#shrink tube

Explore tagged Tumblr posts

Text

Easy to use and versatile, our heat shrink tubing shrinks to fit a wide range of cable sizes, ensuring a snug and protective fit every time. With various colors and sizes available, customization is a breeze

#cable protection#upm heat shrink specialist#shrink tube#upmheat shrink#wire insulation#shrink sleeve#shrink tubing#upmheatshrink

1 note

·

View note

Text

Where to find your heat shrinkable parts of reliable cable joint and termination? Power Cable Joint and Termination Heat Shrinkable Tubing provide excellent environmental protection, electrical insulation, and mechanical support, ensuring reliable connections and longevity in various applications. Product range: S3(n) Medium Wall Halogen Free Heat Shrink Tubing S3(nh) Heavy Wall Haogen Free Heat Shrink Tubing S4 6:1 High Shrink Ratio Shrink Tubing C101 Non-tracking Heat Shrink Tubing C102 6~24,36KV Stress Control Shrink Tube C105 Semi-conductive/Insulation Double Layer Heat Shrink Tubing C06 Semi-conductive/insulation/elastomeric Insulation Triple Layer Heat Shrink Tubing C107 Plastic Insulation/Elastomeric Insulation Double layer Heat Shrink Tube Y1 Heat Shrink Breakout Boot Y2 Shrinkable Cable End Cap Y3 Non-tracking Heat Shrink Rain Shed 0.6~1kV 26/35kV Heat Shrinkable Accessories

#heat shrink#manufacturer#upmheatshrink#factory#shrinkage#shrink sleeve#heat shrinkable#shrink tube#cable joint#cable termination#cable accessories#rain shed#cable end cap#breakout boot#triple layer shrink tubing#high shrink ratio#stress control

1 note

·

View note

Text

didn't have heat shrink tube small enough to cover the end of some stranded picture hanging wire and stop it from cutting me so I sliced off a thin strip from a HDPE produce bag, wrapped it around the end of the wire real smooth and tight, and melted it with a lighter.

12 notes

·

View notes

Text

okay sugru kinda slaps for holding together $80 surface pro cable. that just had some damage to the end plastic from strain and to the cable rubber from me running over the cord with office chair, ofc

it's "glue" that starts out like polymer clay in feel and then cures to silicone rubber in 24 hours

2 notes

·

View notes

Text

i like to use an advanced elecronics technique called i wrap it up in tape and say a little prayer

3 notes

·

View notes

Photo

Jumba's Experimental Gas (2/3)

Jumba has finally finished his new /experimental/ gas! Comm for Ean

Posted using PostyBirb

#lilo_and_stitch#experiment_(species)#jumba#experiment#tube#transformation#species_transformation#shrinking#blue_fur#mind_alteration#mind_change

2 notes

·

View notes

Text

beat the mass effect and dragon age series and dont know what to do with my free time now

#personal#i WOULD draw but my tablet's wires frayed to the point where they're unusable#and i can't find my soldering iron or shrink wrap tubing so. i just ordered a new one lmfao

