#Siemens Logistics

Text

Jewar Airport partners with Siemens Logistics for baggage handling system

Jewar Airport partners with Siemens Logistics for baggage handling system

Noida International Airport, also known as Jewar Airport, has partnered with Siemens Logistics India Pvt Ltd for design, supply, installation, commissioning, operation and maintenance of departure and arrival baggage handling systems.

The Siemens Variotray system is a modular and expandable technology. It will provide fast and safe transportation of goods with a high degree of accuracy. It will…

View On WordPress

#airport#aviation#baggage#handling#Jewar#Jewar Airport#Logistics#Noida International Airport#partners#Siemens#Siemens Logistics#system#VarioTray technology

0 notes

Text

Last Monday of the Week 2023-06-26

I have learned so many new things about the specifics of the GPL against my will.

Listening: Remembered that I was kind of hyped for Rodrigo y Gabriela's new album "In Between Thoughts... A New World" which is just a lot of showing off on the guitar. Very much the soundtrack to a movie that doesn't exist.

Reading: Finally remembered the books I was reading long enough to finish Children of Time. Bizzare ending, not bad, but I can see why this might lead to a less well received second book. Spidertech gets increasingly ridiculous in ways that are just on the balance of predictable and ridiculous that I find very funny. They do computing on ants. Also there is an entire society of intelligent mantis shrimp in the periphery of this book. They need a spin-off.

Started Kaiju Preservation Society by Scalzi. I have not in fact read very much Scalzi but this one did sound funny and I was down for sci-fi comedy.

Watching: Continuing the Fast and Furious Watch, with The Fast And The Furious (2009) which is the second movie called that. This feels like it's resetting the storyline so that they can go wherever they're planning on going with this. I liked it a normal amount! There is a level of restraint on display that does not come to mind when I tell you that within 5 minutes of the movie starting, Vin Diesel has driven a car underneath an exploding fuel tanker truck.

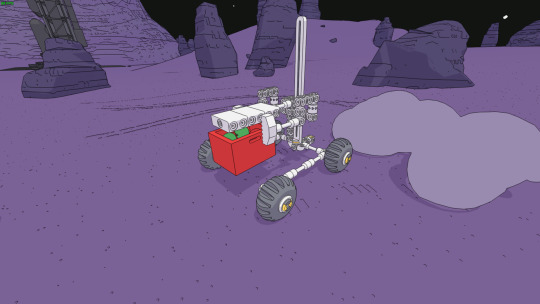

Playing: a lot of Mars First Logistics, the recently-in-early-access mars cargo robot building game.

A good balance of constrained and freeform, parts are slowly meted out as you progress through the "story missions" in as much as those exist, which sees you building a rocket, a biosphere, a rover soccer stadium, a resort, etc. out of ever more unwieldy components in ever more inhospitable terrain.

At times navigation can become just straight up ridiculous, forcing you to either charge up and down steep hills with unstable cargo or attempt to gradually work your way the slow way around. A very forgiving vehicle reset and a less forgiving cargo reset goes a long way to making this manageable. You always have the option to strap rockets to your vessel and cast yourself to the wind, which comes in handy pretty often.

Making: Sat down with FreeCAD and sketched out the apartment for future use, now I need to do the furniture. FreeCAD is not the best or the worst CAD package I've used but it's basically the only one that runs on Linux, unless you have several thousand dollars to drop on Siemens NX. A halfhearted attempt to throw the skeleton of the apartment at povray resulted in this brutalist masterpiece.

Tools and Equipment: I got the iFixit Prying and Opening Tool Kit which is a set of plastic wedges, spudgers, and cards intended for opening electronics. I've always just kind of done this with whatever is lying around and I gotta say it's a big improvement. They're decidedly consumable parts, but they're also cheap enough to justify that.

8 notes

·

View notes

Text

Sustainable Power Generation Drives Floating Power Plant Market

Triton Market Research presents the Global Floating Power Plant Market report segmented by capacity (0 MW- 5 MW, 5.1 MW- 20 MW, 20 MW – 100 MW, 100.1 MW – 250 MW, above 250 MW), and source (non-renewable power source, renewable power source), and Regional Outlook (Latin America, Middle East and Africa, North America, Asia-Pacific, Europe).

The report further includes the Market Summary, Industry Outlook, Impact Analysis, Porter's Five Forces Analysis, Market Maturity Analysis, Industry Components, Regulatory Framework, Key Market Strategies, Drivers, Challenges, Opportunities, Analyst Perspective, Competitive Landscape, Research Methodology & Scope, Global Market Size, Forecasts & Analysis (2023-2028).

Triton's report suggests that the global market for floating power plant is set to advance with a CAGR of 10.74% during the forecast period from 2023 to 2028.

Request Free Sample Report:

Floating power plants are innovative power generation units on floating platforms on water bodies. They serve as primary or backup power sources for specified facilities, utilizing renewable energy sources (solar, wind, etc.) and non-renewable (diesel, natural gas, etc.). These plants offer the advantage of mobility, making them ideal for temporary power generation to tackle local energy shortages.

The increasing popularity of offshore wind projects is due to several market factors, such as the growing demand for clean and sustainable energy sources and advances in offshore wind technology. Also, supportive government policies and the urgent need to combat climate change by reducing carbon emissions further elevate the demand for floating power plants.

Furthermore, the popularity of floating power plants based on IC offers opportunities to the floating power plant market. These innovative power generation systems offer flexibility, scalability, and rapid deployment, catering to remote areas and serving as backup solutions in grid instability situations.

However, challenges like technical complexities, high costs associated with logistics and accessibility, and a shortage of skilled workers for solar panel installation limit the floating power plant market's expansion.

Over the forecast period, the Asia-Pacific region is expected to register the fastest growth. A growing population and increasing industrialization fuel growth prospects. The region is home to a rapidly growing population, which in turn drives the need for expanded power generation capacity. Furthermore, Asia-Pacific is experiencing significant economic growth, with many countries emerging as major global players. This economic expansion is accompanied by a surge in industrial activities and the establishment of new manufacturing units, creating a heightened demand for electricity to support these sectors. Floating power plants present a viable solution to meet this demand, especially in areas with limited land availability.

Floating Power Plant AS, Upsolar Group Co Ltd, SeaTwirl AB, Caterpillar Inc, Mitsubishi Corporation, Wartsila Corporation, Siemens AG, MAN Energy Solutions SE, Kyocera Corporation, and Vikram Solar Limited are prominent companies in the floating power plant market.

