#high speed permanent magnet alternators

Explore tagged Tumblr posts

Text

youtube

Powerful Performance: Testing a 5KW 500RPM 220VAC Single Phase PMG by J.D. Engineering Works

Welcome to J.D. Engineering Works! In this exciting video, we show you the powerful performance of our 5KW 500RPM 220VAC Single Phase Permanent Magnet Generator (PMG).

Our dedicated team of engineers has put their expertise into creating a high-performance generator that pushes the boundaries of single-phase power generation. In this video, we are showing you the highest standards of quality and reliability of the 5KW 500RPM 220VAC Single Phase Permanent Magnet Generator (PMG). . As we fire up the 5KW PMG, you'll be amazed by its steady 500RPM rotation, producing a clean and stable 220VAC output. The consistent power generation capabilities of our Permanent Magnet Generator (PMG) make it an ideal choice for various applications, from off-grid setups and backup power solutions to integration with renewable energy systems.

Our team at J.D. Engineering Works is committed to sustainability and renewable energy solutions, and this Permanent Magnet Generator (PMG) exemplifies our dedication to delivering cutting-edge technology that drives the future of green power.

Don't forget to like, share, and subscribe to our channel for more exciting updates on our latest innovations and projects.

Thank you for being part of our journey towards a greener and more sustainable tomorrow. Together, let's power the world with clean energy solutions from J.D. Engineering Works.

For any queries regarding 5KW 500RPM 220VAC Single Phase Permanent Magnet Generator (PMG), email us at [email protected], or Call or WhatsApp at +919582345931, +919289311243, +918851614166, +919999467601.

#permanent magnet generator#low rpm permanent magnet generator#axial flux permanent magnet generator#radial flux permanent magnet generator#generator manufacturer#permanent magnet generator manufacturer#permanent magnet generator manufacturer in India#permanent magnet generator manufacturer in Delhi#permanent magnet synchronous generator#permanent magnet alternator#permanent magnet alternator manufacturer in India#permanent magnet alternator manufacturer in Delhi#low rpm permanent magnet alternator#permanent magnet low rpm alternator#permanent magnet alternator manufacturers#high speed permanent magnet alternators#Youtube

2 notes

·

View notes

Text

Permanent Magnet Motor Market to Surge on Energy Efficiency Demand

Permanent magnet motors (PMMs) utilize rare-earth or ferrite magnets embedded in the rotor to generate high torque densities with minimal energy losses. These motors offer superior efficiency, compact form factors, and robust performance across variable speed ranges compared with induction and wound-rotor alternatives. Key advantages include reduced heat generation, lower operational costs, and enhanced reliability—attributes that are driving adoption in electric vehicles (EVs), industrial robotics, aerospace actuators, and renewable energy generation systems. As global regulations tighten around energy consumption and carbon emissions, manufacturers and end users are increasingly specifying PMMs to meet stringent efficiency standards and lifecycle cost targets. Permanent Magnet Motor Market - https://www.patreon.com/posts/permanent-magnet-127718568

#PermanentMagnetMotorMarket#PermanentMagnetMotorMarketShare#EnergyEfficiency#ElectricVehicles#IndustrialRobotics#CoherentMarketInsights

0 notes

Text

Magnetic Levitation Circular Track Motor System

Magnetic Levitation Circular Track Motor System (MLCTMS) Introduction The Magnetic Levitation Circular Track Motor System (MLCTMS) is an advanced electromechanical system that combines magnetic levitation (maglev) and linear/rotary motor technology to enable frictionless, high-speed motion along a circular or curved track. Unlike conventional motors that rely on physical contact (e.g., bearings or gears), MLCTMS uses electromagnetic forces to levitate and propel objects, reducing wear, energy loss, and maintenance. https://www.youtube.com/embed/_uo-JyKC9rA Magnetic Levitation Circular Track Motor System has applications in transportation (maglev trains), industrial automation (high-precision conveyors), energy storage (flywheels), and amusement rides. Key Components 1. Track (Stator) - A circular or loop-shaped guideway embedded with electromagnetic coils (usually arranged as a linear synchronous motor, LSM). - Can be passive (permanent magnets) or active (electromagnets with control systems). 2. Levitation System - Uses repulsive or attractive magnetic forces to suspend the moving part (rotor/vehicle). - Common methods: - Electromagnetic Suspension (EMS) – Attracts ferromagnetic materials. - Electrodynamic Suspension (EDS) – Repels using superconducting magnets or eddy currents. 3. Propulsion System - Linear Induction Motor (LIM) or Linear Synchronous Motor (LSM) principles. - Coils in the track generate a traveling magnetic wave, pushing/pulling the rotor. 4. Control System - Ensures stable levitation and motion using sensors (gap sensors, Hall effect sensors) and feedback loops. - Adjusts current in electromagnets to maintain balance. How It Works 1. Levitation: - The system activates electromagnets to lift the rotor slightly above the track (typically 1–10 cm). - Sensors continuously monitor the gap and adjust magnetic force to prevent contact. 2. Propulsion: - A three-phase alternating current in the stator coils creates a moving magnetic field. - The rotor (equipped with permanent magnets or electromagnets) is either pushed (LSM) or induced (LIM) to move along the track. 3. Stabilization: - Active control systems counteract disturbances (vibrations, external forces). - Some designs use Halbach arrays to enhance magnetic field efficiency. Advantages of Magnetic Levitation Circular Track Motor System Near-zero friction → Higher efficiency & longer lifespan. Low maintenance (no mechanical wear). High-speed operation (useful for maglev trains, centrifuges). Precision control (useful in semiconductor manufacturing, lab automation). Reduced noise & vibration. Applications Transportation:Maglev trains, hyperloop systems. Industrial Automation: High-speed conveyors, robotic arms. Energy Storage: Flywheel energy storage (frictionless rotation). Amusement Rides:Floating roller coasters. Scientific Research: Centrifuges, space simulation (microgravity effects). Future Developments Superconducting magnets for more efficient levitation. Modular & scalable designs for cost reduction. Integration with renewable energy (solar/wind-powered maglev systems). Conclusion of Magnetic Levitation Circular Track Motor System The Magnetic Levitation Circular Track Motor Systemrepresents a cutting-edge fusion of electromagnetics and motion control, enabling ultra-efficient, high-speed, and maintenance-free operation. While challenges like cost and energy use remain, advancements in materials and control algorithms continue to expand its potential across industries. You are welcome to watch more projects or visit our website to check other series or load down e-catalogues for further technical data. Youtube: https://www.youtube.com/@tallmanrobotics Facebook: https://www.facebook.com/tallmanrobotics Linkedin: https://www.linkedin.com/in/tallman-robotics Read the full article

