufacturing Plant Dealers

1 note

·

View note

Text

Industrial Manufacturing Machines for Efficient Production

In the ever-evolving landscape of industrial manufacturing, efficiency and precision are more critical than ever. Whether in pharmaceuticals, cosmetics, or food production, advanced machinery plays a pivotal role in maintaining high-quality standards while boosting productivity. This article provides an in-depth overview of essential manufacturing machines.

Fluid Bed Dryer The Fluid Bed Dryer is designed for efficient and uniform drying of powders, granules, and other particulate materials. It works by suspending the particles in a stream of heated air, ensuring quick and even drying throughout. This technology is widely used in the pharmaceutical, food, and chemical industries for high-quality results. With temperature and humidity controls, the dryer optimizes the drying process while conserving energy. Its easy-to-clean design and robust construction make it suitable for large-scale manufacturing environments.

Fluid Bed Processor The Fluid Bed Processor is a versatile piece of equipment that can handle drying, granulating, and coating applications in a single unit. It provides exceptional fluidization of particles, resulting in efficient and consistent processing. With adjustable air flow and precise temperature control, it ensures that products are treated uniformly, maximizing efficiency. Ideal for pharmaceutical and food manufacturing, it reduces the time needed for multiple processing steps. Built to meet stringent industry standards, it ensures reliability and easy maintenance for high-volume operations.

Ointment Manufacturing Plant The Ointment Manufacturing Plant is an all-in-one solution for producing high-quality ointments and creams. It includes mixing, homogenizing, emulsifying, and cooling equipment, ensuring a seamless manufacturing process. With precision controls, it provides consistent texture and stability of the final product, essential for pharmaceutical and cosmetic formulations. Designed with stainless-steel components, the plant ensures compliance with hygiene and safety regulations. Its efficient workflow minimizes production time while maintaining the highest standards of quality.

Liquid Filling Machine The Liquid Filling Machine is engineered to handle a wide range of liquid products, from thin solutions to thick viscous substances. It features advanced volumetric filling technology, delivering accurate and consistent fills for each container. Ideal for food, pharmaceutical, and chemical industries, it boosts productivity with high-speed operation. The machine is easy to set up and adjust, making it versatile for various container sizes and shapes. Built with durable materials, it ensures long-term reliability and smooth performance even in demanding environments.

V Blenders V Blenders are specially designed for mixing dry powders and granules evenly, making them ideal for the pharmaceutical and food industries. Their V-shaped design ensures efficient blending by creating a tumbling action, achieving uniform results with minimal energy consumption. These machines are built to handle both small and large batches, offering flexibility in production. With easy-to-clean and corrosion-resistant materials, they maintain a high level of hygiene. V Blenders also come with safety features and robust construction, making them reliable for continuous use in industrial settings.

ROPP Capping Machine The ROPP (Roll-On Pilfer Proof) Capping Machine is designed for the secure sealing of bottles, particularly in the beverage, pharmaceutical, and cosmetic industries. It provides a tamper-evident seal that ensures product integrity and prevents leaks during storage or transport. Equipped with advanced capping technology, it offers precise torque control to avoid damaging the container or cap. The machine can handle a variety of cap sizes and materials, making it highly versatile for different production requirements. Its robust construction and easy-to-use interface make it ideal for high-speed, large-scale manufacturing operations.

Shampoo Manufacturing Plant The Shampoo Manufacturing Plant is a comprehensive system for producing high-quality shampoos and hair care products. It includes pre-mixing, homogenizing, and cooling units to ensure a smooth and consistent product texture. Designed to minimize contamination, the plant features closed-loop systems and stainless-steel construction, meeting strict hygiene standards. The automated controls enable precise ingredient mixing and temperature adjustments, ensuring product uniformity. With energy-efficient processes and easy maintenance, the plant is perfect for large-scale shampoo production while ensuring consistent quality and reduced operational costs.

V-Type Blender The V-Type Blender is engineered for the efficient mixing of dry powders and granules, commonly used in the pharmaceutical, food, and chemical industries. The V-shaped chamber ensures optimal blending by allowing the materials to tumble and mix evenly without the risk of particle degradation. It is suitable for both small and large batch processing, providing flexibility to meet various production demands. Easy to load and discharge, the blender also features a polished interior to reduce residue and make cleaning a breeze. Its sturdy and durable design ensures long-lasting performance and consistent results.

Ghee Filling Machine The Ghee Filling Machine is built to handle the thick and viscous nature of ghee, ensuring precise and consistent filling for containers of various sizes. It is equipped with a servo-driven filling system, providing exceptional accuracy and minimal product wastage. The machine’s hygienic design, with food-grade stainless steel, prevents contamination and meets strict health and safety standards. Suitable for large-scale dairy production, it offers high-speed performance without compromising on quality. Easy-to-operate controls and an ergonomic design make it user-friendly and efficient, even under demanding production conditions.

Automatic Servo Liquid Filling Machine The Automatic Servo Liquid Filling Machine is a state-of-the-art system designed for high-speed and high-precision liquid filling. Using servo-driven technology, it delivers exceptional accuracy, reducing waste and ensuring consistency in every fill. This machine can accommodate a wide range of liquid viscosities, from water-like solutions to thick gels, making it versatile for different industries, such as food, pharmaceuticals, and cosmetics. Built for ease of use, it features a user-friendly touchscreen interface and simple calibration settings. Its robust construction and automated operation increase productivity while minimizing downtime.

Ploughshare Mixer The Ploughshare Mixer is designed for intensive mixing of dry powders, granules, and pastes, making it highly effective in the pharmaceutical, food, and chemical industries. It uses plough-shaped mixing elements that rotate at high speed, ensuring thorough blending and achieving uniform product consistency. This mixer can handle both delicate and heavy-duty applications, making it versatile for a wide range of materials. Built with stainless steel construction, it meets high hygiene standards and is easy to clean, minimizing cross-contamination risks. The mixer also offers customizable options for temperature control and additional features like liquid injection for added functionality.

Vacuum Transfer System The Vacuum Transfer System is a powerful and efficient solution for the safe and contamination-free transfer of powders and granules in pharmaceutical and food manufacturing. It uses vacuum pressure to move materials through a sealed pipeline, preventing exposure to external contaminants and minimizing product loss. The system is ideal for transferring materials between different production stages, such as mixing, drying, or packaging. Its robust design ensures minimal maintenance while maximizing throughput, making it a reliable component for continuous operation. The vacuum transfer also minimizes dust generation, promoting a cleaner and safer working environment.

