#Rapid Prototyping Service Industry

Explore tagged Tumblr posts

Text

#Rapid Prototyping Service Market#Rapid Prototyping Service Market Share#Rapid Prototyping Service Market Size#Rapid Prototyping Service Market Research#Rapid Prototyping Service Industry#What is Rapid Prototyping Service?

0 notes

Text

What Processes Are Involved In Sheet Metal Fabrication?

Sheet metal fabrication is a manufacturing process widely used in various industrial fields, which involves processing raw materials such as metal sheets, plates and strips into metal products with specific shape, size and performance requirements through a series of process operations. Sheet metal fabrication covers a multitude of process steps, each with its own unique characteristics and range of applications.

The main processes of sheet metal processing are described briefly in below:

1.Cutting: Cutting is one of the most basic processes in sheet metal fabrication, which is mainly used to cut raw materials into the required shapes and sizes. It includes mechanical cutting, laser cutting, plasma cutting, waterjet cutting and many other methods. Among them, mechanical cutting is suitable for larger thicknesses of plate, while laser cutting and plasma cutting are suitable for thinner materials and enable high precision and efficiency.

2.Punching: Punching is one of the commonly used processes in sheet metal processing, which uses a punch press and a die to punch the raw material to obtain the desired shape and size. The punching process has the advantages of high productivity, low cost and high material utilisation, and is widely used in sheet metal processing in the automotive, electronics and home appliance industries.

3.Bending: Bending is the process of deforming sheet metal material to a predetermined angle and shape. It can be realised by mechanical bending, hydraulic bending, pneumatic bending and many other ways. The bending process occupies an important place in sheet metal fabrication, as many products need to be bent to obtain the desired shape and structure.

4.Welding: Welding is the process of solidifying two or more metal parts into a single unit by melting their contacting parts and then cooling them. In sheet metal fabrication, welding process is commonly used to join multiple sheet metal parts together to form a complete product. Welding processes include arc welding, gas welding, laser welding and other methods, to choose welding method depends on the nature of the material, welding requirements and processing conditions and other factors.

5.Surface finishing: Surface finishing treatment is the process of processing the surface of sheet metal products to improve their corrosion resistance, aesthetics and functionality. Common surface finishing processes include coating, electroplating, anodizing, sandblasting, etc. These processes can give sheet metal products rich colours, good texture and excellent corrosion resistance, so that they can maintain good performance under various environmental conditions.

6.Assembling: Assembling is the process of putting multiple sheet metal parts and other components together as designed. The assembly process includes threaded connection, riveting, welding and many other methods. Assembly process occupies an important position in sheet metal fabrication, as it is directly related to the quality and performance of the final product.

In summary, sheet metal fabrication covers a variety of processes such as cutting, punching, bending, welding, surface finishing and assembly. Each of these processes has its own characteristics and works in conjunction with each other to achieve efficient, high-precision and high-quality production of sheet metal products. With the continuous progress of science and technology and the rapid development of this industry, sheet metal processing technology will continue to innovate and improve, providing more high-quality and efficient metal products for all walks of life.

#design#autos#business#prototyping#prototype#prototype machining#rapid prototyping#sheet metal fabrication#sheet metal manufacturing#sheet metal design#sheet metal services tauranga#sheet metal work contractor financing#cnc machining#precision machining#machining parts#industrial engineering

1 note

·

View note

Text

The Transformative Impact of Professional Scale Modeling in Architecture

In the architectural industry, the ability to effectively communicate and visualize complex designs is critical. Professional scale modeling has long been an essential tool in this process, providing tangible, precise representations of architectural concepts. With the advent of advanced technologies such as 3D printing, professional scale modeling has reached new heights, offering unprecedented levels of detail and accuracy. This article explores the significance of professional scale modeling in architecture and how it enhances design, communication, and project execution.

The Role of Professional Scale Modeling in Architecture

Enhanced Design Visualization: Professional scale models allow architects to visualize their designs in a three-dimensional form, providing a comprehensive understanding of the spatial relationships and proportions of the structure. This helps in identifying potential design flaws and making necessary adjustments early in the design process.

Effective Communication: Scale models serve as an excellent tool for communicating design concepts to clients, contractors, and other stakeholders. They provide a clear and tangible representation of the project, facilitating better understanding and discussions around design elements and modifications.

Detailed Representation: The precision involved in professional scale modeling ensures that every aspect of the design is accurately represented. This includes intricate details such as facades, interiors, and landscapes, which are crucial for comprehensive project presentations and approvals.

Marketing and Presentation: High-quality scale models are powerful marketing tools that can be used in presentations, exhibitions, and client meetings. They showcase the architect’s vision and craftsmanship, helping to secure new projects and impress potential clients.

The Evolution of Scale Modeling with 3D Printing

The integration of 3D printing technology into professional scale modeling has revolutionized the way architectural models are created and utilized. Here are some key advantages:

Precision and Accuracy: 3D printing allows for the creation of highly detailed and accurate scale models. This precision is particularly beneficial for modern architectural designs that include complex geometries and intricate details.

Time and Cost Efficiency: Traditional scale modeling can be labor-intensive and time-consuming. 3D printing significantly reduces the time required to produce models, allowing for faster iterations and quicker project timelines. Additionally, while the initial setup costs for 3D printing can be high, the overall production costs are generally lower than traditional methods.

Customization and Flexibility: 3D printing offers unparalleled flexibility, allowing architects to easily customize models and make quick adjustments. This is especially useful during the design development phase when changes and refinements are frequent.

Material Versatility: 3D printing supports a wide range of materials, from durable plastics to high-quality resins. This versatility enables the creation of models that are not only aesthetically pleasing but also robust and durable.

C3D: Leading the Way in Professional Scale Modeling

At C3D, we are committed to leveraging the latest technologies to provide exceptional scale modeling services for the architectural industry. Our state-of-the-art 3D printing capabilities ensure that your architectural models are of the highest quality, offering both visual appeal and functional precision.

Our Services Include:

Custom 3D Scale Models: We specialize in creating custom models tailored to your specific design needs. Whether you need a simple conceptual model or a highly detailed presentation piece, we have the expertise to deliver.

High-Resolution Printing: Our advanced 3D printers produce high-resolution models that capture the finest details of your design, enhancing the overall presentation quality.

Material Options: We offer a range of materials to suit different project requirements, ensuring that your models are both aesthetically pleasing and durable.

Expert Support: Our team of experts is dedicated to providing exceptional service, from initial consultation to final delivery. We work closely with you to ensure that your vision is accurately represented.

Conclusion

Professional scale modeling plays a vital role in the architectural industry, enhancing design visualization, improving communication, and supporting successful project outcomes. With advancements in 3D printing technology, the possibilities for scale modeling have expanded, offering architects new levels of precision, efficiency, and flexibility. At C3D, we are at the forefront of this evolution, providing high-quality scale modeling services that help bring architectural visions to life. Trust C3D to be your partner in architectural innovation and excellence.

