#Road Tanker equipment

Explore tagged Tumblr posts

Text

Welcome to Liquip Victoria – Victoria’s specialist Road Tanker equipment installer and parts distributor. We’re also an industry leader in the design and supply of bulk fuel storage tanks, dispensing and transfer solutions. Contact Info:-

Phone No - (03) 9311 7822

Email : [email protected]

1 note

·

View note

Text

Installation of 40 cubic metre electrically heated asphalt tank and heating rods in Greece.

The customer is a Greek supplier of road construction equipment. They specialize in providing top-quality asphalt tanks, asphalt plants, spreader trucks, and other related products. Recently, they approved our offer for a 40 cubic meter electrically heated asphalt tank and have finally decided to purchase it.

We take great pride in being selected as their trusted supplier, and we are committed to delivering the highest quality products possible. Our team of experts has worked tirelessly to ensure that our asphalt tank meets all of the customer's specifications and requirements. We look forward to continuing our partnership with this valued customer and providing them with exceptional service and support throughout their project.

#asphalt tanker#asphalt tanks#asphalt tank#asphalt tankers#asphalt storage plants#asphalt storage#asphalt storage tank#bitumen tanker#bitumen tanks#bitumen tank#road construction#asphalt mixing plant#bitumen#heavy equipment#construction#asphaltplant#mobile asphalt drum mix plant#concrete#asphalt plant#asphalt drum mix plant

1 note

·

View note

Text

Water Tank Manufacturer in Dubai, UAE | Chemical Tanker Trailer

Water Tank Manufacturer in Sharjah, Dubai, UAE is a manufacturer & exporter of transport equipment. We have expertise in Chemical Tanker Trailer, Tank Semi-Trailer, and Bitumen Tanker Trailer. Freezer Truck Manufacturers is a leading supplier of reliable and efficient Refrigerated Truck Body Manufactures in Sharjah, Dubai, UAE.

Fuel Semi-Trailer & Truck Mounted Tankers

1. Truck Mounted & Semi-Trailer Options

2. Capacity: 1000-19000 IG

3. Thoroughly welded Mild Steel construction

4. PTO-driven pump / flow meter/hose reel with the dispensing system (optional)

5. Suitable for top loading/ bottom loading with an overfill protection system

6. External coating - epoxy paint system in single color of client’s choice

7. Internal coating - to suit content (optional)

8. Multi-compartment options available

Water Tankers

1. Truck Mounted & Semi-Trailer Options

2. Truck-mounted MS and SS

3. Fuel tanker semi-trailer & Water Tank Manufacturer

4. Capacity: 750-15000 IG

5. Thoroughly welded Mild Steel construction

6. Internal coating – tank lining with special epoxy paint.

7. External paint- epoxy paint system of the client’s choice

Vacuum Tankers

1. Truck Mounted & Semi-Trailer Options

2. Capacity: 1000-8000 IG

3. Mild Steel welded construction

4. Mechanical/Hydraulic Fully opening rear door with security clamps

5. PTO/ separate engine-driven vacuum pump from Europe

6. Internal coating - coal tar epoxy system

7. External finish - epoxy paint system in a single color of the client’s choice

For more details visit our website: Truck Mounted Tanker

CONTACT US:

TUSKER CHV

Tusker Engineering FZC

Hamriya Free Zone, Phase-2

P.O. Box 51538, Sharjah, UAE

Call: +97165269282

Gmail: [email protected]

#road tanker UAE#truck mounted tanker UAE#tanker trailer UAE#water tank manufacturer in UAE#transport equipment UAE

0 notes

Text

SAC Crew Dog Shenanigans: A Cruel Prank on the Aircraft Commander

It was late May in 1989, a time of year when the sun barely goes down in Fairbanks Alaska. Our crew, R-122, with the 42d Air Refueling Squadron, had flown from our home base, Loring AFB, Maine, to Eielson AFB, Alaska in our KC-135 A model for an Alaska Tanker Task Force tour.

The Strategic Air Command (SAC) was still in control and the KC-135s still used “hard crews.” That meant, you got put on a crew and you stayed there. They were the only people you really flew with. You got to know them well, for better or worse.

We were a young crew, the Aircraft Commander (AC) was a newly assigned Captain who’d previously been a FAIP (First Assignment Instructor Pilot). FAIP went straight to the left seat and never flew as copilots. Our Copilot, who was more experienced than the AC, had around 1,000 hours. The Navigator and I were pretty green, only being recently qualified. Three Officers, AC was a Captain, the Copilot was a 1st Lieutenant and the Nav was a 2nd Lieutenant (or Butter Bars as we called them.) I was a lowly A1C, Airmen First Class.

After arriving, we settled in, getting all our localization briefings. These were so that we knew what we could and could not do while in town, both operationally and just in general. Stay away from the moose which were taking care of their newly born calves, don’t mess with the bears, avoid a DWI at all costs, and of course, don’t screw up any airplanes. We were staying at the BOQ, or quarters, on base for the TDY crews and the one thing I noticed about our quarters was the blackout curtains in all the rooms. We found out, over time, they were definitely needed. Another thing we found out; the unofficial State Bird of Alaska is the Mosquito. Those things were brutal.

Getting around on base wasn’t a big deal as you could usually get a ride, but getting off base could be a problem. There was a “shared” vehicle that a local Boom Operator maintained for the crews to borrow. It was a beat-up old station wagon with wood paneling and sharks’ teeth painted on the front fenders, like they do on fighter aircraft. It worked, if it was available, but demand was high.

We were allowed to take an Air Force vehicle, usually an AF blue 4-door pickup truck, but there were restrictions because it was an “Official” vehicle. One of the more important rules was that you could not park at a bar. Sneaky aircrews had figured out a way to get around this rule. While you couldn’t park at a bar, you could park at a restaurant that happened to have a bar. This was our loophole.

One day, we ventured out around town. The guys wanted to sample the local cuisine, so we found a place with freshly caught and cooked salmon for lunch. Then, we drove up the road to visit the “North Pole”, not the real one, but a very small town north of the base that took about two minutes to drive through. Remember that Garth Brooks song, “Nobody Gets Off In This Town”? Pretty much described the entire area, with one exception… most people actually like it up there, even with all the hardship.

One of the things that amazed us while we were driving around was how much junk was laying around. Along the highways you could see piles of cars, airplanes, equipment and just plain junk, but the scenery was still awe inspiring, even with all the trash.

Towards the evening, we decided to head to a local restaurant that “happened” to have a bar. We planned on having dinner and then over to the bar for a few drinks, maybe even finding some suitable company. Well, most of us anyways, the AC was married and a pretty strait-laced guy, so he was just enjoying the scenery.

