#Polyurethane Tubing

Text

Quality Standard Materials For versatile custom plastic extrusions

Discover top-notch standard materials perfect for versatile custom plastic extrusions. Our quality offerings guarantee precision, reliability, and excellence in every project. Trust us for tailored solutions.

0 notes

Text

Thin wall/medium wall/heavy wall heat shrink tubing, wire splice and terminators, switchgear cabinet bus bar protective tube,fibere optic protective shrink tube,automotive wire harness pipeline protection heat shrink tubing, power cable joint and termination, braided sleeve, PVDF,PTFE,Silicone,Fluororubber,Polyurethane shrink tubing.

#upm heat shrink#shrink tube#heat shrink#thin wall heat shrink#cable protection#wire insulation#PVDF tube#PTFE tube#silicone tube#fluororubber tubing#polyurethane shrink tubing

0 notes

Text

Looking For Polyurethane Tubing Manufacturer | Spiratex.com

Investigating for the top Polyurethane Tubing Manufacturer? The best place to get polyurethane tubing is Spiratex.com. This product is produced by our talented team in accordance with customer specifications and is useful for specific applications. To know more about us visit our site.

Polyurethane Tubing Manufacturer

0 notes

Text

The channel steel must be welded on the silo during installation and use

The channel steel must be welded on the silo during installation and use, and installing the air hammer above the channel steel can eliminate the hidden danger of the silo being damaged. Precautions for installation and use of pneumatic hammer After the pneumatic hammer is installed, please be sure to install an anti-falling cable on the body, otherwise it may fall due to the impact force and cause injury.

If the reinforcing plate is welded, please ensure that there is no gap between the reinforcing plate and the hopper, and reserve an exhaust port of about 10mm to facilitate the discharge of air, so that the impact force can be fully transmitted. In order to avoid damage to the hopper, please be sure to weld several layers.

If the plate of the mounting part is relatively thin, please weld the reinforcing plate, otherwise the mounting part may be damaged due to impact. In order to prevent falling off, please hoist and fix the main body with a cable, otherwise the bolt may loosen due to impact and fall off.

When fixing the body and the flange with bolts,Wholesale ltra-light polyurethane air tubes Suppliers please install spring washers on the top and bottom, and tighten them strictly according to the tightening torque and check them regularly.

When installing the pneumatic hammer, please wear a safety helmet, safety shoes, and a safety belt, and perform it under safe equipment. Please install an air filter before piping. If there is garbage or dust mixed in, it may cause malfunction. Do not exceed the required impact force when using, otherwise it may cause damage to the silo or installation site.

Please confirm that the strike surface of the mounting flange must be a solid plane. If necessary, please weld the reinforcing rib. Please keep the time setting of more than 1 second when cyclically hitting continuously. If it is less than 1 second, it may cause malfunction.

1 note

·

View note

Text

switchplate covers update/tutorial

So the thing to keep in mind with this is that we gotta see how well the wear. A switchplate cover is a pretty high-traffic thing, and subject to a lot of wear. If these get too dingy I'm absolutely going to have to go buy fancy ceramic ones or something.

But. That said. Here is my final result, and below the cut is how I did this, partly because I want to remember how it worked LOL.

[Image description: A combo lightswitch/outlet with a black three-prong plug plugged into it, set into a white subway tile wall with a wooden breadboard leaned against it. The plate cover is painted with a mottled effect to look like a turquoise gemstone, complete with inset glitter to mimic the pyrite inclusions found in some raw turquoise.]

A better view of the glitter:

[Image description: Another turquoise-painted outlet faceplate on the background of a rumpled white dropcloth, my fingers visible tilting it toward the light so the flake glitter catches the light from the window.]

So I searched up for tutorials and found a few, each of which was like "can't believe nobody else has done this"; I'm sharing the most helpful one here. What was thee very most helpful thing, though, was the writer's pointing out that many different configurations of turquoise exist, so you can just pick a reference image and build off that. I did not in the end come very close to my reference, but decided instead to make it look sick as hell. LOL. I was just having too much fun doing whatever I wanted. So these are not super realistic! But then you wouldn't... make an outlet faceplate out of real turquoise, so I felt like I wasn't fooling anyone. Anyway--

How To Paint Faux Turquoise.

So the first thing I did was find some very fine-grit sandpaper (I think I got 320? I found a mostly used-up sheet of it in the basement and just used the unused edge from where it had been fastened around a block, LOL) and went over the whole front surface of each plate I was going to paint, and then I washed them with dishsoap and hot water and dried them with a dish towel, because I figured finger grease, hand dirt, and sanding dust would keep the paint from sticking. I started with white plastic ones, the kind you get for up to a dollar at the hardware store.

Then I got a plastic container lid, put dollops of various of my paint samples in it, dug out the craft paints I got cleaning out Auntie's basement and the sole tube of acrylics (Mars black) I could still find from the last time I did any painting, and went to town. The first couple, I did the pale shades and let them dry and came back to add the darker marbling. But then I was like, these are latex/acrylic, you don't have to build them in layers? So I just did the rest of them with all the shading in more or less one pass.

