#SURFACTANT

Explore tagged Tumblr posts

Text

Tweaking Coalescence

When a drop settles gently against a pool of the same liquid, it will coalesce. The process is not always a complete one, though; sometimes a smaller droplet breaks away and remains behind (to eventually do its own settling and coalescence). When this happens, it's known as partial coalescence. (Image and video credit: T. Dong and P. Angeli) Read the full article

#2022gofm#coalescence#coalescence cascade#fluid dynamics#instability#physics#Plateau-Rayleigh instability#science#surface tension#surfactant

51 notes

·

View notes

Text

PIPE-FREEING AGENTS AND SURFACTANT

In the dynamic world of oil and gas exploration, the efficiency and success of drilling operations are paramount. Amid the complexities of drilling through various geological formations, engineers and chemists have harnessed the power of specialized chemicals to overcome challenges. Two key players in this realm are pipe-freeing agents and surfactants, whose unique properties and applications significantly contribute to the optimization of drilling processes.

Pipe-Freeing Agents: Unleashing the Drill Pipe

Drilling for oil and gas often encounters a common adversary – the sticking of the drill pipe in wellbores. This phenomenon, known as differential sticking, arises from the formation of a filter cake on the wellbore wall. Enter pipe-freeing agents, also referred to as lubricants. These agents are designed to tackle this challenge head-on by modifying the properties of the drilling mud or fluid.

Friction Reduction The primary function of pipe-freeing agents is to reduce friction between the drill pipe and the wellbore. This reduction in friction is essential for maintaining the smooth movement of the pipe, preventing costly delays and potential damage.

Filter Cake Modification Pipe-freeing agents alter the composition and characteristics of the filter cake that forms on the wellbore wall. By doing so, they mitigate the risk of differential sticking, ensuring that the drill pipe can move freely through the wellbore.

Lubrication Acting as effective lubricants, these agents ensure the seamless and efficient movement of the drill pipe. In challenging drilling conditions, where forces can impede progress, lubrication becomes a crucial factor in maintaining operational momentum.

Surfactants: The Versatile Solution in Drilling Fluids

Surfactants, with their unique amphiphilic structure, find widespread use in drilling fluids within the oil and gas industry. Their ability to interact with both water and oil makes them versatile players in addressing various challenges associated with drilling operations.

Emulsification Surfactants play a crucial role in breaking down or stabilizing emulsions within drilling fluids. This property improves the overall stability and performance of the fluid, contributing to efficient drilling.

Wetting Enhanced wetting properties of drilling fluids are achieved through surfactants. This ensures better coverage on solid surfaces, promoting improved drilling efficiency.

Foaming/De-foaming Controlling the formation and elimination of foam in drilling fluids is vital for maintaining stability. Surfactants are adept at managing foam levels, preventing issues that can hinder drilling progress.

Cleaning Surfactants assist in the removal of contaminants from surfaces within the drilling system. This cleaning action contributes to the overall effectiveness and cleanliness of the operation.

Conclusion

In the ever-evolving landscape of oil and gas exploration, the role of pipe-freeing agents and surfactants is not only pivotal but transformative. These chemical marvels, with their ability to address challenges ranging from pipe sticking to emulsion stability, are indispensable tools in the hands of drilling professionals. As technology and chemical engineering continue to advance, the development of novel formulations and the strategic application of these agents will undoubtedly remain at the forefront of efforts to optimize drilling processes and ensure the sustainability of oilfield operations.

#PIPE-FREEING AGENTS AND SURFACTANT#PIPE-FREEING AGENTS#SURFACTANT#Universal Drilling Fluids#drillings fluids

3 notes

·

View notes

Text

TSRNOSS, p 801.

#hyperlipidemia#food flavours#detoxification#vitamin A deficiency#vitamin D deficiency#hallucinogens#secondary metabolites#surfactant#capillarity in soils#lithium#hydrogen ion#hydration shell#transpiration#stomata#plant spores#species diversity in the tropics#urea#fish blood

0 notes

Text

From cosmetics to steel manufacturing, SHREE VALLABH surfactants play a crucial role across diverse industries! Our high-performance surfactants are trusted for their versatile applications as antistatic agents, plasticizers, detergents, scouring agents, dispersants, solubilizers, wetting agents, and leveling agents. Experience the power of innovation with solutions that deliver results every time!

