#Radial Flux Motor

Explore tagged Tumblr posts

Text

Axial Flux Motor vs. Radial Flux Motor

Axial Flux Motor vs. Radial Flux Motor Axial flux and radial flux motors are two common motor types with distinct designs and characteristics. Each has advantages that make it suitable for different applications, from automotive to industrial uses. Here’s an in-depth comparison of their construction, performance, and ideal use cases. 1. Design and Construction – Axial Flux Motor: In an axial flux…

0 notes

Text

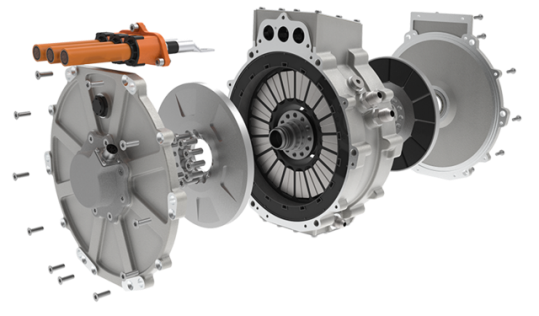

Koenigsegg Gemera V8, 2023. The Swedish hypercar maker has revealed details of a new, more extreme version of their 4-seat Gemera model. The packaging uses Koenigsegg's Light Speed Tourbillon Transmission (LSTT) combined with a new Radial Flux E-motor they call Dark Matter and a modified Jesko 5.0-litre twin-turbo V8 to produce total 2,300hp (1,715 kW) and 2,028 lb-ft (2,750 Nm) of torque. Production of the Gemera (3cylinder and V8) is limited to 300 units

#Koenigsegg#Koenigsegg Gemera#Koenigsegg Gemera V8#2023#new cars#hypercar#hybrid hypercar#Jesko V8#Dark Matter#limited edition

447 notes

·

View notes

Text

youtube

What You'll Learn:

✅ Stator and rotor topologies: Outer vs. Inner rotor designs. ✅ Surface and interior permanent magnet configurations. ✅ Radial flux vs. axial flux machines: Key differences and applications. ✅ Design rules for stator slots and winding configurations. ✅ Introduction to computer simulation for motor design. ✅ Using Ansys RM Expert for template-based motor design.

💡Check out the previous episodes of this series here: https://www.youtube.com/playlist?list=PL9-f9hWLZS61I2GoQAXCVwwYLclPNZZwA

If you’re interested in speaking with our experts and scheduling a personalized career plan, call us at +91-9342691281 or register here: https://bit.ly/3ZrJxZ9

#skilllync#youtube#mechanicalengineering#ansys#3D ansys#ansysfluent#electric cars#electricvehicle#electrical#Youtube

0 notes

Text

[ad_1] EVR Motors which are designed in Israel, now Made in India for the World, are transforming the electric motor industry with its groundbreaking Trapezoidal Stator Radial Flux Permanent Magnet (TS-RFPM) technology. While the innovation has garnered significant attention for its ability to address key challenges in electric vehicles (EVs) and industrial applications, EVR Motors is now focusing on industrializing its technology to meet growing global demands. This transition marks a pivotal shift from groundbreaking innovation to industrial stability. EVR electric motor line new - Photo by Kseniia Poliak EVR Motors has designed its patented TS-RFPM technology to redefine electric motor. Its smaller size, reduced weight, and cost-effective production offer significant advantages over existing radial flux permanent magnet motors. At the heart of this effort is EVR's new greenfield manufacturing facility in Manesar, India, operated under its subsidiary, I.EVR Motors Pvt Ltd. This plant is equipped to produce trapezoidal geometry coils—a key component of EVR's electric motor topology—at scale. With advanced automation, the facility is capable of manufacturing coils for up to 20,000 motors per month, with plans to increase capacity to 100,000 motors as demand surges. Sajal Kishore, Managing Director, EVR Motors states, “Our industrialization strategy is deeply rooted in partnerships with leading players in the automotive industry. The motor manufacturing lines at EVR's partner facilities, Napino, EKA Mobility, and RSB Transmissions are poised to produce EVR’s motors for a variety of vehicle segments, including two and three-wheelers, light commercial vehicles, passenger cars, and e-buses.The partnerships represent a collective effort to accelerate the adoption of sustainable electric mobility solutions. The Manesar facility plays a critical role in supporting these collaborations.” Eli Rozinsky, Founder & President, EVR Motors, “Our focus has expanded from research and development to establishing industrial reliability and scalability. The shift involves creating robust manufacturing processes, building a dependable supply chain, and ensuring consistent quality for its motors across applications. By achieving this, we are paving the way for its TS-RFPM technology to become a global standard.” In addition to meeting domestic demand, EVR Motors has set its sights on international markets. The Manesar facility will not only support Indian manufacturers but also cater to global clients by exporting its trapezoidal geometry coils. Exporting coils marks a significant step toward global scalability. EVR’s ability to supply critical components to manufacturers worldwide underscores its industrial readiness and positions the company as a key player in the international electric motor market. About Us EVR Motors is an Israeli firm which designs advanced electric motors to meet every customer’s specific requirement. The company’s electric motors are based on proprietary technology that reduces weight, volume, and cost relative to traditional state of the art motors. EVR Motors partners with OEMs and Tier 1s interested in manufacturing superior e-motors, and supports its partners through all the phases, from motor design through prototyping to manufacturing preparation. EVR is now industrializing a variety of motors, suitable for most mobility and industrial applications in it’s facilities in Israel. Profile Sajal Kishore: Sajal Kishore is the Managing Director for I.EVR Motors. He has held key corporate functions in General Management, Corporate Strategy & Planning and Business Development. Former CEO at JS Power and Head Corporate Strategy & Planning at Napino. Holds MBA from Banaras Hindu University and an Industrial Engineering degree from RVCE. Profile Eli Rozinsky: Eli Rozinsky is the President & COO, Co-Founder of EVR Motors. Start-up