This article explores a wide array of industrial manufacturing machines, highlighting their unique features, capabilities, and applications across various sectors. It starts with the Fluid Bed Dryer, known for its efficient and uniform drying of powders and granules, followed by the Fluid Bed Processor, which offers versatile processing for drying, granulating, and coating. Machines like the Ointment Manufacturing Plant and Liquid Filling Machine are tailored for pharmaceutical and cosmetic production, ensuring high precision and consistency. The V Blenders and V-Type Blenders provide effective mixing solutions for powders, while the ROPP Capping Machine and Screw Capping Machine ensure secure and reliable sealing for bottles.

youtube

0 notes

Text

GFG Batch Type Fluid Bed Dryer

Our GFG Batch Type Fluid Bed Dryer is a versatile solution designed for drying various materials including mechanical screw extrusion granules, rocking granules, wet high-speed mixing granulation granules, and powdery substances across industries such as medicine, food, feed, and chemicals. Its capabilities extend to handling large particles, small lumps, sticky lumps, and materials prone to volume changes during drying like konjac and polyacrylamide. Its standout features include a circular fluidized bed structure to eliminate dead corners, a hopper equipped for stirring to prevent material agglomeration and ditch formation, and a tipping and unloading section for convenient, rapid, and thorough discharge. The dryer operates under closed negative pressure, with filtered airflow, ensuring ease of operation, cleanliness, and compliance with stringent "GMP" standards. Notably, it boasts rapid drying with uniform temperatures, typically completing each batch within 20-30 minutes.

Email: [email protected] FAX: +86-519-88908383/+86-519-88903727 Inquiry: +86-13806125772/+86-519-88908521 Address: Jiaoxi Industrial Park, Zhenglu Town, Changzhou City, Jiangsu Province, China

0 notes

Text

Exporter of Multi Effect Evaporator in Comoros

Drytech Engineering Systems is an Exporter of Multi Effect Evaporator in Comoros. We are based in Ahmedabad, Gujarat, India. We Expertized in Flash Dryers, Spray Dryers, Spin Flash Dryers, Fluid Bed Dryers, Evaporator Dryers, Rotary Valves, Rotary Atomizers, Hot Air Generators, Centrifugal Blowers, and Dust Collector Systems. As a leading MEE manufacturer, we offer innovative solutions to improve efficiency and lower operational costs in industrial processes. Utilizes multiple stages of evaporation to maximize heat recovery and minimize energy consumption. Designed to accommodate various processing scales, from small laboratory setups to large industrial operations. It is constructed from high-quality materials to withstand harsh operating conditions and ensure long-term reliability. Why Choose Us? Expertise and Experience: With years of industry experience, our team brings unparalleled expertise to the design and manufacturing of Multi Effect Evaporators. Innovative Technology: Our evaporators incorporate the latest technological advancements to enhance efficiency and performance. Custom Solutions: We offer customizable options to match your exact processing needs, from scale to specific features, ensuring you get the most effective and efficient solution. Sustainability Focus: We prioritize eco-friendly practices in our design and manufacturing processes, helping you achieve your sustainability goals while improving operational efficiency. Applications: Pharmaceutical Industry Food and Beverage Sector Chemical Industry Environmental Engineering Biotechnology Drytech Engineering Systems is an Exporter of Multi Effect Evaporator in Comoros including locations Moroni, Moutsamoudou, Fomboni, Domoni, Tsimbeo, Adda-Doueni, Sima, Ouani, Mirontsi, Mkiriwadjumoi, Koni-Djodjo, Moya, Mbeni, Mitsamiouli, Barakani, Chandra, Ouellah, and Mramani. For more information and inquiries, feel free to contact us. View Product: Click Here Read the full article

0 notes

Text

Few Things About Pharmaceutical Granulation

Pharmaceutical granulation is a crucial process in the production of pharmaceuticals, where small particles are aggregated into larger granules to improve flowability, compressibility, and dosage uniformity. Here are a few key points about pharmaceutical granulation:

Purpose: Granulation helps in the formulation of solid dosage forms such as tablets and capsules. It enhances the flow properties of the powder mixture, reduces dustiness, improves compaction properties, and ensures uniform distribution of active pharmaceutical ingredients (APIs) and excipients.

Types of Granulation:

Wet Granulation: Involves the addition of a liquid binder to the powder mixture, followed by mixing, wet massing, drying, and sizing.

Dry Granulation: Also known as roller compaction, this method involves compacting the powder mixture into flakes or ribbons, followed by milling or screening to obtain granules.

Direct Compression: Involves directly compressing the blend of APIs and excipients without prior granulation.

Equipment:

For wet granulation: High shear mixers, fluid bed dryers, and granulators.

For dry granulation: Roller compactors and milling or screening equipment.

For direct compression: Blenders and tablet presses.

Granulating Agents:

Binders: Substances that promote adhesion between particles, such as water, alcohol, or solutions of polymers like hydroxypropyl cellulose (HPC) or polyvinyl pyrrolidone (PVP).

Disintegrants: Aid in the breakup of tablets or capsules in the gastrointestinal tract, ensuring drug release. Examples include croscarmellose sodium and crospovidone.

Process Control:

Granulation process parameters such as mixing time, granulating liquid addition rate, and drying conditions need to be carefully controlled to ensure consistent granule properties.

Monitoring granule size distribution, moisture content, and flow properties is essential for quality control.

Advantages:

Improves flow properties, reducing the likelihood of segregation.

Enhances compressibility, leading to more robust tablets with uniform drug content.

Facilitates controlled release formulations.

Reduces dust generation, improving operator safety and environmental conditions.

Challenges:

Granulation process can be time-consuming and resource-intensive, especially wet granulation.

Risk of over-granulation or under-granulation, leading to issues such as poor flowability or content uniformity.

Some APIs may be sensitive to moisture or heat, requiring careful selection of granulation methods and excipients.

Overall, pharmaceutical granulation is a critical step in the manufacturing of solid dosage forms, ensuring product quality, efficacy, and patient safety.

Sahasrayogam is GMP Certified Granules manufacturer and suppliers in Hyderabad, manufactures 300+ products such as: Softgel, Branded Tablets, Capsules, Syrups, Oils, Powders, Granules and Cosmetics etc.., under Ayurveda, Food & Nutra Ceutics.

0 notes

Text

Fluid Bed Dryer R&D Lab Model

youtube

Lab Fluid Bed Dryer (small dryer) with fluidized bed granulation machine is ideal for pilot scale & R&D lab with updated design makes it truly versatile for Pharmaceuticals, Food, Dyestuff, Chemical, API, Bulk Drugs and Polymer Industries. Fluid Bed Dryers are designed to Uniform drying of the material at low temperature. All contact parts are made of SS 304 / 316 / 316L. The complete unit is supplied with Suitable motor, blower, filters, filter bag, control panel. Heating system provided as per specific customer requirements.

We are R&D Fluid Bed Dryer manufacturer in production capacity of 5 liters, 10 liters and 20 liters. We also manufacture Fluid Bed Processor and Fluid Bed Coater with spray purging arrangements for pilot lab scale operations.

