#Fluid Bed Dryer Manufacturers

Explore tagged Tumblr posts

Text

Top Manufacturing Solutions for Pharma & Cosmetic Industries

In the dynamic world of pharmaceutical and cosmetic manufacturing, quality, efficiency, and precision are paramount. At Pharmachem Cosmetics, we understand the importance of using state-of-the-art equipment to ensure top-tier products. Whether you're producing ointments, oral liquids, or other cosmetic formulations, having the right machinery is crucial for success. In this blog, we'll highlight essential equipment and machinery that every manufacturer in the pharmaceutical and cosmetic industries should consider.

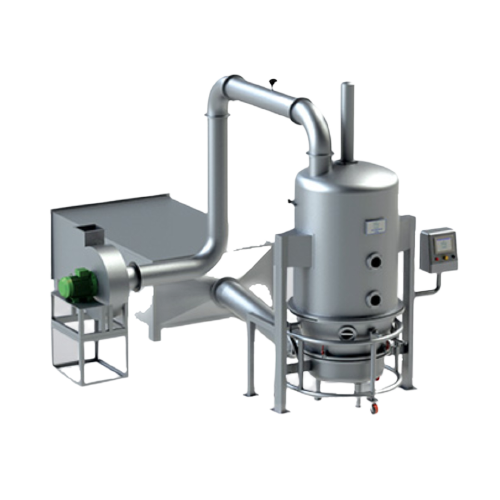

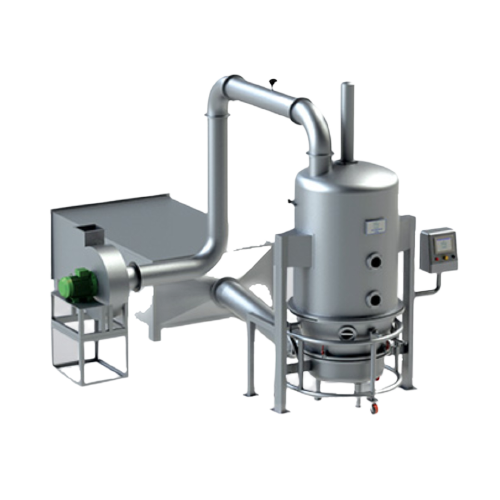

1. Fluid Bed Dryer Manufacturers: Enhancing Product Drying Efficiency

When it comes to drying powders, granules, or other materials in the pharmaceutical and cosmetic industries, Fluid Bed Dryers are indispensable. These dryers operate on the principle of fluidization, where hot air flows through the material, reducing moisture content quickly and efficiently. Fluid Bed Dryer Manufacturers like Pharmachem Cosmetics offer equipment designed for consistency, high-quality results, and energy efficiency, making them ideal for drying sensitive products such as powders, granules, and even some ointments.

Choosing the right Fluid Bed Dryer can significantly impact production timelines and product quality. At Pharmachem Cosmetics, we offer advanced Fluid Bed Dryers that meet industry standards and are customizable for different batch sizes and material types. Our equipment ensures uniform drying, preventing clumping and enhancing the overall product stability.

2. Ribbon Blender Mixer in Maharashtra: Optimal Mixing for Uniform Results

Uniformity in mixing is crucial for the success of any pharmaceutical or cosmetic product. The Ribbon Blender Mixer, a common choice in manufacturing plants, provides an efficient solution for blending powders and granules. This versatile equipment ensures thorough mixing of dry ingredients, resulting in uniform consistency throughout the batch.

Pharmachem Cosmetics, based in Maharashtra, is a leading provider of Ribbon Blender Mixers known for their precision and reliability. Whether you are blending active pharmaceutical ingredients (APIs) or cosmetic powders, our Ribbon Blender Mixers are designed to handle a wide range of formulations with ease. By providing a homogeneous blend, these mixers help in achieving the desired product quality, reducing waste, and optimizing production time.

3. Liquid Oral Manufacturing Plant Suppliers: The Backbone of Liquid Formulations

The demand for liquid oral medications and cosmetic products is on the rise. Whether it’s syrups, tonics, or oral gels, the liquid formulation process requires specialized manufacturing plants equipped with the latest technology. Liquid Oral Manufacturing Plant Suppliers like Pharmachem Cosmetics provide cutting-edge equipment for the smooth production of liquid formulations.