veteran, with a demonstrated history of working in the renewables, electric vehicles and IT industries. B.Sc. in Electrical Engineering. In 2012 together with Victor Kislev, and Ruslan Shabinski, Eli founded EVR Motors re-inventing electric motor topology. !function(f,b,e,v,n,t,s) if(f.fbq)return;n=f.fbq=function()n.callMethod? n.callMethod.apply(n,arguments):n.queue.push(arguments); if(!f._fbq)f._fbq=n;n.push=n;n.loaded=!0;n.version='2.0'; n.queue=[];t=b.createElement(e);t.async=!0; t.src=v;s=b.getElementsByTagName(e)[0]; s.parentNode.insertBefore(t,s)(window,document,'script', 'https://connect.facebook.net/en_US/fbevents.js'); fbq('init', '311356416665414'); fbq('track', 'PageView'); [ad_2] Source link

0 notes

Text

[ad_1] EVR Motors which are designed in Israel, now Made in India for the World, are transforming the electric motor industry with its groundbreaking Trapezoidal Stator Radial Flux Permanent Magnet (TS-RFPM) technology. While the innovation has garnered significant attention for its ability to address key challenges in electric vehicles (EVs) and industrial applications, EVR Motors is now focusing on industrializing its technology to meet growing global demands. This transition marks a pivotal shift from groundbreaking innovation to industrial stability. EVR electric motor line new - Photo by Kseniia Poliak EVR Motors has designed its patented TS-RFPM technology to redefine electric motor. Its smaller size, reduced weight, and cost-effective production offer significant advantages over existing radial flux permanent magnet motors. At the heart of this effort is EVR's new greenfield manufacturing facility in Manesar, India, operated under its subsidiary, I.EVR Motors Pvt Ltd. This plant is equipped to produce trapezoidal geometry coils—a key component of EVR's electric motor topology—at scale. With advanced automation, the facility is capable of manufacturing coils for up to 20,000 motors per month, with plans to increase capacity to 100,000 motors as demand surges. Sajal Kishore, Managing Director, EVR Motors states, “Our industrialization strategy is deeply rooted in partnerships with leading players in the automotive industry. The motor manufacturing lines at EVR's partner facilities, Napino, EKA Mobility, and RSB Transmissions are poised to produce EVR’s motors for a variety of vehicle segments, including two and three-wheelers, light commercial vehicles, passenger cars, and e-buses.The partnerships represent a collective effort to accelerate the adoption of sustainable electric mobility solutions. The Manesar facility plays a critical role in supporting these collaborations.” Eli Rozinsky, Founder & President, EVR Motors, “Our focus has expanded from research and development to establishing industrial reliability and scalability. The shift involves creating robust manufacturing processes, building a dependable supply chain, and ensuring consistent quality for its motors across applications. By achieving this, we are paving the way for its TS-RFPM technology to become a global standard.” In addition to meeting domestic demand, EVR Motors has set its sights on international markets. The Manesar facility will not only support Indian manufacturers but also cater to global clients by exporting its trapezoidal geometry coils. Exporting coils marks a significant step toward global scalability. EVR’s ability to supply critical components to manufacturers worldwide underscores its industrial readiness and positions the company as a key player in the international electric motor market. About Us EVR Motors is an Israeli firm which designs advanced electric motors to meet every customer’s specific requirement. The company’s electric motors are based on proprietary technology that reduces weight, volume, and cost relative to traditional state of the art motors. EVR Motors partners with OEMs and Tier 1s interested in manufacturing superior e-motors, and supports its partners through all the phases, from motor design through prototyping to manufacturing preparation. EVR is now industrializing a variety of motors, suitable for most mobility and industrial applications in it’s facilities in Israel. Profile Sajal Kishore: Sajal Kishore is the Managing Director for I.EVR Motors. He has held key corporate functions in General Management, Corporate Strategy & Planning and Business Development. Former CEO at JS Power and Head Corporate Strategy & Planning at Napino. Holds MBA from Banaras Hindu University and an Industrial Engineering degree from RVCE. Profile Eli Rozinsky: Eli Rozinsky is the President & COO, Co-Founder of EVR Motors. Start-up