Acrylic art paint and latex housepaint are both water-based, so there's no conflict with using them intermingled. I've combined them before, I used to do a lot of sign painting and it works fine. Housepaint's runnier, idk. Don't mix oils and latex, is the thing to keep in mind; they just don't stick to each other real well.

I went to the art supply store to get some water-based varnish, because all i had was polyurethane and that's oil-based. It'd probably work as a topcoat but I was worried and the internet's advice conflicted. I wanted to go get better glitter anyway, so I did. I happen to live near Hyatt's All Things Creative, so I take every excuse I can get to go there.

I bought some sick-ass glitter (over in the resin pouring section, hell yes), and puzzled thru the various offerings. (@sassaffrassa's advice proved invaluable on this thank u.) I got just-- "Gloss varnish acrylic medium", the Hyatt's brand, for four dollars and sixty-nine (nice) cents, and then because I was feeling spendy, I also bought Krylon spray-on glossy varnish. Belt and suspenders, y'know? Also to make the brush strokes less obvious.

The critical thing, though, about the gloss varnish, is that it says right on the bottle that you can either incorporate it into the paint as a medium to enhance the sheen, OR brush it over the finished work as a protective coating. Dries absolutely clear. So I knew, THIS is how I'm attaching the glitter. I'd been thinking like, mod podge? elmer's glue? mix it into the paint? No.

[image description: the gloss varnish bottle. It is this product. The relevant text says "can be used either as a medium to enhance the sheen levels of acrylic paint or as an over-varnish on finished artwork to provide a non-tacky, protective gloss coating".]

So I carefully got open the little bottle of glitter (no sneezing! it was "white gold flake" style and cost eight bucks for like half a gram. to my knowledge it's not actually made of gold but it was priced like it was) and painted little fine patches of gloss varnish onto the spots I wanted glittered, and then used tweezers to apply glitter just in those spots, and mooshed them around with the little varnish-covered brush until they stuck where I wanted them. (I put them on the darkest bits of the veining, because that was what my source image looked like, mostly. I wanted to be really liberal but then I thought, no, a little pop of glitter is more exciting actually. Still not sure, but it does look good so. They say measure that shit with your heart but I went light because I figured I could add more later, and then I didn't.)

Then I came back at the end and painted more gloss varnish just over the glitter, just to make sure it was all really stuck down and wouldn't flake off with wear.

Let that dry for a couple hours, then used a larger brush to spread gloss varnish as evenly as possible over the entirety of each plate. It did leave visible brush strokes, which I didn't mind. The art shop guy suggested using a really soft brush to minimize that, and I was like "yah sure ok" but then, well, I didn't, I just used the brush I had.)

But then I let that dry overnight, and in the morning I put the plates all in my giant overspray cardboard box, and gave them each a liberal coating of the spray varnish. (Yes of course I have a giant cardboard box I keep in my basement to spray paint things in. I know it says use in a well-ventilated space but what I do, see, is I do that and then I leave the room, which is almost as good. LOL it's 24F and snowing I'm not doing it outside.)

That bottle says two hours until handling on it, so I left it two hours, and then I put up the plates that were in spots where the painting was done or wasn't happening, hence my example image being against a tiled wall.

The screwdriver immediately scratched the first one a little bit, but not super obviously. But I kind of would expect a screwdriver to scratch just about anything, so that doesn't mean much.

I won't guarantee how well these'll hold up but if you were interested in doing something like that, there's how it worked. (Hi, future me, you're welcome for writing it down lol.)

I'm sort of sorry for no more process pictures but honestly most of it was following whimsy and doing what I felt like and kind of drawing on what I hadn't realized was a lot lot lot of hours of past paint-handling in my life, so pictures wouldn't help anyone else recreate this. But it did remind me that I love to paint and should do that more. So, I'll try, I guess.

40 notes

·

View notes

Text

Hero and Villain go to Sky Zone

Hero dodged to the left, then quickly to the right. Bright red pillars scattered around them, and they weaved gracefully between them. They grabbed the coarse ropes of a net, and scrambled upwards as fast as their tangled limbs could take them. They risked a glance to their left and caught a glimpse of Villain doing the same. They quickly reached up, using their trained grip strength to traverse a ten foot gap in their path. They had to be faster. They had to work harder. They had to win.

Their feet hit the ground with painful reverberation, but there was no time to stop and rest. Diving forward, they crawled through the darkened tunnel, their knees sliding on the slick material as they pushed forward. Up ahead, they could see the light at the end of the tube illuminating an open plain occupied only by the spinning blades of the final obstacle.

They reached it in record time, wasting not even a second to deliberate. They saw a gap and they lunged for it. A blade came hurtling towards them and they jumped, moving forward a step before the next one came. They leapt over the following blade, clearing it just before something crashed into them from behind. Sprawled out flat, they lifted their head to locate their assailant. Unfortunately, they forgot to calculate for the velocity of the forgotten obstacle. While Villain ducked under the last blade and made it to the gap in the wall, Hero was left behind to get smacked in the head.

Dazed, Hero finally managed to stumble off the padded plain and onto more solid ground.