#maglevtestcirculartracksystem#Magneticlevitation#MagneticLevitationforFreedom#Magneticlevitationplanarmotor

1 note

·

View note

Text

The Role of Permanent Magnet Synchronous Motors in Energy Efficiency

The Role of Permanent Magnet Synchronous Motors in Energy Efficiency

Understanding Permanent Magnet Synchronous Motors (PMSM) Permanent Magnet Synchronous Motors (PMSM) are advanced electrical machines that operate by using permanent magnets to produce synchronized motion with alternating current (AC). These motors are characterized by their use of high-energy permanent magnets, often made from rare earth materials like samarium-cobalt, which are embedded in the rotor to create a magnetic field. Unlike traditional synchronous motors that require an external DC source for rotor excitation, PMSMs leverage these magnets to achieve their functionality, resulting in a more compact and efficient design due to the absence of rotor windings.Get more news about Synchronous Motors,you can vist our website!

The importance of PMSMs in modern applications is notable due to their superior efficiency in energy conversion and precise control over motor operations. These motors are widely applied in various industries such as automotive, robotics, aerospace, and many more because they offer excellent torque performance and energy efficiency, making them ideal for applications requiring constant speed and precise control. Their ability to perform efficiently under varying load conditions without significant loss of energy makes them a preferred choice in applications where efficiency and precision are paramount.

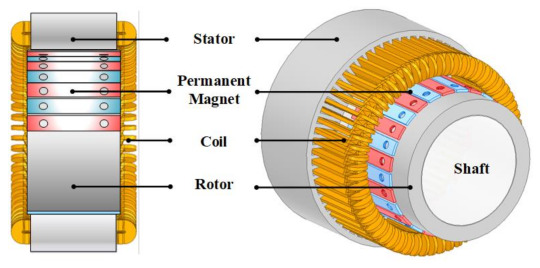

Construction and Design Principles of PMSM The construction and design of a Permanent Magnet Synchronous Motor (PMSM) involves several key components, each playing a crucial role in its operation. The main parts of a PMSM include the stator, rotor, and permanent magnets. The stator, the stationary part of the motor, is responsible for creating a rotating magnetic field when supplied with alternating current (AC). This field interacts with the rotor, which is equipped with permanent magnets that create their magnetic field, enabling the motor to operate with high efficiency and precise torque control.

There are different types of rotors used in PMSMs, each affecting the motor’s performance in various ways. The two main types are surface-mounted and interior-mounted rotors. Surface-mounted rotors have magnets affixed to the surface of the rotor, which tends to simplify the motor design and enhances high-speed applications. On the other hand, interior-mounted rotors have magnets embedded within the rotor, providing greater mechanical strength and improved performance in low-speed and high-torque applications. The choice between these rotor types depends on the specific requirements of the application and desired performance characteristics.

How Permanent Magnet Synchronous Motors Operate Permanent Magnet Synchronous Motors (PMSM) operate by exploiting the interaction between the magnetic fields generated by the stator and the rotor. This interaction generates a rotational motion that drives the motor. When the stator winding is energized with an electrical supply, it creates a magnetic field that rotates around the stator. The rotor, embedded with permanent magnets, is locked to this rotating field at synchronous speed, producing torque and motion. This magnetic lock ensures that the rotor turns at the same speed as the rotating magnetic field of the stator.

The magnetic field plays a crucial role in the operation of PMSMs. It directly influences torque generation and the motor's efficiency. According to Faraday's law of electromagnetic induction, a change in the magnetic environment of a coil of wire will induce an electromotive force (EMF) in the coil. In PMSMs, the consistent magnetic field from the permanent magnets together with the rotating magnetic field of the stator leads to efficient energy conversion. This ensures that PMSMs are highly efficient and capable of maintaining performance across various applications without the losses associated with rotor winding, distinguishing them from traditional induction motors.

Advantages of Using Permanent Magnet Synchronous Motors Permanent Magnet Synchronous Motors (PMSMs) offer excellent efficiency compared to traditional motor types. Expert analyses reveal that PMSMs can deliver energy savings of up to 15% in various applications. This efficiency stems from their design, which minimizes energy loss and optimizes performance. Traditional motors often waste energy due to friction and heat generation, whereas PMSMs utilize high-performance materials and precise engineering to achieve a high efficiency. As a result, industries using PMSMs can significantly lower operational costs and reduce energy consumption.

Additionally, the environmental benefits of using PMSMs are substantial. Due to their high efficiency, these motors contribute to lower carbon emissions. This can play a crucial role in meeting environmental regulations and sustainability goals. By reducing the overall energy demand and minimizing CO2 output, businesses can improve their environmental footprint. The adoption of PMSMs not only helps in achieving energy efficiency but also supports global efforts towards cleaner and more sustainable industrial practices. Such environmental advantages make PMSMs a preferable choice for industries aiming to reduce their impact on the planet.

1 note

·

View note

Text

Design features and selection principles of linear stepper motors

1.Working principle of linear stepper motors The working principle of linear stepper motors is to drive the slider to move along a straight line through an electromagnetic field. Its basic structure includes a stator and a mover. The stator is usually composed of two electromagnets, and the mover is composed of a slider with a permanent magnet. The working principle is to generate an alternating magnetic field by alternately exciting the electromagnets, which pushes the slider to move along a straight line. When one electromagnet is activated, it generates a magnetic field that attracts the slider and moves toward it; when the other electromagnet is activated, it generates an opposite magnetic field that pushes the slider to move in the opposite direction. By alternately activating these two electromagnets, the slider can reciprocate along a straight line.

2.Common application areas of linear stepper motors 1.Industrial automation: Linear stepper motors are widely used in industrial robots, mold machinery, printing machinery and other equipment, and can provide high-precision, high-stability and high-efficiency motion control. 2.Planar mobile devices: Linear stepper motors are often used in planar mobile devices such as laser cutting machines, printers, scanners, etc., and achieve high-quality processing and printing effects by precisely controlling the movement of the motor. 3.Measuring instruments: In high-precision 3D scanners, optical measuring equipment and other measuring instruments, linear stepper motors are used for precise measurement and positioning to ensure the accuracy of measurement. 4.Medical equipment: Linear stepper motors are widely used in medical equipment such as medical instruments and surgical instruments to drive the movement of scanning frames to ensure accurate imaging of medical imaging equipment. 5.Other applications: Linear stepper motors can also be used in scenes such as focusing of camera lenses and moving optical equipment to provide high-precision position control.