From raw material mixing to bottling and packaging, our liquid oral manufacturing plants are designed to ensure safety, hygiene, and efficiency. With automated systems and robust machinery, we help streamline your liquid production process, reducing contamination risks and ensuring consistent product quality. As a trusted supplier in the industry, Pharmachem Cosmetics ensures that your plant meets regulatory standards and operates at peak performance.

4. Ointment Manufacturing Plant Dealers: Producing High-Quality Ointments

Ointments are among the most widely used formulations in both the pharmaceutical and cosmetic industries. From topical treatments to skincare products, the right manufacturing process is essential to ensure the effectiveness and safety of the ointment. Pharmachem Cosmetics offers high-quality Ointment Manufacturing Plants, designed to produce consistent and reliable ointments for a variety of applications.

Our ointment manufacturing plants are equipped with advanced machinery such as mixers, homogenizers, and filling machines, designed to handle both small and large batches. As leading Ointment Manufacturing Plant Dealers, we provide you with everything you need to produce high-quality ointments while adhering to strict regulatory guidelines.

5. Multi Mill Manufacturers: Versatile and Efficient Milling Solutions

The Multi Mill is one of the most versatile machines used in the pharmaceutical and cosmetic industries. Capable of performing a range of functions such as grinding, milling, shredding, and crushing, the Multi Mill is an essential tool for reducing the size of materials for further processing. Whether you are working with APIs, herbal ingredients, or cosmetic raw materials, the Multi Mill ensures uniform particle size reduction, improving product consistency and performance.

At Pharmachem Cosmetics, we are proud to be recognized as leading Multi Mill Manufacturers, offering equipment that guarantees high throughput, durability, and ease of maintenance. Our Multi Mills are designed with user-friendly controls and are highly adaptable to different production needs.

Conclusion: Quality Equipment for Exceptional Products

At Pharmachem Cosmetics, we are committed to providing the highest quality manufacturing equipment for the pharmaceutical and cosmetic industries. Whether you are in need of Fluid Bed Dryers, Ribbon Blender Mixers, Liquid Oral Manufacturing Plants, Ointment Manufacturing Plants, or Multi Mills, we offer cutting-edge solutions to meet your production requirements.

Partner with Pharmachem Cosmetics today and elevate your manufacturing process to new heights. Our equipment ensures precision, efficiency, and safety in every batch, helping you deliver exceptional products to your customers.

#Multi Mill Manufacturers#Ribbon Blender Mixer in Maharashtra#Fluid Bed Dryer Manufacturers#Liquid Oral Manufacturing Plant Suppliers#Ointment Manufacturing Plant Dealers

1 note

·

View note

Text

Fluid Bed Dryer, Fbd Dryer Manufacturers, Suppliers, India

Pharmax Engineers : Manufacturers, Suppliers and Exporters of Fluid Bed Dryer, Fluidized Bed Dryer, Fluid Bed Processor, Mumbai, India.

Fluid Bed Dryer, Fbd Dryer, Fluid Bed Drying Machine, Fluid Bed Dryer Machine, Fluid Bed Dryer Price, Fluid Dryer Bed, Fluid Bed Dryer Manufacturers, Fluid Bed Dryer Suppliers, Fluid Bed Dryer Exporters, Mumbai, India.

#Fluid Bed Dryer#Fbd Dryer#Fluid Bed Drying Machine#Fluid Bed Dryer Machine#Fluid Bed Dryer Price#Fluid Dryer Bed#Fluid Bed Dryer Manufacturers#Fluid Bed Dryer Suppliers#Fluid Bed Dryer Exporters#Mumbai#India

0 notes

Text

Fluid Bed Dryer Manufacturers in Mumbai

Introducing Pharmachem Cosmetics Industries, the best place to get premium Fluid Bed Dryer Manufacturers in Mumbai. We are leaders in the industry, providing state-of-the-art technology and dependable solutions that are customized to meet your demands. We are dedicated to excellence and innovation. With our cutting-edge fluid bed dryers, which have been painstakingly designed for the best outcomes, you can enjoy unparalleled performance and efficiency. Put your faith in Pharmachem Cosmetics Industries to transform your drying procedures and take your business to new heights.