“That’s the most impressive run I’ve seen today,” a man in a red polo shirt congratulated, but the two finishers were already racing past him.

Seeing an opening, Villain ran past and grabbed a long pole, then dashed onto a long beam and turned to face Hero.

All around the open building, young eyes followed the two enthusiastic players.

Hero, accepting the challenge, grabbed a pole for themselves and followed Villain out onto the beam.

“You picked the wrong section. My balance is unmatched,” Hero taunted, holding up their red weapon with two cushioned ends.

Villain replied, matching Hero’s stance with their blue padded weapon, “Really? How’s your hit absorption?”

Villain swung for the ribs and was blocked, red colliding with blue in a struggle for leverage. Both opponents swayed unsteadily, their feet wobbling and their eyes scanning for possible landing zones below them.

When they inevitably both went tumbling into a sea of primary colors, screams of victory followed them both.

Foam blocks were flying five, then ten feet in the air. Blurs of red, yellow, and blue obscured the views of the children who stood wide-eyed at the edge of the pit. One cube veered far off course, hitting a young girl in the face. She and the others wisely took a step back. Oblivious to the stunned—but unharmed— child, the polyurethane war continued.

Villain was the first to their feet, and they abandoned the pit and headed for where the floor turned black and bouncy, broken by a grid of red padding. They bounced diagonally to the farthest corner where the trampolines covered the walls as well as the floor. Hero, hot on their tail, jumped between the squares at an impressive speed.

Before they could reach Villain, they were caught on the wrist by different man in a red shirt and khaki shorts.

“Hey, it’s time to go,” he said, tapping his wrist at his watch.

“What?” Hero asked in confusion, looking down at their own wrist where a yellow paper band laid.

Beyond them, Villain stopped bouncing to watch the scene unfold.

“I’m sorry, you only paid for an hour,” the attendant explained patiently.

“But- But! What about him!” Hero pointed an accusatory finger towards the villain, who looked nothing short of absolutely overjoyed by Hero’s situation.

“His band is purple. He paid for two hours.”

“What?! Then can’t I just pay for more?”

“Sorry sir, we’re full. You’re going to have to give back the socks and leave,” he spoke politely, but the corners of his mouth were frayed even with the classic customer-service smile, and it was clear he was reaching the end of his shift.

Hero deflated, knowing they couldn’t argue with the poor minimum-wage employee in front of them without compromising their morals and their public image.

“You heard the man,” Villain mocked, moving closer to the hero.

Hero’s jaw remained discarded on the floor as they reached a bench on which they could sit down and start peeling to borrowed socks from their feet.

“This isn’t over,” they called over their shoulder as they walked past a smug Villain who stood with their arms crossed over their chest.

“Sure it isn’t, just like you weren’t knocked off first.”

Hero froze, seething, but wisely chose to keep walking.

The kids were watching, after all.

#he/they#hero and villain#because i refuse to fix it#villain#hero#hero/villain#heroes and villains#hero/villain snippet#writing#trampoline park#theyre totally fighting#definitely not for fun#they should do dodgeball next#beta reader#my beloved#came up with most of this honestly

15 notes

·

View notes

Text

it's that time of year again where i share the gifts i have made because no one i know is on this webbed site :)

we'll start with the little cat bowl holders i made for my friend to go with her boho x cottagecore theme she's aiming for in her home, and ironically ended up matching the cat tree she purchased after i painted these. i used interior paint samples i had left over from last year (don't do that), but being latex they were going to remain forever soft so i had to coat them in epoxy resin for durability against bumps and water. but in the end, that was better than the other option of polyurethane which would have risked yellowing them as polycrylic in my experience is also a softer finish. but make note to use a cabinet paint for anything that could possibly receive daily use (eyeing my dresser and nightstands).

next is for my other friend: two simple, elegant yet rustic geometrical plant propagation wall decor pieces - brought to you by late night googling. had to invest in a router for this one, and a new drill bit, because apparently i am good at picking projects i don't have the tools for. i love the espresso stain - which i used on a record crate and record cubbie - and felt the gold tied the rich grains and matte of the chalkboard paint together well. yeah! chalkboard paint! that way she can write the plant and propagation start date, should she choose. (sadly the tape pulled off the gold and the black bled, so i didn't risk a repaint outside of small touch-ups.)

this one is a last minute gift for my brother. i recently painted ornaments we've had for years (some dating back to 2007) that were to "represent" each of our pets - past and present. they never looked like them, so decided to fix that this year. he was quite impressed with the end result, specifically of the cats, so i got a tube of cats and found one that best represented his (bullet) in structure, stance, and coat length.

i'm quite pleased with the outcome of all of these. they're all handmade so contain a multitude of imperfections, but i still think everyone will love them (at least hope). i am considering making some propagation hangers for myself, but twas not an easy feat, so may hold off for a while lol

#drilling for the test tubes was fine and dandy until hitting knots. my drill was SCREAMING and people came into the garage like ?????#anyways i be blogging#things i make#woodworking#babble post#my photos are kind of out of focus bc my astigmatism has been acting up a lot lately and i have glasses ordered so we'll see how that goes