0 notes

Text

Unveiling the Pillars of Pharmaceutical Manufacturing: Tablet Coater, Spheronizer, and FBD Fluid Bed Dryer

In the realm of pharmaceutical manufacturing, the importance of specialized equipment cannot be overstated. Three such pieces of equipment that play a pivotal role in this industry are the Tablet Coater, Spheronizer, and FBD Fluid Bed Dryer.

Tablet Coater

The Tablet Coater is an indispensable tool in the pharmaceutical industry. It is used to apply a uniform coating to tablets, which not only enhances their aesthetic appeal but also makes them easier to swallow. Moreover, the coating serves as a protective layer, safeguarding the tablet from external factors and ensuring the active ingredients remain effective. The Tablet Coater is a testament to the industry’s commitment to quality and efficiency.

Spheronizer

The Spheronizer, another crucial piece of equipment, is used to transform drug-loaded granules into small, spherical pellets. These pellets offer numerous benefits, including improved flow properties, uniform coating, and controlled drug release. The Spheronizer is instrumental in the production of multi-particulate dosage forms, contributing significantly to the effectiveness of the final product.

FBD Fluid Bed Dryer

The FBD Fluid Bed Dryer is a key player in the drying stage of pharmaceutical production. It employs a technique known as fluidization to dry granules, ensuring quick and uniform drying. Known for its efficiency, the FBD Fluid Bed Dryer reduces drying times and enhances the overall production process.

The Interplay of Tablet Coater, Spheronizer, and FBD Fluid Bed Dryer

These three pieces of equipment work in harmony to ensure the production process is seamless and efficient. The Tablet Coater ensures the tablets are well-protected and easy to consume, the Spheronizer enhances the effectiveness of the medication, and the FBD Fluid Bed Dryer ensures the granules are properly dried before moving on to the next stage of production.

Conclusion

The Tablet Coater, Spheronizer, and FBD Fluid Bed Dryer are more than just pieces of equipment; they are the pillars of pharmaceutical manufacturing. They each play a unique role in ensuring the production process is efficient and the final product is of the highest quality. By understanding these machines and their functions, we gain insight into the intricate processes involved in creating the medicines that enhance our health and well-being.

0 notes

Text

How to Boost Your Pharmaceutical Production with Tablet Coater, Spheronizer, & Retsch Fluid Bed Dryer

Introduction:

In the fast-paced world of pharmaceutical production, efficiency and product quality are paramount. To stay competitive, pharmaceutical manufacturers are constantly seeking innovative ways to optimize their processes. Three essential pieces of equipment that play a pivotal role in enhancing pharmaceutical production are the Tablet Coater, Spheronizer, and Retsch Fluid Bed Dryer. In this comprehensive guide, we'll delve into the capabilities and benefits of these devices and how they can significantly boost your

pharmaceutical production.

Tablet Coater: The Art of Precision Coating

Tablet coating is a vital step in pharmaceutical manufacturing, as it ensures the drug's effectiveness and improves its appearance. Tablet Coaters are specialized machines designed for the application of coatings on tablets, granules, or pellets. Here's how they boost pharmaceutical production:

• Uniform Coating: Tablet Coaters ensure an even and consistent coating application, preventing overcoating or undercoating, which can lead to product wastage.

• Reduced Manufacturing Time: With their high-speed capabilities, Tablet Coaters save valuable time during the coating process, enabling faster production turnaround.

• Enhanced Product Quality: Precise control of the coating process results in improved product quality and a more appealing final product.

By utilizing a Tablet Coater in your pharmaceutical production process, you can achieve higher production volumes and better product quality.

Spheronizer: Shaping the Future of Pharmaceuticals

The Spheronizer is a powerful tool in pharmaceutical production, primarily used for shaping and rounding particles or extrudates. Here's how it can boost your production:

• Uniform Spheroids: Spheronizers excel at producing uniform spherical particles, a crucial factor in achieving consistent dosing in pharmaceuticals.

• Improved Flowability: Rounded particles flow more smoothly through processing equipment, reducing the likelihood of clogs and blockages.

• Precision and Control: Spheronizers offer excellent control over the size and shape of the particles, allowing you to tailor your products to specific requirements.

• Waste Reduction: By producing uniform, high-quality particles, Spheronizers help minimize waste, making your production process more cost-effective.

Retsch Fluid Bed Dryer: Drying with Precision

Drying is a critical step in pharmaceutical production, and the Retsch Fluid Bed Dryer is a game-changer in this regard. Here's how it can significantly enhance your pharmaceutical production:

• Rapid Drying: Retsch Fluid Bed Dryer use a fluidized bed to dry materials quickly and evenly, reducing drying times and increasing throughput.

• Gentle Handling: The gentle drying process ensures that delicate or heat-sensitive materials are not damaged during drying.

• Energy Efficiency: These dryers are energy-efficient, helping to reduce operational costs and environmental impact.

• Easy Scale-Up: Whether you're a small or large-scale manufacturer, the Retsch Fluid Bed Dryer is easily scalable to meet your production needs.

Boosting Pharmaceutical Production with the Trio

Now that we've explored the individual benefits of Tablet Coaters, Spheronizers, and Retsch Fluid Bed Dryer, let's see how combining these three technologies can supercharge your pharmaceutical production.

Improved Efficiency: The precision and speed of Tablet Coaters, the spherical consistency achieved with Spheronizers, and the rapid drying of Retsch Fluid Bed Dryers together create a more efficient production process.

Enhanced Product Quality: The uniformity and control offered by these machines result in higher-quality pharmaceuticals, meeting or even exceeding industry standards.

Reduced Costs: By minimizing waste and optimizing drying times, you'll reduce operational costs and improve your bottom line.

Conclusion:

In the competitive world of pharmaceutical production, staying ahead means continually improving your processes. The combination of Tablet Coaters, Spheronizers, and Retsch Fluid Bed Dryer can be a game-changer, enhancing efficiency, product quality, and your overall competitiveness. By investing in these technologies, you can take a significant step toward boosting your pharmaceutical production to new heights. Remember, the key to success is not just in acquiring the equipment but in understanding how to best utilize them in your specific production processes.

0 notes

Text

Filtration and Drying Equipment: Ensuring Quality and Efficiency in Industrial Processes

In many industrial processes, the separation of solids and liquids is a crucial step that requires advanced filtration and drying equipment. Filtration is the process of removing suspended solids from a liquid or gas stream, while drying involves the removal of moisture from a solid material. The use of efficient and reliable filtration and drying equipment can ensure product quality, reduce production costs, and improve overall efficiency. In this article, we will explore the different types of filtration and drying equipment, their applications, and their benefits.

Filtration Equipment

There are various types of filtration equipment available, ranging from simple mesh screens to advanced membrane filters. The choice of filtration equipment depends on the type of material to be filtered, the desired level of filtration, and the required flow rate.