Due to its complexity, the floating power plant market poses a moderate threat of new entrants. Capital-intensive development and deployment, along with the need for specialized expertise, act as barriers. Additionally, a skilled workforce in offshore engineering and renewable energy is crucial. Nevertheless, government policies supporting renewable energy adoption, such as feed-in tariffs, subsidies, and favorable regulations, are vital in attracting new players by mitigating financial risks and offering long-term incentives.

Contact Us:

Phone: +44 7441 911839

Website: https://www.tritonmarketresearch.com/

#Floating Power Plant Market#Floating Power Plant#energy power & utilities#power industry#triton market research#market research reports

2 notes

·

View notes

Text

Top Brands in Industrial Automation

Leading Company Segments of Industrial Automation

Industrial automation has brought changes in the manufacturing and processing industries, where the company's productivity and production quality have improved while the operating costs have been cut. Many leading market players deliver innovative technologies such as robotics, control systems, and automation software applications to popular brands about industrial automation, their contributions, and their offerings.

1. Siemens

Overview: Siemens is a well-established global organization specializing in industrial automation and electrification solutions and products. This company offers its customers automation solutions, which include but are not limited to the following: programmable logic controllers (PLCs), human-machine interfaces (HMIs), and industrial communication products.

Key Products:

• SIMATIC PLCs: Siemens called its SIMATIC series a highly reliable and adaptable product in various automation applications in simple machine and complicated process control.

• TIA Portal: The Totally Integrated Automation or TIA Portal is an assured engineering environment for scheming, programming, and commissioning automation systems.

• SINAMICS Drives: These drives regulate the electric motor's speed and torque, which is imperative in many industrial applications.

2. ABB

Overview: ABB is a well-established global company creating innovative technologies for the utility, industrial, and commercial sectors, emphasizing digitalization and energy management. It deals with various products and services that seek to improve the operations of organizations and reduce their impact on the environment.

Key Products:

• ABB Robotics: ABB is one of the world's largest industrial robot manufacturers in the automotive, electronics, and logistics industries. Their robots are highly precise and very flexible in their applications.

• Control Systems: One is ABB's Distributed Control System (DCS), ABB Ability™ System 800xA, which combines process automation, electrical control, and safety into a single system for increased power.

• Servo Motors and Drives: Servo motors are products of ABB that the company designs for various operations requiring precision and accuracy in using power.

3. Rockwell Automation

Overview: Rockwell Automation is an organization operating in America. The company mainly specializes in industrial automation and information technology. The company is now set on designing and integrating hardware and software solutions, a reformative wheel in industrial utilization.

Key Products:

• Allen-Bradley PLCs: Therefore, the main product of Rockwell is Allen-Bradley, which manufactures and supplies excellent quality PLCs needed by all departments.

• FactoryTalk Software: This set of software applications brings real-time monitoring, control, and analysis of the collected data, allowing companies to make the right decisions based on the data collected.

• Motion Control: Therefore, motion control solutions offered by Rockwell are to be implemented into high-performance machines that perform operations with enhanced precision and speed.

4. Mitsubishi Electric

Overview: Mitsubishi Electric is the market leader in industrial automation solutions, offering a wide range of products to satisfy almost all demands of different industries. It is so well known for automating bits and aspects, as necessitated by high quality in the organization.

Key Products:

• MELSEC PLCs: Mitsubishi's MELSEC PLCs are also acknowledged for reliability and scalability and thus can be used for small and large automation purposes.

• GOT HMIs: Some examples of excellent, friendly, and convenient interfaces are Mitsubishi Graphic Operation Terminals (GOT), which allow users to control and supervise systems in industries.

•Servo Systems: Mitsubishi continues to improve its servo systems, mainly when the speed is high. At the same time, it is used selectively and where the level of precision is comparatively high, thus being mostly applicable to the manufacturing and assembling industry.

5. Schneider Electric

Overview: Schneider Electric is a global company that markets its products worldwide and is in the energy and automation business. Product: The products from the company are supposed to force industries to become more efficient and have cleaner, less problematic production processes.

Key Products:

• Modicon PLCs: The Modicon PLCs of the Schneider Electric Company are highly reliable and multifunctional, which is why they are applied in many fields.

• EcoStruxure: Schneider's EcoStruxure employs IoT Cloud and big data analytics to create intelligent, sustainable automation solutions.

• Variable Frequency Drives (VFDs): VFDs from Schneider help control motor speeds and are significant for energy conservation in industrial businesses.

Why RAM Automations – Industrial Automation Solutions & Services Company in India, UAE & Saudi Arabia?

As you may see, these manufacturers provide some of the best industrial automation solutions.

That is why, when working with our clients at RAM Automations, we ensure we can get all their products. Read our HMI tutorial and learn how our best hardware and advice improve your performance, whether it be PLC, robotics, or drives.

You are in business, and thus, you stand to benefit a lot from the growth and success of your business by choosing RAM Automations. Our team comprises professionals willing to assist you in selecting the best solutions to suit your needs by offering sound, dependable, and forward-compatible systems.

You can read more about Oxley and our wide range of industrial automation products here on the website, or contact us to learn how we can help you gain a competitive edge. As a ranging company at RAM Automations, we aim to deliver the best automation services to improve your industries.

0 notes

Text

Automated Guided Vehicle Market Report: Industry Manufacturers Analysis 2024-2030

Automated Guided Vehicle Industry Overview

The global automated guided vehicle market size was estimated at USD 4.79 billion in 2023 and is expected to grow at a CAGR of 9.4% from 2024 to 2030.

Automated guided vehicle (AGV) systems assist in moving and transporting items in manufacturing facilities, warehouses, and distribution centers without any permanent conveying system or manual intervention. It follows configurable guide paths for optimizing storage, picking, and transport functions in the environment of premium space. AGVs are being highly adopted owing to several benefits, such as reduced labor costs, reduced product damage, increased productivity, and scale to support automation processes. These notable advantages encourage transportation and logistics firms to deploy AGVs to boost the efficiency of their operations.

Gather more insights about the market drivers, restrains and growth of the Automated Guided Vehicle Market

For instance, in May 2021, AUDI AG stated that they use AGVs in their manufacturing centers, which helps them indirectly plan the production process to know which component is out of stock and needs to be available. Further, it also helps in carrying items supply trolleys which helps them maintain safety.

Retailing and other logistics-related companies are collaborating and partnering with tech giants to transform the material handling industry. For instance, in November 2021, OTSAW Digital Pte Ltd, an autonomous mobile robot solution, partnered with Swisslog Healthcare to develop automated guided vehicles for the healthcare sector to enable better patient care. Further, this partnership would expand their business by deploying AGV in Asia Pacific, Europe, and MEA.

