#Printed circuit board PCBA

Explore tagged Tumblr posts

Text

Experience the Difference with Top PCBA Providers

Greetings and welcome to our journal, in which we delve into the intriguing domain of PCBA production! Individuals employed in the electronics industry are cognizant of the criticality of an efficient and streamlined PCB assembly procedure to the manufacture of superior products. Nonetheless, as with any manufacturing procedure, obstacles may arise along the way. But have no fear! This article will analyze several common challenges that are commonly encountered during Printed circuit board PCBA manufacturing and propose viable resolutions. Presently, prepare your soldering iron and prepare to embark on an intriguing investigation into the intricacies inherent in the assemblage of printed circuit boards!

Understanding the PCB Assembly Process

Each phase of the intricately coordinated dance-like printed circuit board assembly procedure is critical for the production of electronic devices. The design phase commences with the creation of the circuit board's layout and schematic diagram by engineers. This design serves as a road map for production.

Once the design phase is concluded, fabrication can commence. Copper layers are etched onto the board in order to create conductive channels through which electrical signals can travel. Component placement, which entails soldering through-hole or tiny surface mount components into their designated locations on the board, is the subsequent procedure.

The final stage, testing and inspection, entails a meticulous examination of every connection and function present on the assembled PCB. We can solemnly affirm that our printed circuit boards are operationally ready upon their successful completion of these rigorous examinations.

Preparation for the PCBA Method

Thorough planning is essential for ensuring an efficient production process for printed circuit board assembly (PCBA). Prior to commencement of production, several critical duties must be accomplished.

It is of utmost importance to initially and thoroughly understand your design requirements. This involves determining the PCB's shape and dimensions, as well as designating any required components or features. Schemas and the bill of materials (BOM), which will serve as the blueprint for the project, are two of the documents that you will be required to gather.

Once the design specifications are finalized, the next step is to select a reputable PCBA manufacturer. When evaluating multiple companies, consider their reputation in the industry, timeliness, and track record of successfully completing relevant projects. Maintaining effective communication with the manufacturer of your choice is also vital throughout the entire process, including design review meetings and providing feedback on prototypes.

Keep in mind to complete tests! In order to ensure the dependability and quality of products, testing is vital. Before production commences, exhaustive testing strategies should be devised to identify potential issues early on and prevent costly delays in the future.

By adhering to these instructions and maintaining organization at each stage, you will be in an excellent position to complete the PCB assembly successfully. Consequently, ensure that you cross every possible T and dot every possible A, as meticulous planning in the present will lead to more streamlined manufacturing in the future!

Frequent Challenges in PCBA Manufacturing

Manufacturing PCBAs is a challenging endeavor that must surmount numerous obstacles. Managing manufacturing defects and ensuring quality control are recurring obstacles in PCBA production. Upon investing time and resources in the process of assembly, discovering defects or inferior components can be disheartening. However, these issues can be mitigated by manufacturers through the implementation of stringent quality control procedures, including thorough testing and inspections throughout the entire manufacturing process.

Ensuring compliance with industry standards and regulations introduces an extra challenge to the PCBA manufacturing procedure. Maintaining awareness of the most recent advancements and ensuring adherence to established protocols can present difficulties in the context of swiftly evolving technologies and stringent regulations. In order to ensure adherence, manufacturers must allocate resources towards continuous employee training, remain informed about the latest legislative developments, and conduct regular audits.

Additionally, supply chain logistics management in PCBA manufacturing can be quite challenging. Effective communication channels and meticulous planning are required to coordinate multiple vendors for diverse components while maintaining transparency in the process. To surmount this challenge, it is imperative to establish strong relationships with reliable suppliers who prioritize timely delivery.

Several challenges are associated with the production of PCBAs, necessitating meticulousness, proactive quality control protocols, adherence to industry regulations and laws, and effective management of supply chain logistics.

Errors in Production and Quality Control

In the production of PCBAs, one of the most prevalent issues is the management of manufacturing defects. These defects, which may manifest at any stage of production, have the potential to significantly compromise the functionality and quality of the end product. Errors in soldering or improper placement of components are examples of minor defects that could lead to more significant complications.

To address these concerns, rigorous quality control procedures must be implemented throughout the entire manufacturing process. This encompasses the entire procedure, starting from fundamental component verification and culminating in exhaustive functional testing. Manufacturers can ensure that their clients receive only superior PCBAs by promptly identifying and rectifying any potential defects.

The presence of well-informed specialists who possess the ability to promptly identify and resolve problems is an additional critical element in the successful implementation of robust quality management. Employees should receive ongoing training to remain current on PCBA manufacturing best practices and industry standards. Additionally, the implementation of state-of-the-art equipment and technologies can facilitate the automation of certain inspection processes, thereby augmenting both precision and productivity.

PCBA production is significantly impeded by manufacturing defects; however, these issues can be mitigated and high-quality products ensured to market through the implementation of rigorous quality control protocols, employment of qualified professionals, and utilization of cutting-edge equipment.

Compliance with regulations and industry norms

Observance of industry standards and regulations is critical in the production of PCBAs. Through this process, it is ensured that the final printed circuit boards adhere to all relevant safety and quality criteria. Nonetheless, many obstacles may arise when attempting to navigate the intricate regulatory landscape.

Ensuring producers remain compliant with continuously evolving regulations can pose a formidable undertaking. As regulations alter frequently and new technologies emerge, it is vital to remain informed. Research and training must be conducted continuously to ensure that your PCBA processes adhere to the most recent standards.

Compliance with industry-specific standards and regulations is required. Medical devices, automotive, consumer electronics, and aerospace are among the industries that have their own set of regulations regulating PCBA manufacturing processes. Adhering to these specific standards requires an extra level of effort.

To ensure conformance, meticulous documentation and record-keeping are required throughout the entire production process. It is imperative to maintain comprehensive records of each phase, encompassing the procurement of components and the assembly methods utilized, in order to substantiate adherence to industry standards when required.

By implementing proactive measures to resolve these concerns and consistently providing education and training for staff involved in PCBA production processes, organizations can successfully navigate regulatory barriers and deliver high-quality products that meet client expectations.

Overcoming Challenges in the Production of PCBAs

While the PCB assembly process does entail some challenges, it is essential to remember that these can be resolved through meticulous planning and execution. By acquiring a thorough understanding of the process, adequately preparing themselves, and taking proactive measures to address common issues, manufacturers can ensure a smoother manufacturing cycle and deliver higher-quality printed circuit board assemblies.