#fdm 3d printing#custom trophies#bespoke trophy manufacturing#professional scale modeling#custom scale models#industrial 3d scanning#3d scanning services cost#sls 3d printing service#scale model prototyping#online 3d printing services#custom 3d printing#3d printing service#rapid prototyping 3d printing#3d printing online services#3d scale model maker#3d printer service near me#3d printing companies near me#3d scanning services#fused deposition modeling 3d printer#high strength 3d printed parts#scale modeling#precision model making#industrial grade 3d printing#unique 3d printed floral containers#custom 3d printed vases#high resolution 3d scanning#corporate recognition awards#prototyping#reverse engineering services#3d print vase

0 notes

Text

The Power of Precision: FDM 3D Printing at C3D

11. High-Quality 3D Scale Model Maker in Dubai

C3D is a leading 3D scale model maker in Dubai, offering high-quality scale models for various industries. Our expertise in precision model making ensures that every detail is captured, providing accurate and visually appealing representations of your designs. Whether for architectural projects, product prototypes, or marketing displays, our scale models are crafted to the highest standards, helping you effectively communicate your vision.

12. The Cost of 3D Scanning Services

Understanding the cost of 3D scanning services is essential for budgeting your projects. At C3D, we offer competitive pricing for our high-resolution 3D scanning services. The cost varies depending on the complexity and size of the object, but the investment is justified by the accuracy and detail provided by our advanced scanning technology. Our services help streamline design and manufacturing processes, ultimately saving time and resources.

13. Enhancing Designs with High-Resolution 3D Scanning

High-resolution 3D scanning is a game-changer for capturing intricate details and creating precise digital models. At C3D, our high-resolution 3D scanning services provide exceptional accuracy, making them ideal for reverse engineering, quality control, and product development. The detailed scans enable designers and engineers to enhance their designs and ensure that every aspect meets the required specifications.

14. Custom Awards Design: Unique Recognition for Achievements

At C3D, we specialize in custom awards design, creating unique and personalized trophies and plaques to celebrate achievements. Our bespoke trophy manufacturing process allows for intricate detailing and customization, ensuring that each award is a true reflection of the recipient’s accomplishments. From corporate recognition awards to sports trophies, our custom designs stand out for their quality and creativity.

15. Innovative Prototyping with 3D Printing

Prototyping with 3D printing at C3D offers innovative solutions for developing and testing new products. Our rapid prototyping services use advanced 3D printing technology to produce accurate and functional prototypes quickly. This allows for efficient design iteration and testing, helping to bring products to market faster. Our expertise in 3D printing ensures that your prototypes meet the highest standards of quality and performance.

16. Reverse Engineering Services for Modern Manufacturing

Reverse engineering services at C3D provide valuable insights into existing products and components. Using advanced 3D scanning technology, we capture precise measurements and create detailed digital models. This process is essential for redesigning and improving products, as well as for manufacturing spare parts and replacements. Our reverse engineering services help businesses optimize their products and processes, ensuring they stay competitive in the market.

17. Creating Unique 3D Printed Floral Containers

C3D offers custom 3D printing services for creating unique and decorative floral containers. Our advanced 3D printing technology allows for intricate designs and personalization, making each container a work of art. These custom 3D printed vases are perfect for adding a touch of elegance to any space, whether for personal use or as gifts. Explore our range of designs and create your own unique floral containers with C3D.

18. Industrial Grade 3D Printing for High-Performance Parts

C3D’s industrial grade 3D printing services produce high-strength and durable parts for various applications. Using advanced materials and technologies, we create components that meet stringent performance requirements. Our industrial 3D printing solutions are ideal for producing functional prototypes, end-use parts, and custom components, offering reliability and precision for demanding industries.

19. High-Quality Resin Casting for Detailed Prototypes

High-quality resin casting at C3D provides detailed and durable prototypes for a range of applications. Our resin casting process captures intricate details and offers excellent mechanical properties, making it suitable for both prototyping and small-scale production. Whether you need custom resin prototyping or high-quality parts, our expertise ensures that your projects meet the highest standards.

20. The Benefits of Decorative 3D Printed Vases

Decorative 3D printed vases from C3D combine functionality with artistic design. Our custom 3D printing services allow for unique and intricate vase designs that enhance any interior space. These vases are perfect for home decor, gifts, or special events, offering a personalized touch that stands out. Explore our collection of decorative 3D printed vases and bring a touch of innovation and elegance to your surroundings.

Conclusion

The adaptability and precision of FDM 3D printing make it a pivotal technology in today's manufacturing landscape. At C3D, we leverage this innovative method to deliver customized solutions, from bespoke trophies to precise scale models and industrial-grade parts. Our commitment to quality and detail ensures that our clients receive products that meet their exact specifications and exceed expectations. As FDM technology continues to evolve, the potential for creating more complex and high-quality designs will only expand, solidifying its role as an essential tool for innovation and excellence in various industries.

#fdm 3d printing#custom trophies#bespoke trophy manufacturing#professional scale modeling#custom scale models#industrial 3d scanning#3d scanning services cost#sls 3d printing service#scale model prototyping#online 3d printing services#custom 3d printing#3d printing service#rapid prototyping 3d printing#3d printing online services#3d scale model maker

0 notes

Text

#custom 3d printing near me#custom 3d printing services#custom 3d printing#3d print service near me#3d printing companies near me#3d printing cost#online 3d printing#3d printing online services#3d print vase#fused deposition modeling#3d printer service near me#large 3d printing services#sls 3d printing service#fused deposition modeling 3d printer#large industrial 3d printer#rapid prototyping 3d printing#3d scanning services cost#3d scale model maker#High resolution 3d scanning#Industrial 3d scanning#Reverse engineering services#Rapid Prototyping#Scale modeling#3d printing services#large 3d printing#best 3d printing service#large format 3d printing#3d model printing service#sls printing service#large scale 3d printing service

0 notes

Text

6 MOST POPULAR INDUSTRIES TO USE METAL 3D PRINTING

Will you disagree with me if I say that the long-term success of any society is highly dependent on its manufacturing? I hope you will not. Every society needs a very strong and vibrant manufacturing base. There is a well-known saying that 'If you always do what you always did, you'll always get what you have always got. This clearly states the significance of development and automation in the manufacturing industry. Additive manufacturing is fundamentally changing what we can do. There are three key elements to effectively utilize the additive manufacturing process. Additive thinking, accessible processes and cost are those elements which provide the most efficient solutions to the hindrances in the additive manufacturing sector. Metal additive manufacturing is the one that requires special mention here. Let us understand the concept, types, and major metal additive manufacturing applications.

What is Metal 3D Printing

Metal 3d printing, also known as metal additive manufacturing is one of g fastest growing technologies in the manufacturing industry. It is the most heavily invested technology in industrial and business applications. Any technology that creates metal objects layer by layer with sintering, melting and welding could be called metal 3D printing. Metal additive manufacturing stands as an umbrella term for several families of AM technologies. The application of metal 3d printing is boundless when manufacturing objects with complicated geometry. 3D printing is highly recommended for intricate parts where other types of manufacturing are inefficient or difficult to use.