4 notes

·

View notes

Text

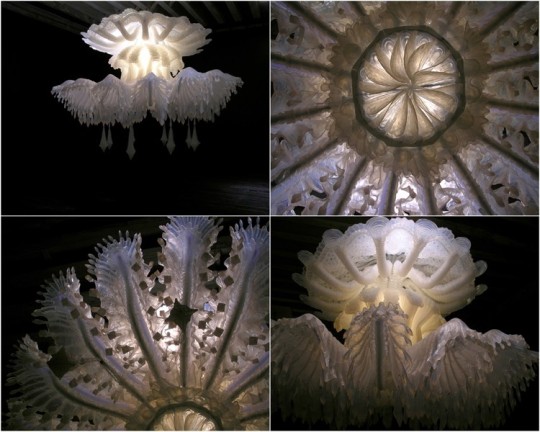

Timothy Horn

Villa Medusa, 2006

Exhibition of 3 large chandelier-like structures, based on 19th-century engraved images by German zoologist Ernst Haeckel, made of transparent silicone rubber. Hosfelt Gallery, New York, November 2006

The 3 works are based on the 19th-Century German zoologist Ernst Haeckel's engravings of medusae (the Greek word for jellyfish). As images themselves, they're strongly suggestive of some sort of organic chandeliers or lighting . Of great inspiration were Leopold and Rudolph Blaschka exquisitely wrought, tiny glass marine specimens, which include jellyfish, within the collection of the Harvard Natural History Museum.

Using a scaled up 2-D pattern, I made the initial forms in clay, from which I made 2-part plaster molds, then cast each form in polyurethane rubber. There are about 800 pieces of individual pieces of rubber in total, stitched together with monofilament. The rubber forms are suspended by an armature made of copper tubing. The works radiates light by internal lighting fixtures.

All 3 works took about a year and a half to make. I made most of the forms and molds whilst on a 7-month residency at the Fine Arts Work Center in Provincetown, on the tip of Cape Cod, Massachusetts. During that winter I read Herman Melville's Moby Dick, which at times seemed as interminable as a New England winter. Especially the 10-page comparison of the "whiteness of the whale"... Somehow, engaged in the construction of my own behemoth, and the not so thin veiling of homoerotic longing, helped keep me aboard the Pequod.

6 notes

·

View notes

Text

The Role of MSERW Pipes in Oil and Gas Industry: Challenges and Solutions

The oil and gas industry is one of the largest and most important sectors in the world. It plays a crucial role in meeting the energy demands of modern societies. In this industry, MSERW (Mild Steel Electric Resistance Welded) pipes have emerged as a popular choice for transporting oil and gas from drilling sites to refineries and other facilities.

If you are looking for the most reliable MSERW Pipe Provider in Gujarat, Tube Trading Co. is the name you can trust.

MSERW pipes are manufactured by rolling a steel sheet into a cylindrical shape and welding the edges together. They are widely used in the oil and gas industry because of their high strength, durability, and cost-effectiveness. However, like any other material used in harsh environments, MSERW pipes face a variety of challenges that need to be addressed.

Tube Trading Co. is an excellent MSERW Pipe Supplier in Gujarat. Tube Trading Co. is a stockist / Distributor of all varieties of Jindal pipes in Vadodara, Gujarat.

Challenges Faced by MSERW Pipes in Oil and Gas Industry

Corrosion: One of the biggest challenges faced by MSERW pipes in the oil and gas industry is corrosion. Corrosion can occur due to the presence of water, chemicals, and other substances in the oil and gas pipelines. This can cause leaks, failures, and other safety hazards.

High Pressure: Oil and gas pipelines operate under high pressure, which puts significant stress on the MSERW pipes. This can lead to deformation, cracks, and other failures.

Extreme Temperatures: Oil and gas pipelines are subjected to extreme temperatures, which can cause thermal expansion and contraction in the MSERW pipes. This can lead to stress and deformation, which can affect the performance and safety of the pipelines.

Tube Trading Co. is an excellent MSERW Pipe distributor in Gujarat. Tube Trading Co. is a stockist / Distributor of all varieties of Jindal pipes in Vadodara, Gujarat.

Solutions Provided by MSERW Pipe

Corrosion Resistance Coatings: MSERW pipe suppliers offer coatings that protect the pipes from corrosion. These coatings include epoxy, polyurethane, and other materials that can resist the corrosive effects of the substances flowing through the pipelines.

High-Quality Materials: MSERW pipe distributors ensure that the pipes they provide are made of high-quality materials. This can include using steel with specific chemical compositions that are resistant to corrosion, high pressure, and extreme temperatures

Regular Inspection and Maintenance: MSERW pipe providers offer inspection and maintenance services to ensure that the pipes are in good condition. This can help detect any issues before they become major problems and help extend the lifespan of the pipelines.

If you are looking for the most reputed as well as noteworthy stainless steel pipes Dealer in Vadodara Gujarat, Tube Trading Co. is the best pick for you.