Establishing a robust quality control system is a critical component in resolving challenges encountered during PCBA manufacturing. In order to detect errors or defects early in the production process, exhaustive testing procedures must be implemented at various stages. Manufacturers have the ability to avert significant issues by preemptively investing in cutting-edge inspection equipment and personnel with extensive expertise.

Compliance with industry standards and guidelines is an additional critical component of achieving success in the production of printed circuit boards. Remaining informed about safety regulations, environmental factors, and other regulatory rules promotes legal compliance and inspires trust among consumers who prioritize ethical considerations.

Moreover, technical advancements can substantially facilitate the process of overcoming challenges in PCBA manufacturing. Automation and intelligent apparatus have provided manufacturers with access to tools that boost output while reducing human error. Contemporary hardware and software solutions facilitate enhanced precision, accelerated production cycles, and overall improved results.

Cooperation among the various parties involved in the Printed circuit assembly process is also crucial to its success. A streamlined operation is facilitated by effective communication among designers, engineers, suppliers, assemblers, and customers through the establishment of explicit expectations for each party involved. Regular meetings or check-ins are conducted throughout the production process to ensure that all parties are remaining on track to achieve their goals.

0 notes

Text

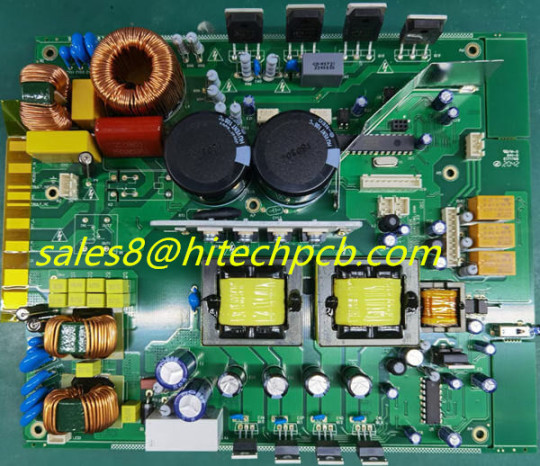

PCBA assembly manufacturing services provides by Hitech provides, from PCBA sample to medium or mass production volume. Our professional SMT factory has advanced equipments help us to offer rich experience in various PCBA manufacturing. Contact susie [email protected]

3 notes

·

View notes

Text

Multilayer PCBs (Printed Circuit Boards) offer numerous advantages over their single-layer or double-layer counterparts. These benefits arise from their enhanced design capabilities, improved performance, and greater flexibility. Here are some key advantages of multilayer PCBs:

#PCB#printed circuit board manufacturers#electronic cable assembly#pcb manufacturing#pcb assembly manufacturer#pcb assembly services#pcb board manufacturer#printed circuit board manufacturer in india#circuit board manufacturing#pcb exporters#pcba#pcb manufacturer#pcb design#pcbassembly#multilayer pcb

2 notes

·

View notes

Text

PCB Assembly manufacturer

PCB Assembly & Electronic Assembly service & electronics manufacturing company – Hitech Circuits Co., Limited As leading one-stop PCB Assembly services provider in China, Hitech Group offers high quality, cost effective and express PCB board products and provides PCB manufacturing, electronics assembly manufacturing, components sourcing, Box build assembly and PCBA testing services for our customers. [email protected] www.hitechcircuits.com

0 notes

Text

Medical PCB Assembly

Medical PCB Assembly Manufacturer – One-stop service

Medical PCB Assembly Manufacturer – One-stop service

Medical devices (medical PCB assembly) refer to instruments, devices, instruments; in vitro diagnostic reagents and calibrators, materials, and other similar or related items. There are used directly or indirectly in the human body, including the required computer software.

Hitech Circuits has extensive experience in providing medical PCB assembly services to our medical industry customers, and we deeply understand that our medical PCBA will be used in life-critical medical devices, which have extremely high requirements for precision and reliability.

We are committed to offering the world-class PCBA by strictly controlling the quality of every piece, our medical PCB assembly, box build assembly, and prototypes assembly capacities allow us to assemble kinds of medical devices such as diagnostic imaging equipment, lasers, and handheld dental tools.

At Hitech Circuits, we take care of the medical PCB assembly of your product so you can spend more time running your business and marketing your medical devices.

Hitechpcba medical PCB assembly technique:

Whether in a controlled environment such as a hospital or in an uncontrolled environment such as a home health care center, medical equipment must protect the lives of patients and surgeons. Medical PCBA refers to instrumented circuit boards that are used directly or indirectly in the human body. Such as instruments, equipment, instruments, in vitro diagnostic reagents, and calibrators, materials, and other similar or related instruments.

Therefore, the requirements for component procurement and processing are very strict, and a more precise technique is required, which is produced by IPC Class 3 standard. Hitechpcba is fully certificated, apart from certifications of ISO9001:2015, ISO14001, REACH and IATF16949, we have also obtained the ISO13485 certification, which means that our PCBs can meet the high standards required by medical devices, and all of our finished medical devices are of FDA Class II. Working with us can avoid you from worrying about the quality problem.

This standard provides you with the ability to produce and manufacture to meet higher customer needs. In the medical device industry, safety and quality are not negotiable. At every step of the product life cycle, including service and delivery, regulatory requirements are becoming more stringent.

More and more industry organizations want to showcase their quality management processes and make sure that everything they do is best practice. PCBA is used in the medical industry to bring good news to patients. Hitechpcba is a certified manufacturer offering a one-stop PCB and PCBA turnkey service with 15 years experience and we have the confidence to become your preferred supplier.

Hitechpcba advantages:

We offer unprecedented service and flexibility for any medical device PCB. Without a small batch test, you can’t start your concept prototype so that it doesn’t help you get it to market. We offer comprehensive engineering support to make your medical device printed circuit board manufacturing process reality in the most cost-effective way.

We provide high-end customized processing services for PCBA in medical machinery customers. It is manufactured by PCB circuit board, component procurement, SMT chip processing, patch plug-in soldering, assembly testing and other one-stop services.

QC was set up in front of the furnace for poor screening, PCBA 100% visual inspection after furnace, PCBA 100% optical inspection, and 13 temperature zone reflow soldering each product independently set temperature. Must undergo rigorous tests, such as ICT, FCT, Burn-in test. The products produced include monitors, pacemakers, sphygmomanometers, etc.