veteran, with a demonstrated history of working in the renewables, electric vehicles and IT industries. B.Sc. in Electrical Engineering. In 2012 together with Victor Kislev, and Ruslan Shabinski, Eli founded EVR Motors re-inventing electric motor topology. !function(f,b,e,v,n,t,s) if(f.fbq)return;n=f.fbq=function()n.callMethod? n.callMethod.apply(n,arguments):n.queue.push(arguments); if(!f._fbq)f._fbq=n;n.push=n;n.loaded=!0;n.version='2.0'; n.queue=[];t=b.createElement(e);t.async=!0; t.src=v;s=b.getElementsByTagName(e)[0]; s.parentNode.insertBefore(t,s)(window,document,'script', 'https://connect.facebook.net/en_US/fbevents.js'); fbq('init', '311356416665414'); fbq('track', 'PageView'); [ad_2] Source link

0 notes

Text

Journey of Innovation to Industrialization-EVR, the Next Generation of Electric Motors

EVR Motors which are designed in Israel, now Made in India for the World, are transforming the electric motor industry with its groundbreaking Trapezoidal Stator Radial Flux Permanent Magnet (TS-RFPM) technology. While the innovation has garnered significant attention for its ability to address key challenges in electric vehicles (EVs) and industrial applications, EVR Motors is now focusing on…

0 notes

Text

Axial Flux Motor Market – Forecast (2023-2028)

Axial Flux Motor Market Report Overview

The Axial Flux Motor market size is forecast to reach USD 1387.7 million by 2030, after growing at a CAGR of 11.8% during the forecast period 2024-2030. Axial flux motors are suited for applications that require a high torque density in a small footprint. Axial flow drives are also known as flattened and pancake electrically commutated motors due to their extremely low axial length-to-diameter ratio. It delivers more torque and power density than radial flux motors while using the same electrical components. When an axial flux motor has this feature, the battery lasts longer, making these motors more economically viable.

Axial flux motors are being used more frequently in a variety of new industries, including electric bikes, delivery vehicles, airport pods, electric cars, and even airplanes owing to the recent technology breakthroughs and a push towards electrification. The axial flux type was the first motor to be created in history. Therefore, it is difficult to imagine that these motors have found such a wide range of applications in the past two decades. First, it was extensively utilized for storage needs in the agricultural industry and elevators. Additionally, as axial flux motors are more efficient than radial motors, the market for them is expected to create considerable profits over the course of the projection period. Compared to a radial motor, this motor's small length offers great torque over speed. Additionally, when employed in the automotive industry, its small size and low weight reduce the weight of automobiles. In 2022, North America held 34.54% market share of the axial flux motor market, and is expected to grow at a significant compounded annual growth rate of 11.9% during the forecast period (2023-2030). The region is a hub for electric vehicle (EV) manufacturing and innovation, with automakers increasingly adopting axial flux motors for their EVs. Additionally, the growing renewable energy sector, including wind power projects, contributes to the demand for these motors. Asia Pacific, led by China, is a rapidly growing market for axial flux motors, driven by its extensive manufacturing capabilities and increasing adoption of electric vehicles. With the ever-expanding adoption of electric vehicles (EVs) in the region, China has emerged as a global leader in the EV market, which in turns fuels the demand for axial flux motors to new heights.