1 note

·

View note

Text

Octagonal Blender: Efficient Mixing Solutions for Granules and Powders Discover how the octagonal blender ensures uniform mixing of dry powders and granules with its unique design and low energy consumption. Perfect for pharmaceuticals, chemicals, and food processing industries.

#zero holdup filter press manufacture#sparklar filter press manufacture#Fluid Bed Dryer manufacture#Tray Dryers manufacture#Vacuum Tray Dryer manufacture#Rapid Mixer Granulator manufacture#Sterile Manufacturing Vessel manufacture#Oral Liquid Manufacturing Plant manufacture#Octagonal Blender manufacture

0 notes

Text

Fluid Bed Dryer manufacture-Bipin Pharma Equipment

Bipin Pharma Equipment is a leading Fluid Bed Dryer manufacturer, offering high-quality, efficient drying solutions for the pharmaceutical industry. Trust us for innovative designs and exceptional performance in your processes.

0 notes

Text

Fluid Bed Dryer Machine Manufacturers

Fluid bed dryers are important for efficient and uniform drying of various materials. Our corporation stands as a surest Fluid Bed Dryer Machine Manufacturers, turning in modern answers tailored to your precise desires. With understanding and superior generation, we provide excellent machines for greatest drying processes throughout industries.

0 notes

Text

Fluid Bed Dryer - Riddhi Pharma

Fluid bed dryers are used for drying a variety of materials. The material to be dried is suspended in a stream of air, and as the air moves through the bed, it causes the material to behave like a boiling liquid. Fluid bed dryers are commonly used in the pharmaceutical, chemical, food, and mineral industries due to their efficient and gentle drying process. They are known for their high heat and mass transfer rates, making them suitable for drying heat-sensitive materials.

0 notes

Text

Tablet coating machines are essential equipment in pharmaceutical and food industries, enabling the application of coatings to tablets, pills, or confectionery products. These machines serve a variety of functions, from providing a protective layer to enhancing visual appeal and taste masking. Understanding the functions, specifications, and costs associated with these machines is essential for manufacturers seeking efficient and cost-effective solutions.

#Tablet Coating Machines#Fluid Bed Dryer for Pharma Industry#Fluid Bed Dryers#Rapid Mixer Granulator for Pharma Industry#Rapid Mixer Granulators#Multi Mill Manufacturers

1 note

·

View note

Text

Fluid Bed Dryer Manufacturer in India

Ravi Kiran Industries is a well known Fluid Bed Dryer Manufacturer all over India. We offer solid and dependable service and confirm worldwide standards of emissions. Our group understands that the physical design of the fluid dryer is critical for drying proficiency and viability.

0 notes

Text

Anyone interested in a cheap old brothel in Fallon, NV? The living quarters is a manufactured building w/3bds, 3ba, (the whole building is 4,400 sq ft), reduced $34k to $275k. Man, is it yucky inside- bring your UV light to detect all the body fluids and several cases of bleach.

It's the old Pink Cadillac brothel and all of the furnishings are also for sale. It looks so unappealing. Why isn't it painted pink and black?

This must be the common area where the girls hung out.

Open mezzanine above with a nice gold railing. Is that a bar or a reception desk?

What in the world is this setup? Is this a drive-in movie simulation? It's upstairs, and it's a 1955 T-Bird that will convey, but it's just a shell.

Grungy old hot tub room.

Oh, lockers. Maybe for the girls' or clients' belongings?

Depressing looking powder room. Why would they install that style sink w/those old exposed pipes?

I don't know if all these things are included or not. Look at the big cage. I wonder if that was for go-go dancing. There's a stripper pole in the opposite corner.

Ugly kitchen with the flooring taped down.

Small, dingey lounge off the kitchen.

Old washer and dryer right off one of the rooms.

This is depressing.

1/2 bath ensuite. So dreary.

Just burn the mattresses and bedding.

This room has a full ensuite. It will take more than that spray cleaner to sanitize this.

5 acres of desolate dessert.

https://www.zillow.com/homedetails/2700-King-Dr-Fallon-NV-89406/71185528_zpid/?