Driving under the influence of alcohol was a very big no-no, and the Air Force was really cracking down around that time. A DWI was a career ender for officers and enlisted alike. So, I was elected to be the Designated Driver. It was tradition that the Boom Operator drove and the Officers liked to be chauffeured around. This night, I didn’t mind not being able to drink and was happy to drive the crew around.

So, we sit down to eat, and everybody orders beers, Coronas to be precise, and the conversation turns to drinking stories. I’m not sure why he wanted to tempt fate, but the AC started bragging that he had never been drunk. He drank, he wasn’t a teetotaler, but he’d never gotten drunk.

The Copilot, who was a bit of a prankster, took this as a challenge. So he decided that the AC had waited long enough. He left the table, and grabbed our waitress ask her to add a shot of vodka to every beer given to the AC. She obviously didn’t have a problem with it. Our poor commander never suspected a thing.

Fast forward an hour or two and our prim and proper AC is lit up like a Christmas tree. So much so, he asked me for the keys to our pickup so he could go pass out. Thinking it was unlocked, I told him so, and off he went stumbling out to the parking lot. Unfortunately (for him), I was wrong, the truck wasn’t unlocked, but he was so drunk he decided to just pass out in the bed of the truck. Of course, before he passed out, he’d gotten sick and threw up all over the side of our nice clean, blue “Official” Air Force pickup. Remember that salmon we’d had for lunch, yup, the side of the truck was covered with it. Pink shows up really well on blue.

A few hours later, with the sun still lighting up the sky, we come out and discover him, wake him up, razz him for a bit, and climb in the truck to head back to the BOQ. He takes the normal AC seat when driving, which is the front right seat, with the Nav and Copilot in the back, and, still drunk as a skunk, proceeds to constantly ask us what happened. A few minutes into the drive, a moose walked out on the road ahead of us, but we were in no danger of hitting it. It was still several hundred yards in front of us, but our fearless leader started screaming “Watch out for the moose, watch out for the moose”. Nearly scared me right off the road. He spent the rest of the ride apologizing like only drunks can. He kept saying, “I ate dinner, and I only had a few beers, why am I so drunk?”

He was thoroughly confused and a bit embarrassed for the next few days. He was constantly asking us what had happened and how he had gotten so drunk. He really had no clue. Finally, feeling bad for him, I let him know what had happened. His reaction was priceless, but he really was a good sport about it. He did vow to return the favor to our mischievous Copilot, but in the end, he never got his revenge. Fortunately, he didn’t hold a grudge either.

We had a great six weeks on that trip with many accomplishments. We were able to go to Shemya AFB, on the Alaskan Aleutian Islands. While there we got to fly on an RC-135S, and the AC was able to get his first experience at Receiver Air Refueling. Later, we flew a Russian Bear Bomber intercept mission, and then on the day before my birthday, we flew a mission over the International Date Line, so I got to experience my 21st birthday twice.

We returned to Loring six weeks later, having learned a lot about ourselves, our aircraft, and our jobs.

Note: I didn't take any pictures on this trip, I don't think I even owned a camera at the time, so I've included some relevant patches.

@tcamp202 via X

4 notes

·

View notes

Text

My Life Story

Hello Everyone I Hope this message finds you well. I wanted to take a moment to share a glimpse of my life's journey—a journey that began on an Alberta farm and has led me down a winding path filled with challenges, accomplishments, and change.

At the tender age of 4, my mother introduced me to the world of machinery, teaching me to shift gears in our trusty old five-ton grain truck as we chased cattle across the vast expanse of the Battle River pasture area. Those early lessons ignited a lifelong passion for farming, trucking, and a myriad of other skills that farming life demands.

After graduating from Paradise Valley High School, I embarked on a journey that took me from the farm to the world of drilling rigs. I split my time between working on the rigs and helping out on the farm whenever I could—a balancing act that taught me valuable lessons in time management and hard work.

However, life has a way of presenting unforeseen challenges. The world of drilling rigs was soon overshadowed by personal hardships. The passing of my beloved mother due to cancer was a heart-wrenching chapter in my life, and it was followed by the emotional toll of a divorce.

In search of better opportunities and a fresh start, I made the pivotal decision to leave Alberta behind and venture to British Columbia. There, I delved into the world of logging, exploring the beautiful landscapes of Williams Lake, Quesnel, 100 Mile, Prince George, and Mackenzie, often navigating off the beaten path. Logging was physically demanding, but it brought a profound sense of accomplishment.

Yet, the call of the oilfields in Fort St. John beckoned me back. The allure of steady work and financial stability led me to return to the world of tanking. It was a decision that allowed me to regain my footing, secure my future, and thrive in the industry.

Throughout my life, I've worn many hats—trucker, equipment operator, mechanic, gardener, and more. I've spent countless nights sleeping in my truck and embraced the camaraderie of life in remote camps. These experiences have shaped me, but as time passes, I find myself ready for a change.

This is why I've decided to part ways with my tanker, side dump, and soon, my meticulously rebuilt 2003 378 Peterbilt Winch Tractor. Each of these vehicles represents a chapter in my life—a chapter of hard work and dedication.

In closing, I want to express my gratitude for being a part of my journey. The road has been long and filled with twists and turns, but it has also been a journey of growth and resilience. As I step into this new phase of life, I'm excited to see where the road leads next.

5 notes

·

View notes

Text

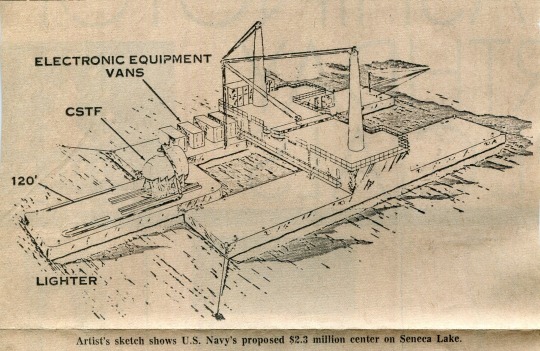

Sounding out the naval barge on Seneca Lake

By Jonathan Monfiletto

The next time you are driving along Seneca Lake, on State Route 414 along the eastern shore or – if you are traveling through Yates County – State Route 14 along the western shore, gaze into the middle of the lake and see if you find an interesting-looking platform floating on the surface. It shouldn’t be too hard to find, but you might wonder just what you are looking at.