For more information, visit - https://www.shreechem.in/fatty-alcohol-ethoxylate

#ShreeVallabhChemical#surfactant#antistatic#Plasticizer#detergent#scouringagent#solubilizer#wettingagent#levelingagnet#dispersants

0 notes

Text

Oilfield Surfactants Market - Forecast(2024 - 2030)

Oilfield Surfactants Market Overview:

Oilfield Surfactants Market Size is forecast to reach $2044.1 Million by 2030, at a CAGR of 4.5% during forecast period 2024-2030.The global market for Oilfield Surfactants was estimated at $2044.1 million in 2030 and is predicted to witness robust and accelerated growth in the coming years, especially in the oil producing countries such the US, China and members of the OPEC. Demand for oilfield surfactants has grown since the need for chemicals in sustainable oil exploration, extraction and production has skyrocketed as witnessed in the rigorous EOR (Enhanced Oil Recovery) activities. Furthermore, there has been a growing interest in the bio-based oil surfactants, although being a niche market, for its environment friendly effects that can counter-act the wide environmental concerns about the oil and gas industries.

Oilfield Surfactants Market Outlook:

Oilfield surfactants are chemicals that effectively lower the surface tension between a fluid and a solid or between various fluids. Oilfield surfactants have various physical and chemical properties that can be exploited in the stages of drilling, production, refining, enhanced oil recovery and stimulation. Its applications vary from asphaltene dispersants, corrosion inhibition, emulsifiers, demulsifier intermediates, oil-wetters, paraffin inhibitors, water-wetters, foamers and defoamers. The type of surfactant behavior is dictated by the chemical structure, specifically the structural groups on the molecule). The oilfield surfactant market is segmented based on the stage of application such as drilling, production and stimulation as well as its applications as mentioned above.

Request Sample

Oilfield Surfactants Market Growth drivers:

Global oil and natural gas production has been increasing steadily since the last decade with oil production recording 92.6 million barrels per day (BPD) with US being the largest oil producing country in the world. These statistics imply that as oil production, extraction and exploration activities increase, there is clearly a huge growth potential for oilfield surfactants to meet this large demand capacity. Surfactants such as emulsifiers, demulsifiers, biocides etc. would highly in demand at various stages of drilling, production and stimulation in oilfields. In addition, as the world plans to move towards a more sustainable and environment friendly future, bio-based oilfield surfactants would be in high demand. Enhanced Oil Recovery (EOR) is gaining increasing popularity in the oil industry as it cuts costs and maximizes yield, and thus this could clearly boost the Oil Surfactants market as EOR is only possible due to the usage of such surfactants.

Oilfield Surfactants Market Challenges:

The prime challenge faced by the Oilfield Surfactants market is the dangerous carbon footprint that the oil and gas industries leave behind in the world’s atmosphere. The use of fossil fuels has always been criticized and many developed countries in the EU planning to phase out their energy dependence on oil and natural gas. Growing environmental concerns about oilfield production levels coupled with massive oil spills are the major challenges to the Oilfield Surfactant market.

Inquiry Before Buying

Oilfield Surfactants Market Research Scope:

The base year of the study is 2017, with forecast done up to 2023. The study presents a thorough analysis of the competitive landscape, taking into account the market shares of the leading companies. It also provides information on unit shipments. These provide the key market participants with the necessary business intelligence and help them understand the future of the Oilfield Surfactants market. The assessment includes the forecast, an overview of the competitive structure, the market shares of the competitors, as well as the market trends, market demands, market drivers, market challenges, and product analysis. The market drivers and restraints have been assessed to fathom their impact over the forecast period. This report further identifies the key opportunities for growth while also detailing the key challenges and possible threats. The key areas of focus include the types of plastics in the Oilfield Surfactants market, and their specific applications in different types of vehicles.