We ensure the quality, reliability, and traceability of our medical PCB manufacturing assembly.

Over 15 Years of Medical PCBA Experience

With more than 10 years of experience in offering PCB assembly services, we have a good understanding of the medical industry, our experts have participated in a host of projects to provide medical PCBA solutions to leading medical companies and get trusted by them.

Types of Medical PCB Assemblies

As a PCB expert, Hitechpcba is capable of assembling types of medical PCBs such as multi-layer PCBs, rigid, rigid-flex PCB, and flexible PCBs, and there are various PCB materials available including copper, aluminum, and standard FR4, etc. So our medical PCB assembly solutions can be used for almost all medical devices.

High Efficiency

We utilize state-of-the-art equipment for medical PCB assembly that can reduce errors during the assembly process, meanwhile, we have proficient workers who know how to assemble PCBs correctly and efficiently.

The trend of PCB Medical Industry

The medical field is not like it used to be. Advances in technology have revolutionized the industry. This change is even more evident in electronic diagnostic, research, and treatment systems and tools. Every day, several complex electronic devices and instruments are introduced to simplify various medical procedures. This growth has largely benefited the PCBA technology industry because, without PCB in medical, new inventions would not be impossible. To meet the ever-changing needs of medical device and diagnostic machine manufacturers, today's PCB manufacturers are manufacturing extremely simple parts into highly complex PCB in medical industry. Using specialized high-speed laminates, copper and aluminum substrates, ceramics, and coatings, PCB manufacturers can make these boards best suited for medical industry applications.

Custom Medical PCB Assembly

Custom circuit board design in medical is the trend today. The medical industry has chosen the same approach when it comes to PCB. Customers can provide the correct specifications with the full form of PCB in medical for board size in X-direction, board size in Y-direction, total number of holes, minimum alignment and pitch size in inches, board material, number of layers, surface coating, etc. Therefore, the manufacturer will work according to the given specifications and deliver the right product for your application.

#pcb assembly#pcba#SMT & PCBA manufacturer#OEM assembly manufacturing#Printed Circuit Board Assembly

0 notes

Text

Unveiling PCB Assembly Cables: Bridging the Gap in Electronic Design

In the world of electronics, the assembly of Printed Circuit Boards (PCBs) is a complex process that requires precise attention to detail. One crucial aspect often overlooked in the PCB assembly process is the role of PCB assembly cables. These cables are vital for connecting and integrating different electronic components and systems, ensuring that your devices operate efficiently and reliably. If you’re curious about PCB assembly cables and their significance, this blog post will provide a comprehensive overview, including their types, applications, and considerations for choosing the right cables for your project.

What are PCB Assembly Cables?

PCB assembly cables, often referred to as cable assemblies or wire harnesses, are integral to the interconnection of various components within an electronic device. These cables facilitate communication and power transfer between PCBs and other system elements, such as sensors, connectors, and displays. They are designed to ensure that electronic systems function as intended by providing reliable and efficient connections.

Key Functions of PCB Assembly Cables:

Signal Transmission: PCB assembly cable carry electrical signals between different parts of a system, ensuring accurate data transfer and communication.

Power Distribution: These cables deliver power from the power supply to various components, maintaining the required voltage and current levels.

Mechanical Support: By securing connections and reducing stress on PCB connectors, assembly cables help prevent damage and ensure durability.

Types of PCB Assembly Cables

There are several types of PCB assembly cables, each suited to different applications and requirements. Here’s a look at some common types:

Flat Ribbon Cables:

Description: These cables consist of multiple wires arranged parallel to each other and encased in a flat, flexible insulation.

Applications: Often used in applications where space is limited and a large number of connections are needed, such as in computer motherboards and internal devices.

Round Cables:

Description: These cables feature a round cross-section and can include multiple wires insulated individually or as a bundle.

Applications: Common in power distribution and general-purpose connections where flexibility and durability are required.

Flexible Flat Cables (FFC):

Description: FFCs are thin, flexible cables that consist of flat conductors and are ideal for space-constrained applications.

Applications: Frequently used in compact electronic devices such as smartphones, cameras, and portable electronics.

Coaxial Cables:

Description: Coaxial cables have a central conductor surrounded by an insulating layer and an outer conductive shield.

Applications: Used for high-frequency signal transmission, such as in RF applications, video signals, and data communication.

Custom Cable Assemblies:

Description: Custom cables are designed and manufactured according to specific requirements and specifications provided by the client.

Applications: Ideal for specialized applications where off-the-shelf solutions are not suitable.

Applications of PCB Assembly Cables

PCB assembly cables find applications across a wide range of industries and devices. Some common areas include:

Consumer Electronics:

Devices: Smartphones, tablets, laptops, and gaming consoles.

Role: Connect internal components like displays, processors, and batteries.

Automotive Industry:

Devices: In-vehicle infotainment systems, engine control units, and sensors.

Role: Facilitate communication and power distribution within vehicle electronics.

Medical Devices:

Devices: Diagnostic equipment, patient monitoring systems, and imaging devices.

Role: Ensure reliable connections for data transfer and power supply in critical medical applications.

Industrial Equipment:

Devices: Manufacturing machinery, robotics, and control systems.

Role: Provide robust and durable connections to withstand harsh operating conditions.

Telecommunications:

Devices: Networking equipment, routers, and signal processors.

Role: Enable high-speed data transmission and connectivity.

Choosing the Right PCB Assembly Cable

Selecting the appropriate PCB assembly cable is essential for ensuring the reliability and performance of your electronic devices. Here are some factors to consider:

Application Requirements:

Considerations: Determine the specific requirements of your application, such as signal type, power needs, and environmental conditions.

Cable Specifications:

Factors: Evaluate cable specifications including gauge, insulation type, shielding, and flexibility based on your design requirements.

Durability and Reliability:

Assessment: Ensure the cables are durable and reliable, particularly in harsh environments or critical applications.

Custom vs. Standard Solutions:

Decision: Decide whether off-the-shelf cables are sufficient or if custom solutions are needed to meet specific design constraints.

Quality and Compliance:

Standards: Choose cables that meet industry standards and certifications to ensure MT PCB Assembly quality and compliance.

PCB assembly cables are crucial components in the electronic design and assembly process, playing a vital role in connecting various parts of a system and ensuring seamless operation. Understanding the different types of cables, their applications, and the factors to consider when selecting them can significantly impact the performance and reliability of your electronic devices.