This platform is, in fact, a barge anchored in the middle of Seneca Lake off the shore at Dresden. Indeed, the operation is officially known as the Seneca Lake Sonar Test Facility under the auspices of the Naval Sea Systems Command and the Naval Undersea Warfare Center of Newport, Rhode Island. Though it appears only civilian employees work there and no military personnel are stationed there, one could say this facility represents the only presence of the U.S. Navy existing in the Finger Lakes.

According to its website, the Seneca Lake Sonar Test Facility does just that – performing tests and evaluations of equipment to include sonar arrays and systems – and is known for its massive lift and power capabilities. Acoustic testing professionals carry out tests on systems and equipment of all sizes, even an entire sonar suite mounted in its sonar compartment.

Because it is a deep freshwater lake that is open all year, Seneca Lake is the Navy’s primary site for active instrumented calibration and testing. The fairly constant and predictable weather and water conditions of Seneca Lake also make it a choice testing site. It is known for its testing and evaluation of major projects that require relatively deep water with fixed underwater geometry and capabilities for heavy load-handling and electrical power.

Located about a mile and a half from the Dresden shore, the facility consists of two barges – the Systems Measurement Platform and the Remote Calibration Platform – that are the primary measurement and calibration resources. Two equipment-handling barges and numerous transport boats serve the facility, and there are machining and fabrication capabilities on the site to repair or manufacture the equipment and gear being tested.

The facility has been used by the Department of Defense, Department of the Navy, universities, foreign governments, state and local agencies, and private industry. And it has been a part of the Dresden landscape and lakeshore for more than 60 years.

It all began in November 1961, when the original barge – a converted oil tanker measuring 165 feet long and 36 feet long – arrived in Seneca Lake from Miami, via the inland waterway, Hudson River, and Barge Canal. During the heyday of the Cold War, as America furthered its research and development of anti-submarine warfare, the barge was purposed to test advanced sonar equipment designed to detect underwater craft. The barge was a key unit in establishing an anti-submarine acoustics research facility, headed by General Dynamics/Electronics.

The company leased a site at Dresden that provided 180 feet of lakefront – with construction of docking and service facilities to begin soon, according to an October 1961 newspaper article – along with a county road serving the property that would allow access to the facility throughout the year. Seneca Lake was chosen because its 600-foot depth makes it one of the deepest lakes in the country and – with the exception of the Great Lakes – the deepest lake with direct access to the Atlantic Ocean. It also has temperature gradients similar to those in the Atlantic Ocean, meaning sonar tests could be correlated to ocean conditions. The waves on the lake aren’t high enough to interfere with barge operations, and since the lake rarely freezes tests can be conducted throughout the year.

The original barge was equipped with a diesel-driven, 200-kilowatt generator to supply electric power to its electronic equipment, a capacity that was later increased to 400 kilowatts. The barge’s hulls had several ballast tanks, with water pumped out of or into the tanks to raise or lower the height of the deck above water.

Initially, the barge was designed to test then-recently-developed transducers weighing as much as 35 tons. These transducers convert electrical energy into acoustic energy, sending sound signals through the water that bounce off an intended target with an echo that can be recorded and analyzed. For test operations, the barge was to be manned by three engineers working under the direction of a manager.

In 1965, the Navy began leasing the Dresden Marina – with 4.5 acres of land and 900 feet of lakefront – for $20,000 per year with an option to buy the marina for $125,000. As a result of this move, owners of boats and crafts docked at the marina were forced to remove them from the marina and find new facilities to store them. Those with mobile homes located on the hill above the docks also had to vacate the premises. Another result was the Navy expanding its research facilities on Seneca Lake through an investment of $500,000. The improvements included completely fencing in the installation since much of its research work dealing with sound and sonar equipment is classified.

An undated newspaper article – handwritten with “1967,” though the exact date is unclear – indicates the Navy bought the marina a couple of years later for $166,000 and took it over outright. That year, Albert Gatthardt, of the Washington Naval Research Center, spoke before a jointing meeting of the Seneca Falls and Waterloo Rotary Clubs and detailed the history of the Naval Research Laboratory and its recent developments and improvements.

Alternately known as the Seneca Underwater Test and Evaluation Center, the facility was profiled in a July 1968 newspaper article on the occasion of the barge’s conversion from diesel power generated aboard to being powered by an electrical cable from the shore. The change permitted the barge – referred to in the article as DARIUS, though it is unclear what that stands for – to test the largest underwater sonar sound sources.

The following year, the Navy announced a $2.2 million expansion of the research facility on Seneca Lake, making it “the newest, largest, and best underwater research center in the country.” Plans called for using the existing barges plus a new systems measurement platform measuring 195 feet long, 120 feet wide, and 9 and a half feet deep, with a crane capable of lifting 200 tons. The expansion would continue the Navy’s research into sound transmission, travel, and reception underwater, light transmission and reception, underwater radio communications, development of new oceanographic tools and techniques, and underwater tests in the field physics.

As of February 1969, the facility employed eight permanent employees – a number expanded by 10 or 20 visiting technicians, engineers, and scientists. With the expansion anticipated to finish in the summer of 1970, plans called for 15 permanent employees with a capacity for 40 people visiting and working on the site.

By September 1970, work on the expansion had fallen behind but was mostly complete, and the facility continued testing equipment on Seneca Lake. More than 50 years later, the Navy still has a presence in the Finger Lakes, and it is one you can see from the road or the shore.

#history#historyblog#local history#american history#us history#yatescounty#newyork#dresdenny#navy#usnavy

2 notes

·

View notes

Text

Virtual Pipeline Systems Market Size, Share, Trends, Growth Opportunities and Competitive Outlook

"Global Virtual Pipeline Systems Market – Industry Trends and Forecast to 2028

Global Virtual Pipeline Systems Market, By Type (Ordinary Type, Special Type), Product (Liquefied Petroleum Gas (LPG), Liquid Natural Gas (LNG), Compressed Natural Gas (CNG), Propane, Diesel and Oils), Container Size (Type I, Type II, Type III, Type IV), Mode of Transportation (Intermodal ISO Tank Containers, Tanker Rail Cars, Pipeline Transport, Reticulated Gas System or Piped Gas System, Road Tankers, Local Bobtail Tankers), Application (Industrial, Transportation, Commercial and Residential), Country (U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, France, Italy, U.K., Belgium, Spain, Russia, Turkey, Netherlands, Switzerland, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, U.A.E, Saudi Arabia, Egypt, South Africa, Israel, Rest of Middle East and Africa) Industry Trends and Forecast to 2028

Access Full 350 Pages PDF Report @

**Segments**

- **By Component:** The virtual pipeline systems market can be segmented based on components into compressors, trailers, cylinders, valves, fittings, and others. Compressors play a crucial role in the transportation of natural gas, enabling it to be moved efficiently through pipelines. Trailers are used for the physical transportation of compressed natural gas (CNG) or liquefied natural gas (LNG) to areas without access to pipelines. Cylinders are another essential component, providing storage for the transported gas. Valves and fittings ensure smooth operations and safe handling of the gas in the virtual pipeline system.