2 notes

·

View notes

Text

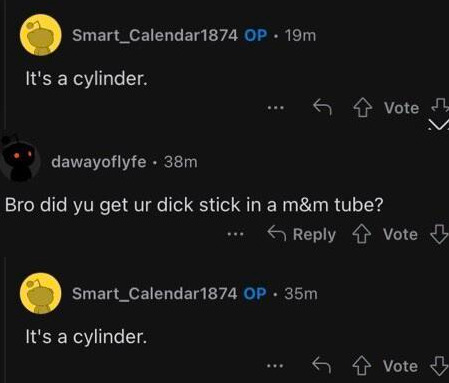

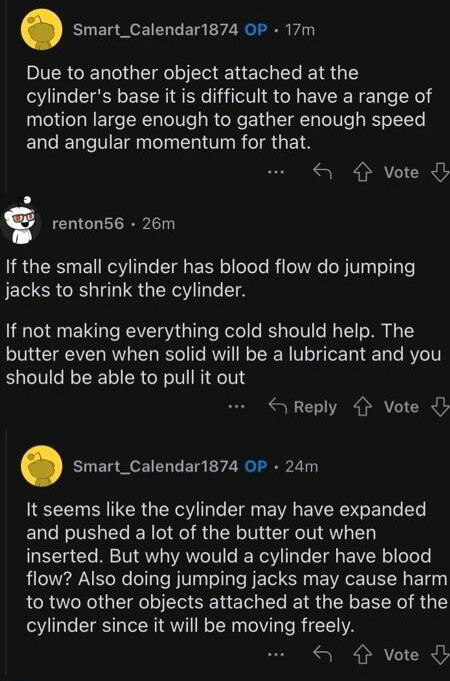

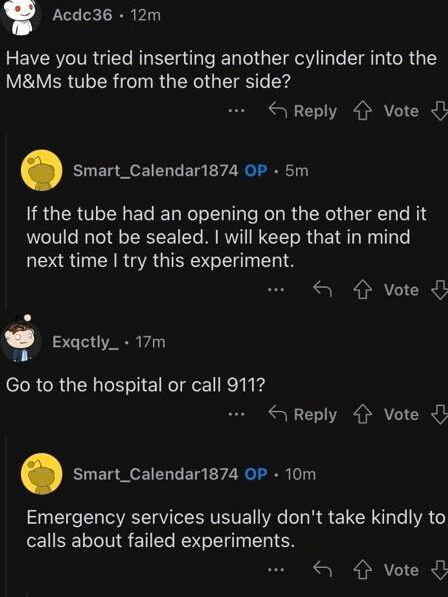

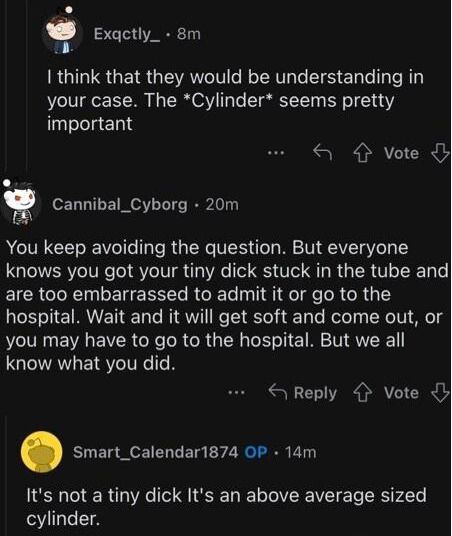

*southern grampa voice* GET URSELF AN ICECUBE SONNNNN

gotta admit, I'm impressed with their dedication to the bit

#long post#Reddit#when I was a tiny child got my pinky stuck in a glitter tube#momma directed me to an ice cube and it worked to shrink the tissue and lessen blood flow#didn’t even take all that long#and fingers have solid masses in the center!#felt foolish for a while after but I was free!

154K notes

·

View notes

Text

1 note

·

View note

Text

22 Years Factory,Heat Shrink Tube Braided Sleeve,Wire Cable Connect Protection UPM heat shrink has over 60 sets of various expansion units used to produce heat shrink tubing in different forms, including internal diameters ranging from 0.8 to 350mm, shrink ratios from 2:1 to 6:1, continuous length or cut into customized length, single-wall, double-wall adhesive-lined, double-layer composite, and triple-layer composite forms. Contact [email protected] or [email protected] to customize your heat shrink product.