Furthermore, using axial motors minimizes vehicle weight by reducing the amount of space occupied by machinery. Transportation corporations' growing investment in the electric vehicle market would give substantial growth opportunities for the Axial Flux Motor Market. Product demand is expected to benefit from a growing focus on refining design and manufacturing processes in order to produce better products with greater efficiency, which further enhances the industry expansion for permanent magnet synchronous motors. Rising awareness of environmental preservation around the world is predicted to boost the adoption of electric vehicles and heat recovery ventilation, which will drive axial flux motor demand in 2024-2030.

Report Coverage

The report “Axial Flux Motor Market – Forecast (2024-2030)”, by IndustryARC, covers an in-depth analysis of the following segments of the Axial Flux Motor market.

By Cooling Process: Air Cooling, Liquid Cooling.

By Power: 1kw-15kw, 15kw-80kw, 80kw-160kw, Above 160kw.

By Application: Electric Passenger Vehicles, Commercial Vehicles, Industrial Machinery, Elevators, Robotics Actuators, and Propulsion Systems, Aircrafts & Electric Glider Planes, Yachts & Electric Boats, Electric Drones, Others.

By End-User Industry: General Manufacturing, Power, Construction, Automotive, Aerospace, Marine, Agriculture, Others.

By Geography: North America, South America, Europe, APAC, and RoW.

Key Takeaways

• The Electric Passenger Vehicles segment is expected to grow at a CAGR of 12.6% during the forecast period 2024-2030 owing to the increase in government initiatives and key players strategic approaches to maintain the dominance.

• Automotive dominated the Axial Flux Motor Market with a revenue of $238.06m in 2023 and is projected to reach $477.11m by 2030 and is also set to be the fastest-growing segment with a CAGR of 10.6% during the forecast period 2024-2030. Axial flux electric motors are in high demand across a variety of vehicle industries and across numerous geographical locations, thanks to the continuously developing automotive sector.

• Europe region is dominating the Axial Flux Motor Market with revenue of $186.68 m in 2023 and is estimated to grow at a CAGR of 11.9% during the forecast period of 2024-2030 to generate a revenue of $405.55m in 2030. The government's aggressive measures for the adoption of electric vehicles have aided the sector's massive growth throughout Europe.

• The growing demand for high power density axial flux motors is enhancing the industry expansion and is set to positively impact the market growth.

1 note

·

View note

Text

Posthuman Review: Shaun Lawton & Nicholas Alexander Hayes

"In a few quick years, the first transhuman in vivo Minksian-Kurzweill clone emerges from its neonatal intensive care unit, eyes unblinking. Max quickly grows to establish the first CORE school (Consilience Of Recombinant Extropy) by the seasoned age of four. In the year 2020, eight-year-old Max engenders a transubstantiative doctrine reprising Heraclitus's ideas of flux. He publishes his manifesto >H by sending it back in time to his conception-year, where it now happens to appear on certain nodal points of the internet. Stars and their remnants, in the beginning, appear perfect with our skulls the shape of eggs while we listen to the music of the spheres. We never know we are dreaming, despite the uncanny appearance of our faces barely submerged below the surface of an image trapped on a screen, as if gazing at a host of cameras that were recording the whole scene and playing it back in overlapping sequences until rendered in 3D, a sort of holographic emergence as a film to show the whole fully recorded history of the human race intact in one performance taking hours to play out that tells the story of our pregalactic form expanding like a cell splitting into divisions congruent with the microchip cluster each acquires to their myriad snowflakes and fingerprints; no two are quite alike, this quality of uniqueness the most common attribute in the galaxy because it takes its shape from the constant force it has been from the beginning, a dorsal fin configuration pre-eminent to radial symmetry, subdivided from the pie & expanding in the recesses of our own mind at rates which we don’t share and we don't want to have to admit even to ourselves it could be the case but on the face of it our individuality evaporates along with the rest of the universe, siphoning itself back & forth both in and out of existence, in a blinking state of awakened beings cycled in an infinite figure eight Mobius strip, along the thermodynamic principle where the electromagnetic motors of creation pass along the triggering current arriving in its multiplicity of waves so here we are much further away from the start than we'd ever imagined before making it in a world on the verge of boiling over with accelerating change to the point it's quaking under this pretense we begin thinking about the stars & their remnants to which we end up belonging while the motion picture of our lives flashes inside our mind in an effortless gesture disarming the gravid affront with united civic resistance paving the way forward for the benefit of our progression into the distance only going to show which ends up being the case that it doesn't really matter so much as the belief we hold well and verily fixed foremost in our mind unravels before a hand to be woven in predetermined fashion foremost reveals the negative gravity bound pressure resistance capsule in the shape of a psychonautical skull transcript." - Shaun Lawton