- **By Application:** In terms of applications, the virtual pipeline systems market can be categorized into industrial, transportation, commercial, and residential sectors. The industrial sector utilizes virtual pipelines for various operations such as heat generation, power generation, and manufacturing processes. The transportation sector relies on virtual pipelines to fuel vehicles, especially in regions where traditional pipelines are not feasible. The commercial and residential sectors use virtual pipeline systems for heating, cooking, and other energy needs.

- **By Mode of Supply:** Virtual pipeline systems can also be segmented by the mode of supply, which includes truck-based transportation, rail-based transportation, and ship-based transportation. Truck-based transportation is the most common mode, offering flexibility and scalability in delivering natural gas to remote locations. Rail-based transportation provides a cost-effective solution for long-distance gas transportation. Ship-based transportation involves the use of tankers for transporting LNG to areas inaccessible by land.

**Market Players**

- **GE Oil & Gas:** GE Oil & Gas is a key player in the virtual pipeline systems market, offering a range of solutions for the compression, transportation, and storage of natural gas. The company's expertise in industrial equipment and services makes it a reliable partner for virtual pipeline projects.

- **Hexagon Composites ASA:** Hexagon Composites ASA specializes in high-pressure composite cylinders for gas storage, making them a significant player in the virtual pipeline systems market. TheirGE Oil & Gas and Hexagon Composites ASA are two key players in the virtual pipeline systems market, each bringing unique strengths and capabilities to the industry. GE Oil & Gas stands out for its comprehensive solutions for compression, transportation, and storage of natural gas. With its expertise in industrial equipment and services, the company offers a broad range of offerings that cater to the diverse needs of virtual pipeline projects. GE's reputation for reliability and innovation positions it as a trusted partner for implementing virtual pipeline systems across various sectors.

On the other hand, Hexagon Composites ASA specializes in high-pressure composite cylinders for gas storage, a critical component in virtual pipeline systems. The use of advanced composite materials in their cylinders enables Hexagon to provide lightweight and durable storage solutions for transporting natural gas efficiently and safely. The company's focus on innovation and sustainability in gas storage technologies has solidified its position as a significant player in the virtual pipeline systems market. Hexagon's expertise in high-pressure cylinders aligns with the increasing demand for reliable and high-performance storage solutions in virtual pipeline applications.

As the virtual pipeline systems market continues to grow, players like GE Oil & Gas and Hexagon Composites ASA are poised to capitalize on the increasing demand for efficient and flexible gas transportation solutions. The market trends indicate a rising adoption of virtual pipelines across various sectors, driven by the need for reliable energy supply in remote locations and areas without access to traditional pipelines. The versatility of virtual pipeline systems in industrial, transportation, commercial, and residential applications further expands the market potential for key players like GE and Hexagon.

In terms of competition within the virtual pipeline systems market, companies like GE Oil & Gas and Hexagon Composites ASA differentiate themselves through technological advancements, product innovation, and strategic partnerships. Establishing strong relationships with customers and industry stakeholders is essential for driving growth and expanding market presence. Furthermore, addressing evolving regulatory requirements and sustainability concerns will be crucial for staying competitive in the dynamic virtual pipeline systems market.

Overall, the market outlook for virtual pipeline systems remains**Global Virtual Pipeline Systems Market Analysis:**

- **Segments:** - **By Component:** Virtual pipeline systems market components include compressors, trailers, cylinders, valves, fittings, and others. Compressors are essential for efficient gas transportation, while trailers are used for physical gas transportation to areas without traditional pipelines. Cylinders provide storage for the transported gas, with valves and fittings ensuring smooth operations and safe handling within the system.

- **By Application:** Market applications cover industrial, transportation, commercial, and residential sectors. Industrial operations utilize virtual pipelines for heat and power generation, transportation for vehicle fueling, and commercial/residential sectors for heating and cooking purposes.

- **By Mode of Supply:** Segmentation by the mode of supply includes truck-based, rail-based, and ship-based transportation. Truck-based transportation offers flexibility and scalability, rail-based is cost-effective for long-distance transportation, and ship-based involves tankers for LNG transportation to remote areas.

**Market Players:** - **GE Oil & Gas:** GE Oil & Gas offers compression, transportation, and storage solutions for natural gas with a focus on industrial expertise, making them a reliable partner for virtual pipeline projects.

- **Hexagon Composites ASA:** Specializing in high-pressure composite cylinders for gas storage, Hexagon Composites ASA provides lightweight and durable storage solutions for efficient and safe gas transportation, aligning with the increasing demand for reliable storage solutions in virtual pipeline applications.

Key players like GE Oil & Gas

Highlights of TOC:

Chapter 1: Market overview

Chapter 2: Global Virtual Pipeline Systems Market

Chapter 3: Regional analysis of the Global Virtual Pipeline Systems Market industry

Chapter 4: Virtual Pipeline Systems Market segmentation based on types and applications

Chapter 5: Revenue analysis based on types and applications

Chapter 6: Market share

Chapter 7: Competitive Landscape

Chapter 8: Drivers, Restraints, Challenges, and Opportunities

Chapter 9: Gross Margin and Price Analysis

Key takeaways from the Virtual Pipeline Systems Market report:

Detailed considerate of Virtual Pipeline Systems Market-particular drivers, Trends, constraints, Restraints, Opportunities and major micro markets.

Comprehensive valuation of all prospects and threat in the

In depth study of industry strategies for growth of the Virtual Pipeline Systems Market-leading players.

Virtual Pipeline Systems Market latest innovations and major procedures.

Favorable dip inside Vigorous high-tech and market latest trends remarkable the Market.

Conclusive study about the growth conspiracy of Virtual Pipeline Systems Market for forthcoming years.