3.Design features of linear stepper motors 1.High precision: Linear stepper motors adopt a direct drive structure, with no backlash and high structural rigidity. The accuracy of the system mainly depends on the position detection element, which can reach the submicron level through a suitable feedback device. 2.No mechanical contact wear: There is no mechanical contact wear between the stator and the mover of the linear stepper motor. The system motion contact is borne by the linear guide rail, with fewer transmission parts, smooth operation, low noise, simple structure, simple maintenance, or even maintenance-free, high reliability and long service life. 3.Modular structure: The stator of the linear stepper motor adopts a modular structure, and the running stroke is theoretically unlimited. 4.Wide operating speed range: The speed range of the linear stepper motor is from a few microns to several meters per second, which can meet different application requirements. 5.High acceleration and speed: In practical applications, the linear stepper motor has achieved an acceleration of 5.5g and a speed of 2.5m/s. 6.High efficiency: Since there is no intermediate transmission link, the energy loss during mechanical friction is eliminated, and the efficiency is high. 7.Fast response speed: Since some mechanical transmission parts with large response time constants, such as lead screws, are eliminated, the dynamic response performance of the entire closed-loop control system is greatly improved, and the response is extremely sensitive and fast. 8.Wide application: Linear stepper motors are mainly used in automatic control systems, long-term continuous operation drive motors, and devices that need to provide huge linear motion energy in a short time.

4.Selection principles of linear stepper motors 1.Load characteristics: Select a suitable motor according to the rotational inertia and friction load of the load. Loads with large moment of inertia should use motors with large frame sizes, while friction loads need to consider static torque, which is usually 2-3 times the friction load. 2.Speed and step angle: The step angle of the stepper motor should be selected according to the load accuracy requirements, and the step angle should be equal to or less than the resolution required by the load. For example, if the positioning accuracy of the load is ±0.5°, the angle rotated by one pulse of the motor should be less than 0.5°. 3.Current parameters: Motors with the same static torque have very different operating characteristics due to different current parameters. The current of the motor can be judged by the torque-frequency characteristic curve. 4.Working environment: Select a suitable stepper motor according to the use environment. For example, for special environments that require waterproofing and oil resistance, special stepper motors should be selected. 5.Application scenarios: Linear stepper motors are generally used in low-speed situations, with a speed not exceeding 1000 revolutions per minute. It is best to control the speed between 1000-3000PPS (0.9 degrees). Appropriate deceleration devices can improve work efficiency and reduce noise.

0 notes

Text

Understanding BLDC Technology: How It Works and Why It Matters

In recent years, there has been a growing shift towards energy-efficient appliances in homes and offices. One technology leading this change is BLDC (Brushless Direct Current) motors, especially in fans. As the demand for smarter and more efficient cooling solutions increases, BLDC fans have become a popular choice. But what exactly is BLDC technology, and why does it matter?

In this blog, we’ll break down how BLDC technology works, its advantages over traditional motors, and why Breezalit offers the best BLDC fans for your home or office.

What is BLDC Technology?

BLDC, or Brushless Direct Current, refers to a type of electric motor that, unlike traditional motors, doesn’t rely on brushes to transfer current to the motor. Instead, it uses electronic circuits to control the motor, making it more efficient and long-lasting. In BLDC fans, the motor operates on direct current (DC), which ensures lower energy consumption while maintaining high performance.

Traditional fans with brushed motors experience friction due to the physical contact between the brushes and the commutator, leading to wear and tear over time. However, BLDC fans eliminate this friction, resulting in a longer lifespan and reduced maintenance.

How Does BLDC Technology Work?

The core of BLDC fans lies in their electronic commutation system. Here’s a simple breakdown of how it works:

Permanent Magnets: A BLDC motor consists of a rotor with permanent magnets attached. These magnets create a magnetic field necessary for the motor's operation.

Stator with Coils: Surrounding the rotor is a stator, which contains multiple coils of wire. When electric current passes through these coils, they generate a magnetic field.

Electronic Controller: Instead of brushes, BLDC motors use an electronic controller to manage the current flow. The controller switches the current between different coils, causing the rotor to spin.

Precise Speed Control: The electronic controller also allows for precise speed regulation, meaning that BLDC fans can offer variable speed options without any significant increase in power consumption.

This combination of electronic control and direct current makes BLDC fans highly efficient compared to traditional AC (Alternating Current) fans.

Why BLDC Technology Matters

BLDC technology offers numerous benefits that make it a preferred choice for modern homes and offices. Here are a few reasons why it matters:

1. Energy Efficiency

One of the biggest advantages of BLDC fans is their energy efficiency. Traditional ceiling fans consume about 70-80 watts of power, whereas BLDC fans use only 30-35 watts. This means that households and businesses can significantly reduce their electricity bills by switching to BLDC fans, especially in areas where fans are used frequently.

2. Longer Lifespan

As mentioned earlier, BLDC motors don't rely on brushes, which are prone to wear and tear. This results in a longer lifespan for the fan motor. By eliminating the need for brushes, BLDC fans from Breezalit require minimal maintenance and are more durable, making them a cost-effective solution in the long run.

3. Silent Operation

Because of the lack of friction from brushes, BLDC fans operate almost silently. This is particularly important for bedrooms, study rooms, and offices where noise can be a distraction. With Breezalit BLDC fans, you can enjoy a peaceful environment without the annoying humming sound that often accompanies traditional fans.

4. Better Speed Control

Traditional fans usually come with three or four-speed settings. However, BLDC fans offer a wider range of speed options, thanks to their electronic controllers. This means you can adjust the fan speed more precisely to suit your comfort, leading to a better user experience.

5. Environmentally Friendly

By consuming less electricity, BLDC fans contribute to reduced energy consumption, which is good for both your wallet and the environment. Lower power usage also means a reduced carbon footprint, making these fans an eco-friendly choice for sustainable living.

Why Choose Breezalit BLDC Fans?

At Breezalit, we pride ourselves on providing top-quality BLDC fans that not only save energy but also add style and comfort to your home or office. Here’s why our BLDC fans stand out:

Design and Aesthetics: Our fans are designed to suit modern interiors, offering a sleek and sophisticated look without compromising functionality.

Innovative Features: Breezalit BLDC fans come equipped with features like remote control operation, timer settings, and sleep modes, giving users ultimate control over their cooling experience.

Energy Saving: With our BLDC fans, you can save up to 60-70% on electricity consumption compared to regular fans. This is ideal for anyone looking to reduce their energy bills without sacrificing comfort.

Durability: Breezalit BLDC fans are built to last, with high-quality materials and components ensuring reliable performance over the years.