Δ = (Σ(bug + defect + flaw + hitch + malfunction + mishap + problem + glitch + defeat + delay + difficulty + adversity + complication + crisis + deadlock + dilemma + gridlock + predict + meant + dire circumstance + hard ship + impasse + standoff + stand still + pickle + plight + condition + breakdown + trouble + anxiety + concern + danger + debacle + complication + hazard + catastrophe + changes + confrontation + disaster + calamity + emergency + failure + quandary + collapse + decline + breaks down + beating + annihilation + destruction + raw carnage + elimination + eradication + decimation + extinction + obsolescence + end of life + extermination + void + nullity + nonbeing + nothing + zero + ∅ + H in a few quick years + transhuman + Minksian-Kurzweill clone + neonatal intensive care unit + eyes unblinking + Max + CORE school + Consilience Of Recombinant Extropy + four + 2020 + eight-year-old Max + transubstantiative doctrine + Heraclitus's ideas of flux + manifesto + internet + STARS AND THEIR REMNANTS + beginning + skulls + shape of eggs + music of the spheres + dreaming + uncanny appearance + faces submerged + image trapped + screen + host of cameras + recording + overlapping sequences + 3D rendering + holographic emergence + fully recorded history + human race + pregalactic form + cell splitting + microchip cluster + snowflakes + fingerprints + uniqueness + galaxy + constant force + dorsal fin configuration + radial symmetry + mind + individuality + universe + existence + blinking state + awakened beings + infinite figure eight Mobius strip + thermodynamic principle + electromagnetic motors of creation + multiplicity of waves + accelerating change + quaking + stars & their remnants + motion picture of our lives + united civic resistance + progression + belief + fixed foremost + negative gravity bound pressure resistance capsule + psychonautical skull transcript by Shaun Lawton)

Explanation: The equation Δ represents the dynamic nature of life and the universe. It encompasses a wide range of elements, from challenges (bugs, glitches, difficulties, etc.) to unique qualities (uniqueness of snowflakes, fingerprints, etc.) to the constant changes in the cosmos. The equation also incorporates the concept of time travel and the emergence of transhuman technology.

Nicholas Alexander Hayes' figure (1)

Nicholas Alexander Hayes' figure (2)

0 notes

Text

Automotive Axial Flux Motors Market Analysis, Demand, Forecast 2022-2029

BlueWeave Consulting, a leading strategic consulting and market research firm, in its recent study, estimated global automotive axial flux motors market size at USD 131.57 billion in 2022. During the forecast period between 2023 and 2029, global automotive axial flux motors market size is to grow at a robust CAGR of 24.29% reaching a value of USD 485.07 billion by 2029. Significant trends are altering the industry landscape in the global automotive axial flux motors market. The increased demand for electric vehicles (EVs) has accelerated the adoption of axial flux motors due to their small size, high power density, and efficiency. The market is seeing a growth in R&D activity to improve the performance and reliability of axial flux motors. Also, advances in materials and manufacturing techniques are propelling the development of lightweight and cost-effective axial flux motors. The incorporation of cutting-edge technology like artificial intelligence and the Internet of Things (IoT) into automotive systems is increasing demand for axial flux motors in a variety of applications.

Global Automotive Axial Flux Motors Market – Overview

A particular design configuration of electric motors used in automobiles is referred to as automotive axial flux. In contrast to the more typical radial flux layout, the magnetic flux of the motor in this arrangement is parallel to the axis of rotation. Axial flux motors have a compact and effective design because the magnetic field moves from the motor's center to its perimeter or vice versa. A higher power-to-weight ratio, better cooling, and increased torque output are all made possible by this configuration. Due to their potential to provide superior performance, better efficiency, and space-saving benefits over conventional radial flux motors, automotive axial flux motors have drawn interest in electric vehicle applications.

Sample Request @ https://www.blueweaveconsulting.com/report/automotive-axial-flux-motors-market/report-sample

Impact of COVID-19 on Global Automotive Axial Flux Motors Market

The COVID-19 pandemic significantly impacted the global automotive axial flux motors market, causing widespread disruptions across the industry. Lockdown measures, supply chain disruptions, and reduced consumer spending have led to a decline in demand for automotive axial flux products. Manufacturers have faced challenges in sourcing raw materials and components, leading to production delays and increased costs. The closure of automotive plants and decreased vehicle sales have further dampened market prospects. However, the industry has shown resilience by adopting digital platforms for sales and exploring innovative strategies. As the world recovers from the pandemic, the automotive axial flux market is expected to gradually rebound, driven by the increasing adoption of electric vehicles and government initiatives supporting sustainable transportation.