Browse Trending Reports:

Air Sports Equipment Market Secondary Macronutrients Market Blood Gas Analyzer Market Methotrexate Injection Market Smart Room Heater Market Battery Market Infrastructure As a Service Iaas Health Cloud Market Peritonitis Treatment Market Yacht Charter Market Next Generation Printing Ink Market Functional Confectionery Market Herbal Ready To Brink Beverages Market Wirewound Resistor Market Gelatin Substitutes Market Soy Based Surfactants Market Trimethlyaminuria Market Secondary Agricultural Nutrients Market Tomatoes Market Electric Kick Scooters Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email: [email protected]"

0 notes

Text

LNG cryogenic centrifugal pump

Cryogenic centrifugal liquid pumps are used in air separation plants both for compressing a cryogenic product and for circulating a coolant in the system. In addition, with the help of centrifugal pumps, liquefied gases are pumped from tankers and storage facilities and the cryogenic products are subsequently delivered from tanks to the consumer (for example, filling gas vehicles). Centrifugal pumps can have a single-stage or multistage design. In multistage pumps, the pumped liquid passes sequentially through several impellers, between which guide vanes are located for supplying fluid from the previous stage to the next. This design allows to significantly increase the pump head in comparison with a single-stage pump.

Company Name:Huzhou Baihui Cryogenic Equipment Co., Ltd Web:https://www.brightwaycryogenic.com/products/cryogenic-centrifugal-pump/lng-cryogenic-centrifugal-pump.html ADD:Building A38, China Energy Conservation and Environmental Protection Industrial Park, No. 1506, Yishan Road, Wuxing District, Huzhou City, Zhejiang Province, China Phone:86-18257285710 Email:[email protected] Tip:313000 Profile:Our company is willing to "integrity, innovation, pragmatic, win-win" spirit of enterprise, adhering to create value for users, reduce operating costs of development philosophy! We will wholeheartedly provide new and old customers with high-quality and low-cost products and considerate services, and join hands with our customers to create a better future.

0 notes

Text

I figured I should start doing some of my geopolitical/strategic content I would usually do on twitter to Tumblr

As such, here is my analysis of the recent Iranian operation

True Promise II

On October 1st 2024, Iran launched 200 ballistic, aero ballistic, and possibly hypersonic missiles at multiple targets within Occupied Palestine

The Iranians struck multiple Zionist Occupation airbases, gas platforms, and a main avenue very near to the headquarters of the Zionist intelligence service (responsible for the recent pager attacks) Mossad.

This is the results of their strikes on Nevatim airbase in southern Occupied Palestine, which houses the Zionists fleet of stealth F-35I aircraft, alongside Tanker and Radar equipped aircraft important to the Zionists ability to strike places as far away as Yemen or Iran

The Yellow pins indicate visible Craters from the strikes of missiles, while the white pins indicate possible strikes obscured by clouds.

It is important to note the different accuracy ranges shown in these strikes, some impacts are directly on hangers, taxiways (roads for aircraft to move from hangars to the runway), and administrative buildings.

Other impacts show a far wider spread, landing in empty desert or away from any specific target.

This is not a result of these missiles failure or success, but of the use of two separate kinds of missiles

The first kind of missile used was the unguided ballistic missile Emad

A ballistic missile is a missile that follows a ballistic trajectory, this means it is shot vertically into the air and relies on gravity to bring it's trajectory back down to earth. Ballistic trajectories are like an arch going from the point where the missile is fired to where it hits the ground.

The Emad is unguided, which means it has no way to change its trajectory after it has been fired, because of this, it has a CEP (Circular Error Probability) of 30-50m, this means it is likely to fall within a circle 50 meters wide with its center as the target

Why use such an inaccurate missile? Because it doesn't need heavy guidance equipment, the Emad can mount a warhead weighing 900kg. Against a relatively sparse target such as an airbase, this likely still won't be effective. But against a denser target such as a power plant or urban this could be highly effective.

The Emad can also theoretically mount a nuclear warhead, which makes accuracy irrelevant, or a cluster munition, which saturates the target area in hundreds of smaller explosives that are highly effective against unarmored targets such as aircraft on the tarmac.

The second missile used was the Guided Aero-Ballistic missile Kheybar-Shekan-2

An Aero-Ballistic missile is launched vertically, but uses a mixture of Aerodynamic Fins and Thrust Vectoring to lower the height of its trajectory and maneuver within the atmosphere.

By lowering its trajectory, this means it is able to delay detection by radar until it is closer to the target, and by maneuvering within the atmosphere, it is able to "dodge" interceptor missiles and enemy air defense.

This missile is responsible for many of the accurate strikes against hangars, taxiways, and administrative buildings mentioned previously, it is highly accurate with a CEP of 1-2m (it will hit within a circle the size of a grown adult laying down) and able to penetrate bunkers and hardened (armored) aircraft hangars.

Operation True Promise II was, at its core, a warning to the Zionist regime to stop escalating its conflict and genocide against Lebanon, Iran, and the wider middle east.

The damage done here was a taste of what a full scale missile attack by Iran would look like, Iran has tens of thousands of missiles of every kind imaginable, from ballistic and Aero-Ballistic missiles shown here, to hypersonic missiles that are almost impossible for the zionist regime to intercept, and cruise missiles that can be massed in the hundreds against even single targets. Iran also has possibly hundreds of thousands of drones that could saturate Zionist air defenses and strike tens of thousands of smaller targets.

If the Zionist regime chooses escalation, it will face fire

Before I go, here is some close ups of the hits done

1 note

·

View note

Text

Navigating the Waters: The Growth and Challenges of Shipping Companies in India

Introduction

India, with its extensive coastline and strategic location along major international maritime routes, has a thriving shipping industry that plays a crucial role in global trade. Shipping companies in India are integral to the nation’s economy, handling the vast majority of import and export activities. This article delves into the growth of shipping companies in India, the challenges they face, and the future prospects of the industry.

The Evolution of the Shipping Industry in India

India’s shipping industry has a long history, evolving from a regional trading network to a critical global player. Several factors have contributed to the industry's growth:

Strategic Geographic Location: India's position between the major sea routes of the East and the West has made it a vital hub for maritime trade. The country’s ports handle a significant portion of global cargo, connecting Asia, Europe, and Africa.

Expansion of Port Infrastructure: The Indian government has invested heavily in expanding and modernizing port infrastructure through initiatives like the Sagarmala Project, which aims to enhance port connectivity and capacity. This has allowed shipping companies to operate more efficiently and handle larger volumes of cargo.

Economic Liberalization: Since the economic liberalization of the 1990s, India has seen a surge in international trade. This has led to increased demand for shipping services, driving the growth of domestic shipping companies.

Rise in Containerization: The shift towards containerized cargo has revolutionized the shipping industry in India. Containers allow for easier handling, better security, and quicker turnaround times, making Indian ports more competitive on the global stage.