Besides, in February 2022, Siemens, a Germany-based industrial manufacturer, partnered with Parmley Graham Ltd. and AR Controls to build, design, and manufacture automated guided vehicles. The partnership and the launch of AGV would bring a lot of advantages, such as low labor costs, reduced risk of workplace injury, logistics management, and faster delivery. Furthermore, retail and commerce-based companies and businesses are deploying collaborative robots in their warehouses and expanding their businesses through acquisitions of large-scale cobot providers.

For instance, in February 2022, SAVE MART SUPERMARKETS, a grocery store company, partnered with Starship Technologies, a provider of autonomous delivery vehicles. The initiative aims to deliver groceries using the Starship robot, a combination of artificial intelligence and machine learning. With the installation of the starship robot, SAVE MART SUPERMARKETS expanded its delivery area. Besides, in January 2023, Barcoding, Inc., a prominent player in supply chain efficiency, connectivity, and accuracy, announced the acquisition of FRED AGV, an automated guided vehicle manufacturer. The acquisition illustrates continuous investment and expansion in industrial automation for Barcoding, Inc.

Automated guided vehicles are used in various end-use industries, such as logistics, automotive, healthcare, manufacturing, food & beverages, and others. Increased productivity and reduced labor costs are the key factors driving the need for industrial equipment. The demand for AGVs is expected to grow owing to the increasing automation in industries. Increasing industrialization has led to the continuous need for customized material handling and transport solutions for fuel efficiency.

For instance, in February 2023, The SSI Schaefer Group, a prominent supplier of systems, components, and software for warehouse automation, acquired DS AUTOMOTION GmbH, a global supplier of automated guided vehicles and autonomous mobile robotics. The acquisition intends to expand the minority interest of SSI Schaefer to reminisce the growing significance of AGV and autonomous and mobile robotics business in intralogistics.

Browse through Grand View Research's Next Generation Technologies Industry Research Reports.

The global material informatics market size was estimated at USD 134.6 million in 2023 and is projected to grow at a CAGR of 16.5% from 2024 to 2030.

The global military sensors market size was estimated at USD 11.40 billion in 2023 and is expected to grow at a CAGR of 6.9% from 2024 to 2030.

Key Automated Guided Vehicle Company Insights

Key automated guided vehicle companies include Swisslog Holding AG; Daifuku Co., Ltd.; JBT; Seegrid Corporation; TOYOTA INDUSTRIES CORPORATION; Hyster-Yale Materials Handling, Inc.; and Kollmorgen. Increasing collaborations and mergers & acquisitions are expected to maximize the environmental and economic benefits for the market players by enabling them to share ideas and enhance their internal skills and technologies. For instance, in March 2022, Seegrid Corporation, an autonomous mobile robot provider, partnered with ROBEX. This initiative towards partnership would allow Seegrid Corporation to expand its business, and clients of ROBEX would also be introduced to Seegrid Corporation products. Further, this would help grow the demand for automation in supply chain management. It would also make it easier to supply clients and partners with complete end-to-end warehouse management solutions.

Key Automated Guided Vehicle Companies:

The following are the leading companies in the automated guided vehicle market. These companies collectively hold the largest market share and dictate industry trends.

Swisslog Holding AG

Egemin Automation Inc.

Bastian Solutions, Inc.

Daifuku Co., Ltd.

Dematic

JBT

Seegrid Corporation

TOYOTA INDUSTRIES CORPORATION

Hyster-Yale Materials Handling, Inc.

BALYO

E&K Automation GmbH

Kollmorgen

KMH Fleet Solutions

ELETTRIC80 S.P.A.

Fetch Robotics, Inc.

inVia Robotics, Inc.

Locus Robotics

Schaefer Systems International, Inc.

System Logistics Spa

Transbotics (A division of Scott Systems International Incorporated)

Recent Developments

In November 2023, Movella, Inc., an American sensor technology provider, collaborated with Taiwanese industrial IoT-provided Advantech to develop advanced automated guided vehicles and autonomous mobile robot systems. By developing these systems, the companies aim to simplify material deployment for their customers, thereby minimizing solution compatibility issues and expediting time to market.

In October 2023, Align Production Systems, an American material handling solution provided collaborated with Kollmorgen, a vehicle control solution provider, to develop and offer efficient and reliable automated guided vehicle systems designed by Align Production Systems and comprising of Kollmorgen’s NDC solutions. This partnership aims to revolutionize the manufacturing sector by enabling manufacturers to move large and heavy products across their facilities.

In March 2023, Mitsubishi Logisnext Americas group announced the launch of their new AGV product, Jungheinrich EKX 516ka / 516a Automated High-Rack Stacker, initially planned to deploy for their U.S.-based customers. With very narrow aisle operations and greater storage density, this product allows users to gain maximum efficiency and productivity in their business operations.

Order a free sample PDF of the Automated Guided Vehicle Market Intelligence Study, published by Grand View Research.

0 notes

Text

TEUS Expands its Wagon Fleet: New Grain Cars to Improve Agricultural Logistics

TEUS is expanding its fleet of grain wagons, this is reported by the railway transport news portal Railway Supply.

The company has announced the acquisition of 10 new hopper wagons for grain transportation.

China Halts Locomotive Deliveries to Belarus Due to U.S. Sanctions

This deal was made possible thanks to financial support from Raiffeisen Bank. It’s not the only planned purchase — soon, the company plans to add another 60 units to its own rolling stock.

Currently, TEUS operates 800 leased wagons, but the management aims to increase the number of its own units to 300.

This step will reduce dependence on leased resources, lower logistics costs, and improve delivery speed.

The purchase of these wagons is part of a strategy to strengthen the company’s position in the agricultural logistics market, which is crucial given the growing export of agricultural products.

A recent example of successful growth in agricultural logistics is the purchase of 40 grain wagons by the company "Astarta-Kyiv," supported by USAID. This confirms the high demand for efficient logistics solutions in the agricultural sector.

TEUS’s current investments in its transport fleet are just part of the company’s long-term strategy.

Systematic infrastructure development and the implementation of new logistics solutions will enable the company to meet growing market demand and solidify its position among competitors.

Rail business, industry, and railway technology news from Railway Supply that you might have missed:

EP Cargo Invest Expands Locomotive Fleet: Tenth Siemens Vectron Now in Operation

Read the full article

0 notes

Text

Siemens SIMATIC S7-300: An Efficient Automation System

Siemens SIMATIC S7-300 is very popular, and it is known as a versatile and robust programmable logic controller (PLC) for many industrial applications. The S7-300 has been with us in industries that require accuracy and integration due to its flexibility, trustworthiness, and productivity.