Types of Metal 3D Printing

For a better understanding of the types of metal additive manufacturing, one should differentiate between powder-bed welding and deposition processes such as laser deposition welding. In powder bed welding, a slider is used to apply a thin layer of metallic material onto the building platform. Then a laser or electron beam cuts out the desired shape. Then the installation space is lowered a little and the next layer of metal powder is pushed over the object. In this way, the component is created layer by layer. The methods of metal 3d printing are categorised into four namely Selective Laser Melting (SLM), Electron Beam Melting (EBM), Laser Metal Deposition (LMD) and Metal Powder Application (MPA). SLM technology uses a bed of powder with a source of heat to create metal parts and includes Selective Laser Melting (SLS), which is also called Direct Metal Laser Sintering (DMLS) or Laser Metal Fusion (LMF). EBM is a type of additive manufacturing where the raw material is placed under a vacuum and fused from heating by an electron beam. LMD is a laser-based DED technique that selectively adds metal material onto a base workpiece in a layer-by-layer process. In powder-based LMD, a nozzle aggregates metal powder onto a workpiece, where a fibre laser melts both the powder and the workpiece into a melt pool. MPA involves blasting a fine metal powder at a target using a custom-designed nozzle.

3D Printing in Automobile Industry

3D printing has greater scope in the automobile industry. Metal additive manufacturing can be used to make moulds and thermoforming tools, and also in manufacturing grips, jigs, and fixtures. This allows automakers to produce samples and tools at low costs and to eliminate future losses in production when investing in high-cost tooling. With 3D printing, automotive designers can quickly fabricate a prototype of a physical part or assembly, from a simple interior element to a dashboard or even a scale model of an entire automobile.

3D Printing in Medical Industry

Medical 3D printing is highly in demand in both clinical and research-based healthcare activities. It involves the creation of physical replicas of anatomical structures using additive manufacturing processes. The application of 3D printing in medicine can provide many benefits like the customization and personalization of medical products, drugs, and equipment; cost-effectiveness; increased productivity; the democratization of design and manufacturing; and enhanced collaboration.

3D Printing in Aerospace Industry

In the Aerospace industry, metal additive manufacturing is used to manufacture metal brackets that perform a structural function inside aircraft. 3D printing services produce interior aircraft components such as cockpit dashboards and door handles. 3D printed prototypes enable designers to refine the form and fit of finished parts. Because component precision is a critical factor in aircraft design, 3D printers are used in the aircraft industry to provide extremely high accuracy in parts and components.

3D Printing in Architecture Industry

3D printing will simplify the process in architecture. It can render highly detailed physical models from a range of materials and colours based on a CAD model. It is an efficient process that lets architects turn out models quickly and more accurately. 3D printing allows architects to design and develop everything ranging from buildings, townships, and cities right down to terrains, landscapes and fauna with fine detail and full colour. Well-designed 3D-printed architectural models can help architects create a lasting impression on their clients.

3D Printing in Defense Industry

The additive manufacturing technique is widely used by the defence sector worldwide. Considering that speed, lighter weights, and lower costs are all paramount in this sector, additive manufacturing certainly has a role to play. 3d printing provides new ways to 3D print replacement parts on demand, whilst reducing production costs and enabling new design engineering possibilities in the defence industry.

3D Printing in Tooling Industry

Tooling is any part manufacturers use to make other parts. 3D printing provides new opportunities for different business sectors to enable easier prototyping. It could directly form the part or like a pattern for a mould that manufacturers would then use to cast a different part. It gives them the ability to create designs that are way too difficult to produce with other methods. It also allows manufacturers to build high-quality products rapidly.

Some new frontiers with 3D printing technology

A new frontier for 3D printing develops state-of-the-art soft materials able to self-heal. The scientific community is focusing its research on the multiple applications of hydrogels, polymeric materials which contain a large amount of water, that have the potential to reproduce the features of biological tissues. Direct Sound Printing is a potential game-changer in 3D Printing. Metal additive manufacturing creates physical objects from a geometrical representation by successive addition of materials. 3D printing technology is a fast-emerging technology nowadays. Apart from Metal 3D Printing, there are new frontiers like 3D Printed Lattice Structures, Bone-Like 3D Printed Structures and more efficient Engines in Drones. 3D printing can help manufacturers save time, material, and costs from traditional tooling processes. As technology in 3D printing has improved, the ability to make larger items as well as more detailed objects has become more commonplace. Ultimately, three-dimensional printing is revolutionizing the production of new devices and structures in a wide range of sectors.

Conclusion

Metal additive manufacturing has recently developed a lot to bring great benefits to different business sectors. These benefits include reduced material use, lowered costs, and production acceleration. It also enables designers and engineers to create anything from jigs and fixtures to more advanced forms like visualisation aids. The possibilities of using 3D printing for product development and manufacturing in different industries are limitless. The days are not far for you to think of outsourcing metal 3d printing for your industry. The countdown begins!

#3d metal printing companies#3d priniting post processing services#3d printing in defence industry#additive manufactured products#additive manufacturing companies in bangalore#additive manufacturing company in india#additive manufacturing material#additive manufacturing metal parts#additive manufacturing service in india#additive metal 3d printing#dmls printer manufacturers#materials for additive manufacturing#metal 3d printing bangalore#metal 3d printing companies in bangalore#metal 3d printing companies in india#metal 3d printing in mumbai#metal 3d printing in rapid prototyping#metal 3d printing india#metal 3d printing manufacturing#metal 3d printing post processing#metal 3d printing process#metal 3d printing rapid prototyping#metal 3d printing raw material#metal 3d printing service bangalore#metal 3d printing services in india#metal additive manufacturing#metal additive manufacturing applications#metal additive manufacturing companies#metal additive manufacturing in india#metal additive manufacturing machine

0 notes

Text

U.S. Air Force Testing New Sensors On The F-22

The F-22 recently tested multiple new sensors as part of the modernization, with plans for a rapid prototyping effort to field them and expand the capabilities of the jet.

Stefano D'Urso

F-22 new sensors

U.S. Air Force F-22 Raptors assigned to the 27th Expeditionary Fighter Squadron and Philippine Air Force FA-50PH light jet fighters conduct joint combined exchange training, above Basa Air Force Base, Philippines, on Aug. 9, 2024. (U.S. Air Force photo by Senior Airman Mitchell Corley)

The U.S. Air Force is testing multiple new advanced sensors on the F-22 Raptor, which could extend its service life and also be applied to systems of the Next Generation Air Dominance family. The info was disclosed during the Life Cycle Industry Days conference.

“The F-22 team is working really hard on executing a modernization roadmap to field advanced sensors, connectivity, weapons, and other capabilities,” said Brig. Gen. Jason D. Voorheis, Program Executive Officer for Fighters and Advanced Aircraft. “The Raptor team recently conducted six flight test efforts to demo advanced sensors.”

Voorheis also added that the service is planning for a rapid prototyping effort to get these sensors fielded quickly. “We’re executing that successfully, and that will lead to […] a rapid fielding in the near future,” he said.

The news was first reported by Air and Space Forces Magazine, which also added that Air Force officials have also confirmed that the stealthy pods seen since last year being tested on the F-22 are indeed InfraRed Search and Track (IRST) sensors. The development of a new IRST sensor for the Raptor was also confirmed by the service’s budget document, however they did not mention the sensor being podded.

The sensors are part of an upgrade program worth $ 7.8 billion before 2030, of which $ 3.1 billion are for research and development and the remaining $ 4.7 billion are for procurement. This is in contrast with previous statements that the Air Force was looking to retire the F-22 around 2030.