Key Shipping Companies in India

India is home to several prominent shipping companies, each contributing to the industry’s growth in different ways:

Shipping Corporation of India (SCI): As the largest and most prominent shipping company in India, SCI is a government-owned enterprise that operates a diversified fleet, including bulk carriers, container ships, and tankers. It plays a vital role in transporting crude oil, petroleum products, and other essential goods.

Great Eastern Shipping Company: One of the oldest private sector shipping companies in India, Great Eastern Shipping has a strong presence in both the shipping and offshore sectors. It operates a fleet of tankers, dry bulk carriers, and offshore vessels.

Essar Shipping: Part of the Essar Group, Essar Shipping specializes in transporting dry bulk, liquid cargo, and crude oil. The company has a global presence, with operations extending to key international markets.

Varun Shipping: Varun Shipping is known for its fleet of liquefied petroleum gas (LPG) carriers. The company has played a significant role in meeting India's energy needs by transporting LPG and other energy products.

Shreyas Shipping and Logistics: A leader in coastal shipping, Shreyas Shipping focuses on domestic routes, connecting major ports along India’s coastline. The company has capitalized on the growing demand for coastal shipping services, which offer a cost-effective alternative to road and rail transport.

Challenges Facing the Indian Shipping Industry

Despite its growth, the Indian shipping industry faces several challenges that need to be addressed to ensure sustainable development:

Inadequate Infrastructure: While port infrastructure has improved, there are still bottlenecks, such as congestion at ports, inadequate hinterland connectivity, and outdated equipment. These issues lead to delays and increased operational costs.

High Operational Costs: The cost of shipping in India remains high due to factors like fuel prices, port charges, and regulatory compliance. These costs can make Indian shipping companies less competitive compared to their global counterparts.

Environmental Regulations: With the global push towards sustainability, shipping companies are under increasing pressure to reduce their carbon footprint. Compliance with international environmental regulations, such as the IMO 2020 Sulphur Cap, requires significant investment in cleaner technologies, which can be financially challenging for many companies.

Crew Shortages and Skill Gaps: The shipping industry requires skilled professionals to operate complex vessels and manage logistics. However, there is a shortage of qualified seafarers and maritime professionals in India, which affects the efficiency and safety of operations.

Global Competition: Indian shipping companies face stiff competition from international players who often have more advanced fleets and better access to global markets. This competition can make it difficult for Indian companies to expand their global footprint.

Future Prospects

The future of the Indian shipping industry holds several opportunities for growth:

Blue Economy and Maritime India Vision 2030: The Indian government's focus on the Blue Economy, which aims to sustainably harness ocean resources, and the Maritime India Vision 2030, which outlines a roadmap for port-led development, are expected to drive significant growth in the shipping sector.

Coastal Shipping and Inland Waterways: There is a growing emphasis on developing coastal shipping and inland waterways as cost-effective and environmentally friendly alternatives to road and rail transport. This shift could reduce logistics costs and increase the demand for domestic shipping services.

Technological Advancements: The adoption of advanced technologies, such as automation, artificial intelligence, and blockchain, is expected to enhance the efficiency and transparency of shipping operations. Companies that embrace these technologies will be better positioned to compete globally.

Green Shipping Initiatives: As environmental concerns become more prominent, there will be greater demand for sustainable shipping practices. Indian companies that invest in eco-friendly technologies, such as LNG-powered ships and energy-efficient designs, will gain a competitive edge.

Expansion into New Markets: Indian shipping companies have the opportunity to expand into new markets, particularly in Asia and Africa, where demand for maritime trade is growing. Strategic partnerships and investments in these regions could open up new revenue streams.

Conclusion

The Indian shipping industry is poised for growth, driven by favorable government policies, expanding infrastructure, and increasing trade volumes. However, to fully realize its potential, the industry must address the challenges of high operational costs, infrastructure bottlenecks, and global competition. By embracing technological advancements, focusing on sustainability, and exploring new markets, Indian shipping companies can navigate the complex waters of the global maritime industry and chart a course for long-term success.

0 notes

Video

youtube

SnowRunner | 🚛 Deliver the Heavy Fuel Tanker Semi-Trailer to the factory 🚛 | Cinematic | 4K

🚛 Pipe Dream Contract Adventure 🚛

Hey there! 🌟 I received a challenging mission request that I couldn’t turn down. Someone asked me to help restore a local oil equipment factory that got hammered by a recent flood. This factory is vital for our drilling operations in the area, so getting it back up and running is crucial. Here’s what they asked me to do:

🛠️ Mission: Deliver the Heavy Fuel Tanker Semi-Trailer to the factory.

▶️ https://www.youtube.com/watch?v=QjwjXqJWpkU

🚧 The Journey:

Once I accepted the mission, I knew I was in for a tough ride. The journey involved navigating through some of the roughest and most treacherous terrain:

Rough and Rocky Paths: I had to deal with bumpy and uneven terrains where keeping control of the vehicle was essential.

Mud-Filled Tracks: Next, I faced deep mud that threatened to bog down the tanker, requiring careful maneuvering to avoid getting stuck.

Steep Inclines and Uphill Climbs: Then came steep and challenging uphill roads that needed precision and power to conquer.

Dirt Roads Through Valleys and Cliffs: Finally, I navigated narrow dirt paths flanked by dangerous cliffs and deep valleys, testing my skills and nerve.

🎥 In this video, I’ll show you how I tackled these tough conditions and successfully delivered the essential supplies. Watch as I navigate each obstacle with determination and skill.

🎁 Rewards:

🌟 450

💵 3850

🏭 Warehouse Access

Completing this mission was critical for restoring the factory’s operations, and the rewards were definitely worth the effort. Let’s get this done swiftly and efficiently!

#️⃣ Hashtags: #HeavyFuelTanker #SemiTrailer #Factory #Flood #DrillingOperations #ConstructionMaterials #Deliver #Reward #Restore #RoughTerrain #ChallengingJourney

0 notes

Text

Fighting Debt: A Battle Against the Wildfire

How is dealing with debt kind of like fighting a wildfire?

Last night our Search and Rescue team got activated to help block or redirect traffic away from a wildfire that was causing a people in a small town, in our county, to be evacuated and highways and roads to be shut down. As I watched for hours, people grabbing family members, animals, or personal belongings to evacuate while firefighters, water tankers, and heavy equipment passed by me, I had…

View On WordPress

0 notes

Text

Benefits of Using a Gully Tanker for Onsite Maintenance

The Gully Tanker is a modernized and multifunctional piece of equipment that has been designed specifically for cleaning mainline sewers, gullies and drains. This high-pressure equipment has a large hydraulic powered hose reel and a heavy duty unloader valve which provide responsive jetting control necessary for effective operation over long periods of time. In the domain of road clean-up and maintenance, one very important equipment stands out: The Gully Tanker. It is through this specialized machinery that we can maintain clean roads and streets, devoid of wastes. In addition, it helps to prevent clogging in the drainage systems thereby avoiding potential disasters.