What is the Siemens SIMATIC S7-300?

The SIMATIC S7-300 is a modular PLC system used for carrying out many different types of operations. Its CPU (Central Processing Unit) acts as the main controller but it can also accept several input/output (I/O) and function modules. As such, this makes it applicable to control routines that are simple as well as those which are more involved in manufacturing, logistics or electricity distribution.

Key Features of the SIMATIC S7-300

Modular Design: The S7-300 modular design enables users to tailor the system based on their own requirements. More functionalities can be achieved by adding extra modules which do not alter the central CPU.

Wide Range of CPUs: Various CPUs are available for the S7-300, ranging from basic versions for simple tasks to high-performance versions capable of solving complex automation problems.

Integrated Communication: Thanks to integrated communication possibilities such as PROFINET and PROFIBUS, S7-300 guarantees seamless transfer of information between machines and networks.

High-Speed Processing: Quick reaction periods of the PLC suit industries that are highly dependent on accuracy and time.

Reliability: The S7-300 is highly enduring equipment meant for unfriendly industrial settings and durable construction thus meaning that it will remain operational always.

Seamless Integration: Incorporated with Siemens TIA (Totally Integrated Automation) Portal, S7-300 offers perfect compatibility hence facilitating simple integration of other Siemens automation products and solutions.

Advantages of the Siemens SIMATIC S7-300

Scalability: S7-300 is an incredibly modular system and one of its most remarkable features is its scalable design that is based on the demands of the project. Small automation as well as high complexity projects are easily accommodated thanks to this unique modular architecture.

Cost-Effective: With its low costs, the S7-300 is a high-performance device which takes care of businesses’ automation needs without stretching their budgets.

User-Friendly Programming: It is simple to program the S7-300 even for challenging automatization jobs due to the TIA Portal’s assistance.

Energy Efficiency: You know that the S7-300 is built for efficiency, which reduces energy use and allows it to be considered green in today’s world of heavy-duty manufacturing.

Applications of the SIMATIC S7-300

Manufacturing: The S7-300 guides through operations from assembly lines to process management, ensuring efficacy and accuracy.

Logistics: The automated warehousing systems and conveyor belts can make use of S7-300 which improves the processes of material handling.

Power Distribution: They are essential for the control and administration of electric supply networks used in industry.

Water Treatment: For water treatment processes to be automated and optimized for efficiency as well as safety, the PLC plays its role.

Building Automation: In large institutions such as hotel buildings and others, HVAC systems, lighting as well as security systems can be controlled using S7-300.

Conclusion: Why Choose the Siemens SIMATIC S7-300?

Siemens SIMATIC S7-300 is not only a PLC but a full solution for industrial automation that has brought about flexibility, scalability, and efficiency. Its reliable performance and adaptable design make it suitable for use in both small-scale operations and complex manufacturing processes.

The S7-300 remains a preferred option for industries that want to boost productivity and make operations more efficient due to its established performance and compatibility with new automation technologies.

0 notes

Text

Automated Guided Vehicle Market Trends, Statistics and Analysis Report 2024-2030

The global automated guided vehicle market size was estimated at USD 4.79 billion in 2023 and is expected to grow at a CAGR of 9.4% from 2024 to 2030.

Automated guided vehicle (AGV) systems assist in moving and transporting items in manufacturing facilities, warehouses, and distribution centers without any permanent conveying system or manual intervention. It follows configurable guide paths for optimizing storage, picking, and transport functions in the environment of premium space. AGVs are being highly adopted owing to several benefits, such as reduced labor costs, reduced product damage, increased productivity, and scale to support automation processes. These notable advantages encourage transportation and logistics firms to deploy AGVs to boost the efficiency of their operations.

Gather more insights about the market drivers, restrains and growth of the Automated Guided Vehicle Market

For instance, in May 2021, AUDI AG stated that they use AGVs in their manufacturing centers, which helps them indirectly plan the production process to know which component is out of stock and needs to be available. Further, it also helps in carrying items supply trolleys which helps them maintain safety.

Retailing and other logistics-related companies are collaborating and partnering with tech giants to transform the material handling industry. For instance, in November 2021, OTSAW Digital Pte Ltd, an autonomous mobile robot solution, partnered with Swisslog Healthcare to develop automated guided vehicles for the healthcare sector to enable better patient care. Further, this partnership would expand their business by deploying AGV in Asia Pacific, Europe, and MEA.

Besides, in February 2022, Siemens, a Germany-based industrial manufacturer, partnered with Parmley Graham Ltd. and AR Controls to build, design, and manufacture automated guided vehicles. The partnership and the launch of AGV would bring a lot of advantages, such as low labor costs, reduced risk of workplace injury, logistics management, and faster delivery. Furthermore, retail and commerce-based companies and businesses are deploying collaborative robots in their warehouses and expanding their businesses through acquisitions of large-scale cobot providers.

For instance, in February 2022, SAVE MART SUPERMARKETS, a grocery store company, partnered with Starship Technologies, a provider of autonomous delivery vehicles. The initiative aims to deliver groceries using the Starship robot, a combination of artificial intelligence and machine learning. With the installation of the starship robot, SAVE MART SUPERMARKETS expanded its delivery area. Besides, in January 2023, Barcoding, Inc., a prominent player in supply chain efficiency, connectivity, and accuracy, announced the acquisition of FRED AGV, an automated guided vehicle manufacturer. The acquisition illustrates continuous investment and expansion in industrial automation for Barcoding, Inc.

Automated guided vehicles are used in various end-use industries, such as logistics, automotive, healthcare, manufacturing, food & beverages, and others. Increased productivity and reduced labor costs are the key factors driving the need for industrial equipment. The demand for AGVs is expected to grow owing to the increasing automation in industries. Increasing industrialization has led to the continuous need for customized material handling and transport solutions for fuel efficiency.

For instance, in February 2023, The SSI Schaefer Group, a prominent supplier of systems, components, and software for warehouse automation, acquired DS AUTOMOTION GmbH, a global supplier of automated guided vehicles and autonomous mobile robotics. The acquisition intends to expand the minority interest of SSI Schaefer to reminisce the growing significance of AGV and autonomous and mobile robotics business in intralogistics.

