#Fluid Bed Dryer

Explore tagged Tumblr posts

Text

Fluid Bed Dryer R&D Model

Fluid Bed Dryer R&D lab model is uses for fluidized bed drying which is a pretty common process in the pharmaceutical industry. This process is needed in order to achieve optimum moisture apart from applying coatings or binders before proceeding for other processes for tablet formulation.

Our 5 liters fluid bed dryer is an efficient and economical solution for small batch sizes, but due to its scalable capabilities it can be scaled up for growing needs in future. Specifically designed for lab work and small batch processing, our lab scale fluidized bed drying system is equipped with features that allow maximum flexibility for batch. It also has height adjustability features and an ultra-modern touch screen that offers easy to read schematics for better control and diagnostics. The operator can seamless monitor the smallest of bit of every operation and since it has a robust dust collection system with cartridge filter system that’s easy to maneuver, you can expect phenomenal productivity.

Our 5 liters fluid bed dryer is loaded with satin type filter bag with fingers. Its sampling system (optional) allows you to keep an eye on all results during every cycle.

For more information related to our fluid bed dryer R&D lab model, feel free to get in touch with us.

0 notes

Text

https://www.vjinstruments.com/products/fluidbeddryer/?utm_source=Digital-Paid-Google-Ads&utm_medium=Conversion&utm_campaign=Retsch&gclid=Cj0KCQjwgrO4BhC2ARIsAKQ7zUlpnX6qvclWb2NaeFcsrywGs_ZjZq1In2NxJ3T7-oM_sqotwFwtLrAaAjp1EALw_wcB

The VJ Instruments Fluid Bed Dryer is designed to optimize the drying process for various materials, particularly in laboratory and industrial settings. This equipment uses a fluidization technique to ensure uniform drying, which enhances product quality and efficiency. Key features include precise temperature control, adjustable airflow rates, and scalability for different batch sizes, making it suitable for pharmaceutical, food, and chemical industries. The dryer aims to streamline operations while maintaining high standards of precision and consistency.

0 notes

Text

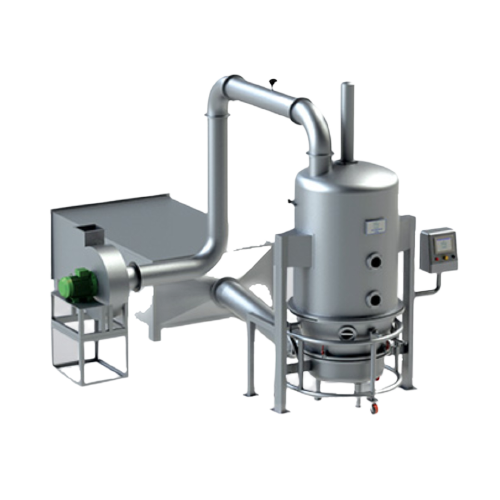

Romaco IFT Fluid Bed Dryer: Reliable and Efficient Drying Equipment

Upgrade your drying process with the Romaco IFT Fluid Bed Dryer. Designed for reliability and efficiency, this equipment ensures optimal performance across various industries. Learn more about our solutions.

0 notes

Text

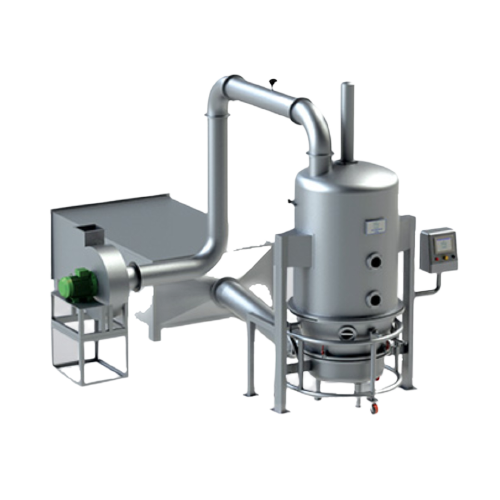

Fluid Bed Dryer, Fbd Dryer Manufacturers, Suppliers, India

Pharmax Engineers : Manufacturers, Suppliers and Exporters of Fluid Bed Dryer, Fluidized Bed Dryer, Fluid Bed Processor, Mumbai, India.