79 notes

·

View notes

Text

Exploring the World of Industrial Machinery: Ball Mill Manufacturers, FBD Fluid Bed Dryers, and Spheronizers

In the realm of industrial machinery, three key players stand out: Ball Mill Manufacturers, FBD Fluid Bed Dryers, and Spheronizers. Each plays a crucial role in various industries, contributing to the global economy.

Ball Mill Manufacturers

Ball mills are indispensable in industries such as mineral processing, paints, and ceramics, among others. They are used for grinding and blending materials into very fine powders. The manufacturers of these machines are known for their engineering prowess and commitment to quality. They ensure that these machines are designed and built to withstand the rigors of heavy-duty operations, while providing optimal performance.

FBD Fluid Bed Dryers

Next, we have the FBD Fluid Bed Dryers. These machines are essential in the pharmaceutical industry, where they are used for drying granules, powders, and other particulate materials. The principle behind their operation is simple yet effective - hot air is introduced into a plenum below a perforated plate, and as the air rises, it lifts and mixes the material, allowing for efficient and uniform drying. Manufacturers of these machines prioritize precision, reliability, and energy efficiency, ensuring that their products meet the stringent requirements of the pharmaceutical industry.

Spheronizers

Last but not least, we have Spheronizers. These machines are used to form spherical pellets from a wet mixture or granulation. The process involves spinning the material in a friction plate, causing the particles to roll and form into spheres. This technique is widely used in the pharmaceutical industry, particularly in the production of controlled-release drugs. Spheronizer manufacturers focus on ensuring that their machines offer high levels of precision and consistency, which are critical in pharmaceutical applications.

In conclusion, Ball Mill Manufacturers, FBD Fluid Bed Dryers, and Spheronizers are key players in the industrial machinery sector. Their contributions are vital in various industries, particularly in pharmaceuticals, where precision, reliability, and efficiency are of utmost importance. As we continue to advance technologically, we can expect these machines to evolve and become even more efficient and reliable, further solidifying their roles in the industrial sector.

2 notes

·

View notes

Text

Fbd Bag Manufacturers

Makpol Industries is one of the reputed Fbd Bag Manufacturers in India. Fbd stands for Fluidized bed dryer which is used to dry the granules in pharmaceuticals. We are using best quality products to make these bags. We never compromise with quality because customer satisfaction is our aim. The applications of the Fbd Bag in the Chemical industry, Pharmaceutical industry, Agricultural industry and Processing industry. For more details, you can visit our website.

Address : 56, Ist Floor, Hariniwas Market, Panchwati Colony, Ghaziabad- 201001, Uttar Pradesh Email Id : [email protected] Contact No: +91-9871525385 , +91-9999175385 Website : https://www.makpolindustries.com/fluid-bed-dryer-filter.html

2 notes

·

View notes

Text

The Importance of Fluid Bed Processor Manufacturers in India

In the rapidly advancing pharmaceutical and chemical industries, fluid bed processors have become indispensable for their efficiency, precision, and versatility. As a leading fluid bed processor manufacturer in India, the industry plays a crucial role in meeting the growing demands for high-quality processing equipment. This blog explores the significance, applications, and benefits of fluid bed processors, along with insights into why choosing the right manufacturer is essential.

What is a Fluid Bed Processor?

A fluid bed processor is an advanced machine used for drying, granulating, and coating particles in various industries. It operates by fluidizing a bed of particles with a stream of air or gas, ensuring uniform processing and precise control over critical parameters. Fluid bed processors are widely used in pharmaceuticals, food, chemicals, and other sectors where high standards of quality and efficiency are mandatory.

Why Fluid Bed Processors Are Essential

Fluid bed processors have become a cornerstone in industries that require precision and consistency. Here’s why they are indispensable:

Efficient Drying: Fluid bed processors provide rapid and uniform drying, ensuring product consistency and quality.

Granulation: These machines are essential for forming granules with precise size and density, a critical step in tablet manufacturing.

Coating: Fluid bed processors allow even coating of particles, improving product functionality and stability.

Energy Efficiency: Advanced fluid bed processors are designed to optimize energy usage, reducing operational costs.