Low Noise: Our fans are perfect for areas where silence is crucial, ensuring you enjoy quiet and efficient air circulation.

Conclusion

BLDC technology represents a significant advancement in fan motors, offering numerous benefits like energy efficiency, silent operation, and longer lifespan. As more homes and businesses look for ways to save on electricity costs and reduce their carbon footprint, BLDC fans are becoming an essential part of modern living.

If you’re in the market for high-quality, durable, and energy-saving fans, Breezalit has you covered. Our range of BLDC fans is designed to meet all your cooling needs while ensuring you stay on top of energy efficiency trends.

Make the switch to Breezalit BLDC fans today and experience the perfect blend of technology, style, and sustainability!

This Blog Was Originally Published At: https://breezalitfan.blogspot.com/2024/09/understanding-bldc-technology-how-it.html

0 notes

Text

Understanding the Different Types of Elevator Motor Technology

Elevators are an essential part of modern buildings, enabling efficient vertical transportation for people and goods. The heart of any elevator system is its motor, which drives the movement of the elevator car. Over the years, elevator motor technology has evolved significantly, enhancing performance, efficiency, and reliability. Understanding the different types of elevator motors is crucial for selecting the right system for a building’s specific needs. This article delves into the primary types of elevator motors, their applications, advantages, and impact on elevator systems.

AC Motors: Alternating Current Efficiency

AC motors are widely used in modern elevator systems due to their efficiency and reliability. There are two main types of AC motors used in elevators: induction motors and synchronous motors.

Induction Motors: These motors are the most common type of AC motor. They operate on the principle of electromagnetic induction, where the rotor is induced to move by the magnetic field of the stator. Induction motors are robust, cost-effective, and require minimal maintenance, making them ideal for a wide range of elevator applications, especially in residential and low to mid-rise commercial buildings.

Synchronous Motors: Unlike induction motors, synchronous motors operate at a constant speed, regardless of the load. This is achieved by maintaining a constant frequency of the AC power supply. Synchronous motors offer high efficiency and precise speed control, making them suitable for high-rise buildings where smooth and consistent elevator operation is critical.

DC Motors: Direct Current Precision

DC motors were among the first types of motors used in elevator systems and are still in use today, particularly in older installations and specific applications that require precise speed control.

Series Wound DC Motors: These motors provide high starting torque and are capable of handling varying loads effectively. They are well-suited for elevators that experience frequent stops and starts, such as those in busy commercial buildings. However, series-wound DC motors require more maintenance than their AC counterparts due to brush and commutator wear.

Permanent Magnet DC Motors: These motors use permanent magnets to create the magnetic field instead of relying on windings. This design reduces maintenance needs and increases efficiency. Permanent magnet DC motors are often used in smaller, low-capacity elevators where precise control and efficiency are desired.

Gearless Traction Motors: The Modern Standard

Gearless traction motors represent a significant advancement in elevator motor technology. These motors are typically AC synchronous motors that drive the elevator directly without the need for a gearbox. This direct drive mechanism offers several benefits:

Smooth Operation: Gearless traction motors provide exceptionally smooth and quiet operation, making them ideal for high-end residential and commercial buildings where noise reduction is important.

Energy Efficiency: By eliminating the gearbox, gearless traction motors reduce energy losses and improve overall efficiency. This makes them a sustainable choice for modern buildings focused on energy conservation.

Low Maintenance: The simplified design of gearless traction motors, with fewer moving parts, translates to lower maintenance requirements and longer service life compared to traditional geared systems.

Regenerative Drives: Harnessing Energy Efficiency

Regenerative drive technology is a recent innovation that enhances the efficiency of elevator motors, particularly in high-rise buildings. Regenerative drives capture the energy generated during the braking process of the elevator and convert it back into usable electricity, which can be fed back into the building’s power grid. This not only reduces energy consumption but also lowers operating costs.

Environmental Impact: By reducing the overall energy demand, regenerative drives contribute to a building’s sustainability and help reduce its carbon footprint.

Cost Savings: The energy savings achieved through regenerative drives can be substantial, leading to lower utility bills and a quicker return on investment for building owners.

Conclusion

Choosing the right elevator motor technology is critical for ensuring efficient, reliable, and cost-effective elevator operation. AC motors, including induction and synchronous types, offer reliability and efficiency for various applications. DC motors, particularly in older systems, provide precise control and high starting torque. Gearless traction motors represent the pinnacle of modern elevator technology, offering smooth operation, energy efficiency, and low maintenance. Additionally, regenerative drive technology further enhances energy efficiency by capturing and reusing energy.

Understanding these different types of elevator motors and their respective benefits allows building designers, engineers, and owners to make informed decisions that align with their specific requirements and sustainability goals. As elevator technology continues to evolve, these advancements promise even greater efficiency, reliability, and environmental benefits for the future of vertical transportation.

0 notes

Text

Unlocking Growth: Exploring the IE4 Permanent Magnet Synchronous Motor Market

The global economy is undergoing a significant shift towards sustainability and energy efficiency, driven by environmental concerns and regulatory mandates. In this transformative landscape, the IE4 Permanent Magnet Synchronous Motor (PMSM) market has emerged as a critical enabler of progress. According to a study by Next Move Strategy Consulting, the global IE4 Permanent Magnet Synchronous Motor Market size is predicted to reach USD 308.6 million with a CAGR of 8.97% by 2030. This underscores the growing importance of these advanced electric motors in various industries worldwide.

Request for a sample, here: https://www.nextmsc.com/ie4-permanent-magnet/request-sample

Understanding IE4 Permanent Magnet Synchronous Motors:

IE4 Permanent Magnet Synchronous Motors represent a paradigm shift in electric motor technology. Unlike conventional motors that rely on electromagnetic induction, PMSMs utilize permanent magnets to generate magnetic fields, resulting in higher efficiency, precision control, and reduced energy consumption. These motors are characterized by their synchronous operation, where the rotor rotates at the same speed as the magnetic field produced by the stator, enabling precise speed control and torque regulation.

Key Drivers of Market Growth:

The growth of the IE4 Permanent Magnet Synchronous Motor market is driven by several key factors. Firstly, stringent environmental regulations aimed at reducing carbon emissions and improving energy efficiency have prompted industries to adopt eco-friendly technologies, including high-efficiency electric motors. IE4 PMSMs offer significant energy savings compared to traditional motors, making them an attractive choice for applications where energy efficiency is paramount.