One of the most common types of filtration equipment is the bag filter. Bag filters are typically made of a porous material such as nylon or polyester and are used to remove particles from a liquid or gas stream. They are simple to use and can be easily replaced when they become clogged.

Another type of filtration equipment is the cartridge filter. Cartridge filters are used to remove fine particles from a liquid or gas stream. They are made of a porous material such as paper or polymer and are available in various sizes and shapes. Cartridge filters are widely used in the pharmaceutical and food industries, where product quality is critical.

Membrane filters are another type of filtration equipment that are widely used in the biotechnology industry. Membrane filters are made of a thin, porous material that allows small particles to pass through while retaining larger particles. They are used to purify water and other liquids and can be used to remove bacteria, viruses, and other contaminants.

Drying Equipment

Drying equipment is used to remove moisture from solid materials. The choice of drying equipment depends on the type of material to be dried, the desired level of moisture removal, and the required production rate.

One of the most common types of drying equipment is the tray dryer. Tray dryers are used to dry small batches of solid materials and are commonly used in the pharmaceutical industry. Tray dryers consist of a series of trays that are stacked on top of each other, and the material to be dried is spread out on the trays.

Fluid bed dryers are another type of drying equipment that are commonly used in the chemical and food industries. Fluid bed dryers use a stream of hot air to fluidize the material to be dried, allowing for efficient heat transfer and moisture removal.

Vacuum dryers are used to dry materials that are sensitive to heat or that may react with oxygen. In vacuum drying, the material is heated under reduced pressure, which lowers the boiling point of the water and allows for faster and more efficient drying.

Benefits of Filtration and Drying Equipment

The use of efficient and reliable filtration and drying equipment can provide numerous benefits to industrial processes. Some of the key benefits include:

Improved product quality: Filtration and drying can remove impurities and contaminants from materials, ensuring that the final product is of high quality and meets industry standards.

Reduced production costs: Efficient filtration and drying equipment can reduce production costs by minimizing the amount of waste generated and maximizing the yield of the desired product.

Increased efficiency: Filtration and drying can improve the efficiency of industrial processes by reducing processing time and improving product consistency.

Enhanced safety: Filtration and drying equipment can improve safety in industrial processes by reducing the risk of contamination and minimizing the potential for accidents.

In conclusion, filtration and drying equipment play a critical role in many industrial processes, and their importance cannot be overstated. By choosing the right filtration and drying equipment and maintaining it properly, industrial companies can ensure that their products meet the highest standards of quality.

1 note

·

View note

Text

Maximizing Efficiency: Integrating Rapid Dryers, Rapid Mixer Granulators, and Drying Machines in Pharmaceutical Manufacturing

In the fast-paced world of pharmaceutical manufacturing, efficiency and precision are paramount. The integration of advanced equipment, such as rapid dryers, rapid mixer granulators, and drying machines, plays a crucial role in streamlining production processes, ensuring product quality, and enhancing overall productivity. This blog explores how these technologies can be effectively integrated to maximize efficiency in pharmaceutical manufacturing.

The Role of Rapid Dryers in Pharmaceutical Manufacturing

Rapid dryers are designed to remove moisture quickly and efficiently from pharmaceutical products, reducing processing time and improving batch consistency. These dryers use high-speed airflow and precise temperature control to achieve rapid drying without compromising the integrity of the product.

Benefits of Rapid Dryers:

Speed: Rapid dryers significantly reduce drying time, allowing for faster production cycles.

Consistency: Uniform drying ensures consistent product quality and reduces the risk of spoilage.

Energy Efficiency: Advanced rapid dryers are designed to optimize energy usage, reducing operational costs.

Enhancing Granulation with Rapid Mixer Granulators

Granulation is a critical process in pharmaceutical manufacturing, where powders are converted into granules to improve flowability, compressibility, and uniformity. Rapid mixer granulators combine mixing and granulation in a single step, streamlining the process and improving efficiency.

Key Features of Rapid Mixer Granulators:

High Shear Mixing: Ensures thorough mixing of ingredients, resulting in uniform granules.

Rapid Processing: Accelerates the granulation process, reducing production time.

Versatility: Can handle a wide range of formulations, making them suitable for various pharmaceutical products.

Advantages of Using Rapid Mixer Granulators:

Improved Product Quality: Consistent granule size and composition lead to higher quality end products.

Reduced Processing Time: Combining mixing and granulation in one machine cuts down on processing time and increases throughput.

Enhanced Control: Advanced control systems allow for precise adjustment of mixing and granulation parameters.

The Importance of Drying Machines in the Manufacturing Process

Drying machines are essential in the final stages of pharmaceutical production, ensuring that products achieve the desired moisture content before packaging. These machines come in various types, including tray dryers, fluid bed dryers, and rotary dryers, each offering unique advantages for specific applications.

Common Types of Drying Machines:

Tray Dryers: Ideal for small batches and products that require gentle handling.

Fluid Bed Dryers: Provide efficient drying with excellent heat and mass transfer rates.

Rotary Dryers: Suitable for large-scale production and continuous operation.

Benefits of Advanced Drying Machines:

Consistency: Achieve uniform drying across all batches, ensuring product quality.

Scalability: From small batches to large-scale production, drying machines can be tailored to meet specific needs.

Energy Efficiency: Modern drying machines are designed to optimize energy consumption, reducing operational costs.

Integrating Rapid Dryers, Rapid Mixer Granulators, and Drying Machines

The integration of rapid dryers, rapid mixer granulators, and drying machines in pharmaceutical manufacturing can significantly enhance overall efficiency. By streamlining processes and reducing production times, manufacturers can achieve higher throughput and better product quality.

Steps for Effective Integration:

Assess Production Needs: Evaluate the specific requirements of your manufacturing process to determine the best combination of equipment.

Choose Compatible Equipment: Select rapid dryers, mixer granulators, and drying machines that are compatible and can be seamlessly integrated into your production line.

Optimize Workflow: Design a workflow that maximizes the efficiency of each piece of equipment, ensuring smooth transitions between processes.

Implement Advanced Controls: Utilize advanced control systems to monitor and adjust parameters in real-time, ensuring optimal performance of all integrated equipment.

Regular Maintenance: Maintain equipment regularly to ensure peak performance and minimize downtime.

Conclusion

Integrating rapid dryers, rapid mixer granulators, and drying machines into pharmaceutical manufacturing processes is a strategic approach to maximizing efficiency and ensuring product quality. By leveraging the unique advantages of each technology, manufacturers can streamline operations, reduce production times, and achieve higher throughput. As the pharmaceutical industry continues to evolve, the adoption of advanced equipment and integrated processes will remain crucial for maintaining a competitive edge.