Scalability: From lab-scale to industrial production, fluid bed processors are adaptable to varying production needs.

Applications of Fluid Bed Processors

As a versatile piece of equipment, fluid bed processors are used in a wide range of applications, including:

Pharmaceutical Industry:

Drying active pharmaceutical ingredients (APIs) and excipients.

Granulating powders for tablets and capsules.

Coating tablets or pellets for controlled drug release.

Food and Beverage Industry:

Drying food powders and granules.

Coating products for enhanced flavor or preservation.

Chemical Industry:

Granulating and drying chemicals for industrial applications.

Producing fertilizers, detergents, and specialty chemicals.

Nutraceuticals:

Preparing dietary supplements with precise granule size and uniform coatings.

Why India is a Hub for Fluid Bed Processor Manufacturing

India has emerged as a global leader in manufacturing fluid bed processors, thanks to its robust industrial base, skilled workforce, and cost-effective production capabilities. Key reasons for India’s prominence include:

Technological Expertise: Indian manufacturers leverage advanced technology to produce world-class equipment.

Cost Efficiency: Competitive pricing without compromising quality makes India a preferred destination for buyers worldwide.

Compliance with Standards: Indian manufacturers adhere to international quality standards, such as GMP, FDA, and CE certifications.

Customization: Many manufacturers offer tailored solutions to meet the specific needs of their clients.

Global Reach: Indian manufacturers export fluid bed processors to countries across Asia, Europe, and the Americas, cementing their reputation as reliable suppliers.

Features to Look for in a Fluid Bed Processor

When selecting a fluid bed processor manufacturer in India, it’s essential to consider the following features to ensure optimal performance and reliability:

Customizable Design: Equipment that can be tailored to your specific production requirements.

Advanced Control Systems: Integration of PLCs and touch-screen interfaces for precise process control.

Energy Efficiency: Systems designed to minimize energy consumption while maintaining productivity.

Robust Construction: High-quality materials like stainless steel ensure durability and compliance with hygiene standards.

Easy Maintenance: Features like clean-in-place (CIP) systems reduce downtime and improve efficiency.

How to Choose the Right Manufacturer

Partnering with the right fluid bed processor manufacturer in India is crucial for the success of your operations. Here are some tips to make the right choice:

Evaluate Experience: Look for manufacturers with a proven track record in the industry.

Check Certifications: Ensure the manufacturer complies with global quality standards.

Review Client Feedback: Testimonials and case studies can provide insights into the manufacturer’s reliability and service quality.

Assess Customization Capabilities: Choose a manufacturer who can adapt their products to your unique needs.

After-Sales Support: Reliable after-sales service and technical support are essential for smooth operations.

Advancements in Fluid Bed Processor Technology

Indian manufacturers are at the forefront of innovation, incorporating cutting-edge features into fluid bed processors. Some of the latest advancements include:

IoT Integration: Real-time monitoring and predictive maintenance through IoT-enabled systems.

Enhanced Heat Transfer: Improved drying efficiency with advanced heat transfer mechanisms.

Reduced Footprint: Compact designs that save space while maintaining high output.

Eco-Friendly Designs: Energy-efficient models that reduce environmental impact.

Automated Cleaning Systems: CIP systems for faster and more effective cleaning.

Conclusion

As industries continue to evolve, the demand for high-quality processing equipment like fluid bed processors is set to rise. India’s position as a leading fluid bed processor manufacturer ensures that businesses worldwide have access to cutting-edge technology at competitive prices. By choosing a reliable manufacturer, you can enhance your production capabilities, maintain high-quality standards, and meet the growing demands of your industry.

Whether you’re in pharmaceuticals, food processing, or chemicals, investing in a fluid bed processor from a trusted Indian manufacturer is a step toward operational excellence and sustainable growth.

0 notes

Text

Fluid Bed Dryer Manufacturer, Supplier & Exporter India

Get advanced Fluid Bed Dryers for efficient drying solutions from Bipin Pharma Equipment, a leading manufacturer, supplier, and exporter in India.