Moreover, the rapid expansion of industrial automation and the adoption of smart manufacturing technologies have fueled the demand for high-performance motors capable of delivering optimal efficiency and reliability. IE4 PMSMs are well-suited for use in robotics, CNC machines, conveyor systems, and other automated processes, where precision control and high torque density are essential.

Furthermore, the growing adoption of electric vehicles (EVs) and hybrid vehicles is driving demand for IE4 PMSMs in the automotive sector. These motors play a crucial role in powering electric propulsion systems, offering superior efficiency, power density, and torque characteristics compared to traditional internal combustion engines. As governments worldwide implement policies to reduce vehicle emissions and promote electric mobility, the demand for IE4 PMSMs in the automotive industry is expected to surge in the coming years.

Challenges and Opportunities:

Despite the promising growth prospects, the IE4 Permanent Magnet Synchronous Motor market faces several challenges. One of the primary challenges is the high initial cost associated with these motors, primarily due to the use of rare-earth magnets such as neodymium and dysprosium. The limited availability of these materials and their fluctuating prices pose a significant risk to manufacturers and end-users alike. However, ongoing research and development efforts aimed at alternative magnet materials, such as ferrite and samarium cobalt, are expected to mitigate this challenge in the long term.

Additionally, the complexity of motor design and integration presents challenges in terms of manufacturing, installation, and maintenance. IE4 PMSMs require sophisticated control systems and advanced manufacturing techniques to achieve optimal performance and efficiency. Moreover, the customization requirements for different applications and industries add further complexity to the production process, potentially increasing lead times and costs.

Despite these challenges, the IE4 Permanent Magnet Synchronous Motor market presents significant opportunities for growth and innovation. The emergence of new applications and industries, such as renewable energy, robotics, and IoT, is driving demand for high-performance motors with enhanced efficiency, reliability, and durability. For instance, the rise of wind and solar power generation has created a growing need for IE4 PMSMs in wind turbines, solar tracking systems, and grid stabilization solutions. Similarly, the integration of robotics and IoT technologies in manufacturing, logistics, and healthcare sectors is driving demand for IE4 PMSMs in robotic arms, automated guided vehicles (AGVs), and medical devices.

Adoption Challenges in Traditional Industries: Despite the advantages of IE4 Permanent Magnet Synchronous Motors, the adoption rate in traditional industries such as HVAC, pumping systems, and material handling equipment has been relatively slow. This can be attributed to factors such as entrenched reliance on conventional motor technologies, lack of awareness about the benefits of PMSMs, and concerns about compatibility with existing infrastructure. Overcoming these adoption challenges will require targeted education and awareness campaigns, along with incentivization programs to encourage businesses to transition to more energy-efficient motor solutions.

Regulatory Compliance and Standards: Compliance with industry standards and regulations poses another challenge for the IE4 Permanent Magnet Synchronous Motor market. Manufacturers must ensure that their products meet stringent performance, safety, and efficiency standards set forth by regulatory bodies and industry associations. Failure to comply with these standards can result in costly recalls, penalties, and damage to brand reputation. Therefore, investing in research and development to develop motors that not only meet but exceed regulatory requirements will be essential for gaining a competitive edge in the market.

Inquire before buying, here: https://www.nextmsc.com/ie4-permanent-magnet/inquire-before-buying

Supply Chain Vulnerabilities: The IE4 Permanent Magnet Synchronous Motor market is susceptible to supply chain disruptions, particularly concerning the procurement of rare-earth magnets and other critical components. Dependence on a limited number of suppliers, geopolitical tensions, and trade restrictions can lead to shortages, price fluctuations, and delays in production. To mitigate supply chain vulnerabilities, manufacturers must diversify their supplier base, invest in vertical integration, and explore alternative sourcing options to ensure a reliable and resilient supply chain.

Technological Innovation and Advancements: Continuous technological innovation is imperative for driving growth and differentiation in the IE4 Permanent Magnet Synchronous Motor market. Manufacturers must invest in research and development to enhance motor efficiency, reliability, and performance while reducing costs and environmental impact. Advancements in materials science, motor design, power electronics, and digital control systems offer opportunities to develop next-generation PMSMs that meet the evolving needs of industries and consumers alike.

Lifecycle Sustainability and End-of-Life Management: Ensuring the sustainability of IE4 Permanent Magnet Synchronous Motors throughout their lifecycle presents both challenges and opportunities for manufacturers. From raw material extraction to manufacturing, use, and end-of-life disposal, minimizing environmental impact and maximizing resource efficiency are paramount. Implementing circular economy principles, such as remanufacturing, recycling, and responsible disposal, can help reduce waste and extend the lifespan of PMSMs, thereby contributing to a more sustainable and circular economy.

Market Fragmentation and Competition: The IE4 Permanent Magnet Synchronous Motor market is characterized by intense competition and market fragmentation, with numerous players vying for market share across different regions and industry verticals. As a result, manufacturers must differentiate their products through innovation, quality, and value-added services to stand out in the crowded marketplace. Strategic partnerships, mergers and acquisitions, and market consolidation may also be necessary to strengthen market position and achieve economies of scale.

Skills Gap and Talent Shortage: Addressing the skills gap and talent shortage in the IE4 Permanent Magnet Synchronous Motor industry is essential for driving innovation and sustaining market growth. As technology advances and the demand for specialized skills increases, manufacturers must invest in workforce development, training programs, and knowledge transfer initiatives to cultivate a skilled workforce capable of designing, manufacturing, and servicing advanced PMSM systems. Collaboration with educational institutions, vocational training centers, and industry associations can help bridge the skills gap and ensure a steady supply of talent for the future.

Conclusion:

In conclusion, the IE4 Permanent Magnet Synchronous Motor market is poised for substantial growth and innovation in the coming years. With increasing emphasis on energy efficiency, sustainability, and technological advancement, IE4 PMSMs are expected to play a pivotal role in powering the industries of the future. By leveraging their superior efficiency, reliability, and performance, these advanced electric motors are unlocking new opportunities for growth and transformation across various sectors. However, addressing the challenges associated with cost, materials, and complexity will be crucial for realizing the full potential of IE4 PMSMs and driving widespread adoption. As manufacturers, researchers, and policymakers collaborate to overcome these challenges, the IE4 Permanent Magnet Synchronous Motor market will continue to evolve and thrive, shaping a more sustainable and efficient future for generations to come.

#IE4 Permanent Magnet Synchronous Motor#construction and manufacturing#market research#market trends#business insights

1 note

·

View note

Text

Efficiency and Comfort: Navigating the HVAC Electronically Commutated Motor (ECM) Market

Heating, ventilation, and air conditioning (HVAC) systems are essential components of modern buildings, providing comfort, indoor air quality, and energy efficiency. The electronically commutated motor (ECM) has emerged as a key innovation in HVAC technology, offering enhanced energy efficiency, precise control, and improved performance compared to traditional motors. This article explores the significance of ECMs in the HVAC industry, their diverse applications, and the factors shaping the market landscape.