“From an F-22 sunsetting perspective, I don’t have a date for you,” said Voorheis when asked about the topic. “What I can tell you is that we are hyper-focused on modernization to sustain that air superiority combat capability for a highly contested environment for as long as necessary.”

This also reflects recent comments by Gen. Kenneth Wilsbach, head of Air Combat Command, who mentioned that the service should retain also the older F-22s in the Block 20 configuration, together with the latest ones. The General added that several upgrades are being planned and even the older Block 20s are still very capable, should they be needed for combat in an emergency.

An F-22 Raptor assigned to the 1st Fighter Wing, Joint Base Langley-Eustis, Virginia, approaches the boom of a 134th Air Refueling Wing KC-135R Stratotanker to refuel along the east coast of the United States Aug. 14, 2024. (U.S. Air Force photo by Tech. Sgt. Teri Eicher)

Voorheis also mentioned a software being integrated on the Raptor, which he defined as Government Reference Architecture Compute Environment, or “GRACE.” He further explained this open architecture software would allow “non-traditional F-22 software” to be installed on the aircraft and provide “additional processing and pilot interfaces.”

It’s unclear if the new GRACE is related to Project FOX, the innovation project tested last year which allowed to integrate on the F-35 software applications developed for the F-22. This allowed both 5th gen fighters to fly with common tactical software applications.

The F-22 upgrades

Some of the upgrades expected for the F-22 Raptor were unveiled in the Fiscal Year 23 budget request documentation and in an official artwork shared by Gen. Mark Kelly, then Commander of Air Combat Command. In the artwork we can see three Raptors loaded with new stealthy external fuel tanks, two underwing faceted pods and a new unknown air-to-air missile, but there are even more novelties in the documents, which unveils a previously undisclosed relationship between the F-22 and the development of the Next Generation Air Dominance (NGAD).

Two years after the upgrades were announced, we might have gotten, earlier this year, the first glimpse of the new stealthy external fuel tanks being developed for the F-22 Raptor. The aircraft was, in fact, spotted near the Mojave Air and Space Port and shows the Raptor with two fuel tanks, whose shape is reminiscent of the one shown in 2022.

The new tanks are officially known as Low Drag Tank and Pylon (LDTP) and designed to be stealthier and more aerodynamically efficient than the current 600-gallon fuel tanks. In the FY2023 budget request, the Air Force mentioned that the F-22 LDTPs are advanced technological designs providing increased persistence and range while maintaining lethality and survivability, critical to future mission execution and to maintaining Air Superiority.

U.S. Air Force Capt. Samuel “RaZZ” Larson, F-22 Raptor Demonstration Team commander and pilot, practices different maneuvers while training for the upcoming 2023 airshow season, at Joint Base Langley-Eustis, Virginia, Jan. 6, 2023. (U.S. Air Force photo by Airman 1st Class Mikaela Smith)

The low drag tanks are intended to reduce drag, facilitate supersonic flight with external tanks and extend the range of the F-22. The pylons are equipped with smart rack pneumatic technology to accurately control ejection performance and smooth wind swept surface for minimum drag without stores.

The two pods installed under the outer underwing hardpoints have already been spotted during flight testing on an F-22 at the Air Force’s Plant 42 facility in Palmdale, California, in February 2022. The latest budget documents mention an InfraRed Search and Track (IRST) sensor being developed for the F-22, which is now confirmed to be the sensor housed inside the two pods, although they could host also other capabilities in addition to the IRST.

In July 2024 we got an up-close look at one of the pods installed under a Rockwell Sabreliner 65 testbed after a test campaign at Nellis AFB, Nevada. It would have been expected to see some kind of transparent surface associated with the IRST, however the surfaces on the nose of the pod appeared to be opaque. We still cannot exclude that there are two different variants of the pod, depending on the equipment inside.

The last upgrade featured in the artwork is a new unknown air-to-air missile. While there are a number of air-to-air missile programs in the works, it is possible that the one in the image could be a representative design, which may or may not correspond to the real deal, for the highly secretive AIM-260 missile. So far, the missile has never been depicted in any kind of image and details about the program are very scarce.

The development of the AIM-260, also called Joint Advanced Tactical Missile, was first unveiled in 2019 and has been in the works at least since 2017. The goal of the new long-range air-to-air missile is to replace the AIM-120 AMRAAM (Advanced Medium Range Air-to-Air Missile) and counter the threat posed by the Chinese PL-15 missile, while avoiding any foreign threats being able to outrange the AIM-120.

Among the few known technical details, the new missile will be compatible with the AMRAAM dimensions, but obviously with greater range, and is planned to be carried in the F-22 weapons bay and on the F/A-18 at first, with the F-35 to follow. Flight tests are already in progress and the missile is expected to be fielded by next year. Because of these reasons, it would be reasonable to suppose that the one shown in the image could be at least a hint at the AIM-260.

Other upgrades mentioned in the budget request are a Mode 5 Identification Friend or Foe (IFF), Link 16 and Multifunction Information Distribution System Joint Tactical Radio System (MIDS JTRS), a new Operational Fight Program, advanced radar Electronic Protection, Embedded GPS/Inertial Navigation System (INS) Modernization (EGI-M), Open System Architecture (OSA), new encrypted radios.

File photo of the U.S. Air Force’s 5th gen aircraft, the F-22 and the F-35. (Photo: U.S. Air Force)

A new helmet is also being tested by F-22 pilots, as part of the Next Generation Fixed Wing Helmet program to replace the current HGU-55P helmet, which has been the standard issued helmet for the last 40 years. The goal is to provide pilots a more comfortable, stable, and balanced platform to accommodate helmet-mounted devices usage without imposing neck strain and discomfort to the user.

Despite various integration efforts in the past, the F-22 is not equipped yet with a helmet that provides the essential flight and weapon aiming information through line of sight imagery: the shape of the Raptor’s canopy, optimized to preserve Low Observability, doesn’t allow enough range of motion and minimum visibility to a pilot wearing the JHMCS or the Scorpion.

About Stefano D'Urso

Stefano D'Urso is a freelance journalist and contributor to TheAviationist based in Lecce, Italy. A graduate in Industral Engineering he's also studying to achieve a Master Degree in Aerospace Engineering. Electronic Warfare, Loitering Munitions and OSINT techniques applied to the world of military operations and current conflicts are among his areas of expertise.

@The Aviationist.com

14 notes

·

View notes

Text

Elevating Precision Manufacturing: The Role of Mekalite’s CNC Machining Service

In today’s competitive manufacturing landscape, precision, efficiency, and adaptability are key to staying ahead. CNC machining has emerged as a vital technology, enabling manufacturers to produce complex and high-precision parts consistently. At Mekalite, we are redefining excellence in CNC machining services by combining advanced technology, a skilled workforce, and a commitment to quality.

https://mekalite.com/

What is CNC Machining?

CNC (Computer Numerical Control) machining is a process that uses computerized controls to operate machinery and tools with high accuracy. This enables the production of intricate parts from a variety of materials, including metals and plastics, while maintaining tight tolerances. CNC machining is critical in industries such as aerospace, automotive, medical devices, and electronics.