Granulation System, Rapid Mixer Granulator, Fluid Bed Dryer, Double Cone Blender, Octagonal Blender, Vibro Sifter, Multi Mill, Colloid Mill, Paste Kettle, Coating Pan, IPC Bin, Cream & Lotion System, Oral Liquid Systems, Filtration System, Zero Hold Up Filter Press, Nutsche Filters, Drying System, Vacuum Tray Dryer, Tray Dryer, Fluid Bed Dryer, Chemical Reactors, SS Reactor, Shell & Tube Condenser, Box Type Condenser, Receiver, Sterile Preparation, Multi Column Distillation Plant, Sterile Manufacturing Vessel, Manufacturer, Supplier, Exporter, Mumbai, India.

0 notes

Text

Improve Efficiency with F&D Machines: Fluid Bed Drying and Granulation Solutions

In today's fast-paced manufacturing world, efficiency is key. Whether you're in pharmaceuticals, chemicals, or food processing, optimizing your production process can significantly impact your bottom line. This is where F&D machines come in, offering innovative solutions for drying and granulation needs.

What are F&D Machines?

F&D machines refer to a range of equipment designed for fluid bed processing, a versatile technique used across various industries. These machines utilize the principle of fluidization, where a bed of solid particles is lifted and agitated by an upward flow of air. This creates a fluid-like state, allowing for efficient heat and mass transfer.

Two Key Applications:

FBD Fluid Bed Dryer: FBD Fluid Bed Dryer. These machines are highly effective in drying powders, granules, and crystals. The fluidization process ensures uniform drying by exposing each particle to the drying air, resulting in consistent moisture content and improved product quality. FBDs are particularly beneficial for heat-sensitive materials as the controlled environment prevents overheating and degradation.

Fluid Bed Processor for Granulation: Fluid bed processors can also be used for granulation, a process of creating granules from fine powders. This is achieved by spraying a binding solution onto the fluidized bed of particles. The controlled environment and efficient mixing ensure uniform granule formation, resulting in improved flow properties, compressibility, and solubility.

Benefits of Using F&D Machines:

Increased Efficiency: F&D machines offer faster drying and granulation times compared to traditional methods, leading to increased throughput and reduced production costs.

Improved Product Quality: The uniform processing environment ensures consistent particle size distribution, moisture content, and other critical quality attributes.

Enhanced Process Control: Precise control over parameters like temperature, airflow, and spray rate allows for reproducible results and minimized batch-to-batch variability.

Versatility: F&D machines can handle a wide range of materials, from fine powders to coarse granules, making them suitable for diverse applications.

Reduced Labor Costs: Automated operation and minimal manual intervention translate to lower labor costs and improved workplace safety.

Applications Across Industries:

Pharmaceutical Industry: Drying and granulation of drug formulations, excipients, and intermediates.

Chemical Industry: Processing of chemicals, catalysts, and polymers.

Food Industry: Drying of food products like coffee, tea, and spices; granulation of sugar, salt, and other ingredients.

Choosing the Right F&D Machine:

Selecting the appropriate F&D machine depends on several factors, including:

Material properties: Particle size, density, and heat sensitivity.

Production capacity: Batch size and throughput requirements.

Process requirements: Drying or granulation, desired particle size distribution.

Budget and space constraints: Cost of the equipment and available floor space.

It's crucial to consult with experienced equipment manufacturers to determine the best solution for your specific needs. They can provide guidance on machine selection, process optimization, and ongoing support.

Conclusion:

F&D machines, including FBD fluid bed dryers and fluid bed processors for granulation, offer significant advantages in terms of efficiency, product quality, and process control. By adopting this technology, businesses can optimize their production processes, reduce costs, and enhance their competitive edge in the market.

0 notes

Text

Consistent Drying Solutions: Pramukh Pharma Tray Dryer Machines

Pramukh Pharma, a main tray dryer machine manufacturer, gives wonderful gadgets for pharmaceutical packages. Their dryers ensure regular, uniform airflow for green material drying, disposing of worries approximately choppy moisture content material. Pramukh Pharma's machines boast particular temperature management and individual tray tracking, taking into account superior drying techniques for diverse materials. Energy-green operation minimizes expenses and environmental impact. Invest in pleasant and agree with Pramukh Pharma for your Tray Dryer needs.

0 notes