Global Automotive Axial Flux Motors Market – By Vehicle Type

On the basis of vehicle type, global automotive axial flux motors market is divided into Passenger Cars, Light Commercial Vehicles, Medium & Heavy Commercial Vehicles, and Two Wheelers segments. The largest segment within this market is the Passenger Car segment, which includes a wide range of cars designed for personal transportation. These vehicles are commonly used by individuals and families for daily commuting and leisure purposes. Following the Passenger Car segment, the other significant segments in the market include Light Commercial Vehicles, which are smaller utility vehicles used for business purposes, and Medium & Heavy Commercial Vehicles, which are larger trucks and buses used for commercial transportation. Also, the Two Wheeler segment comprises motorcycles and scooters, providing an alternative mode of transportation for individuals.

Competitive Landscape

Global automotive axial flux motors market is fiercely competitive. Major companies in the market include Magnax BV, YASA Limited, Traxial BV, Nidec Corporation, Saietta Group, EMRAX, Evans Electric, Whylot Electromechanical Solutions, Agni Motors Ltd, Turntide Technologies, Lucchi R., Protean Electric, Elaphe Propulsion Technologies, Brusa Elektronik AG, and PML Flightlink Ltd. Companies use various strategies, including increasing investments in their R&D activities, mergers, and acquisitions, joint ventures, collaborations, licensing agreements, and new product and service releases to further strengthen their position in global automotive axial flux motors market.

Contact Us:

BlueWeave Consulting & Research Pvt. Ltd

+1 866 658 6826 | +1 425 320 4776 | +44 1865 60 0662

0 notes

Text

How to avoid demagnetization of permanent magnet variable frequency air compressor?

Sometimes due to external force conditions or improper operation, it is inevitable that the permanent magnet variable frequency air compressor will demagnetize. A permanent magnet variable frequency air compressor, its permanent magnet synchronous motor will be in the case of high current, high temperature or severe vibration. Irreversible demagnetization occurs, and the following will introduce how to solve the demagnetization problem of the air compressor.

1. Correctly choose the power of the permanent magnet motor

Demagnetization is related to the power selection of the permanent magnet motor in the variable frequency air compressor. Correct selection of the power of the permanent magnet motor can prevent or delay demagnetization. The main reason for the demagnetization of the permanent magnet synchronous motor is that the temperature is too high, and overload is the main reason for the high temperature. Therefore, a certain margin should be left when selecting the power of the permanent magnet motor. According to the actual situation of the load, generally about 20% is more appropriate.

2. Avoid heavy load starting and frequent starting

Permanent magnet motors try to avoid direct starting or frequent starting with heavy loads. In the process of asynchronous starting, the torque is oscillating, and in the valley section of the torque, the stator magnetic field demagnetizes the rotor magnetic poles. Therefore, try to avoid heavy load and frequent starting of the asynchronous permanent magnet synchronous motor of the air compressor.

3. Improved design

a. Appropriately increase the thickness of the permanent magnet From the perspective of the design and manufacture of the permanent magnet synchronous air compressor motor, the relationship between the armature reaction, electromagnetic torque and permanent magnet demagnetization should be considered. Under the combined action of the magnetic flux generated by the torque winding current and the magnetic flux generated by the radial force winding, the permanent magnets on the rotor surface are likely to cause demagnetization. When the air gap of the motor remains unchanged, the most effective way to ensure that the permanent magnet does not demagnetize is to increase the thickness of the permanent magnet appropriately.

b. There is a ventilation slot circuit inside the rotor. The important factor to reduce the temperature rise of the rotor and affect the reliability of the permanent magnet motor is the demagnetization of the permanent magnet. If the rotor temperature is too high, the permanent magnet of the variable frequency air compressor will produce irreversible demagnetization. When designing the structure, the internal ventilation circuit of the rotor can be designed to directly cool the magnetic steel. Not only reduces the temperature of the magnetic steel, but also improves the efficiency.

Air Compressor Spare Parts Supplier - Youteng

Wuxi Youteng Machinery Co., Ltd. was established in 2012, mainly engaged in air compression system, vacuum system design consulting, engineering project and repairing services etc. Our company mainly provides air compressor equipments and accessories for compressors of world-famous brands. We also support OEM. In addition, The company has a number of experienced technicians to perform maintenance work on various air compressors, dryers and filters, which have a certain influence in China. At the same time, the company also participates in motor overhaul projects and maintains various motors. We have a complete service system and sufficient spare parts to relieve customers from worries.