0 notes

Text

The Fallen Wolves Brotherhood - Part Eleven

Series Summary: Lori "Babycakes" Tate swore she would never date a biker but when her life is in danger, she is put under the protection of a small club known as The Fallen Wolves Brotherhood. She suddenly finds herself attracted to not one, but five bikers.

A reverse harem, biker AU.

Part Eleven Summary: Lori asks Marshall for some assistance.

Pairing: Captain Syverson x OFC, Walter Marshall x OFC, Mike x OFC, Geralt x OFC, August Walker x OFC

Word Count: Approx. 3.6k

Warnings:

Series Warnings: Reverse harem, age gap (OFC 23, ages range from 23 to mid 40s), oral sex (male and female receiving), unprotected p in v sex, anal sex, group sex, masturbation, praise kink, mentions of body fluids, drug use, recreational drinking, sex work, criminal activities, mention of death, violence, use of weapons, mentions of war, mentions of abuse, angst, fluff, probably a lot more that I will add as they come up.

Part Eleven Warnings: masturbation (female), drug use, angst, fluff

Authors Note: Thanks as always to my lovely BBFs (Best Beta's forever) @henryobsessed and @nashibirne .

Sorry its a little late, its Thursday for me, but I think its still Wednesday for most of you!

Divider made by me. Edited by me, there will be errors. (Probably a lot in this chapter, I apologise)

Masterlist

Parts Masterlist

Part Ten Part Twelve

Lori

I sat on the ground next to Mike’s bike, watching the oil leak slowly into the drip pan and I felt safe for the first time since seeing Jake that morning. I could still feel Mike’s kiss on my lips and his soft, hesitant caress of my cheek.

We sat for another few minutes, until Mike cleared his throat, “Got to change the filter.”

I hummed and felt his lips on the top of my head. A heady rush of warmth coiled its way through my body and I bit my lip. Shit, it was easy with Mike, so comfortable, I felt like I’ve known him for years.

I moved out of his way, leaning against a bench to watch him work. I’m not going to lie and say that it wasn’t also so I could get a better look at him. That boy was damn easy on the eyes as well as cute and mischievous. I couldn’t take my eyes off him, nor the tantalising slither of the tattoo that peaked above the neckline of his shirt.

I was still perving on Mike when Marshall came in to take me to my room. He led me across the yard to the main building, insisting on carrying my bag and helmet for me. The clubhouse itself was much larger than you’d think it needed to be for just five guys. It was at least as big as my brothers, but much more understated. The halls could have been corridors in a simple office building, they were so bland and non-descript. The common room was clean and homey though which made me both happy and sadly nostalgic.

Marshall stopped at a door that looked no different to the six or seven doors that lined the hallway. He opened the door and silently gestured for me to go in.

The room was large but basic and furnished the same way a motel would be with a queen bed, a small dining table with two chairs, a tv on the wall and a sofa with a coffee table. Marshall pointed out a small bathroom, and closet, although I had next to no clothes to wear, and I pointed that out.

“Give Walker a list in the morning and he will see that you get what you need,” Marshall said.

“I can’t choose the stuff myself?”

Marshall crossed his arms over his chest and raising an eyebrow he sighed, “I can ask him if he will let you use a computer to order things yourself.”

“I’m not going to be able to leave the Clubhouse at all, am I?”

“No sweetheart,” Walter said, his tone indicating that while there was no room for argument, he was empathetic to my situation.

While I wasn’t entirely happy, I couldn’t exactly argue with the logic of staying hidden, especially after seeing Jake.

“Well, in the meantime, do you have a laundry room I can use?” I asked.

Marshall nodded and I grabbed my bag and followed him down the hall, past a large kitchen and pantry to a room with two large machines and dryers.

“I’ll leave you to it,” Marshall said leaning his shoulder into the door frame.

I nodded but he didn’t go, instead cocked his head as he stared at me and continued speaking.

“Sy’s room is to the left of yours and my room is opposite his door. If you need anything during the night, you can come to me.”

I looked into his eyes and saw the desire in them that he was trying to hide beneath his gruff exterior. The vast dark blue of his iris seemed to draw me in so deep and I found it hard to concentrate. I turned away, before I got lost. Jesus, Sy’s barely gone, Mike just kissed me and now Marshall…

I forced my attention to my bag and opened it. I gasped in shock at the faded black Lynyrd Skynyrd t-shirt on top of the clothes. I checked the bag quickly, thinking I must have gotten Sy’s by mistake. I dug through the clothes and was confused when the rest of the bag was full of my stuff.

A sob threatened to hurtle up my throat, but I suppressed it as I ran my fingers over the soft cotton shirt. Had Sy left it for me? Had he given me the shirt I had worn in bed with him last night? When had he done that? Why had he done that? It was such a simple gesture, and yet, it meant more to me than I ever thought it would.

Marshall was in front of me, taking hold of the bag as I pulled the shirt out.

“Don’t let Noah fool you,” Marshall said softly. “He can be a sentimental bastard when he wants to be.”

“Noah?” I asked.

Marshall chuckled. “Syverson. His name is Noah.”

Noah. Noah Syverson. A good name. I liked it. “He didn’t tell me that.”

“Well, you didn’t hear it from me,” Marshall grinned. It made me smile back, he so rarely smiles.

“What’s your name?” I asked, gripping the shirt tight to my chest.

“Walter.”

My jaw went a little slack. It wasn’t a name I would have associated with him, thinking it would be something cooler, like Evan or Ryan. Marshall’s mouth was tight, as if unsure what I would think of his name, almost like he expected me to hate it.

“Walter Marshall,” I said, letting myself get used to the name. Walter took a small step closer, and I asked, “You ever go by Wally or…?”

Walter scowled, and I laughed but the sob I was suppressing fell out as well. I tried to hold it back, sucking in deep gulps of air but I couldn’t stop. He had me in his arms, rubbing big circles on my back as I burrowed my face into his chest. I felt ridiculous, crying again, this time over a freaking t-shirt.

“I’m sorry,” I muttered into Walter’s shirt. “I don’t know why I keep crying.”

“You’ve been through a lot.”

“I don’t want to cry about it.”

I tried to shake off, to ignore all the reasons I had to cry. I wanted to be hard, to be strong, to be my mother’s daughter and handle this life and all the bullshit that went with it. But I wasn’t. I can’t handle it. I just want to go home and be with normal people again. The problem was I don’t know any; even Jake isn’t who I thought he was.

Everything just felt like it was too much, too heavy, too much of a burden. I wanted to be free, even for a few moments, I needed to breathe. Walter lifted my chin to look at him. His look was almost pitiful.

“It’s late,” Walter said. “Leave this for tomorrow and get a good night’s rest, okay?”

As if his words were a trigger, I felt a weariness crash over me. I had one pair of clean underwear left and Sy’s t-shirt, I supposed the washing could wait until the morning. I nodded.