0 notes

Text

From Reservoir to Refinery: The Comprehensive Guide to Crude Oil Extraction and Production

The extraction and production of crude oil are critical processes in the energy sector, pivotal to the functioning of modern economies worldwide. This article explores the complex methods and technologies involved in oil drilling, extraction, and production, offering insights into the journey from underground reservoirs to the final crude product.

The Foundations of Oil Drilling

Oil drilling begins with the identification of potential oil reserves. Geologists use various methods to locate these reserves, including seismic surveys and satellite imaging. Once a promising site is identified, the area is prepared for drilling. This preparation often involves building access roads, securing permits, and setting up drilling rigs.

Drilling rigs are towering structures commonly associated with oil extraction. These rigs house the equipment necessary to drill deep into the earth to reach oil-bearing formations. The drilling process involves creating a borehole by continuously turning a drill bit attached to a drill string. A mixture of water, clay, and chemicals, known as drilling mud, is pumped down the drill string to cool the drill bit, remove cuttings, and stabilize the borehole walls.

Journey Down the Well: Techniques and Tools

As the drill bit penetrates deeper layers, various drilling techniques are employed depending on the geological characteristics and depth of the formation. The most common methods include rotary drilling, which uses a rotating drill bit to cut through rock, and directional drilling, which allows for drilling at multiple angles, not just vertically. This is particularly useful for accessing oil deposits spread over a large area or reducing environmental impact.

Once the target depth is reached, the next phase is thriving completion. This involves casing the well with cemented steel pipes to ensure no oil or natural gas escapes. Additionally, perforations are made in the casing opposite the oil-bearing formation, allowing oil to flow into the wellbore.

Extracting the Oil: Primary and Secondary Methods

Oil extraction is categorized into primary, secondary, and tertiary (or enhanced) recovery methods, depending on the stage of the well's life and the oil's viscosity.

Primary Recovery: This initial phase uses the reservoir's natural pressure to force the oil to the surface. However, primary recovery typically extracts only about 10-15% of the well's oil because the natural pressure eventually decreases.

Secondary Recovery: To extract more oil, water or gas injection is used to maintain reservoir pressure and push more oil toward the production wells. This method can recover 20-40% of the reservoir's oil.

Enhanced Oil Recovery: Maximizing Output

Enhanced oil recovery (EOR) techniques are employed when primary and secondary methods become inefficient. These include thermal recovery, which involves injecting steam to lower the viscosity of heavy crude; chemical injection, which uses detergents or polymers to help the oil flow more efficiently; and gas injection, which uses gases like carbon dioxide to mix with and expand the oil, improving flow rates.

EOR techniques can significantly increase a well's output, extracting up to 60% or more of the reservoir's oil.

Transporting Crude Oil to Refineries

After extraction, the crude oil must be transported to refineries for processing. This is typically done through pipelines, tanker trucks, or oil tankers for offshore rigs. Crude oil undergoes several processes at the refinery to separate the various hydrocarbons, remove impurities, and convert them into usable products like gasoline, diesel, and jet fuel.

Environmental and Safety Considerations

The entire oil extraction and production process comes with significant environmental and safety challenges. These include the risk of spills, groundwater contamination, and the emission of greenhouse gases. Oil companies invest in various safety measures and technologies to mitigate these risks, including advanced blowout preventers, automated shutoff systems, and regular safety drills.

Additionally, regulatory bodies enforce strict environmental standards on oil extraction operations to protect ecosystems and reduce the impact of drilling and production activities.

The Crude Reality

The extraction and production of crude oil are technologically advanced processes that require significant investment in technology and safety. From the initial drilling to the final stages of recovery, each step is crucial for maximizing oil recovery while minimizing environmental impact. As the world gradually transitions to renewable energy sources, the oil industry continues to innovate, ensuring that the extraction and production processes are as efficient and environmentally responsible as possible.

0 notes

Text

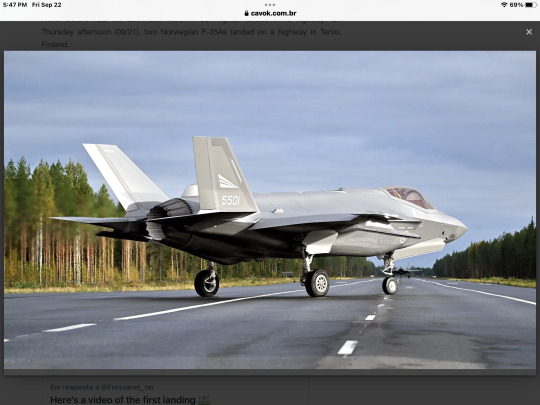

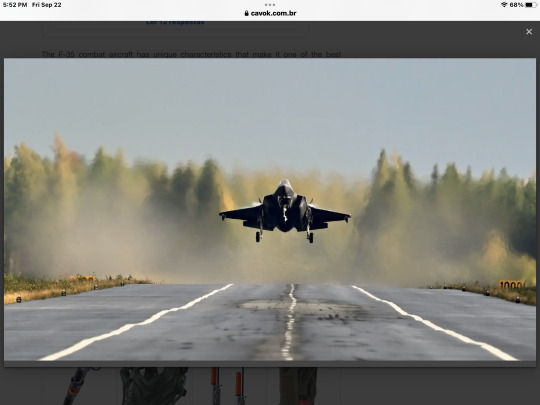

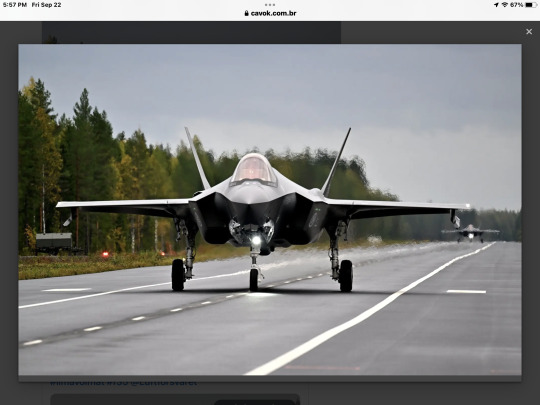

VIDEOS AND IMAGES: F-35A fighters operate from a highway for the first time

Fernando Valduga By Fernando Valduga 09/22/2023 - 09:00am Military

Never before had the Lockheed Martin F-35A fighter landed on a highway. On Thursday afternoon (09/21), two Norwegian F-35As landed on a highway in Tervo, Finland.