By focusing on quality and choosing the right cables for your specific needs, you can ensure that your PCB assemblies operate efficiently and effectively, paving the way for successful and reliable electronic products.Pcb Assembly Cable

#Pcb Assembly Cable#4 Cores Power Cable#4pin Connector Cable#5pin Connector Cable#MT PCB Assembly#printed circuit assembly#pcba circuit board

0 notes

Text

#smart watch assembly#smart watch factory#smart wearable tws assembly#cable wiring harness factory#quality Smart Watch Assembly#affordable Smart Watch Assembly#best Smart Watch Factory#electronics pcba factory#printed circuit board assembly#electronics#smt pcb jobwork#electronics manufacturer

0 notes

Text

if you just engage in or somehow need this printed circuit assembly or custom another new one,welcome contact me to know more details

#PCB Assembly#PCBA#Printed circuit board assembly#SMT board#SMD board#surface mounted technical board#surface mounted device board

0 notes

Text

LED PCB Assembly

What is the LED Circuit Board assembly?

Generally, LED PCB assembly is considered to be a circuit board that has the LED components soldered to it. The LED is soldered to the printed circuit board and features a chip that creates the light as electrically connected. A thermal heat sink and a ceramic base are used to bond the chip. Not all the PCB products can be used in Led industry, as an LED PCB is easy to create a high volume of heat, but making it hard to cool with traditional methods. For this reason, metal core PCB is widely used in LED application because of their enhanced ability to dissipate heat, especially aluminum pcb is often used to fabricate PCB for LED lights.

We’ve had great LED PCB assembly experiences with top LED chips to brand such as Cree, Luxeon, Osram, Nichia, Lumileds, MLS, EVERLIGHT, Samsung, LG, Seoul., etc. PCB LED lights can be incorporated into numerous lighting applications due to their combination of excellent energy efficiency, low cost and maximum design flexibility.

Application of LED PCB Assembly

Hitechpcba serves customers in different industries, providing highly reliable and innovative LED PCBs for various applications:

• Horticulture light LED PCB Assembly

• LED controller PCB Assembly

• Computer LED display and indicators

• LED lights PCB Assembly for medical use

• Automotive LED PCBs Assembly include PCBs for brake lights and headlights

• Street lighting LED PCB Assembly

• Flashlights and camping accessories

• Traffic light PCB Assembly

• Commercial lighting LED PCB Assembly

LED PCB Assembly specification

Number of layers for LED PCB

These layers are made up of aluminum and magnesium, but now have Copper base material and Ceramic base materials for LED PCB industry, we can meet it.

Aluminum LED PCBs stand out among other PCBs because it has a good insulation characteristic and has a better machinery performance, the cheap cost is one important factor too.

Types of layers for LED PCB Assembly

Normally, the base layer is made using aluminum alloy metal.

This aluminum alloy substrate used in making the base makes it ideal for through-hole technology which transfers and dissipates heat.

A thermal insulation layer is made using some ceramic polymer which has good viscoelasticity characteristics.

It is highly heat resistant and protects the PCB against heat and mechanical stress.

The circuit layer, which is covered by a copper foil which can range from one to ten ounces.

LED Board type- single or in panel

Some boards are shapeless. For this reason, LED PCB panels are used. This reduces time, labor production and testing time.

Some LED PCB Assembly is done on a single board while others are done on panel boards.

LED PCB Assembly Process

Roughly, the PCBA process can be divided into theses phases: soldering paste printing > SMT (surface mounted technology) > reflow soldering > AOI (automated optical inspection)> THT (through-hole technology) > wave soldering > touch-up and cleaning > IC-programming > FCT (functional tests) > aging testing.

Below we show you the process.

Step1. Summarizing Project Information

Before contacting your supplier, make sure you have all the project information. Suppliers will need info following for quoting LED PCB assembly:

Gerber

BOM

LED PCB specification

Quotation quantity

Once you have gathered these information, you can contact us and request for a quote.

Of course, you can also provide the schematic, LED PCB Assembly pictures and even samples to us. The more details they have, the more accurate the supplier’s quotation will be.

Step2. Discussion and details about custom LED PCB Assembly

Different projects will have different requirements. Remember the special requirements mentioned in step 1? That’s going to be the focus of this session. Equipment and engineering capacity will not be identical between suppliers. Make sure your supplier has the equipment to produce and assemble major components and the corresponding testing capabilities.

For example, some vendors don’t have X-ray testing equipment, which means they can’t check the mount quality of BGA chips. Outsourcing this step will increase risk and cost. That’s what you don’t want.

Also, pay attention to time taken by the supplier to quote. Motherboards often contain hundreds or even thousands of components, and they are supplied by different manufacturers. To ensure the quality of the components, the supplier sourcing team will make multi-inquiries from these manufacturers or authorized suppliers to match customer’s requirement, which usually takes 2-3 business days, and even longer for some scarce chips. Therefore, if your project is complex and the supplier quotes you within few hours, double check with them.

Step3. Sample and feedback

After confirming the PI, the supplier will usually provide pre-production samples for your approval. At the same time, the supplier will also confirm with you the logistics plan of the bulk goods. Make sure they understand your shipping requirements, including details on packaging, customs clearance, taxes, etc.

For us to have a successful LED PCB Assembly process, its functions must be defined. Compliance requirement is defined to reduce the effect when components are selected.

The Bill of Materials is then generated from the information installed on the LED PCB.

All this information is used to assemble components which are identified from MOB to the LED PCB.

After that, the routing of traces is determined to each component, based on the size, shape of the circuit board and location of connectors.

Hitech Circuits is trusted by thousands of electronic engineers on their LED PCB assembly projects, from consumer, led bulb to precisely medical LED light, we can help you from the beginning of design stage; From commercial flood LED to industrial high power LED, from automotive LED to military LED, Venture is the perfect place for your LED PCB assembly requirement.

Hitech Circuits has been participated in hundreds and thousands of LED lighting projects, by providing LED PCB and also LED PCB assembly service.

Our LED PCB assembly had covered both ends of the Lighting Class LED size spectrum, assembling some of the largest (2 meter long boards) and some of the smallest LED Lighting applications which used in Medical Endoscopes.

LED PCB Assembly is very crucial in the current industrial development. Many electrical devises are being innovated and the old once being improved.