ECMs, also known as brushless DC motors, are advanced electric motors that utilize electronic controls to regulate speed, torque, and power consumption. Unlike conventional alternating current (AC) motors, which operate at fixed speeds and rely on mechanical brushes for commutation, ECMs employ sophisticated control algorithms and permanent magnets to achieve variable speed operation and optimal energy efficiency.

One of the primary advantages of ECMs in HVAC applications is their ability to modulate airflow and adjust motor speed to match the specific heating or cooling demands of a space. By dynamically adjusting fan speed and airflow based on real-time conditions, ECMs help HVAC systems maintain precise temperature control, humidity levels, and indoor air quality while minimizing energy consumption and operating costs.

Request the sample copy of report @ https://www.globalinsightservices.com/request-sample/GIS21891

Moreover, ECMs offer significant energy savings compared to traditional motors, thanks to their high efficiency, variable speed operation, and advanced control features. By operating at lower speeds when heating or cooling loads are reduced, ECMs reduce energy waste associated with constant-speed motors, resulting in substantial cost savings and environmental benefits over the lifetime of HVAC systems.

In addition to energy efficiency, ECMs contribute to improved comfort and occupant satisfaction by reducing noise levels, minimizing temperature fluctuations, and providing consistent airflow throughout a building. The ability of ECMs to deliver precise and quiet operation makes them well-suited for applications in residential, commercial, and industrial HVAC systems, where comfort, reliability, and performance are paramount.

Furthermore, ECMs support the integration of advanced HVAC technologies such as variable refrigerant flow (VRF) systems, heat pumps, and zoning controls, enabling greater system flexibility, scalability, and responsiveness to changing environmental conditions. By optimizing motor speed and airflow based on real-time feedback from sensors and controls, ECMs facilitate the implementation of energy-efficient HVAC strategies such as demand-controlled ventilation and thermal comfort optimization.

The market for ECMs in the HVAC industry is driven by factors such as regulatory mandates, energy efficiency standards, and technological advancements. As governments and regulatory agencies worldwide continue to prioritize energy conservation and environmental sustainability, the demand for energy-efficient HVAC solutions, including ECMs, is expected to increase, creating opportunities for manufacturers, contractors, and building owners.

Moreover, advancements in motor design, materials science, and electronic controls are driving innovation in ECM technology, leading to smaller, lighter, and more efficient motors with enhanced performance and reliability. Manufacturers are investing in research and development to improve motor efficiency, reduce power consumption, and extend the lifespan of ECMs, further driving adoption in the HVAC market.

In conclusion, ECMs are playing an increasingly important role in the HVAC industry, offering improved energy efficiency, comfort, and performance in heating, ventilation, and air conditioning systems. As building owners, operators, and consumers seek to reduce energy costs, enhance indoor comfort, and minimize environmental impact, the demand for ECMs is expected to grow, driving innovation and investment in this critical component of modern HVAC systems. By navigating the ECM market effectively, stakeholders can achieve greater efficiency and comfort while realizing the full potential of advanced HVAC technology.

0 notes

Text

youtube

Testing Video of 11KW 1500RPM 5000VAC Three Phase Permanent Magnet Generator (PMG) In this video, we are testing this Three Phase Permanent Magnet Generator (PMG) step by step according to RPM from 100RPM to 1500RPM.

For any queries, please Call or WhatsApp at +919289311243, +919582345931, +918826634990, or +919999467601. Email:- [email protected]

#permanent magnet alternator#permanent magnet alternator manufacturer#permanent magnet generator#permanent magnet generator manufacturer#permanent magnet synchronous generator#low rpm permanent magnet alternator#low rpm permanent magnet generator#axial flux permanent magnet generator#radial flux permanent magnet generator#permanent magnet low rpm alternator#permanent magnet alternator manufacturers#high speed permanent magnet alternators#alternator manufacturer in Delhi#alternator manufacturer in India#generator manufacturer in India#generator manufacturer in Delhi#alternator#generator#generator manufacturer#alternator manufacturer#Youtube

1 note

·

View note

Text

The Evolution of Tachogenerators: From Analog to Digital

Tachogenerators have long served as simple and rugged rotary speed transducers across a diverse range of automation, instrumentation, and control applications. Traditionally based on analog electromagnetic induction principles, tachogenerator technologies have evolved over decades improving performance, capabilities, and integration. In particular, the advent of digital tachometer generators has brought precision rotational speed sensing into the digital era.

In this article, we’ll explore the progression of tachogenerator designs from legacy analog approaches to emerging digital implementations. We’ll compare technical capabilities and benefits offered by both analog and digital tach variants for speed measurement and control.

Analog Tach Generators

Analog tachogenerators utilize magnets and wire windings to induce sinusoidal or DC voltages proportional to the shaft rotation rate. Small permanent magnet DC tach designs have existed for over a century relying on simple electromagnetic induction principles harnessing rotating magnetic fields intersecting across stationary armature coils. The generated voltages serve as analog signals reflecting speed. Alternating current output tachs generating clean sine waves emerged later for more precision applications.

Legacy analog tachs directly translate speed input into continuously variable voltage or current outputs. The simplicity provides inherent durability and cost advantages. Drawbacks of traditional analog approaches include susceptibility to electrical noises, significant drift across temperature shifts, limited distance signal transmission capability, challenges interfacing with modern digital electronics, and restricted customization or intelligence capacities onboard.

Emergence of Digital Tach Technology

The proliferation of computing, microcontroller and digital processing technologies has fueled migration of analog tach designs into far more capable digital implementations. Rather than just passively generating induced analog voltages or currents, next generation digital tachogenerators incorporate onboard electronics and processing. This unlocks smarter features and allows digital serial network communications natively for precision speed telemetry and control.

Most digital tachometers retain the analog electromagnetic foundations with magnet/coil induction principles generating base sine wave signals proportional to rotation. High resolution analog to digital conversion and microcontroller-based electronics then digitize the signals enabling precision calibration, compensation, analysis and conversions into optimized outputs. Serial data protocols like SPI, I2C, USB, CAN, Modbus, Profibus and more help transfer rich processed readings to controllers and hosts without analog signal loss or noise concerns that plague legacy tach designs over distances.