Why Choose Mekalite for CNC Machining?

Mekalite sets itself apart by offering a comprehensive approach to CNC machining, ensuring every project is handled with precision and care.

Advanced Machinery and Capabilities Our cutting-edge, multi-axis CNC machines allow us to handle even the most complex designs with precision and consistency. Whether you need rapid prototyping, low-volume manufacturing, or full-scale production, Mekalite’s technology enables us to meet your unique needs.

Customized Solutions We understand that every project is different. Mekalite works closely with each client to understand their specific requirements, delivering tailored solutions that align with their design and functionality goals.

Strict Quality Assurance At Mekalite, quality is our top priority. Our rigorous quality control protocols cover every step of the production process, from material selection to final inspection. This commitment ensures every part meets the industry’s highest standards.

Industries Served by Mekalite

Mekalite’s CNC machining services support a diverse range of industries, including:

Aerospace: High-precision components for engines, structural parts, and aircraft interiors.

Automotive: Custom engine parts, suspension components, and detailed bodywork.

Medical: Surgical instruments, implants, and diagnostic equipment requiring tight tolerances.

Electronics: Housing frames, connectors, and precision parts for delicate devices.

Benefits of Partnering with Mekalite

Choosing Mekalite as your CNC machining service provider offers numerous advantages:

High Precision and Accuracy Our state-of-the-art CNC machines, combined with skilled operators, enable us to achieve exceptional accuracy and repeatability across all projects.

Wide Range of Materials Mekalite’s expertise spans across various materials, from metals like stainless steel and aluminum to specialized plastics. This flexibility allows for innovative product designs and customized applications.

Cost Efficiency and Scalability With automated processes and minimal manual intervention, CNC machining reduces labor costs while enhancing efficiency. Whether you need a single prototype or a large production run, Mekalite’s scalable services can adapt to your requirements.

Timely Deliveries Time is crucial in manufacturing. Our efficient workflows and commitment to meeting deadlines ensure that your projects are completed on schedule, every time.

Looking Ahead: Mekalite’s Commitment to Innovation

Mekalite is committed to staying ahead of industry trends and technological advancements. By continually investing in the latest CNC machinery and refining our processes, we aim to provide even more innovative and reliable solutions to our clients. Our vision is to be a trusted partner in helping businesses achieve new levels of success through precision manufacturing.

Conclusion

CNC machining is revolutionizing the manufacturing industry, and Mekalite is at the forefront of this transformation. Our combination of cutting-edge technology, tailored solutions, and a dedication to quality makes us a preferred partner for businesses across various sectors.

If you’re looking for a reliable CNC machining service provider that delivers precision and value, Mekalite is here to help. Contact us today to discuss your next project!

https://mekalite.com/

2 notes

·

View notes

Text

Precision and Efficiency in CNC Metal Cutting with Fuson Precision Machining

In modern manufacturing, achieving precision and efficiency is critical to producing high-quality components. CNC metal cutting is a pivotal process that allows industries to create intricate metal parts with exceptional accuracy. Fuson Precision Machining is at the forefront of providing superior CNC metal cutting services. In this blog, we will explore the importance of CNC metal cutting, the benefits it offers, and why Fuson Precision Machining should be your go-to choice for this essential service.

Understanding CNC Metal Cutting

CNC (Computer Numerical Control) metal cutting is a manufacturing process that uses computer-controlled machines to remove material from a metal workpiece, creating precise shapes and designs. The process involves programming the desired dimensions into the CNC machine, which then guides cutting tools to perform precise cuts on the metal. This method ensures high levels of accuracy, repeatability, and efficiency, making it ideal for producing complex metal parts.

The Importance of CNC Metal Cutting

1. Precision and Accuracy

One of the key advantages of CNC metal cutting is its ability to achieve extremely tight tolerances. This precision is crucial in industries such as aerospace, automotive, and medical, where even the slightest deviation can lead to significant issues. With CNC metal cutting, manufacturers can produce parts that meet exact specifications, ensuring the highest levels of quality and reliability.

2. Efficiency and Productivity

CNC metal cutting is highly efficient, allowing for rapid production of metal components. The automation of the process reduces the need for manual intervention, minimizing errors and increasing productivity. This efficiency translates into faster turnaround times and cost savings for manufacturers, making CNC metal cutting an essential part of modern production.

3. Versatility

CNC metal cutting is versatile and can handle a wide range of metals, including steel, aluminum, brass, and titanium. This flexibility makes it suitable for producing a variety of components, from simple parts to complex geometries. Whether you need prototypes or high-volume production, CNC metal cutting can accommodate your needs.

Benefits of Choosing Fuson Precision Machining for CNC Metal Cutting

1. Expertise and Experience

Fuson Precision Machining boasts extensive experience and expertise in the field of CNC metal cutting. Our skilled technicians and engineers are proficient in handling complex projects and delivering precise metal components that meet the highest standards of quality. With years of industry experience, we understand the nuances of CNC machining and are equipped to tackle any challenge.

2. State-of-the-Art Equipment

We invest in state-of-the-art CNC machines and technology to ensure the best results for our clients. Our advanced equipment enables us to produce CNC metal cutting components with unparalleled accuracy and consistency. By leveraging cutting-edge technology, we can handle intricate designs and tight tolerances with ease.

3. Quality Assurance

Quality is at the core of everything we do at Fuson Precision Machining. We adhere to stringent quality control processes to ensure that every CNC metal cutting component meets or exceeds client expectations. Our commitment to quality is reflected in our ISO certification and our reputation for delivering reliable and precise metal parts.

4. Custom Solutions

We understand that each project is unique, and we offer customized solutions to meet specific requirements. Whether you need specialized materials, unique geometries, or specific finishes, we work closely with you to deliver CNC metal cutting components tailored to your needs. Our collaborative approach ensures that we provide solutions that align perfectly with your objectives.

Applications of CNC Metal Cutting

1. Aerospace Industry

In the aerospace industry, precision is critical. CNC metal cutting is used to produce components such as engine parts, landing gear components, and structural elements. The accuracy and reliability of these parts are essential for ensuring the safety and performance of aircraft.

2. Automotive Industry

The automotive industry relies on CNC metal cutting for the production of engine components, transmission parts, and various other critical elements. CNC metal cutting ensures that these parts meet the stringent standards required for vehicle performance and safety.

3. Medical Industry

In the medical field, CNC metal cutting is used to manufacture components for medical devices, implants, and surgical instruments. The precision and biocompatibility of these parts are vital for patient safety and effective medical treatment.

4. Electronics Industry

The electronics industry uses CNC metal cutting to create components for devices such as connectors, housings, and heat sinks. The ability to produce small, intricate parts with high precision is crucial for the functionality and reliability of electronic devices.

Success Stories: Fuson Precision Machining in Action

Client A: Aerospace Component Manufacturer

A leading aerospace component manufacturer turned to Fuson Precision Machining for the production of high-precision engine parts. Our expertise in CNC metal cutting enabled us to deliver components that met the stringent tolerances and quality standards required. The success of this project solidified our reputation as a reliable partner in the aerospace industry.