Conclusion

MSERW pipes play an important role in the oil and gas industry. They are widely used for their durability, strength, and cost-effectiveness. However, the challenges of corrosion, high pressure, and extreme temperatures can affect the performance and safety of these pipelines. MSERW pipe providers offer solutions such as corrosion resistance coatings, high-quality materials, and regular inspection and maintenance services to address these challenges. By working closely with MSERW pipe suppliers and distributors, the oil and gas industry can ensure the safe and efficient transportation of oil and gas to meet the energy needs of the world.

#MSERW Pipe Provider in Gujarat#MSERW Pipe Distributors in Gujarat#MSERW Pipe Supplier in Gujarat#busines#spiral welded pipe#ERW pipes#IBR pipe

5 notes

·

View notes

Text

Margulies Collection Visit

Disliked piece:

Peter Bagehot, On Hold #3, 2015, mixed media (aluminum, wood, etalon, plastic, iron, textile, and polyurethane foam), 115 3/8 × 135 3/4 × 90 1/2 in

In Peter Buggenhout’s “On Hold #3” we see an arrangement of various objects, that seem to be construction materials and decoration items. To me, it almost looks like a room that imploded and those are the only remains of it. Visually, I must admit, that it is an interesting piece, specially the way it seems to balance only on that object (which I clearly could not identify) and the wall. However, I can’t help but dislike it, I find it visually unappealing, possibly because it reminds me of the piles of waste that constructions leave behind, and honestly, I don’t understand it (there was also no description of the piece). I know those are very shallow reasons to dislike an artwork, but besides of the impressive balance of the piece, there is nothing I find visually appealing.

2. Liked piece:

Bertozzi & Casoni

Composizione No. 8, 2005

Glazed ceramic

62 3/16 x 35 x 16 ½ inches

In this piece by Giampaolo Bertozzi and Stefano Dal Monte Casoni, “Composizione No.8,” we see a series of abandoned medicine cabinets filed with seemingly used items. It does not seem like a very impressive or beautiful piece at first glance, in fact I find the rendered unsanitary conditions of the cabinets quite unappealing. What I find incredibly interesting about this piece, is the media it is made from. Almost everything, from the cups, the figurines, to the tubes and cans “made of metal,” and the cabinets, is actually made out of ceramic. The attention to detail and mastery of this medium -which is not the easiest to use, specially for hyperrealism- had me speechless.

2 notes

·

View notes

Video

youtube

4PR 4.80/4.00-8 Wheelbarrow Air Wheels, Wagon and Trolley Tire And Tube,...

Provide polyurethane PU Solid and PU foaming equipment, processes, formulas and raw material services Web: www.modicasterwheels.com Email: [email protected] #Lawnmower #Tooltrolley #aerospacemanufacturing #equipment #Lawnmowertire #rollen #flatfreelawnmowertires #factories #productionengineering #flatfreetire #punctureprooftire #industrialsolutions #nhsengland #hospitalmanagement #castors #government #amazing #movingforward #aerospace #automation #gbmfg #innovationculture #innovation #quality #safety #automotiveindustry #engineering #supplychainsolutions #Trolley #manufacturingexcellence #automotive #manufacturinguk #industry #nhslongtermplan #ukmfg #wheels #engineeringuk #manufacturers #retweeet #protectthenhs #blickle #supportthenhs #nhs #supplychain #sourcing #industrial #b2b #industrialsupplies #casters #manufacturing #manufacturingindustry #materialhandling #Wheelbarrow #Dolly #Tools #garden #barrow #carts #caster #castor #cart #pu #Plastic #Solidtire #gardentools #tire #Tyre #weeder #Kart #gokart #shoppingcart #tractor #Handtruck #Handcart #toolcart #Toolbox #wheelchair #stroller #Constructiontools #manufacturer #manufacture #Factory #machine #production #plasticbox #wheelsandtires #casterwheels #wheelchairaccessories #solidtires #wheelchairwheels #wheelchairparts #mobilityscooteraccessories #solidtyres #solidtires #mobilityscooterparts

0 notes

Text

#UKDEALS (3 Tubes) PU18 Black Polyurethane Sealant Adhesive Strong Flexible for Construction, Auto and Marine applications. Non Shrinking High Grab Suitable for Expansion Joints . Paintable . https://www.bargainshouse.co.uk/?p=121744 https://www.bargainshouse.co.uk/?p=121744

0 notes

Text

The Peripheral Intravenous Catheter Market is projected to grow from USD 6,484.00 million in 2024 to USD 11,224.28 million by 2032, reflecting a compound annual growth rate (CAGR) of 7.10%.The global Peripheral Intravenous Catheter (PIVC) market has seen significant growth in recent years, driven by the increasing prevalence of chronic diseases, the aging population, and the rising demand for minimally invasive procedures. Peripheral Intravenous Catheters are small, flexible tubes inserted into a peripheral vein, typically in the arm or hand, to administer medications, fluids, or draw blood. These catheters are critical in healthcare settings, from emergency care to routine hospital procedures, making their market one of the essential segments in the medical devices industry.