Fluid Bed Dryer, Fbd Dryer, Fluid Bed Drying Machine, Fluid Bed Dryer Machine, Fluid Bed Dryer Price, Fluid Dryer Bed, Fluid Bed Dryer Manufacturers, Fluid Bed Dryer Suppliers, Fluid Bed Dryer Exporters, Mumbai, India.

#Fluid Bed Dryer#Fbd Dryer#Fluid Bed Drying Machine#Fluid Bed Dryer Machine#Fluid Bed Dryer Price#Fluid Dryer Bed#Fluid Bed Dryer Manufacturers#Fluid Bed Dryer Suppliers#Fluid Bed Dryer Exporters#Mumbai#India

0 notes

Text

Fluid Bed Dryer manufacturers in India

Riddhi Pharma Machinery Fluid Bed Dryer is a versatile and efficient drying option for different industries. It utilizes a bed of fluidized particles to ensure consistent drying with effective heat and mass transfer. Perfect for pharmaceuticals, chemicals, and food items, this dryer improves product quality and decreases drying time, serving as a key tool for achieving the best production efficiency and consistency.

0 notes

Text

Fluid Bed Dryer Manufacturers in Mumbai

Introducing Pharmachem Cosmetics Industries, the best place to get premium Fluid Bed Dryer Manufacturers in Mumbai. We are leaders in the industry, providing state-of-the-art technology and dependable solutions that are customized to meet your demands. We are dedicated to excellence and innovation. With our cutting-edge fluid bed dryers, which have been painstakingly designed for the best outcomes, you can enjoy unparalleled performance and efficiency. Put your faith in Pharmachem Cosmetics Industries to transform your drying procedures and take your business to new heights.

1 note

·

View note

Text

The Evolution of Drying: Latest Trends in Pharma Fluid Bed Dryers

In the heart of pharmaceutical production lies a workhorse technology: the fluid bed dryer. Beyond simply removing moisture, these versatile machines play a crucial role in shaping the quality and efficiency of countless medications. But just like the medicine they help create, fluid bed dryers are constantly evolving, embracing cutting-edge trends to elevate pharmaceutical manufacturing to new heights.

Smarter Drying with IoT and AI: Forget dials and knobs; the future is data-driven drying. Integrated sensors and real-time analysis powered by the Internet of Things (IoT) provide granular insights into temperature, airflow, and product moisture content. This data is then harnessed by Artificial Intelligence (AI) to optimize drying parameters, ensuring consistent quality and minimizing energy waste. Imagine an AI predicting and preventing potential issues before they affect production – a dream becoming reality within these intelligent dryers.

Greener Steps with Energy Efficiency: Sustainability isn't just a buzzword; it's a necessity. Closed-loop systems are emerging, capturing waste heat from the drying process and recycling it to power other operations. This not only reduces energy consumption but also lowers emissions, aligning with stricter environmental regulations and contributing to a greener future for pharma.

Adaptability is Key: Gone are the days of one-size-fits-all drying. Modular designs are taking center stage, allowing manufacturers to tailor their equipment to specific needs. Need to handle diverse materials or scale up production? Simply add or remove modules, providing unparalleled flexibility and agility. Multi-stage drying further amplifies this versatility, employing multiple fluid bed units with varying conditions to tackle complex materials and processes with surgical precision.

Safety & Purity Reign Supreme: Patient safety is paramount, and fluid bed dryers are stepping up. Containment systems safeguard operators from potentially hazardous materials during the drying process, while advanced filtration technologies meticulously remove even the tiniest particles from the air, ensuring the final product is pristine and defect-free.

Continuous Flow, Seamless Production: Batch processing is giving way to a new paradigm: continuous processing. Imagine a world where materials flow seamlessly through multiple fluid bed units, each optimized for a specific stage of drying. This translates to increased efficiency, improved product quality, and reduced operating costs, propelling the pharma industry towards a leaner, more efficient future.

The trends shaping the world of fluid bed dryers are more than just technological advancements; they're a reflection of the evolving needs of the pharmaceutical industry. From patient safety and environmental responsibility to efficiency and adaptability, these innovations are paving the way for a brighter future of medicine, one meticulously dried granule at a time.

Want to learn more? Dive deeper into the specifics of these exciting trends, explore the latest models from leading manufacturers, and discover how fluid bed dryers are shaping the future of pharma.