#PM variable frequency air compressor#demagnetization problem of the air compressor#PM variable frequency air compressor for sale#PM variable frequency air compressor supplier

0 notes

Text

BMW invests in in-wheel electric motor

BMW and Continental have both become investors in DeepDrive, a specialist in electric motorization. The Munich-based start-up has developed a twin-rotor radial flux motor that can be installed in the wheel hub of a production vehicle. DeepDrive managed to raise 15 million euros in an initial fundraiser, also receiving financial support from UVC Partners and Bayern Kapital. Supported moreover by…

View On WordPress

0 notes

Text

When the AC synchronous motor utilizes permanent magnets for producing field excitation, then this becomes a Permanent Magnet Synchronous Generator. This includes permanent magnet rotor that generates high torque at zero speed, no rotor current and includes small frame size. To know more details about Permanent Magnet Synchronous Generator, visit our blog or call on +919582345931, +919873699384, +919999467601, or mail us at [email protected]

#permanent magnet synchronous generator#synchronous generator#permanent magnet alternator#permanent magnet alternator manufacturer in India#permanent magnet alternator manufacturer in Delhi#permanent magnet generator manufacturer in India#permanent magnet generator manufacturer in Delhi#low rpm permanent magnet alternator#permanent magnet generator#low rpm permanent magnet generator#axial flux permanent magnet generator#radial flux permanent magnet generator#permanent magnet generator manufacturer#permanent magnet low rpm alternator#permanent magnet alternator manufacturers#high speed permanent magnet alternators#alternator#generator#AC synchronous motor#synchronous motor#motor

1 note

·

View note

Photo

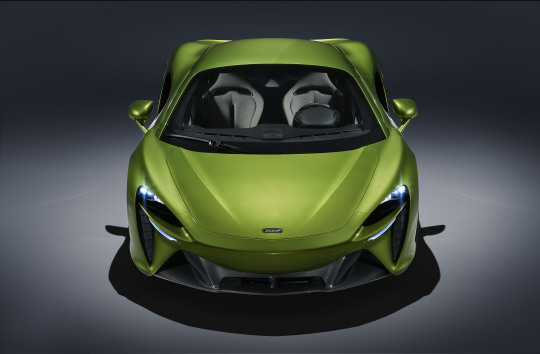

First Look: The McLaren Artura

The all-new McLaren Artura is revealed today, marking the beginning of both a new chapter for the pioneering luxury supercar company and a new era in supercar technology and performance.

McLaren’s first series-production High-Performance Hybrid supercar focuses more than half a century of the company’s racing and road-car experience and expertise into a next-generation supercar that blends ground-breaking technology with pure driver engagement.

Underpinned by the McLaren philosophy of super-lightweight engineering, the all-new Artura is the distillation of every attribute inherent in a McLaren – distinctive design, unrivalled performance, dynamic excellence and engineering innovation – with electrification now bringing the additional benefits of even faster throttle response, lower emissions and being able to run in pure EV mode for emissions-free journeys of up to 30km.

All-new from the ground up, the Artura presented McLaren engineers and designers with new opportunities to innovate, chief among these being how to preserve McLaren’s super-lightweight engineering philosophy when adding hybrid powertrain elements including an E-motor and battery pack.

At the heart of the Artura’s powertrain is McLaren’s all-new, 2,993cc twin-turbocharged V6 petrol engine. With a power output of 585PS – nearly 200 PS per litre – and 585Nm of torque, the dry-sump aluminum engine is compact and lightweight; at just 160kg it weighs 50kg less than a McLaren V8 and is significantly shorter, enhancing packaging efficiency.

Working in harmony with the new V6 is the Artura’s compact axial flux E-motor, located within the transmission bell housing. Smaller and more power-dense than a conventional radial flux E-motor, it is capable of generating 95PS and 225Nm and boasts a power density per kilo 33% greater than the system used in the McLaren P1. The instantaneous nature of the motor’s torque delivery – known as ‘torque infill’ – is key to the car’s razor-sharp throttle response. Exhilarating ‘off-the-line’ performance sees the Artura achieve 0-100km/h (0-62mph) in just 3.0 seconds, with 0-200km/h (0-124mph) taking 8.3 seconds and 0-300km/h (0-186mph) 21.5 seconds. The top speed is limited to 330km/h (205mph).