Oilfield Surfactants Market Report: Industry Coverage

Oilfield Surfactants–By Class of Substrate: Synthetic and Bio-based

Oilfield Surfactants– By Application: Drilling, Stimulation and Stimulation

Oilfield Surfactants– By Surfactant Class: Non-Ionic, Anionic, Cationic, Polymeric, Amphoteric and others

The Oilfield Surfactants market report also analyzes the major geographic regions for the market as well as the major countries for the market in these regions. The regions and countries covered in the study include:

North America: The U.S., Canada, Mexico

South America: Brazil, Venezuela, Argentina, Ecuador, Peru, Colombia, Costa Rica

Europe: The U.K., Germany, Italy, France, The Netherlands, Belgium, Spain, Denmark

APAC: China, Japan, Australia, South Korea, India, Taiwan, Malaysia, Hong Kong

Middle East and Africa: Israel, South Africa, Saudi Arabia

Schedule a Call

Oilfield Surfactants Market Key Players Perspective:

Some of the Key players in this market that have been studied for this report include: CP Kelco Oil Field Group, Huntsman Corporation, Croda International PLC, Weatherford International, Stepan Company, Enviro Fluid, Rimpro-India, Evonik Industries AG, Flotek Industries and others

Market Research and Market Trends of Oilfield Surfactants Market

Researchers at the University of Houston discovered an innovative technique using nanotechnology to maximize oil recovery from oil wells, as oilfields yield only 30-35% on average. The researchers have developed a graphene amphilic nanosheet designed from Janus nanoparticles that could aid in tertiary oil recovery. If producers can unlock this untapped potential, the crude oil supply could be boosted and could drive the selling price lower.

According to the 2018 BP Statistical Review of World Energy global oil production hit a record of 92.6 million barrels per day (BPD). This large increase in oil production levels would indicate a large demand for oilfield surfactants in the oil and gas industries.

Based in Texas, U.S, Huntsman Corporation is a global key player with a significant market share in the oilfield surfactant market. Huntsman Corporation recently acquired Nanocomp Technologies Inc., a company specialized in manufacturing advanced carbon materials based in New Hampshire, USA. Its popular product is an advanced carbon-based material branded as Miralon, which could have potential use in corrosion inhibition and can lead to a new class of nanomaterial based oilfield surfactant.

Buy Now

Key Market Players:

The Top 5 companies in the Oilfield Surfactants Market are:

Exxon Mobil

Arlanxeo

Sibur International

Reliance Industries

BRP Manufacturing

#surfactant#oilfield chemicals#oilfield surfactant#oil field surfactant#suspending agents#oilfield surfactant industry#oilfield surfactant market#oilfield surfactant companies#cationic surfactants market#Fatty Alcohol Ethoxylate#Fatty Acid Ethoxylate#Silicon Oil Emulsifier#oilfield surfactants market size

0 notes

Text

"Introduction To Paper Marbling - Making A Custom Design For Dune"

youtube

1 note

·

View note

Text

Chemical Products---Chemical Raw Material Sles70% Detergent Solvent N70 (Sles 70)

AES, or Ammonium Laureth Sulfate, is a widely used surfactant and foaming agent in personal care and household cleaning products. It is derived from ethoxylated lauryl alcohol and sulfated with ammonium ions. AES is valued for its excellent cleansing properties, ability to create rich lather, and its relatively mild nature compared to other sulfates. It is commonly found in shampoos, body washes, hand soaps, and household cleaners, where it helps to remove dirt, oil, and other impurities effectively. AES is favored by manufacturers for its versatility and compatibility with various formulations, contributing to its widespread use in the consumer goods industry.