0 notes

Text

Fluid Bed Equipment (FBE) from Tapasya is a unit designed specifically for top spray granulation that complies with international quality standards and incorporates all the most recent features. Our FBDs have a working pressure of 2 Bar at 80 degrees Celsius, increasing their drying capabilities by 18 to 20 percent. This shortens the drying time…

0 notes

Text

Things you need to know about Fluid Bed Dryer.

VJ Instruments has introduced the Fluid Bed dryer Processor, Fbd Fluid bed dryer, and Rapid dryer. VJ Instruments are one of the most trusted Fluidized-bed dryer manufacturing company in India. Dryers are used in a variety of industries, such as the food processing, pharmaceutical, paper, pollution control, and agricultural sectors.VJ Instruments can provide important information about the different technologies available and what makes the most sense for your specific need.

Fluid Bed Dryer

A fluid bed dryer is a revolutionary dryer. including fluid bed granulation machine is ideal for production. a truly versatile for Pharmaceuticals, Dyestuff, Food, Chemical, Bulk Drugs, and Polymer Industries. Fluid Bed Dryers are designed to Uniform drying of the material at low temperatures. fluid bed dryers have established themselves as dependable and multi-functional processors. a fluid-bed system is a machine in which a continuous flow of “wet” powder, granular, or flakes material is conveyed over a perforated bed. Hot drying air is blown through the holes of a perforated plate.

What You Need in a Fluid Bed Dryer

When you’re looking to invest in a fluid bed dryer system, keep in mind all the features that are important to you, and don’t compromise.

Ø Heat transfer with minimal energy consumption: energy efficient

Ø Manufactured from stainless steel, carbon steel, or nickel alloy

Ø Customized for your individual needs

Ø Low maintenance

Ø Multi-functional: capable of heating, drying, cooling, coating, and more

Ø Adaptable to continuous or batch processing

Ø Vibration to aid in processing

Key Benefits Of Fluid Bed Dryer :

ü High Specific Drying Capacity

ü High Operational Safety

ü High Hygienic Standard

ü High-Temperature Stability

ü Optimal Energy Efficiency

FBD Fluid Bed Dryer

FBD Fluid Bed dyer is a top choice for fast and uniform drying of a multitude of products. The FBD is widely used in pharmaceutical, chemical, food, and allied industries to reduce the moisture/solvent content of particulate materials. The smart system combines best-in-class features with an intelligent automation platform to deliver reliable, safe, and sustainable performance over decades. A fluidized bed dryer (FBD) is well known and widely used equipment in the granulation area of pharmaceutical manufacturing.

Advantages Of FBD

Ø Excellent gas-particle constant results in strong heat and mass transfer rates, resulting in high moisture removal rates.

Ø Lower initial and ongoing cost

Ø Stability and easy to use

Disadvantages of FBD

Ø Considerable pressure drops are caused by the necessity to suspend the entire bed in gas, resulting in high energy usage.

Ø When organic solvents must be eliminated, this is not the best equipment to use.

Ø For certain types of fluidized bed dryers, product quality is non-uniform.

Rapid Dryer

This instrument is used for Drying sand samples for determining Moisture percentage, Clay percentage, and Fineness number.

The Rapid Dryer works fast and gently. Bulk materials whether organic, inorganic, chemical, pharmaceutical, coarse, fine, crystalline, fibrous, or leafy – will be dried in a single pass without hot spots and they are loosened and mixed at the same time. Glass components, such as pipettes, ceramics, plastics, textiles, wood, or metal (such as test sieves) can be dried with superb results using this equipment.

Drying in the Rapid Dryer makes use of the fluidized bed process, a technique similar to the one used in large industrial dryers. Ambient air is drawn in through a filter. A blower moves the air around the motor and across heating elements and ultimately forces it through the perforated plate and into the detachable drying container. The solid particles are blown upward and agitated and thus kept separate one from another so that their surfaces cannot stick together. The air stream extracts moisture from the particles and then exits through the filter bag in the cover of the drying container.

Advantages

flØ Drying periods of just a few minutes.

Ø Glass container for visual monitoring of the drying process.

Ø Simple operation thanks to a quick-clamping cover with bayonet catch.

Ø Versatile with a choice of drying chambers and exhaust air filters.

Ø Gentle drying even of temperature-sensitive substances.

0 notes

Text

Octagonal Blender: Efficient Mixing Solutions for Granules and Powders Discover how the octagonal blender ensures uniform mixing of dry powders and granules with its unique design and low energy consumption. Perfect for pharmaceuticals, chemicals, and food processing industries.