Automated Guided Vehicle Market Segmentation

Grand View Research has segmented the global automated guided vehicle market report based on vehicle type, navigation technology, application, end-use industry, component, battery type, mode of operation, and region:

Vehicle Type Outlook (Revenue, USD Million, 2017 - 2030)

• Tow Vehicle

• Unit Load Carrier

• Pallet Truck

• Forklift Truck

• Hybrid Vehicles

• Others

Navigation Technology Outlook (Revenue, USD Million, 2017 - 2030)

• Laser Guidance

• Magnetic Guidance

• Vision Guidance

• Inductive Guidance

• Natural Navigation

• Others

Application Outlook (Revenue, USD Million, 2017 - 2030)

• Logistics and Warehousing

o Transportation

o Cold Storage

o Wholesale & Distribution

o Cross-docking

• Assembly

• Packaging

• Trailer Loading and Unloading

• Raw Material Handling

• Others

End-use Industry Outlook (Revenue, USD Million, 2017 - 2030)

• Manufacturing Sector

o Automotive

o Aerospace

o Electronics

o Chemical

o Pharmaceuticals

o Plastics

o Defense

o FMCG

o Tissue

o Others

• Wholesale and Distribution Sector

o E-commerce

o Retail Chains/Conveyance Stores

o Grocery Stores

o Hotels and Restaurants

Component Outlook (Revenue, USD Million, 2017 - 2030)

• Hardware

• Software

• Service

Battery Type Outlook (Revenue, USD Million, 2017 - 2030)

• Lead Battery

• Lithium-Ion Battery

• Nickel-based Battery

• Others

Mode of Operation Outlook (Revenue, USD Million, 2017 - 2030)

• Indoor

• Outdoor

Regional Outlook (Revenue, USD Million,2017 - 2030)

• North America

o U.S.

o Canada

• Europe

o Germany

o U.K.

o France

• Asia Pacific

o China

o Japan

o India

o Australia

o South Korea

• Latin America

o Brazil

o Mexico

• Middle East and Africa (MEA)

o Kingdom of Saudi Arabia (KSA)

o UAE

o South Africa

Browse through Grand View Research's Next Generation Technologies Industry Research Reports.

• The global material informatics market size was estimated at USD 134.6 million in 2023 and is projected to grow at a CAGR of 16.5% from 2024 to 2030.

• The global military sensors market size was estimated at USD 11.40 billion in 2023 and is expected to grow at a CAGR of 6.9% from 2024 to 2030.

Key Automated Guided Vehicle Company Insights

Key automated guided vehicle companies include Swisslog Holding AG; Daifuku Co., Ltd.; JBT; Seegrid Corporation; TOYOTA INDUSTRIES CORPORATION; Hyster-Yale Materials Handling, Inc.; and Kollmorgen. Increasing collaborations and mergers & acquisitions are expected to maximize the environmental and economic benefits for the market players by enabling them to share ideas and enhance their internal skills and technologies. For instance, in March 2022, Seegrid Corporation, an autonomous mobile robot provider, partnered with ROBEX. This initiative towards partnership would allow Seegrid Corporation to expand its business, and clients of ROBEX would also be introduced to Seegrid Corporation products. Further, this would help grow the demand for automation in supply chain management. It would also make it easier to supply clients and partners with complete end-to-end warehouse management solutions.

Key Automated Guided Vehicle Companies:

The following are the leading companies in the automated guided vehicle market. These companies collectively hold the largest market share and dictate industry trends.

• Swisslog Holding AG

• Egemin Automation Inc.

• Bastian Solutions, Inc.

• Daifuku Co., Ltd.

• Dematic

• JBT

• Seegrid Corporation

• TOYOTA INDUSTRIES CORPORATION

• Hyster-Yale Materials Handling, Inc.

• BALYO

• E&K Automation GmbH

• Kollmorgen

• KMH Fleet Solutions

• ELETTRIC80 S.P.A.

• Fetch Robotics, Inc.

• inVia Robotics, Inc.

• Locus Robotics

• Schaefer Systems International, Inc.

• System Logistics Spa

• Transbotics (A division of Scott Systems International Incorporated)

Recent Developments

• In November 2023, Movella, Inc., an American sensor technology provider, collaborated with Taiwanese industrial IoT-provided Advantech to develop advanced automated guided vehicles and autonomous mobile robot systems. By developing these systems, the companies aim to simplify material deployment for their customers, thereby minimizing solution compatibility issues and expediting time to market.

• In October 2023, Align Production Systems, an American material handling solution provided collaborated with Kollmorgen, a vehicle control solution provider, to develop and offer efficient and reliable automated guided vehicle systems designed by Align Production Systems and comprising of Kollmorgen’s NDC solutions. This partnership aims to revolutionize the manufacturing sector by enabling manufacturers to move large and heavy products across their facilities.

• In March 2023, Mitsubishi Logisnext Americas group announced the launch of their new AGV product, Jungheinrich EKX 516ka / 516a Automated High-Rack Stacker, initially planned to deploy for their U.S.-based customers. With very narrow aisle operations and greater storage density, this product allows users to gain maximum efficiency and productivity in their business operations.

Order a free sample PDF of the Automated Guided Vehicle Market Intelligence Study, published by Grand View Research.

#Automated Guided Vehicle Market#Automated Guided Vehicle Industry#Automated Guided Vehicle Market size#Automated Guided Vehicle Market share#Automated Guided Vehicle Market analysis

0 notes

Text

Industrial Ethernet Market: Powering the Future of Connected Industries

The Industrial Ethernet market has become a cornerstone of modern industrial automation, transforming how industries operate and innovate. Valued at USD 9.76 billion in 2023, this market is anticipated to reach USD 18.57 billion by 2031, growing at a CAGR of 8.7% from 2024 to 2031.

As industries embrace digital transformation, the demand for reliable, high-speed communication networks that can handle the complexities of connected machinery and industrial IoT (IIoT) has skyrocketed. Industrial Ethernet has emerged as the preferred solution, offering robust connectivity and real-time data exchange capabilities crucial for optimizing production processes and enhancing operational efficiency.

Request for sample:

https://www.kingsresearch.com/request-sample/industrial-ethernet-market-961

Market Overview and Emerging Trends

The increasing adoption of Industry 4.0 technologies, such as smart factories and IIoT, has spurred the growth of the Industrial Ethernet market. As manufacturing environments become more interconnected, the need for high-bandwidth, low-latency networks is becoming paramount. Furthermore, Industrial Ethernet networks are increasingly being integrated with edge computing solutions to enable real-time decision-making and predictive maintenance.

The rise of 5G technology is also expected to complement Industrial Ethernet networks, creating hybrid solutions that combine the benefits of wired and wireless connectivity for more flexible and dynamic industrial applications.