LED PCBs are useful due to the fact that they are made using materials that can transfer and dissipate heat. This characteristic increases device durability.

The world is changing with new technology, especially PCB technology that plays an essential role in the application of LED circuits. And the LED industry is taking advantage of this technology and growing faster.

As a full feature PCB solutions provider with more than a decade of experience, we're capable to provide LED PCB fabrication, components procurement and LED PCB assembly all under one roof. We can work with you to develop metal core PCB, aluminum circuit boards customized to your specific applications. We feature competitively priced PCBs made with standard FR-4 material that includes a thermal aluminum clad layer that will efficiently dissipate heat, keep all LED PCB components cool and significantly enhance the performance of your products.

LED pcb board, LED pcb assembly

LED with its advantages of high brightness, high efficiency, low heat, long life, is considered the most development potential in the 21st century lighting. In the market and policy driven by the rapid development of the domestic LED industry blowout has formed a relatively complete industrial chain, including the production of epitaxial wafers, chip preparation, packaging, integration, LED application. In 2010, China's LED industry scale, up from $ 827 billion in 2019 to 220 billion yuan, an annual growth rate of over 70%, higher than the 50% level of growth of the global LED lighting industry output value. Among them, the middle and lower reaches of the most complete industrial chain, accounting for 90% of the overall percentage of the GDP.Chinahas become the world's leading LED manufacturing base and important application market.

To further promote the technological innovation of the LED industry, construction and wide application of independent industry chain, China Electronic Appliance Corporation and industry associations to organize the theme of "Focus on the core energy LED Exhibition will be held November 9-11, 2010 in Shanghai International Expo Center and the 78th China Electronics Fair over the same period will be held will create from raw materials, epitaxial wafers, chip, LED bracket, LED accessories, LED packaging and supporting materials, the LED backlight upstream firm to the upstream and downstream enterprises of the display, lighting, landscaping, decorative lighting, traffic lights, automotive lighting, special lighting, to the equipment, instrumentation, software, finance, consulting and other service enterprises and technological exchanges and market trading platform, help the domestic industry sustained and healthy development, and promote the steady expansion of the LED application market.

In the LED industry chain upstream of the epitaxial wafers and LED chips accounted for 70% of the profits of the whole industry, and technology-intensive, capital-intensive, where the core technology of the LED. Well-known epitaxial wafer and chip production enterprises will be exhibited a number of energy-efficient, low heat, cost-effective LED products, many of whom have excellent products of international advanced level.

LED electronic pcb assembly manufacturing 100% Original LED Chip with one-stop in-house pcba services

3 notes

·

View notes

Text

Multilayer SMT Manufacturing PCBA Board

For a Express PCB prototype assembly quote, please email the following files to [email protected] :

BOM list

Gerber files

Quantity required

Our team is qualified to manage the complete process, which includes the sourcing of all components (PCB and Components), online order tracking and their management, PCB assembly, quality control and delivery.

We have specialized experts to deliver fast-turnaround, prototype printed circuit board assembly with surface-mount (SMT), through-hole (THT) and mixed-technology components. Our efficient and express PCBA prototyping service team can assemble printed circuit boards in as little as 24 hours.

5 notes

·

View notes

Text

youtube

IBE offers full feature PCB & PCBA Manufacturing Services

Visit us at https://pcbassemblymanufacturing.com/ Visit us at https://www.pcba-manufacturers.com Our PCB & PCBA services also specialize in prototyping and small-volume production, making IBE the one-stop destination of boards fabrication and assembly. This arrangement makes your R&D work easy and time-saving. Our professional engineers and technicians will work closely with you through our customer service people to ensure the best quality and quickest possible lead time. Fulfilling thousands of orders daily from around the world, we have established us as the leading supplier of PCB and PCBA services for our consistent quality and excellent services. IBE PCBA capabilities: SMT Assembly, BGA Assembly, Through-Hole Assembly, Mixed Assembly, Rigid Flex PCB Assembly Services. Compliant with a wide range of standards including IPC 610 Class 2 and Class 3. IBE PCBA service provides printed circuit board manufacture, components procurement, and assembly under one roof. This video shows how it's done and our PCBA facility.

Facebook: https://www.facebook.com/IBE-PCBA-Manufacturing-109762978486032

Youtube: https://www.youtube.com/channel/UCqWPg5Wjqra2YWHa26h_2dA

Twitter: https://twitter.com/IBEpcba

Pinterest: https://www.pinterest.com/ibepcbaaa/

Instagram: https://www.instagram.com/ibepcba/

Please subscribe us, and keep updated with the latest news.

2 notes

·

View notes

Text

Choosing the Right China PCB Supplier: Key Factors to Consider

In this dynamic world of electronics, Printed circuit boards (PCBs) are the skeleton of every device, from digital clocks to laptops and smartphones. China has become one of the largest hubs of producing PCBs worldwide.

Choosing the right China PCB supplier can be challenging, so make sure to read the factors we will discuss in this article. Let’s get started!

Key Factors to Consider When Choosing a China PCB Supplier

youtube

1. Understanding your PCB Requirments

The first step is to understand what kind of PCBs you need. Do you want single-layer, multilayer PCBs or a specific type? Knowing whether you want standard or customized PCBs will help you shortlist China PCB suppliers. Discuss your project specifications in detail with the supplier for better understanding.

2. Manufacturing Capabilities

While selecting a PCB supplier, check their manufacturing capabilities to ensure they have the right machines and sound technology to meet your specific requirements.

3. Pricing

Every buyer wants to purchase from a supplier that provides the best quality at affordable prices. So, just list suppliers you want to buy from and compare their quality and price. Remember that there may be additional costs like assembly or testing. Buying in bulk can be cost-effective.

4. Quality Control Standards

Ask suppliers for samples and check if they have an in-house inspection team to certify high-quality PCBs. PCBs must pass visual and functional tests to ensure they are durable and reliable. Research if the PCB supplier has globally recognized certifications like ISO 9001 and IPC-A-600.

5. Customization Options

You may have unique requirements for PCBs, so look for a supplier who can customize the boards for you. Whether you are looking for single-layer or multilayer PCBs, make sure the supplier has your desired materials and production techniques for customization.

6. Deadlines & Production Capacity

When working on an urgent project, you may want a supplier with high production capacity to meet your deadlines without compromising quality. Therefore, you should evaluate the supplier’s previous track record to assess their delivery timelines.