#zero holdup filter press manufacture#sparklar filter press manufacture#Fluid Bed Dryer manufacture#Tray Dryers manufacture#Vacuum Tray Dryer manufacture#Rapid Mixer Granulator manufacture#Sterile Manufacturing Vessel manufacture#Oral Liquid Manufacturing Plant manufacture#Octagonal Blender manufacture

0 notes

Text

Why the VJ Instruments Rapid Dryer is a Game Changer When it comes to lab drying

All scientists know this all too well: waiting for clean glassware to dry. In this respect, every laboratory is bound by a limitation-that little obstruction that just slows their work down. The traditional problem of wet glassware turning out to dry slowly has forever become a challenge in any laboratory, from research labs to full-fledged industrial laboratories. Now, VJ Instruments Rapid Dryer brings fresh new efficiency to lab operations by remedying this long-standing problem of trying to dry wet glassware.

The Laboratory Drying Challenge

Everyone in the lab knows the scenario-wet glassware delays experiments, or worse, water spots on just calibrated equipment. It's traditional drying means a choice between time-consuming air drying or potentially damaging heat exposure. This is where VJ Instruments' Rapid Dryer comes to change the procedure.

Features That Stand Out as Difference Makers

1.Intelligent Temperature Control System

The smart temperature control system of the Rapid Dryer is its best feature. It does not support one-size-fits-all, but instead, ensures that the drying temperature is set according to the kind of equipment. Thus, it means that there are:

· Proper temperatures for various materials

· Sensitivity of heat-sensitive equipment to damage

· Different types of equipment produce stable and consistent results

2.Revolutionary 360° Drying Technology

The new technology in drying is a great break from the conventional methods of drying. The system ensures:

· Uniform airflow patterns to ensure that all surfaces are coated

· Comprehensive coverage of any shape of glassware

· No water spots and untouched areas

3.Intelligent Energy Efficiency

In this ever-responsive environment of laboratories, the Rapid Dryer stands out from the rest through its:

· Automatic shut-down when products are dry

· 40% more energy efficiency compared to standard dryers

· Intelligent monitoring to minimize unnecessary run time

Technical Excellence in Design

The engineering of the Rapid Dryer really pays attention to actual needs of the practical laboratory

1. Adaptive Rack System

· Can house multiple sizes of equipment

· Configuration flexibility

· Rigorously constructed to laboratory standards

2.User Interface

· Easy-to-read controls

· Configurable for different sizes and types of equipment

· Status alarms and completion

3.Maintenance Features

· Alerts for Preventive Maintenance

· Components designed for easily serviced access

· Diagnostic systems built-in

Application Impact on Lab Operations

1.Time Management

· No more long waits between experiments

· Better predictability of when equipment will be available

· Workflow efficiency

2.Quality Control

· Results are repeatable

· Risk of contamination reduced

· Better protection of better equipment

3. Resource Optimization

· Energy conservation savings

· Less inventory of equipment

· Improved Laboratory Efficiency

· Less energy and labor expenses

· Increased productivity

Industry Recognition and Technical Specifications

The VJ Instruments' Rapid Dryer has earned its reputation through measurable performance metrics and technical excellence. Let's dive into the specifics that make this system stand out in laboratory equipment:

1.Performance Metrics

· Drying time reduced by up to 60% compared to conventional methods

· Temperature range: 40°C to 150°C with ±1°C precision

· Digital humidity monitoring with real-time feedback

· Capacity to handle up to 200 pieces of standard laboratory glassware simultaneously

2.Safety and Compliance

The system adheres to rigorous laboratory safety standards including:

· CE certification for laboratory equipment

· Built-in overheating protection mechanisms

· Automatic fault detection system

· Emergency shutdown features

· Low-voltage safety circuits for user protection

3.Environmental Impact

In today's sustainability-focused laboratory environment, the Rapid Dryer stands out with:

· Reduced carbon footprint through energy-efficient operation

· EPA-compliant materials and construction

· Zero chemical emissions during operation

· Recyclable components for sustainable lab practices

This data-driven perspective reinforces why leading laboratories worldwide are increasingly adopting this technology as their standard drying solution.