Digital Tach Strengths and Benefits

Upgraded digitized tach implementations offer numerous performance, accuracy, flexibility, reliability and interfacing advantages including:

Temperature Compensated Calibration – Mitigates drift improving stability

Multi-Point Linearization Calibration – Reduces nonlinearity errors

Precision Ball Bearing Construction – Low noise floor enhances resolution

Tolerant of Mechanical Vibrations and Shocks – Rugged resilience

Short to Long Range Serial Networking – Flexible integration connectivity ● Immune to EM and RF Interference – Robustness in industrial settings

Advanced Programmable Embedded Features:

Custom Inputs/Outputs – Tailor analog/digital I/O needs

Failure and Status Diagnostics – Health monitoring and telemetry

Custom Calibration and Speed Ranges – Tunable performance

Speed Threshold Alarms – Cutting edge programmable limit triggering

Do-It-Yourself Firmware Updates – Evolving capabilities over product lifetimes

Built-In Self-Test Features – Assisted diagnostics and validation

The complete feature set allows precision smart sensing and control even through demanding speed measurement challenges outperforming purely analog predecessors.

Typical Applications Choosing Digital Tachometers

Next generation digital tachometer generators bring premium accuracy, reliability, interfacing and intelligence advancing rotational speed measurement and control. Example use cases choosing to upgrade analog approaches include:

Factory Automation and Robotics – Precision feedback for positioning and coordination of equipment, tasks and movement is essential. Networked digital tachs provide key velocity telemetry.

Industrial Gearbox/Transmission Monitoring – Critical to prevent overspeed conditions leading to catastrophic failures. Smart protection thresholds can alert operators to take preventative actions in time.

Agricultural Machinery – Managing speeds of tillers, fertilizer/pesticide sprayers, harvesters and processing conveyors brings efficiency while avoiding crop or mechanical damage.

Motorsports – Peak engine and wheel RPMs must be monitored to ensure design thresholds are not exceeded while optimizing performance outputs.

Aviation – Monitoring propeller, turbine and gearbox shaft speeds enables engine thrust calibration and confirming safe operating ranges.

Research Instrumentation – High accuracy speed control stands crucial for physics, chemistry, biology and engineering experimental consistency and repeatability.

This reveals only a partial scope where precision rotational speed measurement and control systems powered by digital tachogenerator technologies promises to keep advancing instrumentation and automation system capabilities across every industry.

The Road Ahead

Tach technology progression over decades from analog to digital parallels similar evolutions realized across sensing and embedded controls landscape - leveraging the virtues of analog roots while augmented by digital design innovations. As capabilities expand further, next generation tachogenerators are primed to displace legacy analog predecessors thanks to enhanced accuracy, connectivity, programmability and intelligence. Moving forward, field-oriented networked digital tach designs represent the new era ushering smarter rotational speed sensing and control solutions.

To know more about best industrual automation products visit www.visheshgroup.in

1 note

·

View note

Text

Optimizing Efficiency and Performance: Advancements in Permanent Magnet Machines

Permanent magnet machines, including motors and generators, have become integral components in various industries, owing to their high efficiency, reliability, and compact design. Enhancing the efficiency and performance of these machines is crucial for achieving energy savings, reducing environmental impact, and ensuring optimal operation across diverse applications.

Optimizing the efficiency and performance of permanent magnet machines involves a multi-faceted approach that encompasses design, materials, control systems, and thermal management strategies.

Magnetic circuit design stands at the forefront of optimizing the performance of permanent magnet machines. The design of the magnetic circuit significantly influences the machine's efficiency. Engineers focus on maximizing magnetic flux density in the air gap while minimizing losses caused by magnetic resistance and eddy currents. Advanced simulation tools aid in modeling and optimizing magnetic circuits, ensuring optimal design parameters for achieving higher efficiencies.

Additionally, the selection and utilization of permanent magnet materials play a pivotal role in enhancing machine performance. The continuous advancement of magnet materials, such as neodymium-iron-boron (NdFeB) and samarium-cobalt (SmCo), has led to magnets with higher energy densities and improved magnetic properties. These materials allow for stronger magnetic fields and higher operating temperatures, contributing to improved overall machine efficiency.

Control algorithms and systems also contribute significantly to optimizing permanent magnet machine performance. Advanced control strategies, including field-oriented control (FOC) and sensorless control techniques, enable precise control of motor parameters such as torque, speed, and flux. These algorithms maximize efficiency by minimizing losses and improving dynamic response, particularly in variable speed applications.

Moreover, thermal management plays a critical role in maintaining the efficiency and reliability of permanent magnet machines. Heat generated during operation can degrade magnet properties and reduce machine efficiency. Effective cooling techniques, such as liquid cooling systems or improved ventilation designs, help dissipate heat efficiently, preventing thermal degradation and ensuring stable performance over extended operational periods.

Furthermore, the integration of innovative materials and manufacturing techniques contributes to improved performance. Advances in magnetization processes, such as magnet shaping and segmenting, enable enhanced utilization of magnetic materials, reducing losses and improving efficiency. Moreover, the use of advanced composite materials for structural components can reduce weight, enhancing machine dynamics and overall efficiency.

Despite significant advancements, challenges persist in the quest to further optimize the efficiency and performance of permanent magnet machines. Demagnetization risks due to high temperatures, material costs, and production scalability remain areas of concern. Researchers and engineers continually explore novel magnet designs, alternative materials, and manufacturing methods to address these challenges and further enhance machine performance.

Looking ahead, the future of permanent magnet machines revolves around pushing the boundaries of efficiency and performance. Emerging trends, such as the development of rare-earth-free magnets, magnetocaloric materials, and advancements in computational modeling for precise design optimization, hold promise for even greater advancements in efficiency and performance.

In conclusion, optimizing the efficiency and performance of permanent magnet machines is a continuous endeavor driven by advancements in design, materials, control systems, and thermal management. As technological innovations continue to evolve, the pursuit of higher efficiencies, improved reliability, and sustainable solutions remains at the forefront, ensuring the widespread adoption and continued advancement of these machines across various industries.

0 notes

Text

ZONHAN wind turbine are made of strong cast steel that makes them durable. ZONHAN wind turbines can withstand harsh environments like strong winds and cold weather. wind turbine generator Using high performance NdFeB permanent magnet, the alternator is high efficient and compact. domestic wind turbine The unique electro-magnet design makes the bonding force and cut-in speed very low. For more information visit our website.

Website: https://www.zonhan.com

0 notes

Text

What are the types of spindle motors?