7. Communication & Support

Smooth communication and customer support are important to build a relationship between the two parties. Therefore, choose a supplier who gives you updates during the manufacturing process and is pleased to answer your queries in detail.

8. Industry Reputation

A supplier’s reputation is a powerful symbol of their performance and reliability. To check a supplier’s reputation in the industry, read their testimonials, case studies, and customer reviews. This will help you to be confident while selecting a supplier.

Why Choose a China PCB Supplier?

Here are some reasons you should choose a China PCB supplier.

China offers competitive manufacturing costs, making it a perfect choice for buyers seeking quality on a budget. Plus, it is more cost-effective compared to other countries.

China suppliers provide high-quality PCBs using innovative technologies and modern machines.

They have built a solid global reputation, with customers worldwide acknowledging their expertise in shipping PCBs efficiently.

Conclusion

Choosing a China PCB supplier can impact the progress and reliability of your electronic devices. By understanding your requirements and the factors mentioned, you can select a supplier that meets your specific material and production techniques requirements.

#pcb assembly#pcb#pcb manufacturer#pcba manufacturing#flex pcb#pcb fabrication#flexible pcb board#flex circuit pcb#flexible circuit board#Youtube

0 notes

Text

Darüber hinaus gibt es thermoelektrische Trenntechnik (auch Direktberührungstechnologie genannt) für Leiterplatten auf Kupferbasis. Es bedeutet, durch Lötmaskenöffnung und Galvanisierung von Kupfer die Kupferdicke der erforderlichen Positionen zu erhöhen, leitet die Wärme direkt von den LEDs oder anderen Komponenten zur Kupferbasis, während das Schaltungsnetzwerk unabhängig vom thermischen Netzwerk ist.

Als MCPCB-Hersteller stellte Hitech Circuits verschiedene Kupfer-Basis-PCB für Kunden her,

Das für High Power LED Feuerzeug mit 1000W+ und Netzteil verwendet wurde.

Im LED-Bereich gibt es vier Arten von kupferbasierten Leiterplatten.

0 notes

Text

Circuit Board Functional Test | East/West

East/West Manufacturing offers full Pcb Functional Testing (FCT), in addition to In-Circuit Testing (ICT) services, as a final step in the manufacturing process. Functional Testing provides a pass/fail result on finished Printed Circuit Board Assemblies (PCBAs) before they are shipped.

#east west manufacturing austin#electronics manufacturers#electronics contract manufacturing#electronics manufacturing services#defense electronics manufacturing#aftermarket services#aerospace and defense manufacturing#east west electronics#integration system#system integration testing

0 notes

Text

What is PCB Assembly ?

PCB Assembly manufacturer - Hitech Circuits Co., Limited

It’s the step in the manufacturing process in which you populate a blank board with the electronic components needed to make it into a functional printed circuit board. It’s these components that make a board into the circuit that enables an electronic product to function. PCB assembly typically takes place via one of two processes:

1. Surface-mount technology

SMT: SMT stands for “Surface Mount Technology“. The SMT components are very small sizes and comes in various packages like 0201, 0402, 0603, 1608 packages for resistors and capacitors. Similarly for Integrated circuits ICs we have SOIC, TSSOP, QFP and BGA.

The SMT components assembly is very difficult for human hands and can be time taking process so it is mostly done by automated pick and place machine.

2. Through-hole manufacturing

THT: THT stands for “Through hole Technology”. The components with leads and wires, like resistors, capacitors, inductors, PDIP ICs, transformers, transistors, IGBTs, MOSFETS are example.

The component has to be inserted on one side of PCB and pulled by leg on other side and cut the leg and solder it. The THT components assembly is usually done by hand soldering and is relatively easy.

Printed Circuit Board Assembly Techniques

There are only two common PCBA techniques available for use by a PCB designer. The methods are:

1. Automated PCB Assembly Techniques

Generally, this technique employs the use of state of the art machines, which are fully automatic. For example, the surface mount components are worth positioning with the aid of an automated pick and place machine.

Again, reflow soldering is commonly for surface mount components usually done in a reflow oven. An automated solder stencil is also used to apply the solder paste on the PCB.

Finally, high tech inspection machines are used to confirm and check the quality of the PCBA. Some of which include: Automated optical inspection machine (AOI), X-ray inspection machines, etc.

Above all, due to the precise monitoring, control of soldering, no human input and versatile machines.

This technique ensures utmost efficiency, output consistencies, and limits defects.

2. Manual PCB Assembly Techniques

This method is favorite for use with through-hole parts, which needs manual placement on the board. Besides, with these through-hole parts, it’s advisable you use wave soldering. Note that in the through- hole assembly process, you need to place the components and electronics on the PCB.

After that, you use wave soldering to solder the leads. Typically, you will need an individual to insert a component into a marked PTH. Once done, transfer the PCB to the next station where the next person will be on standby tasked with fixing another part.

What are the Benefits of SMT PCB Assembly?

SMT assembly provides many benefits and some of them are as follows:

It can be used to incorporate small components.

In SMT, the components can be placed on both sides of the board.

It assures high component densities.

Fewer holes need to be drilled for surface mounting than through-hole.

It require low initial costs and time for setting up the mass production.

SMT is the simpler and faster-automated assembly when compared to through-hole.

Errors regarding the component placement can be easily rectified.

Surface mount PCBs feature strong joints, which can easily withstand vibrations.

What are the techniques used in Surface Mount Technology?

There are several techniques for the reflow process. After applying the solder paste or a flux mixture on the board and after placing the components, the boards are conveyed to a reflow soldering oven. The techniques used for reflowing soldering include infrared lamps, hot gas convection, fluorocarbon liquids with a high boiling point, and so on.

What are the different testing methods used in SMT PCB Assembly?

Hitech Circuits as the PCB assembly manufacturer, we perform the following testing and inspection to ensure the quality of surface mount PCBs.

Automated Optical Inspection (AOI): This is performed before and after the soldering to identify the component placement, presence, and solder quality.

X-ray Testing: In this type of testing, the operator relies on the X-ray images of the PCB to check the solder joints and lead-less components such as Quad Flat Packs and ball grid arrays, which are generally not visible to naked eyes.

In-Circuit Testing (ICT): This method is used to detect manufacturing defects by testing the electrical properties in the SMT Assembly.

What type of files or documents should I send for SMT PCB Assembly?