Client B: Medical Device Company

A medical device company required custom components for a new surgical instrument. Fuson Precision Machining provided tailored solutions, delivering precise CNC metal cutting components that ensured the instrument’s functionality and biocompatibility. Our collaborative approach and commitment to quality played a key role in the successful launch of the product.

Conclusion: Partner with Fuson Precision Machining for Superior CNC Metal Cutting

CNC metal cutting is essential for achieving precision, efficiency, and versatility in manufacturing. Fuson Precision Machining offers unparalleled expertise, state-of-the-art equipment, and a commitment to quality, making us the ideal partner for all your CNC metal cutting needs. Whether you operate in aerospace, automotive, medical, or electronics industries, we provide customized solutions that meet your specific requirements.

Contact Fuson Precision Machining today to learn more about our CNC metal cutting services and discover how we can help you achieve your manufacturing goals with precision and efficiency.

#CNC Metal Cutting#cnc metal fabrication#cnc metal process#CNC Work#prototype machining#cnc machining prototype

2 notes

·

View notes

Text

Unlocking the Potential of 3D Printing: A Guide to PrintPrizm3D

Welcome to the world of 3D printing with PrintPrizm3D! Whether you’re a hobbyist, a small business owner, or an innovator looking to turn your ideas into reality, 3D printing offers limitless possibilities. At PrintPrizm3D, we specialize in providing high-quality 3D printing services that cater to a wide range of needs. Discover how our services can help you bring your visions to life and explore the benefits of incorporating 3D printing into your projects.

What is 3D Printing?

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects from a digital file. By layering materials such as plastic, metal, or resin, 3D printers can produce complex shapes and intricate designs with precision and accuracy. This technology has revolutionized industries, including aerospace, automotive, healthcare, and fashion, by offering rapid prototyping, custom manufacturing, and cost-effective production.

Why Choose PrintPrizm3D?

At PrintPrizm3D, we pride ourselves on delivering top-notch 3D printing services. Here’s why you should choose us for your next project:

High-Quality Prints: We use advanced 3D printers and materials to ensure your prints are of the highest quality. Whether you need a prototype, a functional part, or a decorative item, we’ve got you covered.

Expertise and Experience: Our team has extensive experience in 3D printing and design, enabling us to handle a variety of projects with skill and efficiency.

Customer Satisfaction: We are committed to providing exceptional customer service. From the initial consultation to the final product, we work closely with you to meet your specific needs and expectations.

Our Services

PrintPrizm3D offers a comprehensive range of 3D printing services to cater to various requirements:

Prototyping: Quickly and accurately create prototypes to test and refine your designs.

Custom Manufacturing: Produce custom parts and products tailored to your specifications.

Design Services: Our expert designers can help you create and optimize your 3D models for printing.

Educational Workshops: Learn about 3D printing technology and its applications through our informative workshops.

Visit Our Online Stores

Explore our wide range of 3D printed products and services on our online platforms:

PrintPrizm3D Website: PrintPrizm3D Website

PrintPrizm3D eBay Store: PrintPrizm3D eBay Store

Connect with Us on Social Media

Stay updated with our latest projects, promotions, and 3D printing tips by following us on social media:

Facebook: PrintPrizm3D Facebook Page

Instagram: PrintPrizm3D Instagram

Rippin-R-Us Instagram: Rippin-R-Us Instagram

Rippin-R-Us Facebook: Rippin-R-Us Facebook

Get in Touch

Have questions or need assistance with your 3D printing project? Contact us at [email protected]. We’re here to help you every step of the way!

Conclusion

3D printing is transforming the way we create and innovate. At PrintPrizm3D, we’re dedicated to providing high-quality 3D printing services that help you turn your ideas into reality. Visit our online stores, connect with us on social media, and discover how we can assist you with your next project. Embrace the future of manufacturing with PrintPrizm3D!

For further insights and tips on 3D printing, subscribe to our blog and stay tuned for more updates. Happy printing!

#ShopNow#OrderNow#BuyNow#LimitedEdition#NewArrival#3DPrinting#AdditiveManufacturing#3DPrint#3DPrintingCommunity#3DPrintingTechnology#3DPrinted#3DPrinter#3DPrintingService#Prototyping#ProductDesign#CustomManufacturing#RapidPrototyping#Engineering#ProductDevelopment#TechInnovation#eBayStore#eBayDeals#ShopOnEbay#EbayFinds#EbaySeller#FacebookMakers#3DPrintingFB#MakerSpace#Insta3DPrinting#3DPrintingArt

2 notes

·

View notes

Text

Top providers for 3D printing Services in Malaysia.

Projet Technology : This company provides 3D printing services catering to individuals, industrial, and educational institutions. While they are one of the leading 3D printing service providers in Malaysia, they also provide their services to hobbyists nationwide. They offer prototyping, production, and customization services using a range of materials. Projet is Malaysia’s reliable, one-stop 3D printing service provider. WEBSITE : http://projet.my

Why Choose Projet.my for Rapid Prototyping and 3D Printing in Malaysia?

Cutting-Edge Technology: At Projet.my, we leverage cutting-edge 3D printing technology to deliver unparalleled precision and quality in every prototype. Our state-of-the-art machinery ensures that your designs are brought to life with utmost accuracy, allowing for seamless iterations and improvements.

Custom Solutions:

No two projects are alike, which is why we offer tailor-made solutions to suit your specific needs. Whether you require intricate prototypes for product testing or high-volume production runs, our team at Projet.my is equipped to handle it all with finesse.

Speedy Turnaround:

Time is of the essence in the world of product development. With Projet.my, you can expect swift turnaround times without compromising on quality. Our streamlined processes and efficient workflows ensure that your prototypes are delivered promptly, giving you the edge in today’s competitive market.

Rapid Prototyping & 3D Printing Service Malaysia | Projet.my

Cost-Effective Solutions: We understand the importance of cost-effectiveness in every project. That’s why we offer competitive pricing options without compromising on the quality of our services. With Projet.my, you can achieve cost-effective solutions that meet your budgetary requirements without sacrificing on excellence.

Expert Guidance:

Navigating the world of rapid prototyping and 3D printing can be daunting, but fear not — our team of experts at Projet.my is here to guide you every step of the way. From initial concept to final production, we provide comprehensive support and expertise to ensure your project’s success.

Rapid Prototyping:

From concept to prototype, we specialize in rapid prototyping services that help you iterate quickly and efficiently. Whether you’re testing new designs or refining existing ones, our rapid prototyping solutions are designed to accelerate your product development process.

3D Printing:

Our advanced 3D printing capabilities allow for unparalleled precision and detail in every print. Whether you need functional prototypes or intricate models, our 3D printing services deliver exceptional results that exceed expectations.

Customization:

We understand that every project is unique, which is why we offer customizable solutions to meet your specific requirements. Whether you need bespoke materials, finishes, or design modifications, our team at Projet.my is dedicated to bringing your vision to life with precision and care.