Regional and Segment Analysis

North America and Europe currently lead the Industrial Ethernet market due to their advanced industrial infrastructure and early adoption of IIoT. However, the Asia Pacific region is poised for rapid growth, driven by expanding manufacturing sectors in countries like China and India. Segment-wise, the automotive, aerospace, and energy industries are among the leading adopters of Industrial Ethernet technology, leveraging its capabilities to enhance production quality and reduce downtime.

Investment and Expansion Opportunities

The Industrial Ethernet market presents significant opportunities for investment, particularly in areas such as advanced manufacturing, smart energy grids, and autonomous logistics. As industries continue to modernize, companies offering innovative Ethernet solutions that can handle the demands of next-generation industrial applications are likely to experience substantial growth.

Competitive Landscape

The competitive landscape of the Industrial Ethernet market is shaped by several key players, including Siemens AG, Cisco Systems, Rockwell Automation, and Schneider Electric. These companies are at the forefront of technological advancements, continuously innovating to provide cutting-edge solutions that meet the evolving needs of industries worldwide.

Why Invest in This Market?

Drive Growth: Tap into the expanding market driven by digital transformation in industries.

Stay Ahead: Leverage precise market forecasts and trend analysis for strategic planning.

Capitalize on Regional Growth: Identify high-growth regions like Asia Pacific for market expansion.

Gain a Competitive Edge: Understand competitor strategies to develop effective business approaches.

List of Key Companies in Industrial Ethernet Market

Belden Inc.

Cisco Systems, Inc.

Huawei Technologies Co., Ltd.

Moxa Inc.

Rockwell Automation

Schneider Electric

Siemens

OMRON Corporation

ABB

SICK AG

The global industrial Ethernet market is segmented as:

By Offering

Hardware

Software

Services

By Protocol

EtherCAT

EtherNet/IP

Profinet

Powerlink

Sercos III

CC-Link

Others

By Application

Oil & Gas

Aerospace and Defense

Energy and Power

Electrical and Electronics

Automotive & Transport

Chemicals

Others

By Region

North America

U.S.

Canada

Mexico

Europe

France

U.K.

Spain

Germany

Italy

Russia

Rest of Europe

Asia-Pacific

China

Japan

India

South Korea

Rest of Asia-Pacific

Middle East & Africa

GCC

North Africa

South Africa

Rest of Middle East & Africa

Latin America

Brazil

Argentina

Rest of Latin America

0 notes

Text

Logistic Coordinator - Siemens Energy

A Snapshot of Your DayLead all aspects of and coordinate daily logistics activities such as timely pick-up and delivery of orders, import, export, Custom clearance, CD payments, SABER certificate issuance, maintain and updates shipments/orders reports & logistics service providers KPI’s, customs visits If required.How You’ll Make an Impact

Prepare / review related documents required for the…

0 notes

Text

Electrical Enclosure Market will grow at highest pace owing to increased demand from oil & gas sector

The electrical enclosure market comprises enclosures that protect electrical components from environmental factors such as dust, moisture, and corrosion. Electrical enclosures are manufactured using various materials such as metal, plastic, and Fiberglass Reinforced Polyester (FRP). They provide mechanical protections as well as adhere to safety standards set by regulatory authorities. Electrical enclosures find wide applications in industries such as oil & gas, mining, power generation, and transportation among others. Rising investments in infrastructure development and urbanization are fueling the demand for electrical enclosures.

The global electrical enclosure market size was valued at USD 5894.4 million in 2021 and is anticipated to witness a compound annual growth rate (CAGR) of 4.20% from 2022 to 2030.

Key Takeaways

Key players operating in the electrical enclosure are Adalet (Scott Fetzer Company), Schneider Electric SE, Rittal GmbH Co. Kg., Legrand SA, Nvent Electric PLC, Hubbell Inc., Siemens AG, Emerson Electric Co., Austin Electrical Enclosures, ABB Ltd., AZZ Inc., Eaton Corporation, and Eldon Holding AB. Rising demand from utilities industry owing to increasing investments in T&D networks is a key factor driving the electrical enclosure market. Rapid industrialization and urbanization in emerging economies are also pushing the demand for reliable power infrastructure and safer electrical components. Advancements in material sciences have led to the development of lightweight, corrosion resistant, and fire-retardant enclosure materials.

Market trends

The Electrical Enclosure Market Demand is witnessing increased adoption of FRP and polycarbonate materials over conventional metals. FRP enclosures offer benefits such as resistance to corrosion, lightweight, and ease of fabrication. This is positively impacting their use in hazardous and wet industrial locations. Enclosures equipped with Intrinsic Safety (IS) / Increased Safety (IS) barriers for Zone 1 and Zone 2 areas of oil &gas refineries and petrochemical plants are also gaining traction.

Market Opportunities

Growing investments in renewable energy generation projects present significant growth opportunities. Solar and wind farms require reliable electrical enclosures to house control gear and distribution components. Developing infrastructure in countries like India, Brazil and Southeast Asia will further drive the demand. Enclosures with IECEx and ATEX certifications for use in underground mining sites also offer lucrative opportunities.

Impact of COVID-19 on Electrical Enclosure Market

The COVID-19 pandemic has adversely impacted the growth of the Electrical Enclosure Market Regional Analysis. The imposition of lockdowns across various countries led to the temporary closure of manufacturing facilities. This disrupted the supply chain and logistics network, thereby hampering the production and distribution of electrical enclosures. With the halt in construction projects, the demand from end-use industries such as infrastructure, construction also witnessed a steep decline during this period.

Get more insights on Electrical Enclosures Market

Alice Mutum is a seasoned senior content editor at Coherent Market Insights, leveraging extensive expertise gained from her previous role as a content writer. With seven years in content development, Alice masterfully employs SEO best practices and cutting-edge digital marketing strategies to craft high-ranking, impactful content. As an editor, she meticulously ensures flawless grammar and punctuation, precise data accuracy, and perfect alignment with audience needs in every research report. Alice's dedication to excellence and her strategic approach to content make her an invaluable asset in the world of market insights.