1 note

·

View note

Text

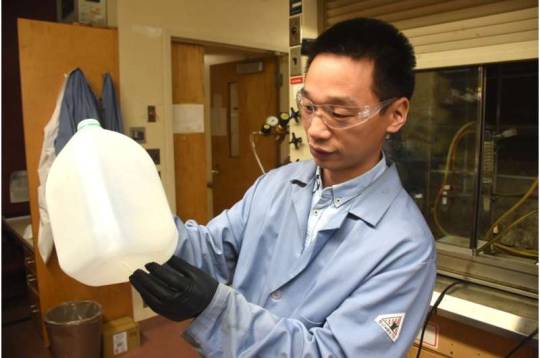

Researchers develop method for upcycling plastic waste into soap

A team led by Virginia Tech researchers has developed a new method for upcycling plastics into high-value chemicals known as surfactants, which are used to create soap, detergent, and more. The work was published in Science. Plastics and soaps tend to have little in common when it comes to texture, appearance, and, most importantly, how they are used. But there is a surprising connection between the two on a molecular level: The chemical structure of polyethylene—one of the most commonly used plastics in the world today—is strikingly similar to that of a fatty acid, which is used as a chemical precursor to soap. Both materials are made of long carbon chains, but fatty acids have an extra group of atoms at the end of the chain. Guoliang "Greg" Liu, associate professor of chemistry in the Virginia Tech College of Science, had long felt this similarity implied that it should be possible to convert polyethylene into fatty acids—and with a few additional steps to the process—to produce soap. The challenge was how to break a long polyethylene chain into many short—but not too short—chains and how to do it efficiently. Liu believed there was the potential for a new upcycling method that could take low-value plastic waste and turn it into a high-value, useful commodity.

Read more.

111 notes

·

View notes

Text

Lasers and Soap Films

Soap films are a great system for visualizing fluid flows. Researchers use them to look at flags, fish schooling and drafting, and even wind turbines. In this work, researchers explore the soap film's reaction to lasers. (Image and research credit: Y. Zhao and H. Xu) Read the full article

#elasticity#flow visualization#fluid dynamics#laser#marangoni effect#physics#science#shockwave#soap film#surface tension#surfactant

71 notes

·

View notes

Text

2-Methyl-2,4-pentanediol, is a widely used diol, colorless and tasteless, completely miscible with water, solubility of advanced organic solvents, can be used in the production of metal surface treatment agents to remove rust and oil additives, textile auxiliaries, coatings and latex paints, cosmetics, used as a pesticide stabilizers outside of the daily moisturizing agent, flavors and fragrances raw materials, hydraulic oil, high-temperature lubricating oils, brake fluids, dry cleaning agents,Printing ink, pigment dispersant, wood preservative and so on. It can be used as penetrating agent, emulsifier and antifreeze.

17 notes

·

View notes

Text

TSRNOSS, p 572.

#surfactant#paraffin#absorption of radiation#gamma radiation#albedo#RBE#deuterium oxide#lithium#neutron absorption#cosmic radiation#tuberculosis#eskimoes#thiamine deficiency#psychosis#redwoods#typhus#enzymes#rotational energy#hemoglobin#diffusion rate of hemoglobin#infrared radiation

0 notes

Text

proud to say the anti-sulfate fearmongers never got me I’d scrub my shit with dawn if I could

#I 🫶 SURFACTANTS#technically you very much can scrub your shit with dawn. like it’s soap it’ll clean your head. it’s just a little excessive

3 notes

·

View notes

Text

At Shree Vallabh Chemical, we don't just supply products - we provide solutions. With a strong focus on quality, innovation, and customer satisfaction, we go the extra mile to understand your needs and deliver tailor-made solutions quickly and efficiently. Backed by years of expertise, cutting-edge R&D, and state-of-the-art manufacturing, we ensure cost-effective products that meet the highest standards. Let us be your trusted partner for success

For more information, visit - https://www.shreechem.in/

#ShreeVallabChemical#surfactant#polysorbates#phosphateesters#surfactantsmanufacturer#ETHOXYLATES#AlkylPhenolEthoxylates#chemicals

0 notes

Text

Of all the damn hobby rabbitholes to fall down, it’s not fountain pen collection that gotten to me. It’s fountain pen ink formulation. Which is not a hobby I need to be getting into right now. But the thought of making my friends custom ink is soooo tempting.

#but the pretty COLORS#and i have procion dye powders in my fucking bathroom#and some automotive-grade colorshifting pigment powders???#so like. i have many of the necessary materials at my fingertips#i just need some preservatives for shelf-life purposes and some surfactants or thickeners for adjusting the flow#which. dish soap will tide me over for a surfactant and i can try gum arabic#and get some cosmetic-grade biocides for the shelf-life problem

15 notes

·

View notes