#3d printing#3dprintingservice#additivemanufacturing#malaysia#penang#3d scanning services#3d printing service#rapid prototyping#fabrication#solution

2 notes

·

View notes

Text

PTS-Rapid Prototyping & On-demand Production Services https://www.ptsindu.com/

PTS Industrial Ltd was founded in 2002, located in Dong Guan and Shenzhen, China. PTS starts from precision plastic injection molds making, and step into plastic injection molding services, cnc machining services, After 20 years of development, now we have 4 subsidiaries. Since 2002, PTS has been proudly providing high-quality CNC machining parts, injection molding services, and plastic injection molds to a diverse range of industries, Serving well-known companies such as HUA WEI, BMW, EPSON, etc.

plastic injection molding services, cnc machining services, cnc milling services, cnc turning services, plastic injection molds maker

9 notes

·

View notes

Text

Are you looking for a reliable and precise low-volume manufacturing service?

Look no further! 🌟

At ProtoTech Machining, we are not just a manufacturer; we innovate with precision.🛠️

Our company specializes in top-notch low-volume manufacturing services that are tailored to various industry needs such as aerospace, medical, automotive, robotics, and many other sectors. From CNC machining to Rapid prototyping and Sheet Metal Fabrication, our expert team can leverage cutting-edge technologies to turn complex designs into reality. 🚀

Plus, whether you need 3D printing, 5-axis, or Swiss CNC machining, we have the best capabilities to provide innovative and cost-effective solutions without compromising quality. ✨

So don’t wait any longer! Contact us now and let us be your partner in all your manufacturing needs. 📞

Browse https://prototech-machining.com/low-volume-manufacturing/ to learn more.

#prototechmachining#3dprinting#cncmachining#technologies#swisscncmachining#manufacturing#innovative#metalfabrication#aerospace#medical#automative#robotics

2 notes

·

View notes

Text

Exploring the Python and Its Incredible Benefits:

Python, a versatile programming language known for its simplicity and adaptability, holds a prominent position in the technological landscape. Originating in the late 1980s, Python has garnered substantial attention due to its user-friendly syntax, making it an accessible choice for individuals at all levels of programming expertise. Notably, Python's design principles prioritize code clarity, empowering developers to articulate their ideas effectively and devise elegant solutions.

Python's applicability spans a multitude of domains, encompassing web development, data analysis, artificial intelligence, and scientific computing, among others. Its rich array of libraries and frameworks enhances efficiency in diverse tasks, including crafting dynamic websites, automating routine processes, processing and interpreting data, and constructing intricate applications.

The confluence of Python's flexibility and robust community support has driven its widespread adoption across varied industries. Whether one is a newcomer or an accomplished programmer, Python constitutes a potent toolset for software development and systematic problem-solving.

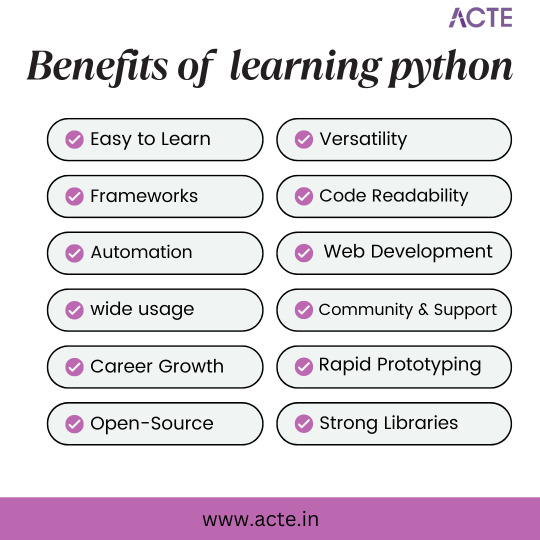

The ensuing enumeration underscores the merits of acquainting oneself with Python:

Accessible Learning: Python's straightforward syntax expedites the learning curve, enabling a focus on logical problem-solving rather than grappling with intricate language intricacies.

Versatility in Application: Python's versatility finds expression in applications spanning web development, data analysis, AI, and more, cultivating diverse avenues for career exploration.

Data Insight and Analysis: Python's specialized libraries, such as NumPy and Pandas, empower adept data analysis and visualization, enhancing data-driven decision-making.

AI and Machine Learning Proficiency: Python's repository of libraries, including Scikit-Learn, empowers the creation of sophisticated algorithms and AI models.

Web Development Prowess: Python's frameworks, notably Django, facilitate the swift development of dynamic, secure web applications, underscoring its relevance in modern web environments.

Efficient Prototyping: Python's agile development capabilities facilitate the rapid creation of prototypes and experimental models, fostering innovation.

Community Collaboration: The dynamic Python community serves as a wellspring of resources and support, nurturing an environment of continuous learning and problem resolution.

Varied Career Prospects: Proficiency in Python translates to an array of roles across diverse sectors, reflecting the expanding demand for skilled practitioners.

Cross-Disciplinary Impact: Python's adaptability transcends industries, permeating sectors such as finance, healthcare, e-commerce, and scientific research.

Open-Source Advantage: Python's open-source nature encourages collaboration, fostering ongoing refinement and communal contribution.

Robust Toolset: Python's toolkit simplifies complex tasks and accelerates development, enhancing productivity.

Code Elegance: Python's elegant syntax fosters code legibility, promoting teamwork and fostering shared comprehension.

Professional Advancement: Proficiency in Python translates into promising career advancement opportunities and the potential for competitive compensation.

Future-Proofed Skills: Python's enduring prevalence and versatile utility ensure that acquired skills remain pertinent within evolving technological landscapes.

In summation, Python's stature as a versatile, user-friendly programming language stands as a testament to its enduring relevance. Its impact is palpable across industries, driving innovation and technological progress.

If you want to learn more about Python, feel free to contact ACTE Institution because they offer certifications and job opportunities. Experienced teachers can help you learn better. You can find these services both online and offline. Take things step by step and consider enrolling in a course if you’re interested.

10 notes

·

View notes

Text

7 Facts You Must Know Regarding Startups In 2023

You are saying that you have a burning inkling that you think could transform the world in any way? Oh, you are desiring about earning millions or even billions of dollars by launching a business around this boiling idea? Then you could probably be the father of a Startup.

Industry professional, Ashish Aggarwal, CEO of Acube Ventures insinuates that Startups are prominent business prototype that steers invention and economic promotion across the world. An exotic set of products and services are established by startups each year. They are the articulation of imaginative and ambitious entrepreneurs who have remarkable ideas.

India has evolved to be the third-largest startup ecological community in the world after the US and China. The first Unicorn was seen in India in 2011, and almost after a decade in 2022, India crossed the mark of 100 Unicorns. The bragging of 100 Unicorns is not an ordinary affair, and that is why the startup ecosystem is flinging in joy and bulging with dignity.

"Startups in India have grown remarkably over the last six years.

The number of newly recognised startups around the world has heightened to over 14,000 in 2021-22 from only 733 in 2016-17, a survey said.

When someone says the word “startup”, we usually instantly think of diverse triumph stories and exponential business expansion. However, in actuality, not all startups are prosperous. We usually only hear about the winners, and that is one-sided information that doesn’t tell the entire story. Everyone wants to listen to favourable achievement anecdotes, but you need to know all of the details if you want your startup to prosper.