(LinkedIn: www.linkedin.com/in/alice-mutum-3b247b137 )

#Coherent Market Insights#Electrical Enclosures Market#Electrical Enclosures#Electrical Equipment#Protective Housing#Industrial Enclosures#Electrical Safety#IP Rating#NEMA#Weatherproof Enclosures

0 notes

Link

0 notes

Text

Metlen: Μετέφερε εξαρτήματα χιλιάδων τόνων στη Βρετανία

Μια εξαιρετικά δύσκολη πρόκληση στο επίπεδο των logistics έφερε εις πέρας η Metlen (τ. MYTILINEOS), καθώς ολοκλήρωσε τη μεταφορά εξαρτημάτων χιλιάδων τόνων σε τρεις διαφορετικές τοποθεσίες στη Μεγάλη Βρετανία

Ενώ τα ενεργειακά έχουν από μόνα τους υψηλό βαθμό δυσκολίας, είναι τα logistics που αντιπροσωπεύουν συχνά την μεγαλύτερη πρόκληση, λόγω του όγκου και του βάρους των εξαρτημάτων που απαιτούνται.

Ενα εξαιρετικά σύνθετο και πολύπλοκο στοίχημα κερδήθηκε όταν μεταφέρθηκαν με απόλυτη ασφάλεια τα ογκώδη εξαρτήματα που απαιτούνται για την ανάπτυξη τριών μονάδων παραγωγής ηλεκτρικής ενέργειας, σε ανοιχτό κύκλο (OCGT) που κατασκευάζει η Metlen Energy & Metals (πρώην MYTILINEOS) στο Ηνωμένο Βασίλειο για τη Drax.

Κάθε OCGT έχει παραλάβει πλέον έναν αεριοστρόβιλο Siemens Energy SGT5-4000F βάρο��ς 332 τόνων, μια γεννήτρια βάρους 327,5 τόνων και έναν μετασχηματιστή βάρους 222 τόνων. Τα 9 αυτά τα φορτία έπρεπε να παραδοθούν μέσω του οδικού δικτύου του Ηνωμένου Βασιλείου, σε κάθε μία από τις τρεις τοποθεσίες: Hirwaun κοντά στο Aberdare στην Ουαλία, Progress in Eye στο Suffolk και Millbrook στο Bedfordshire.

Η μεγαλύτερη και πιο περίπλοκη παράδοση ήταν η διαδρομή που μετέφερε τα εξαρτήματα στο Millbrook. Ένα ταξίδι 79 μιλίων από το λιμάνι του Tilbury στο Essex προς τον σταθμό παραγωγής Millbrook, διασχίζοντας ��ερικούς από τους πιο πολυσύχναστους δρόμους στο Ηνωμένο Βασίλειο, συμπεριλαμβανομένων των M25 και M1, μερικές φορές διασχίζοντας διασταυρώσεις και κατοικημένες περιοχές, με ταχύτητα πεζοπορίας.

Η παράδοση αυτών των εξαρτημάτων απαιτούσε ένα εκτεταμένο πρόγραμμα επικοινωνίας και συντονισμού, το οποίο προϋπέθετε συνεργασία με τις υπηρεσίες έκτακτης ανάγκης, τις τοπικές αρχές, τις υπηρεσίες κυκλοφορίας, κυβερνητικούς φορείς και άλλους βασικούς ενδιαφερόμενους, συμπεριλαμβανομένων δεκάδων χιλιάδων κατοίκων, αλλά και του κοινού που χρησιμοποιούσε τους οδικούς άξονες.

Με την ολοκλήρωση και αυτού του σημαντικού οροσήμου σε όλες τις εγκαταστάσεις, οι εργασίες συνεχίζονται εντατικά, ώστε οι σταθμοί παραγωγής ενέργειας να μπορούν να αρχίσουν να υποστηρίζουν την ενεργειακή ασφάλεια του Ηνωμένου Βασιλείου.

Συγκεκριμένα, τα OCGTs θα χρησιμοποιούνται κατά τη διάρκεια περιόδων αιχμής, όταν οι ανανεώσιμες πηγές ενέργειας δεν επαρκούν για την ασφαλή και αδιάλειπτη ηλεκτροδότηση, αλλά και υποστηρίζοντας την αυξημένη ζήτηση και τη σταθερότητα του δικτύου. Υπολογίζεται ότι κάθε μία μονάδα θα έχει τη δυνατότητα να παράγει αρκετή άμεση ηλεκτρική ενέργεια για να καλύψει τις ανάγκες 150.000 νοικοκυριών.

Βάσει του προγραμματισμού, οι εν λόγω μονάδες αναμένεται να τεθούν σε λειτουργία εντός του 2024.

Read the full article

0 notes

Text

SINAMICS G120 by Siemens: Achieve Seamless Automation

Siemens has developed the SINAMICS G120 Drive, which is a multi-purpose and high-performance drive solution for today’s industrial applications. When it comes to optimizing energy savings, enhancing motor control or maintaining a steady functioning of machines, then you should turn to this drive as it fits perfectly within these parameters.

Key Features:

Flexible Modularity: With its modular design, the G120 Drive enables you to personalize the system as per your specifications. To create a solution that meets your application needs find diverse power modules and control units and blend them.

Energy Efficiency: Consistent with its technical specifications, SINAMICS G120 embraces the cutting-edge innovation that reduces energy consumption to save on operational costs. In this way, the drive has been helpful in delivering variable speed levels while maximizing efficiency at the same time.

Safety Integrated: The SINAMICS G120 is built around the concept of safety first. This means that it has been made to offer maximum possible protection through its integrated safety functions such as Safe Torque Off (STO) and Safe Stop 1 (SS1) in order to provide you with an uninterrupted production process that is also secure.

Comprehensive Communication: The SINAMICS G120 can be seamlessly incorporated into your present automation environment. This drive’s various communication protocols which include PROFINET, PROFIBUS and EtherNet/IP enable simple and dependable data transfer.

User-Friendly Operation: The installation, commissioning, and maintenance of the SINAMICS G120 Drive are made easy by its friendly interfaces and simple software tools. Your operations will experience less downtimes and run more smoothly if you do this.

Applications:

The SINAMICS G120 Drive is ideal for various industries and uses, for example:

Pumping and Ventilation Systems: Optimizing energy consumption while controlling accurately both flow rates as well as pressures.

Conveyor Systems: In manufacturing and logistics operations, ensuring smooth and precise handling of materials is important.

Compressors and Fans: In HVAC, industrial refrigeration as well as air compression systems enhance efficiency levels and performance.

Material Processing: Ensure departments maintaining quality all the time perform extrusion mixing, milling so consistent quality and processes.

Why Choose SINAMICS G120?

When one opts for the SINAMICS G120 Drive they make an investment in a solution that is characterized by flexibility, energy efficiency and safety. It is an optimum choice for industries that want to enhance their automation systems and remain ahead of the pack in the game of competition. You can be sure of reliable performance of bounce back in those years through the SINAMICS G120 Drive from Siemens whose name stands for quality above all else.