Browse the full report at https://www.credenceresearch.com/report/peripheral-intravenous-catheter-market

Market Drivers

1. Rising Prevalence of Chronic Diseases

The global burden of chronic diseases, such as diabetes, cancer, and cardiovascular disorders, has been steadily increasing. These conditions often require long-term management, including regular intravenous (IV) therapy. The need for effective and reliable venous access devices, such as PIVCs, has thus become more pronounced. As healthcare systems across the world grapple with the growing demand for chronic disease management, the PIVC market is poised to benefit significantly.

2. Growing Geriatric Population

The world is witnessing a demographic shift with an increasing number of elderly individuals. The aging population is more susceptible to chronic diseases and often requires repeated hospital visits, surgeries, and long-term care. This demographic trend is a key driver for the PIVC market, as elderly patients frequently need intravenous access for various treatments.

3. Advancements in Technology

Innovations in catheter design and materials have enhanced the safety and efficacy of PIVCs. For instance, the development of safety-engineered catheters with features like retractable needles and closed systems has reduced the risk of needlestick injuries and infections. Furthermore, the use of advanced materials like polyurethane and silicone has improved catheter flexibility and patient comfort, driving the adoption of these devices in clinical settings.

4. Demand for Minimally Invasive Procedures

There is a growing preference for minimally invasive procedures in the medical field, driven by their advantages, including reduced patient discomfort, shorter recovery times, and lower risks of complications. PIVCs play a crucial role in these procedures, providing reliable venous access with minimal trauma. The increasing adoption of minimally invasive techniques is, therefore, contributing to the expansion of the PIVC market.

Challenges and Opportunities

While the PIVC market is growing, it faces challenges such as the risk of catheter-related bloodstream infections (CRBSIs) and the high cost of advanced PIVCs. However, these challenges also present opportunities for innovation. Companies are investing in research and development to create PIVCs with improved safety features and infection control mechanisms. Additionally, the rise of home healthcare services is expected to open new avenues for market growth, particularly for portable and easy-to-use PIVCs.

Key Player Analysis

Terumo Corporation

R. Bard, Inc.

Teleflex Incorporated

Braun Melsungen AG

Argon Medical Devices, Inc.

Venner Medical

Vygon

Smiths Group plc.

NIPRO Medical Corporation

Becton, Dickinson, and Company

Segments:

Based on Product Type:

Short Peripheral IV Catheter

Ported PIVC

Non-Ported PIVC

Integrated/Closed PIVC

Closed with Extension Sets

Closed PIVC

Based on Technology:

Conventional PIVC

Safety PIVC

Closed with Extension Set

Active PIVC with Blood Control

Passive PIVC with Blood Control

Active PIVC

Passive PIVC

Based on End User:

Hospitals

Ambulatory Surgical Centers (ASCs)

Clinics

Home Use

Others

Based on the Geography:

North America

U.S.

Canada

Mexico

Europe

Germany

France

U.K.

Italy

Spain

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

South-east Asia

Rest of Asia Pacific

Latin America

Brazil

Argentina

Rest of Latin America

Middle East & Africa

GCC Countries

South Africa

Rest of the Middle East and Africa

Browse the full report at https://www.credenceresearch.com/report/peripheral-intravenous-catheter-market

About Us:

Credence Research is committed to employee well-being and productivity. Following the COVID-19 pandemic, we have implemented a permanent work-from-home policy for all employees.

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

Website: www.credenceresearch.com

0 notes

Text

Choosing the Best Feeding Tubes for Your Patient’s Needs

Choosing the right feeding tube for a patient is important. It can make a big difference in their comfort, health, and overall care. There are many types of feeding tubes, and each one is designed for different needs. In this guide, we’ll compare different feeding tubes, explain what to consider when choosing one, and help you understand the materials and designs available.

Understanding the Different Types of Feeding Tubes

Feeding tubes come in several types. Here’s a simple look at the most common ones:

Nasogastric (NG) Tubes

Nasogastric tubes are put in through the nose and go down to the stomach. They are usually used for short-term feeding, like after surgery or during a short illness. NG tubes are easy to place and remove, but they can be uncomfortable, especially if used for a long time. They can also slip out of place easily.

Gastrostomy (G-Tube)

Gastrostomy tubes, or G-tubes, are inserted directly into the stomach through the abdomen. They are meant for long-term feeding. G-tubes stay in place better than NG tubes and are more comfortable over time. However, they require surgery to be put in, which comes with some risks like infection.

Jejunostomy (J-Tube)

Jejunostomy tubes, or J-tubes, are similar to G-tubes but are inserted into the small intestine instead of the stomach. They are used for patients with severe stomach problems or those who can’t have food go into their stomach. J-tubes work well for these patients, but they are more complicated to care for.

Percutaneous Endoscopic Gastrostomy (PEG) Tubes

PEG tubes are a type of G-tube that are placed using a camera (endoscope) in a less invasive procedure. They are used for long-term feeding and are similar to G-tubes in many ways. The main benefit is that they are easier to put in, so recovery is faster. However, there is still a chance of complications like infection.

Factors to Consider When Choosing a Feeding Tubes

There are several things to think about when choosing a feeding tube. These will help you find the best option for your patient.