“Good girl.” Walter lowered my head and his lips pressed softly against my forehead. He slung my bag over his shoulder and with an arm wrapped around my waist he guided me back to my room.

I leaned my head on Walter’s shoulder, his warmth was comforting. His fingers were light, but every so often he would tug me tighter as we walked. He must have shortened his stride, because each step he took was as small as mine, and I wondered if he was impatient with my short, tired gait.

When we got to my room, he didn’t let me go, he dropped my bag on the bed and brought his other arm around me.

“Do you need anything before I go?” Walter asked.

I shook my head.

“Remember where my room is?”

“Across the hall, opposite Sy’s.”

He hummed and stepped away. “Make sure you come get me if you need anything, anything at all, okay sweetheart?”

I nodded and he closed my door. I looked around my bare room, it was so impersonal, worse than a hotel room; at least in a hotel they have art on the walls, something to look at. Even the bedspread was an uninteresting beige.

I stripped off and showered, the water once again became my personal masseuse, warming my aching bones and muscles. I put on Sy’s shirt and my last clean pair of panties and slid into bed. I felt cold, and lonely, and although dead tired, my mind was a whirl. I replayed in my head over and over the events that led me to this night. My parents murder, my brothers drug use, being at the clubhouse again, and Jake. I wracked my brain, trying to understand how he could possibly fit into the mess.

Though I yawned, I just wasn’t able to shut my thoughts off. My hand slid between my legs, and I tried to hold onto thoughts of Sy. Memories of his body pressed against mine, of his lips on my skin, the hardness of his muscles, the softness of his touch. My breathing grew hard as my fingers started to slide over me, my sticky arousal coming fast. I thought of Sy’s words, his filthy mutterings and as I climbed closer to my peak, I remembered another voice low in my ear.

Good girl, Walter’s voice echoed in my head. I couldn’t stop the thought of both of their hands on me, each man kissing, exploring, seeking and giving me pleasure. Then there were more hands, Mike’s eager tongue on my neck, Geralt’s long silvery locks tickling my thighs and Walker’s cruel lips wrapped around my nipple. My orgasm hit me hard, crashing over me with the force of a tsunami, and I covered my mouth to muffle my shout.

Like it sometimes does, as the warmth of my climax left me, I felt shame. What kind of person is attracted to five men? What kind of person wants to be taken by five men at once? It’s not normal. Sure, group sex was a thing, a lot of people fantasise about that, but that’s not what this was. I wanted them all, I wanted each of them both alone and together. They were all so different, but I found myself attracted to them equally.

Sleep was even more elusive now. I kept thinking about the things Sy had said to me about the Brothers; that they all cared about me like he did, and he knew I felt the same way about them. Why was he telling me that? What did it mean? Why was he giving me tacit approval to be with them? What kind of man wanted to share me with other men? And not just in a random threesome, but with the men he was closest to. Did I mean nothing to him? I didn’t believe that. Especially not after he left me his shirt, like he wanted me to remember him while he wasn’t there.

After maybe another hour of trying to sleep, I was starting to get desperate. I thought about the joint I had in my bedside table at home, and I cursed myself for not picking it up and slipping it into my bag. I hadn’t because I didn’t know how these guys felt about drugs. Sy, for all his tattoos and rough exterior, didn’t strike me as a pothead. I was 99% sure Mike would indulge, at least occasionally, but I couldn’t go to his room. Not after that kiss. I thought maybe Walter and Geralt might be my best options. August looked like he’d never touched a drug in his life, probably didn’t even drink very often, he seemed to like being in control too much.

I tossed and turned a little longer before I got out of bed and went to Walter’s room, and I knocked on his door. This was a bad idea. He’s probably asleep. I had no phone, no watch, no real way of knowing what the time was.

I couldn’t hear anything from inside. He was probably asleep. I turned to walk away when the door finally opened. Walter was in a pair of low hanging grey sweats, leaving very little to the imagination.

My eyes moved over his body taking in the small gages in his ears, the three red roses on his neck, the colourful Japanese style koi fish on his hairy, veiny forearms that went into a full sleeve ending in a half circle at his shoulders in the traditional style. His broad chest with well-defined pecs and the unmistakable bulge of his heavy cock hidden beneath his grey sweats. His body was a little softer than Sy, his belly was flat but had none of the definition of Sy’s. He looked like he had the perfect body to snuggle with, like he would be so warm.

My cheeks burned, my body hummed with nervous tension, and I could barely breathe as my eyes met his. Walter’s eyes were red rimmed and darkened on the delicate skin below. I immediately felt bad that I had interrupted his sleep.

This was a really bad idea.

“Sweetheart? You okay?” Walter asked.

“I uh…”

Walters' lips pulled into a tight line. “Come in,” he said a little impatiently.

I regretted this so much.

I walked into his room and looked around. His room was almost as bare as mine. There were barely any personal items anywhere except for a bookshelf and a record player. A few records were scattered on a desk, Oasis, Franz Ferdinand, The Beatles, David Bowie. I guess you could take the man out of Britain, but you couldn’t take the British out of the man.

“Can’t sleep?” Walter asked, letting out a tired groan as he laid on his bed. I shook my head. “It’s a common problem around here.”

“What do you do?” I asked.

“Listen to ambient sounds or music, sometimes that helps. Other times, I read.”

I looked at his bookshelf. It was almost a carbon copy of my own. Crime novels by Michael Connelly, James Patterson, P.D. James, and others filled his shelf.

“You can take one if you like.”

I chuckled. “Unfortunately, I’ve read most of these.”

“Do you read a lot?”

“I do, now that I’m not studying anymore.” My eyes were caught by a small photo of a much younger looking Walter sans beard in a police uniform. Jesus, he almost looked like Mike; just as handsome, but none of the mischievous glint in his eye that Mike had. It seems Walter had always been a serious guy. I picked it up. “You were a cop?”

Walter raised both his eyebrows, smirked, and tilted his head in what could look like agreement.

“A detective. Up north.”

I was floored. “How does one go from a cop to a Biker?”

“A long story, for another night,” Walter said with a hint of a smile.

“I’ll hold you to that.”

“You do that,” Walter chuckled, then he yawned.

I should go. I should ask him for what I want and leave. Let the poor guy get some sleep. I opened my mouth to speak, but my eyes went back to the cop photo and it made me pause. What if he still had some prejudices against drugs from those days? I glanced back at Walter, he definitely didn’t look like any cop I’ve ever seen.

“Was there something you wanted?” Walter prompted.

Get this over with.

“Do you have any pot?” I asked in a rush. Walter raised an eyebrow. “Oh, come on, it’s not like coke or anything.”

“It’s not that. I didn’t realise you smoked.”

“I don’t,” I said. “Not really… I just want to sleep, and I can’t.”