Brushed DC Spindle Motors: These motors use a brushed commutation system, where the rotor is connected to a commutator and brushes. The brushes supply power to the rotor windings, creating the rotational motion. Brushed DC spindle motors are relatively simple and cost-effective but tend to have lower efficiency and shorter lifespan compared to other types.

Brushless DC (BLDC) Spindle Motors: BLDC motors use electronic commutation instead of brushes. They typically have a permanent magnet rotor and use a controller to switch the current in the stator windings. BLDC motors offer higher efficiency, longer lifespan, and better control compared to brushed DC motors. They are widely used in applications requiring high performance and reliability, such as computer hard drives, CNC machines, and electric vehicles.

AC Induction Spindle Motors: AC induction motors are widely used in industrial applications. They operate on alternating current (AC) and consist of a stationary stator and a rotating rotor. The stator windings create a rotating magnetic field, inducing currents in the rotor, which in turn produces the rotational motion. AC induction motors are known for their robustness, simplicity, and wide availability. They are used in various applications, including machine tools, pumps, fans, and compressors.

Synchronous Spindle Motors: Synchronous motors operate at a fixed speed determined by the frequency of the power supply. They require synchronization with the supply frequency to maintain their rotational speed. Synchronous spindle motors are often used in precision applications where constant speed is critical, such as clock movements, record players, and some industrial machinery.

0 notes

Text

What are the types of spindle motors?

Brushed DC Spindle Motors: These motors use a brushed commutation system, where the rotor is connected to a commutator and brushes. The brushes supply power to the rotor windings, creating the rotational motion. Brushed DC spindle motors are relatively simple and cost-effective but tend to have lower efficiency and shorter lifespan compared to other types.

Brushless DC (BLDC) Spindle Motors: BLDC motors use electronic commutation instead of brushes. They typically have a permanent magnet rotor and use a controller to switch the current in the stator windings. BLDC motors offer higher efficiency, longer lifespan, and better control compared to brushed DC motors. They are widely used in applications requiring high performance and reliability, such as computer hard drives, CNC machines, and electric vehicles.

AC Induction Spindle Motors: AC induction motors are widely used in industrial applications. They operate on alternating current (AC) and consist of a stationary stator and a rotating rotor. The stator windings create a rotating magnetic field, inducing currents in the rotor, which in turn produces the rotational motion. AC induction motors are known for their robustness, simplicity, and wide availability. They are used in various applications, including machine tools, pumps, fans, and compressors.

Synchronous Spindle Motors: Synchronous motors operate at a fixed speed determined by the frequency of the power supply. They require synchronization with the supply frequency to maintain their rotational speed. Synchronous spindle motors are often used in precision applications where constant speed is critical, such as clock movements, record players, and some industrial machinery.

0 notes

Text

Revolution on Wheels: Unraveling the Intricacies of Cutting-Edge EV Powertrains and China's Role

Introduction:

Electric vehicles (EVs) have taken the automotive world by storm in the era of rapid technological advancement and environmental consciousness. A sophisticated marvel lies at the heart of these revolutionary vehicles: the electric powertrain. The dynamics of cutting-edge EV powertrains are reshaping how we think about transportation. In this comprehensive exploration, we delve into these powertrains' intricate workings, highlighting their pivotal role in the EV revolution. Additionally, we'll shed light on China's substantial contributions to the global EV powertrain landscape.

The Core of Innovation: Understanding Cutting-Edge EV Powertrains

The Essence of EV Propulsion: Electric Powertrains Defined

An electric powertrain is the driving force behind an electric vehicle, comprising a complex system of components that harmoniously convert electrical energy into motive power. Unlike conventional internal combustion engines, electric powertrains are characterized by efficiency, instantaneous torque delivery, and zero tailpipe emissions. The primary components of an EV powertrain include the electric motor, battery pack, power electronics, and transmission.

Breaking Down the Components

Electric Motor: The electric motor is at the heart of every electric powertrain, responsible for generating rotational motion from electrical energy. Due to their high efficiency and compact size, permanent magnet synchronous motors (PMSMs) and asynchronous motors are common choices.

Battery Pack: The battery pack stores and supplies energy to the electric motor. Lithium-ion battery technology dominates the EV market due to its high energy density and rechargeable capabilities. Battery chemistry and design advancements continue to extend EV range and charging efficiency.

Power Electronics: Power electronics serve as the bridge between the battery and the electric motor, controlling the flow of electrical energy. Inverter systems convert the battery's direct current (DC) into alternating current (AC) for the engine, allowing for precise power delivery control.

Transmission: Many EVs feature single-speed messages due to the electric motor's wide torque range. This simplicity enhances efficiency and reduces maintenance compared to multi-speed dispatches found in traditional vehicles.

China's Impact on the EV Powertrain Landscape

Leading the Charge: China's Contribution to Cutting-Edge EV Powertrains

China's ambition to become a global leader in electric mobility has translated into substantial advancements in EV powertrain technology. With a proactive approach to research, development, and investment, Chinese manufacturers have significantly improved powertrain efficiency, battery technology, and motor performance.

Pioneering Innovations

Battery Innovations: Chinese companies have been at the forefront of battery technology, driving improvements in energy density, charging speed, and safety. These innovations extend EV range, reduce charging times, and enhance overall performance.

Motor Development: China's focus on motor design and manufacturing has resulted in high-performance electric motors with reduced size and weight. These advancements contribute to more agile and responsive EVs.

Integrated Systems: Chinese EV manufacturers are integrating powertrain components for optimized efficiency. Intelligent energy management systems ensure seamless motor, battery, and power electronics interaction, enhancing overall system performance.

Personal Insights: A Glimpse into China's EV Powertrain Innovations

I witnessed China's rapid progress in the EV powertrain domain during my visits to various automotive expos and technology conferences. At a recent event, I engaged with engineers from a leading Chinese EV manufacturer who showcased a prototype powertrain boasting enhanced regenerative braking capabilities. This feature extended the vehicle's range and demonstrated China's commitment to pushing the boundaries of powertrain innovation.

Credible Sources Confirm China's EV Powertrain Prowess

The report highlights China's robust EV market growth, driven by advancements in powertrain technology and government incentives. These insights align with my own experiences and observations, reinforcing China's authority in shaping the future of EV powertrains.

Conclusion: Paving the Road Ahead

As the automotive industry undergoes a profound transformation, the dynamics of cutting-edge EV powertrains are steering us toward a cleaner, more sustainable future. These intricate systems are redefining propulsion and pushing the boundaries of technological innovation. China's unwavering dedication to advancing EV powertrains underscores its role as a global leader, ensuring that the wheels of revolution continue to turn, propelling us toward a cleaner and more electrified tomorrow.

0 notes