Patient’s Medical Condition

The patient’s health condition is the most important factor. For example, patients with trouble swallowing might do well with a G-tube or PEG tube, while those with severe stomach problems may need a J-tube. Knowing the patient’s specific needs will help you choose the right tube.

Duration of Tube Feeding

Think about how long the patient will need the tube. NG tubes are good for short-term use because they are easy to put in and take out. But for long-term feeding, a more permanent option like a G-tube, J-tube, or PEG tube is better. These tubes are more stable and comfortable over time.

Comfort and Quality of Life

Patient comfort is key. Low-profile tubes, often called “button tubes,” are small and sit close to the skin, making them more comfortable and easier to hide under clothes. They also allow patients to move around more easily. It’s important to consider how easy it is for the patient or caregiver to manage the tube, as this will affect daily life.

Ease of Use and Maintenance

Different tubes require different levels of care. For example, NG tubes are simple to insert and remove, while J-tubes need more specialized care. Consider how much support the patient has when choosing a tube, as proper care is important to avoid problems like infections or blockages.

Comparing Feeding Tube Products by Material and Design

Feeding tubes are made from different materials and come in various designs. Here’s a look at what you need to know:

Silicone vs. Polyurethane Tubes

Feeding tubes are usually made from silicone or polyurethane. Silicone tubes are flexible and comfortable, making them a good choice for long-term use. However, they might not last as long as polyurethane tubes, which are stronger and more durable. Polyurethane tubes are also thinner, which can make them easier to insert, but they may not be as comfortable.

Single vs. Double Lumen Tubes

Feeding tubes can have one channel (single lumen) or two channels (double lumen). Single lumen tubes are simple and easy to manage. Double lumen tubes offer more functions, like giving medication through one channel while feeding through the other. This can be helpful for patients with complex care needs.

Low-Profile Tubes (Button Tubes)

Low-profile tubes are designed to sit close to the skin, making them less likely to be pulled out and less noticeable under clothing. These tubes are often chosen by patients who want to be more active. While they might need to be replaced more often due to their design, the extra comfort and ease of use can be worth it.

Additional Considerations and Services

When choosing a feeding tube, there are other things to think about beyond the tube itself.

Cost and Insurance Coverage

The cost of feeding tubes can vary, depending on the type and brand. Some types of tubes may be covered by insurance, but it’s important to check what coverage is provided and what costs you may need to pay yourself.

Manufacturer Support and Warranty

Some companies offer extra support, like customer service hotlines, educational materials, and warranties on their products. Choosing a top feeding tube manufacturer that offers good support can be reassuring, especially if you have any issues with the tube.

Nutritional Services and Accessories

Patients with feeding tubes often need special nutrition formulas and tools, like syringes, extension sets, and feeding pumps. Working with a dietitian or healthcare provider can help make sure the patient gets the right nutrition and that all the accessories work well with the chosen tube.

Conclusion

Choosing the right feeding tube for your patient is an important decision. By thinking about the patient’s health, comfort, and the type of tube that will work best, you can make an informed choice. It’s also important to consider the costs, support services, and any extra needs the patient might have. Always work with healthcare providers to make sure you’re choosing the best tube for your patient’s needs, so they can have the best possible care and comfort.

Source : Choosing the Best Feeding Tubes for Your Patient’s Needs

#Feeding Tube#Right Feeding Tube#Tubes#Healthcare#Feeding Tube Selection#Medical Equipment#Feeding Tube Guide

0 notes

Text

Essential Components for Efficient Systems: Pneumatic Tubing and Hose

As a reliable and efficient method of powering tools, machinery, and automation systems, pneumatics are the backbone of many industrial operations. Air, gases, or fluids are transported through pneumatic tubing and hose, which are essential to their effectiveness. A system's performance, longevity, and safety depend heavily on selecting the right tubing and hose. Pneumatic tubing and hose are explored in this article, along with the importance, types, applications, and how they integrate with Push-In Fittings and Composite Push In Fittings.

Industrial Pneumatic Tubing and Hose

A pneumatic system relies heavily on pneumatic tubing and hose to transport compressed air or gases. Air is transported from the compressor to pneumatic tools, actuators, valves, and other devices via them. These components have a direct impact on the performance and reliability of a pneumatic system based on their efficiency, flexibility, and durability. Get more info about air hosing.

Material compatibility, pressure ratings, environmental conditions, and ease of installation are some of the factors to consider when choosing the right tubing or hose for a particular application. In addition to ensuring smooth operation, the right selection also ensures operator safety and equipment longevity.

Pneumatic tubing and hose types

Pneumatic tubing and hoses come in many different types and are designed for specific applications and environments. Knowing what each type is used for will allow you to make an informed decision.

1. Polyurethane Tubing:

An excellent abrasion resistance and flexibility make polyurethane tubing a popular choice for applications requiring tight bending radiuses. Air tools, robotic systems, and other dynamic applications where flexibility and durability are essential are made possible by polyurethane tubing.

2. Tubing made from nylon:

The high strength, chemical resistance, and strength of nylon tubing make it ideal for applications that require exposure to harsh chemicals or solvents. Furthermore, nylon tubing is lightweight, making it ideal for applications where weight reduction is a priority, such as mobile equipment and other equipment.