Mr Ashish Aggarwal, an Industry Expert and Consultant has laid out 7 most crucial details about startups, including statistics, facts, and trends that will help you give a decent awareness of the universal startup landscape:

1. Dispersion of startups worldwide as per industry - 7.2% of the startups in the world function in the Fintech industry which is followed by the healthcare sector with 6.9%, Artificial intelligence with 4.9%, Gaming industry with 4.7%, Adtech commerce with 3.2%, and Edtech sector with 2.9%. Even though there isn’t entirely accurate data about enterprise dispersion, it’s clear that contemporary startups gravitate more towards the online network, cyberspace, the internet and digital technologies. With this information, we can also discern which industry is adequate for startups at the moment.

2. The valuation of E-Commerce revenues globally is approximately $3.5 trillion - E-Commerce is one out of the most prominent industries for young startups with rapid growth expected in the future. The next enterprise in line is “FinTech” i.e. Financial technology. Another huge focus of new startups is cybersecurity. These companies realize how crucial online security will be in the future. FoodTech combines food and technology and is another famous enterprise for startups. With over $16 billion of investments in 2018, EdTech is coming to be another outstanding startup industry that provides educational technology remedies to people worldwide.

3. Over 68% of startup businesses started as home businesses - The idea has to commence somewhere and form posture. Even though maximum startups don’t have the integral allocation at the onslaught to insulate office expenses, they can launch their operations from home.

4. The ‘sharing economy market' is expected to cross a total revenue of $335 billion by 2025 - In just a matter of a few years, sharing economy startups namely, Airbnb and Uber have grown exponentially and solidified a global existence. At the moment, Airbnb is valued at $24 billion, and Uber is worth $50 billion. In 2014, the total revenue of market sales was $17 billion, which means that in just eight years, the projected earnings of this market grew more than 20 times.

5. AI is presently the most profitable innovation technology -Over 63℅ of entrepreneurs agree that AI, not just presently but for at least the next 10 years is the most prominent technology. The tracts of this technology with the highest potential are autonomous transportation and huge data. Even though these two sectors are already making strides, it’s anticipated that they will flourish substantially in the close future.

6. ByteDance is valued at over $350 billion - The most profitable unicorn company in the world, ByteDance (China) is a tech company that owns Tiktok. There are presently 1000+ Unicorn companies around the world. However, the maximum of them is tracked down in China or the United States.

7. 95% of entrepreneurs that establish startups have at least a bachelor’s degree - Many people claim that education isn’t significant. They talk about Mark Zuckerberg and Elon Musk as instances. However, the majority of the people who birthed the world’s most triumphant startups have a higher education.

Ashish Aggarwal aspires to watch numerous Indian Startup Parents succeed in their entrepreneurial endeavours, which is why he shares his invaluable insights about startups. According to him, The startup industry will persist to be the driving component for global innovation and business development for many years. Nonetheless, companies must learn how to adapt to trends while being endurable and productive so that more startups can withstand the dynamic business environment.

#ashish aggarwal#ashish aggarwal indo innovation#ashish aggarwal acube venture#ashish aggarwal space mnatra

2 notes

·

View notes

Text

Grak't could not understand what they were hearing. They tapped the translation device mounted to the side of their scaly head and motioned for their human counterpart to repeat their statement.

Brittany, a human scientist, sighed, "We just finished early work on what is essentially hardlight."

"I am afraid the translator does not like this combination of words. How is it that light is stiffened?" Grak't tilted their head inquisitively as they scratched their neck with a claw, a common gesture of puzzlement in their saurian species.

Grak't and Brittany had been friends for many cycles so she readily understood the gesture and explained further, "I won't bore you with the details but the part you will like is that it slows down bullets and can block out many forms of radiation."

"Bullets being slowed is usually good, stopped better. The radiation blocking sound like Yillid projection shielding for ships."

"I always forget you were a spacer before you came here," Brittany smiled up at her friend. Grak't was a Makitian, one of many reptile-like species collectively referred to as saurians, with Makitians being known specifically for their size and strength. A species relegated largely to more physical positions such as labor, or combat; Grak't was a seeming rarity in that they had pursued high education and secured a decade of service as security aboard a space faring vessel. This had made them perfect for working as a guard for a then newly built research facility. Most species had found a niche or two where they fit in on the galactic scale but not humans. "The technology is based on Yillid designs, but we've focused on making it man portable. It's not perfect yet but, we know we're on the right track. In a few years we'll have proper prototypes to show the Alliance scientists."

"This is sounding like it will be another Walker situation," Grak't said, a tone of admiration clear in their voice. Grak't had always been enamored of the human made Walkers. The technology for them had been around in many societies and known by many names: vertical tanks, mobile gun platforms, and walking assault vehicles were a few of the more popular naming conventions. The idea had been scrapped by most as impossible to produce in a meaningful way until humans came along and combined the technology of at least twelve different species to create the modern Walker, though humans insisted on calling them mechanized armored chassis or mechs for short. This became a runaway success and changed so many fields at such a rapid pace that entire industries on a galactic scale had to shift design to account for Walker usage. Such revolutions in technology had become the human's hallmark. While they rarely were the ones to lay down groundwork, they had proven ad nausem that they were able to adapt, expand, and perfect any tech left within grabbing distance of their five-fingered hands. The Makitian drummed their claws excitedly on the cafeteria table, before they suggested with a polite cough, "I am willing to ah, test, some of this if extra hands are needed, yes?"

Brittany paused before the spoon reached her mouth, "Of course Grak't, as always."

"This is good! I am very excited, new shields for Alliance members means better safety measures, and better safety, fewer casualties." Grak't paused before continuing in a more conspiratorial tone, leaning their body lower and closer to Brittany's, unable to disguise their joy, "The Yillids will be so angry they did not make first, oh-ho the little buggy faces will be filled with chitterings and moanings of the numbers needed for 'review'."

"That's the plan!" the human laughed with her Makitian friend. Brittany knew Grak't had a bad history with a Yillid hive but had never seen them so excited at the prospect of humiliating the insectoid beings. Then again, the Yillid announcement of a new propulsion system had ruffled more than a few feathers, literal or otherwise, across the science NetBoards. A new technology being built up from something they had left behind might be to some the perfect way to get a leg up on them. Brittany winked as she gave an exaggeratedly evil smile, "And you know by the time they've finished their review we'll have gotten a hold of those new engines of theirs, maybe even corrected a flaw or two!"

"This why I took job here, humans always looking to make things best. Like with metal, always refining, adapting and overcoming always. That why humans have best standard of living this side of galaxy. I wanted piece of mind and way to make the oh-so-smarts blink in frustration," Grak't gave a rumbling laugh as they stood up from the table, "Tell the team I offer service as assistant should they need, I know a few others in security team who would be interested."

Brittany nodded and waved as their companion left the table. Being able put 'Makitian tested' or 'Makitian proof' was shorthand for durable as all hell and if they can get a few others on board, the launch of the new shields would do wonders to advance human aligned interests. Humanity may have found themselves lacking compared to insectoid intelligence, saurian strength, felinid grace, and a great many other traits that other species in the known galaxy might boast but, it doesn't matter if humans can run technological circles around everyone collectively. "Adapt and overcome indeed."

Turns out that humans are painfully average compared to the rest of the galaxy. This fact is so embarasssing that humanity starts rapidly advancing technologically just to show those aliens who’s boss.

9K notes

·

View notes