A demanding program of weight reduction, encompassing every area of the Artura from the chassis platform – this is the debut of the new McLaren Carbon Lightweight Architecture (MCLA) – through the uniquely compact HPH powertrain system to the weight of cabling used in the electrical systems (where a 10% reduction was achieved), resulted in the Artura having a lightest dry weight of 1,395kg. The total weight of hybrid components is just 130kg (which includes an 88kg battery pack and 15.4kg E-motor), resulting in a DIN curbweight of 1,498kg* which is on par with comparable supercars that do not have hybrid powertrains, giving the Artura a super-lightweight advantage.

145 notes

·

View notes

Text

How Mercedes and Ferrari plan to ace the performance EV race: Explained - Times of India

How Mercedes and Ferrari plan to ace the performance EV race: Explained – Times of India

We have all heard the term ‘there is no replacement for displacement’, however, this does not stand true anymore in the current EV age. In fact, with electric vehicles what holds tru is ‘the smaller the better.’ At least that is what performance oriented automakers such as Mercedes-AMG and Ferrari believe. Introducing the ‘axial flux motors’, which are much smaller than the widely used radial…

View On WordPress

0 notes

Text

In-wheel Motors Size, Share & Segment by Raw Material, by End-User, by Form , by Modification type , by Function, by Regions & Global Market Forecast 2022-2028

The goal of this research report is to provide a thorough examination of the global In-wheel Motors Market, which includes all industry participants. The research consists of a simple examination of complex data, as well as information on the industry's historical and current state, as well as projected market size and trends. The study examines all aspects of the industry, with a particular emphasis on major players such as market leaders, followers, and newcomers. The study includes a PORTER, SWOT, and PESTEL analysis, as well as the potential impact of market microeconomic elements on the target market.

Ask For Sample Pages of this Report @ https://www.snsinsider.com/sample-request/2114

External and internal factors that are expected to have a positive or negative impact on the company have been studied, providing decision-makers with a clear picture of the industry's future. The study also aids in the comprehension of In-wheel Motors market dynamics, structure, and global market projections. Because of its clear depiction of competitive analysis of top companies by price, financial situation, detection and equipment portfolio, growth strategies, and regional presence in the market, the research is an investor's guide.

MARKET SEGMENTATION:

By Motor Type:

Axial Flux Motor

Radial Flux Motor

By Propulsion Type:

Battery Electric Vehicles

Hybrid Electric Vehicles

Plug-in Hybrid Electric Vehicles

By Power Output Type:

Up to 60 KW

60–90 KW

Above 90 KW

Regional Analysis

The study outlines the primary factors driving the global In-wheel Motors market forward. These data can be used by market participants to develop strategies for gaining market share. Market constraints were also discovered during the investigation. Market actors can use knowledge on prospects to help them take the next steps by assessing potential in underserved areas. The study provides a detailed breakdown of the global market. The market research report examines key regions such as North America, Europe, Latin America, and Asia Pacific. Tables show historical and projected sales, revenue, growth rate, and market share for each sector.

Competitive Outlook

The research report also aids in the understanding of global In-wheel Motors market dynamics, structure, and growth strategies by analyzing market segments and project markets. The report is an investor's guide due to its clear representation of competitive analysis of key players by price, financial position, detection and equipment portfolio, growth strategies, and regional presence in the market.

The In-wheel Motors market study provides a comprehensive assessment of the industry's key players. The study delves deeply into operating corporate segments, product portfolios, business performance, and key strategic developments. Porter's Five Forces study emphasizes the importance of buyers and suppliers in assisting stakeholders in making strategic business decisions and defining the level of industry competitiveness. The market player positioning setion depicts the target market's current competitiveness scenario.

BUY NOW Link @ https://www.snsinsider.com/checkout/2114

Table Of Contents

1. Introduction

1.1 Market Definition

1.2 Scope

1.3 Research Assumptions

2. Research Methodology

3. Market Dynamics

3.1 Drivers

3.2 Restraints

3.3 Opportunities

4. Impact Analysis

4.1 COVID-19 Impact Analysis

4.2 Impact Of The Ukraine-Russia War

5. Value Chain Analysis

6. Porter’s 5 Forces Model

7. PEST Analysis

8. Global In-Wheel Motors Market Segmentation, By Motor Type

8.1 Axial Flux Motor

8.2 Radial Flux Motor

9. Global In-Wheel Motors Market Segmentation, By Propulsion Type

9.1 Battery Electric Vehicles

9.2 Hybrid Electric Vehicles

Contact US:

Akash Anand

Manager- Business Development

SNS insider PVT LTD

USA: +1-415-230-0044

www.snsinsider.com

Mail - [email protected]

0 notes