Capital Expenditure Benefits Compared to Costs

While installation of new technology will require an initial investment, the Rapid Dryer offers numerous attractive long-term advantages including:

· Labor hour reduction from the handling of equipment

· Commuting energy consumption with effective operation

· Longer equipment life due to proper handling

· Potential increase in laboratory throughput

Conclusion

The Rapid Dryer from VJ Instruments is more than a mere replacement in the equipment; rather, it marks an evolution towards better laboratory practice with enhanced efficiency and reliability. In a time where labs are being forced to do more than ever before with minimum tolerance for error, such innovations are all the more desirable.

The Rapid Dryer is the solution for laboratories seeking an upgrade to their drying systems while balancing their immediate practical needs with long-term operational efficiency. Contact a VJ Instruments representative to learn more about how this technology can especially benefit your laboratory setup.

1 note

·

View note

Text

Fluid Bed Dryer: Streamlining Granulation Processes

Are you looking to optimize your granulation processes? A Fluid Bed Dryer could be the solution you need. This innovative equipment plays a crucial role in pharmaceutical and chemical industries by efficiently drying granules while maintaining product integrity. Let's delve deeper into how a Fluid Bed Dryer can benefit your production line.

What is a Fluid Bed Dryer?

A Fluid Bed Dryer operates on the principle of fluidization, where hot air is passed through a perforated bed of solid particles. This creates a fluid-like motion of the particles, allowing for efficient drying as the moisture is rapidly evaporated. This process not only dries but also coats, granulates, and agglomerates the materials, making it versatile for various applications.

Advantages of Using a Fluid Bed Dryer

Uniform Drying: Ensures consistent moisture removal across all particles.

Gentle Handling: Prevents degradation of heat-sensitive materials.

Energy Efficiency: Rapid drying times reduce energy consumption.

Process Control: Easily adjustable parameters for different product requirements.

Applications in Granulation

In the realm of granulation, a Fluid Bed Dryer plays a pivotal role post-wet granulation. It efficiently dries the wet granules to the desired moisture content, preparing them for subsequent processing steps like sizing, blending, and coating. This ensures the final product meets stringent quality standards without compromising on efficiency or uniformity.

How to Choose the Right Fluid Bed Dryer

When selecting a Fluid Bed Dryer for your operation, consider factors such as capacity, airflow design, control systems, and compliance with industry regulations. The dryer should integrate seamlessly into your existing production line while enhancing productivity and product quality.

In conclusion, incorporating a Fluid Bed Dryer into your granulation process can significantly improve efficiency, product quality, and overall operational control. Whether in pharmaceuticals, chemicals,, this versatile equipment offers a reliable solution for drying, coating, and granulating various materials. Explore how a Fluid Bed Dryer can streamline your processes and elevate your production capabilities today.

1 note

·

View note

Text

Fluid Bed Dryer - Riddhi Pharma

Fluid bed dryers are used for drying a variety of materials. The material to be dried is suspended in a stream of air, and as the air moves through the bed, it causes the material to behave like a boiling liquid. Fluid bed dryers are commonly used in the pharmaceutical, chemical, food, and mineral industries due to their efficient and gentle drying process. They are known for their high heat and mass transfer rates, making them suitable for drying heat-sensitive materials.

0 notes

Text

Top Manufacturing Solutions for Pharma & Cosmetic Industries

In the dynamic world of pharmaceutical and cosmetic manufacturing, quality, efficiency, and precision are paramount. At Pharmachem Cosmetics, we understand the importance of using state-of-the-art equipment to ensure top-tier products. Whether you're producing ointments, oral liquids, or other cosmetic formulations, having the right machinery is crucial for success. In this blog, we'll highlight essential equipment and machinery that every manufacturer in the pharmaceutical and cosmetic industries should consider.

1. Fluid Bed Dryer Manufacturers: Enhancing Product Drying Efficiency

When it comes to drying powders, granules, or other materials in the pharmaceutical and cosmetic industries, Fluid Bed Dryers are indispensable. These dryers operate on the principle of fluidization, where hot air flows through the material, reducing moisture content quickly and efficiently. Fluid Bed Dryer Manufacturers like Pharmachem Cosmetics offer equipment designed for consistency, high-quality results, and energy efficiency, making them ideal for drying sensitive products such as powders, granules, and even some ointments.