Marshall considered me for a long time. His eyes slowly moved down my body and I was suddenly aware of how I was dressed. Sy’s shirt was big on me, but still barely covered my ass, and I wondered if he could see my panties. I bit my lip and resisted the overwhelming urge to pull on the hem of the shirt down.

Sighing, he stood up. “Wait here,” he said.

I nodded. As soon as he left, I pulled the shirt down only to realise it then made my nipples very noticeable. I felt like such a tease. What the fuck was Marshall thinking of me right now, coming into his room in the middle of the night, barely dressed and asking for drugs? I was no better than the stupid women who threw themselves at my brother.

I thought about leaving, but that would make me look like a dumbass as well. So, I waited nervously for Marshall to come back, staring at the walls and hating myself. He came back in a few minutes with a spliff in his hand.

“Mike,” he said by way of explanation.

Marshall got back on the bed, sat cross legged with his back against the headboard. He pulled out a lighter and an ashtray from his bedside and jerked his head, motioning for me to sit with him.

“I was just going to take it back to my room,” I said.

“I thought we could share it,” Marshall said, putting the joint between his lips.

He patted the bed next to him and with a sigh of resignation, I climbed onto the bed next to him, mirroring his position.

He lit the joint and took a deep breath before passing it to me and he released his held breath slowly. I took a hit, letting the smoke fill my lungs until they almost burned, and held it in for a few moments, passing the rollie back to Marshall before slowly letting it out.

After a few back and forth’s I started to feel my muscles relax and although my mind felt sluggish, the negative thoughts melted away.

“Good?” Marshall asked.

“Yeah,” I said softly. “Just what I needed.”

Marshall chuckled.

“You laughing at me?”

“No sweetheart. Never,” he was grinning, but it was probably from the pot more than anything about me.

My head felt heavy, and I leaned it on Marshall’s shoulder.

“Hang on,” he said, passing me the ashtray.

Marshall got off the bed and walked around to his record player. He flicked through his vinyl’s with purpose until he found the one he was looking for. When the music started, I smiled and soon the unmistakable voice of Thom Yorke filled the room. He turned the lights off, leaving just the soft light of his bedside lamp. He got back on the bed and laid on his back, his head on the pillows.

Taking the ashtray out of my hands he motioned for me to join him. Feeling tired, I followed his lead sliding down the bed until my head was level with his. He laid the ashtray on his chest and wrapped an arm around my shoulders.

“Comfortable?” he asked.

“Yeah.” I put my head on his shoulder and passed him what remained of the spliff.

“Good.”

“I like your music,” I said.

“You like this old stuff?” he asked after taking a hit. He looked like he wasn’t sure if he believed me, raising his eyebrow and smirking.

“I like most stuff. New, old, rock, metal, indie. As long as it’s good.”

“Country?”

“Does Johnny Cash count?” I laughed.

“Yeah, of course he does.”

“Then yes.”

Marshall took another hit, inspected the roach and frowning he stubbed it out and put the ashtray on his bedside. I rolled on my side to look at Marshall better, laying my hand on the middle of his chest and lifting my leg onto him. He gave me a strange look but didn’t say anything.

It seemed as though the pot had done its job. My eyelids were heavy, and I didn’t feel so nervous or wrong for being here with Marshall. It felt natural, easy, and comforting. He kept looking at me, and I stared back, taking in his features.

God, he was attractive, his features stern, even when he smiled, and that unruly mop on the top of his head… I’d bet it was really soft.

“Can I touch your hair?” I asked.

Yeah the pot definitely worked. Inhibitions, gone.

“Can I touch yours?”

I grinned and reached up, letting my hand sink into his curls. He closed his eyes and I felt his hand stroke the top of my head.

“That’s nice,” I said softly.

Marshall hummed.

“Can I sleep here tonight?”

He cracked an eye and looked at me. Taking a deep breath through his nose, he rolled over and put a hand to my cheek. His eyes were heavy, pupils slightly dilated and a little redder than before. He seemed so tired.

“I’d like that,” he whispered.

He reached down and pulled the covers up over us and turned off his lamp, plunging the room into darkness. He left the music going, I’m not sure if it was to help us sleep or if he couldn’t be bothered to get up. I didn’t mind either way, Radiohead was an easy band to sleep to.

I closed my eyes and Marshall pressed the pad of his thumb between my brows and made slow circular movements. My eyes widened as I felt the touch of the man I could sense but couldn't see. My breathing became steady, I felt like liquid as the sensation of his gentle touch further eased my already quiet mind and after a time, I drifted to sleep.

#henry cavill#henry cavill fanfic#henry cavill fanfiction#captain syverson#syverson fanfiction#captain syverson fanfic#captain syverson fanfiction#captain syverson x ofc#syverson#syverson x ofc#cpt syverson#captain sy#august walker fanfiction#august walker#august walker fic#august walker x ofc#walter marshall#walter marshall fanfiction#walter marshall x ofc#walter marshall fic#geralt x ofc#geralt of rivia#geralt fanfic#geralt of rivia x ofc#geralt of rivia fanfiction#mike (hellraiser)#mike hellraiser#hellraiser mike#mike hellraiser fic#mike (hellraiser) fic

356 notes

·

View notes

Note

Deku nsfw alphabet please?

My bb BOY

A: Aftercare (What they’re like after sex)

He is wonderful at aftercare! The second he catches his breath, hes running to the bathroom to get a damp cloth and to throw a blanket in the dryer to warm it up and make your as comfortable as possible. After youre both cleaned up and huddled under the warm blanket, he cuddles you for at least a couple hours

B: Body Part (Their favorite body part of theirs and also their partner)

His favorite body parts of his own are his legs. Hes self conscious of the scars on his arms, and he knows his legs are strong as hell since he transitioned to training them more. On you, he loves your chest, boobs or nah. He adores kissing your chest and lightly tracing the contours

C: Cum (Anything to do with cum)

He is a safe and responsible hero, so he prefers to use condoms. Plus, he cant imagine that the feeling of cum dripping on/out of you is terribly pleasant

D: Dirty Secret

He secretly wants you to dom the hell out of him, but hes way too shy to ask. You know hes a switch, but he tries not to make it obvious how much he likes when you take control

E: Experience (How experienced are they? Do they know what they’re doing?)

The most experience he might have is some heavy petting and grinding in a past relationship. Hes come a long way since UA though, so hes more comfortable with himself and his partner.

That being said, he knows what hes doing. He absolutely researches techniques and positions and stuff before getting intimate with you

F: Favorite Position

He likes cowgirl, missionary, and lotus mostly. Pretty much, he wants to see your face to make sure hes doing everything right (also, access to your chest :) )

G: Goofy (Are they more serious in the moment, or are they humorous, etc.)