Gerber Files: The file contains all details of physical board layers including solder masks, copper layers, drill data, legends, and so on.

Bill of Materials (BOM): This contains information on the list of items needed for the PCB manufacturing and the instructions of manufacturing.

Pick and Place File: This file contains information on all components to be used in the PCB design and their rotation and X-Y coordinates.

The whole process of PCB Assembly

1. Bare board loader machine

The first step in the PCB assembly is to arrange the bare boards on the rack, and the machine will automatically send the boards one by one into the SMT assembly line.

2. Printing solder paste

When PCB on the SMT production line, firstly, we have to print solder paste on it, and the solder paste will be printed on the pads of the PCB. These solder pastes will be melt and solder the electronic parts to the circuit board when it passes through the high-temperature reflow oven.

In addition, when testing new products, some people will use film board/adhesive cardboard instead of solder paste, which can increase the efficiency for adjusting the SMT machines.

3. Solder paste inspection machine(SPI)

Since the quality of solder paste printing is related to the quality of welding of subsequent parts, some SMT factories will use optical machine to check the quality of solder paste after printed the solder paste in order to ensure stable quality. If there any poorly printed solder paste board, we will wash off the solder paste on it and reprint, or remove the excess solder paste if there is redundant solder paste on it.

4. High speed SMT machine

Usually, we will put some small electronic parts (such as small resistors, capacitors, and inductors) to be printed on the circuit board first, and these parts will be slightly stuck by the solder paste just printed on the circuit board, so even if the speed of printing is very fast and the parts on the board will not fall away. But large parts are not suitable for use in such high speed SMT machines, which will slow down the speed of small parts assembly. And the parts will be shifted from the original position due to the rapid movement of the board.

5. Universal SMT machine

Universal SMT machine is also known as "slow machine", it will be assembled some large electronic components, such as BGA IC, connectors, etc., these parts need more accurate positions, so the alignment is very important. Use a camera to take a picture to confirm the position of the parts, so the speed is much slower than High speed SMT machine we taked before. Due to the size of the components here, not all of them are packed in tape and reel, and some may be packed in trays or tubes. But if you want the SMT machine to recognize the trays or tube-shaped packaging materials, you must configure an additional machine.

Generally, traditional SMT machines are using the principle of suction to move electronic parts, and in order to place the parts successfully, and there must be the flat surface on these electronic components for the suction nozzle of the SMT machine to absorb. However, for some electronic parts don’t have a flat surface for these machines, and it is necessary to order special nozzles for these special-shaped parts, or add a flat tape on the parts, or wear a flat cap for thees electronic parts.

6. Manual parts or visual inspection

After assembled all parts by the high speed SMT machine or Universal SMT machine and before going through the high-temperature reflow oven, and we will set up a visual inspection station here and to pick out the deviation parts or missing components boards etc., because we have to use a soldering iron to repair if there are still defectives boards after passing the high-temperature oven, which will affect the quality of the product and will also increase the cost. in addition, for some larger electronic parts or traditional DIP parts or some special reasons cannot be processed by the SMT machine before, they will be manually placed on pcb here.

7. Reflow oven

The purpose of reflow oven is to melt the solder paste and form a non-metallic compound on the component feet and the circuit board, that means to solder electronic components on the circuit board. The temperature rise and fall curves often affect the soldering quality of the entire circuit board. According to the characteristics of the solder materials, usually the reflow oven will set the preheating zone, soaking zone, reflow zone, and cooling zone to achieve the best soldering effect.

For example, the melting point for SAC305 solder paste with lead-free is about 217°C, which means that the temperature of the reflow oven must be higher than the melting points to remelt the solder paste. What's more, the maximum temperature in the reflow furnace should not exceed 250°C, otherwise many parts will be deformed or melted because they cannot withstand such a high temperature.

Basically, after the pcb passed through the reflow oven, the assembly for the entire circuit board is almost complete. If there are hand-soldered parts, we need to transfer to DIP process, and then we have to check the quality after reflow oven by QC department.

8. Automatic optical inspection(AOI)

The main purpose of setting up AOI is because some high density boards can’t be process the following ICT test, so we used AOI inspection to replace it. But even using AOI inspections, there still have the blind spots for such checking, for example, the solder pads under the components cannot be checked by AOI. At present, it can only check whether the parts have side standing issue, missing parts, displacement, polarity direction, solder bridges, lack of soldering etc., but cannot checking the BGA solderability, resistance value, capacitance value, inductance value and other components quality, so far AOI inspection can’t completely replace ICT test.

Therefore, there is still some risk if only AOI inspection is used to replace ICT testing, but ICT test is also not 100% make sure the good quality, we suggest these two ways can be combined with together to make sure the good quality.

9. PCB unloader machine

After the board is fully assembled, it will be retracted to the unloder machine, which has been designed to allow the SMT machine to automatically pick and place the board without damaging the quality for PCB.

10. Visual inspection for finished products

Normally there will be a visual inspection area in our SMT production line whether there is an AOI station or not, and it will help to check if there are any defectives after completed assembled the pcbs. If there is an AOI station, it can reduce the visual inspection worker on our SMT line, and to reduce the potential cost, and because it is still necessary to check some places that cannot be judged by AOI, many SMT factories will provide the mainly visual inspection templates at this station, which is convenient for visual inspection worker to inspect some key parts and polarity for components.

11. DIP process

DIP process is a very important process in the whole PCBA processing, and the processing quality will directly affect the functional for PCBA boards, so it is necessary to pay more attention to the DIP process. There are many preliminary preparations for DIP process. The basic process is to re-process the electronic components first, like to cut the extra pins for some DIP components, our staff received the components according to the BOM list, and will check whether the material part numbers and specifications are correct or not, and performs pre-production pre-processing according to the PCBA samples. The steps are: Use various related equipment (automatic capacitor pins cutting machine, jumper bending machine, diode and triode automatic forming machine, automatic belt forming machine and other machines) for processing.

12. ICT test

Printed Circuit board open/short circuit test (ICT, In-Circuit Test), The purpose of ICT test is mainly to test whether the components and circuits on the printed circuit board are open or short issues. It can also measure the basic characteristics of most components, such as resistance, capacitance, and inductance values to judge whether the functions of these parts are damaged, wrong parts or missing parts etc. after passing through the high-temperature reflow oven.