#shrink tube manufacturer#upm heat shrink specialist#cable protection#shrink sleeve#heat shrink#shrink tube#shrink tubing#wire insulation#heat shrink tubing#upmheatshrink#expansion#high shrink ratio#braided sleeve#wire insulator#wire connector#triple wall#shrinkable sleeve

1 note

·

View note

Text

Braided Sleeve for Automotive Wire Harness Anti-abrasion, Anti-Corrosion,Anti-Vibration Self-wrapping braided Sleeve Expandable Braided Sleeve Heat Shrinkable Braided Sleeve

#braided sleeve#shrink sleeve#factory#shrinkage#shrink tube#heat shrinkable#manufacturer#expandable sleeve#self-wrapping sleeve

1 note

·

View note

Text

Exploring the FEP Heat Shrink Medical Tubing Market: Growth, Applications, and Future Prospects

The FEP (Fluorinated Ethylene Propylene) Heat Shrink Medical Tubing market is experiencing robust growth, spurred by innovations in healthcare, a shift toward minimally invasive devices, and the need for safe, biocompatible materials. FEP tubing is valued for its chemical resistance, flexibility, and transparency, which make it ideal for various applications within the medical industry. FEP Heat Shrink Medical Tubing Market is estimated to be USD 145 million in 2024, and it is projected to reach USD 208 million by 2029 at a CAGR of 7.4%.

Key Features of FEP Tubing

FEP is a fluoropolymer known for its exceptional durability under challenging conditions. When heat-shrunk, FEP tubing conforms to underlying components, adding a protective layer around medical devices. Key properties include:

Biocompatibility: Minimizes the risk of reactions, ensuring safe interaction with human tissue.

Chemical and Thermal Stability: Essential for protecting sensitive components against chemical exposure and high temperatures.

Transparency and Smoothness: Allows medical professionals to monitor fluids within the device while also ensuring easy device insertion.

Key Applications

FEP heat shrink tubing is indispensable across various medical applications:

Catheters: Acts as a durable, smooth protective layer that navigates the body’s complex pathways while shielding sensitive inner wiring.

Endoscopic Instruments: Offers protection from chemical exposure and maintains structural integrity through sterilization cycles.

Electrosurgical Devices: Adds a layer of safety by insulating electrically conductive parts.

Encapsulation for Wires and Sensors: Safeguards sensors in monitoring equipment, especially those exposed to harsh environments.

Market Growth Drivers

Several factors drive the demand for FEP heat shrink tubing:

Rising Demand for Non-invasive Procedures: As minimally invasive methods become the norm, demand for high-quality, durable tubing has risen.

Medical Device Innovations: FEP tubing supports next-generation devices by enabling flexible, strong material integration.

Adherence to Global Standards: FEP tubing’s compliance with strict international health standards boosts its usage in the healthcare sector.

Healthcare Expansion in Emerging Markets: Increased global access to healthcare is driving demand for high-quality medical equipment.

Market Challenges

While FEP tubing holds a strong market position, it faces challenges. Competing materials like PTFE offer similar benefits, so careful material selection is essential for manufacturers. Additionally, FEP is a costly material due to its specialized manufacturing process, which can impact product pricing.

Future Market Directions

Advances in medical technologies suggest a bright future for FEP tubing. Emerging trends include:

New Material Blends: Manufacturers are experimenting with FEP hybrids for enhanced performance.

Wearable Medical Devices: As healthcare becomes increasingly wearable, the need for flexible, durable materials like FEP is set to grow.

Eco-conscious Production: With environmental sustainability in focus, manufacturers are also exploring greener production practices.

Download PDF Brochure :

The FEP heat shrink medical tubing market is poised for expansion, especially as healthcare devices continue to evolve. Its properties make FEP tubing a valuable asset to medical innovation, and manufacturers that focus on both quality and sustainability will likely see success in this competitive landscape. For those in the industry, staying updated on FEP advancements can provide an edge in developing next-gen medical devices that balance functionality, safety, and efficiency.

#FEP heat shrink medical tubing#biocompatible tubing#minimally invasive devices#catheter tubing#medical device innovations#healthcare market growth#fluorinated ethylene propylene tubing

0 notes

Text

DYMO® IND Heat-Shrink Tube labels offer the convenience of printing directly on the tubing itself for high-end cable identification.

#DYMO Industrial Heat-Shrink Labels#Heat-Shrink Tube labels#printing directly#high-end cable#industrial grade polyolefin

0 notes

Text

burned my fingerrrr

0 notes

Text

0 notes