3. Polyethylene tubes:

Due to its low cost, flexibility, and chemical resistance, polyethylene tubing is widely used in pneumatic systems. It can be used for a wide variety of applications, including air distribution lines, fluid transfer, and general pneumatic systems. A variety of colors are also available for polyethylene tubing, which can be used for color coding pneumatic circuits.

4. Hoses made of PVC:

Besides being flexible and resistant to chemicals and abrasion, PVC hose is also available in reinforced versions, which provide increased strength and durability. PVC hose is typically used in low-pressure pneumatic applications, including air lines and fluid transfer systems.

5. Teflon (PTFE) Tubing:

Because Teflon tubing is highly resistant to chemicals, heat, and moisture, it can be used in extreme environments. It is commonly used in applications where corrosive substances or high temperatures are a concern. Aside from being non-stick, Teflon tubing can also prevent blockages and maintain a smooth flow.

Pneumatic tubing and hose applications

Pneumatic tubing and hoses can be used in a wide range of applications across various industries. They are commonly used in:

1. Automation Systems:

Pneumatic tubing and hose are used in automation systems to connect actuators, valves, and sensors. The flexibility and reliability of the tubing ensure the system runs smoothly and efficiently, reducing maintenance and downtime.

2. Air Tools:

To operate pneumatic tools, such as drills, sanders, and impact wrenches, high-quality tubing and hoses are required. The tubing must be durable enough to withstand the high pressures and constant movement associated with these tools.

3. Transfer of fluid:

Besides air, pneumatic tubing and hose can transfer various fluids, including water, oil, and chemicals. The tubing must be compatible with the fluid being transported to prevent degradation.

4. Equipment used in medicine:

Medical equipment such as ventilators and oxygen delivery systems use pneumatic tubing, which must meet strict quality standards to ensure patient safety.

5. Air conditioning and ventilation systems:

Air flow, temperature regulation, and humidity levels are all controlled by pneumatic tubing and hose in HVAC systems. Among the environmental conditions within HVAC systems are temperature fluctuations and moisture exposure, which must be considered when choosing the tubing.

Push-in fittings and composite push-in fittings integration

Fittings ensure leak-free operation and optimal performance by securely connecting pneumatic tubing and hose to other components within the system. Two popular options are Push-in Fittings and Composite Push In Fittings.

Fittings that push in:

A push-in fitting is designed for quick and easy connection of pneumatic tubing without the use of tools. Tubing is simply pushed into the fitting, creating a secure and leak-proof connection. In applications where frequent connection and disconnection are required, push-in fittings are very popular due to their ease of use. They are available in various materials, including brass, stainless steel, and composite, making them suitable for a wide range of applications.

Push-in composite fittings:

A composite push-in fitting is a variation of a push-in fitting made of advanced composite materials. These fittings have several advantages, including reduced weight, corrosion resistance, and cost-effectiveness. For applications such as mobile equipment or aerospace, composite push-in fittings are particularly suitable for weight reduction. These fittings provide excellent strength and durability despite their lightweight construction, so they will last a long time in demanding environments.

Many industries find Push-in Fittings to be a reliable and efficient way to connect pneumatic tubing and hose. Their ability to provide a secure, leak-proof connection makes them a preferred choice.

Pneumatic Tubing and Hose Selection Factors

Consider the following factors when choosing pneumatic tubing and hose for your application:

1. Compatibility of materials:

Make sure the tubing or hose material is compatible with the fluids or gases being transported, as well as the environment in which the system will be used.

2. Temperature and pressure ratings:

When selecting tubing or hose for your pneumatic system, make sure that it can withstand the pressures and temperatures your system will operate at. Failures or safety risks can occur if the tubing or hose cannot meet these specifications.

3. Flexibility and Bend Radius:

It is especially important to consider the flexibility of the tubing, and its ability to bend without kinking. This is especially true in dynamic applications.

4. Fit and size:

Make sure the tubing and hose are the correct size for your fittings and system components to prevent leaks.

5. Durability and Resistance:

The right tubing and hose will extend the life of your system and reduce maintenance costs. They should be resistant to abrasion, chemicals, and environmental factors.

In conclusion

Compressed air, gases, and fluids are transported through pneumatic tubing and hose in a variety of industrial applications. For pneumatic systems to be efficient, reliable, and safe, they must be chosen and integrated with fittings such as Push-in Fittings and Composite Push-In Fittings. For more info about air hosing, Visit our website.

You will be able to enhance the performance and longevity of your pneumatic systems if you understand the different types of tubing and hose, their applications, and the factors to consider when selecting them. It doesn’t matter if you work in automation, fluid transfer, or HVAC systems, investing in high-quality pneumatic tubes and hose will improve efficiency, reduce downtime, and lower maintenance costs.

Pneumatic systems remain at the forefront of performance and reliability as industries evolve, creating the need for innovative and efficient solutions. By staying informed and selecting the right components, you can ensure your pneumatic system stays at the forefront of performance and reliability.

0 notes