Choosing the right Fluid Bed Dryer can significantly impact production timelines and product quality. At Pharmachem Cosmetics, we offer advanced Fluid Bed Dryers that meet industry standards and are customizable for different batch sizes and material types. Our equipment ensures uniform drying, preventing clumping and enhancing the overall product stability.

2. Ribbon Blender Mixer in Maharashtra: Optimal Mixing for Uniform Results

Uniformity in mixing is crucial for the success of any pharmaceutical or cosmetic product. The Ribbon Blender Mixer, a common choice in manufacturing plants, provides an efficient solution for blending powders and granules. This versatile equipment ensures thorough mixing of dry ingredients, resulting in uniform consistency throughout the batch.

Pharmachem Cosmetics, based in Maharashtra, is a leading provider of Ribbon Blender Mixers known for their precision and reliability. Whether you are blending active pharmaceutical ingredients (APIs) or cosmetic powders, our Ribbon Blender Mixers are designed to handle a wide range of formulations with ease. By providing a homogeneous blend, these mixers help in achieving the desired product quality, reducing waste, and optimizing production time.

3. Liquid Oral Manufacturing Plant Suppliers: The Backbone of Liquid Formulations

The demand for liquid oral medications and cosmetic products is on the rise. Whether it’s syrups, tonics, or oral gels, the liquid formulation process requires specialized manufacturing plants equipped with the latest technology. Liquid Oral Manufacturing Plant Suppliers like Pharmachem Cosmetics provide cutting-edge equipment for the smooth production of liquid formulations.

From raw material mixing to bottling and packaging, our liquid oral manufacturing plants are designed to ensure safety, hygiene, and efficiency. With automated systems and robust machinery, we help streamline your liquid production process, reducing contamination risks and ensuring consistent product quality. As a trusted supplier in the industry, Pharmachem Cosmetics ensures that your plant meets regulatory standards and operates at peak performance.

4. Ointment Manufacturing Plant Dealers: Producing High-Quality Ointments

Ointments are among the most widely used formulations in both the pharmaceutical and cosmetic industries. From topical treatments to skincare products, the right manufacturing process is essential to ensure the effectiveness and safety of the ointment. Pharmachem Cosmetics offers high-quality Ointment Manufacturing Plants, designed to produce consistent and reliable ointments for a variety of applications.

Our ointment manufacturing plants are equipped with advanced machinery such as mixers, homogenizers, and filling machines, designed to handle both small and large batches. As leading Ointment Manufacturing Plant Dealers, we provide you with everything you need to produce high-quality ointments while adhering to strict regulatory guidelines.

5. Multi Mill Manufacturers: Versatile and Efficient Milling Solutions

The Multi Mill is one of the most versatile machines used in the pharmaceutical and cosmetic industries. Capable of performing a range of functions such as grinding, milling, shredding, and crushing, the Multi Mill is an essential tool for reducing the size of materials for further processing. Whether you are working with APIs, herbal ingredients, or cosmetic raw materials, the Multi Mill ensures uniform particle size reduction, improving product consistency and performance.

At Pharmachem Cosmetics, we are proud to be recognized as leading Multi Mill Manufacturers, offering equipment that guarantees high throughput, durability, and ease of maintenance. Our Multi Mills are designed with user-friendly controls and are highly adaptable to different production needs.

Conclusion: Quality Equipment for Exceptional Products

At Pharmachem Cosmetics, we are committed to providing the highest quality manufacturing equipment for the pharmaceutical and cosmetic industries. Whether you are in need of Fluid Bed Dryers, Ribbon Blender Mixers, Liquid Oral Manufacturing Plants, Ointment Manufacturing Plants, or Multi Mills, we offer cutting-edge solutions to meet your production requirements.

Partner with Pharmachem Cosmetics today and elevate your manufacturing process to new heights. Our equipment ensures precision, efficiency, and safety in every batch, helping you deliver exceptional products to your customers.

#Multi Mill Manufacturers#Ribbon Blender Mixer in Maharashtra#Fluid Bed Dryer Manufacturers#Liquid Oral Manufacturing Plant Suppliers#Ointment Manufacturing Plant Dealers

1 note

·

View note

Text

Fluid Bed Dryer manufacture-Bipin Pharma Equipment

Bipin Pharma Equipment is a leading Fluid Bed Dryer manufacturer, offering high-quality, efficient drying solutions for the pharmaceutical industry. Trust us for innovative designs and exceptional performance in your processes.

0 notes