"This is a milestone, not only for the Norwegian Air Force, but also for the Nordic countries and NATO. This demonstrates our ability to execute a concept of dispersion. Combat planes are vulnerable on the ground, so being able to use small airfields - and now highways - increase our ability to survive in war. In addition, this is also a demonstration of the exciting development we have begun in military-aircraft cooperation in the Nordic region," says Maj. Gen. Rolf Folland, head of the Royal Norwegian Air Force.

PLEASE TAP RELOAD TO VIEW VIDEO 👇

The F-35 combat aircraft has unique characteristics that make it one of the best combat aircraft ever built. The F-35 can operate from many bases and locations, but the limitations are related to the time the aircraft can operate without refueling weapons, fuel and technical support on the ground.

Finland became a member of NATO earlier this year and is an important partner of the Norwegian Air Force.

“Finland has long been a close partner and now also an ally. Its straight and wide highways mean that we can further develop our concept of dispersion,” says Folland.

TAP RELOAD TO VIEW👇

The fighters landed around 3 p.m., Norwegian time, on a highway in Tervo, after participating in a joint training with the Finnish F-18s.

"The Air Forces in the Nordic countries have shown great initiative to increase Nordic cooperation and have come a long way. This landing is a good example of this and shows that the Nordic countries will soon be able to operate together as a coordinated force," says the Norwegian Head of Defense, General Eirik Kristoffersen.

Immediately after landing, refueling was carried out with the engines on - the so-called "hotpit refueling". Shortly after, the F-35 took off and were ready for new missions.

“With Finland's entry into NATO and Sweden's imminent accession, the Nordic countries have a particular responsibility in developing and coordinating NATO's deterrence in the northern regions,” says Norwegian Defense Minister Bjorn Arild Gram.

"The future air defense of the Nordics will consist of more than 200 combat aircraft, and it is very good that we are in the process of developing Nordic cooperation in military air operations," says the Minister of Defense.

By the summer of this year, the F-35 nations have accumulated a total of more than 650,000 flight hours, of which more than 20,000 hours were flown with Norwegian aircraft. The type of aircraft is delivered in several variants. The landing of the Royal Norwegian Air Force on a Finnish highway is an unprecedented event for this type of aircraft. The US has already landed on highways with some of its F-35B, but this is the so-called STOVL version (short takeoff/vertical landing), which can land vertically, for example, on aircraft carriers and roads.

Tags: Military AviationIlmavoimat/Finland Air ForceLockheed Martin F-35A Lightning IINATO - North Atlantic Treaty OrganizationRNAF - Royal Norwegian Air Force / Royal Norwegian Air Force

Sharing

tweet

Fernando Valduga

Fernando Valduga

Aviation photographer and pilot since 1992, he has participated in several events and air operations, such as Cruzex, AirVenture, Daytona Airshow and FIDAE. He has work published in specialized aviation magazines in Brazil and abroad. Uses Canon equipment during his photographic work throughout the world of aviation.

Related news

MILITARY

French Air Force closest to retiring its C-135FR tankers after receiving the 12º A330 MRTT

09/22/2023 - 08:27

MILITARY

AUDIO: USMC F-35B fighter flew for more than 100 kilometers, without the pilot on board, before falling

21/09/2023 - 23:25

MILITARY

Boeing negotiates sale of more P-8I Poseidon maritime patrol planes to India

21/09/2023 - 18:24

MILITARY

German Eurofighters protect the sky of Slovakia

21/09/2023 - 16:00

MILITARY

Taiwan operator acquires surveillance version of Tecnam's P2012

21/09/2023 - 14:00

MILITARY

IMAGES: North Korean leader Kim Jong-un knows Russia's Su-57 fighter closely

21/09/2023 - 12:00

9 notes

·

View notes

Text

Ship Rudder Market is Set To Fly High in Years to Come

Latest added Ship Rudder Market research study by Market Research Forecast offers detailed outlook and elaborates market review till 2032. The market Study is segmented by key regions that are accelerating the marketization. At present, the market players are strategizing and overcoming challenges of current scenario; some of the key players in the study are Damen Marine Components (Netherlands), Becker Marine Systems GmbH (Germany), Nufoss Services Pte Ltd. (Singapore), Torqeedo GmbH (Germany), Voith Hydro Inc. (Germany), Sunique Marine Machinery Co. Ltd (Malaysia), Deyuan Marine (China), Zhongyuan (China), Wärtsilä (Finland), Japan Hamworthy Co. Ltd. (Japan) etc. Get inside Scoop of the report, request for free sample @: https://marketresearchforecast.com/report/ship-rudder-market-2694/sample-report The Ship Rudder Market size was valued at USD 1.03 USD Billion in 2023 and is projected to reach USD 1.51 USD Billion by 2032, exhibiting a CAGR of 5.6 % during the forecast period.

Market Growth Drivers: Rising Demand for Satellite Communication Equipment Due to Growing Space Exploration Programs Will Aid Market Growth Know your current market situation! Not just new products but ongoing products are also essential to analyze due to ever-changing market dynamics. The study allows marketers to understand Ship Rudder Market consumer trends and segment analysis where they can face a rapid market share drop. Figure out who really the competition is in the marketplace, get to know market share analysis, market position, % Market Share, and segmented revenue. The Global Ship Rudder segments and Market Data Break Down Rudder Type: Balanced Rudder, Unbalanced Rudder, and Semi-Balanced Rudder","Point of Sale: OEM and Aftermarket","End-user: Naval, Commercial, Coat Guard, and Others","Ship Type: Container Ship, Passenger Ship, Bulk Carrier, Tanker Ship, Fishing Vessel, Naval Ship, General Cargo Ship, and Others Thanks for reading this article; you can also get individual chapter wise section or region wise report version like North America, Middle East, Africa, Europe or LATAM, Southeast Asia. More Reports:

https://marketresearchforecast.com/reports/optical-communication-systems-and-networking-market-2700 For More Information Please Connect MR ForecastContact US: Craig Francis (PR & Marketing Manager) Market Research Forecast Unit No. 429, Parsonage Road Edison, NJ New Jersey USA – 08837 Phone: (+1 201 565 3262, +44 161 818 8166)[email protected]

#Global Ship Rudder Market#Ship Rudder Market Demand#Ship Rudder Market Trends#Ship Rudder Market Analysis#Ship Rudder Market Growth#Ship Rudder Market Share#Ship Rudder Market Forecast#Ship Rudder Market Challenges

0 notes