Conclusion:

With the SINAMICS G120 Drive, you can upgrade your industrial processes and enjoy state-of-the-art motor control, energy efficiency and seamless integration features. If you are in need of reducing expenditures, increasing safety or raising operational effectiveness then SINAMICS G120 is the solution.

0 notes

Text

The role of outsourcing in the renewable energy industry

Outsourcing is a key strategy in the renewable energy industry, allowing companies to optimize their operations, reduce costs and access specialist knowledge. In this context, outsourcing covers a wide range of activities, from engineering and construction to the maintenance and operation of renewable energy facilities. Below we detail how outsourcing is shaping the renewable energy industry in various aspects.

1. Specialization and Expertise

Outsourcing allows renewable energy companies to leverage the experience and specialized knowledge of third-party contractors. In an industry that requires advanced technical skills, such as installing solar panels, building wind turbines and managing energy storage systems, having external specialists is crucial. For example, companies such as Siemens Gamesa and Vestas outsource the manufacturing of specific components of their wind turbines to specialized suppliers, thus guaranteeing the quality and efficiency of their products.

2. Cost Reduction

Outsourcing can result in a significant reduction in operating costs. By outsourcing specific tasks, companies can avoid the expenses associated with hiring and training specialized personnel, as well as investing in equipment and technology. This is especially important on large projects, where upfront costs can be prohibitive. For example, outsourcing the installation of solar panels to a specialized company can be cheaper than making the initial investment in your own personnel and equipment.

3. Flexibility and scalability

The ability to outsource allows renewable energy companies to scale their operations quickly in response to market demand. This is vital in an industry subject to fluctuations in demand and rapid technological evolution. For example, in periods of high demand for solar energy, a company can outsource to multiple installers to complete projects faster without having to permanently increase its employee headcount. This flexibility also allows companies to handle temporary spikes in work without compromising quality or efficiency.

4. Innovation and Technology

Third-party providers are often at the forefront of technological innovations. Outsourcing to these suppliers allows renewable energy companies to implement the latest technologies and innovative practices without having to invest in research and development internally. This is crucial in an ever-evolving industry, where keeping up with technological advances can mean the difference between success and failure. For example, outsourcing the development of energy storage systems to specialized companies allows renewable energy companies to benefit from the latest innovations in batteries and storage technology.

5. Complex Project Management

Outsourcing makes it easier to manage large and complex projects. Specialist outsourcing companies can take responsibility for specific areas of the project, such as logistics, construction and resource management. This allows the core company to focus on overall supervision and strategy, improving project efficiency. For example, in the construction of a wind farm, a company can outsource the installation of wind turbines to a specialized company, while focusing on obtaining permits and negotiating energy contracts.

6. Regulatory Compliance and Risk Management

Outsourcing companies typically have in-depth knowledge of local and international regulations related to the renewable energy industry. Outsourcing these experts helps ensure legal compliance and reduces the risk of sanctions.

0 notes

Text

Edge Computing Market: Exploring Growth Trajectory and Technologies 2024

The primary goal of Edge Computing market report is to assist clients in making informed business decisions. It guides them in identifying areas that require enhancement, recognizing those that are already flourishing, and supporting new participants as they establish and navigate the competitive landscape. The report also sheds light on the prevailing challenges within the Edge Computing market. The major players in the Edge Computing market are evaluated based on their product and service offerings, financial statements, key developments, strategic approach to the market, position in the market, geographical penetration, and other key features. The chapter also highlights the strengths, weaknesses, opportunities, and threats (SWOT analysis), winning imperatives and current focus strategies. Furthermore, the list of companies included in the market study can also be customized as per the client’s requirements.

The Edge Computing Market is expected to grow at 30% CAGR from 2024 to 2030. It is expected to reach above USD 106.04 billion by 2030 from USD 10.0 billion in 2023.

Full Report of the Edge Computing Market @:

Competitive Analysis:

In this section, we assess the competitive landscape of the Edge Computing Market, focusing on key players.

Key Players:

ABB, Amazon Web Services (AWS), Inc., Aricent, Inc., Atos, Cisco Systems, Inc., General Electric Company, Hewlett Packard Enterprise Development, Honeywell International Inc., Huawei Technologies Co., Ltd., IBM Corporation, Intel Corporation, Microsoft Corporation, Rockwell Automation, Inc, SAP SE Siemens AG

Market Segmentation:

In this section, we provide a breakdown of the Edge Computing Market into segments based on different criteria, including the type of analysis, industry verticals, and geographic regions.

Edge Computing Market By Component Type, 2020-2029, (Usd Billion)

Hardware Services

Software Services

Edge-Managed Platforms

Edge Computing Market By Vertical, 2020-2029, (Usd Billion)

Industrial

Energy & Utilities

Healthcare

Agriculture

Transportation & Logistics

Retail

Datacenters

Wearables

Smart Cities, Smart Homes, Smart Buildings

Edge Computing Market By Application, 2020-2029, (Usd Billion)

Iiot

Remote Monitoring

Content Delivery

Video Analytics

Ar/Vr

Other

Regional Analysis:

Geographically, this report is segmented into several key Regions, with production, consumption, revenue (million USD), and market share and growth rate of the Edge Computing Market in these regions, from 2024 to 2030 (forecast) covering:

Europe, China, Japan, Southeast Asia, India, North America (USA, Canada, and Mexico)

Europe (Germany, France, UK, Russia, and Italy)

Asia–Pacific (China, Japan, Korea, India, and Southeast).

** Access your free sample copy of this strategic report today@:

What Information does this report contain?

Historical data coverage: Growth Projections: 2024 to 2030.

Expert analysis: industry, governing, innovation and technological trends; factors impacting development; drawbacks, SWOT.

6-year performance forecasts: major segments covering applications, top products and geographies.

Competitive landscape reporting: market leaders and important players, competencies and capacities of these companies in terms of production as well as sustainability and prospects.

Edge Computing Market Size and Share Report 2023-2030 Table of Contents – Major Key Points

Introduction

Research Methodology

Market Dynamics

Impact Analysis

Value Chain Analysis

Porter’s 5 Forces Model

PEST Analysis

Edge Computing Market Segmentation, By Platform Type

Edge Computing Market Segmentation, By Ad Format

Edge Computing Market Segmentation, By Enterprise Size

Edge Computing Market Segmentation, By Industry Vertical

Regional Analysis

Company Profiles

Competitive Landscape

Conclusion

0 notes