ICT test machines are divided into advanced and basic machines. The basic ICT test machines are generally called MDA (Manufacturing Defect Analyzer). It’s just to measure the basic characteristics of electronic components and judge open and short circuits issue we talked above.

In addition to all the functions of the basic ICT test machines, for advanced ICT test machine can also test the whole PCBA by using power, start to testing the PCBA boards by setting the program in the test machine. The advantage is that it can simulate the function of the printed circuit board under the actual power-on condition, this test can partly replace the following functional test machine (Function Test). But the cost for the test fixture of this advanced ICT test can probably buy a car, it’s too expensive and we suggest it can be used in mass production products.

13. PCBA function test

Functional testing is to make up for the ICT test, because ICT only tests the open and short circuits on the the PCBA board, and other functions such as BGA and other fuctions are not tested, so it is necessary to use a functional testing machine to test all functions on the whole PCBA board.

14. Cutting board (assembly board de-panel)

Normally, printed circuit boards will be produced in panel, and it will be assembled to increase the efficiency of SMT production. It means several single boards in one panel, such as two-in-one, four-in-one etc. After finished all the pcb assembly process, it needs to be cut into single boards, and for some printed circuit boards with only single boards also need to cut off some redundant board edges.

There are several ways to cut the printed circuit board. You can design the V-cut using the blade cutting machine (Scoring) or directly manually break off the board (not recommended). For more high density circuit boards, it will be used the professional splitting machine or the router to split the board without any damage the electronic components and printed circuit boards, but the cost and working hours will be a little longer.

Why Choose Hitech Circuits PCB Assembly Manufacturer for Your PCB Assembly Projects?

There are several PCB manufacturers specializing in PCB assemblyservices. However, Hitech Circuits PCB Assembly stands out owing to the following:

Assistance in Material Procurement:

Technically, in PCB assembly services, the quality of parts is the responsibility of the OEM; however, we ease your job by assisting you to make the right selection. We can help you procure all your parts of the same type own a single part number, thanks to our supply chain and vendor network as well as experience. This saves time and cost that goes in ordering single parts as you plan.

Testing procedures:

We are very focused on quality and thus implement stringent testing procedures at each stage of the assembly and after completion.

Fast Turnaround Times:

Our well-equipped facility and the right tools enable us to complete your requirements well before time, and without compromising on the quality or functioning of the PCBs. For simple designs we revert in 24 to 48 hours.

Cost Effectiveness:

While PCB assembly is a cost-effective alternative, we go a step further and assure that the parts you list are of a good quality and suitable for your requirement. Also, you can control the part flow and replenish them as needed. This eliminates the need to buy extra stock and store it.

Quick Quote:

We offer a quick quote based on your BOM. All you need is a detailed BOM, Gerber files, your application requirement sheet, and quantity.

We’re not one to stand still, which is why we use the latest equipment and the finest minds to create your PCB projects. We’re constantly keeping our finger on the pulse of the latest trends. And as a result, we know how to deliver the highest standards of PCB assembly to meet all your requirements.

Our dedicated, friendly customer service team also means that we support you every step of the way. Offering our expert guidance to ensure a complete PCB project that you’re happy with.

Contact us today

No matter what your printed circuit board assemblyneeds are, we always aim to deliver efficient, dependable solutions. For more information about our services, do not hesitate to get in touch with us today for a no-obligation quote

2 notes

·

View notes

Text

Achieving High-Quality Protection with the SL-940 Conformal Coating System

In the world of electronics manufacturing, ensuring the longevity and performance of sensitive components is critical. Conformal coating plays a significant role in providing this protection by shielding electronic assemblies from harsh environmental conditions such as moisture, dust, and chemicals. At Absolute EMS, we utilize cutting-edge technologies like the SL-940 Conformal Coating System to deliver superior protection and reliability for your products.

What is the SL-940 Conformal Coating System?

The SL-940 Conformal Coating System is an advanced, precision-driven solution designed to apply protective coatings uniformly across electronic assemblies. This system is ideal for printed circuit board assemblies (PCBAs), offering unmatched precision and reliability. By using this system, we ensure that the coating is applied with the utmost accuracy, providing protection for even the most intricate designs and sensitive components.

Key Features of the SL-940

Precision Coating: The SL-940 system ensures a consistent application of coating material across the entire surface of the PCBA, significantly reducing the risk of defects and enhancing the overall durability of the electronics.

Automated Process: With advanced automation, the SL-940 guarantees efficiency and repeatability, making it ideal for high-volume production environments.

Customizable Settings: Tailored to meet specific project requirements, the system offers flexibility in coating thickness, material type, and application speed, ensuring that each project receives the right level of protection.

Meeting Industry Standards with Imperial Code 008004 - UNIQUE

At Absolute EMS, our commitment to quality extends beyond just the use of advanced equipment. We adhere to the highest industry standards, including compliance with Imperial Code 008004 - UNIQUE, ensuring that every product we manufacture meets the required specifications. This code represents our dedication to maintaining excellence in material usage and manufacturing processes.

Why Choose Absolute EMS?

State-of-the-Art Technology: With the SL-940 Conformal Coating System, we can provide unparalleled protection for your electronics, ensuring that they perform optimally in challenging environments.

Quality and Compliance: Adhering to Imperial Code 008004 - UNIQUE, we guarantee that every product manufactured at Absolute EMS meets industry-leading standards of quality and durability.

Expertise and Experience: Our team of skilled professionals brings years of experience in electronics manufacturing, ensuring that your project is handled with precision and care.

The Impact of Conformal Coating on Product Longevity

Conformal coating, when applied using advanced systems like the SL-940, significantly extends the lifespan of electronics by protecting against corrosion, moisture ingress, and environmental contaminants. This is especially important in industries such as aerospace, automotive, and medical devices, where reliability is paramount.

At Absolute EMS, we are proud to offer advanced conformal coating solutions that ensure the highest level of protection for your electronic assemblies. With our commitment to quality, compliance with Imperial Code 008004 - UNIQUE, and the use of state-of-the-art equipment like the SL-940 Conformal Coating System, we stand ready to meet your manufacturing needs.

Conclusion

By choosing Absolute EMS, you are investing in high-quality conformal coating solutions that guarantee your products' longevity and performance. Our use of the SL-940 Conformal Coating System and compliance with Imperial Code 008004 - UNIQUE ensures that your electronics are protected to the highest standard. Reach out to us today to learn more about how we can support your manufacturing needs.

0 notes