He can be a little goofy, but hes mostly prettt serious. The most he would do is crack a joke about how awkward it is to change position or something similar

H: Hair (How well-groomed are they, does the carpet match the drapes, etc.)

The carpet does indeed match the drapes, just a little darker.

The first time yall had sex, he wasnt trimmed at all. To be fair, he wasnt expecting it to happen. After that, though, he was neatly trimmed

I: Intimacy (How are they during the moment, romantic aspect…)

Hes so intimate you want to cry omg. Hes constantly whispering in your ear how much he loves you, caressing your cheek, placing soft kisses on your lips and forehead, checking to make sure everythings alright, etc

J: Jack Off (Masturbation headcanon)

He usually masturbates twice a week or so. Sometimes, hes too shy to ask you to help, or he knows youve had a tough day and just want to chill, so he takes care of it himself. Hell juat duck into the shower for a quick wank and join you in bed afterwards

K: Kink (One or more of their kinks)

He has a massive praise kink. He l i v e s for being told how good hes doing and what a good boy he is. He also lowkey enjoys roleplay where youre a civilian that needs to be rescued and hes your savior.

If he ever tells you about his desire to be dommed, he would LOVE to get pegged

L: Location (Favorite places to do the do)

He prefers the bed, but hes also comfortable with your couch if youre too comfy to move

M: Motivation (What turns them on, gets them going)

Mostly, midoriya gets turned on by how much he loves you. A small peck turns into making out turns into sensual sex. He also might get flustered if you wear something tight-fitting or revealing

N: NO (Something they wouldn’t do, turn offs)

He absolutely wont use his quirk or do anything to hurt you, not even spanking. Also no degredation, humiliation, bodily fluids, etc

O: Oral (Preference in giving or receiving, skill, etc)

He prefers giving over receiving. After some practice, he becomes a GOD at giving oral to the point that he wants you to come in his mouth before getting to the main event.

He enjoys receiving, he just really likes pleasing you first and foremost

P: Pace (Are they fast and rough? Slow and sensual? etc.)

99% of the time, hes more slow and sensual. Sex, to him, is more of an act of love than just getting off. However, if hes had a rough day and is frustrated, he'll pick up the pace a bit

Q: Quickie (Their opinions on quickies rather than proper sex, how often, etc.)

Not a fan, tbh. He wants to take his time with you. That being said, if you really, really want one, he'll cave. Hes absolutely going to take his time with you later, though

R: Risk (Are they game to experiment, do they take risks, etc.)

Izu isnt huge on risks. Hes down to experiment, sure, but he doesnt want to get caught. He might actually die if somebody saw you two like that

S: Stamina (How many rounds can they go for, how long do they last…)

With as much training as hes done, he has so much goddamn stamina its insane. If he really wanted to, he could go /several/ rounds, each lasting a long time. Hes not gonna overstimulate you though

T: Toy (Do they own toys? Do they use them? On a partner or themselves?)

He's too shy to buy anything for himself, but hed use it if you gave it to him. Hes most likely to enjoy a strap-on if anything

U: Unfair (how much they like to tease)

He only teases you if hes in a really playful mood. Normally, he wont tease because it makes him feel mean

V: Volume (How loud they are, what sounds they make)

He can get pretty loud sometimes, especially when hes close to cumming. Hed let out a deep groan/moan and the occasional curse and maybe cry out your name. Aside from that, his moans are loud enough for you to hear, but not loud enough to worry about the neighbors hearing

W: Wild Card (Random headcanon)

He once found All Might themed condoms and bought them with absolutely no intention of ever using them, but he did end up using them on one occasion when you ran out if the normal ones. He couldnt look all might in the eye for weeks

X: X-Ray (Let’s see what’s going on in those pants, picture or words)

Hes lowkey kinda packing. Slightly bigger than average with good girth. He didnt know it was anything special until you came along and told him

Y: Yearning (How high is their sex drive?)

Pretty average tbh, but he knows how to control his urges and only act upon them when appropriate and reciprocated. As i said before, sex to him is more intimacy than getting off

Z: ZZZ (… how quickly they fall asleep afterwards)

Not fast at all. He can stay awake for hours talking to you or taking notes or doing paperwork or whatever. Unless yall have sex just before bed, it doesnt affect his sleep schedule at all

#midoriya izuku#midoriya x reader#boku no hero academia#bnha#bnha x reader#my hero academia#mha#mha x reader#spicy

126 notes

·

View notes

Text

Exporter of Spin Flash Dryer in Nigeria

Drytech Engineering Systems is an Exporter of Spin Flash Dryer in Nigeria. Drytech Engineering Systems is a Spin Flash Dryer Manufacturer in Ahmedabad, Gujarat, India. We are a Manufacturer, Supplier, Stockiest, and Exporter of Flash Dryers, Spray Dryers, Spin Flash Dryers, Fluid Bed Dryers, and Evaporator Dryers, Rotary Valves, Rotary Atomizers, Hot Air Generators, Centrifugal Blowers, and Dust Collector Systems. Innovative Spin Flash Dryer Systems Discover our extensive range of Spin Flash Dryer systems, tailored to suit diverse operational needs, from compact models perfect for small-scale operations to robust industrial units. Each unit is fully customizable to meet your exact specifications. Comprehensive Customer Support At our core, we prioritize customer satisfaction. From your initial inquiry through to post-sales support, we ensure a seamless experience. Our commitment goes beyond product delivery, offering comprehensive technical assistance, expert installation services, and ongoing maintenance to guarantee optimal performance throughout the product lifecycle. Advanced Technology at Work Central to our Spin Flash Dryer systems are meticulously engineered components, including our patented drying chamber and efficient bag filter. The feed system, featuring a precision-driven feed vat and feed screw or pump, ensures smooth material transition for maximum drying efficiency. Efficient Drying Solutions Inside the drying chamber, our state-of-the-art rotor design facilitates the fluidization of product particles, optimizing the flow of hot air to swiftly disintegrate wet lumps and achieve uniformly dried output. Count on us to elevate your drying processes with unparalleled quality, reliability, and dedicated support. Features: Achieve high drying efficiency and cost-effective energy consumption. Dry materials directly without the need for pre-dilution. Experience continuous processing coupled with swift drying capabilities. Benefit from low maintenance expenses and minimal operator overheads. Operate with minimal environmental impact. Ensure safe drying of organic materials with a chamber capable of withstanding pressure shocks. Accessible in Good Manufacturing Practice (GMP) configuration. Drytech Engineering Systems is an Exporter of Spin Flash Dryer in Nigeria including locations like Lagos, Kano, Ibadan, Benin City, Port Harcourt, Jos, Ilorin, Abuja, Kaduna, Enugu, Zaria, Warri, Maiduguri, Aba, Bauchi, Akure, Abeokuta. For detailed information and inquiries, please feel free to contact us. View Product: Click Here Read the full article

0 notes